Page 1

DUAL PIVOT MK3 TONEARMS

Specific instructions - essential reading

Upward points - Encounter, Illustrious, Conqueror

First of all please note that if you ever send

the arm anywhere via post or courier it must

be packed according to the instructions at

the end of this leaflet or damage will occure

to the bearings - For this reason keep all

the packing and these instructions in a safe

place.

Dual pivot bearing design – why?

The Mk 3 Illustrious arm is a significant performance upgrade

over the Mk2 versions by virtue of it’s innovative dual pivot

bearing on the horizontal axle. This design is similar in many

respects to uni-pivot designs – low friction and high decoupling

which give excellent definition and transparency. However

uni-pivots can be fiddly to set up and because of their relative

instability exhibit a mediocre bass performance. Dual pivot

design has all the advantages of uni-pivots but none of the

drawbacks. Vertical movement of the arm is handled by the dual

pivot and horizontal movement by our usual highly specified

conventional bearings.

Handles like a conventional gimballed arms

You should handle the arm in exactly the same way as a

conventional gimballed arm. In other words you do not need

to worry about setting up azimuth and balancing the arm. The

azimuth has already been set, such that the headshell is parallel

to the arm mounting surface. We strongly recommend that you

never adjust the factory setting even though it is possible via

the pivot screws. Correct azimuth setting is tricky at the best of

times and unless careful record is kept on the original factory

settings, one can end up in difficulty. If in trouble see technical

support on our web site www.originlive.com/troubleshooting_

tonearms.htm

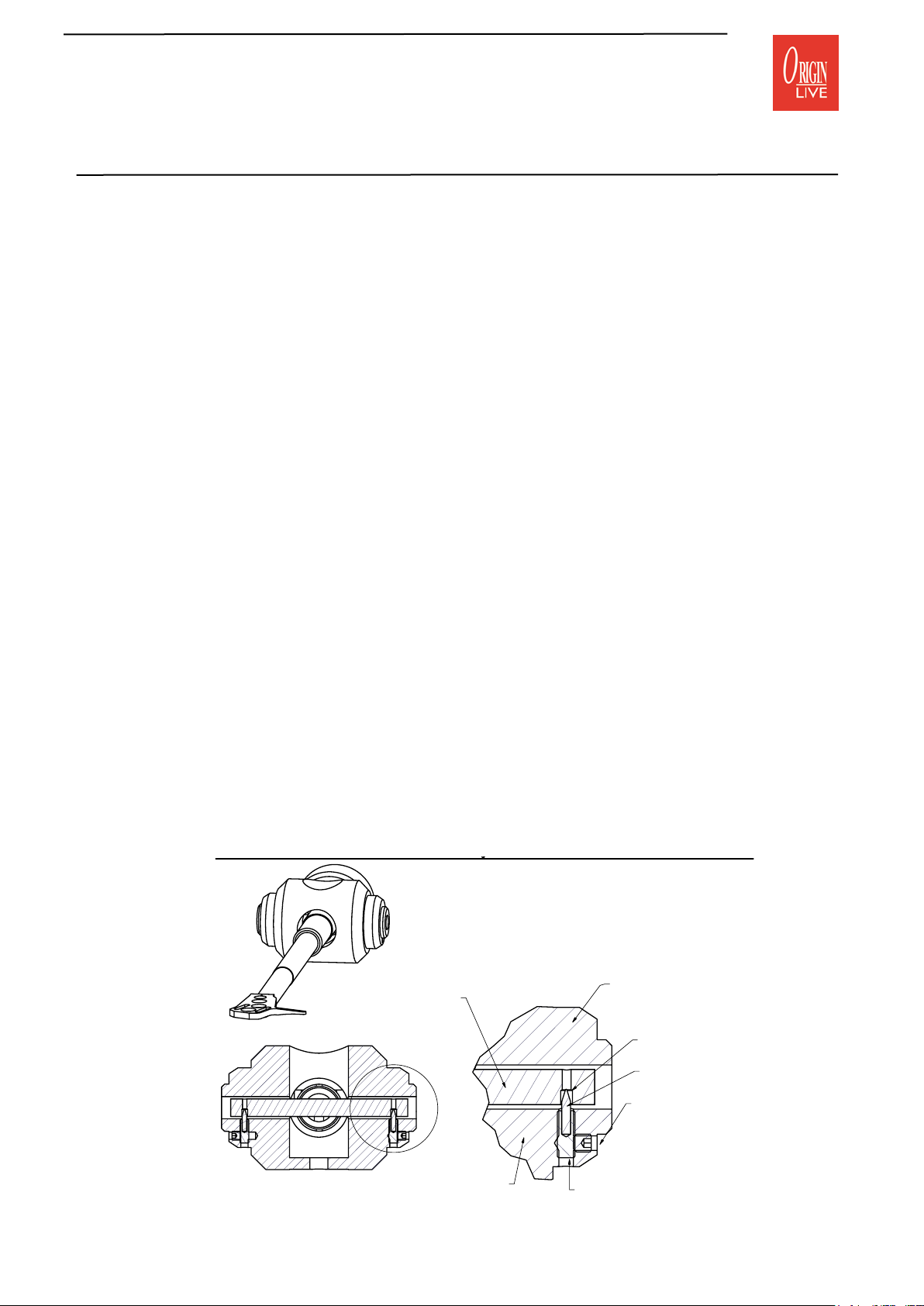

Understanding dual pivot

The below diagram showing an illustration of the dual pivot

bearing is shown to give an understanding of why the horizontal

axle is free to move a little in all directions except downwards.

This may be a little disconcerting until you become confident of

the inherent virtues delivered in performance. It is also reassuring

to know that the arm cannot be knocked off it’s bearings or

come loose in any way. You can turn the arm upside down and

nothing will fall off as it would in the case of a uni-pivot!

The pivot bearings are designed to reduce friction to the absolute

minimum practical level. In doing this there is a fine balance

to achieve both a long lasting, robust design and realizing the

potential of extremely low friction. In practice this means that

the arm must have a slight degree of movement due to a rounded

tungsten point in a shallow radiused (nearly flat) bearing cup.

The alternative to this is a very sharp, potentially fragile point

in a deep v shaped cup – this would certainly restrain the

movement of the point but would also increase friction.

The pivot points will “self centre” by sliding into the bottom

of the shallow low friction cup. However the final resting place

of the point in the cup may vary by 0.01mm or so. This would

not be noticed without the use of a very accurate digital stylus

force gauge – as the pivot position changes fractionally so can the

tracking force by up to plus or minus 0.05grams. In practice this

has no effect on performance and is also common among certain

unipivot designs with very low friction bearings.

A-A ( 1.50 : 1 )

CROSS SECTION OF ARM YOKE

PIVOT ARRANGEMENT FOR

CONQUEROR, ILLUSTRIOUS &

ENCOUNTER ARMS

(ignore differences in armtubes

and yoke shapes - these diagrams

show principles of operation

HORIZONTAL AXLE

fixed in arm

B

DETAIL INSIDE CIRCLE B

B ( 3 : 1 )

YOKE

SAPPHIRE CUP

for needle point

PIVOT NEEDLE

M3 AZIMUTH

CLAMPING

GRUB SCREW

Do not adjust

PIVOT HOLDER SCREW

do NOT adjust as you

this can only be factory set

Page 2

Making the dual points operational

The cork packing peices shown below are critical, to prevent damage to the

bearing points in transit. Gently remove these to make the arm operational

and keep the cork in a safe place. This MUST be replaced whenever you

send the arm by post or any form of courier as they throw boxes around

severely and damage to the points and cups occures unless the cork is in

place.

If you ever lose these instructions they can be downloaded from our web site under technical

support.

CORK PACKING PEICE

WEDGING ARM TUBE

TIGHTLY INTO TOP OF YOKE

AND TAPED ON

2 PEICES OF CORK PACKING EITHER

SIDE OF ARM TUBE AND THEN

WEDGED INTO THE YOKE HOLE TO

ENSURE THE ARM REMAINS CENTRAL

IN THE YOKE

CHECK THAT ALL IS WELL - Once you have installed the arm as per the general instruction

sheet, check the arm for accuracy - e stylus down force should be consistently accurate to

within plus or minus 0.1 grams. Higher deviations indicate that the bearing has been damaged or

incorrectly adjusted.

To check consistency measure the stylus down force over a succession of 10 or so movements of

the arm into the arm clip and then onto a stylus force gauge. It is best to use a digital force gauge

for this as a “balance” type can give inconsistent readings with errors of up to 0.5 grams.

Page 2

Page 3

VTA (vertical tracking angle) adjuster wheel

It is important to experimentally set the optimum arm height

by listening to different vta settings. If the arm base is too high

the sound is usually slightly on the bright side and lacking body

in the bass – too low and it veers on the dull side. To enable

precise and repeatable vta setting your origin Live arm has an

integral vta adjuster wheel. This method of height adjustment

is extremely accurate, with obvious benefits in terms of speed of

adjustment. This means better listening comparisons between

different vta settings.

VTA Calibration: The arm must be “unclamped” for the

vta wheel to work – see diagram for clamping grub screw

position. Just under the arm plate is the thin knurled vta height

adjuster wheel – The wheel has silver markings on the edge so

that you to see how far you turn it. There are actually only 2

silver marks to allow you to count each half revolution of the

wheel. Every half revolution is equivalent to a 0.5mm increase

in height. Rotating the wheel clockwise (looking down on the

wheel) raises the arm and lowering is the opposite.

Clamping: For the sake of speed in vta setting, we recommend

that you leave the arm unclamped during the comparisons.

However it will sound FAR better clamped tight, once you have

arrived at the vta “sweet spot”. An Allen key is provided for this

purpose and the position of the clamping grub screw is shown

in the relevant diagram.

The wheel is capable of raising the arm around 30mm but not

more than 20mm is recommended for optimum performance.

Thank you for purchasing an Origin Live arm. Enjoy getting

closer to the original sound and enter the heart of your music.

We hope to serve you in the future.

AZIMUTH CLAMPING SCREWS

(one on each side of yoke) Do not adjust

AZIMUTH PIVOT ADJUSTER SCREW

In underside of yoke - Factory set so do NOT

or your arm will cease to work properly

VTA HEIGHT ADJUSTER WHEEL

Half turn clockwise raises arm 0.5mm

Must slacken VTA clamping screw before turning

Reclamp after adjusting to your preferred tension

VTA CLAMP SCREW HERE

Tighten up hard once vta is set

Loosen when adjusting VTA

Do not adjust any other set screws on this level

COUNTERWEIGHT

CLAMPING SCREW

adjust

Do NOT adjust grub screw

on opposite side

of vta clamping screw

ENCOUNTER, ILLUSTRIOUS

& CONQUEROR

Page 3

Page 4

Repacking the arm for transit

e dual pivot bearing is a very precise and in some

ways delicate mechanism. Every care has been taken to

ensure that the arm reaches you in perfect condition

such that the bearings are accurate and very low in

friction. If you need to send the arm anywhere, the

following proceedure must be followed carefully.

Remove the counterweight and turn the vta adjuster

wheel up as high as possible (i.e anti-clockwise when

looking down on the arm ) - this enablles the arm to sit

in the box at the correct height.

Fit and nip tight the transit bolts and nylon

washers - the nylon washers are critical to avoid

damaging the paint. If you have carried this out

successfully the arm is clamped such that the end

caps are above the horizontal centre line of the

yoke.

Only now can you place the arm in the arm clip

and tape it down to the arm plate as shown on

page 3 - this operation must not be caried out

before inserting the transit bolts.

Pack the arm into it’s wooden box using the

foam packing peices

Pack the arm into it’s wooden box using the

foam packing peices.

CORK PACKING PEICES WEDGING

ARM TUBE TIGHTLY INTO TOP OF

YOKE AND TAPED ON - (use double

thickness of 1.5mm thick cork folded

over)

Origin Live Ltd, Unit 5, 362b Spring Road, Sholing, Southampton, SO19 2PB

www.originlive.com originlive@originlive.com

2 PEICES OF CORK PACKING EITHER

SIDE OF ARM TUBE AND THEN

WEDGED INTO THE YOKE HOLE TO

ENSURE THE ARM REMAINS CENTRAL

IN THE YOKE

Page 4

Loading...

Loading...