Page 1

R E S O L U T I O N T U R N T A B L E

I N S T R U C T I O N S

A V O I D S C R A T C H I N G T H E H I G H G R A D E F I N I S H

To clean the surface use a soft lint free cloth such as a duster – do not use

tissue paper or kitchen towel as these are mildly abrasive – the surface finish

takes approx 2 weeks to reach full hardness.

Page1

Page 2

Introduction (read carefully)

Congratulations on choosing your Origin Live turntable. You now have one of the finest sounding turntables available – not only

will it provide an extraordinary level of performance but also reliability and low maintenance.

It is critical that these instructions are read fully to achieve optimum performance from your turntable. There are aspects of

the deck that run contrary to what you may expect, so before altering anything it is important to fully read the manual or

degradation will result.

The Resolution turntable is simple to set up. If you have a problem please refer to the instructions. If your problem persists you

should speak to your dealer or refer to Origin Live technical support at web site address - ‘www.originlive.com’ under “general

information” then ‘technical support’ from the drop down list.

The instructions are written for people with no previous experience of turntables. Some sections may therefore appear lengthy,

as they need to cater for all potential questions. When reading the instructions refer to the various diagrams for part names and

clarity. The body text in grey is of secondary importance and can be read later if you can’t wait to get your deck up and

running.

The deck can take approximately 15 minutes to set up depending on your expertise. The dc regulator electronics may initially

encounter speed drift when first started (if they have not been run in). You may need at least 4 hours to run in before the speed

can finally be set with accuracy.

We wish you an enjoyable time with your Resolution turntable.

Parts list

Plinth & gloves

Turntable bag

o Belt

o 1 cable clip and attachment screw - (may be on plinth)

o Oil bottle

o 3mm Allen key & 2.5 mm Allen key

o Spring seat, 1 rubber washer, serrated washer & spring

o 3 cork discs for levelling if necessary

Platter

Sub-platter

Sub-chassis

DC100 motor in Motor pod

Control box

Transformer for 230 volt or 110 volt mains supply

Arm (optional), alignment gauge, but no arm instruction sheets as included in deck instructions

P A P E R W O R K

Turntable instructions & strobe card

Page2

Page 3

Turntable set up

When you unpack the deck, check that you have all items listed in the parts list.

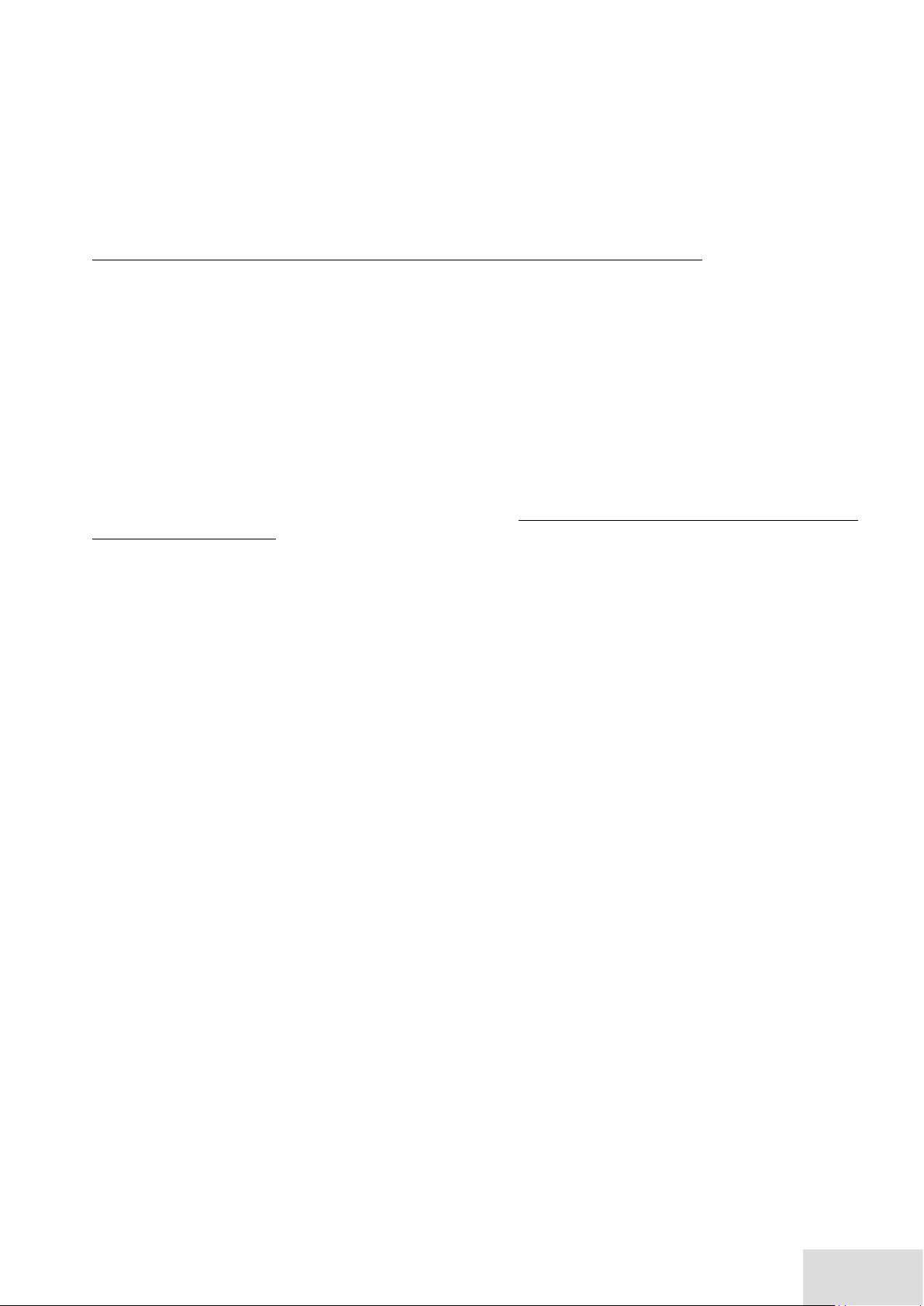

S E T T I N G U P T H E P L I N T H

The spring bolt assembly is fitted as shown in the diagram below (without the serrated washer, spring seat and spring). Fit the serrated washer,

spring seat and spring over the bolt as shown below – the bottom threaded spring adjuster (not needed on latest models of Resolution)

should be rotated anti-clockwise until it moves upward sufficiently to clear and no longer touch the plinth – this important as it reduces

vibration transmitted to the spring.

PHOTO 1

Note bottom height spring adjuster is not required with newer top spring adjusters - performance is not affected with either

version.

Page3

Page 4

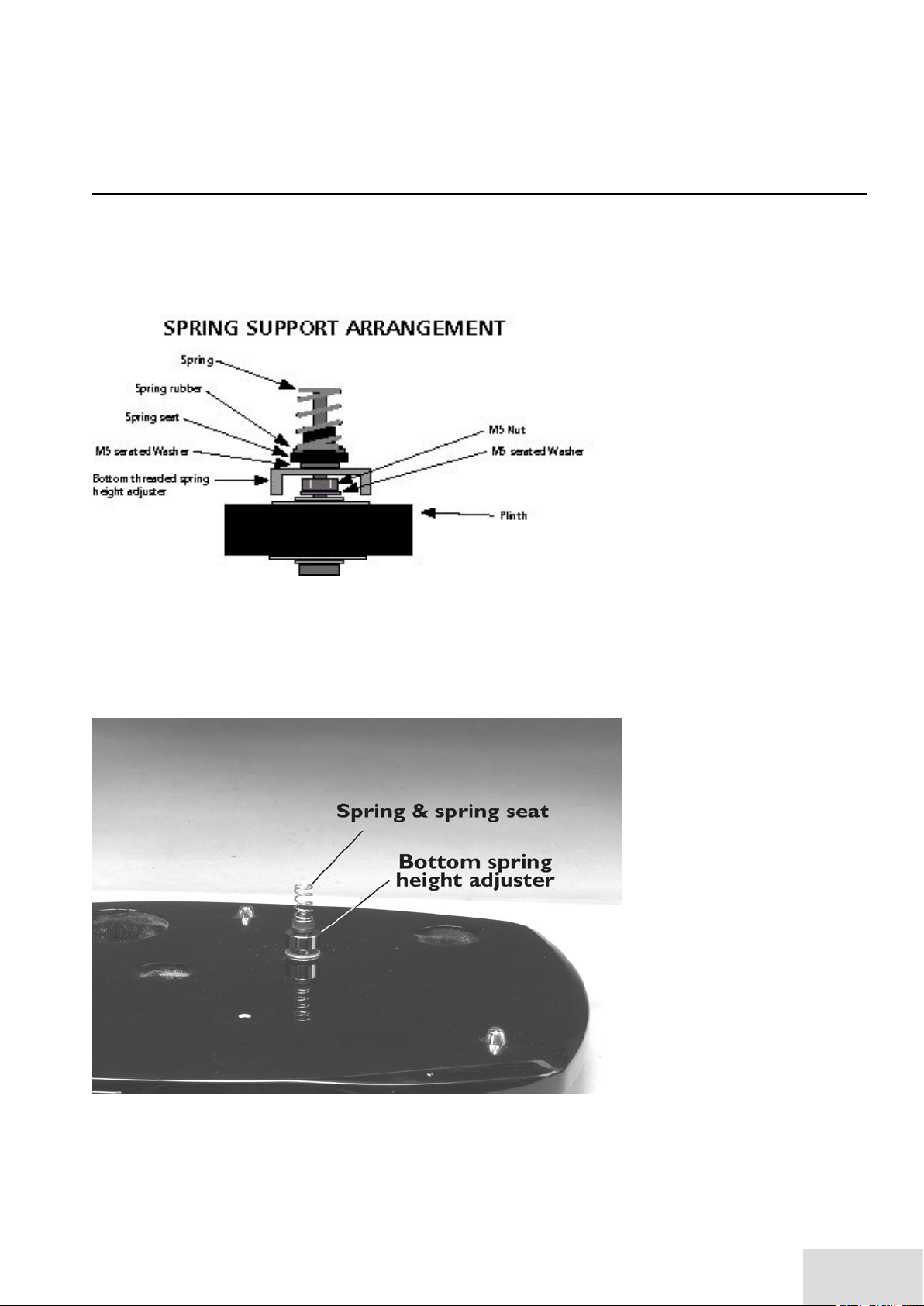

I N S T A L L S U B - C H A S S I S & M O T O R P O D

Photo showing sub-chassis & part names

PHOTO 2

N O T E S :

You may think some bolts on the sub-chassis assembly are loose - they are deliberately set like this at factory - do not adjust them

or performance can be dramaticaly degraded.

Before fitting the sub-chassis examine the top spring adjuster to get an idea of how it works and the extent of it’s adjustment. Remove the

top spring adjuster by unscrewing it completely. You must not allow this to happen once the sub-chassis is set up or the sub-chassis will drop.

Removing the adjuster shows how much thread you have to play with. Refit the top spring adjuster by threading it back into the connector

ring.

T R O U B L E SH O O T I N G N O T E S O N T HE S U B - C H A S SI S ( O P T I ON A L R E A D I N G)

1. The sub-chassis is attached to the “spring plate” by one “pivot bolt” – the two plates should be free to swivel and are loosely

restrained by an “anti-rotate bolt” – this locating bolt should be left alone. The pivot bolt is tightened at factory and should not be

adjusted or performance will degrade significantly.

2. If the correct tension on the pivot bolt is lost for any reason, then the correct tension is such that the spring plate can rotate

minutely but freely in relation to the sub-chassis plate but has minimal “rocking” motion in the vertical plane.

3. The “anti rotate” bolt is tight on the spring plate but has minimal contact with the sub-chassis.

4. If for any reason, tension is lost on any of the other bolts, they should be just “nipped” tight by 1/8 of a turn from the point

where you can just turn the bolt & nut freely in it’s hole – any tighter than this and performance is degraded.

PHOTO 3

Place the motor pod in position at the rear of the plinth – You will need to lift the plinth over the pod to get it in position. Arrange the

plinth in it’s final resting place to get the motor pod position correct. The motor pod should be located approx in the centre of the circular

cut out of the plinth.

Page4

Page 5

PHOTO 4

Place the sub-chassis on the plinth over the spring as shown in the photo above. The small plastic locating pins on the underside of

the two black plastic pods locate in the small holes on the plinth as labelled in Photo 3. DO NOT TIGHTEN THE BOLTS IN THE

PLASTIC PODS - they are set to be loose deliberately - if they are tightened sound degradation will result.

When placing the sub-chassis on the plinth, the spring must be located centrally in the top spring adjuster. If the spring is not located

properly it will not be possible to level the turntable correctly.

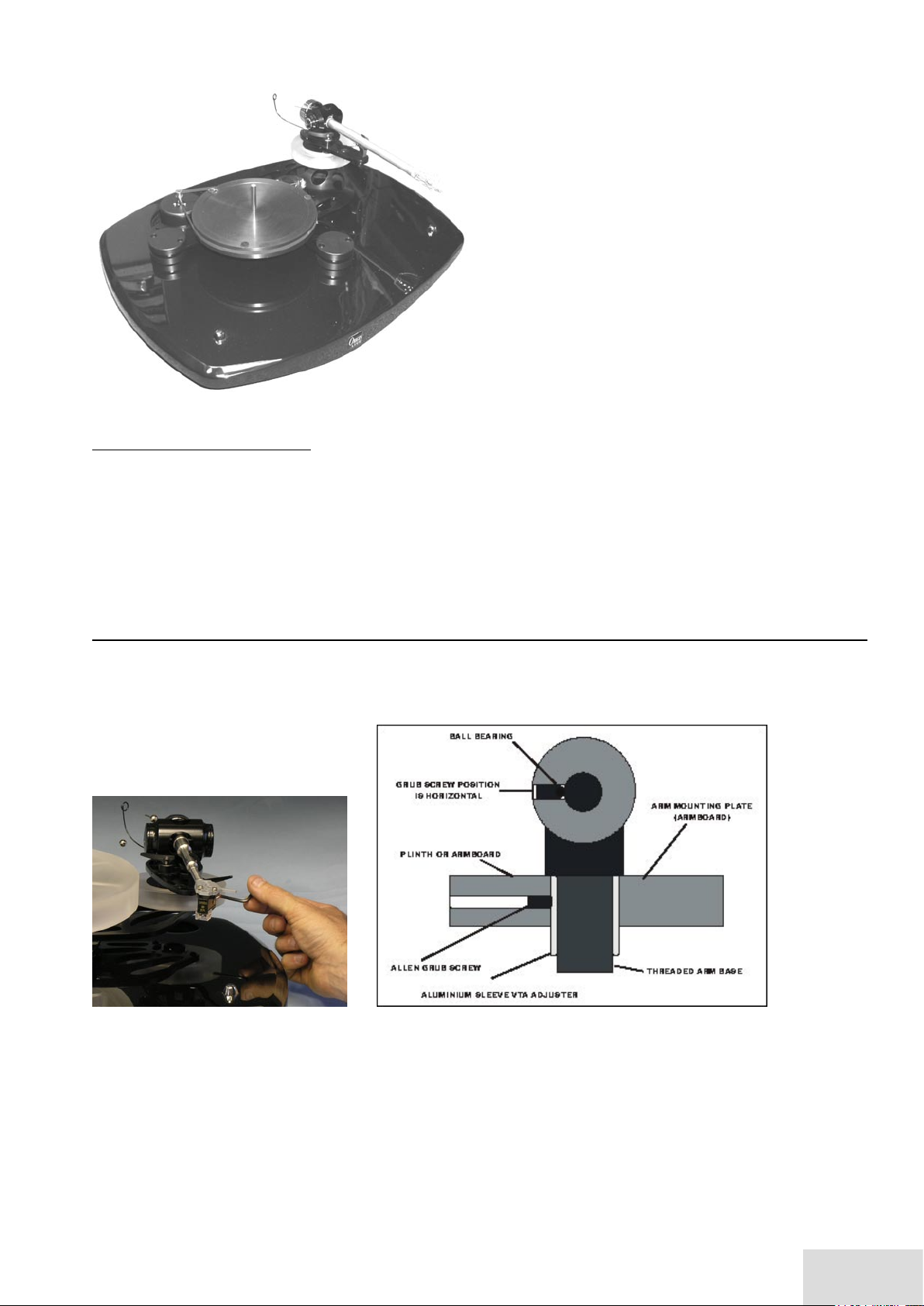

F I T T H E T O N E A R M

Insert your tonearm into the metal sleeve located in the circular arm mounting plate (armboard). You can set the arm to the correct height

using the setscrew located in the arm board as shown in the photo below. This setscrew clamps the sleeve onto the arm board.

It doesn’t matter whether you slide the metal sleeve up and down in the arm board to get the right height or slide the threaded arm base in

the sleeve. Both methods work fine. Note that you should NOT clamp the sleeve hard when there is no arm fitted inside. If you do this,

then permanent deformation can result – the slightest of “nips” is all that is necessary before the arm is fitted. Do not fit the large arm base

nut, or any of the washers. To obtain accurate VTA setting you can mark the sleeve with pencil lines to keep track of trial positions.

Page5

Page 6

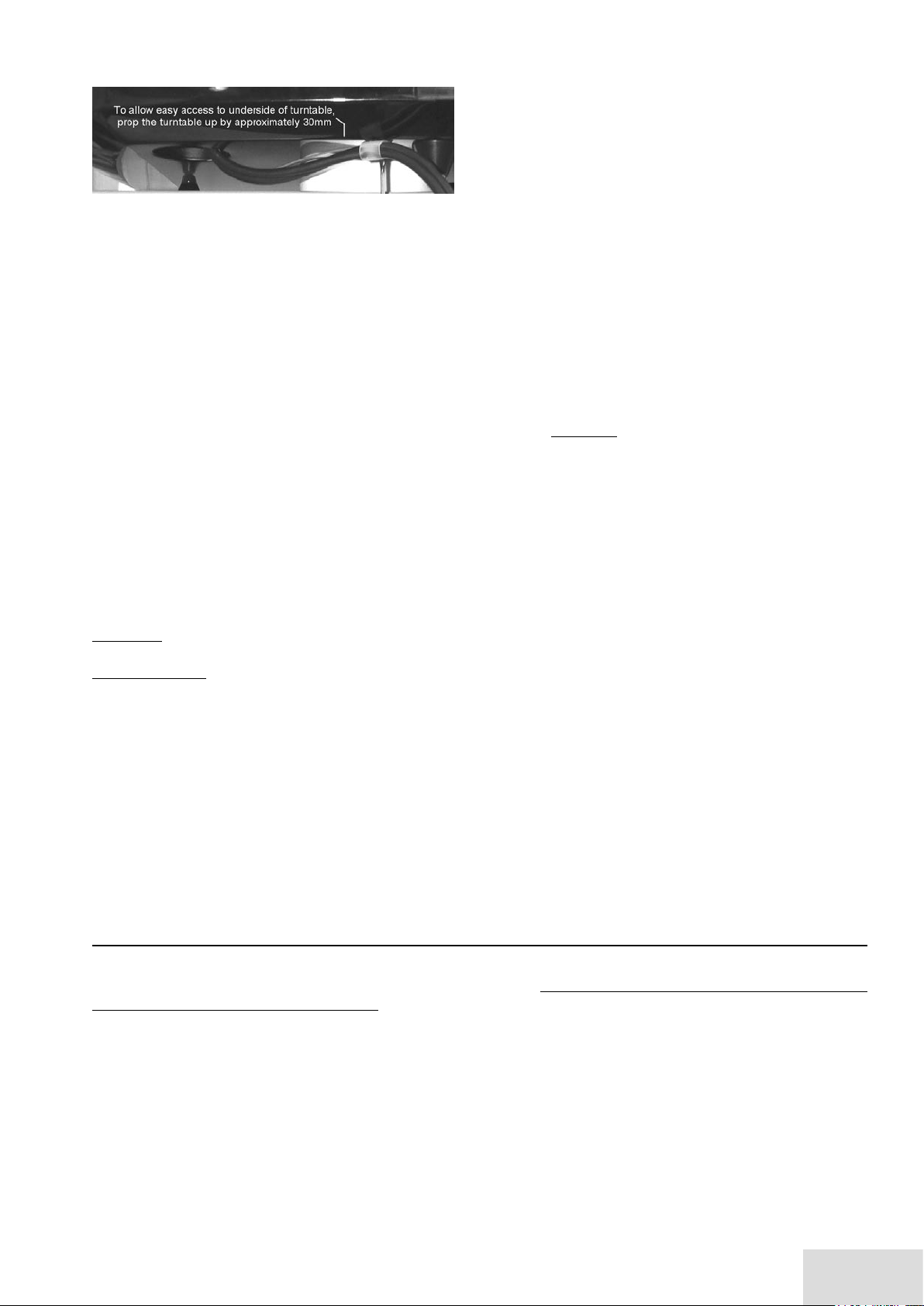

F I T T H E A R M C A B L E C L I P

Fasten the arm cable to the underside of the plinth near the rear foot using the P-clip and screw provided. Leave a slight droop in the cable

between the arm and the cable clip so that it isn’t “tight”. The cable clip is important for best performance as it “earths” vibration in the arm.

If your arm has an earth lead then it should be connected to the earth of your pre-amplifier or amplifier. The earth lead is best separated

slightly from the arm signal leads so do not wind it around them for best performance. Avoid pulling the external arm wires as they are not

indestructible and can become detached if excessive force is used to manipulate them.

F I T T H E S U B - P L A T T E R & P L A T T E R

With the bottle supplied, run approx 5 drops of oil into the top of the bearing house.

Wipe the sub-platter spindle surface to ensure that it is absolutely clean and very gently insert the sub-platter into the bearing

house (If the oil does not overflow when the spindle touches the bottom then try 2 drops at a time till you just achieve overflow

- wipe away excess oil) and then place the platter on top.

NOTE:

The bearing needs a few minutes to “run in” and should run silent when truly vertical and full of oil - if it doesn’t do so, there has

probably been contamination with dust and you will need to clean it out with a lint free paper towel or similar wrapped around a

thin rod. If you do this, be sure to also wipe the oil off the spindle as this also may contain microscopic contamination that is not

visible.

Fit the belt over the motor pulley and sub-platter.

Set the belt tension by positioning the motor pod relative to the turntable. You will find that the sub-chassis can rotate very slightly on the

plinth – rotate it so that the bearing moves towards the motor pod. The centre of the motor pulley should be approx 122mm to 125 mm

to the centre of the bearing house but this can vary depending on belt length variations.

N O T E :

It is common for people to set the belt tension too tight, which can slightly degrade performance. The optimum setting is where there is

enough tension to turn the platter without audible wow and flutter but no more. This may take some experimentation.

It also aids performance to clean the belt and all the running surfaces with mentholated or surgical spirit.

Finally ensure that the motor pod is not touching the plinth.

F I T & L E V E L T H E P L A T T E R

Top and bottom spring adjusters are provided on some sub-chassis for versatility but the new top spring adjuster shown in photo 2 does not

need a bottom spring adjuster and so it is ommited.

Try to initially level the sub-chassis by rotating the top spring adjuster. The plastic pods play no part in the levelling process. Note: both top

and bottom spring height adjusters work by rotating them – you can use these, either in combination or one at a time to achieve level. It

doesn’t matter which you use, providing the spring support bolt does not “bottom” inside the top spring adjuster. Remember not to let the

bottom spring adjuster touch the plinth.Check that the platter is level – if it is not, then level it by levelling the table or surface that the deck

stands on. If this is not possible then use a combination of the spring height adjuster and small cork disc(s) placed under one of the feet of

the deck. This may not seem the most elegant solution but threaded feet adjusters sacrifice sound quality significantly.

Page6

Page 7

C O N N E C T T H E M O T O R D R I V E .

Control Box

Plug in the black control box (switch box), transformer and motor. The LED on the switch box will come on. This light will

remain lit all the time that the switch box is plugged in at the mains supply.

The location of the control box should preferably be kept away from strong electromagnetic fields such as those

generated by transformers, amplifiers, power supplies etc.

It is best to unplug the transformer if the switch box is disconnected from it.

S E T T I N G T H E M O T O R S P E E D

NOTE:

You will need to set the motor speed yourself. In the first 4 hours of use from starting up the motor, the speed tends to drift but then settles

down permanently. To burn in the regulator board components we recommend at least 4 hours of running the motor before you accurately

set the speed.

The thin output wires from the transformer only carry 8 volts and are therefore safe to handle. Voltages inside the transformer are

dangerous so the transformer case should not be unscrewed or opened.

When the rotary switch on the control box is turned fully anti-clockwise the motor is off.

One click of the switch clockwise is 33.3 rpm - The second click clockwise is 45rpm

NOTE: The speed should only be finally set or checked with the cartridge dragging on a centre track of a record as the drag

affects speed setting.

I N S T R U C T I O N S F O R R E A D I N G T H E S T R O B E

Place the strobe disc on the record to be played. Play the record and watch the relevant ring on the disc. Adjust the speed until

marks on the ring appear stationary while the record is rotating. It sometimes helps to stare at infinity whilst doing this as the

marks become easier to see. You can see the strobe effect in florescent light, although an ordinary bulb held about 2 feet from the

strobe disc will also work fine. The bulb flickers at 50 Hz in the EEC and 60 Hz in the USA.

You can purchase bayonet fitting florescent bulbs to fit normal lamps. Try to shut out daylight when carrying out speed setting.

S E T T H E S P E E D

Set the switch on the control box to the first click i.e. 33 rpm setting. Adjust the motor speed as follows: using a small flat

blade screwdriver, turn the screw of P1 for 33 rpm. The screws are accessible at the rear of the control box (See diagram above).

To increase speed, turn the 25 turn presets clockwise until the speed changes. If the screw reaches the end of it’s travel you can

usually hear a faint clicking. You will not damage the preset by over turning it as slippage occurs. The pre-set screw will not fall

out and may need a fair number of turns to set the correct speed so keep turning.

Set P1 so that the platter turns at 33.3rpm. When setting the speed, place the arm on the centre track of a record so that the

Page7

Page 8

cartridge is tracking the grooves this ensures that the drag of the cartridge is taken into account. Speed variations of up to plus or

minus 2% are quite common on decks and the dc motor is capable of plus or minus 0.1% accuracy. Use the strobe disc provided

to set the speed (full instructions are on the card). However if you have problems using the strobe card, then count the rpm using

the following method. Counting the 33.3 revs per minute is best accomplished by placing a small piece of sticky tape on the

perimeter of the platter and then counting 100 revolutions. 33.3 rpm is exactly 100 revolutions completed in 3 minutes. To save

time in the early stages it is easiest to count 50 revs in 1 minute 30 seconds (or 25 revs in 45 seconds) and save the 100 count for

the final check.

Please note the following points when setting the speed. Firstly all the figures below are based on setting the speed on the deck

using the centre track and letting the deck play for a good 5 minutes beforehand with the stylus on the record so that the whole

system has settled down. The regulators seem to take about 5 minutes to warm up, so speed is about 2mins 58 seconds for

100 revolutions when the system starts from cold. In other words it is 2/180 x 100 = 1 % fast when started from cold. Speed

variation with the dc motor can vary minutely depending on the track played and cut of record.

Click the rotary switch to the 2nd click clockwise and set P2 so that the platter rotates at 45 or 78 rpm (if you wish) using the

same procedure as outlined above.

The dc motors are noisy to begin with and are never completely silent in comparison to a/c motors. This is thought to be due

to a different type of precious metal brush. Having said this they still sound a great deal better in performance terms. To assist

“running in” you can turn the speed right up via the control box. The motor then runs at high speed. Allow this for approx 4

hours after removing the belt. After the running in period reset the motor speed. The motor should then be run for approx 3

days under load (i.e. turning the platter) to free it up from vibration and to “bed in” the bearings.

Like most turntable manufacturers we recommend that you leave the turntable running between changing records as this reduces

the belt wear that occurs with constant stopping and starting.

N O T E S O N M O T O R & SP E E D S E T TI N G

-Do not use the power supply for anything other than the dc motor or the power supply will definitely be irreparably damaged

and you could also damage the equipment you are plugging it into.

-The circuit will take at least 20 hours to run in and sound it’s best.

The speed stability of your deck should be excellent once everything has settled down in a listening session i.e.. The power supply

and switch box have been left plugged in on standby for 15 minutes, the platter has been turning for 2 minutes and the cartridge has

been on the record for 30 seconds. Bear in mind that the ear detects when music is playing slightly slow much more easily than it

detects it playing fast. For this reason most manufacturers set their decks to run slightly fast. You can expect a bit of speed variation

when the motor is first switched on - it takes about 2 minutes to warm up properly and then the motor should run at it’s correct

speed but only when the stylus is on the record.

It is highly preferable to keep the transformer plugged in at all times (unless you are away on holiday) because it takes a good

15 minutes to warm up from cold and run correctly. When in standby mode the control box draws a negligible current so you

needn’t worry about your electricity bill.

N O T E S O N S P E ED S T A BI L I T Y

If you keep switching the deck on and off you will get a little speed variation as it takes approx 2 minutes to warm up the circuit

each time even if it’s only switched off for 3 seconds. This is unavoidable although we have tried to design out the variation as much

as possible.

If you measure the speed without a needle on the record the speed will not be perfect, as the speed should only be set with the stylus

tracking the record. If you don’t do this, the record will run slow once you put the stylus on the record.

If you measure the speed within 30 seconds of putting the needle on the record the speed will not be perfect as it takes a while to

settle down.

Some people make the mistake of constantly watching the speed before the deck has settled down and the needle has been on the

record for a good 2 minutes. Strobes are very accurate and the slightest speed variation is picked up. 0.03% variation is observable

which is over 30 times the accuracy of mid-priced decks on the market.

Page8

Page 9

F I N A L C H E C K S

Your turntable is now ready to use. The following checks make sure that you have set up the turntable correctly.

The motor pulley must not foul the underside of the platter and should be inside the platter rim.

The tonearm should be set up with correct VTA i.e. the tube should be approx parallel to the surface of the record – see the

tonearm instructions about this. To get the right sound is often a matter of experimentation.

With the tonearm and cartridge mounted, check once more that the platter is level – if it is not, then level it by levelling the table or

surface that the deck stands on. If this is not possible then use a combination of the spring height adjuster and small cork disc(s)

placed under one of the feet of the deck. We understand that this may not seem the most elegant solution but threaded adjusters

sacrifice sound quality significantly.

Ensure that there is a little “bounce” on the arm end of the sub-chassis. If not then check that the top chrome spring adjuster is

not touching the top of the spring support bolt, as this will render the whole suspension system ineffective.

Checking the sub-platter

The sub-platter spins freely and does not touch the bearing house or anything else.

• If the sub-platter is rubbing on the top spring height adjuster you need to loosen the bearing

house by unscrewing the lower round bearing nut – then thread the bearing house upwards

and retighten. There should be at least 1-2mm clearance between the spring top adjuster and

the sub platter at all times.

Checking the platter

The platter spins freely and does not touch the motor pulley or anything else.

• If the platter catches on the top of the pulley you can adjust the height of the bearing house

by unscrewing it and threading it upwards. This is very rare.

CHECKING THE MOTOR

Check that the motor housing is not touching the plinth at any point.

Check that the motor speed is set correctly.

Check that the belt is not rubbing on either of the flanges on the top or bottom of the motor pulley. If it is, try tightening the belt

and check that the motor pod is siting level.

M A I N T E N A N C E O F T U R N T A B L E

To clean the deck, use a soft lint free cloth and wipe gently – if you have grease marks etc then you can use a general-purpose antismear polish such as Mr Sheen but only if necessary – wax furniture polish is to be avoided and if possible use an anti-static type

of polish. Do not spray the polish on the turntable as it may clog up the cartridge etc but rather spray it onto a soft polishing cloth

and then use it on the turntable.

The Platter works best without any type of mat (including the Ringmat).

It is wise to keep the packing box that the turntable came in so that you can transport the deck securely. Be careful in moving or

transporting the deck - it is possible to bend the spring support bolt if a severe side movement occurs (bear in mind that the subchassis etc. is quite heavy). Ideally it is best to remove the subchassis from the deck when transporting the deck.

The deck is not prone to going out of tune - we recommend that you check the level of the platter after the first few days as the

spring initially “beds in” and every year or so after this.

Depending on your use of the deck, the belt should ideally be replaced every 2 years or so.

If you withdraw the sub-platter spindle more than a few times you should put in a drop of oil to compensate for any possible loss.

In the unlikely event that the support rod becomes loose over time such that it can “rocks” then the nuts need to be re-tightened.

Only “nip” the nut tight by a maximum of 1/8th of a turn after finger tightness has been achieved and it starts to clamp onto the

Page9

Page 10

steel.

T R O U B L E S H O O T I N G

S P E E D V A R I AT I O N

If there is significant speed variation then causes can be down to the following

• Significant changes in room temperature - this especially affects decks that use thick, viscous oil in the bearings e.g. Rega

decks

• Lack of oil in the bearing so check by adding oil.

• Changed belt tension or an oily belt or sub-platter - clean running surfaces.

• Turntable out of level – this affects the main bearing friction.

• After adjusting the tension of the 3 small Philips screws which hold the motor on, you may need to re-adjust the speed

as they affect motor bearing friction very slightly.

• Check the sub-platter is not fouling on anything - on certain decks it can rub against one of the spring covers - it has

also been known to "bottom" against the top of the bearing house - there should be about 1 to 3mm clearance between

the top of the bearing house and the bottom of the sub-platter.

• A dirty bearing that exhibits too much friction - The sub-platter should drift round effortlessly with the slightest of

nudges and go on spinning. If you suspect the bearing friction to be a little high return the bearing to us for checking.

• A worn thrust bearing - this may occur on a small run of bearings, which were too soft.

• Transistors that have developed temperature instability.

E X C E S S I V E M O T O R N O I S E

The motor needs a run in time of around 2 - 4 days continuous running. They are sometimes a little noisy to start with. It is best to run in

the motor on full power with the belt off. Most importantly you can “tune in” the motor to give minimum noise by adjusting the tightness

of the 3 small Phillips screws next to the motor pulley. The best way to set their tension is to tighten the screws until they just nip tight.

Then back off all 3 screws a little way. Now tighten one screw at a time till you hear which ones cause the least noise when tensioned and

then adjust the other two to give minimum noise. It may be necessary to use thread lock or similar to stop the screws vibrating loose. If it

continues to be very noisy please get back to us and we may check it out. However bear in mind that the dc motor is never as silent as a/c

motors are - this is because they are cogless and rely on a different type of brush. Having said this dc motors still sound a lot better in terms

of musical performance.

The other major potential source of noise is the motor vibrating due to lack of tightness and causing it’s top plate to resonate.

The solution is usually to slightly tighten the 3 small screws holding on the motor. This adjustment is fairly critical - if the 3

small screws are too tight then the motor whispers, too slack and the motor can vibrate against it’s top plate.

Please note that by adjusting these screws you affect the angle of the motor. If the belt touches the flanges at the top or bottom of the pulley

then the motor is at too extreme an angle and you will need to re-adjust the bolts.

The ideal is for a vertical pulley with the lowest noise level. If you get a knocking sound from the motor then slightly slacken off

the 3 screws holding the motor to the top plate.

If you have checked the above and are still having trouble please contact us making a note of the serial number on the back of the control

box.

Page10

Page 11

Final setup of tonearm

I N S T A L L I N G T H E A R M

I N T R O D U C T I O N

Rega arms and Origin Live arms require mounting dimensions such that the centre of the platter to the centre of arm hole is approx 223mm

plus or minus 2mm tolerance and the hole diameter for the arm is 24mm to 25 mm.

Please note that for Origin Live Silver, Encounter and Illustrious tonearms - do not adjust bearing tightness - this is carefully set at factory - it

may seem that there is “play” in the bearings - this is deliberate and must be left alone or degradation will result - it is not actually play in

the bearing races but careful bearing fitting to allow a loose bearing fit thus “floating” the arm rather than rigidly coupling it to the deck.

NOTE

If you are fitting a Rega or Origin Live Arm to the Aurora, Aurora Gold, Resolution, Resolution Classic or Sovereign turntables you will only

need the sliding aluminium sleeve VTA adjuster, which is clamped in place by the single grub in the arm base. None of the large washers or

the large nut, if they have been supplied, are needed.

V T A ( V E R T I C A L T R A C K I N G A D J U S T M E N T )

To allow the cartridge needle to track at the correct angle it is important that the base of the arm is at the correct height in relation to the

platter.

For Rega arms, the OL1 series and Silver arm - Usually the optimum setting is such that the TOP edge of the arm is parallel with

the surface of a FLAT record – you can use a piece of card with parallel lines drawn on it to check this once the cartridge is fitted.

For the Encounter, Illustrious and Conqueror arms – the centre line of the tapered arm tube should be parallel with the surface

of a FLAT record. You can use the template supplied to help judge this.

It is always best to experiment with vta height by varying it and listening to the results till you have found the optimum position.

Most cartridges have a height of 17mm and if this is the case, then the base of the arm should rest approximately 31mm below the top of the

platter surface. If your cartridge height is different you can work out where the base of the arm should be from the preceding figures.

U S I N G T H E O R I G I N L I V E V T A S L I D I N G A D J U S T E R

Do not fit a threaded VTA adjuster (supplied with some arms – this is a large knurled disc that can thread onto the arm base). Ensure

that the Aluminium sleeve (this IS the VTA sliding adjuster) is the right way up with the recess on the top side. This ensures that the

arm goes all the way down into the sleeve. Place the arm in the aluminium sleeve and then clamp it in position via the set screw in the

side of the VTA housing (i.e the sleeve is forced in to grip the arm’s threaded base). You do not need the Rega nut on the base of the

arm. Only tighten the set screw sufficiently to clamp the arm firmly in position – over-tightening can make the arm sound bright.

A R M & C A R T R I D G E S E T U P

F I T T H E C A R T R I D G E ( I F N O T F I T T E D A L R E A D Y )

Fit the cartridge to the arm using an alignment gauge and ensure the headshell wires are bent so that they are clear of the record

surface. If you are not familiar with fitting cartridges then please read the section “Hi-Fi Cartridges – Setting up procedures”.

Page11

Page 12

S E T T R A C K I N G F O R C E & S I D E F O R C E B I A S

T R A C K I N G F O R C E

Set the tracking force to the manufacturer’s recommendations using a stylus force gauge (stylus balance).

On all modified arms, Silver, Encounter Illustrious and Conqueror set the tracking force by sliding the counterweight along

the rear stub until the required tracking force is attained, then clamp up the grub screw in the side. When adjusting the

counterweight, set it so that the Allen bolt is at the side of the arm (not at the top) see figure “Rear end view of counterweight” .

You will need a stylus force gauge to measure the force underneath the cartridge tip.

HINT - In conducting this operation it helps to just lightly “nip” the allen bolt in the side of the counterweight onto the stub

– this way the counterweight has a little friction to hold it in position as you slide it backwards and forwards. Once you have

set the tracking force correctly you can firmly tighten the allen bolt in the counterweight to secure it tightly to the rear stub then

check that the tracking force is still correct after tightening.

On the OL1 tonearm which has not been modified (i.e it has a plastic rear stub with spiral groove) – You should turn the

counterweight till the arm balances level – once this is accomplished you can then set the tracking force by turning the

counterweight – half a turn = 1 gram.

R E A R E N D V I E W O F C O U N T E R W E I G H T A N D A R M M O U N T I N G

U S E O F S T Y L U S F O R C E G U A G E

Most stylus force gauges work on the same principle as a set of scales or balances. For example with the Ortofon Stylus Force

Gauge, first place the stylus on the inscribed or graduated portion of the scales. Then try the stylus at different points until you

find the point where the beam “balances” freely in a roughly level position. You then read the force that is being exerted –( 1gram

= 10 mN if the scale is in mN). From this number you can assess whether you need to increase the tracking force or vica-versa.

Move the tonearm counterweight accordingly and re-measure the tracking force. Repeat this procedure until the correct tracking

force is obtained. The Shure stylus force gauge works slightly differently so follow the instructions that come with the gauge.

Page12

Page 13

S I D E B I A S F O R C E

Once the tracking force has been set you can set the sliding control for tracking bias - This should be set to a value of approximately 1 or

less due to the fact that the bias adjustments on Rega arms and similar arms tend to under-read the true value of side force produced. . The

settings you read on the Rega, OL1 or Silver arms are not always dead accurate so it may be worthwhile to fine tune the setting using the

following method. Find a test record or a record with approx 10mm of blank vinyl between the end of the lead out groove and the record

label. Place the stylus needle on the blank uncut vinyl and see whether the needle skates inwards towards the centre of the record or outwards.

You are aiming to achieve a situation where the needle drifts slowly towards the centre of the record so adjust the side bias until this state is

reached.

As the stylus tracks across a record it experiences forces that tend to push it towards the centre of the record. To counteract this

force the arm is best set up with an approximately equal and opposite force called the “side bias”

On Rega, OL1 and Silver arms the side bias force is set using the small sliding knob located beside the lift lower lever.

On the Encounter, Illustrious and Conqueror arms – Carefully twist the wire loop to the correct angle relative to the arm base

– you can use the enclosed plan view of the arm to do this – the angle only needs to be approximate – the wire loop is held in

place by a set screw at it’s base – this can be retightened if necessary using the 1.5mm allen key supplied.

Carefully unpack the 2 balls and joining thread. Set up the 2 balls and thread as shown in photo below. The side bias force is set

using the ball which slides along the silver shaft protruding from the rear of the arm yoke (beside the counterweight) - see photo

below. This ball is clamped in position using a set screw in the ball with 1.5mm allen key. Thread the thin nylon filament line

through the small gap of the wire “eye” to allow the ball weight to hang freely. The adjustment ball is initially set at just under

three-quarters of the way out along the silver rod – this is approx the correct position for most cartridges. If you wish to increase

the side bias force then unclamp the ball using a 1.5mm Allen key and the ball further outwards. To decrease the side force move

the ball inwards. Once you have finalised the correct position re-clamp the ball in position.

S E T T H E V T A ( V E R T I C A L T R A C K I N G A D J U S T M E N T )

To allow the cartridge needle to track at the correct angle it is necessary that the base of the arm is at the correct height in relation to the

platter. Usually the optimum setting is such that the TOP edge of the arm is parallel with the surface of a FLAT record – you can use a piece

of card with parallel lines drawn on it to check this. Place the cartridge on the record with the deck switched off. Hold the card edge onto the

record in a position alongside the arm and see whether the top edge of the arm is parallel.. Raise or lower the base of the arm till you achieve

parallel position. Most cartridges have a height of 17mm. If this is the case, the base of the arm should rest approximately 31mm below the

top of the platter surface –see diagram “cross-section of sub-chassis”.

It is worth experimenting with VTA adjustment. Slightly raise or lower the arm and then listen - if the sound is relatively bright then the arm

is too high, if it is relatively dull and bass heavy then the arm is too low.

If you have no VTA adjuster Raise and lower the arm by fitting spacing washers under the arm. Alternatively you can raise

or lower the height of the platter – this is easily accomplished by removing the platter & sub-platter to re-set the height

of the threaded bearing house (see “diagram showing threaded bearing house arrangement”).

If you have the threaded VTA adjuster Raise and lower the arm by rotating the VTA adjuster. If you find your arm is too

high in relation to the platter with the VTA adjuster set to give the arm it’s lowest position then you need to raise the height

of the platter a few millimetres – this is easily accomplished by removing the platter & sub-platter to re-set the height of

the threaded bearing house (see “diagram showing threaded bearing house arrangement”).

If you have the Origin Live VTA sliding adjuster – Raise and lower the arm in the aluminium sleeve and then clamp it

in position via the set screw in the side of the VTA housing (i.e the sleeve is forced in to grip the arm’s threaded base). You

do not need the Rega nut on the base of the arm. Only tighten the set screw just sufficiently to clamp the arm in position

– over-tightening can make the arm sound relatively bright.

S E T T H E A R M F A S T E N I N G T I G H T N E S S

It is best to experiment with the tightness of the large Rega base nut (if fitted) by listening to music. This may seem laborious but you will

be richly rewarded as this adjustment is CRITICAL for performance. The mistake is often made of over tightening this nut with the result

that the music is deadened.

W A R R A N T Y

We guarantee arms supplied by ourselves to be free from fault for 2 years and will undertake to correct any faults providing the arm has not

Page13

Page 14

been modified by any party other than ourselves and has not received maltreatment of any kind. Our OEM arms and modifications are not

guaranteed by Rega so in the event of a warranty claim you should contact ourselves rather than Rega.

N O T E S

A detailed description of Cartridge set up and care is included in the end sections of this manual.

Please note that the occasional rewired arm can make a slight “rustling” noise through the speakers when it is lifted across the

record. This should not be a cause for concern as it is only caused by microphony of the internal litz cable - under normal playing

conditions this is inaudible.

Check that the arm can move freely across the whole record – if there is a “catch” then it is almost certain that the curved arm rest

is fouling on the yoke – simply rotate the arm rest till it no longer fouls – this can be carried out without loosening the arm rest

grub screw.

On the Illustrious and encounter tone-arms you can get a “gripping” action with the arm rest clip if you rotate it very slightly so

that it is at an angle to the arm ( not too much or you might get wear on the arm ).

The earth lead should be connected to the earth of your pre-amplifier or amplifier. This earth lead is best separated slightly from

the arm signal leads so do not wind it around them for best performance.

Now that all the hard work is over you can settle back and hear the results - we wish you many hours of enjoyable music and rediscovering

your record collection.

You can increase the height of the lift / lower arm rest by loosening the small allen screw in the side of the curved arm rest and raising it

slightly – finish by retightening it in position.

The sound of new arms and rewires will improve significantly over the first 2 weeks as items “bed in” and arm wires burn in.

Fit the cartridge to the arm using an alignment gauge and ensure the headshell wires are bent so that they are clear of the record surface.

Ensure that the bias adjustment slider is set to zero. Set the tracking force to the manufacturer’s recommendations using a stylus force gauge

(stylus balance). When tightening the counterweight, set it so that the Allen bolt is at the side of the arm (not at the top) see figure below

and tighten firmly - check tracking force is still correct after tightening.

It is worth experimenting with VTA adjustment if you can. Slightly raise and lower the arm and then listen - if the sound is bright then the

arm is too high, if it is dull and bass heavy then the arm is too low.

We guarantee arms to be free from fault for 2 years and will undertake to correct any faults providing the arm has not been modified by any

party other than ourselves and has not received maltreatment of any kind.

NOTE: The Ortofon stylus force gauge works on the same principle as a set of scales or balances. First, place the stylus on the inscribed line

on the white portion of the scales. Then try the stylus at different points along the line until you find the point where the white plastic beam

“balances” freely in a roughly level position. You then read the force that is being exerted - 1gram = 10 mN on the numbered scale, . From

this number you can assess whether you need to increase the tracking force or vica-versa. Move the tonearm counterweight accordingly and

re-measure the tracking force. Repeat this procedure until the correct tracking force is obtained.

A detailed description of Cartridge set up and care is included in the end sections of this manual.

Hi-Fi cartridges - setup procedures

I N T R O D U C T I O N

G E N E R A L C O M M E N T S

As we supply most makes of hi-fi cartridge we get asked questions from time to time about various issues regarding set up and care. To

help newcomers to this area we have published the following notes. These guidelines are of a general nature - we publish them only to be

of help and although widely accepted they are not formally authoritative - we cannot accept liability if you choose to use them and neither

do we encourage the time consuming occupation of answering queries surrounding the procedures outlined - these are best referred to the

manufacturer of your specific hi-fi cartridge.

Page14

Page 15

For those new or inexperienced to fitting hi-fi cartridges we would state that this is NOT difficult and much of the detail and perfectionism

outlined below is for those who like to experiment. We ourselves do not normally check azimuth, or vary tracking forces from the

manufacturers recommendations - neither would we worry if the arm was up to 3mm away from the recommended distance from the

spindle - although all these details are audible they are generally of a fairly low order, although tracking force and VTA are worth trying

should you feel anything is lacking. If things seem complicated we would encourage you not to be put off as it all becomes clear once you

get started.

Before fine-tuning the set up as described below you should allow the cartridge to “run in” properly - at least 40 hours for some cartridges.

I M P O R T A N C E O F C A R T R I D G E S E T U P

Hi-Fi cartridges travel like a bobsleigh through the grooves of a record only a few thousandths of an inch wide. You hear groove displacements

of the order of a few millionths. (That’s like splitting a hair into one thousand pieces.) Every bit of motion or vibration allowed at this level

can be heard enormously amplified through your speakers. For this reason it is good to set up the turntable and arm correctly so that the

audio cartridge can do it’s job properly. For instance a turntable out of level can produce side forces on the pickup cartridge tip that will wear

it more on one side than the other as well as have a slightly degrading effect on the wear of your records.

L E V E L N E S S

When a turntable goes out of level, the platter bearing performance and the arm’s dynamics, specifically anti-skate, are negatively affected.

So be sure your turntable platter and tonearm mounting board are level - use a spirit level. If the platter is out of level, first adjust the surface

that the deck stands on. The suspension (in the case of a suspended sub-chassis design) may also need levelling if it has subsided over time.

H I - F I C A R T R I D G E S A L I G N M E N T

Alignment for hi-fi cartridges needs to be optimised in three different planes. However, it cannot be perfect in all three planes, so it must be

optimised for an overall best balance or compromise. The final authority should always be your ears and preferably over an extended period

of listening time. Bear in mind that each record is cut slightly differently. Here again, optimise for an overall balance of good sound over a

wide range of records. The three alignment planes are as follows. (Please note that it is the stylus, not the cartridge that is being aligned.)

Lateral tracking angle

Viewed from above, the hi-fi cartridges arcing movement across the record must maintain the stylus in the same relation to the groove

as that of the cutting stylus’s straight-line tracking; this is Lateral Tracking Angle, or Tangency. Apart from linear tracking arms this is

always a matter of the best compromise.

Azimuth

Viewed from head on, the stylus must be perpendicular in the groove so as not to favour one groove wall, and therefore one channel,

over the other wall/channel; this is Azimuth.

Vertical tracking angle (VTA)

Viewed from the side, the stylus must sit correctly in the groove, at the same angle as the original cutter; this is Vertical Tracking/Stylus

Rake Angle. VTA, however, varies from record to record. Therefore, this alignment must be set by ear, even more than is the case with

the other adjustments).

H I - F I C A R T R I D G E A L I G N I N G T O O L S

Tools required are an alignment gauge, a tracking force gauge, a FLAT record, a screwdriver or Allen keys of the right size (usually 2mm), a

good light may also be helpful. Small needle-nose pliers and a magnifying glass all help. It also helps to have the hi-fi news test record. Treat

the arm with care, as some parts are fragile. To this end ensure that tightening of any bolts is carried out gently and without causing undue

strain.

C H E C K H I - F I C A R T R I D G E C L I P C O N N E C T I O N S A N D M O U N T I N G

Tonearm wiring uses a standard colour code for left channel (L) and right channel (R) and polarity. Coding is as follows: White = L Hot,

Blue = L Ground, Red = R Hot, and Green = R Ground. If the cartridge pins aren’t colour-coded the same way, they will have letter

identifications next to them. Make sure that the arm’s wires, wire clips, and solder joints are in very good condition. At minimum, clean the

Page15

Page 16

contact between cartridge pins and wire clips by removing and replacing each clip. Holding the clips with needle-nose pliers can make this

easier, but be careful that you don’t strain the wires where they join the clip. Check the clips for a proper fit on the cartridge pins, and adjust

them if necessary. “Proper” means snug but not tight. To check clip size, hold the cartridge tail-up close to the head wires, grasp a clip firmly

right behind its tubular part with the tweezers, line it up with the cartridge pin, and press. If it does not slide on with moderate force, the

clip needs opening-up. If it slides on easily but flops around when attached, it needs tightening. Sizing is the operation most likely to detach

a clip. The trick is to avoid bending the wire at its attachment point or putting too much tension on it. To avoid either, always hold the clip

with its wire slightly slack-looped behind it while adjusting. For opening a clip, hold it firmly with the tweezers or needle-noses, right behind

its tubular section, and press the tip of the jeweller’s screwdriver into the open end of its longitudinal slot until you see this widen very slightly.

(Here’s where you’ll probably need the headband magnifier or reading glasses.) You’re dealing with thousandths of an inch here, so a barely

visible spreading may be all that’s needed. Try it for fit, and repeat until it does. For tightening a clip, press a toothpick inside it as far as it will

go, then use the needle-nose pliers to gently squeeze together the sides of the clip near its free end, while watching the slot for any change.

(Attempting to squeeze a clip without the toothpick inside it will flatten its sides.) Try it for size, and re-squeeze if necessary until the fit is

correct. When it is, close up the middle section of the tube to match the end

Cartridge mounting screws (usually 2.5mm Allen bolts) should be tight. Steel Allen bolts are the best for mounting hi-fi cartridges aluminium or brass are OK but difficult to tighten up hard (as they should be).

S E T T I N G U P H I - F I C A R T R I D G E S

M O U N T I N G

Mount the hi-fi cartridge in the headshell if this is not done already. This is best done with the hi-fi cartridge stylus guard in place but it may

be necessary to remove it during at least one phase of the installation. If you do, replace it as soon as possible. Be especially careful when the

stylus guard is off, as many MC cartridges have a strong magnetic field at the base of the cantilever. If this attracts the tip of a steel-bladed

screwdriver, it can destroy the stylus - there is no hope of resisting it. The best precaution is to keep the screwdriver well away from the

cantilever, use a nonferrous screwdriver, or keep the stylus guard on when you’re using the screwdriver near it. The other main hazard is

children so don’t forget to warn prying fingers.

The headshell screws should be finger-tightened just enough that the cartridge cannot fall off but still loose enough that the cartridge is

easily moved around. Work whenever possible with the stylus’s safety cap in place. Set tracking force at nominal, then carry out the tangency

alignment procedures, then the azimuth. Do not deviate from this sequence as each step affects the subsequent one — change the order and

the setup will be wrong.

T R A C K I N G F O R C E

This adjustment is carried out on the counterbalance weight of the tonearm or spring dial if one is in place. At this point, use your tracking

force gauge and setting tracking force according to your cartridge instructions — final adjustment will be done later by ear.

If you do not have a tracking force gauge, but the arm does have a calibrated counterweight, defeat the arm’s anti-skate mechanism or set

it to zero. Set the counterweight so the arm is level and balanced. Be very careful of the unprotected stylus — you cannot do this with its

safety cap in place. Once the arm is balanced, lock it in its cradle and, using the calibrated counterweight, set the tracking force according

to your cartridge’s recommended weight.

T A N G E N C Y A L I G N M E N T

(Lateral tracking angle) - Follow the manufacturer’s literature and the dictates of your alignment gauge — different gauges use slightly

different methods. As you square up the hi-fi cartridge body with the gauge’s markings, be sure that the cartridge sides are square or your

alignment will be wrong. When all adjustments are correct, carefully tighten down the hi-fi cartridge mounting screws. Keeping a firm

grip on hi-fi cartridge and headshell together so nothing shifts, delicately tighten each screw down a turn or so, and then repeat until tight.

Tightening down one screw all the way before tightening the others is almost certain to twist the cartridge out of alignment. However careful

you’ve been, always check the alignment again after tightening.

V E R T I C A L T R A C K I N G A N G L E ( V T A )

Unless your tonearm has a special VTA adjuster, adjusting arm height is usually carried out with the use of spacing washers (as with Rega

arms). In arms with a pillar / collar type vta adjuster it helps to put pencil or pen marks on the pillar to keep track of various heights. See

your tonearm manual for its recommendations on adjusting arm pillar height. The best approach is to tune-in VTA gradually by listening

to music. You know the arm needs to be lowered at the arm pillar when the overall sound is hard and bright, with thin bass or no deep bass,

edgy highs, and harsh midrange (of course, this could also be tracking force which is too light). Distortion obscures low level details between

the musical; notes so dynamic range is reduced. Transient attacks may be too sharp. Raise the arm when the sound is dull and damped, the

highs rolled off, the lows muddy and lacking definition, and transient attacks are dull. Mind you, this sounds an awful lot like the effects of

changes in tracking force (too light is edgy, too heavy is heavy and dull). They are different sounding but hard to explain. Start with the arm

Page16

Page 17

a little low and very gradually raise it, first to where it is parallel to the record, and then so the back of the cartridge is tilting up. Keep track

of your settings so you can return to the one you like best where everything snaps into focus. The range of adjustments can be quite broad,

as much as 3/4” or even more (at the arm pivot). Play with the full range so you know what it sounds like and don’t be diffident.

A N T I S K A T E F O R C E ( P I V O T I N G A R M S O N L Y )

This applies an opposing, balancing force to the natural inward drag of a pivoting arm while playing. Left uncontrolled, the stylus would push

up against the inner groove wall, causing distortion both from mistracking and a cantilever skewed in relation to the cartridge generator. To

set, lower the stylus down near the label of a record with a wide run-out to it. Increase anti-skate until the arm starts to slowly drift outward,

away from the label. Again, this should be finalized by ear as you listen to music. If image placement is a little off-centre, or if things don’t

seem to be locked in solidly, experiment with anti-skate. Also, watch the stylus when you set it into a groove. Does it move to the right or

left relative to the cartridge body? This indicates too much or too little antiskating.

F I N E T U N I N G

You now have three adjustments approximated. Tracking force, VTA, and azimuth. It’s a matter of reiteration to optimize the sound. The

change in sound with each of these individual adjustments can be similar. It’s therefore necessary, in optimizing all three, to experimentally

move from one type of adjustments to the next, then to the next, in order to balance the optimization for all three. It’s helpful to listen to

female vocals as you proceed. Firstly try deviating from the cartridge’s recommended tracking force by small increments - about 0.2 of a

gram deviation above and below the manufacturer’s basic recommendations. Don’t worry about record damage from heavy tracking as most

record damage is actually caused by mistracking in the middle-to-high frequencies with too little tracking force rather than with too heavy.

If you’re getting mistracking at the low (lightest) end of the range and yet the low range is generally sounding the best (and on moderate

signals, not heavy passages), then chances are you have either a dirty stylus, a bad record, an accumulation of crud in your cartridge, or a

cartridge that’s getting old. Changes in tracking force can change how you want VTA and azimuth adjusted. If azimuth was initially adjusted

by ear, experiment with it.

Page17

Page 18

Proper care and maintenance of Hi-Fi

cartridges & records

C A R E O F H I - F I C A R T R I D G E S

Replace your cartridge when due - hi-fi cartridges have a lifespan for their cantilever suspensions and stylus needles. This will vary from

manufacturer and type of cartridge as well as other factors like the cleanliness of your records and the care you take of the cartridge. It is

wise to enquire on the expected life of your cartridge to the manufacturer, so that when the time comes it is replaced accordingly - most

importantly this will preserve your records as well as enable you to enjoy the best performance.

If there is a build-up of dust and dirt where the needle enters the cartridge body you should use a small soft brush to brush the debris out.

Always brush from the direction of the cantilever to the stylus or you may do damage.

Care of stylus - One well known method of cleaning styli is the Linn green stuff which is a very fine abrasive paper - this may is OK on some

cartridges which do not have fine stylus tips and fragile cantilever mechanisms. However there is a danger of causing fractures or chips in

your diamond stylus on certain fineline tips. This method can also strain the cantilever mechanism.

There are a number of fluids on the market that increase stylus life and help to clean gunge from the needle - a word of caution though some of these can loosen the stylus glue on the cantilever over time - some fluids can also attack the cantilever or coil material itself or harden

the suspension - consult your cartridge manufacturer over this. One key factor is to use the liquid very sparingly on a cotton bud such that

it is just damp (not running with fluid) - this minimises the fluid, which can run up inside the cartridge.

R E C O R D C A R E A N D C L E A N I N G

The stylus itself does a pretty good job of cleaning the grooves and should itself therefore be kept clean. The proprietary brushes etc. for

cleaning records will often do little more than brush dirt deeper into the record grooves and are best avoided if possible. Also keep records in

high quality non-scratch record sleeves - preferably good ones.

A record-cleaning machine is really the only answer for cleaning records properly as they suck out the debris and dust in the record grooves

using a powerful vacuum. Tests using a microscope prove that this does the job with 100% success. The performance improvement is also

very noticeable when it comes to even new records being played. We supply and highly recommend the Moth record cleaning machine as

this is very effective from personal experience and comes with many glowing endorsements – see our web site for details and reviews.

Upgrade Options

The Resolution turntable has been developed as a cut down version of our reference Sovereign turntable. As such there are a

number of upgrade options offering various levels of performance improvement. We have listed these below.

Upgrade Transformer

DC200 motor – this is a drop in replacement for the installed DC100

Page18

Loading...

Loading...