Page 1

Orion TrueTrack Dual-Axis DC Motor Drive System

#7832

Thank you for your purchase of an Orion TrueTrack motor drive system. The TrueTrack allows convenient

hands-free sidereal tracking of the night sky for SkyView Pro mounted telescopes. The motor drive system also features a push button hand controller that can move the telescope along the right ascension

(R.A.) and declination (Dec.) axes at speeds of 2x, 4x and 8x the sidereal rate. This provides an easy way

to center objects in the eyepiece.

The Dual-Axis motor drive system is also necessary for doing long-exposure astrophotography. The electronic hand controller allows positional corrections to be made to both the R.A. and Dec. axes of the

mount during an astrophotographic exposure.

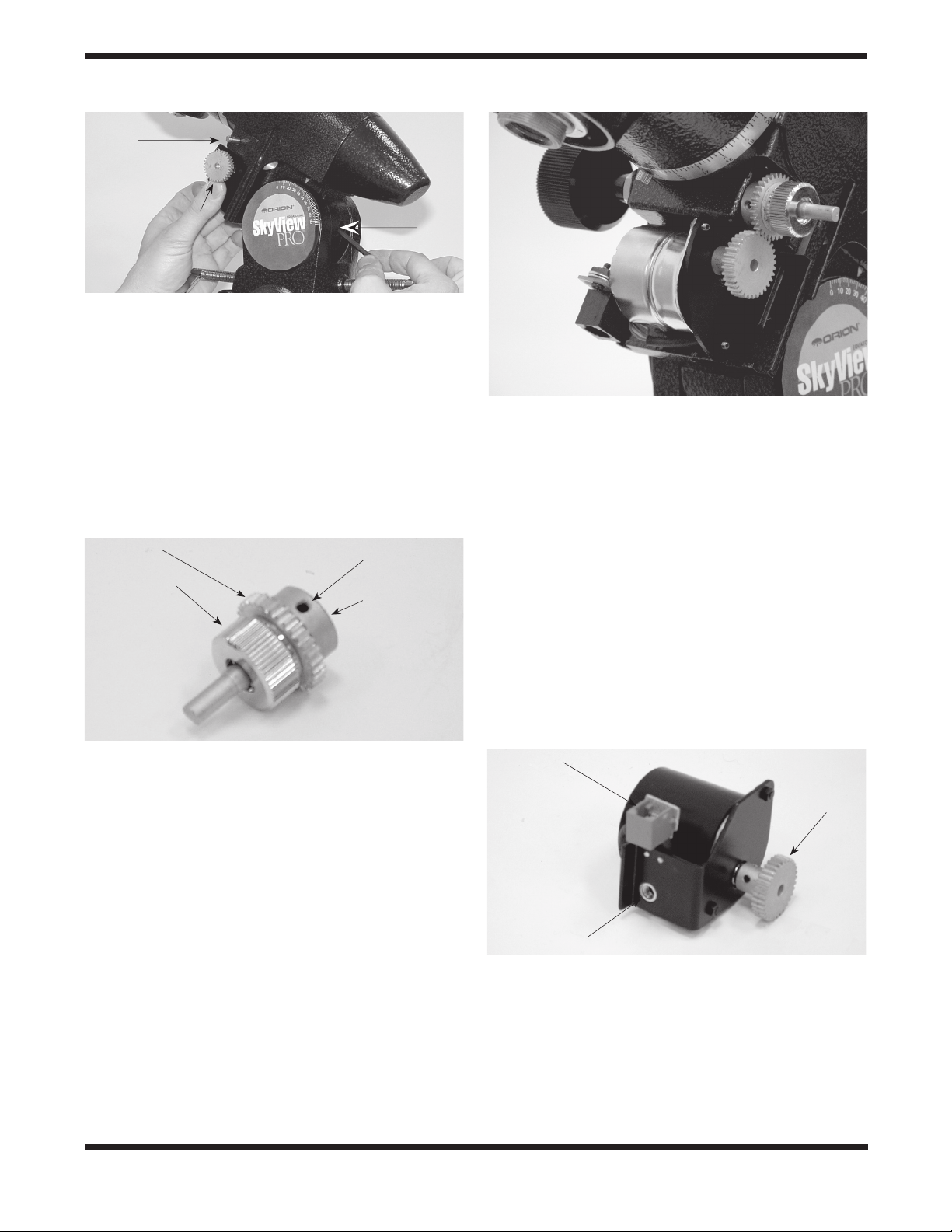

Attaching the R.A. Motor

R.A. motor

cover

Phillips-head

screw

Figure 1. The R.A. motor cover.

Drive

Remove the telescope tube, counterweight, and counterweight shaft from the mount before attaching the motor

drives.

1. Remove the R.A. motor cover from the mount by loosening

the Phillips head screw on the bottom of the cover (Figure

1). Slide the cover off the mount.

2. The R.A. motor assembly is identified by its silver colored

cylindrical body (Figure 2). It will be attached to the mount

by a socket-head cap screw that goes through the hole in

the rear of the equatorial mount, just above the rear latitude adjustment L-bolt (Figure 3). Attach the 4mm

socket-head cap screw to the end of a 4mm hex key and

push it up through the hole in the rear of the equatorial

mount. Hold the R.A. drive in your hand so that its threaded

hole meets up with the screw as it comes out the other end

of the hole. Thread the screw into the threaded hole of the

R.A. motor assembly until secure, but do not overtighten.

Parts List

1 R.A. motor assembly

1 Dec. motor assembly

2 Manual clutch assemblies (brass gears)

1 Hand controller

1 Battery pack

1 4mm Socket-head cap screw

1 5mm Socket-head cap screw

2 Velcro strips (1 “hook” strip, 1 “loop” strip)

Providing Exceptional Consumer Optical Products Since 1975

Modular

jack

Brass gear

Threaded hole

Figure 2. The R.A. motor assembly.

Customer Support (800) 676-1343

E-mail: support@telescope.com

Corporate Offices (831) 763-7000

89 Hangar Way, Watsonville, CA 95076

IN 197 Rev. B 02/09

Page 2

R.A. worm gear

shaft

Brass gear of R.A.

motor assembly

Figure 3. The motor is attached to the front of the mount by a

sockethead cap screw pushed up through the hole in the rear of the

mount.

This attachment process is tricky, and it may take you several tries before you get it right.

3. Remove the R.A. slow-motion control knob from the R.A.

worm gear shaft if it is on the side of the mount that the

motor assembly’s brass gear is on, and attach it to the

opposite end of the worm gear shaft.

4. Slide the open end of the manual clutch assembly (Figure

4) onto the worm gear shaft. Rotate the manual clutch

Brass gear

Thumbwheel

Setscrew

Open end

Hole

Figure 5. The assembled R.A. motor drive.

the manual clutch assembly. Failure to do so may result

in damage to the motor.

Attaching the Dec. Motor

Drive

Before attaching the Dec. motor drive, the telescope tube must

be removed from the mount.

1. The Dec. motor assembly is identified by its black, cylindrical body (Figure 6). It is attached to the equatorial mount

with the 5mm socket-head cap screw that goes through

the hole in the flange at the top of the equatorial mount

(Figure 7). The motor assembly should be attached so that

it is oriented as shown in Figure 8. Hold the motor assembly so that its threaded hole lines up with the hole in the

Figure 4. The manual clutch assembly.

assembly so that the setscrew will press against the flat in

the R.A. worm gear shaft. Secure the manual clutch

assembly by tightening the setscrew with a 2mm hex key.

5. Make certain that the teeth of the motor assembly gear

mesh with the teeth of the manual clutch assembly gear.

Also, make certain the gears are not too tightly pressed

together. You can adjust the way the gears mesh by tightening or loosening the socket-head cap screw that is used

to attach the R.A. motor assembly to the mount. If the

gears are not meshed correctly or are too tightly pressed

together, then the drive will not track properly, or at all.

When finished, the assembled R.A. drive should resemble

Figure 5. You can now replace the R.A. motor cover and secure

it with the Phillips head screw.

Please note that if you wish to use the slow-motion control knob to move the telescope in R.A. with the R.A. motor

drive attached, you must first loosen the thumbwheel on

2

Modular

jack

Brass gear

Threaded hole

Figure 6. The Dec. motor assembly.

top of the mount. Thread the screw with a 5mm hex key

through the mount and into the motor assembly. Thread

the screw into the motor assembly until it is secure, but do

not overtighten.

2. Remove the Dec. slow-motion control knob if it is on the

end of the Dec. worm gear shaft closest to the Dec. motor

Page 3

assembly gear. Attach the slow motion knob to the opposite end of the worm gear shaft.

motor drive attached, you must first loosen the thumbwheel on the manual clutch assembly. Failure to do so

may result in damage to the motor.

Flange

Hole

Figure 7. The location of the flange on the mount.

3. Slide the open end of the manual clutch assembly onto the

worm gear shaft. Make certain that the setscrew on the

manual clutch will press against the flat on the Dec. worm

gear shaft. Secure the manual clutch assembly by tightening the setscrew with a 2mm hex key.

4. Make certain that the gears of the motor assembly mesh

with the gears of the manual clutch assembly. Also, make

certain the gears are not too tightly pressed together. You

can adjust the way the gears mesh by tightening or loosening the socket-head cap screw that is used to attach the

Figure 8. The assembled Dec. motor drive.

Dec. motor assembly to the mount. If the gears are not

meshed properly or are too tightly pressed together, then

the drive will not track properly, or at all.

When finished, the Dec. motor drive should resemble Figure

8.

Please note that if you wish to use the slow-motion control knob to move the telescope in Dec. with the Dec.

Attaching the Velcro

Two strips of velcro (one strip of “hooks” and one strip of

“loops”) have been provided so you can create a place to keep

the hand controller out of the way when not in use. Place the

“hooks” strip of velcro on the back of the hand controller and

the “loops” strip on a tripod leg or on the mount where it will be

in a conveniently reached spot. Simply hang the hand controller by the velcro when it is not in use. Make certain when you

attach the velcro to the mount that the hand controller’s position will not interfere with the motion of the mount.

Operating the Dual-Axis

Drive

For the motor drive system to track properly, the equatorial

mount must be polar aligned. This involves aligning the R.A.

axis of the mount so it is parallel to the Earth’s axis of rotation

(polar axis). Consult the manual that came with your SkyView

Pro equatorial mount for details on how to polar align it.

The telescope must also be precisely balanced for the motor

drive system to properly track the night sky. Consult the manual that came with your mount for details on balancing your

telescope in the R.A. and Dec axes.

Insert four D-cell batteries into the battery pack. Orient the

batteries as indicated on the white plastic battery holder.

Connect the end of the battery pack’s power cord to the DC

power input on the hand controller.

Two cords are permanently connected to the hand controller.

The printing on the bottom of the hand controller’s front panel

indicates the R.A. cord and the Dec. cord. Connect the modular plug on the end of the R.A. cord to the modular jack on the

R.A. motor assembly (through the hole in the bottom of the

R.A. motor assembly cover), and connect the plug of the Dec.

cord to the jack on the Dec. motor assembly.

To turn on the motors, flip the power switch to either the “N”

position (if you are in the Northern Hemisphere) or the “S”

switch (if you are in the Southern Hemisphere). Make sure the

thumbwheels on the manual clutch assemblies are engaged

(i.e. tightened against the brass gears). The LED in the center

of the hand controller should be shining green. If properly

aligned and balanced, the mount should now be tracking the

motion of the night sky, and the telescope should hold any

astronomical object steady in its eyepiece over time.

To move your telescope to a new object, loosen both the R.A.

and Dec. lock levers and move the telescope until it is pointed

in the general direction of the object you wish to view. Retighten

the R.A. and Dec. lock levers. Loosen the thumbwheels on

both the Dec. and R.A. manual clutch assemblies and use the

R.A. and Dec. slow-motion control knobs to center the object

in the eyepiece’s field of view. Retighten the thumbwheels,

3

Page 4

and the motor drive system will keep the object centered over

time. Remember, never use the slow-motion control knobs

when the manual clutches are engaged or you could permanently damage the motors.

There are four pushbuttons on the hand controller (Figure 9).

If no buttons are pushed, the R.A. motor will turn the R.A. axis

at sidereal rate to track the motion of the night sky. The left

and right buttons move the mount about its R.A. axis and the

up and down buttons move the mount about its Dec. axis. The

rate of speed is determined by the rate switch at the top right

of the hand controller. If the switch is at the 2x position, the

mount will move at two times sidereal rate when the right hand

button is pushed, which will case objects to viewed in the eyepiece to move slowly eastward. If the left button is pushed, the

drive will stop turning, which will cause objects in the eyepiece

to move slowly westward. The top and bottom bottoms will

cause the telescope to move in Declination at the 2x speed.

Similarly, if the switch is at the 4x or 8x position, the mount will

move four times or eight times sidereal rate when a button is

pushed.

The 2x sidereal rate is the best setting for making guiding corrections during long-exposure astrophotography. The 4x and

8x rates are best for centering an object within the telescope’s

eyepiece.

Note that whenever any of the four buttons on the hand controller are pressed, the LED in the center of the controller will

shine red; when the button is released, the LED will be green.

Also, when the LED starts to blink at a constant rate, its time

to change the batteries in the battery pack.

Specifications

Power requirements: 6V DC

Battery type: Four D-cells

Operation: Northern or Southern hemisphere

Guiding rates: Sidereal ±100% sidereal

Centering rates: ±4x sidereal, ±8x sidereal

Manual clutches: External, for both R.A. and Dec. axes

Figure 9. The hand controller.

One-Year Limited Warranty

This Orion TrueTrack motor drive system is warranted against defects in materials or workmanship for a

period of one year from the date of purchase. This warranty is for the benefit of the original retail purchaser only. During this warranty period Orion Telescopes & Binoculars will repair or replace, at Orion’s

option, any warranted instrument that proves to be defective, provided it is returned postage paid to:

Orion Warranty Repair, 89 Hangar Way, Watsonville, CA 95076. If the product is not registered, proof of

purchase (such as a copy of the original invoice) is required.

This warranty does not apply if, in Orion’s judgment, the instrument has been abused, mishandled, or

modified, nor does it apply to normal wear and tear. This warranty gives you specific legal rights, and you

may also have other rights, which vary from state to state. For further warranty service information, contact: Customer Service Department, Orion Telescopes & Binoculars, 89 Hangar Way, Watsonville, CA

95076; (800) 676-1343.

Orion Telescopes & Binoculars

89 Hangar Way, Watsonville, CA 95076

Customer Support Help Line (800) 676-1343 • Day or Evening

4

Loading...

Loading...