Page 1

Installation and Operating Manual

Enhanced Model 705

Software v3.x

Guided Wave Radar

Level Transmitter

Page 2

Read this Manual Before Installing

®

This manual provides information on the Eclipse

trans-

mitter. It is important that all instructions are read carefully and followed in sequence. The QuickStart

Installation instructions are a brief guide to the sequence

of steps for experienced technicians to follow when

installing the equipment. Detailed instructions are

included in the Complete Installation section of this manual.

Conventions Used in this Manual

Certain conventions are used in this manual to convey

specific types of information. General technical material,

support data, and safety information are presented in

narrative form. The following styles are used for notes,

cautions, and warnings.

NOTES

Notes contain information that augments or clarifies an

operating step. Notes do not normally contain actions.

They follow the procedural steps to which they refer.

Cautions

Cautions alert the technician to special conditions that

could injure personnel, damage equipment, or reduce

a component’s mechanical integrity. Cautions are also

used to alert the technician to unsafe practices or the

need for special protective equipment or specific

materials. In this manual, a caution box indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

WARNINGS

Warnings identify potentially dangerous situations or

serious hazards. In this manual, a warning indicates an

imminently hazardous situation which, if not avoided,

could result in serious injury or death.

Safety Messages

®

The Eclipse

system is designed for use in Category II,

Pollution Degree 2 installations. Follow all standard

industry procedures for servicing electrical and computer

equipment when working with or around high voltage.

Always shut off the power supply before touching any

components. Although high voltage is not present in this

system, it may be present in other systems.

WARNING! Explosion hazard. Do not connect or dis-

connect designs rated Explosion proof or Non-incendive

unless power has been switched off and/or the area is

known to be non-hazardous.

Low Voltage Directive

For use in Installations Category II, Pollution Degree 2.

If equipment is used in a manner not specified by the

manufacturer, protection provided by equipment may be

impaired.

Notice of Copyright and Limitations

®

Magnetrol

registered trademarks of Magnetrol

& Magnetrol®logotype and Eclipse®are

®

International,

Incorporated.

®

Copyright © 2012 Magnetrol

International, Incorporated.

All rights reserved.

MAGNETROL reserves the right to make changes to the

product described in this manual at any time without

notice. MAGNETROL makes no warranty with respect

to the accuracy of the information in this manual.

Warranty

All MAGNETROL electronic level and flow controls are

warranted free of defects in materials or workmanship for

one full year from the date of original factory shipment.

If returned within the warranty period; and, upon factory

inspection of the control, the cause of the claim is

determined to be covered under the warranty; then,

MAGNETROL will repair or replace the control at no

cost to the purchaser (or owner) other than transportation.

MAGNETROL shall not be liable for misapplication,

labor claims, direct or consequential damage or expense

arising from the installation or use of equipment. There

are no other warranties expressed or implied, except special

written warranties covering some MAGNETROL products.

Quality Assurance

The quality assurance system in place at MAGNETROL

guarantees the highest level of quality throughout the

company. MAGNETROL is committed to providing

full customer satisfaction both in quality products and

quality service.

Electrical components are sensitive to electrostatic discharge.

To prevent equipment damage, observe safety procedures

when working with electrostatic sensitive components.

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

The MAGNETROL quality assurance

system is registered to ISO 9001 affirming

its commitment to known international

quality standards providing the strongest

assurance of product/service quality

available.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 3

Eclipse®Guided Wave Radar Transmitter

Table of Contents

1.0 QuickStart Installation

1.1 Getting Started..........................................................4

1.1.1 Equipment and Tools .....................................4

1.1.2 Configuration Information.............................5

1.2 QuickStart Mounting................................................5

1.2.1 Probe..............................................................5

1.2.2 Transmitter.....................................................6

1.3 QuickStart Wiring ....................................................6

1.4 QuickStart Configuration .........................................7

2.0 Complete Installation

2.1 Unpacking ................................................................8

2.2 Electrostatic Discharge (ESD) Handling Procedure...8

2.3 Before You Begin.......................................................9

2.3.1 Site Preparation ..............................................9

2.3.2 Equipment and Tools .....................................9

2.3.3 Operational Considerations............................9

2.4 Mounting..................................................................9

2.4.1 Installing a Coaxial Probe.............................10

2.4.1.1 To install a coaxial probe.......................10

2.4.2 Installing a Twin Rod Probe .........................11

2.4.2.1 To install a rigid twin rod probe............11

2.4.2.2 To install a Model 7x7 standard

flexible twin rod probe ..........................12

2.4.3 Installing a Single Rod Probe .......................12

2.4.3.1 Installing a rigid probe ..........................13

2.4.3.2 Installing a flexible probe ......................13

2.4.4 Installation Guidelines–

Models 7x2/7x5 Bulk Solids Probes .............14

2.4.4.1 Applications..........................................14

2.4.4.2 Mounting recommendations .................14

2.4.4.3 To install a bulk solids twin rod probe ..14

2.4.4.4 To install a bulk solids single rod probe 15

2.4.5 Installing the Transmitter .............................16

2.4.5.1 Integral Mount......................................16

2.4.5.2 Remote Mount......................................16

2.5 Wiring ....................................................................17

2.5.1 General Purpose or Non-Incendive

(CI I, Div 2) .................................................17

2.5.2 Intrinsically Safe ...........................................18

2.5.3 Explosion Proof............................................18

2.6 Configuring the Transmitter....................................19

2.6.1 Operating Parameters ...................................19

2.6.2 Setting Up for Bench Configuration ............19

2.6.3 Transmitter Display and Keypad ..................20

2.6.4 Password Protection (Default = 0) ................20

2.6.5 Model 705 Menu: Step-By-Step Procedure ..21

2.6.5.1 Measurement Type: Level Only.............21

2.6.5.2 Measurement Type: Level and Volume..24

2.6.5.3 Measurement Type: Interface Level .......27

2.6.5.4 Measurement Type: Interface and Volume.30

2.6.6 Offset Description........................................33

2.6.7 Strapping Table Description.........................34

2.7 Configuration Using HART

2.7.1 Connections .................................................35

2.7.2 Display Menu...............................................35

2.7.3 HART Menu – Model 705 3.x ....................36

2.7.4 HART Revision Table ..................................37

2.8 FOUNDATION fieldbus™Digital Communications ...37

2.8.1 Description ..................................................37

2.8.2 Benefits ........................................................38

2.8.3 Device Configuration ...................................39

2.8.4 Intrinsically Safe ...........................................39

3.0 Reference Information

3.1 Description .............................................................40

3.2 Theory of Operation...............................................40

3.2.1 Micropower Impulse Radar ..........................40

3.2.2 Interface Detection.......................................41

3.2.3 Time Domain Reflectometry (TDR)............42

3.2.4 Equivalent Time Sampling (ETS).................42

3.3 Troubleshooting ......................................................43

3.3.1 Troubleshooting System Problems................43

3.3.2 Status Messages ............................................44

3.3.3 Troubleshooting Applications.......................46

3.3.3.1 Model 705 (Level Application) .............46

3.3.3.2 Model 705 (Interface Application)........46

3.3.3.3 Model 705 (SingleRod Application) .........47

3.4 Agency Approvals....................................................48

3.4.1 Agency Specifications (XP Installation) ........48

3.4.2 Agency Specifications (IS Installation)..........49

3.4.3 Agency Specifications (F

3.5 Parts ........................................................................51

3.5.1 Replacement Parts ........................................51

3.5.2 Recommended Spare Parts ...........................51

3.6 Specifications ..........................................................52

3.6.1 Functional ....................................................52

3.6.1.1 O-ring (Seal) Selection Chart................52

3.6.2 Performance (Model 705) ............................53

3.6.3 Performance (Model 705 Interface)..............54

3.6.4 Process Conditions .......................................54

3.6.5 Probe Specifications......................................55

3.6.6 Physical ........................................................56

3.7 Model Numbers......................................................60

3.7.1 Transmitter...................................................60

3.7.2 Probe............................................................61

Glossary ................................................................................64

Model 705 Configuration Data Sheet ..................................66

®

..................................35

OUNDATION fieldbus).50

57-600 Eclipse®Guided Wave Radar Transmitter

Page 4

1.0 QuickStart Installation

The QuickStart Installation procedures provide the key

steps for mounting, wiring, and configuring the Eclipse

level transmitter. These procedures are intended for experienced installers of electronic level measurement instruments.

See Complete Installation, Section 2.0, for detailed installation instructions.

WARNING: The Model 7xD, 7xG, 7xR or 7xT overfill probes should

be used for Safety Shutdown/Overfill applications. All

other Guided Wave Radar probes should be installed so

the maximum overfill level is a minimum of 6" (150 mm)

below the process connection. This may include utilizing

a nozzle or spool piece to raise the probe. Consult factory to ensure proper installation.

1.1 Getting Started

Before beginning the QuickStart Installation procedures,

have the proper equipment, tools, and information available.

1.1.1 Equipment and Tools

®

• Open-end wrenches or adjustable wrench to fit the

process connection size and type. Coaxial probe 1

(38 mm), twin rod probe 17⁄8" (47 mm), transmitter

11⁄2" (38 mm). A torque wrench is highly desirable.

• Flat-blade screwdriver

3

• Cable cutter and

⁄32" (2.5 mm) hex wrench

(Flexible probes only)

• Digital multimeter or digital volt/ammeter

• 24 VDC power supply, 23 mA minimum

1

⁄2"

4

57-600 Eclipse®Guided Wave Radar Transmitter

Page 5

1.1.2 Configuration Information

Some key information is needed to configure the

ECLIPSE transmitter. Complete the following operating

parameters table before beginning configuration.

Display Question Answer

Probe Model What probe model is listed on the

model information?

(first four digits of probe model number) _____________

Probe Mount Is the probe mounted NPT, BSP,

or flange? _____________

Measurement What is the desired measurement? Choices

Type are: Level only, volume, interface level

or interface level and volume. _____________

Level Units What units of measurement will be

used? (inches, centimeters, feet or meters)

(AI block parameter. Not selectable at

transmitter on Model 705 Fieldbus)

Probe Length What probe length is listed on the

model information? _____________

_____________

Level Offset The desired level reading when the

liquid is at the end of the probe. _____________

Dielectric What is the dielectric constant range

of the process medium? (Upper layer

dielectric for interface applications) _____________

Loop Control Is the output current to be controlled

by level or volume? _____________

Set 4.0 mA What is the 0% reference point for the

4.0 mA value? (EU_0 value for

OUNDATION fieldbus) _____________

F

Set 20.0 mA What is the 100% reference point for

the 20.0 mA value? (EU_100 value for

OUNDATION fieldbus) _____________

F

(Top 6" (152 mm) of Single Rod probes is within

Blocking Distance)

1.2 QuickStart Mounting

NOTE: Confirm the configuration style and process connection

size/type of the ECLIPSE transmitter. Ensure it matches the

requirements of the installation before continuing with the

QuickStart installation.

Confirm the model and serial numbers on the nameplates

of the ECLIPSE probe and transmitter are identical.

57-600 Eclipse®Guided Wave Radar Transmitter

NOTE: For applications using the Model 7xS steam probe, it is manda-

tory to keep the transmitter and probe matched as a set.

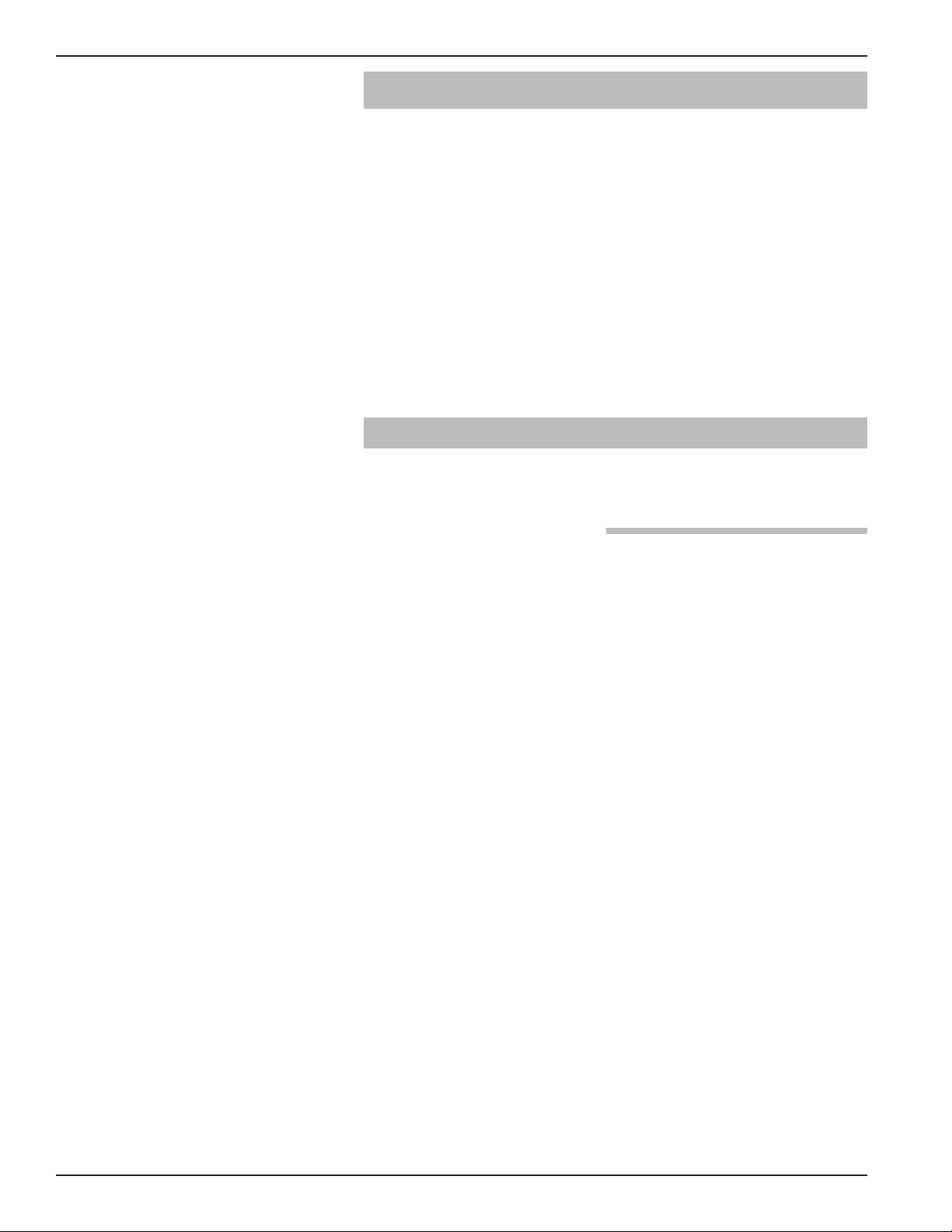

1.2.1 Probe

Carefully place the probe into the vessel. Align the probe

process connection with the threaded or flanged mounting

on the vessel.

5

Page 6

1.2.2 Transmitter

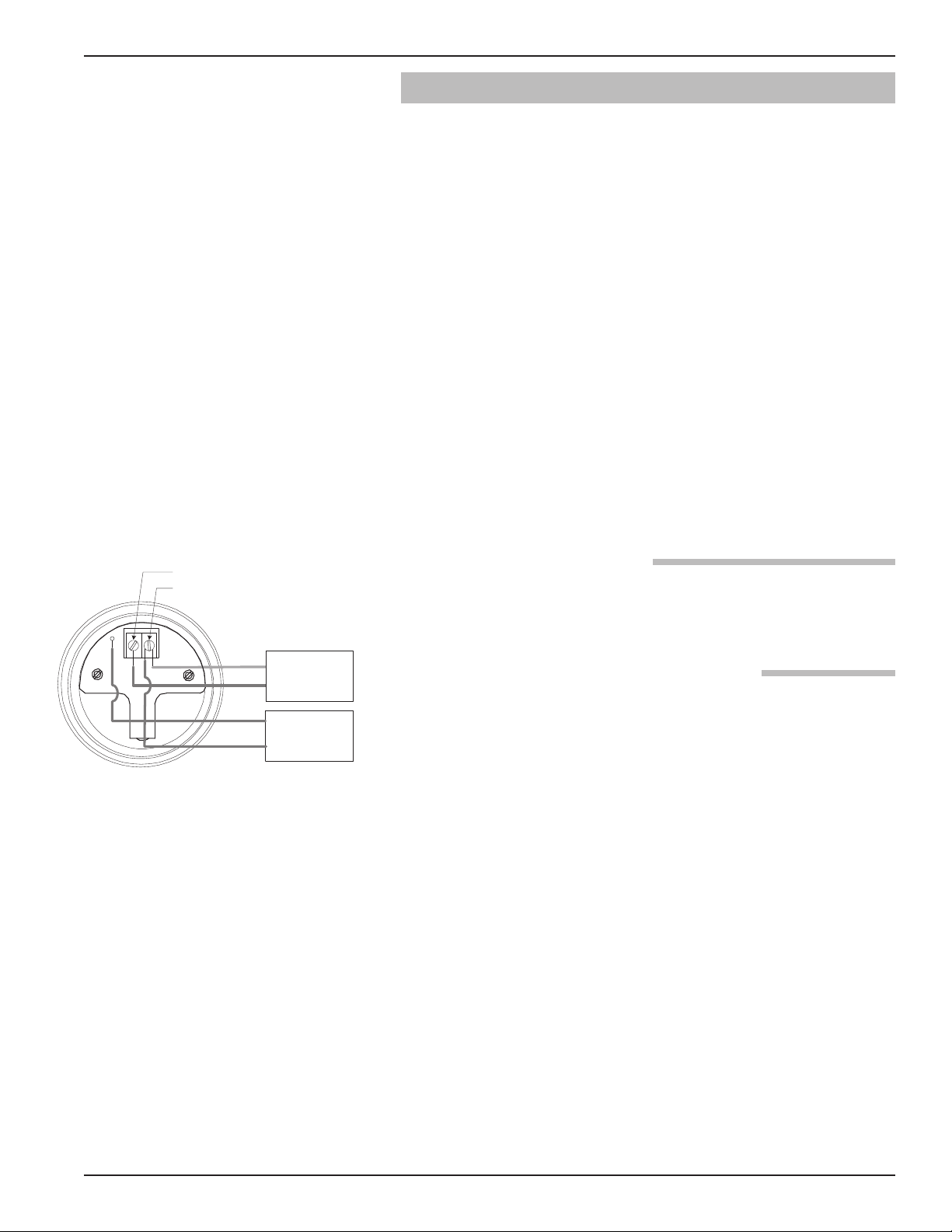

Red (+)Black (-)

(+)

(-)

Tighten the hex nut of the probe process connection or

flange bolts.

NOTE: Leave the plastic protective cap in place until ready to

install the transmitter. Do not use sealing compound or TFE

tape on probe connection to transmitter as this connection is

sealed by a Viton®O-ring.

Remove the protective plastic cap from the top of the probe

and store for future use. Make sure the top probe connector

(female socket) is clean and dry. Clean with isopropyl

alcohol and cotton swabs if necessary.

Place the transmitter on the probe. Align the universal

connection at the base of the transmitter housing with the

top of the probe. Hand-tighten the connection.

Rotate the transmitter so that it is in the most convenient

position for wiring, configuring, and viewing.

Using a 1

1

⁄2" (38 mm) wrench, tighten the universal con-

nection on the transmitter1⁄4 to1⁄2 turn beyond hand-tight.

A torque wrench is highly recommended to obtain

45 ft-lbs. This is a critical connection. DO NOT LEAVE

HAND-TIGHT.

NOTE: Universal connector can be supplied with lock screws for

applications with significant vibration. Contact factory for

additional information.

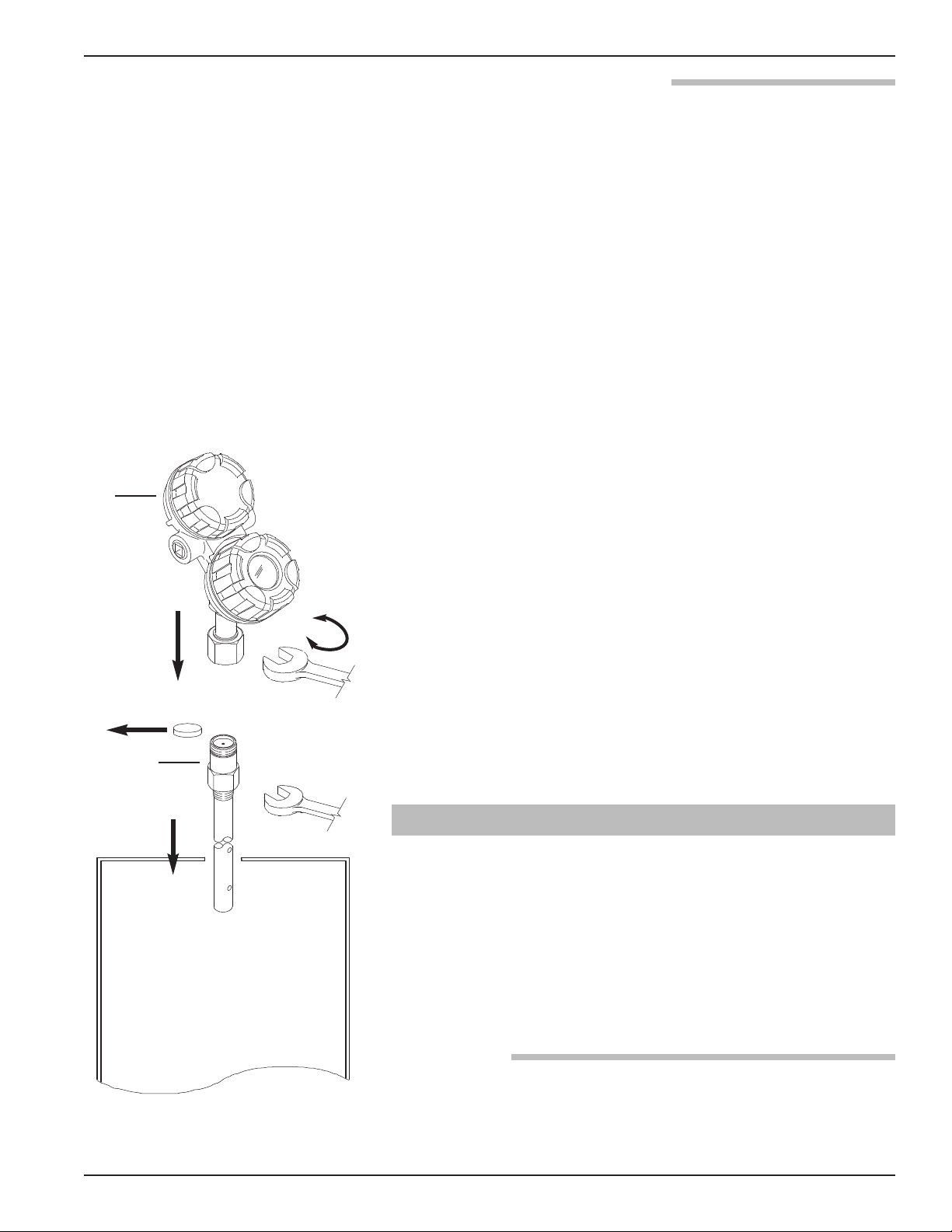

1.3 QuickStart Wiring

WARNING! Explosion hazard. Do not connect or disconnect equip-

ment unless power has been switched off or the area is

known to be non-hazardous.

NOTE: Ensure that the electrical wiring to the ECLIPSE transmitter is

complete and in compliance with all regulations and codes.

1. Remove the cover of the upper wiring compartment of the

transmitter.

2. Attach a conduit fitting and mount the conduit plug in the

spare opening. Pull the power supply wire through the conduit fitting.

3. Connect shield to an earth ground at power supply.

4. Connect an earth ground to the nearest green ground screw.

(Not shown in illustration.)

5. Connect the positive supply wire to the (+) terminal and the

negative supply wire to the (-) terminal. For Explosion

Proof Installations, see Wiring, Section 2.5.3.

6. Replace the cover and tighten.

6

57-600 Eclipse®Guided Wave Radar Transmitter

Page 7

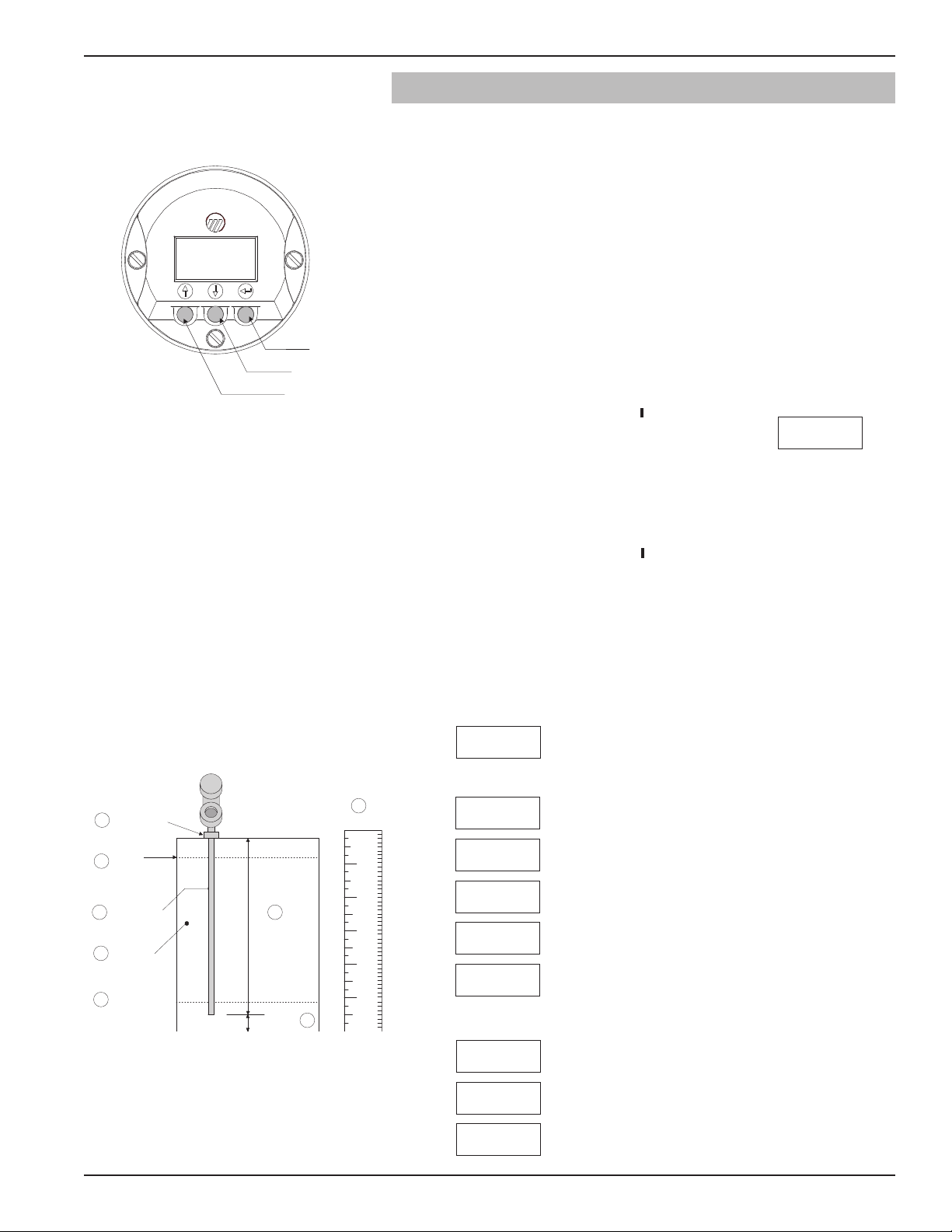

1.4 QuickStart Configuration

Level Offset

Probe Length

Probe Mount

4 mA Level

(0%-point)

Probe Model

Dielectric

of Medium

In or Cm

20 mA

(100% Point)

8

2

6

7

5

4

1

9

Enter

Down

Up

The ECLIPSE transmitter comes configured with default

values from the factory but can be reconfigured in the shop

(disregard any fault messages due to unattached probe). The

minimum configuration instructions required in the field

follow. Use the information from the operating parameters

table in Section 1.1.2 before beginning configuration.

1. Power up the transmitter.

The display changes every 5 seconds to show one of four

values: Status, Level, %Output, and Loop current.

NOTE: A small transition zone (0–6")

may exist at the top and bottom

of the probe. See Specifications,

Section 3.6.

57-600 Eclipse®Guided Wave Radar Transmitter

2. Remove the cover of the lower electronic compartment.

3. Use the Up or Down Arrow ( ) keys to move from one

step of the configuration program to the next step.

4. Press the Enter Arrow ( ) key. The last

character in the first line of the display

LvlUnits!

xxx

changes to an exclamation point (!).

5. Use the Up or Down Arrow ( ) keys to increase or

decrease the value in the display or to scroll through the

choices.

6. Press the Enter Arrow ( ) key to accept a value and move

to the next step of the configuration program (the default

password is 0).

7. After entering the last value, allow 10 seconds before

removing power from the transmitter.

The following configuration entries are the minimum required for

configuration (the default password is 0 from the LCD/keypad).

PrbModel

(select)

PrbMount

(select)

MeasType

(select)

Lvl Units

xxx

Probe Ln

xxx.x

LvlOfst

xxx.x

Dielctrc

(select)

Set 4mA

xxx.x

Set 20mA

xxx.x

Select the Probe Model to be used

Model 705: 7xA-x, 7xB-x, 7xD-x, 7xE-x, 7xF-F, 7xF-P,

7xF-4, 7xF-x, 7xJ-x, 7xK-x, 7xP-x, 7xR-x, 7xS-x,

7xT-x, 7x1-x, 7x2-x, 7x5-x, 7x7-x

Select the type of Probe Mounting to vessel (NPT, BSP,

or flange).

Select from Level Only, Level and Volume, Interface Level

or Interface Level and Volume.

Select the Units of measurement for the level readout (inches,

cm, feet or meters). Not included on Model 705 Fieldbus.

Enter the exact Probe Length as printed on the probe

nameplate.

Enter the Level Offset value. Refer to Section 2.6.6 for

further information. (The unit is shipped from the factory

with offset = 0; i.e., all measurements are referenced to

the bottom of the probe).

Enter the Dielectric range for the material to be measured.

Enter the level value (0%-point) for the 4 mA point.

Enter the level value (100%-point) for the 20 mA point.

7

Page 8

2.0 Complete Installation

This section provides detailed procedures for properly

installing and configuring the ECLIPSE Guided Wave

Radar Level Transmitter.

2.1 Unpacking

Unpack the instrument carefully. Make sure all components

have been removed from the packing material. Check all the

contents against the packing slip and report any discrepancies to the factory.

Before proceeding with the installation, do the following:

• Inspect all components for damage. Report any damage to

the carrier within 24 hours.

• Make sure the nameplate model number on the probe and

transmitter agree with the packing slip and purchase order.

• Record the model and serial numbers for future reference

when ordering parts.

Model Number

Serial Number

2.2 Electrostatic Discharge (ESD) Handling Procedure

Magnetrol

®

electronic instruments are manufactured to the

highest quality standards. These instruments use electronic

components that may be damaged by static electricity present in most work environments.

The following steps are recommended to reduce the risk of

component failure due to electrostatic discharge.

• Ship and store circuit boards in anti-static bags. If an antistatic bag is not available, wrap the board in aluminum foil.

Do not place boards on foam packing materials.

• Use a grounding wrist strap when installing and removing

circuit boards. A grounded workstation is recommended.

• Handle circuit boards only by the edges. Do not touch

components or connector pins.

• Make sure that all electrical connections are completely

made and none are partial or floating. Ground all equipment to a good, earth ground.

8

57-600 Eclipse®Guided Wave Radar Transmitter

Page 9

2.3 Before You Begin

2.3.1 Site Preparation

Each ECLIPSE transmitter is built to match the specific

physical specifications of the required installation. Make

sure the probe connection is correct for the threaded or

flanged mounting on the vessel or tank where the transmitter will be placed. See Mounting, Section 2.4.

Make sure that the wiring between the power supply and

ECLIPSE transmitter are complete and correct for the type

of installation. See Specifications, Section 3.6.

When installing the ECLIPSE transmitter in a general purpose

or hazardous area, all local, state, and federal regulations and

guidelines must be observed. See Wiring, Section 2.5.

2.3.2 Equipment and Tools

No special equipment or tools are required to install the

ECLIPSE transmitter. The following items are recommended:

• Open-end wrenches or adjustable wrench to fit the process

1

connection size and type. Coaxial probe 1

7

rod probe 1

⁄8" (47 mm), transmitter 11⁄2" (38 mm). A torque

⁄2" (38 mm), twin

wrench is highly desirable.

• Flat-blade screwdriver

• Digital multimeter or digital volt/ammeter

• 24 VDC power supply, 23 mA

2.3.3 Operational Considerations

Operating specifications vary based on Probe model

number. See Specifications, Section 3.6.

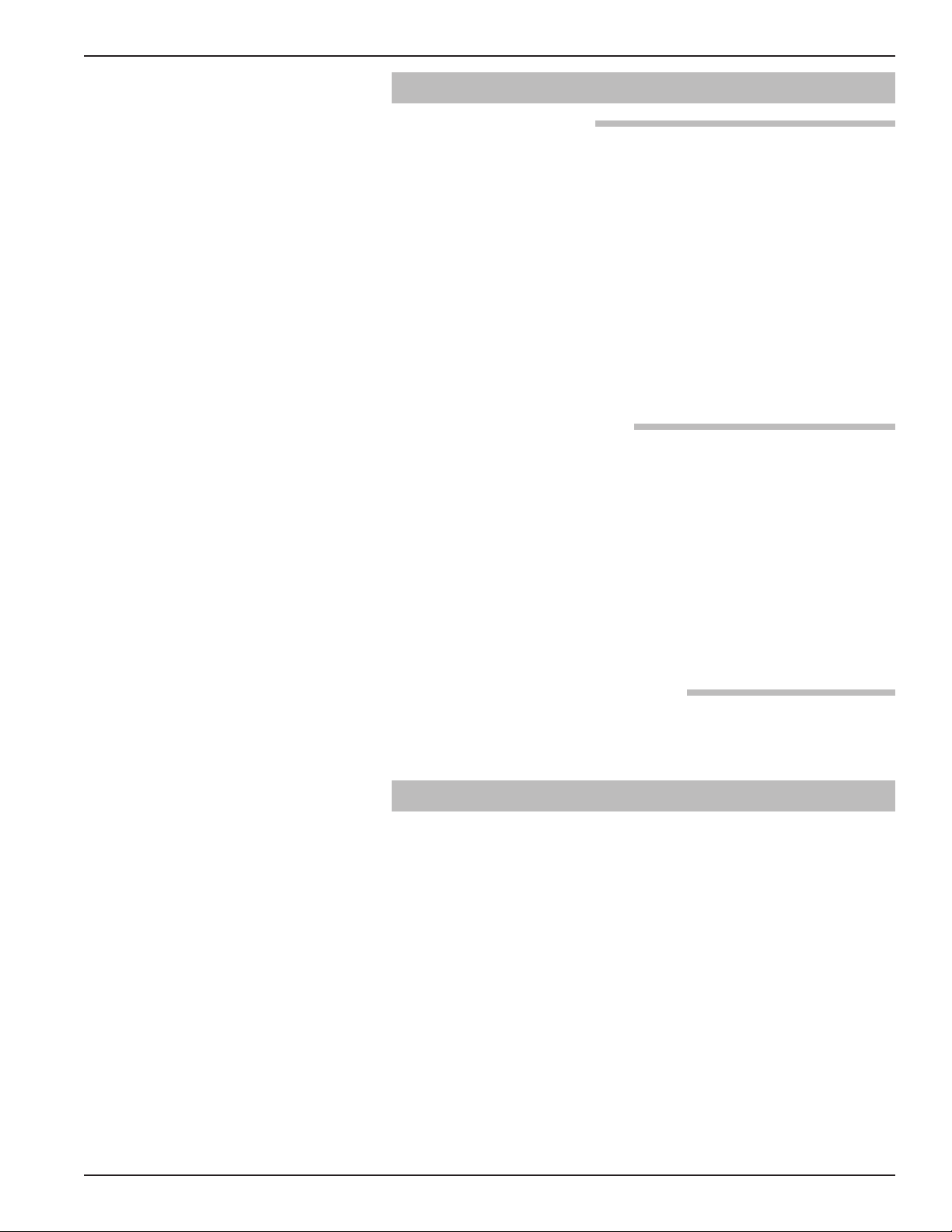

2.4 Mounting

The ECLIPSE transmitter can be mounted to a tank using

a variety of process connections. Generally, either a threaded

or flanged connection is used. For information about the

sizes and types of connections available, see Probe Model

Numbers, Section 3.7.2.

57-600 Eclipse®Guided Wave Radar Transmitter

NOTE: Do not place insulating material around any part of the

ECLIPSE transmitter as this may cause excessive heat buildup.

Make sure all mounting connections are properly in place

on the tank before installing the probe. Compare the nameplate on the probe and transmitter with the product information; make sure the ECLIPSE probe is correct for the

intended installation.

9

Page 10

WARNING! The Model 7xD, 7xR or 7xT overfill probes should be

used for Safety Shutdown/Overfill applications. All other

Guided Wave Radar probes should be installed so the

maximum overfill level is a minimum of 6" (150 mm)

below the process connection. This may include utilizing

a nozzle or spool piece to raise the probe. Consult

factory to ensure proper installation.

WARNING! Do not disassemble probe when in service and under

pressure.

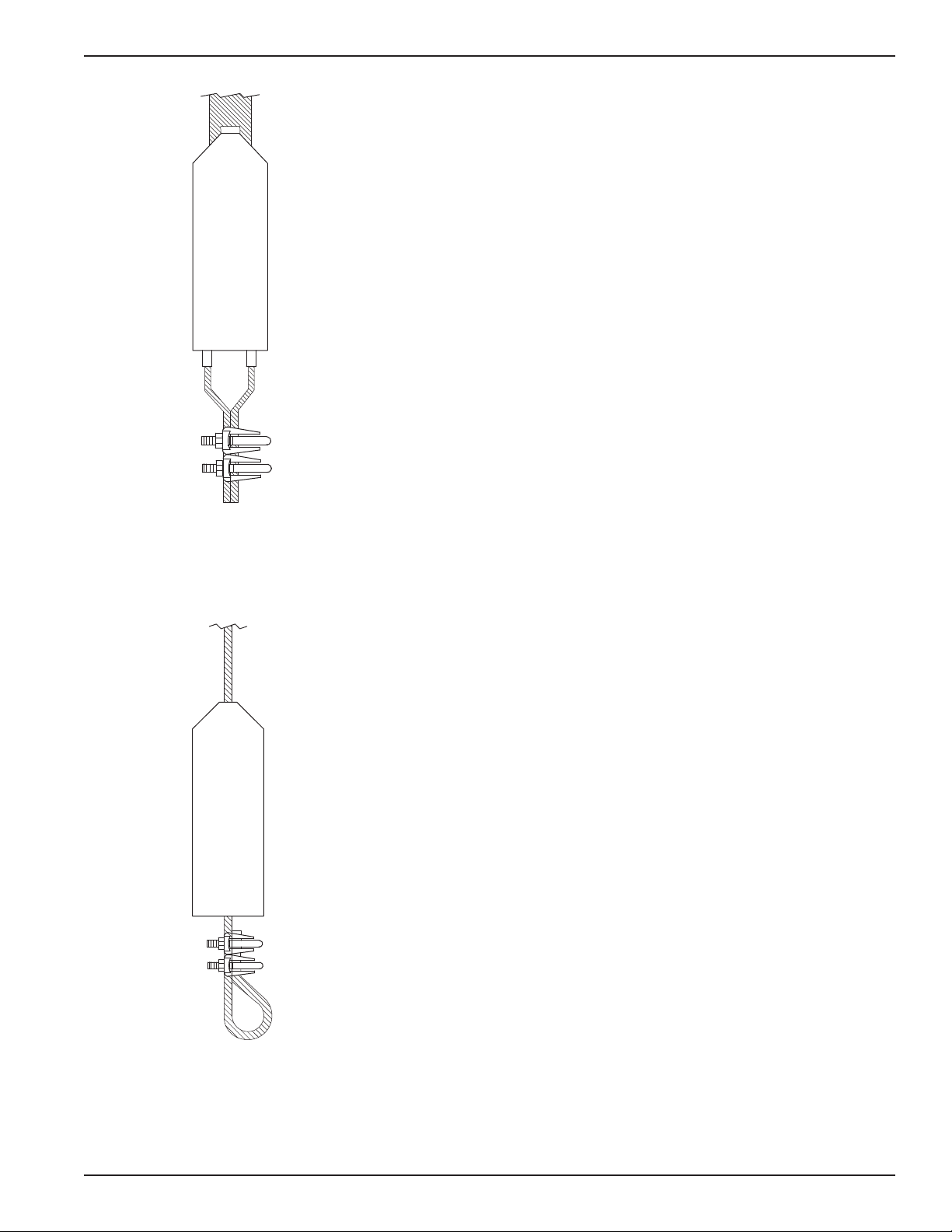

2.4.1 Installing a Coaxial Probe (Models 7xA, 7xD, 7xG, 7xP, 7xR, 7xS, and 7xT)

Before installing, make sure the:

• Model and serial numbers on the nameplates of the

ECLIPSE probe and transmitter are identical.

• Probe has adequate room for installation and has unobstructed entry to the bottom of the vessel. The Model 7xD

(High Temp./High Pressure) probe, Model 7xP (High

Pressure) probe, Model 7xR (Overfill) probe, Model 7xS

(Steam) probe and Model 7xT (Interface) probe require

added clearance. See Physical Specifications, Section 3.6.6.

• Process temperature, pressure, dielectric, and viscosity are

within the probe specifications for the installation.

See Specifications, Section 3.6.

• Model 7xD (High Temp./High Pressure) probes should be

handled with extra care due to the ceramic spacers used

throughout their length.

• Model 7xG (caged GWR) probes should be handled

with extra care. Only handle these probes by the flanges.

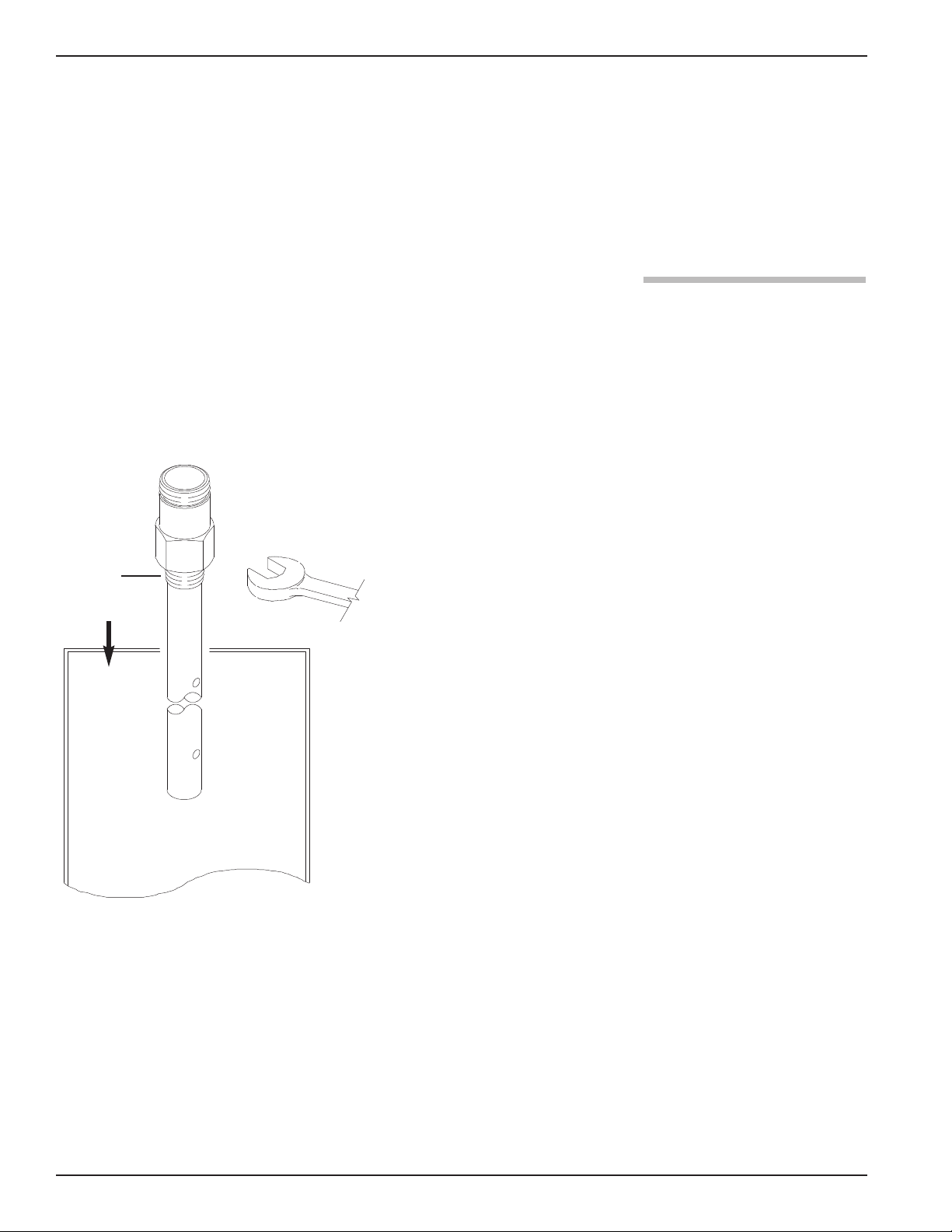

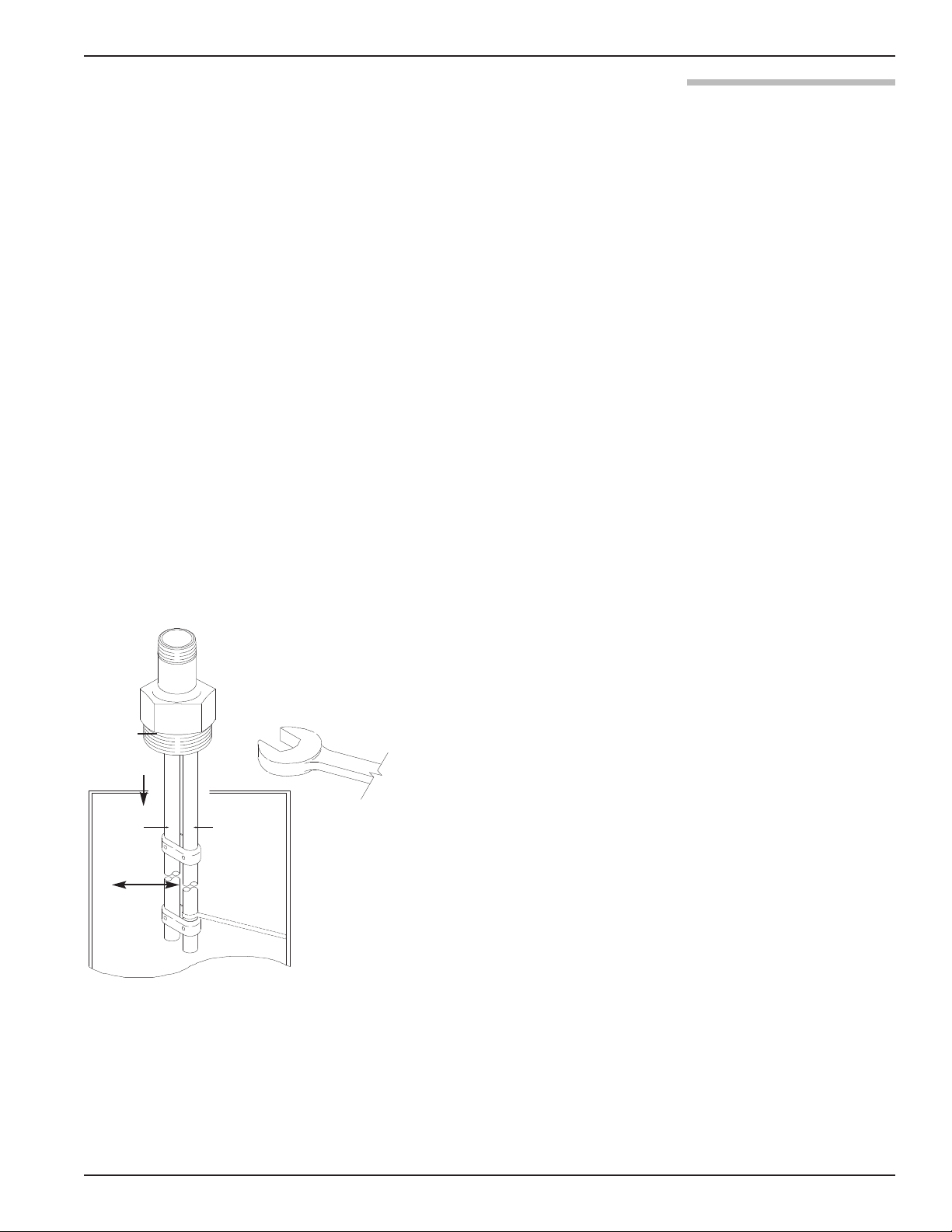

2.4.1.1 To install a coaxial probe:

Make sure the process connection is at least3⁄4" NPT or a

flanged mounting.

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

10

NOTE: If the transmitter is to be installed at a later time, do not remove

the protective cap from the probe. Do not use sealing compound or TFE tape on probe connection to transmitter as this

connection is sealed by a Viton®O-ring.

NOTE: For applications using the Model 7xS steam probe, it is manda-

tory to keep the transmitter and probe matched as a set.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 11

2.4.2 Installing a Twin Rod Probe

Active

probe rod

Inactive

probe rod

(Models 7xB, 7x5, and 7x7)

Before installing, make sure the:

• Model and serial numbers on the nameplates of the

ECLIPSE probe and transmitter are identical.

• Probe has adequate headroom for installation and has unobstructed entry to the bottom of the vessel.

• Process temperature, pressure, dielectric, viscosity, and

media buildup are within the probe specifications for the

installation. See Specifications, Section 3.6.

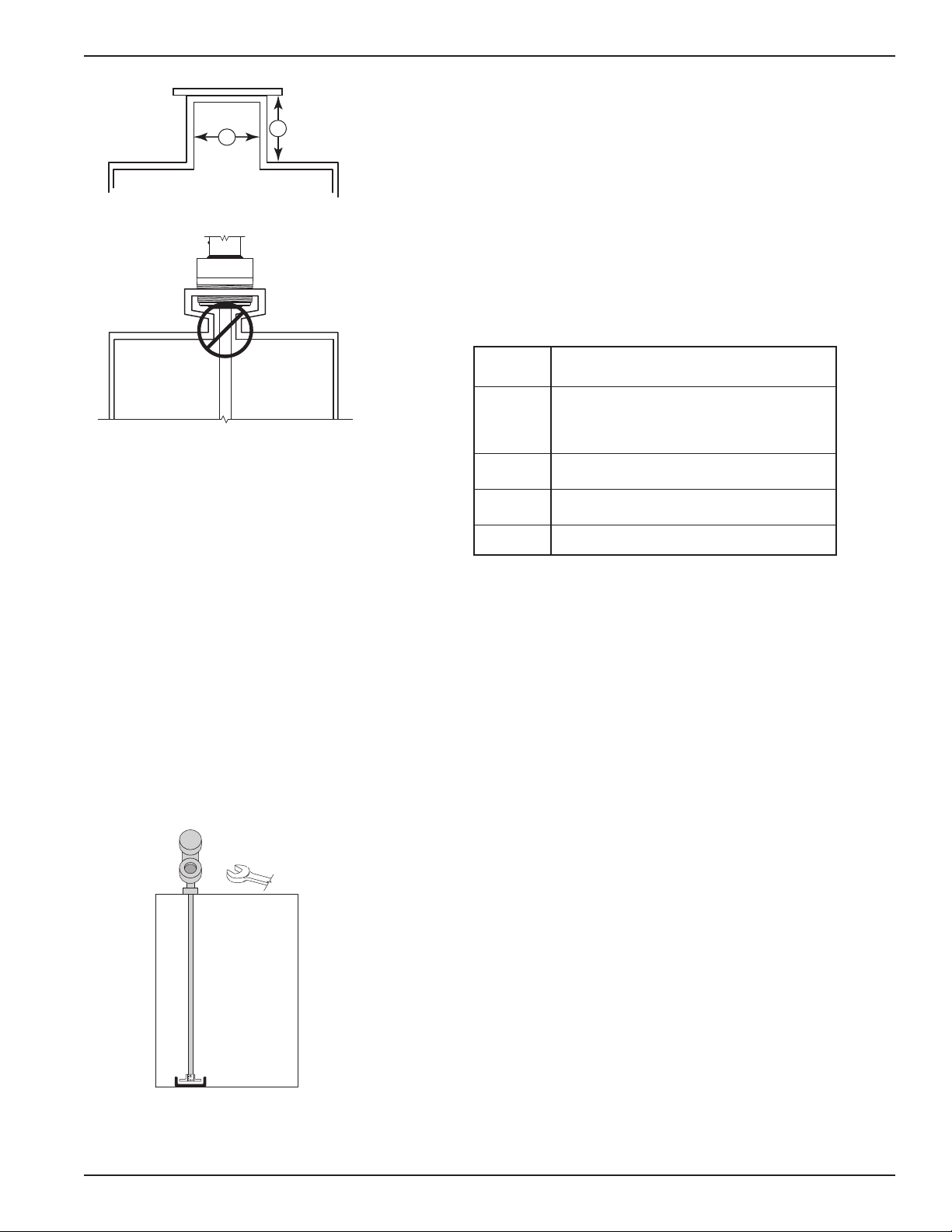

Nozzles:

The 7xB/7x5/7x7 Twin Rod probes may be susceptible to

objects that are in close proximity. The following rules

should be followed for proper application:

1. Nozzles should be 3" (80 mm) diameter or larger.

2. 7xB/7x5/7x7 Twin Rod probes should be installed such that

the active rod is >1" (25 mm) from metallic objects such as

pipes, ladders, etc., (a bare tank wall parallel to the probe is

acceptable).

2.4.2.1 To install a rigid twin rod probe:

Make sure the process connection is at least 2" NPT or a

flanged mounting.

Make sure that there is at least 1" (25 mm) spacing between

the active probe rod and any part of the tank (walls, stillwell, pipes, support beams, mixer blades, etc.). Minimum

stillwell diameter for Twin Rod probe is 3".

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

Probe can be stabilized by attaching the inactive probe rod

to vessel.

NOTE: If the transmitter is to be installed at a later time, do not remove

the protective cap from the probe. Do not use sealing compound or TFE tape on probe connection to transmitter as this

connection is sealed by a Viton®O-ring.

57-600 Eclipse®Guided Wave Radar Transmitter

11

Page 12

2.4.2.2 To install a Model 7x7 standard flexible twin rod probe:

0.50" (13 mm) Ø

1

3

2

4

➀

➁

➅

➅

➂

➃➄

Make sure the process connection is at least 2" NPT or a

flanged mounting.

Make sure that there is at least 1" (25 mm) spacing between

the active probe rod and any part of the tank (walls, stillwell, pipes, support beams, mixer blades, etc.). Minimum

stillwell diameter for Twin Rod probe is 3".

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

Probe can be shortened in the field:

a. Raise the weight (1) to expose the two securing devices (2).

b. Loosen the two #10-32 set screws (3) on both securing

3

devices using a

⁄32" (2.5 mm) hex wrench and slide the

securing devices off of the probe.

c. Slide the TFE weight off of the probe.

d. Cut and remove the required cable (4) length.

1

e. Remove 3

⁄2" of the rib between the two cables.

f. Strip5⁄8" (16 mm) of coating from the two cables.

g. Slide the TFE weight back on to the probe.

h. Reattach securing device and tighten screws.

i. Enter new probe length (inches or cm) in software.

2.4.3 Installing a Single Rod Probe (Models 7x1, 7x2, 7xF, 7xJ)

Before installing, make sure the:

• Model and serial numbers on the nameplates of the

ECLIPSE probe and transmitter are identical.

• Probe has adequate headroom for installation and has unobstructed entry to the bottom of the vessel.

• Process temperature, pressure, dielectric, viscosity, and

media buildup are within the probe specifications for the

installation. See Specifications, Section 3.6.

• Nozzle does not restrict performance by ensuring the

following:

12

1. No nozzle is <2" (50mm) diameter.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 13

2. Ratio of Diameter: Length (A:B) is 1:1 or greater; any

A

B

➄

➀

➁

➂

➃

ratio <1:1 (e.g., a 2"× 6" nozzle = 1:3) may require a

Blocking Distance and/or DIELECTRIC adjustment

(see Section 2.6.5.2 Measurement Type: Level and

Volume).

3. No pipe reducers (restrictions) are used.

• Probe is kept away from conductive objects to ensure proper

performance. See Probe Clearance Table below. A lower gain

(increase in DIELECTRIC setting) may be necessary to

ignore certain objects (see Section 2.6.5.4 Measurement

Type: Interface and Volume).

PROBE CLEARANCE TABLE

Distance

to Probe Acceptable Objects

<6" Continuous, smooth, parallel conductive

>6" <1" (25mm) diameter pipe and beams,

>12" <3" (75mm) diameter pipe and beams,

>18" All remaining objects

2.4.3.1 To install a Model 7xF rigid single rod probe:

surface, for example a metal tank wall;

important that probe does not touch wall

ladder rungs

concrete walls

Make sure the process connection is at least 2" NPT or a

flanged mounting.

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

Probe can be stabilized by placing into a non-metallic cup

or bracket at the bottom of the probe. A TFE bottom

spacer (P/N 89-9114-001) is optional for mounting into

a metallic cup or bracket.

57-600 Eclipse®Guided Wave Radar Transmitter

NOTE: If the transmitter is to be installed at a later time, do not remove

the protective cap from the probe. Do not use sealing compound or TFE tape on probe connection to transmitter as this

connection is sealed by a Viton®O-ring.

2.4.3.2 To install a Model 7x1 flexible single rod probe:

Make sure the process connection is at least 2" NPT or a

flanged mounting.

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

13

Page 14

Align the probe process connection with the threaded or

1

0.50" (13 mm) Ø

2

3

4

➄

➀

➁

➂

➃

➅

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

Probe can be shortened in field:

a. Raise TFE weight (1) exposing securing device (2).

3

b. Loosen both #10–32 set screws (3) using

⁄32" (2.5 mm)

hex wrench and remove securing device.

c. Cut and remove needed cable (4) length.

d. Reattach securing device and tighten screws.

e. Enter new probe length (inches or cm) in software.

Probe can be attached to the tank bottom using the

0.50" (13 mm) ∅ hole provided in the TFE weight.

Cable tension should not exceed 20 lbs.

2.4.4 Installation Guidelines Models 7x2/7x5 Bulk Solids Probes

The Model 7x2 and 7x5 Bulk Solids probes are designed for

a 3000 lb. (1360 kg) pull-down force for use in applications

such as sand, plastic pellets and grains. It is offered with a

maximum 75-foot (22-meter) probe length.

Model 7x2 Single Rod — dielectric ≥4

Model 7x5 Twin Rod — dielectric ≥1.9

NOTE: Avoid cement, heavy gravel, etc.

2.4.4.1 Applications

1. Plastic pellets, sugar: Dielectric constant 1.9-2.0

2. Grain, seeds, sand: Dielectric constant 2.0-3.0

3. Salts: Dielectric constant 4.0-7.0

4. Metallic powder, coal dust: Dielectric constant >7

2.4.4.2 Mounting recommendations

1. Use a weight instead of securing the probe to the vessel.

2. Mount probe at least 12 inches from the wall. Ideal

1

location is

of repose.

⁄4 to1⁄6 the diameter to average the angle

3. A metal flange must be used when mounting on plastic

vessels.

14

2.4.4.3 To install a Model 7x5 bulk solids flexible twin rod probe:

Make sure the process connection is at least 2" NPT or a

flanged mounting.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 15

Make sure that there is at least 1" (25 mm) spacing

between the active probe rod and any part of the tank

(walls, stillwell, pipes, support beams, mixer blades, etc.).

Minimum stillwell diameter for Twin Rod probe is 3".

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

Refer to Bulk Solid Guidelines, Section 2.4.4.

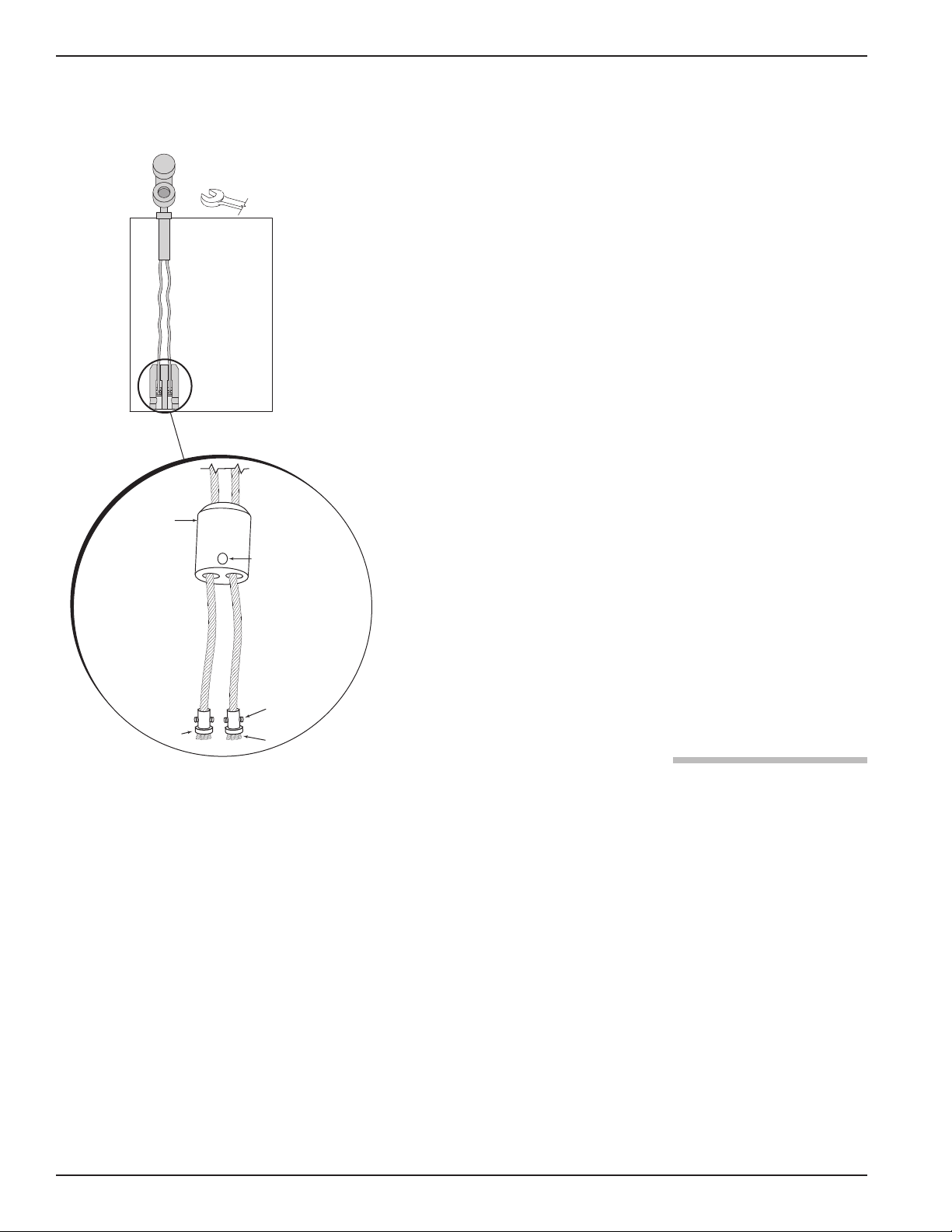

Probe can be shortened in the field:

a. Loosen and remove the two cable clamps.

b. Slide the weight off of the probe.

c. Cut the cable to the required length.

d. Remove 12 inches of the rib between the two cables.

Model 7x5 Dual Rod

Bulk Solids Probe

e. Strip 6 inches of coating from the two cables.

f. Slide the weight back on to the probe.

g. Reinstall the two cable clamps and tighten.

h. Enter the new probe length (inches or cm) in software.

2.4.4.4 To install a Model 7x2 bulk solids flexible single rod probe:

Make sure the process connection is at least 2" NPT or a

flanged mounting.

Carefully place the probe into the vessel. Align the gasket

on flanged installations.

Align the probe process connection with the threaded or

flanged mounting on the vessel.

For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

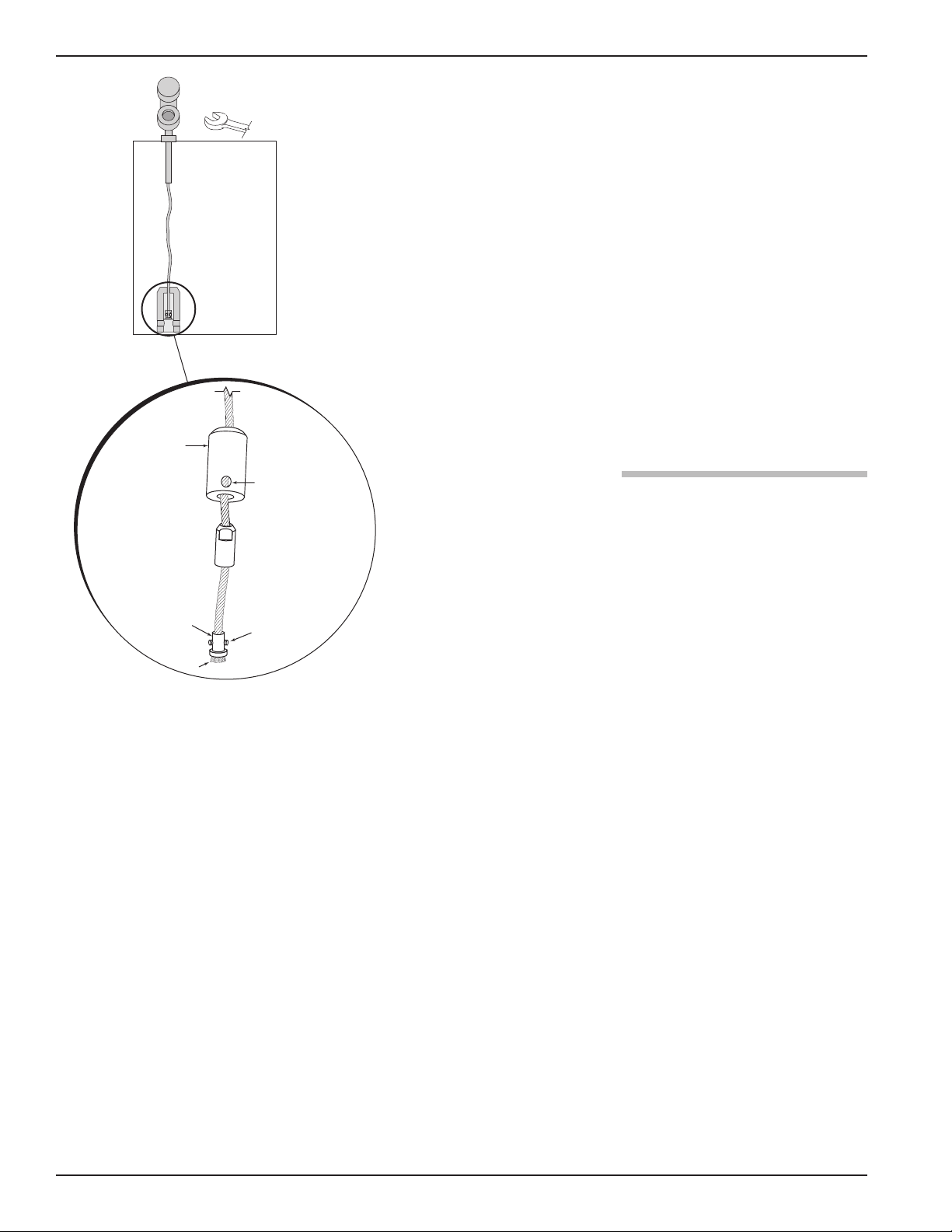

Probe can be shortened in field:

a. Loosen and remove the two cable clamps.

b. Slide the weight off of the probe.

Model 7x2 Single Rod

Bulk Solids Probe

57-600 Eclipse®Guided Wave Radar Transmitter

c. Cut the cable to the required length plus 6.38".

d. Slide the weight back on to the probe.

e. Reinstall the two cable clamps and tighten.

f. Enter the new probe length (inches or cm) in software.

15

Page 16

2.4.5 Installing the Transmitter

The transmitter can be ordered for installation as an

Integral or Remote configuration.

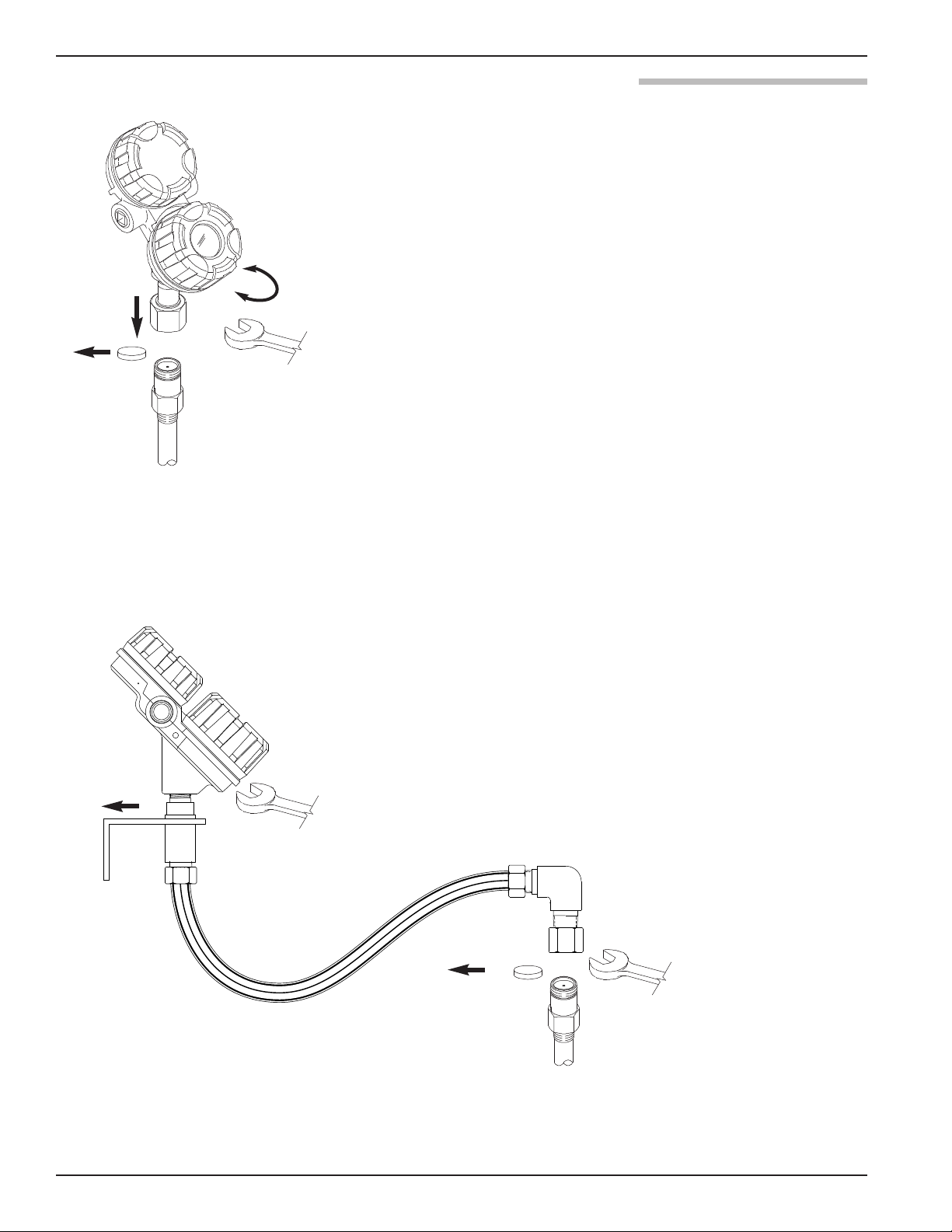

2.4.5.1 Integral Mount

Remove the protective plastic cap from the top of the

probe. Store the cap in a safe place in case the transmitter

has to be removed later.

Place the transmitter on the probe. Be careful not to bend

probe. Do not allow the gold, high frequency (male) connector to get dirty.

Align the universal connection at the base of the transmitter

housing with the top of the probe. Hand-tighten the

connection.

Rotate the transmitter to face the most convenient direction

for wiring, configuration, and viewing.

When the transmitter is facing the desired direction, use a

1

⁄2" (38 mm) wrench to tighten the universal connection on

1

the transmitter to 45 ft-lbs. A torque wrench is highly recommended. This is a critical connection. DO NOT LEAVE

HAND-TIGHT.

2.4.5.2 Remote Mount

Mount the transmitter/remote bracket as an assembly within

33" or 144" (84 or 366 cm) of the probe. DO NOT

REMOVE TRANSMITTER FROM BRACKET.

Remove the protective plastic cap from the top of the

probe. Store the cap in a safe place in case the transmitter

has to be removed later.

16

Align the universal connection at the end of the remote

1

assembly with the top of the probe. Using a 1

⁄2" (38 mm)

wrench, tighten the universal connection on the transmitter

to 45 ft-lbs. A torque wrench is highly recommended. This is

a critical connection. DO NOT LEAVE HAND-TIGHT.

NOTE: Remote mounting is recommended for all cast 316 SS

enclosures due to their extra weight.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 17

Red (+)Black (-)

(+)

(-)

2.5 Wiring

Caution: All HART versions of the ECLIPSE Model 705 transmitter

operate at voltages of 11–36 VDC. Higher voltage will

damage the transmitter.

Wiring between the power supply and the ECLIPSE

transmitter should be made using 18–22 AWG shielded

twisted pair instrument cable. Within the transmitter

enclosure, connections are made to the terminal strip

and the ground connections. The directions for wiring

the ECLIPSE transmitter depend on the application:

• General Purpose or Non-incendive (Cl I, Div. 2)

• Intrinsically Safe

• Explosion Proof

WARNING! Explosion hazard. Do not disconnect equipment unless

power has been switched off or the area is known to be

non-hazardous.

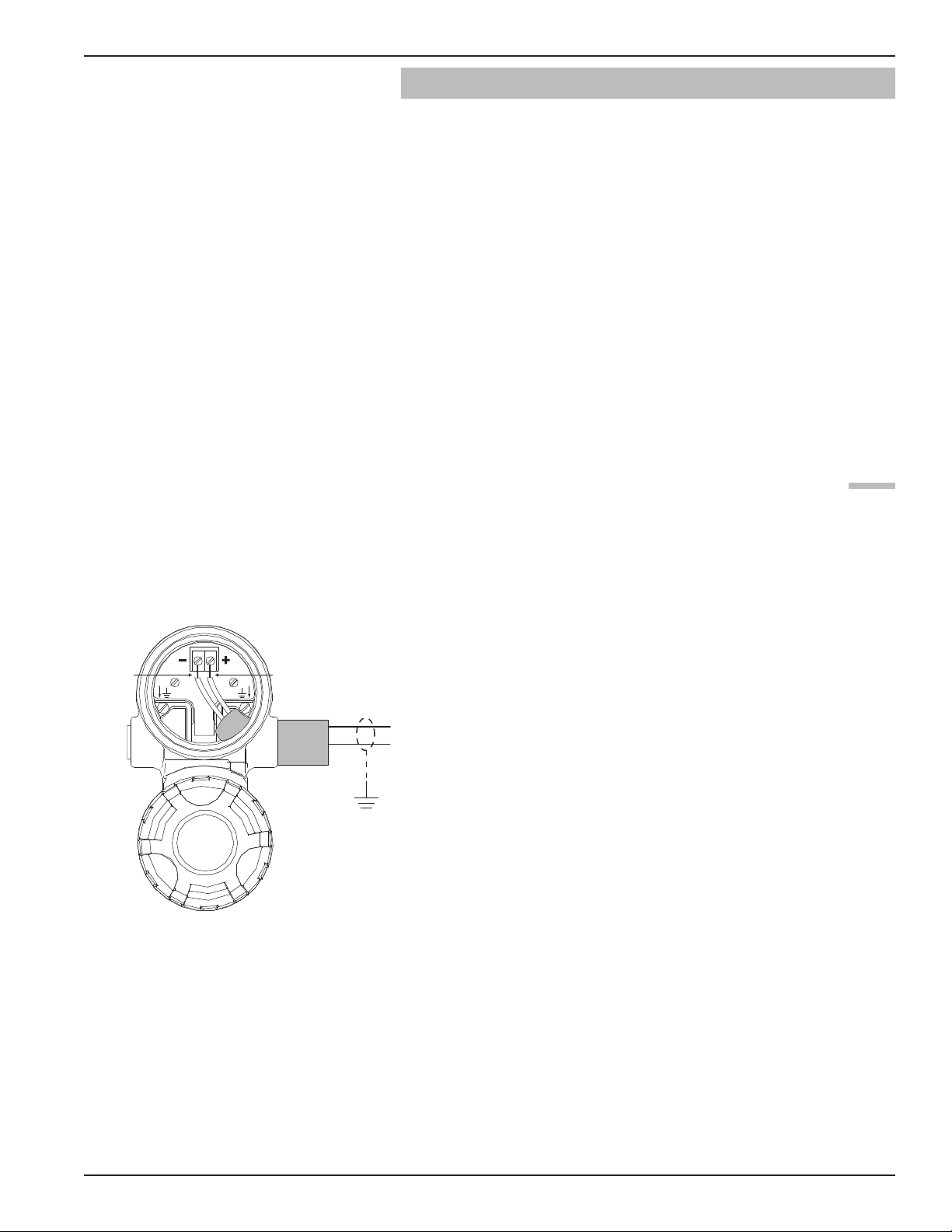

2.5.1 General Purpose or Non-Incendive (Cl I, Div. 2)

A general purpose installation does not have flammable

media present. Areas rated non-incendive (Cl I, Div. 2)

have flammable media present only under abnormal

conditions. No special electrical connections are required.

Wiring Diagram

Caution: If flammable media is contained in the vessel, the trans-

mitter must be installed per Cl I, Div. 1 standards of area

classification.

To install General Purpose or Non-Incendive wiring:

1. Remove the cover to the wiring compartment of the transmitter. Install the conduit plug in the unused opening.

Use PTFE tape/sealant to ensure a liquid-tight connection.

2. Install a conduit fitting and pull the supply wires.

3. Connect shield to an earth ground at power supply.

4. Connect an earth ground wire to the nearest green ground

screw (not shown in illustration).

5. Connect the positive supply wire to the (+) terminal and

the negative supply wire to the (-) terminal.

6. Replace the cover to the wiring compartment of the

transmitter.

57-600 Eclipse®Guided Wave Radar Transmitter

17

Page 18

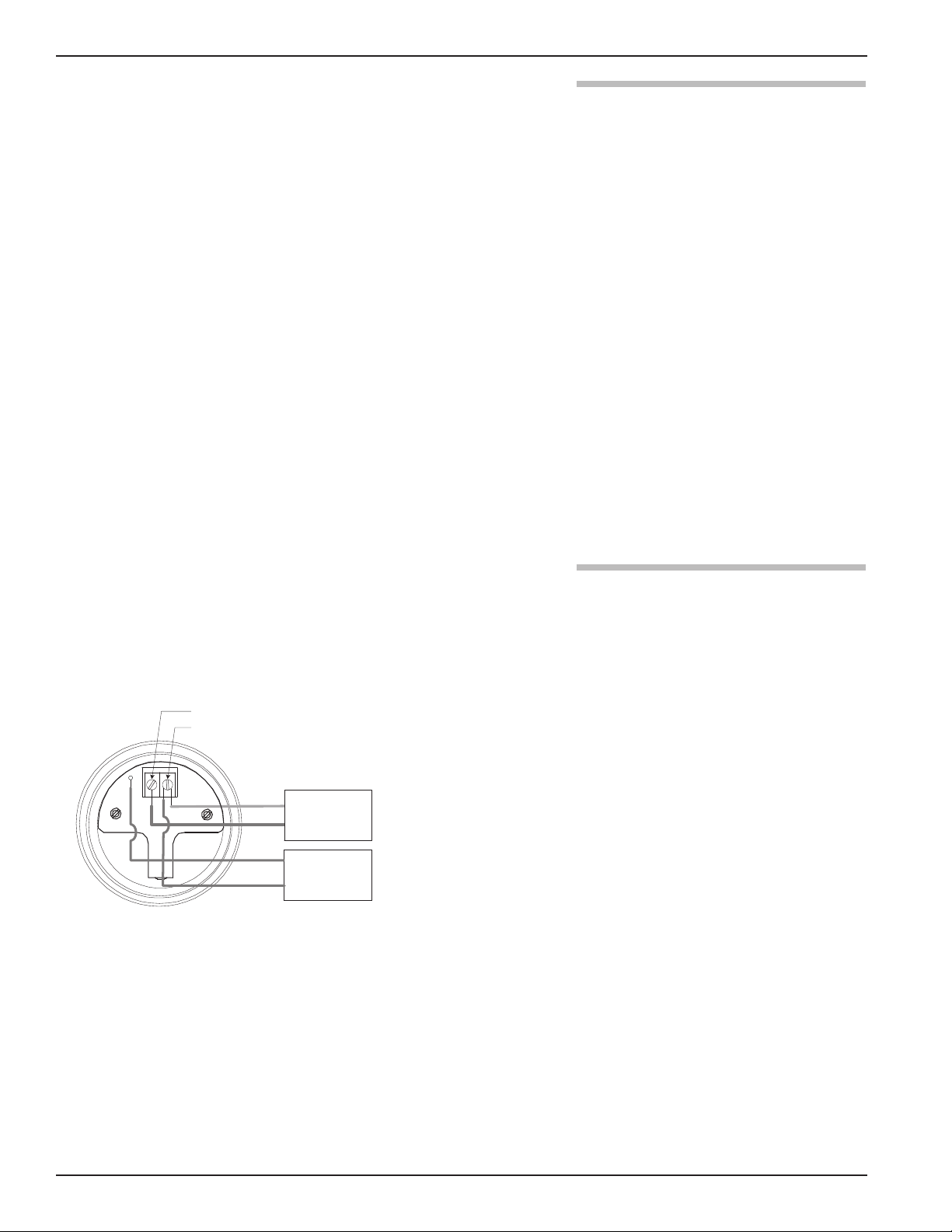

2.5.2 Intrinsically Safe

Current Meter

+

–

Test

Current Meter

Power Supply

24 VDC

–

+

(-) negative

(+) positive

An intrinsically safe (IS) installation potentially has flammable media present. An approved IS barrier must be

installed in the non-hazardous (safe) area. See Agency

Drawing – Intrinsically Safe Installation, Section 3.4.2.

To install Intrinsically Safe wiring:

1. Make sure the IS barrier is properly installed in the safe

area (refer to local plant or facility procedures). Complete

the wiring from the barrier to the ECLIPSE transmitter.

2. Remove the cover to the wiring compartment of the transmitter. Install the conduit plug in the unused opening. Use

PTFE tape/sealant to ensure a liquid-tight connection.

3. Install a conduit fitting and pull the supply wires.

4. Connect shield to an earth ground at power supply.

5. Connect an earth ground wire to the nearest green ground

screw (not shown in illustration).

6. Connect the positive supply wire to the (+) terminal and

the negative supply wire to the (-) terminal.

7. Replace the cover to the wiring compartment of the

transmitter.

G.P./I.S./Explosion Proof Model

2.5.3 Explosion Proof

Explosion Proof (XP) is a method of designing equipment

for installation in hazardous areas. A hazardous location is

an area in which flammable gases or vapors are, or may be,

present in the air in quantities sufficient to produce explosive or ignitable mixtures. The wiring for the transmitter

must be contained in Explosion Proof conduit extending

into the safe area. Due to the specialized design of the

ECLIPSE transmitter, no Explosion Proof conduit fitting

(EY seal) is required within 18" of the transmitter. An

Explosion Proof conduit fitting (EY seal) is required

between the hazardous and safe areas. See Agency

Specifications, Section 3.4.1.

To install Explosion Proof wiring:

1. Install Explosion Proof conduit from the safe area to the

conduit connection of the ECLIPSE transmitter (refer to

local plant or facility procedures).

2. Remove the cover to the wiring compartment of the

transmitter.

3. Connect shield to an earth ground at the power supply.

4. Connect an Earth ground wire to the nearest green ground

screw per local electrical code (not shown in illustration).

18

5. Connect the positive supply wire to the (+) terminal and

the negative supply wire to the (-) terminal.

6. Replace the cover to the wiring compartment of the

transmitter before applying power.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 19

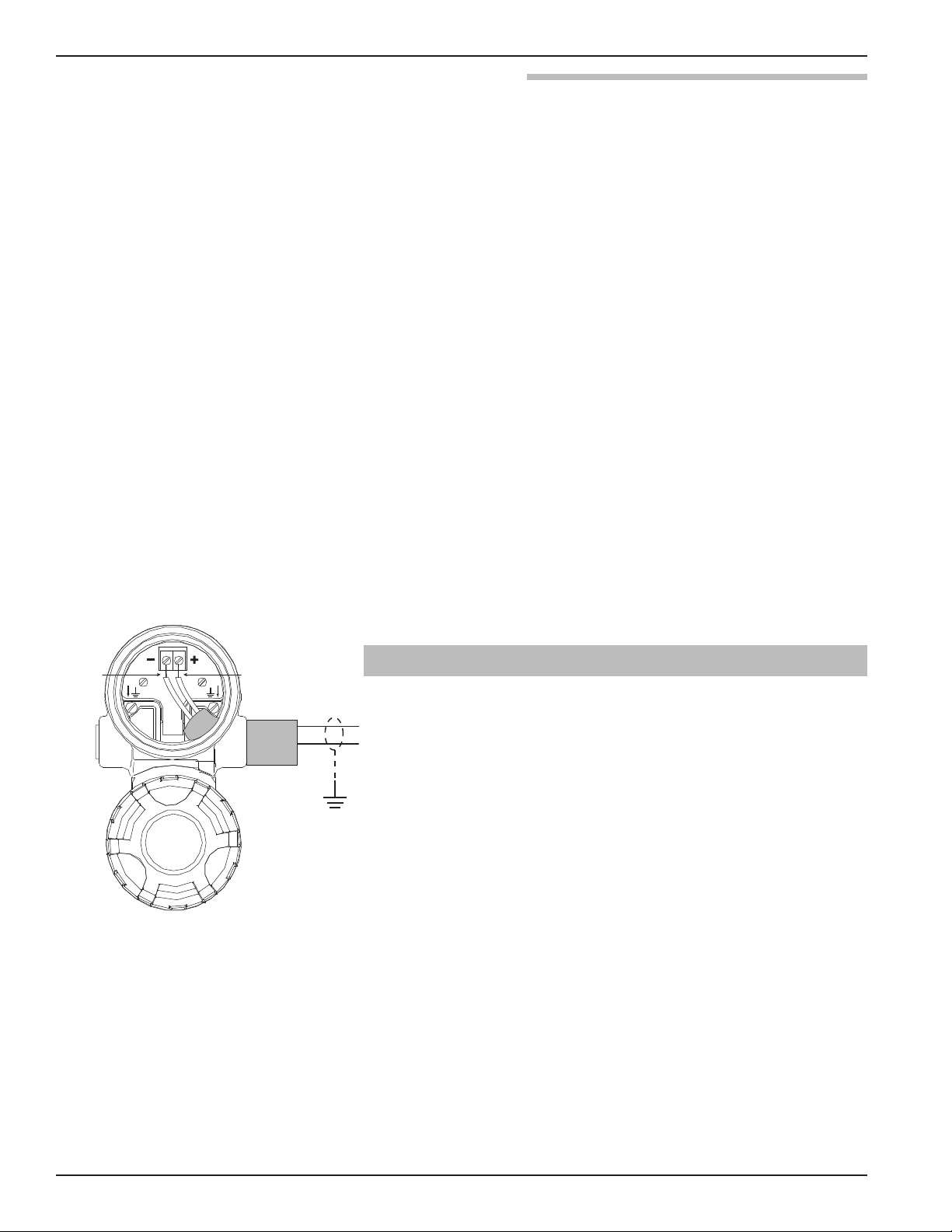

2.6 Configuring the Transmitter

Current Meter

+

–

Test

Current Meter

Power Supply

24 VDC

–

+

(-) negative

(+) positive

The ECLIPSE transmitter comes configured from the factory

but can be reconfigured easily in the shop (disregard error

message due to unattached probe). Bench configuration

provides a convenient and efficient way to set up the

transmitter before going to the tank site to complete the

installation.

Before configuring the transmitter, collect the operating

parameters information (refer to Section 1.1.2). Power up

the transmitter on the bench and follow through the stepby-step procedures for the menu-driven transmitter display.

Information on configuring the transmitter using a HART

communicator is given in Configuration Using HART,

Section 2.7.

Information on configuring the transmitter using

OUNDATION fieldbus is given in Section 2.8.

F

Refer to instruction manual 57-640 for detailed

FOUNDATION fieldbus information.

G.P./I.S./Explosion Proof Model

2.6.1 Operating Parameters

Some key information is needed to calibrate the ECLIPSE

transmitter. Complete the configuration information table

in Section 1.1.2.

2.6.2 Setting Up for Bench Configuration

The ECLIPSE transmitter can be configured at a test

bench by connecting a 24 VDC power supply directly to

the transmitter terminals as shown in the accompanying

diagram. An optional digital multimeter is shown if current measurements are desired.

NOTE: Current measurements taken at these test points is an

approximate value. Accurate current readings should be

taken with the digital multimeter in series with the loop.

1. When using a HART communicator for configuration, a

minimum 250 Ω line load resistance is required. See the

HART communicator manual for more information.

2. The transmitter can be configured without the probe.

(Disregard the error message due to the unattached probe.)

3. After entering the last value, allow 10 seconds before

removing power from the transmitter. This allows the

transmitter to store values.

57-600 Eclipse®Guided Wave Radar Transmitter

19

Page 20

2.6.3 Transmitter Display and Keypad

Enter

Down

Up

The ECLIPSE transmitter has an optional liquid crystal display

(LCD) capable of showing two lines of 8 characters each.

Transmitter measurements and configuration menu screens

are shown on the LCD.

The transmitter default display is the measurement screen.

It cycles every 5 seconds to display STATUS, LEVEL,

%OUTPUT, and LOOP information (LEVEL,

%OUTPUT, and STATUS for Fieldbus version). The

transmitter defaults to this display after 5 minutes if no

keystrokes are sensed.

The keypad has three arrows used to scroll through the displays and to calibrate the transmitter. The Up and Down

Arrow ( ) keys and the Enter ( ) key.

Arrows Display Mode Configuration Mode

Up and Down Moves forward and backward Increases or decreases the

Enter Enters the configuration mode Accepts a value and moves

Function in Function in

in the configuration program value displayed or moves to

from one display to another. another choice.

NOTE: Hold arrow key for

rapid scrolling.

(noted by an exclamation point to the next step of the

as the last character in the top configuration program.

display line).

2.6.4 Password Protection (Default = 0)

The ECLIPSE transmitter is password protected to restrict

access to certain portions of the menu structure that affect

the operation of the system. When the proper password is

entered, an exclamation point (!) appears as the last character of the first line of the display. The password can be

changed to any numerical value up to 255. The password is

required whenever configuration values are changed.

The default user password installed in the transmitter at the

factory is 0. The last step in the configuration menu provides the option to enter a new password. With a password

of 0, the transmitter is no longer password protected and

any value in the menu can be adjusted without entering a

confirming password, except diagnostic values.

20

NOTE: If the password is not known, the menu item New Password

displays an encrypted value representing the present password. Call the factory with this encrypted value to determine

the present password.

57-600 Eclipse®Guided Wave Radar Transmitter

Page 21

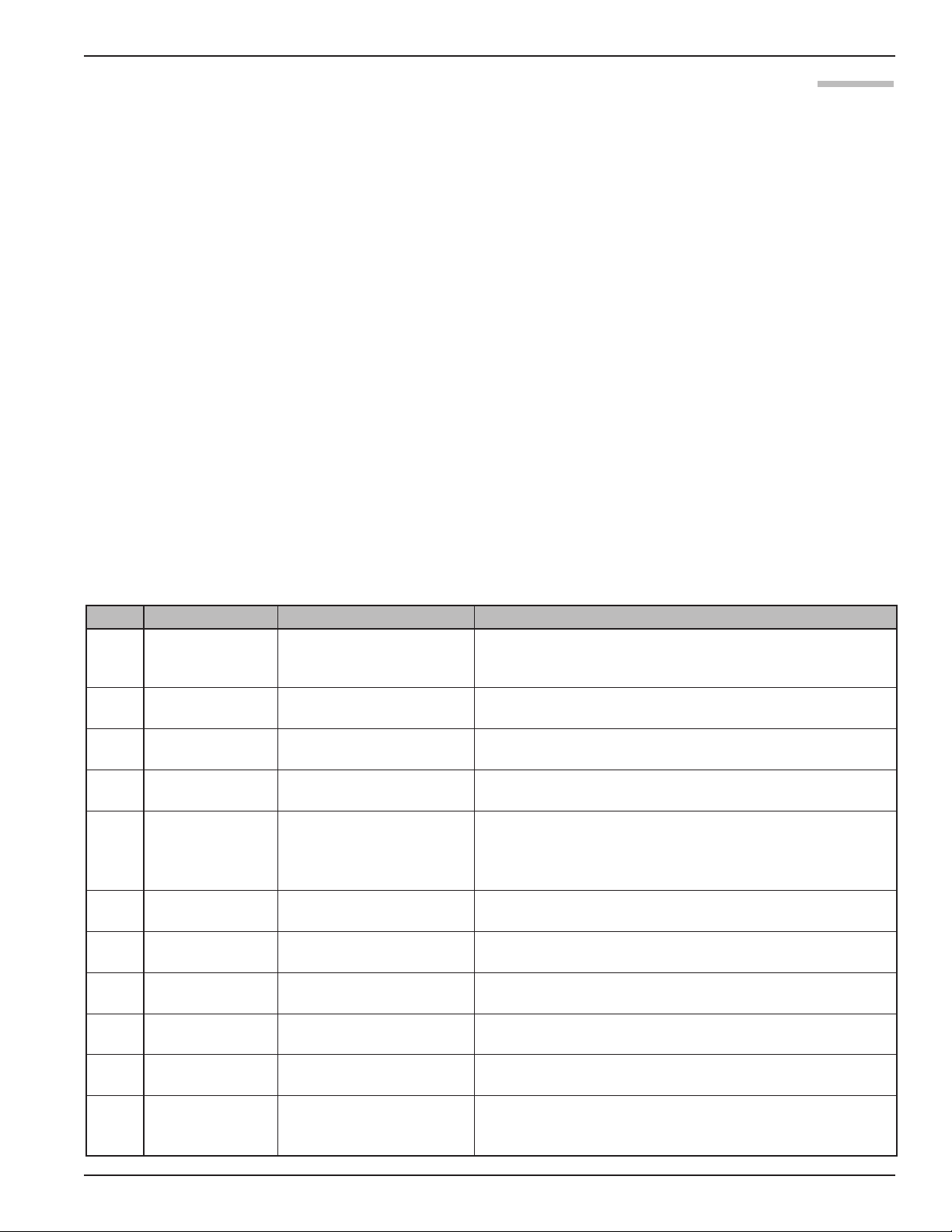

2.6.5 Model 705 Menu: Step-By-Step Procedure

The following tables provide a complete explanation of

the software menus displayed by the ECLIPSE transmitter.

Use these tables as a step-by-step guide to configure the

transmitter based on a desired measurement type of:

• Level Only, Section 2.6.5.1

• Level and Volume, Section 2.6.5.2

• Interface Level, Section 2.6.5.3

• Interface Level and Volume, Section 2.6.5.4

The tables are separated to display the parameters based

on the measurement type. The second column presents

the menus shown on the transmitter display. The displays

are in the order they would appear if the arrow keys were

used to scroll through the menu. The numbers in the first

column are not shown on the display. They are only provided as a reference.

The third column provides the actions to take when configuring the transmitter. Additional information or an

explanation of an action is given in the fourth column.

(Shaded sections are factory menu items).

2.6.5.1 Measurement Type: Level Only (Loop Control = Level)

Display Action Comment

1

2

3

4

5

6

7

8

9

10

11

*Status*

*Level *

*% Out *

* Loop *

Level

xxx.x

% Output

xx.x%

Loop

xx.xx mA

PrbModel

(select)

PrbMount

(select)

MeasType

(select)

LvlUnits

(select)

Probe Ln

xxx.x

Lvl Ofst

xxx.x

Dielctrc

(select)

Transmitter Display LoopCtrl = Level.

Transmitter default display showing Status, Level, % Output, and

Loop values cycles every 5 seconds

Transmitter Display Transmitter displays Level Value in selected units

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span

Transmitter Display Transmitter displays Loop value (mA)

Select the type of probe

used

(Example: 7xR-x)

Select the type of probe

mounting

Select type of measurement Select Lvl Only

Select level units Select from cm, inches, feet or meters

Enter the exact length of

probe

Enter the desired reading

when probe is dry

Select range bounding the

dielectric constant of the

media

Select from 7xA-x, 7xB-x, 7xD-x, 7xE-x, 7xF-x, 7xF-E, 7xF-F,

7xF-4, 7xG-x, 7xF-P, 7xG, 7xJ-x, 7xK-x, 7xL, 7xM, 7xN, 7xP-x,

7xR-x, 7xS-x, 7xT-x, 7x1-x, 7x2-x, 7x5-x, 7x7-x as shown on

the probe nameplate

Select from NPT, BSP, or Flange

Probe length is printed on the nameplate and order information

and is the last three digits of the probe model number

Level Offset is the distance from the probe tip to the desired 0

level point (-90 to 300"). Refer to Section 2.6.6

Select from 1.4–1.7; 1.7–3; 3–10; 10–100

57-600 Eclipse®Guided Wave Radar Transmitter

21

Page 22

2.6.5.1 Measurement Type: Level Only (Loop Control = Level)

Display Action Comment

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Senstvty

xxx

LoopCtrl

(select)

Set 4mA

xxx.x 1u

Set 20mA

xxx.x lu

Damping

xx s

Fault

(select)

BlockDis

xx.x lu

SZ Fault

(select)

SZ Height

(xx.x lu)

SZ Alarm Reset

Threshld

(select)

Poll Adr

xx

Loop Mode

Trim Lvl

xx.x lu

Trim 4

xxxx

Enter value upward or

downward to sense liquid

Allows fine gain adjustment for single rod probes (this parameter

is password protected for coaxial and twin rod probes).

surface

Select variable to control

Select Level

loop current

Enter the PV value for the

4 mA point

Enter the PV value for the

20 mA point

A small transition zone (0–6") may exist at the top/bottom of

the probe. See Functional Specifications Probe, Section 3.6.1

A small transition zone (0–6") may exist at the top/bottom of

the probe. Top 4" (100 mm) of 7xB Twin Rod Probe is inactive.

See Functional Specifications Probe, Section 3.6.1

Enter time constant of

desired damping

Select the loop current value

A Damping factor (0–10 seconds) may be added to smooth the

output due to turbulence

Select from 3.6 mA, 22 mA or HOLD

in presence of a fault

Enter distance below reference point where level is not

Allows user to ignore level measurements near the top of the

probe

sensed

Select loop current behavior

when level is sensed in safety

zone

Safety Zone is a user-defined area just below the Blocking

Distance. Enable Fault if necessary to ensure safe, reliable high-

level readings in critical applications. Choices are None, 3.6 mA,

22 mA, Latch 3.6 or Latch 22. If Latch 3.6 or Latch 22 is

selected, the loop current will remain in alarm until it is manually

cleared with the SZ Alarm Reset below (#21)

Enter distance below

BlockDis where SZ Fault will

be asserted

Press Enter to clear a

Enter a distance value that develops a safety zone just below the

Blocking Distance. Here the unit will report a Safety Zone Fault

(#19) if the level rises into this area.

Clear a latched Safety Zone alarm

latched Safety Zone alarm

Select the type of threshold Unit default CFD. Only select Fixed in application with low

dielectric material over higher dielectric material and unit is reading incorrect level. Example: Oil over water. (Adjustment of Trim

Level may be necessary when threshold is changed)

Enter HART polling address

number (0-63)

Select a HART poll address (0–63). Enter 0 for a single

transmitter installation. Poll address does not affect loop current.

Enable/Disable Determines whether the loop is fixed at 4.0 mA or controlled by

the PV.

Enter value to adjust Level

reading

-10.0 inches ≤ Lvl Trim ≤ +10.0 inches

(Requires superuser password)

Fine tune the 4 mA point Adjust setting to output exactly 4.0 mA on current meter

22

27

28

29

30

31

32

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

Xxxxx

New Pass

xxx

Language

(select)

Mdl705HT

Ver3.0a0

Fine tune the 20 mA point Adjust setting to output exactly 20.0 mA on current meter

Enter a mA Output value Set mA output to any given value to perform loop test

Diagnostic Display Time of flight from fiducial to level signal

Enter new password (0-255) Displays encrypted value of present password

Select from English, Spanish,

Language choice for LCD display

French, German

Transmitter display Product identification Firmware version

57-600 Eclipse®Guided Wave Radar Transmitter

Page 23

2.6.5.1 Measurement Type: Level Only (Loop Control = Level)

Display Action Comment

33

34

(current status)

DispFact

(select)

History

Select Yes to display factory

parameter menus

Press Enter to view history

of exceptions

Diagnostic Display

35

36

37

38

39

40

41

42

43

44

45

46

Run Time

History Reset

HF cable

(select)

FidTicks

xxxx

FidSprd

Fid Type

(select)

Fid Gain

xxx

Window

xxx

Conv Fct

xxxx

Scl Ofst

xxx

Neg Ampl

xxx

Pos Ampl

xxx

Press Enter and select yes

Similar to SZ Alarm Reset

to clear history

Superuser Parameter Select from 3-foot or 12-foot remote

Diagnostic Display Time of flight from start of ramp to fiducial

Superuser Parameter Select from positive or negative

(Selection only allowed for some probes)

Superuser Parameter Amount of gain applied to the fiducial signal

Factory Parameter

Factory Parameter Calibration parameter

Factory Parameter Calibration parameter

Superuser Password Diagnostic parameter

Superuser Password Diagnostic parameter

47

48

49

50

51

52

53

54

55

56

57

58

Signal

xxx

Compsate

(select)

DrateFct

xxxx

Targ Ampl

xxxx

Targ Tks

xxxx

Targ Cal

xxxx

OperMode

(select)

7xKCorr

xxx

ElecTemp

xxx C

Max Temp

xxx C

Min Temp

xxx C

SZ Hyst

xx.x lu

Diagnostic Display Indication of level signal amplitude

Superuser Password Select from None, Manual, Auto

Diagnostic Display Compsate = Auto. Velocity derating factor for Model 7xS Steam

probe

Diagnostic Display Compsate = Auto. Indication of steam reference target amplitude

Diagnostic Display Compsate = Auto. Measured time of flight from fiducial to steam

reference target

Diagnostic Display Compsate = Auto. Calibrated time of flight from fiducial to target

in room temperature air

Superuser Password Compsate = Auto. Select from Run, Cal, Off

Superuser Password Distance in mm from fiducial to user reference point

(7xK probe characteristic)

Diagnostic Display Present temperature in electronics compartment

(degrees Celsius)

Superuser Password Maximum electronics temperature recorded

Superuser Password Minimum electronics temperature recorded

Superuser Password

57-600 Eclipse®Guided Wave Radar Transmitter

23

Page 24

2.6.5.2 Measurement Type: Level and Volume (Loop Control = Volume)

Display Action Comment

*Status*

1

*Volume*

*% Out *

* Loop *

Transmitter Display LoopCtrl = Volume

Transmitter default display showing: Status, Volume, % Output

and Loop values cycles every 5 seconds

2

3

4

5

6

7

8

9

10

11

12

Volume

xxx vu

% Output

xx.x%

Loop

xx.xx mA

Level

xxx.x 1u

PrbModel

(select)

PrbMount

(select)

MeasType

(select)

LvlUnits

(select)

Probe Ln

xxx.x lu

Lvl Ofst

xxx.x lu

VolUnits

(select)

Transmitter Display Transmitter displays Volume in selected units

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span

Transmitter Display Transmitter displays Loop value (mA)

Transmitter Display Transmitter displays Level Value in selected units

Select the type of probe

used

(Example: 7xR-x)

Select the type of probe

Select from 7xA-x, 7xB-x, 7xD-x, 7xE-x, 7xF-x, 7xF-E, 7xF-F,

7xF-4, 7xF-P, 7xG-x, 7xJ-x, 7xK-x, 7xL, 7xM, 7xN, 7xP-x, 7xR-x,

7xS-x, 7xT-x, 7x1-x, 7x2-x, 7x5-x, 7x7-x as shown on the probe

nameplate

Select from NPT, BSP, or Flange

mounting

Select type of measurement Select from Lvl&Vol

Select level units Select from cm, inches, feet or meters

Enter the exact length of

probe

Enter desired Level reading

when probe is dry

Probe length is printed on the nameplate and order information

and is the last three digits of the probe model number

Level Offset is the distance from the probe tip to the desired 0

level point (-90 to 300"). Refer to Section 2.6.6

Select the volume units Select from liters or gallons

13

14

15

16

17

18

19

20

21

StrapTbl

nn pnts

Dielctrc

(select)

Senstvty

xxx

LoopCtrl

(select)

Set 4mA

xxxx vu

Set 20mA

xxxx vu

Damping

xx s

Fault

(select)

BlockDis

xx.x lu

Enter to access strapping

table

Select range bounding the

dielectric constant of the

media

Enter value upward or

downward to sense liquid

surface

Select variable to control

loop current

Enter the PV value for the

4 mA point

Enter the PV value for the

20 mA point

Enter time constant of

desired damping

Select the loop current value

in presence of a fault

Enter distance below reference point where level is not

sensed

20-point strapping table enables conversion from level to volume

(Refer to Section 2.6.7 for more information)

Select from 1.4–1.7; 1.7–3; 3–10; 10–100

Allows fine gain adjustment for single rod probes (this parameter

is password protected for coaxial and twin rod probes)

Select from Level or Volume

A small transition zone (0–6") may exist at the top/bottom of

the probe. See Functional Specifications Probe, Section 3.6.1

A small transition zone (0–6") may exist at the top/bottom of

the probe

A Damping factor (0–10 seconds) may be added to smooth the

output due to turbulence

Select from 3.6 mA, 22 mA or HOLD

Allows user to ignore level measurements near the top of the

probe

24

57-600 Eclipse®Guided Wave Radar Transmitter

Page 25

2.6.5.2 Measurement Type: Level and Volume (Loop Control = Volume)

Display Action Comment

22

23

24

25

26

27

28

29

SZ Fault

(select)

SZHeight

xx.x lu

SZ Alarm Reset

Threshld

(select)

Poll Adr

xx

Loop Mode

Trim Lvl

xx.x lu

Trim 4

xxxx

Select loop current behavior

when level is sensed in safety

zone

Enter distance below

BlockDis where SZ Fault will

be asserted

Press Enter to clear a

latched Safety Zone alarm

Select the type of threshold Unit default CFD. Only select Fixed in application with low

Enter HART polling address

number (0-63)

Enable/Disable Determines whether the loop is fixed at 4.0 mA or controlled by

Enter value to adjust Level

reading

Fine tune the 4 mA point Adjust setting to output exactly 4.0 mA on current meter

Safety Zone is a user-defined area just below the Blocking

Distance. Enable Fault if necessary to ensure safe, reliable high-

level readings in critical applications. Choices are None, 3.6 mA,

22 mA, Latch 3.6 or Latch 22. If Latch 3.6 or Latch 22 is

selected, the loop current will remain in alarm until it is manually

cleared with the SZ Alarm Reset below (#23)

Enter a distance value that develops a safety zone just below the

Blocking Distance. Here the unit will report a Safety Zone Fault

(#21) if the level rises into this area.

Clear a latched Safety Zone alarm

dielectric material over higher dielectric material and unit is reading incorrect level. Example: Oil over water. (Adjustment of Trim

Level may be necessary when threshold is changed)

Select a HART poll address (0–63). Enter 0 for a single

transmitter installation. Poll address does not affect loop current.

the PV.

-10.0 inches <= Lvl Trim <= +10.0 inches

(Requires superuser password)

30

31

32

33

34

35

36

37

(current status)

38

39

40

History Reset

41

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

xxxx

New Pass

xxx

Language

(select)

Mdl705HT

Ver3.0a0

DispFact

(select)

History

HF cable

(select)

Run Time

FidTicks

xxxx

Fine tune the 20 mA point Adjust setting to output exactly 20.0 mA on current meter

Enter a mA Output value Set mA output to any given value to perform loop test

Diagnostic Display Time of flight from fiducial to level signal

Enter new password (0-255) Displays encrypted value of present password

Select from English, Spanish,

Language choice for LCD display

French, German

Transmitter display Product identification Firmware version

Select Yes to display factory

Allows for viewing the factory parameters

parameter menus

Press Enter to view history

Diagnostic Display

of recent exceptions

Superuser Parameter Select from 3-foot or 12-foot remote

Press Enter and select yes

Similar to SZ Alarm Reset

to clear history

Diagnostic Display Time of flight from start of ramp to fiducial

42

43

57-600 Eclipse®Guided Wave Radar Transmitter

Fid Type

(select)

Fid Spread

Superuser Password Select from positive or negative

(Selection only allowed for some probes)

25

Page 26

2.6.5.2 Measurement Type: Level and Volume (Loop Control = Volume)

Display Action Comment

44

Fid Gain

xxx

Superuser Password

45

46

47

48

49

50

51

52

53

54

55

Window

xxx

Conv Fct

xxxx

Scl Ofst

xxx

Neg Ampl

xxx

Pos Ampl

xxx

Signal

xxx

Compsate

(select)

7xKCorr

xxx

ElecTemp

xxx C

Max Temp

xxx C

Min Temp

xxx C

Factory Parameter

Factory Parameter Calibration parameter

Factory Parameter Calibration parameter

Superuser Password Diagnostic factory setting

Superuser Password Diagnostic factory setting

Diagnostic Display Indication of level signal amplitude

Superuser Parameter Select from None, Manual, Auto

Superuser Parameter Distance in mm from fiducial to user reference point

(7xK probe characteristic)

Diagnostic Display Present temperature in electronics compartment

(degrees Celsius)

Diagnostic Display Maximum electronics temperature recorded

Diagnostic Display Minimum electronics temperature recorded

56

SZ Hyst

xx.x lu

Diagnostic Display Diagnostic factory setting

26

57-600 Eclipse®Guided Wave Radar Transmitter

Page 27

2.6.5.3 Measurement Type: Interface Level (Loop Control = Interface Level)

Display Action Comment

*Status*

1

2

*IfcLvl*

*% Out *

* Loop *

IfcLvl

xxxx vu

Transmitter Display LoopCtrl = IfcLevel

Transmitter default display showing Status, IfcLevel, % Output,

and Loop values cycles every 5 seconds

Transmitter Display Transmitter displays interface level in selected units

3

4

5

6

7

8

9

10

11

12

% Output

xx.x%

Loop

xx.xx mA

Level

PrbModel

(select)

PrbMount

(select)

MeasType

(select)

LvlUnits

(select)

Probe Ln

xxx.x

Lvl Ofst

x.xx

Upr Diel

(select)

Transmitter Display Transmitter displays % Output measurement derived from

20 mA span

Transmitter Display Transmitter displays Loop value (mA)

Select the type of probe

used

Select from 7xB-x, 7xD-x, 7xF-x, 7xG, 7xL, 7xM, 7xN, 7xT-x,

7x7-x as shown on the probe nameplate

(Example: 7xT-x)

Select the type of probe

Select from NPT, BSP, or Flange

mounting

Select type of measurement Select from Intrface

Select level units Select from cm, inches, feet or meters

Enter the exact length of

probe

Enter the desired reading

when probe is dry

Enter the dielectric constant

Probe length is printed on the nameplate and order information

and is the last three digits of the probe model number

Level Offset is the distance from the probe tip to the desired 0%

level point (-90 to 300"). Refer to Section 2.6.6

Interface mode or Manual compensation mode

of the upper liquid

13

14

15

16

17

18

19

20

Dielctrc

(select)

Senstvty

xxx

LoopCtrl

(select)

Set 4mA

xxx.x 1u

Set 20mA

xxx.x lu

Damping

xx s

Fault

(select)

BlockDis

xx.x lu

Select range bounding the

dielectric constant of the

lower liquid

Enter value upward or

downward to sense liquid

surface

Select variable to control

loop current

Enter the PV value for the

4 mA point

Enter the PV value for the

20 mA point

Enter time constant of

desired damping

Select the loop current value

in presence of a fault

Enter distance below

reference point where

level is not sensed

Select 10–100

Allows fine gain adjustment for single rod probes (this parameter

is password protected for coaxial and twin rod probes)

Select from Level or IfcLvl

A small transition zone (0–6") may exist at the top/bottom of

the probe. See Functional Specifications Probe, Section 3.6.1

A small transition zone (0–6") may exist at the top/bottom of

the probe

A Damping factor (0–10 seconds) may be added to smooth the

output due to turbulence

Select from 3.6 mA, 22 mA or HOLD

Allows user to ignore level measurements near the top of probe

57-600 Eclipse®Guided Wave Radar Transmitter

27

Page 28

2.6.5.3 Measurement Type: Interface Level (Loop Control = Interface Level)

Display Action Comment

21

SZ Fault

(select)

Select loop current behavior

when level is sensed in safety

zone

Safety Zone is a user-defined area just below the Blocking

Distance. Enable Fault if necessary to ensure safe, reliable high-

level readings in critical applications. Choices are None, 3.6 mA,

22 mA, Latch 3.6 or Latch 22. If Latch 3.6 or Latch 22 is

selected, the loop current will remain in alarm until it is manually

cleared with the SZ Alarm Reset below (#23)

22

23

24

25

26

27

28

29

30

31

32

SZ Height

xx.x lu

SZ Alarm Reset

Threshld

(select)

IfcThrsh

(select)

Poll Adr

xx

Loop Mode

Trim Lvl

xx.x lu

Trim 4

xxxx

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

xxxx

Enter distance below

BlockDis where SZ Fault will

be asserted

Press Enter to clear a

Enter a distance value that develops a safety zone just below the

Blocking Distance. Here the unit will report a Safety Zone Fault

(#21) if the level rises into this area.

Clear a latched Safety Zone alarm

latched Safety Zone alarm

Select from CFD, Fixed For interface, refers to threshold for upper level pulse. (Set to

Fixed for most common applications.)

Select from CFD, Fixed Interface mode only. Threshold for interface level pulse. (Set to

CFD for most common applications.)

Enter HART polling address

number (0-63)

Select a HART poll address (0–63). Enter 0 for a single

transmitter installation. Poll address does not affect loop current.

Enable/Disable Determines whether the loop is fixed at 4.0 mA or controlled by

the PV.

Enter value to adjust Level

reading

-10.0 inches <= Lvl Trim <= +10.0 inches

(Requires superuser password)

Fine tune the 4 mA point Adjust setting to output exactly 4.0 mA on current meter

Fine tune the 20 mA point Adjust setting to output exactly 20.0 mA on current meter

Enter a mA Output value Set mA output to any given value to perform loop test

Diagnostic Display Time of flight from fiducial to interface signal

33

34

35

36

37

38

39

(current status)

40

41

History Reset

42

IfcTicks

xxxx

Medium

New Pass

xxx

Language

(select)

Mdl705HT

Ver3.0a0

DispFact

(select)

History

Run Time

HF cable

(select)

Diagnostic Display Interface mode only. Time of flight through upper liquid

Diagnostic Display Interface mode only. Displayed messages are: Unknown,

Oil Only, Thin Oil, Thick Oil, Dry Probe

Enter new password (0-255) Displays encrypted value of present password

Select from English, Spanish,

Language choice for LCD display. (no HART counterpart)

French, German

Transmitter display Product identification. Firmware version

Select Yes to display factory

Access for viewing the factory parameter

parameter menus

Press Enter to view history

Diagnostic Display

of recent exceptions

Press Enter and select yes

Similar to SZ Alarm Reset

to clear history

Superuser Parameter Select from 3-foot or 12-foot remote

28

57-600 Eclipse®Guided Wave Radar Transmitter

Page 29

2.6.5.3 Measurement Type: Interface Level (Loop Control = Interface Level)

Display Action Comment

43

FidTicks

xxxx

Diagnostic Display Time of flight from start of ramp to fiducial

44

45

46

47

48

49

50

51

52

53

54

Fid Sprd

xxx

Fid Type

(select)

Fid Gain

xxx

Window

xxx

Conv Fct

xxxx

Scl Ofst

xxx

Neg Ampl

xxx

Ifc Ampl

Pos Ampl

xxx

Signal

xxx

Compsate

Diagnostic Display Spread in fiducial ticks readings

Superuser Parameter Select from positive or negative

(Selection only allowed for some probes)

Superuser Parameter Amount of gain applied to fiducial signal

Factory Parameter

Factory Parameter Calibration parameter

Factory Parameter Calibration parameter

Superuser Password

Superuser Password

Superuser Password

Diagnostic Display Indication of level signal amplitude

Superuser Parameter Select from None, Manual, Auto

55

56

57

58

59

7xKCorr

xxx

ElecTemp

xxx C

Max Temp

xxx C

Min Temp

xxx C

SZ Hyst

xx.x lu

Superuser Parameter Distance in mm from fiducial to user reference point

(7xK probe characteristic)

Diagnostic Display Present temperature in electronics compartment

(degrees Celsius)

Superuser Password Maximum electronics temperature recorded

Superuser Password Minimum electronics temperature recorded

Superuser Parameter Safety Zone hysteresis height

57-600 Eclipse®Guided Wave Radar Transmitter

29

Page 30

2.6.5.4 Measurement Type: Interface and Volume

Display Action Comment

*Status*

1

2

*IfcLvl*

*% Out *

* Loop *

IfcLevel

xxx.x lu

Transmitter Display LoopCtrl = IfcLevel and Volume

Transmitter default display showing Status, Interface Level,

Volume, % Output, and Loop values cycles every 5 seconds

Transmitter Display LoopCtrl = IfcLevel

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Ifc Vol

xxxx vu

% Output

xx.x%

Loop

xx.xx mA

Level

Volume

PrbModel

(select)

PrbMount

(select)

MeasType

(select)

LvlUnits

(select)

Probe Ln

xxx.x lu

Lvl Ofst

xxx.x lu

VolUnits

(select)

StrapTbl

nn pnts

Upr Diel

(select)

Transmitter Display LoopCtrl = Ifc Vol

Transmitter Display Transmitter displays % Output measurement derived from

20 mA span