Page 1

Page 1

Mk2 Turntable Manual

for Aurora, Calypso, Resolution & Sovereign

*** NOTE : Speed must be reset accurately after 3 days of continuous running at

33rpm ***

It cannot be overstated that it is VERY important to read these instructions to

really get the best out of your deck and avoid making incorrect assuptions some things about the deck are counter intuitive.

Page 2

Page 2

I N T R O D U C T I O N

Read Carefully - Congratulations and thankyour for

choosing an Origin Live turntable. You now have one of the

finest sounding turntables available – not only will it provide

an extraordinary level of performance but also reliability and

low maintenance. These instructions cover all decks listed on

the front cover, so photos and diagrams are for illustration

only. Specific instructions for a particular deck are always

included.

Critical performance factors should be noted as follows:

Adjustable feet to be clear of plinth

Belt tension as it affects speed

Arm fastening tightness (read carefully as it depends on the

arm)

The portions of the instructions printed in grey are optional

reading that provide additional information if required. It is

critical that the remainder of the instructions are read fully

to achieve full potential performance. Underlined text is

especially important.

Although the instructions are written for owners with no

previous experience of turntables, there are aspects of the deck

that run contrary to expections, so experts should note that

before altering anything it is important to have fully read the

“non greyed” instructions or degradation will result.

An Origin Live turntable is simple to set up. If you have a

problem, please refer to the instructions - failing this, you

should speak to your dealer or refer to technical support

on the Origin Live web site www.originlive.com - See top

navigation bar “dealers & information” then “technical

support” from the drop down list.

The deck can take approximately 20 minutes to set up

depending on your expertise. It can then be played and

later on the speed can finally be set with absolute accuracy.

As explained later this is because the electronics initially

experience speed drift (if they have not been run in) and may

need at least a day to run in properly.

We wish you an enjoyable time with your Origin Live

turntable.

P A R T S L I S T

Check that all parts are present.

Plinth & Sub-chassis - including 1 cable clip

with nut & bolt.

Turntable bags

o Threaded VTA adjuster (not for

Resolution or Sovereign )

o Cork washer for arm

o 4mm thick spacer for 3 point mounting

on Aurora & Calypso only

o Oil bottle

o screwdriver

o 2.5mm & 3mm allen key for arm clip

o 2 plastic + 1 steel foot (Sovereign only)

Platter (+ upgrade plattter mat for Resolution

& Sovereign only)

(Sovereign only) Sub-platter

1 Belt

Motor pod

Standard or upgrade transformer for 230 volt

or 110 volt mains supply

Arm (optional)

Turntable instructions & Strobe card

A V O I D S C R A T C H I N G T H E

H I G H G R A D E F I N I S H

To clean the surface use a soft lint free cloth

such as a duster – do not use tissue paper or

kitchen towel as these are mildly abrasive.

P R E P A R A T O R Y N O T E S

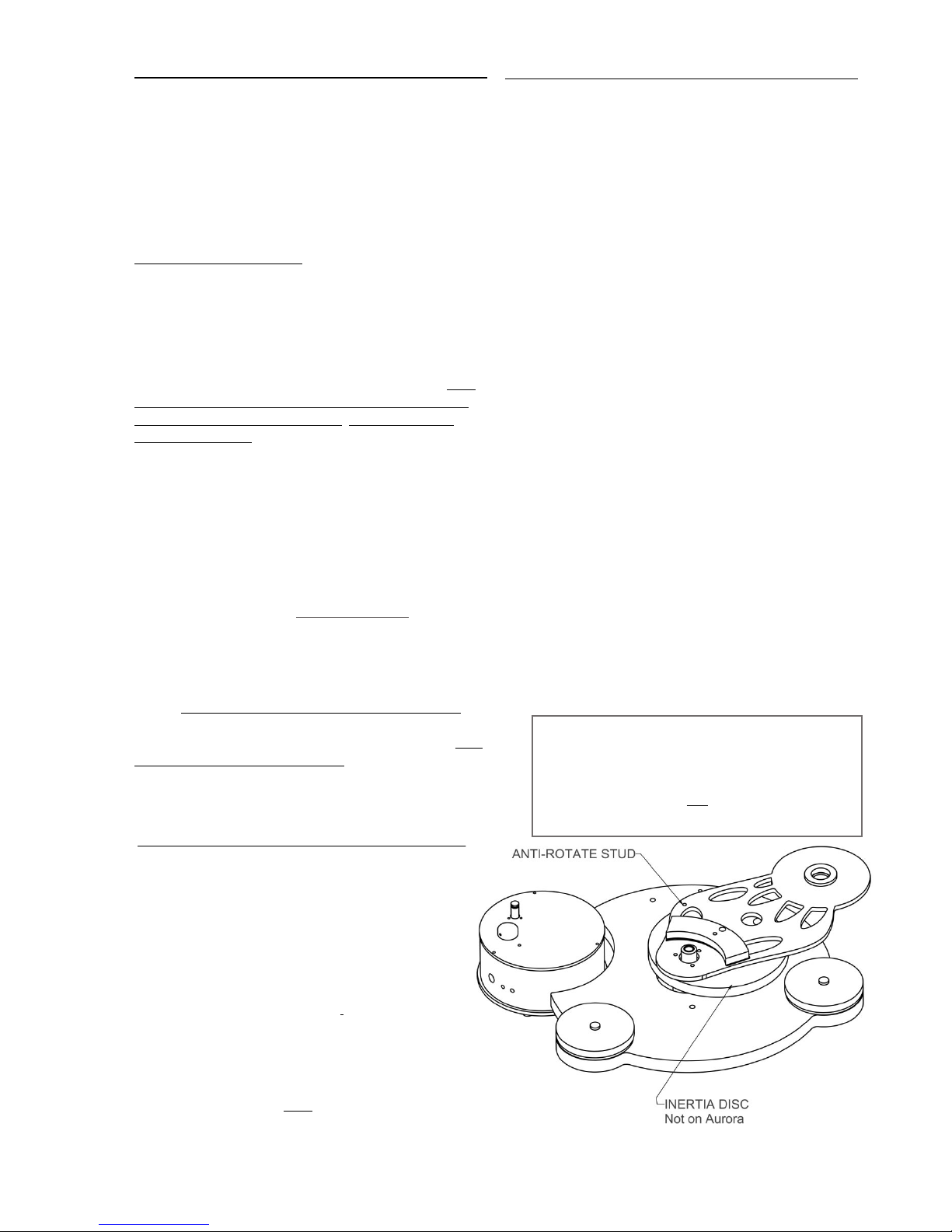

Your pre-assembled deck is illustrated in the adjacent

diagram. It is not necessary or advisable to dismantle the

deck.

You might make the mistake of thinking that the subchassis is loose but in fact it is designed with freedom to

rotate very slightly from side to side but not “rock” up and

down much.

AURORA & SOVEREIGN ONLY - Note the anti-rotate

stud is replaced by a bolt which is factory fitted to the subchassis. This should not be tampered with – it does not

bolt to the plinth as it’s only function is to stop the subchassis rotating.

ALL OTHER DECKS - Note “the anti-rotate studs”

protrude either side of the inertia disc and locate in the

sub-chassis and plinth to prevent rotation.

DECK PRIOR TO INSERTING PLATTER

Page 3

Page 3

Sovereign deck only - Thread on the 2 plastic feet into the 2

front pods and the steel foot into the rear pod.

F I T T H E T O N E A R M

Mounting Origin Live arms

Thread the threaded vta adjuster onto your arm if it is an Origin Live

Encounter or above. If your deck is a Resolution or Sovereign and

you have an Encounter arm or above - do not fit the threaded vta

adjuster. The adjuster must be oriented such that the largest diameter

is uppermost. Insert your tonearm into the armboard hole such that

the vta adjuster locates centrally. Next fit the cork washer as shown in

the diagram below before threading on the large clamping nut. You

can set the arm to the correct height later but for now just clamp the

arm in position using the large nut. To adjust the height of the arm,

screw the vta adjuster up or down and reclamp the arm using the large

base clamping nut.

NOTE - For Origin Live arms with integral vta adjuster i.e Encounter

and above you should raise the arm height to just below the right level

using the threaded vta adjuster and then use the arm vta wheel for

fine adjustment.

A R M

REAR VIEW OF ARM ON ORIGIN LIVE DECK WITH

THREADED VTA AND CORK WASHER

ARM MOUNT

SURFACE

CORK WASHER

LARGE CLAMPING NUT

THREADED ARM BASE

THREADED

VTA ADJUSTER

If you have the OL1 or Rega arm with 3 hole

mounting

The arm is bolted or screwed to the deck using the 3 mounting holes

in the base of the arm. To raise the arm for VTA adjustment you will

need to fit 3 or more spacing washers under the arm base holes. One

peice spacers are available from Rega if you want a neater looking

solution.

3 POINT ARM MOUNTING

Sub-chassis or

armboard

3 off bolts or

wood screws

Spacers

For other makes of tonearm

Origin Live can provide the correct cut out in the sub-chassis or

armboard for other makes of arm and after this refer to your arm

installation instructions.

F I T T H E P L A T T E R

NOTE - On newer decks (April 2009 onwards) the platter is a

“loose” fit over a metal bush on the spindle. This means the platter

can be removed from the spindle.

Oil the bearing - with the small oil bottle supplied, run approx 10

drops of oil into the top of the bearing house.

SPINDLE FOR PLATTER

(OR SOVEREIGN SUB-PLATTER)

Insert the spindle - Wipe the platter spindle surface first

to ensure that it is absolutely clean and very gently insert it

into the bearing house (If the oil does not overflow when the

spindle touches the bottom then try 2 drops at a time till you

achieve overflow - wipe away excess oil without withdrawing

the spindle. Ideally you should spin the spindle slowly as it

settles into the bearing to ensure distribution of oil.

When you oil the bearing you can get a false impression of

overflow if the spindle has oil on it - the oil simply scrapes off

as the bearing goes in and ends up on the top of the bearing

Page 4

Page 4

house. You can “feel” overflow when inserting the spindle, it

meets resistance at the bottom which is not a “thud” of the

spindle hitting the bottom but rather a build up of pressure of

the bearing landing on a bed of oil. By further pressing, you can

then see the oil being squeezed out at the top.

Carefully lower the platter over the spindle till it rests on the

lower flange of the platter bush (ensure mating surfaces are

clean). Once the platter is fitted over the bush it pays to spin it

slowly by hand while holding the top of the spindle stationary

with your other hand - this helps the platter to “bed down”

onto the bush and become more level.

SOVEREIGN DECK ONLY: NOTE - On newer decks

(April 2009 onwards) the sub-platter is a “loose” fit over the

spindle and can detatch from the sub-platter.

Wipe the sub-platter spindle surface first to ensure that it

is absolutely clean and very gently insert it into the bearing

house (If the oil does not overflow when the spindle touches

the bottom then try 2 drops at a time till you just achieve

overflow - wipe away excess oil without withdrawing the subplatter. Next place the sub-platter on the spindle such that the

less recessed side is uppermost.

UNDERSIDE OF

SUB-PLATTER

TOPSIDE OF

SUB-PLATTER

Lastly, place the platter on top of the sub-platter and follow this

with the thin black platter mat .

If you have the heavyweight platter then raise the plinth more

than normal by winding out the adjustable feet, till the platter

no longer fouls on the motor pod. The belt must NOT run in

the groove of the platter. Do not tighten up the allen bolts in

the underside of the platter - these sound best with minimum

tension.

NOTES:

The bearing fit is carefully toleranced to run fully loaded

with the specific oil we supply. It needs at least 10 minutes to

distribute the oil evenly over the running surfaces and approx

24 hours to properly “run in”. It needs this because of the exact

tolerances (0.0001”)which “float” the bearing off the side walls

to avoid metal to metal contact and also minimize viscous drag.

Eventually it should run virtually silent when truly vertical

and full of oil - if it doesn’t do so, there has probably been

contamination with dust and you will need to clean it out with

a lint free paper towel or similar wrapped around a thin rod. If

you do this, be sure to also wipe the oil off the spindle as this

also may contain microscopic contamination that is not visible.

Do not use any other oil than Origin Live oil.

Do not tamper with the bolt in the bottom of the bearing

or oil leaks will occur and you will probably not succeed in

re-tightening it.

The thrust plate at the bottom of the bearing house may

appear to be discoloured or dirty - you should not attempt

to clean this up as it is part of the hardening process - the

centre of the plate is polished as this is the only part that

the spindle touches.

The Platter works best with the Origin Live platter mats but these are

not necessarily included in the lower part of the deck range - all of the

many other mats we have tried do not work on the OL decks.

L E V E L T H E D E C K

The 3 feet under the plinth are all threaded so that by rotating

them you can adjust the level of the deck - Rotate all three feet

so that the top of the foot does not touch the plinth and only

sits on the thread alone - this is for best performance. At this

stage check that the bearing house is at least 1mm clear

of touching the surface your deck is standing on (Aurora

only).

Note that when you level the deck, the only thing that matters

is that the platter (not the plinth) is level. Sometimes there

may be a slight discrepancy between the level of the plinth and

platter but this does not matter and is usually imperceptible

visually.

P O S I T I O N M O T O R P O D & F I T

B E L T

Position the motor pod roughly as shown in previous diagrams.

The pod should be oriented as shown, such that the switch is at

the front. Ideally the centre of the pulley should be somewhere

between 215mm (8.45inches) to 225mm (8.9 inches) from

the centre of the platter. We recommend and set up the speed

at factory at 217mm. The pod must not touch the plinth so

rotate it if necessary. Fit the belt over the platter first and then

pull it over the motor pulley taking care not to twist it.

Page 5

Page 5

If you don’t have a ruler handy, another method of setting

the belt tension is to install the belt first. Do this by placing it

round the platter and then pull it onto the pulley, taking care

that there is no twist in the belt.

Now, lift the belt off the pulley and let it lose it’s tension

almost completely whilst still holding it gently - With no

tension whatsoever in the belt, you should stretch it approx

25mm to fit over the pulley. If this is not the case, move the

pod to achieve correct pulley position.

Alternative method of belt fitting (greyed text).

Refer to photos showing belt being fitted - Fit the belt over

the motor pulley and outer rim of platter. This is most

easily carried out by placing the belt over the pulley and then

holding it there loosely with one finger of your left hand.

Whilst retaining the belt on the pulley, hold the belt onto the

rear rim of the platter with the index finger of your right hand.

Now rotate the platter slowly clockwise with your right hand

index, all the time pressing the belt on the rim, till the belt is

completely on. Allow the motor pulley to rotate under your

finger whilst retaining the belt on the pulley and maintaining

slight tension on the belt between the pulley and rear of

platter.

The belt has an ideal tension for best performance - too

tight and motor bearing friction increases causing possible

speed instability and increased wear plus a decrease in sonic

performance. The correct distance is not hypercritical to

performance and the above dimensions may need to be

increased after a year of use due to belt stretch. Experiment

with different distances if you wish for best sound but you will

need to adjust speed between different distance settings, as

speed varies slightly with different belt tension.

You can fine tune this just by listening to the sound with the

pod in slightly different positions.

If the belt falls off the platter on start up you may need to

lower the turntable if the feet are adjusted too far down. Also

you can try increasing belt tension by moving the pod away

from the platter.

Insert the power supply jack plug into the pod’s largest side

hole. The LED on the top of the pod will light up. Note: green

LED is advanced supply and Blue LED is Ultra supply.

Sometimes the pulley has 2 curved surfaces to run on - this is

not for an additional belt ( which is not an advantage on OL

decks) but is to allow for different deck heights.

BELT ON PULLEY

Do not plug the power supply into mains conditioners, filters

or anything with surge protection - this can be disastrous

to performance. The aforementioned items will not harm

the pod, but they almost always results in performance

degradation.

The location of the motor pod should preferably be kept

away from strong electromagnetic fields typically generated by

transformers, amplifiers, power supplies etc.

S E T T I N G T H E M O T O R S P E E D

You will need to set the motor speed yourself. In the first 72 hours

of continuous running the motor, the speed tends to drift but then

settles down permanently. Motor running should be carried out

with platter turning (no faster than 45rpm).

The thin output wires from the transformer only carry a very

low voltage and are therefore safe to handle. Voltages inside the

transformer are dangerous so the transformer case must not be

unscrewed or opened.

(At front or rear)

When the rotary switch on the pod is turned fully anticlockwise and the line on the knob aligns to the LED, the

motor is off.

Page 6

Page 6

One click of the switch clockwise is 33.3 rpm - The

second click clockwise is 45rpm

NOTES: The speed should only be finally set with

the pod in it’s FINAL position and at normal room

temperature as speed varies slightly with belt tension

and temperature.

If you move the pod, you will need to re check the

speed and if necessary correct it, by repositioning the

pod till the speed is correct. This is a quick operation, just

leave the motor and platter spinning, as you slide the pod to

adjust tension. Always set the speed with the cartridge dragging

on a centre track of a record. The drag can affect speed setting

to a small degree. Do not move the pod beyond the ideal

distances mentioned in “fitting the belt”.

If you change transformer to the upgrade transformer may

need to reset the speed.

If the speed drifts significantly then correct it using the speed

adjuster screws.

Instructions for reading the strobe

Place the strobe disc on the record to be played. Play the record

and watch the relevant ring on the disc. Adjust the speed

until marks on the ring appear stationary while the record is

rotating. It sometimes helps to stare at infinity whilst doing

this as the marks become easier to see. You can see the strobe

effect in fluorescent light, although an ordinary bulb held

about 2 feet from the strobe disc will also work fine. The bulb

flickers at 50 Hz in the EEC and 60 Hz in the USA.

You can purchase bayonet fitting fluorescent bulbs to fit

normal lamps. Try to shut out daylight when carrying out

speed setting.

Set the speed

Set the switch on the pod to the first click i.e. 33 rpm

setting. Adjust the motor speed as follows: using the small

screwdriver, turn the speed adjuster screw shown in the photo

for 33 rpm. This is accessible through the hole (furthest to

the right hand side) in the side of the pod and the slots in the

screw heads are visible if you look into the holes (See diagram

at start of this section).

To increase speed, turn the screw clockwise until the speed

changes. If the screw reaches the end of it’s travel you can

usually hear a faint clicking. You will not damage the speed

trimmer by over turning, as slippage occurs. The trimmer

screw will not fall out. The trimmer screw is adjusted at factory

so should only need fractional adjustment of less than a turn.

However the capacity is 25 turns and in some cases more turns

may be required to set the correct speed.

Setting the 33.3rpm. When setting the speed, place the arm

on the centre track of a record, so that the cartridge is tracking

the grooves. This ensures that the drag of the cartridge is taken

into account. Speed variations of up to plus or minus 1% are

quite common on decks and the dc motor is capable of plus or

minus 0.1% accuracy. Use the strobe disc provided to set the

speed (full instructions are on the card).

Click the rotary switch to the 2nd click clockwise and

set 45rpm speed (or 78 rpm if you wish) using the same

procedure as for 33rpm.

The dc motors can be slightly noisy initially and are never

completely silent in comparison to a/c motors. This may be

due to the precious metal brushes. However it is the much

lower levels of vibration that is important not the audible noise

and this is why they are great deal better in performance terms.

Like most turntable manufacturers we recommend that you

leave the turntable running between changing records as this

reduces the belt wear that occurs with constant stopping and

starting.

N OT E S O N M OT O R & S P EE D SE T T I NG

-Do not use the power supply for anything other than the dc

motor or the power supply is highly likely to be irreparably

damaged and you could also damage the equipment you are

plugging it into.

-The motor and main bearing will take at least 4 days to fully

run in and sound it’s best. For this reason it is best to do a final

speed check at the end of this period.

The speed stability of your deck will be excellent once

everything has settled down in a listening session.

When checking speed - Be aware that the speed is subject

to temperature variation. This is due to oil thickening as the

temperture drops. 1 degree centigrade drop in temperature

results in a 0.1% drop in speed ( a 5 degree drop will be 0.5%

slow). 0.5% speed drift is barely noticable to the average

listner so this is not significant. Rega decks used to run 1% fast

all the time to put things in perspective.

The ear is less tolerant to music running slow than it is to

fast. For this reason it is worth setting the deck to run very

slightly fast at your average room temperature. Most houses

are centraly heated and maintain the temperature such that

significant variations simply do not occure.

Note that the main bearing and oil can take 2 hours to reach

operating temperature if the deck is left in a cold room. The

air in the room may warm up quickly but the metal in the

turntable will take a lot longer. For this reason it is not worth

constantly changing speed settings for absolute accuracy.

It is worth explaining that absolute speed accuracy is easy

to achieve at the expense of sound quality. The ac motors,

common to most decks are not prone to speed drift - however

they do inject a great deal of vibration. This, sadly is never

measured in technical reviews or people would be a lot wiser.

The subjective effect of vibration is highly detrimental to

sound quality when compared to fractional speed drift. For this

reason we prefer to offer superior sound quality rather than the

flawed illusion of technical perfection.

Further to this it is worth adding that we have experimented

with the latest highly sophisticated dc speed controls (£1000

plus trade cost) and found that although they hold speed with

unerring accuracy, the sound and dynamics of the music are

degraded to such a degree that a little speed drift is far more

preferable.

F I N A L S E T U P O F T O N E A R M

Refer to your tonearm instructions. Use the following, only

Page 7

Page 7

as a rough guide on aspects relevent to the turntable. VERY

IMPORTANT NOTE - Do not use the serrated washer

supplied with some Origin Live arms - it is only meant for

non-metalic armboards and degrades Origin Live decks

very significantly.

VTA (vertical tracking adjustment)

To allow the cartridge needle to track at the correct angle it is

important that the base of the arm is at the correct height in

relation to the platter - this can be set by rotating the chrome

threaded VTA adjuster supplied with the deck for Origin Live

and Rega derived arms. One complete turn of the adjuster

clockwise raises the arm 1mm. For Origin Live arms that

have an integral vta adjuster the threaded vta adjuster is best

ommitted.

Set the arm fastening tightness

It is best to experiment with the tightness of the large base nut (if

fitted) by listening to music. This may seem laborious but you will be

richly rewarded as this adjustment makes a clearly audible difference

to performance.

IMPORTANT TIP: For Origin Live dual pivot arms tighten the

arm bottom nut fairly hard, but for OL1, Rega and Silver arms use

minimum tension on the fastening nut.

Fit the arm cable clip

Pass the arm cable through the cable clip and fasten in position

with the nut & bolt supplied. Leave a slight droop on the

cable so that it isn’t “tight”. The clip fastens to the underside

of the plinth using the hole near the rear foot. This is helpful

to “earth” vibration in the cable. The earth lead should be

connected to the earth of your pre-amplifier or amplifier. This

earth lead is best separated slightly from the arm signal leads so

do not wind it around them for best performance.

Note - The linear flow 2 cable is thicker than most, use the

larger cable clip to cope with this - if the cable is problamatic

to bend round the confines of your particular set up, then you

will not lose a great deal of performance by simply not using

the arm clip.

U P G R A D E S

It is possible to upgrade the turntable

Further upgrades would be

Origin Live upgrade platter mat

DC200 motor in the case of the Aurora and Calypso

Upgrade Transformer - (Sovereign comes with this

included as standard)

M A I N T E N A N C E O F D E C K

It aids performance to clean all the running surfaces every 3

months or so with mentholated or surgical spirit.

To clean the deck, use a damp soft lint free cloth and wipe

gently – if you have grease marks etc then you can use a

general-purpose anti-smear, car window cleaner such as

Autoglym Fast glass, but only if necessary – wax furniture

polish is to be avoided . Do not spray directly on the turntable

as it may clog up the cartridge etc but rather spray onto a

soft polishing cloth and then use it on the turntable. Do not

use tissue paper or kitchen cleaning paper towels as paper is

abrasive and can put faint scratches in the polished surface.

If you do get minor abrasions on the surface then you can

remove them using a fine car paint abrasive polish such Tcut or Autoglym paint renovator - this is especially usefull to

remove stubborn grease marks on the platter.

It is wise to keep the turntable packing box so that you can have it

transported securely.

The deck is not prone to going out of tune - Check that the

sub-chassis damper is tensioned lightly onto the plate every 2

years or so as the damping can compress a little over time.

Depending on your use of the deck, the belt should ideally be

replaced every 2 years or so.

If you withdraw the main spindle you should put in a drop of

oil in the bearing, to compensate for any possible loss.

T R O U B L E S H O O T I N G

Omit reading this greyed out section unless you have a problem

S P EE D V A RI AT IO N

If there is significant speed variation then possible causes are as

follows.

• Significant changes in room temperature - this affects the

viscosity of the oil in the bearing.

• Lack of oil in the bearing so check by adding oil.

• Changed belt tension or an oily belt or platter - clean

running surfaces.

• Turntable out of level – this affects the main bearing

friction.

• After adjusting the tension of the 3 small Philips screws

which hold the motor on, you may need to re-adjust the

speed as they affect motor bearing friction very slightly.

• Check the platter is not fouling on anything.

• A dirty bearing that exhibits too much friction - The platter

should drift round effortlessly with the slightest of nudges (

the lighter the touch the better) and go on spinning very slowly

before gradualy coming to a stop. If you suspect the bearing

friction to be a little high return the bearing to us for checking.

• A worn thrust bearing - this may occur after many years of

continuous use in common with all turntables.

• Transistors that have developed temperature instability.

• Most of the pulleys are a push fit on the motor shaft however they can sometimes work loose in transit or in use. If

this is the case then you can easily rectify it by lightly tapping

the pulley back onto the spindle with your fingers - Do not use

a hard object or excessive force as this can damage the spindle.

E X CE S SI VE M OT O R NO IS E

The motor needs a run in time of around 4 days continuous running.

Page 8

Page 8

They are sometimes a little noisy to start with so it is best to run

in the motor by continuously running it for 4 days on 33rpm.

Do not run at over 78rpm as this can harm the brushes over

prolonged periods.

Most importantly you can “tune in” the motor to give minimum

noise by adjusting the tightness of the screws next to the motor

pulley. The best way to set their tension is to tighten the screws

until they just nip tight. Then back off all the screws a little

way. Now tighten one screw at a time till you hear which

ones cause the least noise when tensioned and then adjust the

other(s) to give minimum noise. If it continues to be very noisy

please contact Origin Live. However, bear in mind that dc

motors are rarely as silent as a/c motors.

The other major potential source of noise is a lack of pod top

plate tightness or motor fastening tightness. This can cause the

top plate to resonate. The solution is usually to slightly tighten

the small screws holding on the motor. This adjustment is

fairly critical - if the small screws are too tight then the motor

whispers, too slack and the motor can vibrate against it’s top

plate.

If you get a knocking sound from the motor then slightly

slacken off the screws holding the motor to the top plate.

If you have checked the above and are still having trouble please

contact us .

Page 9

Page 9

Page 10

Page 10

Wrap plith in polythene bag

and place on bottom layer of

foam - ensure that feet and

bearing house all locate in holes

in foam. The hole for the rear

foot is marked with an R

Place top layer of foam on top

of plinth - top foam has no

holes in it.

Place components on top layer of foam as show below

R E P A C K I N G M E T H O D

Please read carefully and do not deviate, do not cut up foam etc

or damage will result - see seperate sheet for Sovereign packing

instructions.

Wrap platter in polythene bag then

tape blue edging foam to protect

edges - lastly place thick foam square

over platter - place in corner of box ,

upside down as shown.

Instruction manual

Arm if included or empty

box - larger arms will not

fit - i.e Encounter and

above

Wrap motor pod in polythene and

then tape ( or rubber band) round

the cardboard tube which has a slit

in it’s side - the tube sits on top of

the base plate, not round it. This

is to provide protection against

anything that might knock the end

of the motor shaft as this can cause

damage. Note that the motor

pod must be positioned in this

corner of the box where there is

the greatest depth i.e not over

the plinth armboard

Place the strobe card and belt in the

top of the motor pod card tube.

Place the wall wart transformer in

the remaining cardboard tube as

shown and then place the bubble bag

containing the following items on top

of the transformer

Bag contains - threaded vta adjuster,

Oil bottle, screw driver, 2.5mm allen

key

REAR FOOT

POSITION

Ensure base foam is

in position in box as

shown

EDGE SURROUND FOAM STRIP

MOTOR POD PACKED WITH ELASTIC BANDS

ROUND SPLIT CARDBOARD TUBE - TUBE SITS

ON TOP OF MOTOR POD BASE FLANGE.

FOAM CUSHION INSIDE

CARDBOARD TUBE

Loading...

Loading...