Page 1

Aurora & Calypso MK3

Turntable Manual

*** NOTE : Final Speed must be

reset accurately after 1 day of

continuous running at 33rpm ***

It cannot be overstated that it is VERY

important to read these instructions

to really get the best out of your

deck. There are details that are

remarkably+ counter intuitive.

Arm shown is not included

PLINTH

PLATTER

SUB-CHASSIS

MOTOR POD

Page 2

Introduction

Congratulations and thank you for choosing an Origin

Live turntable. This should give many years of

enjoyment, reliability and low maintenance.

It's critical that these instructions are read fully to

achieve best performance. Underlined text is especially

important.

The instructions are written for owners with no previous

experience, however there are aspects of the deck that

run contrary to expectations, so experts should not alter

anything without absorbing these instructions first.

Diagrams cover 3 different turntables so are for guidance

not exact representation.

Origin Live turntables are simple to set up. The

instructions appear lengthy because they give proper

explanation of factors that are different to conventional

set ups. If you have a problem not covered in the

instructions - you should speak to your dealer or refer to

technical support on the Origin Live web site

www.originlive.com - See top navigation bar “ support”.

There is a wealth of 3rd party information online.

YouTube videos are particularly helpful on how to set up

cartridges and tonearms should you need more help –

Just Google what you need to know.

Keep the turntable packing box for secure future

transport.

Safety Warnings

Voltages inside the wallwort or Upgrade transformer

(optional) are dangerous so they must not be opened.

The output wires from the transformers carry a very low

voltage and are therefore safe to handle, as are all

components inside the motor pod.

Never use the transformer on equipment other than the

turntable or irreparable damage may occur.

Ensure Mains lead to the Upgrade transformer cannot be

pierced by spikes or similar abuse. Also ensure the leads

cannot cause anyone to trip.

Keep transformer and leads away from areas where

liquids could spill on them.

Parts list

Plinth & Sub-chassis - including 1 cable clip with nut

& bolt.

Bag of parts

Cork washer for arm

4mm black acrylic spacing washer for arm (white

protective film to be removed)

Oil bottle

screwdriver

2.5mm allen key for arm clip

4mm Allen key

8mm A/F spanner – (12 inch arms only)

Platter

Upgrade platter mat

1 Belt + Spindle for platter + Strobe card

Motor pod

Wallwart

Fully balanced pgrade transformer for 230 volt or 110

volt mains supply (Optional)

Owner manual, assembly sheet, Packing instructions

Set up & operation

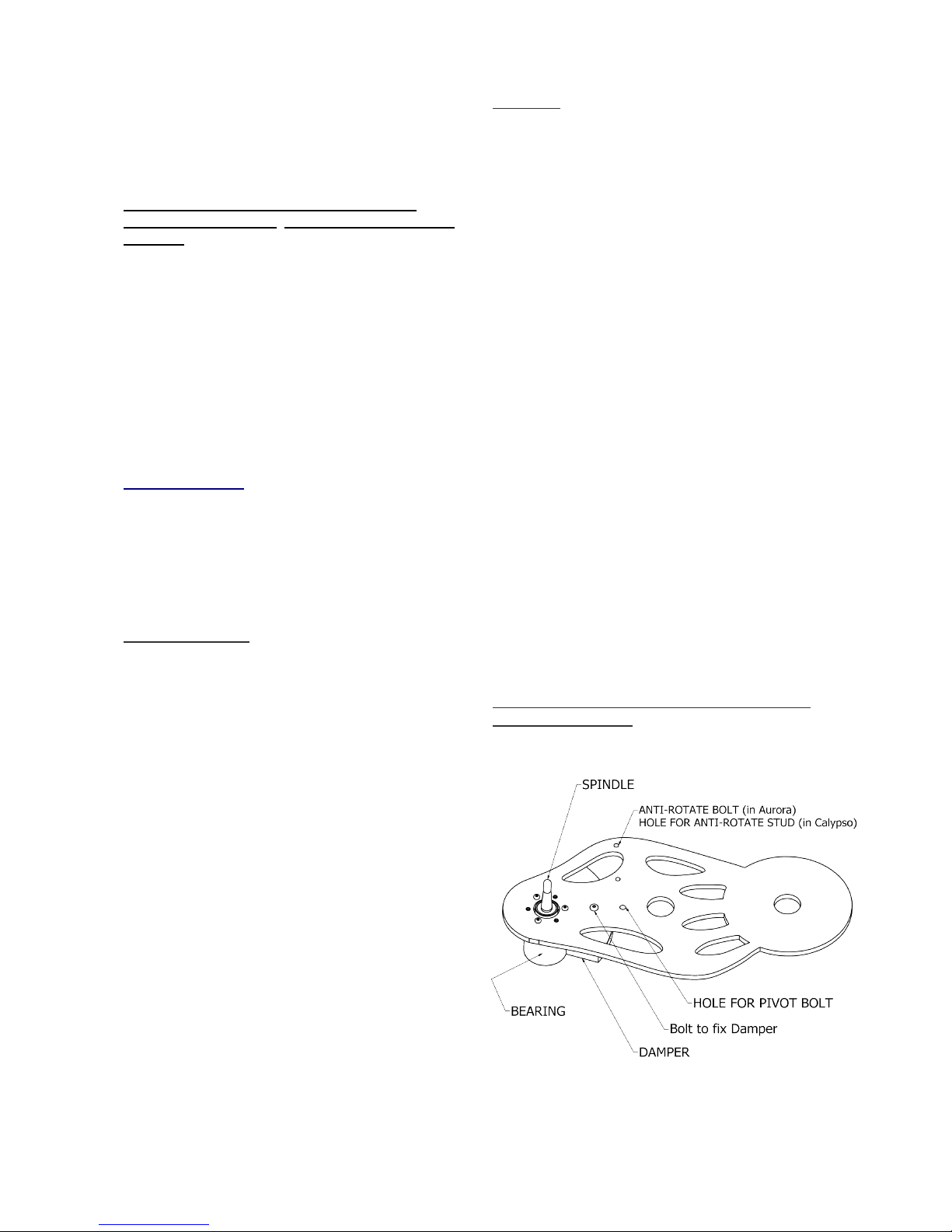

Subchassis for 12 inch tonearms need to be

assembled to Plinth

Fit the 12 inch sub-chassis version to the deck as per

instruction sheet at the beginning of this booklet.

Note the above diagram is for guidance only – it's not an

exact representation

Page 3

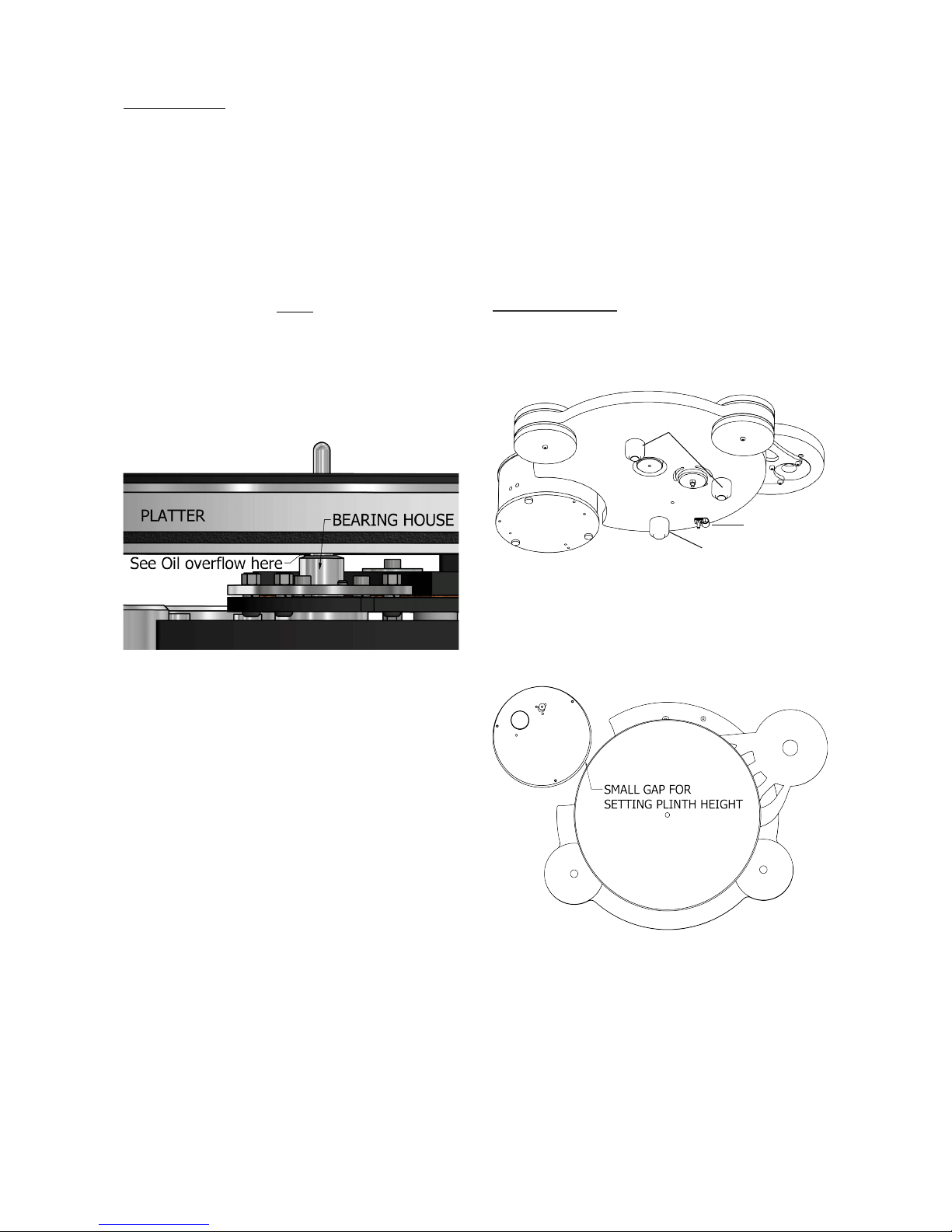

Fit the platter

Oil the bearing

Run 7 drops of the oil supplied into the top of the

bearing house. The spindle will appear a loose fit in the

bearing house until the oil is added. Do not use anything

other than Origin Live oil for performance reasons.

Insert the spindle

Inserting the spindle into the bearing house needs

attention as careless handling can damage the bearing

surfaces. Wipe the spindle surface first to ensure that it's

absolutely clean and very gently insert it into the bearing

house. If the oil does not overflow when the spindle

touches the bottom then try 2 more drops repeatedly till

you achieve overflow. Overflow can only be seen by

looking at the top of the bearing house with the spindle

inserted. You should notice an oil ridge around the

spindle – see diagram below.

Wipe away excessive overflow at the top of the bearing

house but be careful to leave oil clinging to the spindle

as you need the top of the bearing to be lubricated by oil

overflow and things like tissue paper can suck this area

dry by capillary action. You should spin the spindle

slowly after it has settled into the bearing to ensure even

distribution of oil.

Note that when you oil the bearing, you can get a false

impression of overflow if the spindle has oil on it - the

oil simply scrapes off as the bearing slides in and ends

up on the top of the bearing house. You can “feel”

overflow when you insert the spindle and it meets

resistance at the bottom. This is not a “thud” of the

spindle hitting the bottom but rather a build up of

pressure as the bearing lands on a bed of oil. By further

pressing, you can then see the oil being squeezed out at

the top.

Ensure the spindle tapered mating surface is absolutely

clean before assembly. Place the platter on the spindle

and finally add the platter mat.

Notes on bearing:

For lowest friction, the oil film has a significant depth of

“float” so an almost imperceptible platter movement is

inevitable. Small low frequency deviations of this nature

are insignificant to performance.

All platters are rigorously checked for level spinning up

to 45rpm - if you notice significant platter flutter once

the belt is fitted, then remove the platter and clean taper

surfaces. Refit it till it sits true. It may help to rotate the

platter slighty before refitting so that it's at a different

orientation.

Do not spin the platter faster than 45rpm as the bearing

relies on a high precision oil film designed for optimal

sound quality within a specific speed range. At higher

than normal running speeds there will be slight platter

flutter.

Adjust deck feet

No foot should be tightened fully onto the plinth as

performance is best when the foot sits on the thread

alone.

Set the plinth height by rotating the 3 adjustable feet. It

helps to lift the deck slightly for access to each foot in

turn.

To set the plinth height correctly, place the motor pod

just beside the platter as shown below.

REAR METAL THREADED FOOT

PLASTIC THREADED FEET

CABLE CLIP

Page 4

Correct height description

Set plinth height using the adjustable feet, to give the

platter 1 to 7mm clearance between the top of the motor

pod screws and the underside of the platter as shown

below.

Level the deck using platter as reference

For accurate levelling place a bubble gauge on the

platter. Now adjust the feet till the armboard is level.

Position motor pod & fit belt

Power up

Plug the Wallwort transformer or larger fully balanced

transformer directly into a mains plug. We suggest

omitting mains conditioners, filters or anything with

surge protection as these can be highly detrimental for

performance. The aforementioned items inflict no

damage so you can experiment with their inclusion if

you wish.

Ensure items such as power amps or power supplies with

strong electromagnetic fields are kept away from the

motor pod (i.e not directly underneath or alongside).

Insert the jack plug of the transformer output cable into

the motor pod’s largest side hole at the rear.

Motor Pod position

Move the pod into position as shown below. The pod and

pod cable should not touch the plinth so rotate the pod if

necessary. Check the pulley to platter distance is initially

217mm or slightly more.

Fit the belt over the platter first and then pull it over the

motor pulley taking care not to twist it.

To set belt tension, simply move the pod.

As a rough guide, centre of platter spindle to centre of

motor pulley should be between 217 - 227mm. Note Low belt tension can result in slight platter flutter but for

a new belt start at 217mm.

The belt initially stretches slightly during the first hours

of use so leave final tension adjustment till 48 hours

have passed.

Page 5

Final positioning of motor pod

To set correct belt tension finally, lift the belt off the

pulley and let it lose it’s tension almost completely

whilst still holding it gently - With no tension

whatsoever in the belt it should be approx 7mm off the

nearside of the motor pulley (flange edge) as per

diagram below. Move the pod till the pulley is this

distance from the belt, then stretch the belt to fit over the

pulley.

Check belt rides correctly

Rotate the platter by hand for a couple of turns and

check that the belt still sits between the 2 flanges of the

pulley. If this is not the case and it has ridden up onto a

flange push the belt back onto the crown (Curved portion

between the flanges) and turn the platter. Check the belt

remains on the crown.

People comment that the plastic pulley looks cheap However it's made from a special plastic which sounds

better than metal and is notably more expensive to

machine.

Controlling the motor & speed

Note that belt grip varies according to the way it's fitted.

This means the deck will run at a slightly different speed

if you refit the belt inside out or upside down from

previously. Therefore when removing and refitting the

belt take care to replace it with the same side in contact

with the running surfaces.

You will need to set the motor speed yourself. In the first

24 hours of continuous running the motor, the speed

tends to drift but then settles down permanently. You can

listen to the deck from the outset but remember to reset

the speed after the 24 hour run in period and then check

again after a week or so.

Initially motors may be a little noisy but soon settle

down within a couple of days continuous running. Do

not run at over 78rpm as this can harm the brushes over

prolonged periods.

Fine Tuning Motor screws

It should not be necessary but you can fine tune the

motor mount to give minimum noise by adjusting the

tightness of the 3 screws next to the motor pulleyfor

minimal tension - “just nipped” on the small rubber O

ring. Always check that the motor pulley is

approximately vertical and that the belt runs clear above

the bottom flange as per earlier diagram.

Motor “running in” should be carried out with platter

turning (no faster than 45rpm).

Control knob operation

The motor is “off” when the speed control knob on the

pod is turned fully anti-clockwise and the indent on the

knob aligns to the LED.

Turn the knob one click clockwise to turn the motor on

at 33.3 rpm - The second click clockwise is 45rpm

Operating the strobe

Place the strobe disc on the record to be played. The

strobe rings are labelled on the centre of the disc for

speed and mains frequency.

When setting speed, place the arm on the centre track of

a record, so that the cartridge is tracking the grooves.

This ensures that the drag of the cartridge is taken into

account. Speed variations of up to plus or minus 1% are

quite common on decks and the dc motor is capable of

plus or minus 0.1% accuracy.

MOTOR POD

PULLEY

33 rpm Speed adjuster

POWER

INPUT

LED

45 rpm Speed adjuster

SPEED CONTROL KNOB

Page 6

Use correct lighting

You can see the strobe effect best in fluorescent light,

although an ordinary bulb held about 2 feet from the

strobe disc will also work fine. The bulb flickers at 50

Hz in the EEC and 60 Hz in the USA.

You can purchase bayonet fitting fluorescent or halogen

bulbs to fit normal lamps. Try to shut out daylight when

carrying out speed setting. Also be aware that energy

saving lighting with switch mode high frequency power

supplies or certain energy saving bulbs will not work

with the strobe disc.

Reading the strobe

As you play the record. watch the relevant ring on the

strobe disc. Adjust the speed as described in next subheading until marks on the ring concerned appear

stationary. It sometimes helps to stare the strobe but

focus your eyes on infinity.

Alternative methods

There are other strobes which are easier to read such as

the KAB strobe which can be found on our web site

under vinyl measurement accessories.

There is also a phone app that you can download for

Android or IOS. You simply then place the phone on the

platter and it reads the speed.

Adjust the 33rpm speed

Set the switch on the pod to the first click i.e. 33 rpm

setting.

Fine adjust the motor speed by inserting a small

screwdriver into the hole indicated on the Motor pod

illustration. This is not easy but you need to locate the

screwdriver blade in the slot of the speed adjuster screw.

It helps to look into the hole to see the “slot” orientation

before inserting the screwdriver.

To increase speed, rotate the screw clockwise a small

fraction of a turn. To decrease speed, rotate in the

opposite direction.

Notes on Trimmer screws

Full speed adjustment takes place over 18 turns of the

trimmer screw but you normally need never adjust by

more than half a turn.

If the screw reaches the end of it’s travel you can usually

hear a faint clicking. You will not damage the speed

trimmer by over turning, as slippage occurs. Neither will

the trimmer screw fall out. The trimmer screws are

adjusted at factory to give approximately the right speed,

so you need only fine adjust.

Adjust the 45 rpm speed

Click the speed control knob to the 2nd click clockwise.

Now set 45rpm speed (or 78 rpm if you wish) by

inserting the screwdriver in the 2nd hole indicated on

motor pod diagram and use the same procedure as for

33rpm.

Notes on Belt & Motor running

Motor Tilt

Check that the belt rides clear of the flanges – nearly

touching is OK but if the belt sinks down to touch the

flange you need to either increase belt tension slightly or

adjust the tilt of the motor by turning the small crosshead

motor mounting screw positioned nearest the platter.

Motor Noise

DC motors are often slightly noisy initially and never

completely silent in comparison to a/c motors. This may

be due in part to the high conductivity precious metal

brushes. These produce much lower levels of vibration

and hence better performance.

Like most turntable manufacturers we recommend you

leave the turntable running between changing records as

this reduces belt wear due to constant stopping and

starting.

Notes on final speed setting:

The motor and main bearing can take at least 4 days to

fully run in and sound it’s best. For this reason it is best

to do a final speed check at the end of this period.

Set final speed only in following conditions

• Motor pod is in it’s final position.

• Room temperature is normal and has been so

for 2 hours or more.

• Transformer and motor pod have been plugged

in for over 1 hour as the circuit takes a while to

warm up.

If you move the pod, you will need to re check the speed

and if necessary correct it, by repositioning the pod till

the speed is correct. Never move the pod beyond the

ideal distances mentioned in “fitting the belt”. This is a

quick operation if you just leave the motor and platter

spinning, as you slide the pod to adjust tension.

Remember to always set speed with the cartridge

dragging on a centre track of a record.

If moving the pod does not achieve correct speed then

use the speed adjuster screws.

Affect of temperature on speed

The speed stability of your deck is excellent once

everything has settled down in a listening session.

Be aware that speed is slightly affected by temperature

variation. However most houses are centrally heated and

maintain temperature without significant variations.

Speed variation due to temperature is due to oil

thickening as the temperature drops. 1 degree centigrade

drop in temperature results in a 0.1% drop in speed ( a 5

degree drop will be 0.5% slow). 0.5% speed drift is

barely noticeable to the average listener so this is not

significant. Rega decks used to run 1% fast all the time

to put things in perspective.

Bearing oil can take 2 hours to reach operating

temperature if the deck is left in a cold room. The air in

Page 7

the room may warm up quickly but the metal in the

turntable takes a lot longer. For this reason it is not worth

constantly changing speed settings for absolute accuracy.

The ear is more tolerant to music running fast than it is

to slow. For this reason it's best setting the deck to run

very slightly fast at your average room temperature.

Why measurements can be misleading

It's worth explaining that absolute speed accuracy is easy

to achieve at the expense of sound quality. The AC

motors, common to most decks are not prone to speed

drift - however they do inject a great deal of vibration.

This, sadly is never measured in technical reviews or

people would be a lot wiser. The subjective effect of

vibration is highly detrimental to sound quality when

compared to fractional speed drift. For this reason we

prefer to offer superior sound quality rather than the

flawed illusion of technical perfection.

Further to this it's worth adding that we've experimented

with highly sophisticated encoder speed controls (£2000

trade cost) and found that although they hold speed with

unerring accuracy, the sound and dynamics of a more

subtle approach is far superior.

Fit the tonearm

Mounting Origin Live arms

All newer Origin Live arms have built in VTA

adjustment and can be fitted directly to the arm board as

illustrated below.

If you have an older Origin Live or Rega tone-arm which

has a threaded base but no vta adjustment, you can fit a

threaded VTA adjuster. The adjuster must be threaded

onto the base of the arm first and oriented such that the

flange is uppermost.

Insert your arm through the hole in the arm board.

Next fit the cork washer followed by the large clamping

nut as shown in the diagram on this page.

Lastly fit the tone-arm cables through the cable clip on

the underside of the deck. This improves performance

slightly and safeguards the cables from stressing their

joint at the arm base in the event of being “tugged”. The

cables should not be tight but form a gentle loop.

If clamping the cable is undesirable you can omit this

step.

We will cover setting the arm to exactly the correct

height later as you need to do a number of other things

first.

Final setup of tonearm

You should refer to your tone-arm instructions for

detailed set up of the arm and cartridge alignment.

Fit the arm cable clip

Pass the arm cable through the cable clip supplied and

fasten in position with the M5 bolt located in the

threaded hole near the rear foot. Leave a slight droop on

the cable so that it isn’t “tight”. The bolt is helpful to

minimize cable vibration.

Note – Silver Hybrid cable is relatively thick but both

left and right channels will fit trough one of the cable

clips supplied.

Maintaining your deck

Cleaning

It aids performance to clean all running surfaces every 3

months or so with mentholated or surgical spirit but do

not use this on the belt.

Belts should only be cleaned with water as rubber care

products can leave behind a slippery residue.

To clean the deck, use a damp soft lint free cloth and

wipe gently – if you have grease marks etc then you can

use a general-purpose anti-smear, car window cleaner

such as Auto-glym “Fast glass”, but only if necessary.

Wax furniture polish is to be avoided . Do not spray

directly on the turntable as it may clog up the cartridge

internals etc but rather spray onto a soft polishing cloth

and then use it on the turntable. Do not use tissue paper

or kitchen cleaning paper towels as paper is abrasive and

can put faint scratches in the polished surface.

Scratch removal

If minor abrasions occur on the surface, you can remove

them using a proper plastic scratch remover polish such

as “Xerapol” by E.V.I of Germany or “Plastic Clean &

Shine by Novus inc of USA. Avoid Car and other

Page 8

polishes as they leave light scratching or bloom.

Every 2 Years or so

The deck is not prone to going out of tune:

Check that the sub-chassis curved damper is

tensioned lightly onto the plate every 2 years or so as the

damper can compress a little over time.

Check belt tension is correct using the method

described for final pod positioning. All belts stretch over

the years so the motor pod may need to be moved out

further than the initially specified 227mm maximum.

Depending on your use of the deck, the belt should

ideally be replaced every 2 to 4 years.

Every 3 years

Only use Origin Live oil. Oil should be replaced every 3

to 4 years so you will need to clean out the old oil with a

lint free paper towel or similar wrapped around a thin

rod. When you do this, be sure to also wipe oil off the

spindle as this may contain microscopic contamination

that's not visible.

If you ever withdraw the main spindle you should put a

few drops of oil into the bearing house to compensate for

any possible loss occuring in the withdrawal.

Never tamper with the bolt in the bottom of the bearing

or oil leaks will occur and you will probably not succeed

in re-tightening it.

Alternative Mats?

Many of the mats on the market have been tried on our

platters and do not work so we recommend saving

yourself the expense of trying them.

Troubleshooting

Refer to the Origin Live website > Support > Turntables if you

have any problems

Page 9

Wrap motor pod in polythene bag then tape ( or

rubber band) round the cardboard tube which has

a slit in it’s side - the tube sits on top of the base

plate, not round it. This is to provide protection

against anything that might knock the end of the

motor shaft as this can cause damage. Note that

the motor pod must be positioned in this corner

of the box where there is the greatest depth i.e

not over the plinth armboard

Place the strobe card and belt in the top of the

motor pod card tube.

WRAP PLINTH IN POLYTHENE BAG BEFORE

LOWERING INTO BOX

VERY IMPORTANT This card and foam peice

must be placed here as

shown to protect platter

and ensure no damage to

sub-chasses

BELT & STROBE CARD PLACED IN MOTOR

POD PACKING

The belt needs to be rolled into a spiral and

placed in a small polythene bag - if loose packed

the belt can get crushed on bends and

permanently deformed.

REPACKING METHOD - Please read carefully and pack exactly as

instructions show.

Place the wall wart transformer here and then place

the bubble bag containing the following items on top

of the transformer

Wrap platter and platter

mat in polythene bag

before placing in foam

cut out

Instruction manual

Bag contains - Cork washer for arm, Oil bottle,

screw driver, 3mm & 2.5mm allen key

Loading...

Loading...