Page 1

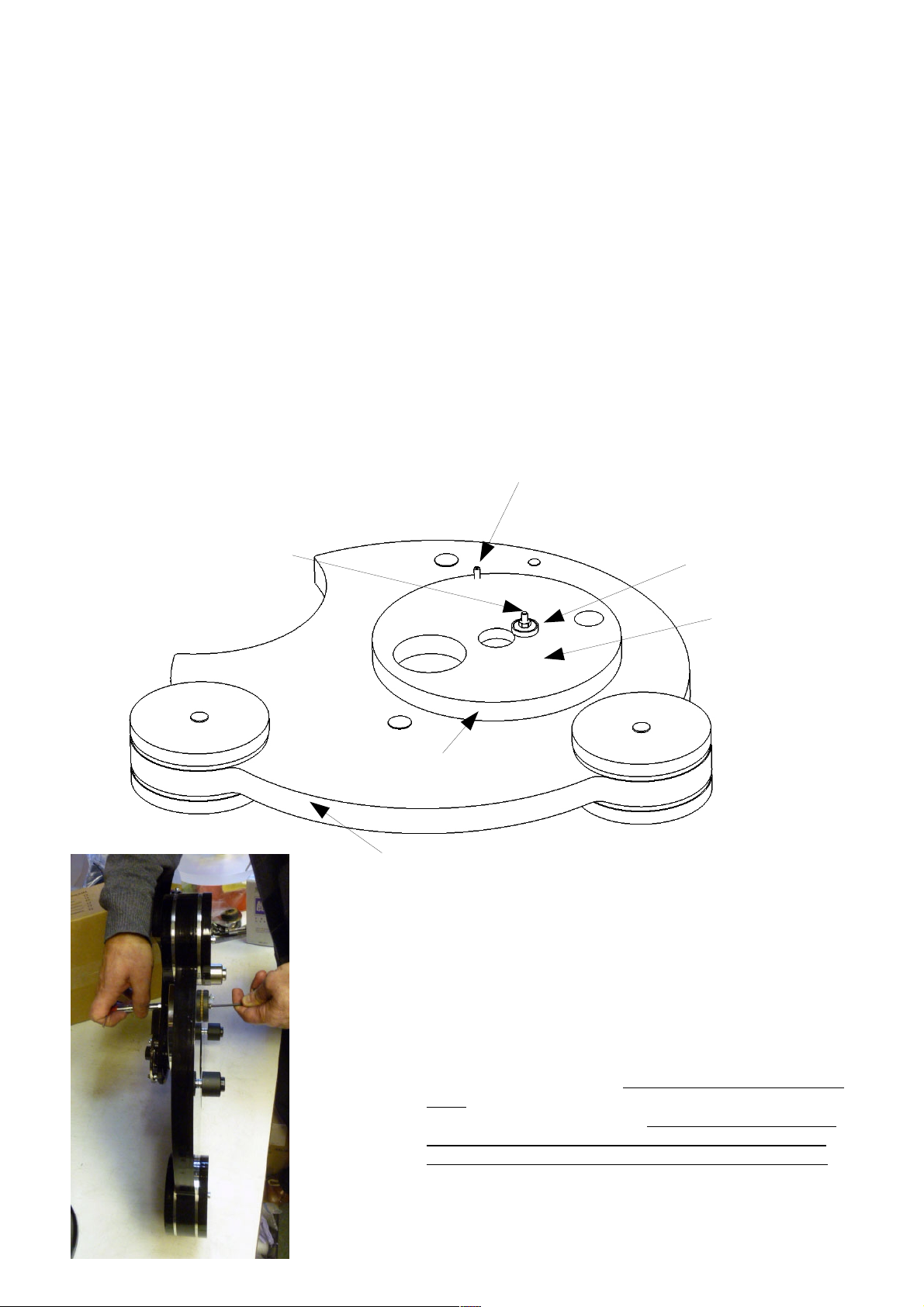

Assembly of deck sub-chassis to plinth

Read carefully or damage can occur

Please fit the Subchassis to the plinth following the instructions on these sheets. This part

is not pre-assembled to prevent potential distortion that can occur in transit if it is rigidly

attached to the plinth.

Preliminary notes The subchassis is carefully built such that the platter is parallel to the

armboard. Do not tamper with any of the bolts on the sub-chassis even if they may not

appear to be seriously tight.

On the Resolution and Sovereign decks - When you finally level the deck, note that the

acrylic part of the armboard is not a reference surface – only the chrome inner disc is true

to the platter level.

Anti-rotate stud - do not

Turntable as packed / on arrival

Adjust or remove

Pivot bolt – cap head

On TOP

Pivot Spacer

Pivot nut hidden

From view UNDER

plinth

Inertia disc

Plinth

The deck arrives as shown above. First, undo the

Pivot nut using the spanner provided whilst holding

the bolt head on top with the Allen key. It is easiest to

rest the deck on it's side (see photo alongside) whilst

you carry out this operation.

Once the nut is removed, do not allow everything to fall

apart. Hold the pivot bolt in, and keep the inertia disc

pressed onto the plinth. Also check that the anti-rotate

stud in the underside of the inertia disc remains in its

restraining hole in the plinth (see illustration overleaf)

Page 2

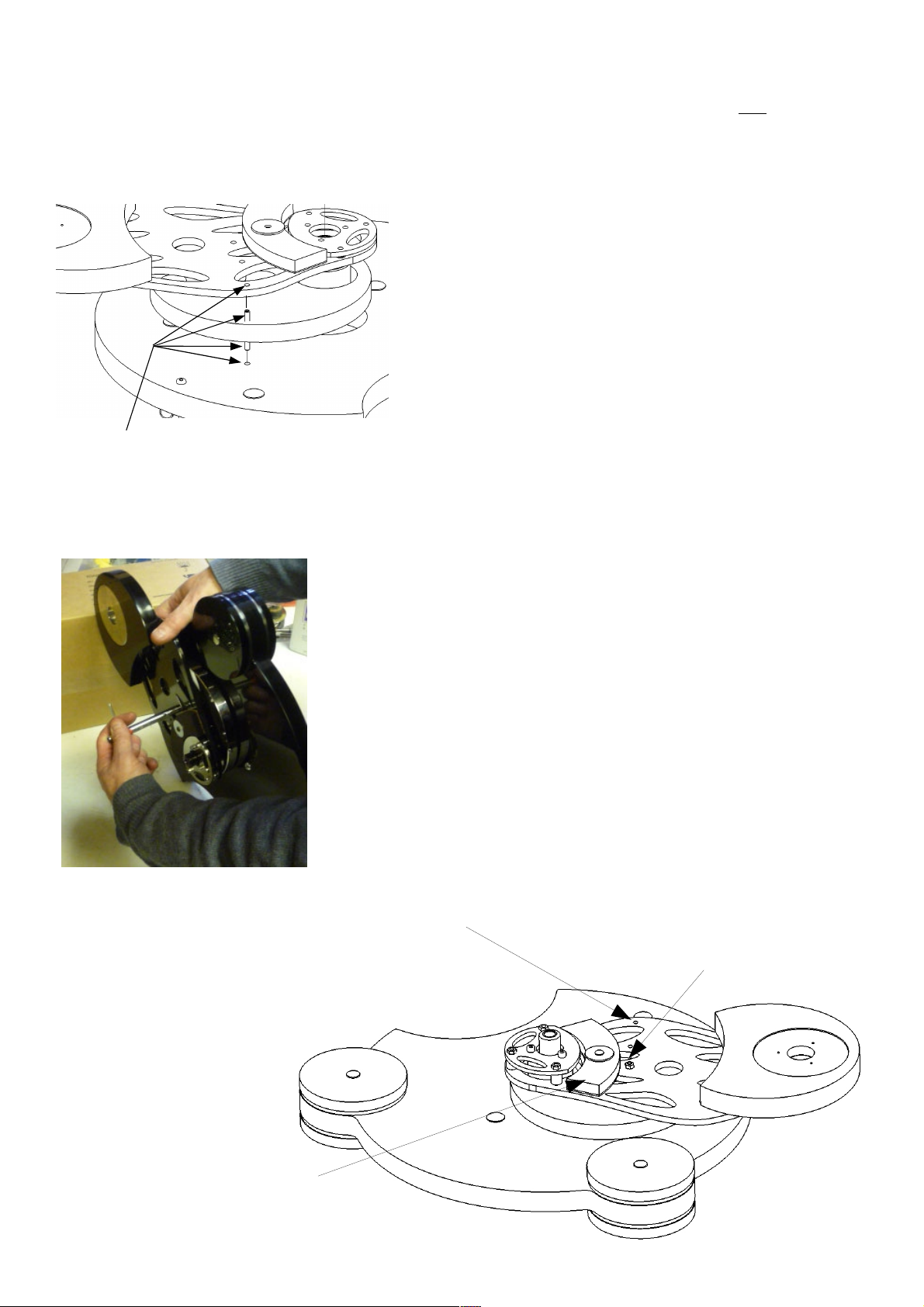

EXPLODED VIEW OF ASSEMBLY

Still holding the deck on it's side, ensure that the pivot

spacer (see Fig 1 illustration) is in position and and then

place the sub-chassis over the pivot bolt and ant-rotate

stud. The sub-chassis has 2 small holes that locate

precisely over the aforementioned bolt and stud so

ensure these are both penetrated.

Only the pivot bolt needs to be tightened, by fitting the

pivot nut on top of the sub-chassis. Tighten the pivot nut

firmly. If you only have a pair of pliers this is best carried

out using a 3mm Allen key applied to the bolt head.

Ensure the anti-rotate stud stays located in the subchassis while you tighten the nut and once tightened

ensure that you can see the anti-rotate stud is located in

the subchassis hole. This is CRITICAL or the sub-chassis

will not be level with the inertia disc and performance will

be severely affected. If all is finished correctly then the

sub-chassis should be free to rotate almost imperceptibly

in the horizontal plane.

Top & bottom anti-rotate

bolts must locate in hole

in plinth AND hole in subchassis as shown

NOTES If the assembly comes apart before you get to

tighten the nut then the exploded diagram below shows

how to re-assemble everything. It is best not to allow this

to happen in the first place.

If you need to send the deck by carrier then remove the

sub-chassis and pack according to packing instructions –

remember to tighten the inertial disc onto the plinth using

the pivot nut.

You are now ready to move on to the owner manual for

final set up.

Placing spanner over pivot nut

for final tightening

Anti rotate Stud located in Sub-chassis hole

Note: On the Calypso the curved damper

is on the underside of the sub-chassis &

The armboard is not as shown here.

Pivot bolt tightened firmly

Page 3

Anti-rotate stud

Pivot nut

Pivot spacer

Inertia disc

Cork washer glued to top of pivot lower disc

Pivot lower disc

Pivot bolt

Loading...

Loading...