Page 1

***essential reading***

Instructions for

MK3C - Encounter , illustrious & Conqueror

INSTRUCTIONS BY ORIGIN LIVE 10/2011 ©

PLEASE NOTE: The sound of new arms

and rewires will improve signifi cantly over the

fi rst 2 weeks as items bed down and arm wires

burn in.

Introduction

Thank you for ordering from Origin Live. We trust you will enjoy

getting closer to the original sound and appreciating your music in

a new way.

Please give special attention to underlined text in these

instructions. First of all, note that it may seem there is “play”

in the bearings - this is a design feature and bearing tension

should not be altered or degradation will result - The bearings

on the vertical axle are high quality, however the vertical bearing

house is carefully dimensioned to allow a slightly loose fi t, thus

“fl oating” the arm rather than rigidly coupling it to the deck.

Mounting the arm

If possible, refer also to the mounting instructions from your

turntable manufacturer.

Arm mounting methods vary depending on the make of your

turntable. This section caters for various scenarios.

Mounting hole dimensions

Some decks come with an arm hole position specifi caly set up

for arms with “ Rega “ geometry. If this is not the case with

your deck, then Origin Live arms require centre of platter,

to centre of arm hole, to be approx 223mm (222.7 precise )

plus or minus 2mm tolerance. The hole diameter for the arm

is 23mm to 25 mm (23mm will accept the arm but not a

threaded vta adjuster.

arm to fi t, please refer to our web site FAQ (frequently asked

questions) in the tonearm section.

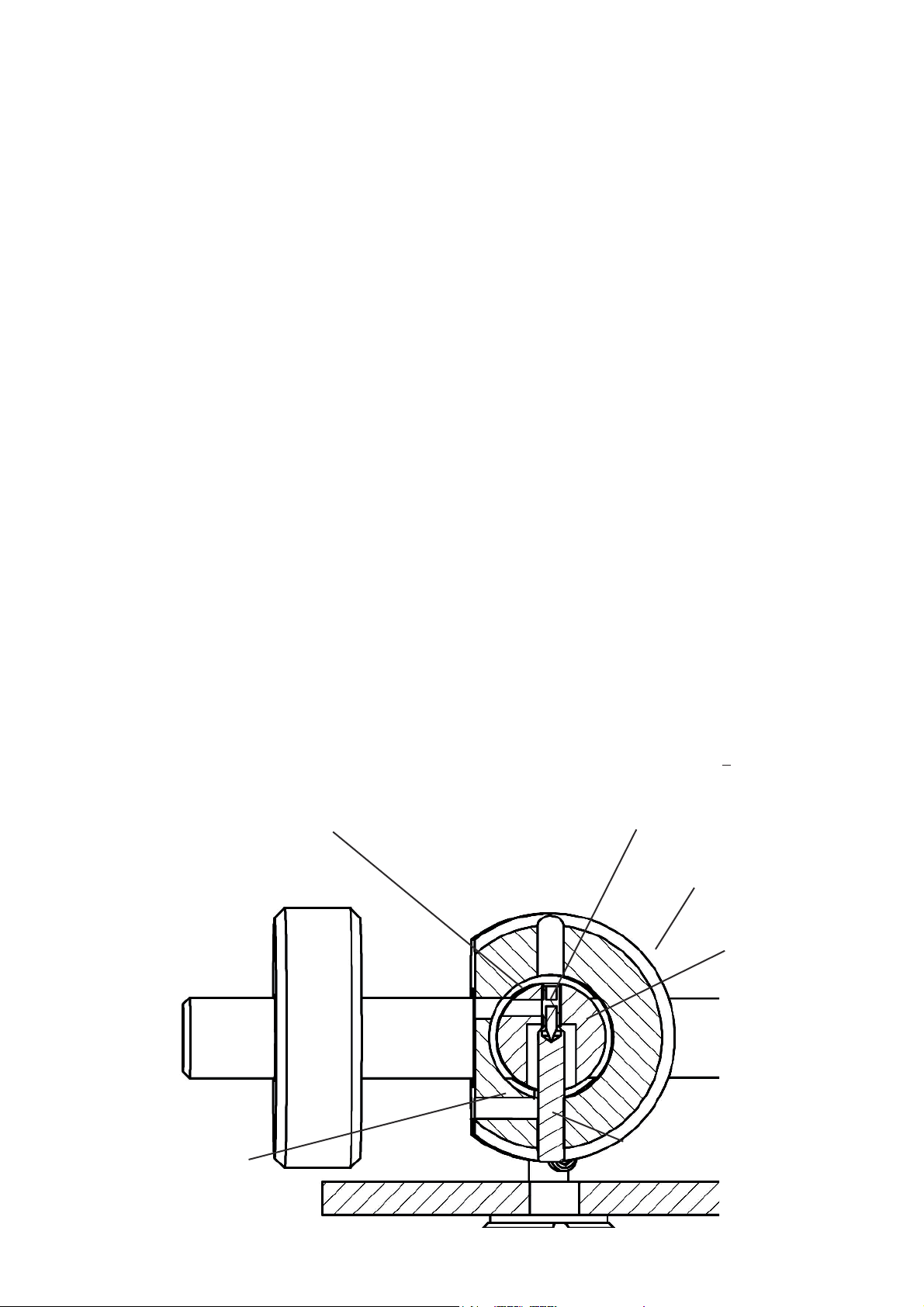

Mount the arm in the armboard as shown in the illustration

below. You can raise the arm height to approximately the right

level using vta wheel for fi ne adjustment.

24 - 25mm ARMBOARD HOLE WITH VTA

ADJUSTER

GRUB SCREW POSITION

IS HORIZONTAL

THREADED VTA ADJUSTER

Do not t normaly

ARM

CORK WASHER

THREADED ARM BASE

If you have the Origin Live threaded VTA adjuster, this should

be threaded onto the tonearms base post BEFORE you fi t it

through armboard (VTA adjuster fl ange on top). You can

later adjust the height of the arm by adjusting the turns of the

threaded vta adjuster

ARM MOUNT SURFACE

LARGE CLAMPING NUT

A threaded VTA adjuster should not be needed except in very

rare instances where the integral VTA adjuster wheel cannot

raise the arm high enough. If a threaded VTA adjuster is

needed as a last resort to raise the arm then the hole must be

24 - 25mm).

If you need to modify your existing armboard to enable an

As a rule of thumb you will fi nd the best tension on the nut is

just a little more than fi nger tight. Just tighten to fi nger tight and

use a spanner, pliers or molegrips to “nip” the nut a tiny fraction

tight, Do not overtighten the arm as it is counterproductive..

Page1

Page 2

Understanding dual Pivot

Your Origin Live arm has innovative bearings. is is best

explained before going any further.

Dual pivot bearing design – why?

One of the many reasons that the Origin Live arms are

performance leaders is due to the dual pivot bearing,

on the horizontal axle (which governs the arms vertical

movement). e design is similar in many respects to

uni-pivot – low friction and high decoupling which give

excellent de nition and transparency. However unipivots can be ddly to set up and because of their relative

instability exhibit a mediocre bass performance. Dual

pivots have all the advantages of uni-pivots but none of

the drawbacks. Vertical movement of the arm is handled

by the dual pivot and horizontal movement by our usual

highly speci ed conventional bearings.

already been set, such that the headshell is parallel to the

arm mounting surface. We strongly recommend that you

never adjust the factory setting without our permission, as

this will invalidate the warranty. Correct azimuth setting

is tricky at the best of times and unless an extremely

careful record is kept on the original factory settings the

arm will probably end up not working correctly.

How dual pivot works

e below illustration of the dual pivot bearing shows

how the horizontal axle is free to move a little in all

directions except downwards. is may be a little

disconcerting until you become con dent of the inherent

performance virtues delivered by this approach. It is also

reassuring to know that the arm cannot be knocked o it’s

bearings or come loose in any way. You can turn the arm

upside down and nothing will fall o as it would in the

case of a uni-pivot!

Floating bearings for horizontal rotation

ere is a certain amount of “rocking movement” on

the yoke vertical axis. Some people mistake this for poor

bearing t but this is far from the case. Whilst most

arms use “rigid” bearing ts, Origin Live is unique in

employing a “ oating” bearing design - this is actauly

much harder to engineer and does not cause alignment

errors as the bearings are self centering and factory

settings of the headshell take account of this.

Handles like a conventional gimballed

arm

You should handle the arm in exactly the same way as a

conventional gimballed arm. In other words you do not

need to worry about setting up azimuth. e azimuth has

SPIKE CLAMPING SCREW

Do not touch

e pivot bearings are designed to reduce friction to an

absolute minimum. In doing this there is a ne balance to

achieve both a robust design whilst maintaining extremely

low friction. In practice, the arm must have a slight degree

of movement due to a sharp tungsten point in a shallow

radiused bearing cup. e alternative to this is a very

sharp point in a deep v shaped cup – this would certainly

restrain the movement of the point but would also

increase friction and potential fracture of the tips.

e pivot points will “self centre” by sliding into the

bottom of the bearing cup. However the nal resting

place of the point may vary by 0.01mm or so. is would

not be noticed without the use of a very accurate digital

stylus force gauge.

As the pivot position shifts fractionally it can cause the

tracking force to vary slightly, by around +0.06 grams

THREADED SPIKE

YOKE BARREL

PILLAR

CLAMPING

SCREW

Do not

touch

END CAP

PILLAR CUP BEARING

Page2

Page 3

from an average reading. In practice this has no e ect

on performance and is also common among certain

unipivot designs with very low friction bearings.

force should be consistently accurate to within plus or

minus 0.06 grams from the average (i.e = 0.12 gram

total variation). Higher deviations indicate that the

bearing might be damaged or incorrectly adjusted.

Connecting the arm

FIT THE ARM CABLE CLIP

For best performance the arm cable should be

supported by a cable clip screwed into position

underneath the plinth - leave a slight droop on it so

that it isn’t “tight”. Clipping the arm helps prevent

vibration feeding into the arm.

CONNECT THE ARM TO YOUR PHONO

STAGE / AMPLIFIER

e bullet phono plugs are usually a very tight t to

your phono stage sockets. To avoid possible damage

to your ampli er sockets, the manufacturers advise

that you should heat the bullet plugs with a hair dryer

(or similar) to soften them slightly till they t easily

onto your phono stage / ampli er phono sockets.

Once tted, you do not need to reheat the plugs in

future as they will maintain the correct tightness.

e earth lead should be connected to the earth of

your phono stage, pre-ampli er or ampli er. is

earth lead is best separated slightly from the arm

signal leads so do not wind it around them for best

performance. Avoid pulling the external wires at the

base of the arm as they are not indestructible and

can become detached if excessive force is used to

manipulate them.

e bearing freedom of movement should be checked

by measuring the stylus down force over a succession

of 10 or so movements of the arm into the arm clip

and then onto a stylus force gauge. e force gauge

should read consistently to within plus or minus 0.06

grams from an average over the 10 measurements if

all is well.

It is best to use a digital force gauge for this as a

“balance” type can give inconsistent readings with

errors of up to 0.5 grams .

TRANSIT BOLTS WITH NYLON

WASHERS UNDERNEATH

Remove and keep for future use

If you have XLR plugs, you will not get both plugs

through the mounting hole for the arm. e hole is

too small to allow the 2nd plug to go through as the

1st cable wire takes up space.

For this reason we normaly t only one XLR plug

and leave you to t the other. Full instructions on

how to t the other XLR are available on our web site

- see top navigation bar, click “general information”

then “technical support” on the drop down list.

Making the dual points

operational

e transit bolts shown in illustration are critical,

to prevent damage to the bearing points in transit.

Gently remove these to make the arm operational.

Keep the bolts and nylon washers in a safe place.

ese MUST be replaced whenever you send the

arm by post or courier as the boxes can get severely

thrown around. Damage to the points occurs, unless

the transit bolts are in place.

DO NOT TAMPER WITH ANY OF THE GRUB

SCREWS IN THE YOKE - ese are precisely set up

at factory and any interference will probably end up

with damage to the pivot points or bearings that don’t

work properly.

CHECK THAT ALL IS WELL - e stylus down

Page3

Page 4

Fitting the counterweight

It is best to t the counterweight at this stage. e

downforce on the cartridge is set by clamping the

large counterweight to approximately the correct

position on the rear stub. e trick here is to lightly

nip the grub screw when it gets close to giving your

desired tracking force setting. You can then gently

twist it slightly while pushing it in the desired

direction till it gives the correct reading. Once this is

achieved, clamp up rmly and recheck the reading.

e ne adjuster is not supplied unless speci cally

ordered - it can be ordered at a later date but is

not generally used as it degrades performance

slightly. If you have the ne adjuster, then once the

counterweight is rmly clamped in approx the right

position, nal adjustment is carried out using the

ne adjuster on the rear of the counterweight - see

illustration below.

nger-tightened just enough that the cartridge cannot

fall o but is still loose enough that the cartridge is

easily moved around. Work whenever possible with

the stylus’s guard in place. Now carry out the set

up procedures outlined below. Do not deviate from

this sequence as each step a ects the subsequent one

— change the order and the setup will be wrong.

SET TRACKING FORCE

Set the tracking force to the cartridge manufacturer’s

recommendations using a stylus force gauge (stylus

balance). is will need to be re-set later on so do not

worry about getting it too exact at this stage - within

0.3 grams of recommended tracking force is ne.

First screw in the ne adjuster on the rear of the

counterweight as far as possible. Now set the tracking

force to within 0 to 0.35 grams OVER the correct

reading using the grub screw in the side of the major

counterweight. Do this, by sliding the counterweight

along the rear stub until the required tracking force

is attained, then clamp up the grub screw so that it

locates in the groove in the side of the rear stub. i.e

When adjusting the counterweight, set it so that the

Allen bolt is at the side of the arm (not at the top)

see gure “Rear end view of counterweight”. You

will need a stylus force gauge to measure the force

underneath the cartridge tip.

Allen grub screw to

clamp large weight

Fine adjuster weight to give

0.35grams adjustment.

Cartridge set up

If you are not familiar with fi tting cartridges then please read the

detailed section “Hi-Fi Cartridges explained” found towards the

end of this manual.

MOUNTING

Mount the cartridge in the headshell of the arm.

Cartridge mounting screws (usually 2.5mm allen

bolts) should be tight. Stainless steel allen bolts are

the best for mounting hi- cartridges - aluminum or

brass are OK but di cult to tighten in comparison to

allen heads. Avoid steel bolts as they are magnetic and

degrade your cartridge magnets.

is is best done with the stylus guard in place but

it may be necessary to remove it during at least one

phase of the installation. If you do, replace it as soon

as possible. Be especially careful when the stylus

guard is o , as many MC cartridges have a strong

magnetic eld at the base of the cantilever. If this

attracts the tip of a steel-bladed screwdriver, it can

destroy the stylus - there is no hope of resisting it. e

best precaution is to keep the screwdriver well away

from the cantilever, use a nonferrous screwdriver,

or keep the stylus guard on when you’re using the

screwdriver near it. e headshell screws should be

HINT - e counterweight is deliberately a very

loose t on the stub for best performance. Because of

this, it helps to just lightly “nip” the allen bolt in the

side of the counterweight onto the stub – this way

the counterweight has a little friction to hold it in

position as you slide it backwards and forwards. Once

you have set the tracking force correctly you can

tighten the allen bolt in the counterweight as rmly

as possible to secure it tightly to the rear stub. Recheck that the tracking force is still 0.3 to 0.35 grams

over the manufacturers recommendation.

USE OF STYLUS FORCE GUAGE

Most stylus force gauges work on the same principle

as a set of scales or balances. For example with the

Ortofon Stylus Force Gauge, rst place the stylus

on the inscribed or graduated portion of the scales.

en try the stylus at di erent points until you nd

the point where the beam “balances” freely in a

roughly level position. You then read the force that

is being exerted –( 1gram = 10 mN if the scale is

in mN). From this number you can assess whether

you need to increase the tracking force or vica-versa.

Move the tonearm counterweight accordingly and

re-measure the tracking force. Repeat this procedure

until the correct tracking force is obtained. A digital

force gauge works slightly di erently so follow the

manufacturer’s instructions.

SET TANGENCY ALIGNMENT (LATERAL

TRACKING ANGLE)

First of all set the cartridge overhang, which is 17mm for

all Origin Live and Rega arms. The overhang of the cartridge

Page4

Page 5

is the measurement from the centre of the spindle to the tip of

the cartridge stylus when the armtube is positioned such that it’s

centre line is directly over the centre of the spindle. Whenever

you rotate the cartridge to align it, the overhang position must

be maintained and checked at the end of the whole procedure.

Follow the manufacturer’s literature and the dictates of your

alignment gauge - different gauges use slightly different methods.

Square up the hi-fi cartridge body with the gauge’s markings, be

sure that the cartridge sides are square or your alignment will be

wrong. When all adjustments are correct, carefully tighten down

the hi-fi cartridge mounting screws. Keeping a fi rm grip on hifi cartridge and headshell together so nothing shifts, delicately

tighten each screw down a turn or so, then repeat until tight.

Tightening down one screw all the way before tightening the

others is almost certain to twist the cartridge out of alignment.

However careful you’ve been, always check the alignment again

after tightening.

VT A Adjustment

To allow the cartridge needle to track at the correct VTA (vertical

tracking angle) it is important that the base of the arm is the

correct height in relation to the platter.

The top or bottom edge of the tube should be roughly parallel

with the surface of a FLAT record. You can use the template card

supplied to help judge this.

It is always best to experiment with vta height by varying it and

listening to the results till you have found the optimum position.

This is necessary because of manufacturing variations in stylus

angle tolerances.

VTA (VERTICAL TRACKING

ANGLE) ADJUSTER WHEEL

Ensure the headshell wires are bent so that they are clear of the

record surface.

Adjustments for vta & tracking force

Ignore minor differences in your arm to below drawing which is for illustration only

DO NOT ADJUST ANY OF THE SET

SCREWS IN THE YOKE BARREL SECTION

VTA Calibration: The arm must be “unclamped” for the

vta wheel to work – see diagram for “vta clamping grub screw”

COUNTERWEIGHT

CLAMPING SCREW

Best on SIDE as shown

VTA HEIGHT ADJUSTER WHEEL

Half turn clockwise raises arm 0.5mm

Must slacken VTA clamping screw

before turning.

Re-clamp after adjusting to your

preferred tension

VTA CLAMP SCREW

Tighten up hard once vta is set.

Loosen when adjusting VTA

Do not adjust any other set screws

on this level

Do not adjust screw on

opposite side of VTA

clamping screw

Page5

Page 6

and slacken it half a turn or so.

Just under the arm plate is the thin silver vta height adjuster

wheel – To raise the arm, turn the wheel clockwise (anticlockwise to lower it). The wheel has a dimple so that you can

see how far you turn it - each half revolution of the wheel is

equivalent to a 0.5mm change in height.

Clamping: For the sake of speed in vta setting, we

recommend that you leave the arm unclamped during the

comparisons. However it will sound FAR better clamped,

once you have arrived at the vta “sweet spot”. An Allen key

is provided for this purpose and the position of the clamping

grub screw is shown in the relevant diagram.

The wheel is capable of raising the arm around 30mm but not

more than 20mm is recommended for optimum performance.

The following calculations are given to try and give a sense of

proportion to a rather intuitive but incorrect notion.

Inertia differences are relatively insignifi cant. To get the weight

closer to the pivot, the counterweight has to be heavier and

this adds inertia - all in all a difference of 20mm or so is not a

big deal.

To illustrate this using laws of physics - the moment of inertia

is m x r squared where m is the mass and r is the distance to its

centre of rotation

Say that a 130gram counterweight is 45mm away from the

pivot - moment of inertia is 0.13 x 0.045 squared = 0.26 x10

to the minus 3

Experiment with vta: It is important to experimentally set

the optimum arm height by listening to different vta settings.

If the arm base is too high, the sound is usually slightly on the

bright side and lacking body in the bass – too low and it veers

on the dull side. To enable precise and repeatable vta setting,

your Origin Live arm has an integral vta adjuster wheel. This

method of height adjustment is extremely accurate, with

obvious benefi ts in terms of speed of adjustment. This means

better listening comparisons between different vta settings.

Do not adjust Azimuth or any of the point settings

in the yoke

The adjuster points are set up very accurately in the factory for

correct azimuth. This is a very fi ne adjustment and one that

needs specialist knowledge of the arm. For this reason if any

of the grub screws are adjusted in the yoke other than by an

authorised dealer it will invalidate the warranty.

Counterweight position too near the

end of the stub? (optional read)

A common idea propogated in Hi Fi circles is that the

counterweight should be as close as possible to the yoke to

minimize inertia and reduce “see / saw” effects over record

warps. We believe this idea is based on certain observations

on particular arms that have then led to a totaly incorrect

diagnosis of the real causes of any performance changes

perceived. Although intuitively the theory of decreasing

the inertia of the counterweight seems very plausible, there

is another more proven explanation. The reason this is

helpfull to realise is that it gives peace of mind that when

the counterweight is positioned at the end of the stub on an

Origin Live arm, you are NOT losing performance.

Equivalent downforce can be achieved with a 235g weight

at 25mm from pivot so - moment of inertia is 0.235 x 0.025

squared = 0.146 x 10 to the minus 3

This is a difference of 0.000114

Now compare this with the MUCH HIGHER increase

in moment of inertia cuased by a 16gram cartridge in

comparison to the average 8grams

16 gram cartidge inertia is 0.016 x 0.220 squared = 0.774 x 10

to the minus 3 (0.220 is pivot to cartridge distance in m)

8 gram cartidge is 0.008 x 0.220 squared = 0.387 x 10 to the

minus 3

This is a difference of 0.000387 - nearly 4 times higher than

the inertia saving of moving the counterweight in.

Another case of observations drawing the wrong conclusions is

the case of low slung counterweights. Low centre of gravity IS

important for unipivot arms but dual pivots and gimbal arms

do not “sway about” and it makes no difference in practice

to sling the weight low. As previously outlined, any benefi cial

observations are down to a heavier weight or different method

of attachment reducing resonance effects on certain arms but

not Origin Live arms. This is something we have tried and

tested repeatedly.

The notion that counterweight position affects performance

has much more to do with vibration and lack of structural

rigidity than inertia effects - in other words on some arms it

pays to keep the counterweight close to the yoke as it decreases

resonance effects from counterweight “waggle”. On these arms

the counterweight causes an increasing vibrational whiplash

effect as it gets further from the pivot.

Origin Live have gone over and over this with their arms

and established conclusively that the counterweight position

simply does not affect performance very signifi cantly on a

properly designed arm. The idea that inertia is an enemy is

also based on pure ideology - the fact is that without inertia

the stylus could not read the record groove at all!

Some systems add weight at the headshell to INCREASE

inertia as it is proven to be benefi cial. 12 inch arms have much

higher inertia than 9 inch ones but nobody seems to bat an

eyelid!

Page6

Page 7

ANTISKATE FORCE (SIDE BIAS)

This applies an opposing, balancing force to the natural inward

drag of a pivoting arm while playing. Left uncontrolled, the

stylus would push up against the groove inner wall, causing

distortion both from mistracking and a cantilever skewed in

relation to the cartridge generator.

frequencies with too little tracking force rather than with too

heavy. If you’re getting mistracking at the low (lightest) end of

the range and yet the low range is generally sounding the best

(and on moderate signals, not heavy passages), then chances are

you have either a dirty stylus, a bad record, an accumulation of

crud in your cartridge, or a cartridge that’s getting old. Changes

in tracking force can change how you want VTA adjusted.

Carefully twist the wire loop to the correct angle relative to the

arm base – you can use the enclosed paper template, showing

a plan view of the arm to do this – the angle only needs to be

approximate – the wire loop is held in place by a set screw at it’s

base – this can be retightened if necessary using the allen key

supplied.

Carefully unpack the 2 balls and joining thread. Set up the 2

balls and thread as shown in photo . The side bias force is set

using the ball which slides along the silver shaft protruding from

the rear of the arm yoke (beside the counterweight). This ball

is clamped in position using a set screw in the ball and 1.5mm

allen key. Thread the thin nylon fi lament line through the small

gap of the wire “eye” to allow the ball weight to hang freely. The

adjustment ball is initially best positioned about 5mm away from

the yoke – this is approx the correct position for most cartridges.

If you wish to increase the side bias force then unclamp the ball

using the1.5mm Allen key and move the ball further outwards.

To decrease the side force move the ball inwards. Once you have

fi nalised the correct position re-clamp the ball in position. To be

on the safe side against excessive side force it is safest not to set

the position of the clamped ball any further out than half way

out along the rod as shown below.

Checking side bias

Ideally you need a test record with a track for checking side bias

(not all do so check before you buy - The Ultimate Analogue

Test LP is one that we can recommend as it has an Anti-skating

test; 315Hz amplitude sweep to +12dbu (Lateral). Also the Hi

Fi News test record has an Anti-skate/bias setting track.

In the absence of a side bias test track then the following method

is better than nothing. Find a test record or a record with approx

10mm of blank vinyl between the end of the lead out groove

and the record label. Lower the stylus needle on the blank uncut

vinyl and observe whether the needle skates inwards towards the

centre of the record or outwards. Increase antiskate until the arm

starts to slowly drift inward towards the label. Also, watch the

stylus when you set it into a groove. Does it move to the right

or left relative to the cartridge body? This indicates too much or

too little anti-skating.

FINE TUNING

You now have three adjustments approximated. Tracking force,

VTA, and azimuth. It’s a matter of reiteration to optimize the

sound. The change in sound with each of these individual

adjustments can be similar. It’s therefore necessary, in optimizing

all three, to experimentally move from one type of adjustments

to the next, then to the next, in order to balance the optimization

for all three. It’s helpfull to listen to female vocals as you proceed.

Firstly try deviating from the cartridge’s recommended tracking

force by small increments - about 0.2 of a gram deviation above

and below the manufacturer’s basic recommendations. Don’t

worry about record damage from heavy tracking as most record

damage is actually caused by mistracking in the middle-to-high

WARRANTY

We guarantee arms to be free from fault for 2 years and will

undertake remedial work, providing the arm has not been

modifi ed by any party other than ourselves and has not received

maltreatment of any kind.

NOTES

Please note that the arm can make a slight “rustling” noise”

through the speakers when it is lifted across the record. This

should not be a cause for concern as it is only caused by

microphony of the internal litz cable - under normal playing

conditions this is inaudible.

If Arm lift is at wrong height - You are able to raise the curved

arm rest piece by undoing the tiny M2.5 allen bolt in it’s side

- Use the 1.27mm size A/F Allen key provided. If you then re

tighten this with the arm rest slightly higher up on it’s shaft, you

should be able to raise the arm off the record. If you do not have

the correct size allen key or it’s lost then try fi ling down a slightly

oversize one to a “wedge” shape thus guaranteeing a tight fi t.

If the arm “sticks” in playing a record, then it is almost certain

that the curved arm rest is fouling on the yoke. To check if this

is the case, hold the arm fi nger lift and check that the arm can

traversed by hand above the surface of the whole record. This

will identify the position of the “stick” – simply rotate the arm

rest till it no longer fouls – this can usually be carried out without

loosening the arm rest grub screw.

The sound of new arms and rewires will improve signifi cantly

over the fi rst 2 weeks as items “bed in” and arm wires burn in.

Now that all the hard work is over you can settle back and hear

the results - we wish you many hours of enjoyable music and

rediscovering your record collection.

Hi-Fi cartidges explained

optional reading for less experienced users

GENERAL NOTES

As Origin Live supply most makes of hi-fi cartridge we get asked

questions from time to time about various issues regarding set

up and care. To help newcomers to this area we have published

the following notes. These guidelines are of a general nature - we

publish them only to be of help and although widely accepted

they are not formally authoritative - we cannot accept liability if

you choose to use them and neither do we encourage the time

consuming occupation of answering queries surrounding the

procedures outlined - these are best referred to the manufacturer

of your specifi c hi-fi cartridge.

For those new or inexperienced to fi tting hi-fi cartridges we

would state that this is NOT diffi cult and much of the detail

and perfectionism outlined below is for those who like to

experiment. We ourselves do not normally check azimuth, or

Page7

Page 8

vary tracking forces from the manufacturers recommendations neither would we worry if the arm was up to 2mm away from the

recommended distance from the spindle - although all these details

are audible they are generally of a relatively low order, however

tracking force and VTA in particular are worth fi ne tuning should

you feel anything is lacking. If things seem complicated we would

encourage you not to be put off as it all becomes clear once you

get started.

Before fi ne tuning the set up as described below you should allow

the cartridge to “run in” properly - at least 40 hours for some

cartridges.

IMPORTANCE OF SET UP

Hi-Fi cartridges travel like a bobsleigh through the grooves of a

record only a few thousandths of an inch wide. You hear groove

displacements of the order of a few millionths of an inch. (That’s

like splitting a hair into one thousand pieces.) Every bit of motion

or vibration allowed at this level can be heard enormously amplifi ed

through your speakers. For this reason it is good to set up the

turntable and arm correctly so that the audio cartridge can do it’s

job properly. For instance a turntable out of level can produce side

forces on the pickup cartridge tip that will wear it more on one side

than the other as well as have a slightly degrading effect on the

wear of your records.

LEVELNESS

When a turntable goes out of level, the platter bearing performance

and the arm’s dynamics, specifi cally anti-skate, are negatively

affected. So be sure your turntable platter and tonearm mounting

board are level - use a spirit level. If the platter is out of level, fi rst

adjust the surface that the deck stands on. The suspension (in the

case of a suspended sub-chassis design) may also need levelling if it

has subsided over time. If the arm board is not level (which means

the arm pivot is not vertical), either return it to your dealer for

repair or re-level it yourself by shimming between the mounting

board and it’s support.

HI-FI CARTRIDGES ALIGNMENT

Alignment for hi-fi cartridges needs to be optimised in three

different planes. However, it cannot be perfect in all three planes,

so it must be optimised for an overall best balance or compromise.

The fi nal authority should always be your ears and preferably over

an extended period of listening. Bear in mind that each record is

cut slightly differently. Here again, optimise for an overall balance

of good sound over a wide range of records. The three alignment

planes are as follows. (Please note that it is the stylus, not the

cartridge that is being aligned.)

the same angle as the original cutter; this is Vertical Tracking/Stylus

Rake Angle. (VTA, however, varies from record to record due to

their varying thicknesses. Therefore, this alignment must be set by

ear, even more than is the case with the other adjustments).

HI-FI CARTRIDGE ALIGNING TOOLS

Tools required are an alignment gauge, a ruler, a tracking force

gauge, a FLAT record, a screwdriver or Allen keys of the right size

(usually 2mm), a good light may also be helpful. Small needle-nose

pliers and a magnifying glass all help. It also helps to have the hi-fi

news test record. Treat the arm with care as some parts are fragile.

To this end ensure that tightening of any bolts is carried out gently

and without causing undue strain.

Tonearm wiring uses a standard color code for channel and polarity

identifi cation: White = L Hot, Blue = L Ground, Red = R Hot,

and Green = R Ground. If the cartridge pins aren’t color-coded

the same way, they will have letter identifi cations next to them.

Make sure that the arm’s wires, wire clips, and solder joints are

in very good condition. At minimum, clean the contact between

cartridge pins and wire clips by removing and replacing each clip.

Holding the clips with needle-nose pliers can make this easier, but

be careful that you don’t strain the wires where they join the clip.

Check the clips for a proper fi t on the cartridge pins, and adjust

them if necessary. “Proper” means snug but not tight. To check

clip size, hold the cartridge tail-up close to the head wires, grasp

a clip fi rmly right behind its tubular part with the tweezers, line

it up with the cartridge pin, and press. If it does not slide on with

moderate force, the clip needs opening-up. If it slides on easily but

fl ops around when attached, it needs tightening. Re-sizing is the

operation most likely to detach a clip. The trick is to avoid bending

the wire at its attachment point or putting too much tension on

it. To avoid either, always hold the clip with its wire slightly slacklooped behind it while adjusting. For opening a clip, hold it fi rmly

with the tweezers or needle-noses, right behind its tubular section,

and press the tip of the jeweler’s screwdriver into the open end of its

longitudinal slot until you see this widen very slightly. (Here’s where

you’ll probably need the headband magnifi er or reading glasses.)

You’re dealing with thousandths of an inch here, so a barely visible

spreading may be all that’s needed. Try it for fi t, and repeat until it

does. For tightening a clip, press a toothpick inside it as far as it will

go, then use the needle-nose pliers to gently squeeze together the

sides of the clip near its free end, while watching the slot for any

change. (Attempting to squeeze a clip without the toothpick inside

it will fl atten its sides.) Try it for size, and resqueeze if necessary

until the fi t is correct. When it is, close up the middle section of the

tube to match the end

Lateral tracking angle

Viewed from above, the hi-fi cartridges arcing movement across

the record must maintain the stylus in the same relation to the

groove as that of the cutting stylus’s straight-line tracking; this is

Lateral Tracking Angle, or Tangency. Apart from linear tracking

arms this is always a matter of the best compromise.

Azimuth

Viewed from head on, the stylus must be perpendicular in the

groove so as not to favour one groove wall, and therefore one

channel, over the other wall/channel; this is Azimuth.

Vertical tracking angle (VTA)

Viewed from the side, the stylus must sit correctly in the groove, at

Proper care and maintenance

of Hi-Fi cartridges & records

CARE OF CARTRIDGES

Replace your cartridge when due - hi-fi cartridges have a lifespan

for their cantilever suspensions and stylus needles. This will vary

from manufacturer and type of cartridge as well as other factors

like the cleanliness of your record and the care you take of the

cartridge. It is wise to enquire on the expected life of your cartridge

to the manufacturer so that when the time comes it is replaced

accordingly - most importantly this will preserve your records as

well as enable you to enjoy the best performance.

Page8

Page 9

Repacking the arm for transit

If you ever lose these instructions they can be

downloaded from our web site under technical support.

Wrap the small polythene bag round the arm tube (in

the position shown in photo) before clipping the tube in

the arm clip.

over the arm tube holds the arm tube in the clip and

must have su cient tension on it. If you double up the

band by putting a twist in it before placing it over the

end of the arm you can get the band tight enough.

Do the same for the cork packing peice.

If you have lost the elastic bands you can use masking

tape or similar instead.

Wrap elastic bands in the positions shown. e band

TRANSIT BOLTS WITH NYLON

WASHERS UNDERNEATH

BEFORE applying tape or placing

arm in arm clip - Nip transit bolts

tight (not too tight as you can

damage the nish on the yoke).

From this reference point, slacken

the transit bolts no more than 1

turn to allow enough slack for the

arm tube to t into arm clip. Do

not force into the clip without

polythene wrapped round arm tube

or the nish can get marked.

Once transit bolts are correctly set,

wrap polythene around arm tube in

clip position ( as shown in photo)

and reclip the arm in arm clip.

e polythene is essential to protect

the arm tube from the edges of the

clip which can cause marking of

the tube coating.

Place the arm in it’s packing box.

ARM CLIP

ARM TAPED DOWN HERE

The arm must be taped or

rubber banded securely into

the arm clip in both positions

shown.

Polythene (bag) wrapped

round arm before placing it

in clip. This is to protect the

tube from getting marked

in transit on the edges of

the clip

Origin Live Ltd, Unit 5, 362b Spring Road, Sholing, Southampton, SO19 2PB

www.originlive.com originlive@originlive.com

Page9

Page 10

Page10

Loading...

Loading...