Page 1

Network converter

MECHATROLINK-II compatible

NETC01-M2

USER MANUAL

R-REM-OMC-111

HM-60091-4

Thank you for purchasing an Oriental Motor product.

This Manual describes product handling procedures and safety precautions.

•Please read it thoroughly to ensure safe operation.

•Always keep the manual where it is readily available.

Page 2

1 Safety precautions .................................. 3

9 Details of command .............................. 20

2 Introduction ............................................. 4

3 Preparation ............................................... 6

3-1 Checking the product ......................................6

3-2 Names and functions of parts .......................6

4 Installation ................................................ 8

4-1 Location for installation ...................................8

4-2 Installation method ..........................................8

4-3 Installing and wiring in compliance

with EMC Directive ............................................9

5 Connection ............................................. 11

5-1 Connection example ..................................... 11

5-2 Connecting the power supply and

grounding the

5-3 Connecting the RS-485 communication

cable .................................................................... 12

5-4 Connecting the MECHATROLINK-II

communication ............................................... 13

5-5 Connecting the data setter ......................... 13

NETC01-M2

..................... 11

6 Guidance ................................................. 14

7 Setting ..................................................... 17

7-1 Transmission rate of RS-485

communication ............................................... 17

7-2 Operation mode ..............................................17

7-3 Station address ................................................ 18

8 MECHATROLINK-II communication

format ...................................................... 19

8-1 Data format ....................................................... 19

8-2 Phase ................................................................... 19

9-1 No operation command (NOP: 00h) ........ 20

9-2 Read ID command (ID_RD: 03h) ................ 22

9-3 Read alarm or warning command

(ALM_RD: 05h) ................................................. 24

9-4 Clear alarm or warning command

(ALM_CLR: 06h) ............................................... 24

9-5 Establish connection command

(CONNECT: 0Eh) ...............................................25

9-6 Release connection command

(DISCONNECT: 0Fh) ........................................ 26

9-7 Data READ/WRITE_A command

(DATA_RWA: 50h) ............................................ 27

9-8 Timing chart of the data READ/

WRITE_A command ....................................... 32

10 Troubleshooting and

remedial actions .................................... 39

10-1 Alarms and MECHATROLINK-II

communication error .................................... 39

10-2 Warning .............................................................. 42

11 Inspection ............................................... 43

12 General specications .......................... 44

13 Operation using the

13-1 Overview of the

13-2 Names and functions of parts .................... 46

13-3 Notation ............................................................. 46

13-4 How to read the display ...............................46

13-5

OPX-2A

13-6 Screen transitions ........................................... 48

13-7 Monitor mode .................................................. 50

13-8 Parameter mode .............................................51

13-9 Copy mode ........................................................52

error display ................................... 47

OPX-2A

OPX-2A

............. 45

............................ 45

14 Accessories .............................................54

2

Page 3

1 Safety precautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through

safe, correct use of the product. Use the product only after carefully reading and fully understanding these

instructions.

Safety precautions

Handling the product without observing the instructions that

accompany a "WARNING" symbol may result in serious injury

or death.

General

•Do not use the product in explosive or corrosive

environments, in the presence of ammable gases, locations

subjected to splashing water, or near combustibles. Doing so

may result in re or injury.

•Assign qualied personnel to the task of installing, wiring,

operating/controlling, inspecting and troubleshooting the

product. Failure to do so may result in re, injury or damage

to equipment.

Connection

•Always keep the power supply voltage of the

within the specied range. Failure to do so may result in re.

•For the power supply of the

supply with reinforced insulation on its primary and

secondary sides. Failure to do so may result in electric shock.

•Connect the cables securely according to the wiring

diagram. Failure to do so may result in re.

•Do not forcibly bend, pull or pinch the cable. Doing so may

result in re. Repetitive stress or overstress on the

connection part may cause damage to the product.

NETC01-M2

NETC01-M2

, use a DC power

Operation

•Turn o the

failure. Otherwise, the motor may suddenly start when the

power is restored, causing injury or damage to equipment.

•When an alarm of the

motor. Failure to do so may result in re, injury or damage to

equipment.

NETC01-M2

power in the event of a power

NETC01-M2

is generated, stop the

Repair, disassembly and modication

•Do not disassemble or modify the

may result in injury. Refer all such internal inspections and

repairs to the Oriental Motor sales oce from which you

purchased the product.

NETC01-M2

. Doing so

Handling the product without observing the instructions that

accompany a "CAUTION" symbol may result in injury or

property damage.

General

•Do not use the

Doing so may result in injury or damage to equipment.

•Keep your ngers and objects out of the openings in the

NETC01-M2

NETC01-M2

. Failure to do so may result in re or injury.

beyond its specications.

Installation

•Install the

may result in injury.

•Keep the area around the

materials in order to prevent re or a skin burn(s).

•Do not leave anything around the

obstruct ventilation. Doing so may result in damage to

equipment.

NETC01-M2

inside an enclosure. Failure to do so

NETC01-M2

free of combustible

NETC01-M2

that would

Connection

•The power supply connector (CN1), MECHATROLINK-II

communication connectors (CN2-1, CN2-2), data edit

connector (CN3) and RS-485 communication connector

(CN6) of the

When grounding the positive terminal of the power supply,

do not connect any equipment (PC, etc.) whose negative

terminal is grounded. Doing so may result in the

NETC01-M2

both.

NETC01-M2

and these equipment to short, damaging

are not electrically insulated.

Operation

•Use the

applicable product. Failure to do so may result in re.

•When operating the product, do so after making

preparations that an emergency stop can be performed at

any time. Failure to do may result in injury.

•Set a suitable operation speed and acceleration/deceleration

rate. Improper setting may cause loss of the motor

synchronism and moving the load to an unexpected

direction, which may result in injury or damage to

equipment.

•Immediately when trouble has occurred, stop running and

turn o the

in re or injury.

•Static electricity may cause the

or suer damage. Do not touch the

power is input. Always use an insulated screwdriver to adjust

the switches of the

NETC01-M2

NETC01-M2

in combination with the designated

power. Failure to do so may result

to malfunction

while the

NETC01-M2

NETC01-M2

NETC01-M2

.

Disposal

•Dispose the product correctly in accordance with laws and

regulations, or instructions of local governments.

3

Page 4

Introduction

2 Introduction

Before use

Only qualied personnel of electrical and mechanical engineering should work with the product.

Use the product correctly after thoroughly reading the “1 Safety precautions” on p.3. In addition, be sure to

observe the contents described in warning, caution, and note in this manual.

The product described in this manual has been designed and manufactured for use in general industrial equipment.

Do not use for any other purpose. For the power supply of the

insulation on its primary and secondary sides. Oriental Motor Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

Related operating manuals

For operating manuals not included with the product, contact your nearest Oriental Motor sales oce or download

from Oriental Motor Website Download Page.

NETC01-M2

, use a DC power supply with reinforced

Name

Network converter MECHATROLINK-II compatible

NETC01-M2

Network converter MECHATROLINK-II compatible

NETC01-M2

OPERATING MANUAL

USER MANUAL (this document)

Included or not included

with product

Included

Not included

Notation on operating manual

The items under this heading contain important handling instructions that the user should

observe to ensure the safe use of the product.

Overview of the product

The

NETC01-M2

By converting the MECHATROLINK-II communication protocol of the upper level to the RS-485 communication

protocol of the lower level, Oriental Motor RS-485 communication compatible products can be operated via

MECHATROLINK-II communication.

The RS-485 communication protocol of the lower level is Oriental Motor’s own RS-485 communication protocol.

is a communication converter between MECHATROLINK-II and RS-485 communication.

Parameters of the

NETC01-M2

When setting the parameters of the

MEXE02

or accessory data setter

cannot be set with the master station.

NETC01-M2

, use a support software

OPX-2A

.

When the

connect a PC and

MEXE02

is used, a communication cable for support software

NETC01-M2

. Be sure to purchase it.

CC05IF-USB

(accessory) is needed to

4

Page 5

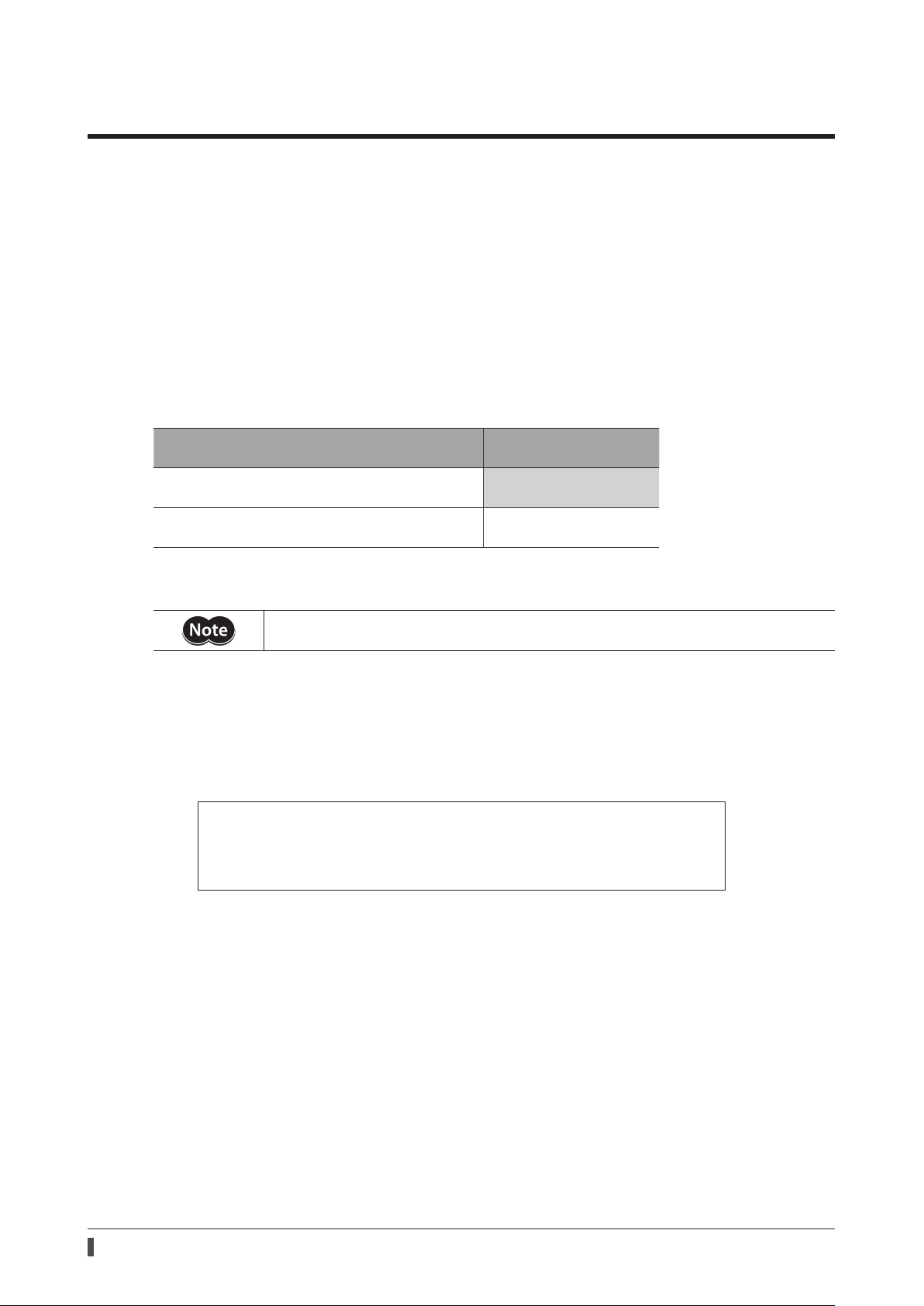

System conguration

compatible products

compatible products

Introduction

Termination

resistor: ON *2

*1 The master device may have a built-in internal termination resistor which functions as the termination resistor on

the master side. For details, refer to the operating manual for the master device.

*2 The termination resistor for RS-485 communication is built into the product.

*3 For the termination resistor on slave side, use a dedicated termination resistor for MECHATROLINK communication,

manufactured by YASKAWA Electric Corporation.

RS-485

communication

RS-485 communication

compatible products

NETC01-M2

MECHATROLINK-II

communication

Termination

resistor *1

MECHATROLINK-II

communication

Master station

Termination

resistor *3

MECHATROLINK-II

communication

CE Marking

The input power supply voltage of this product is 24 VDC. Therefore this product is not subject to the Low Voltage

Directive, but install and connect it as follows.

•This product is designed and manufactured to be incorporated in equipment. Be sure to install the product inside

an enclosure.

•For the power supply of the

secondary sides.

•Overvoltage category: I

•Pollution degree: 2

•Degree of protection: IP20

NETC01-M2

zEMC Directive

This product is conducted EMC testing under the conditions specied in “Example of

wiring” on p.10.

The conformance of your mechanical equipment with the EMC Directive will vary depending on such factors as the

conguration, wiring, and layout for other control system devices and electrical parts used with this product. It

therefore must be veried through conducting EMC measures in a state where all parts including this product have

been installed in the equipment.

Applicable standards

•EMI: EN 55011 group 1 class A, EN 61000-6-4

•EMS: EN 61000-6-2

This equipment is not intended for use in residential environments nor for use on a

low-voltage public network supplied in residential premises, and it may not provide

adequate protection to radio reception interference in such environments.

, use a DC power supply with reinforced insulation on its primary and

NETC01-M2

installation and

Republic of Korea, Radio Waves Act

This product is axed the KC Mark under the Republic of Korea, Radio Waves Act.

RoHS Directive

The products do not contain the substances exceeding the restriction values of RoHS Directive (2011/65/EU).

5

Page 6

Preparation

RS-485 communication transmission

rate setting switch (SW1)

.×1, ×10)

DIN lever

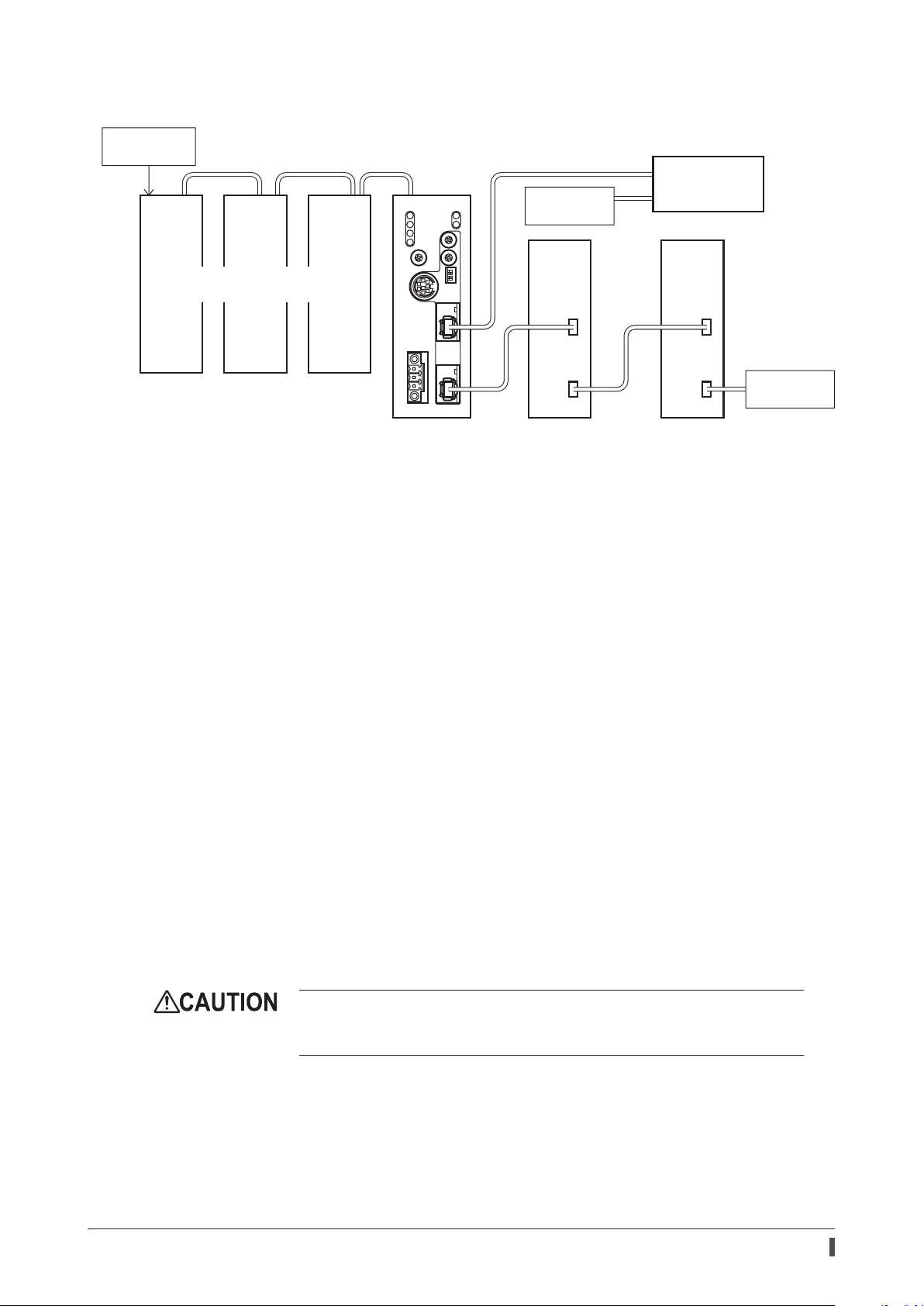

3 Preparation

This chapter explains the items you should check, as well as the name and function of each part.

3-1 Checking the product

Verify that the items listed below are included. Report any missing or damaged items to the Oriental Motor sales

oce from which you purchased the product.

NETC01-M2

•

•CN1 connector (3 pins) ....................... 1 pc.

•RS-485 communication cable .......... 2 pcs. [0.1 m (3.94 in.), 0.25 m (9.84 in.) each 1 pc.]

•OPERATING MANUAL .......................... 1 copy

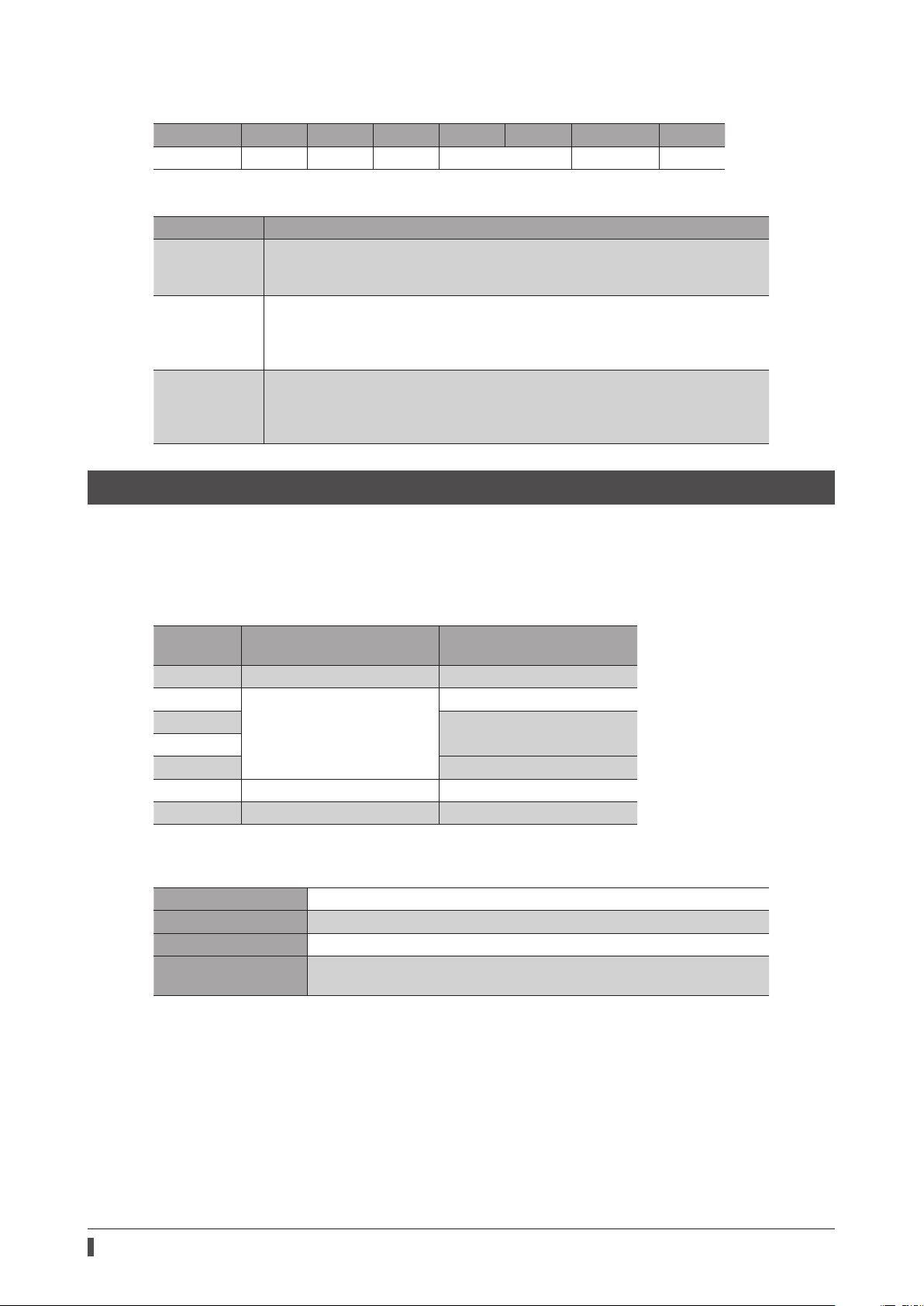

3-2 Names and functions of parts

......................................... 1 unit

RS-485 communication

connector (CN6)

POWER LED (Green)

ALARM LED (Red)

C-DAT LED (Green)

C-ERR LED (Red)

Data edit connector (CN3)

Power supply connector (CN1)

CONT LED (Green)

ERR LED (Red)

MECHATROLINK-II station address

setting switches (STATION No

Operation mode setting switch (SW2)

MECHATROLINK-II

communication connector (CN2-1)

MECHATROLINK-II

communication connector (CN2-2)

6

Page 7

Preparation

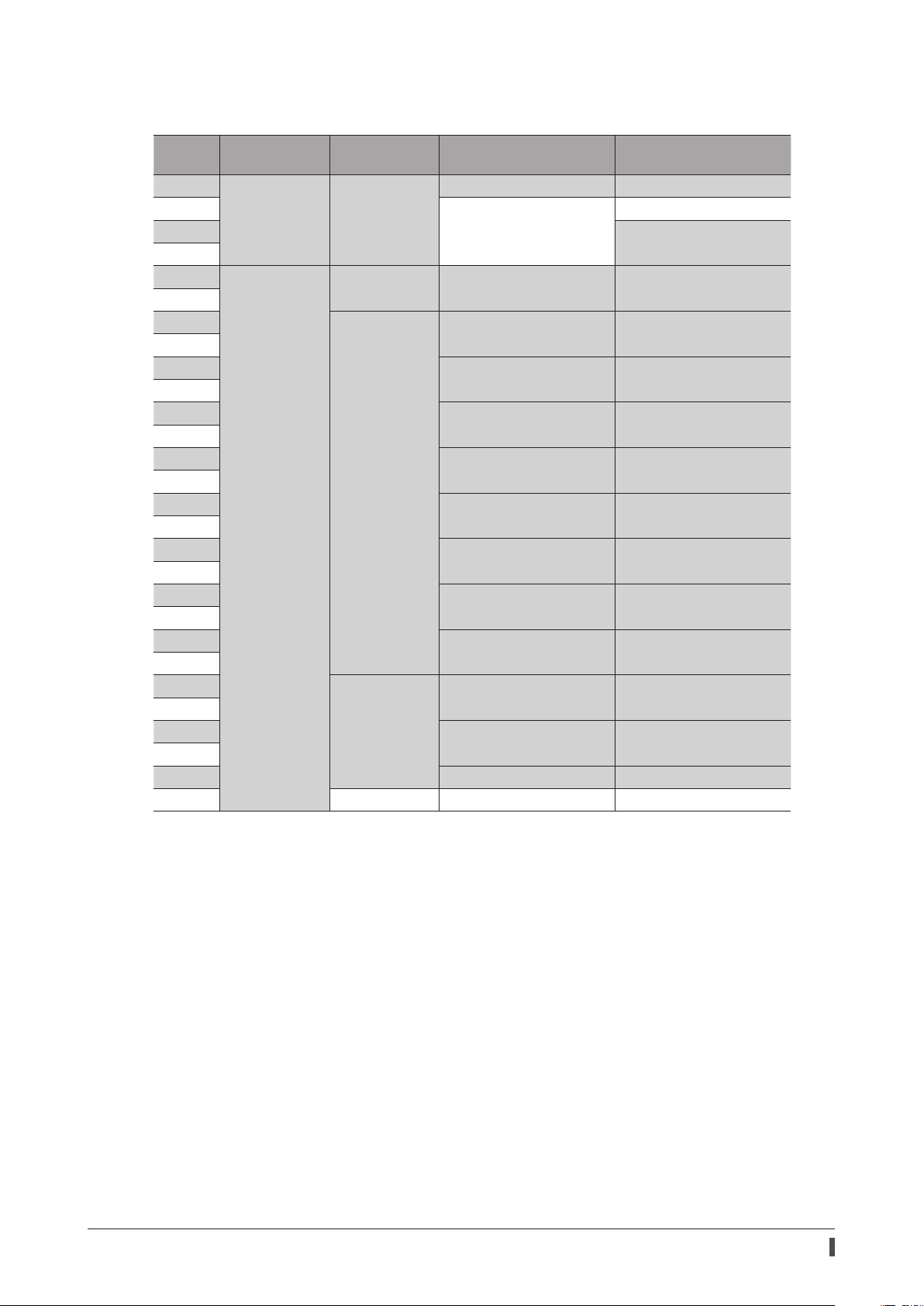

Name Description Ref.

POWER LED (Green) This LED is lit while the power is input. −

ALARM LED (Red) This LED will blink when an alarm generates. p.39

C-DAT LED (Green)

C-ERR LED (Red)

CONT LED (Green) This LED is lit while a connection is established. −

ERR LED (Red)

RS-485 communication transmission

rate setting switch (SW1)

Data edit connector (CN3)

Power supply connector (CN1) Connects a 24 VDC power supply. p.11

MECHATROLINK-II station address

setting switches (STATION No.×1, ×10)

Operation mode setting switch

(SW2-Nos.1 to 3)

MECHATROLINK-II communication

connectors (CN2-1, CN2-2)

RS-485 communication connector

(CN6)

This LED is lit while transmitting and receiving data via RS-485

communication.

This LED is lit when an error has occurred via RS-485

communication.

This LED is lit when the MECHATROLINK-II communication

error has occurred.

Sets the transmission rate of RS-485 communication.

Factory setting: 7 (625 kbps)

Connects a PC in which the

accessory

Set the station address in the 60h to 7Fh range.

Factory setting: 61h (×10=6, ×1=1)

×10: Sets the upper of the station address.

×1: Sets the lower of the station address.

Sets the operation mode.

•SW2-No.1: Sets the remote I/O occupied size.

Factory setting: OFF (16 bit mode)

•SW2-No.2, No.3: Set the number of transmission bytes.

Factory setting: No.2=OFF, No.3=ON (32 bytes)

Connect the MECHATROLINK-II communication cable. p.13

Connects the RS-485 communication cable. p.12

OPX-2A

.

MEXE02

has been installed, or an

−

−

p.39

p.17

p.13

p.18

p.17

7

Page 8

Installation

50 mm (1.97 in.)

or more

50 mm (1.97 in.)

Hook

DIN rail

DIN lever

End plate

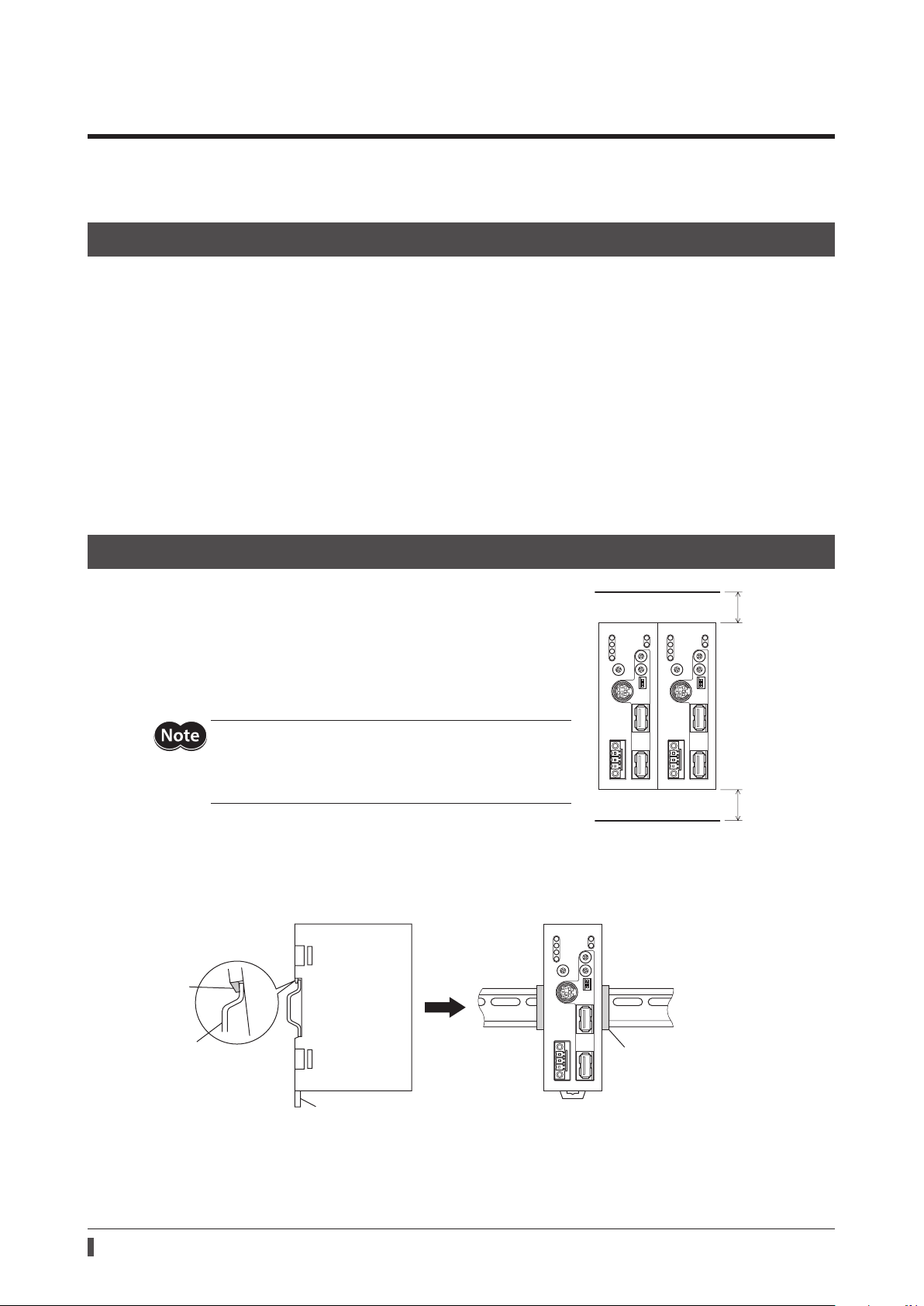

4 Installation

This chapter explains the installation location and installation methods of the

The installation and wiring methods in compliance with the EMC Directive are also explained.

4-1 Location for installation

The

NETC01-M2

Install it in a well-ventilated location that provides easy access for inspection. The location must also satisfy the

following conditions:

•Inside an enclosure that is installed indoors (provide vent holes)

•Operating ambient temperature 0 to +40 °C (+32 to +104 °F) (non-freezing)

•Operating ambient humidity 85% or less (non-condensing)

•Area that is free of explosive atmosphere or toxic gas (such as sulfuric gas) or liquid

•Area not exposed to direct sun

•Area free of excessive amount of dust, iron particles or the like

•Area not subject to splashing water (rain, water droplets), oil (oil droplets) or other liquids

•Area free of excessive salt

•Area not subject to continuous vibration or excessive shocks

•Area free of excessive electromagnetic noise (from welders, power machinery, etc.)

•Area free of radioactive materials, magnetic elds or vacuum

has been designed and manufactured for use as a component to be installed inside equipment.

4-2 Installation method

Install the

There must be a clearance of at least 50 mm (1.97 in.) in the horizontal

and vertical directions, between the

other equipment within the enclosure.

When installing two or more

install them closely in the horizontal direction. Provide a minimum

clearance of 50 mm (1.97 in.) in the vertical direction.

NETC01-M2

to a 35 mm (1.38 in.) width DIN rail.

NETC01-M2

NETC01-M2

and enclosure or

in parallel, it is possible to

NETC01-M2

.

or more

Be sure to install the

position). If the

other than vertical position, its heat radiation eect will

deteriorate.

NETC01-M2

NETC01-M2

vertically (vertical

is installed in the direction

Mounting to DIN rail

Pull down the DIN lever of the

NETC01-M2

. After installation, secure the both sides of the

NETC01-M2

and lock it. Hang the hook at the rear to the DIN rail, and push in the

NETC01-M2

with the end plate.

8

Page 9

Removing from DIN rail

Cable clamp

Shielded cable

Pull the DIN lever down until it locks using a slotted screwdriver, and lift the bottom of

the

NETC01-M2

Use force of about 10 to 20 N (2.2 to 4.5 lb.) to pull the DIN lever to lock it. Excessive

force may damage the DIN lever.

to remove it from the rail.

4-3 Installing and wiring in compliance with EMC Directive

Installation

Eective measures must be taken against the EMI that the

equipment, as well as the EMS of the

machinery. The use of the following installation and wiring methods will enable the

with the EMC Directive. Refer to “CE Marking” on p.5 for the applicable standards.

Oriental Motor conducts EMC measurements on its

installation and wiring” on p.10. The user is responsible for ensuring the machine’s compliance with the EMC

Directive, based on the installation and wiring explained below.

NETC01-M2

NETC01-M2

itself, in order to prevent a serious functional impediment in the

NETC01-M2

may give to adjacent control-system

NETC01-M2

in accordance with “Example of

to be compliant

NETC01-M2

Power supply

This network converter is a product of DC power supply input.

Use a DC power supply (switching power supply etc.) that conforms to the EMC Directive.

Noise lter

•Connect a noise lter in the DC power supply input to prevent the noise generated in the

propagating externally through the power supply line.

•When using a power supply transformer, be sure to connect a noise lter to the AC input side of the power supply

transformer.

•For a noise lter, use HF2010A-UPF (SOSHIN ELECTRIC CO., LTD), FN2070-10-06 (Schaner EMC) or equivalent

product.

•Install the noise lter as close to the AC input terminal of DC power supply as possible. Use cable clamps and other

means to secure the AC input cables (AWG18: 0.75 mm

rmly to the surface of the enclosure.

•Connect the ground terminal of the noise lter to the grounding point, using as thick and short a wire as possible.

•Do not place the AC input cable parallel with the noise lter output cable. Parallel placement will reduce noise lter

eectiveness if the enclosure’s internal noise is directly coupled to the power supply cable by means of stray

capacitance.

2

or more) and output cables (AWG18: 0.75 mm2 or more)

NETC01-M2

from

How to ground

The cable used to ground the

potential dierence is generated. Choose a large, thick and uniformly conductive surface for the grounding point.

NETC01-M2

and mains lter must be as thick and short as possible so that no

Wiring the power supply cable and I/O signal cable

•Use a shielded cable of AWG22 (0.3 mm2) or more for the power supply cable of the

short as possible.

•For the MECHATROLINK-II communication cable, use a dedicated cable with connector.

•To ground the power supply cable , use a metal cable clamp or

similar device that will maintain contact with the entire

circumference of the cable. Attach a cable clamp as close to the end

of the cable as possible, and connect it as shown in the gure.

NETC01-M2

, and keep it as

9

Page 10

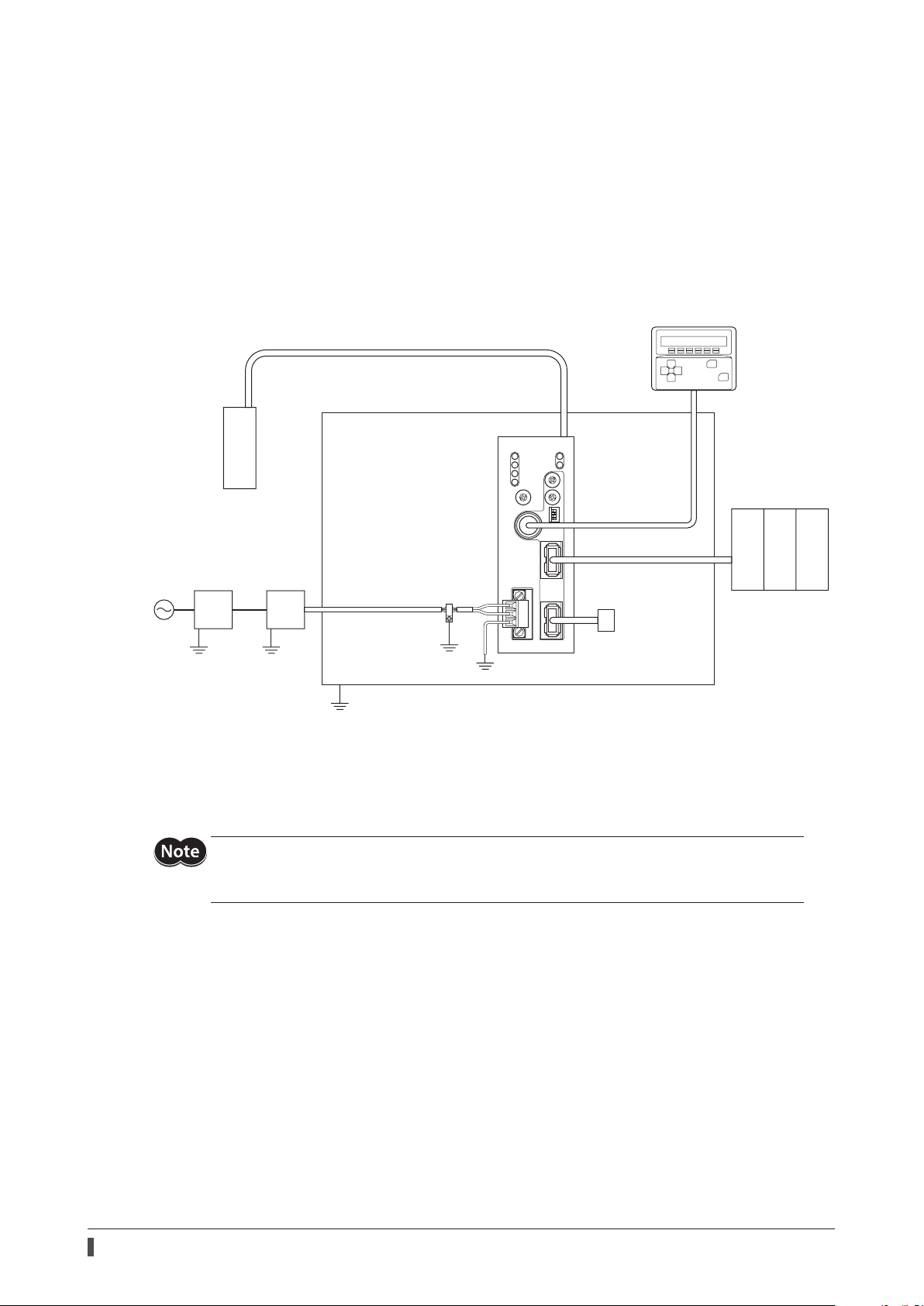

Installation

OPX-2A

Grounding

Notes about installation and wiring

•Connect the

prevent a potential dierence from developing between grounds.

•When relays or electromagnetic switches are used together with the system, use noise lters and CR circuits to

suppress surges generated by them.

•Keep cables as short as possible without coiling and bundling extra lengths.

•Place the power cables such as the motor and power supply cables as far as 100 mm (3.94 in.) from the signal

cables. If the power cables and signal cables have to cross, cross them at a right angle. Place the AC input cable and

output cable of a noise lter separately from each other.

NETC01-M2

and other peripheral control equipment directly to the grounding point so as to

Example of

RS-485 communication

compatible product

Noise

lter

AC

Grounding Grounding

NETC01-M2

DC power

supply

installation and wiring

RS-485 communication cable

NETC01-M2

Power supply cable

(Shielded cable)

Grounding

Grounded panel

Shielded cable

Master station

MECHATROLINK-II

communication cable

Termination

resistor

Grounding

Precautions about static electricity

Static electricity may cause the

power, handle the

Always use an insulated screwdriver to change the switches of the

The

NETC01-M2

charge is impressed on the

NETC01-M2

NETC01-M2

NETC01-M2

with care and do not come near or touch the

uses parts that are sensitive to electrostatic charge. Before touching the

, turn o the power to prevent electrostatic charge from generating. If an electrostatic

to malfunction or suer damage. While the

NETC01-M2

, the

NETC01-M2

NETC01-M2

NETC01-M2

may be damaged.

NETC01-M2

.

.

is receiving

10

Page 11

5 Connection

RS-485 communication

communication cable

Grounding

Use the

OPX

Connection

This chapter explains the connection method of the

the grounding method.

For protection against electric shock, do not turn on the power supply until the wiring

is completed.

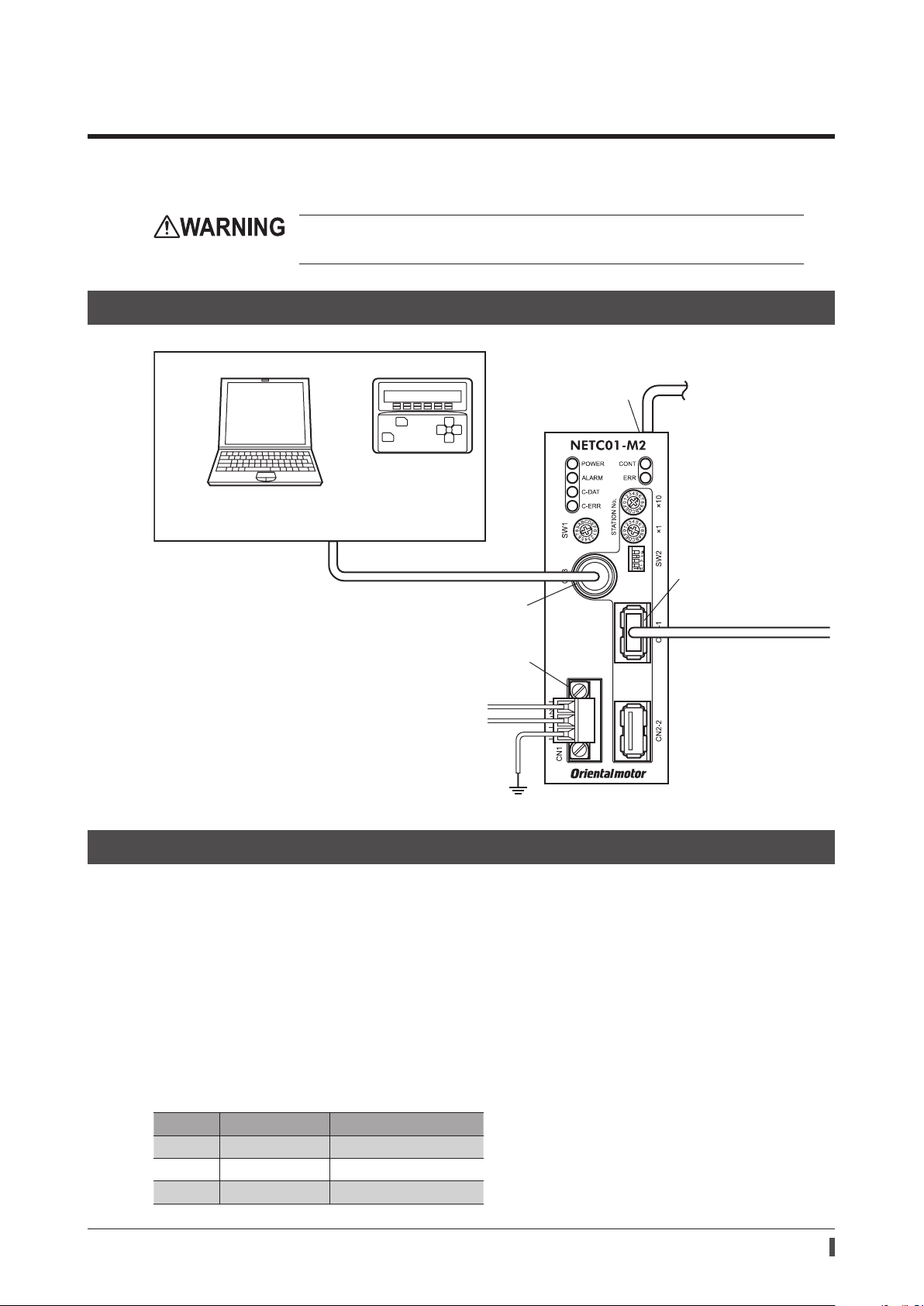

5-1 Connection example

MEXE02

Or

Use the accessory communication

cable for the support software when

connecting the PC and NETC01-M2.

MEXE02 or

-2A to set parameters.

NETC01-M2

OPX-2A

Data edit connector (CN3)

RS-485 communication

and power supply/communication cable, as well as

connector (CN6)

cable

MECHATROLINK-II

communication

connector (CN2-1)

MECHATROLINK-II

Power supply connector (CN1)

24 VDC

GND

5-2 Connecting the power supply and grounding the

Connecting the power supply

Connect the power supply cable (AWG22: 0.3 mm2) to the power supply connector (CN1) of the

the included CN1 connector (3 pins).

Grounding the

Ground the Frame Ground terminal (FG) of the

Ground using a wire of AWG24 to 16 (0.2 to 1.25 mm

any other power equipment.

NETC01-M2

NETC01-M2

2

), and do not share the protective earth terminal with a welder or

CN1 connector pin assignments

as necessary.

NETC01-M2

NETC01-M2

using

Pin No. Signal name Description

1 +24 VDC +24 VDC 0.2 A or more

2 GND Power supply GND

3 FG Frame Ground

11

Page 12

Connection

connector (CN1)

3. Insert the CN1 connector into the CN1

1. Strip the insulation

2. Insert each lead wire into the CN1

RS-485 communication

RS-485 communication

compatible produc

1 N.C.

0 V *

•When connecting, pay attention to the polarity of the power supply. Reverse-polarity connection

may cause damage to the

•Do not wire the power supply cable of the

lines. Doing so may cause malfunction due to noise.

Connecting method

NETC01-M2

.

NETC01-M2

in the same cable duct with other power

cover of the lead wire

by 7 mm (0.28 in.)

7 mm

(0.28 in.)

connector and tighten the screw

using a slotted screwdriver.

Connector screw size: M2

Tightening torque: 0.22 to 0.25 N·m

(31 to 35 oz-in)

Lead wires

CN1 connector

and tighten the screws using a slotted

screwdriver.

Connector screw size: M2.5

Tightening torque: 0.4 N·m (56 oz-in)

24 VDC power supply

5-3 Connecting the RS-485 communication cable

Connect the

communication cable.

Connect the RS-485 communication cable to RS-485 communication connector (CN6). Since RS-485 communication

cables of two lengths are included, use either one of the two.

You can also use a commercial LAN cable (straight cable) to link drivers.

NETC01-M2

and RS-485 communication compatible product using the included RS-485

t

GND

Grounding

Power supply

CN6 connector pin assignments

Pin No. Signal name Description

1 N.C. Not used (Do not connect anything.)

2 GND GND

3 TR+ RS-485 communication signal (+)

4

5

6 TR− RS-485 communication signal (−)

7

8

N.C. Not used

N.C. Not used

NETC01-M2

connector (CN6)

NETC01-M2

•

* The GND line is used in common with CN1 (not insulated)

internal circuit and termination resistor

2 GND

3 TR+

4 N.C.

5 N.C.

-

6 TR

7 N.C.

8 N.C.

120 Ω

12

Page 13

5-4 Connecting the MECHATROLINK-II communication

r

C

suppor

Connection

Connect the MECHATROLINK-II communication cable to the

MECHATROLINK-II communication connector (CN2-1 or CN2-2) of

the

NETC01-M2

use a dedicated cable with connector.

Other MECHATROLINK-II communication compatible products can

be connected to the vacant connector.

Connect a termination resistor to the

positioned at the end from the master device.

. For the MECHATROLINK-II communication cable,

NETC01-M2

5-5 Connecting the data setter

Connect the communication cable for the support software

or

OPX-2A

NETC01-M2

cable to the data edit connector (CN3) on the

.

The power supply connector (CN1), MECHATROLINK-II communication connectors

(CN2-1, CN2-2), data edit connector (CN3) and RS-485 communication connector

(CN6) of the

terminal of the power supply, do not connect any equipment (PC, etc.) whose

negative terminal is grounded. Doing so may cause the

equipment to short, damaging both.

NETC01-M2

MECHATROLINK-II

communication cable

MECHATROLINK-II

that is

Data edit connector (CN3)

ommunication cable for the

t software or OPX-2A cable

are not electrically insulated. When grounding the positive

communication connecto

(CN2-1)

NETC01-M2

and these

13

Page 14

Guidance

6 Guidance

If you are new to the

ow.

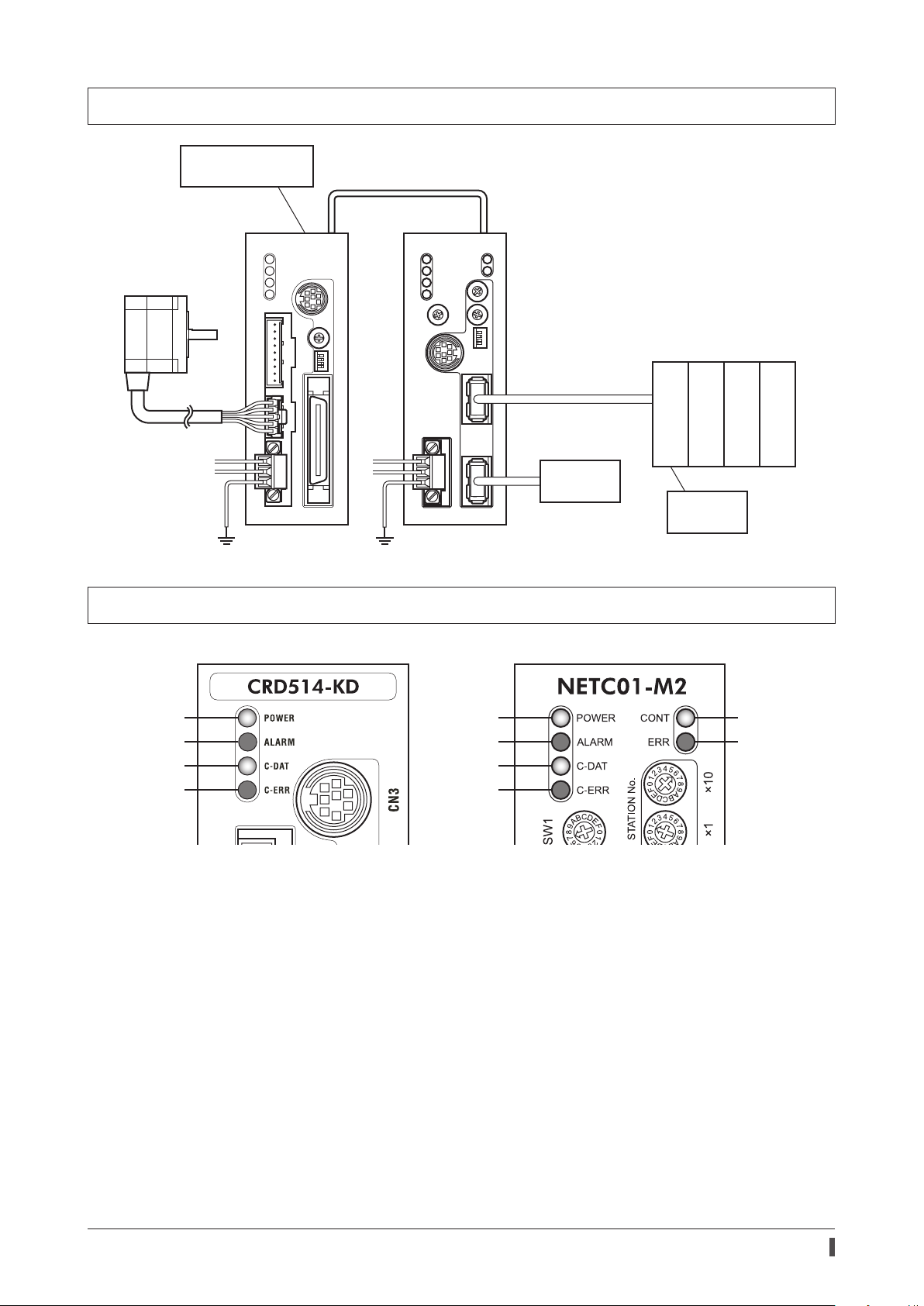

As an example, this chapter explains how to perform positioning operation for the “

type [described as the

•Before operating the motor, check the condition of the surrounding area to ensure safety.

•Refer to “13-8 Parameter mode” on p.51 for how to set parameters.

NETC01-M2

CRD-KD

, read this section to understand the operating methods along with the operation

Series FLEX Built-in controller

CRK

in this manual],” using the

NETC01-M2

via MECHATROLINK-II communication.

STEP 1 Set the transmission rate, station address and address number

Using the parameter

1. Set the “Connection (address number 0)” parameter of the

2. Cycle the

NETC01-M2

•“Connection” parameters will be enabled after the power is cycled.

•When setting the parameters of the

power.

NETC01-M2

NETC01-M2

, use the

to “1: Enable.”

MEXE02

or

OPX-2A

.

Using the switches

zSetting condition of

•Address number of

•Connection device of

CRD-KD

CRD-KD

CRD-KD

: 0

: Network converter

zSetting condition of

•MECHATROLINK-II station address: 61h

•RS-485 transmission rate: 625 kbps

•Remote I/O occupied size: 16 bit mode

•Number of transmission bytes: 32 bytes

NETC01-M2

CRD-KD address

number: 0

SW1: 0

Connection device:

Network converter

SW4: OFF

SW1 to 3: ON

RS-485 transmission

rate: 625 kbps

SW1: 7

MECHATROLINK-II

station address: 61h

×10: 6

NETC01-M2CRD-KD

×1: 1

Remote I/O occupied size:

16 bit mode

SW2-No.1: OFF

Number of transmission

bytes: 32 bytes

SW2-No.2: OFF

SW2-No.3: ON

14

Page 15

STEP 2 Check the connection and set the termination resistor

ogrammable controller

Grounding Grounding

Green Lit

Green Lit

Green Lit

Guidance

Termination

resistor (SW3): ON

CRD-KD

RS-485

communication cable

NETC01-M2

MECHATROLINK-II

communication cable

STEP 3 Turn on the power and check the setting

Pr

or master device

Termination

resistor

Termination

resistor

Check that the LED condition has become as shown in the gures.

Green Lit

O

O

•When C-ERR (red) of the

communication.

•When ERR (red) of the

CRD-KD

NETC01-M2

or

NETC01-M2

is lit: Check the type of the MECHATROLINK-II communication error.

O

Green Lit

O

is lit: Check the transmission rate or address number of RS-485

O

15

Page 16

Guidance

STEP 4 Set the parameters of

Set the parameters of the

communication.

1. Set the “START input mode (1C00h)” parameter of the

(Initial setting: I/O)

2. Set the position (travel amount: 1001h) and operating speed (1101h) to the operation data No.1 of the

3. Set the “Data No. input mode (1C0Dh)” parameter of the

(Initial setting: I/O)

4. Set the “STOP contact conguration (1C03h)” parameter of the

(Initial setting: Normally closed)

•Operation data or parameters set via RS-485 communication or MECHATROLINK-II communication

will be written to the RAM of the

o the power supply of the

the "Batch NV memory write" command of the maintenance command.

•The operation data or parameters set by the

memory of the

•The non-volatile memory can be rewritten approx. 100,000 times.

CRD-KD

using any of the

CRD-KD

CRD-KD

.

CRD-KD

MEXE02, OPX-2A

CRD-KD

CRD-KD

CRD-KD

. The data stored in the RAM will be erased when turning

. When saving the data to the non-volatile memory, execute

MEXE02

, RS-485 communication or MECHATROLINK-II

to “0: RS-485 communication.”

to “0: RS-485 communication.”

CRD-KD

or

to “0: Normally open.”

OPX-2A

will be saved to the non-volatile

STEP 5 Execute positioning operation

Control the I/O signal of the

1. Select the data No.1 by turning the M0 of the address number 0 to ON.

2. Execute positioning operation by turning the START of the address number 0 to ON.

CRD-KD

using the I/O command (DATA_RWA: 50h) of MECHATROLINK-II communication.

CRK-KD

.

STEP 6 Were you able to operate the motor properly?

How did it go? Were you able to operate the motor properly? If the motor does not function, check the following

points:

•Is any alarm present in the

•Are the address number, transmission rate and termination resistor set correctly?

•Are the “Connection” parameters of the

•Is the C-ERR LED lit? (RS-485 communication error)

•Is the ERR LED lit? (MECHATROLINK-II communication error)

•Is the operation data set correctly?

•Is the motor for the

•Are the

•Is the STOP input of the

For more detailed settings and functions, refer to the following pages.

CRD-KD

parameters set correctly?

NETC01-M2

CRD-KD

CRD-KD

excited? Or is the excitation setting correct?

or

CRD-KD

NETC01-M2

I/O turned ON?

?

set correctly?

16

Page 17

7 Setting

-II station

RS-485 communication

transmission rate setting

switch (SW1)

Setting

This chapter explains how to set the functions of the

Be sure to turn o the

the power is still on, the new switch settings will not become eective until the

is cycled.

NETC01-M2

NETC01-M2

power before setting the switches. If the switches are set while

.

MECHATROLINK

address setting switches

(STATION No.×1, ×10)

Operation mode setting

switch (SW2-Nos.1 to 3)

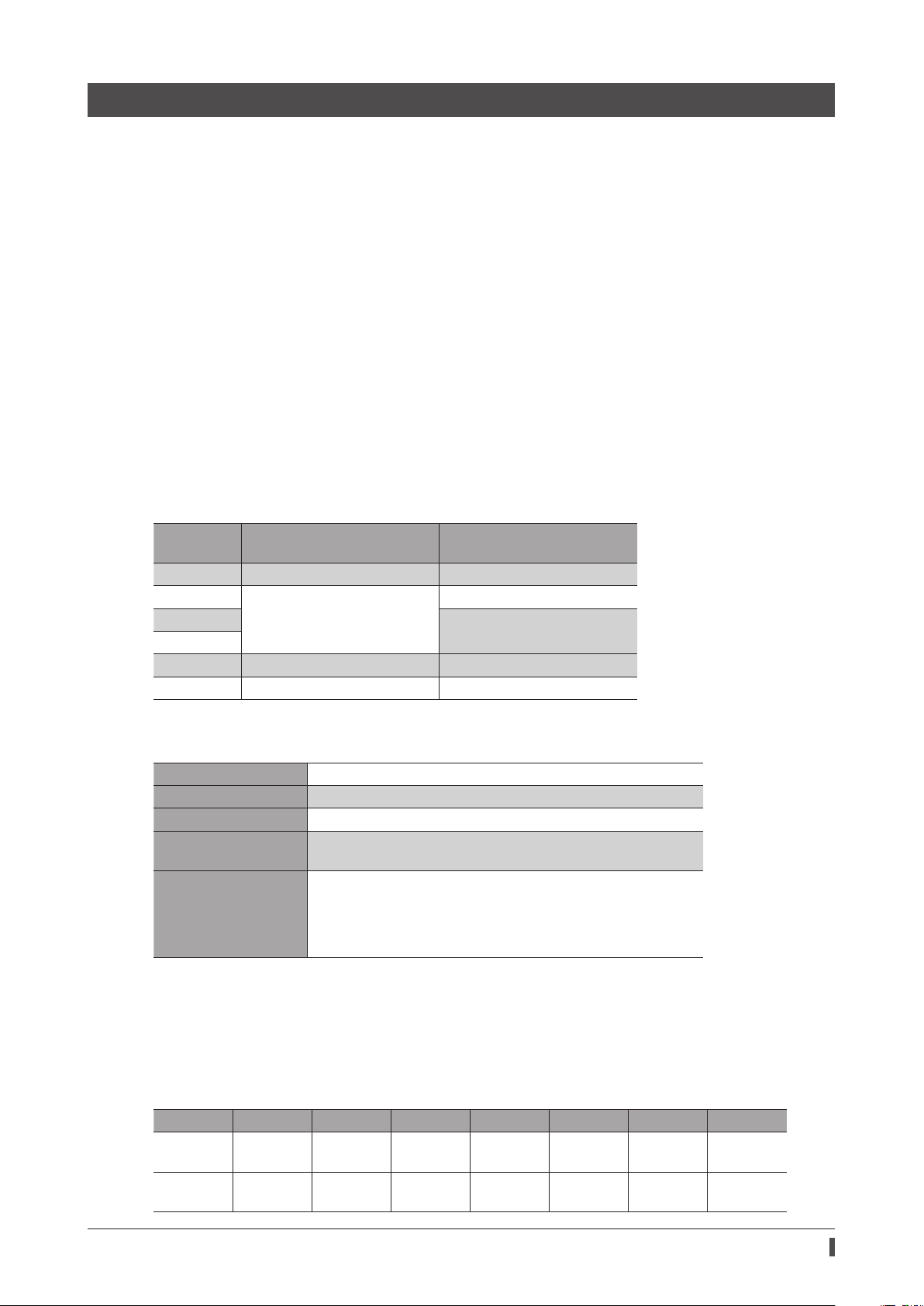

7-1 Transmission rate of RS-485 communication

Set the transmission rate using the transmission rate setting switch (SW1).

Factory setting 7 (625 kbps)

NETC01-M2

power

•For the SW1, always set to "7." If the switch is set to the dial of "8" or higher, the communication

switch setting error alarm will be generated when turning on the power. And do not set the switch

to the dial of "0" to "6" because they cannot be used. (An alarm will not be generated.)

•For the transmission rate of the RS-485 communication compatible product, set to 625 kbps.

7-2 Operation mode

Set the remote I/O occupied size and number of transmission bytes for the RS-485 communication compatible

product connecting to a

SW2-No.1, and set the number of transmission bytes using the SW2-No.2 and No.3.

If the operation mode is changed, cycle the power.

Factory setting No.1: OFF (Remote I/O occupied size: 16 bit mode)

No.2: OFF, No.3: ON (Number of transmission bytes: 32 bytes)

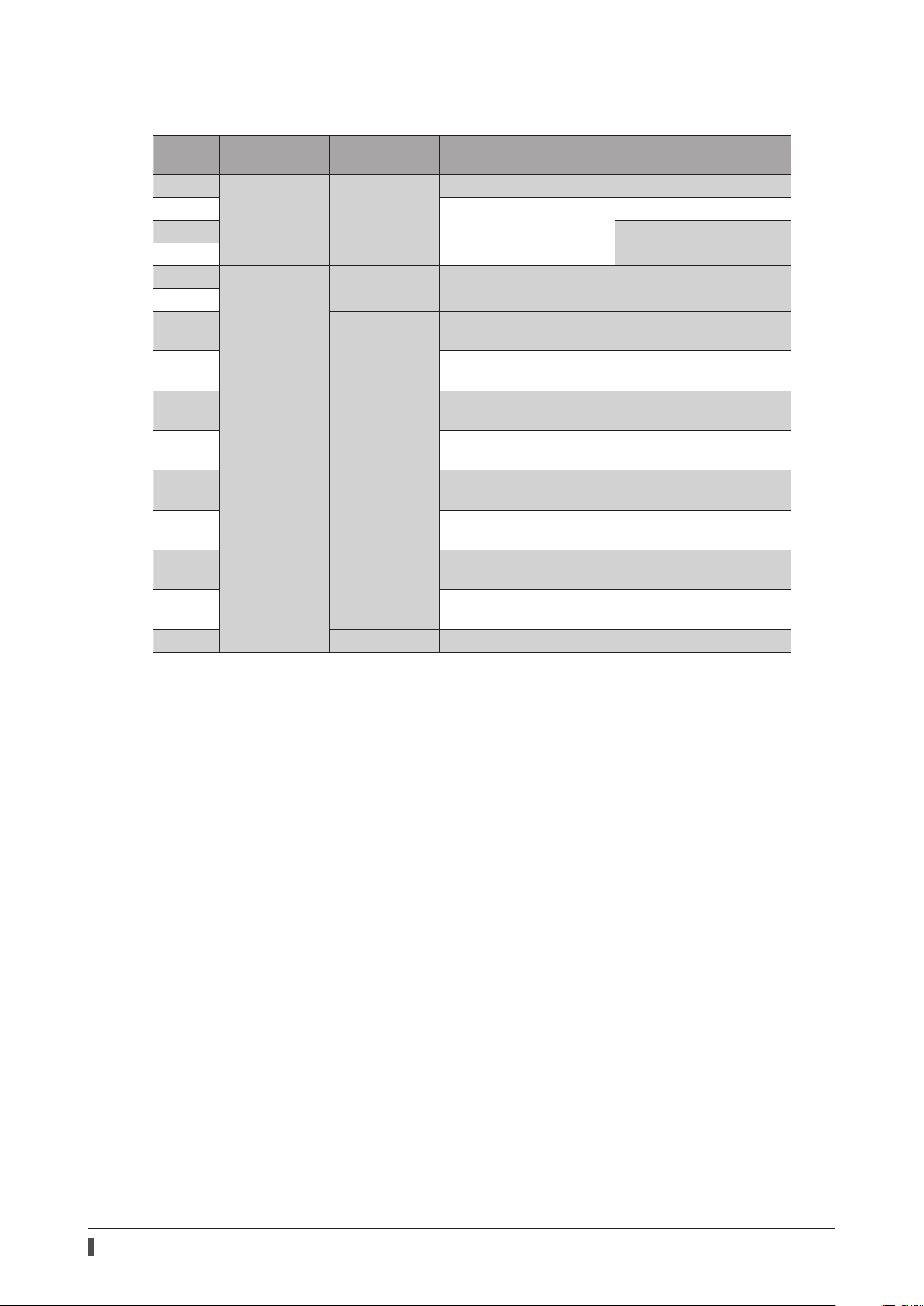

SW2 Description Factory setting

Sets the remote I/O occupied size.

No.1

No.2

No.3

OFF: 16 bit mode (Up to 8 units can be connected)

ON: 8 bit mode (Up to 16 units can be connected)

Set the number of transmission bytes.

No.2=OFF, No.3=OFF: 17 bytes

No.2=OFF, No.3=ON: 32 bytes

The SW2-No.4 is not used.

NETC01-M2

. Set the remote I/O occupied size using the operation mode setting switch

OFF

No.2: OFF

No.3: ON

17

Page 18

Setting

7-3 Station address

Set the station address using the two MECHATROLINK-II station address setting switches (STATION No.×1 and ×10).

When connecting two or more MECHATROLINK-II compatible products, do not set duplicate station address.

Set the tens place with the “STATION No.×10” switch and the ones place with the “STATION No.×1” switch.

Setting range 60h to 7Fh

Factory setting 61h (×10: 6, ×1: 1)

00h to 5Fh and 80h to FFh cannot be used.

18

Page 19

MECHATROLINK-II communication format

8 MECHATROLINK-II communication

format

This chapter explains the MECHATROLINK-II communication format that the

8-1 Data format

The outline of the data format for MECHATROLINK-II communication is shown below. The

with the cyclic communication mode.

The cyclic communication mode of MECHATROLINK-II communication species that the header elds are 1 byte to

4 bytes and the data elds are 5 bytes and later.

Header eld

Data eld 5 to 31 Command data eld Response data eld

8-2 Phase

The communication phases of MECHATROLINK-II communication are classied as follows.

Phase Description

This is a state at power-on. When turning on the power for the master station and slave station,

0

operation switches to phase 1.

1 This is a state waiting for the connection establishment between the master station and slave station.

Asynchronous communication between the master station and slave station is enabled. Only

2

asynchronous command can be used.

Synchronous communication between the master station and slave station is enabled. Both

3

asynchronous command and synchronous command can be used.

This is a state that the communication between the master station and slave station is stopped and the

4

connection is disconnected.

5 This is a state turning o the power for the master station and slave station.

NETC01-M2

Byte

1 DATA_RWA (50h) DATA_RWA (50h)

2

3

4

Command

(Master to

NETC01-M2

OPTION

)

Response

(

NETC01-M2

ALARM

STATUS

to master)

supports.

NETC01-M2

is compatible

19

Page 20

Details of command

9 Details of command

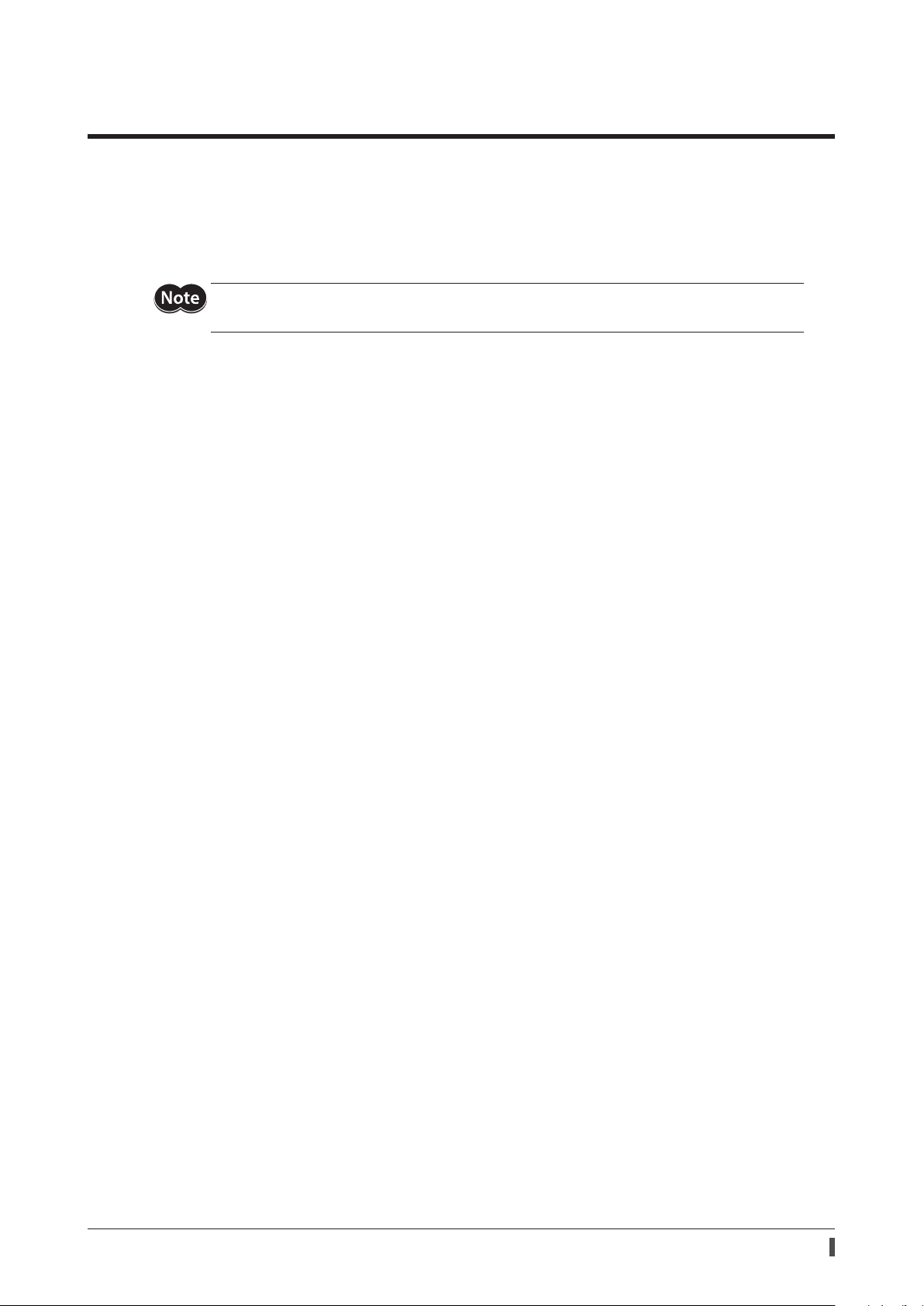

This chapter explains the common commands and I/O command that the

Prole

Common

command

I/O

command

Command

code

00h NOP This command is used as "no operation command." p.20

03h ID_RD

05h ALM_RD

06h ALM_CLR

0Eh CONNECT

0Fh DISCONNECT

50h DATA_RWA

Command Description Ref.

This command is used to read the product information

as ID data.

This command is used to read the alarm code, warning

code or MECHATROLINK-II communication error code

that is currently occurred.

This command is used to reset the alarm, warning or

MECHATROLINK-II communication error that is

currently occurred.

This command is used to establish a connection of

MECHATROLINK-II communication.

This command is used to release a connection of

MECHATROLINK-II communication.

Operation commands to the RS-485 communication

compatible product, reading and writing parameters,

and monitoring can be executed via remote I/O or

remote register.

9-1 No operation command (NOP: 00h)

NETC01-M2

supports.

p.22

p.24

p.24

p.25

p.26

p.27

This command is used as “no operation command.” A response returns the present status.

Data format

Byte

1 NOP (00h) NOP (00h)

2

3

4

5 to 15 Reserved (0h)

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

Response

(

NETC01-M2

ALARM

STATUS

to master)

Explanation of command

Device group Common command group

Function group Network command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=NOP (=00h) and STATUS.CMDRDY=1.

ALARM: Error code occurred in communication

STATUS: Communication status

20

Page 21

ALARM

Details of command

Code Name Description Phase at error

01h

02h

03h Invalid Data

Invalid

Command

Command Not

Allowed

Unsupported command

•Executed the command that was

not implemented.

Command execution condition

error

•The command that has been sent

is inconsistency with the

communication phase.

•The command execution

conditions are not met.

Outside the range of command

data

•The data in the command is not

correct.

P1 to P4

P2, P3

P2, P3

STATUS bit allocations

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Vendor-specic CMDRDY WARNG ALARM

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

Vendor-specic

Transition phase

after error

Phase not

changed

ALARM/

WARNING

WARNING Possible

ALM-CLR

Explanation of bit eld

Item Denition Description

If the MECHATROLINK-II communication error has occurred between the

ALARM

WARNG

CMDRDY

0: No alarm

1: Alarm status

0: No warning

1: Warning status

0: Command cannot be

accepted.

1: Command can be

accepted.

master station and

(ALARM=1). Even if an alarm generates in the

communication compatible product, it will not become "1." Refer to

p.39 for the

If "unsupported command," "command execution condition error" or

"outside the range of command data" has occurred between the master

station and

Even if a warning generates in the

communication compatible product, it will not become "1." Refer to

p.42 for the

CMDRDY=0 (the STATUS bit2 is equal to "0") represents that the

NETC01-M2

becomes "1" (CMDRDY=1), a new command can be accepted.

NETC01-M2

NETC01-M2

NETC01-M2

NETC01-M2

is executing command processing. When the STATUS bit2

alarm.

, the STATUS bit1 becomes "1" (WARNING=1).

warning.

, the STATUS bit0 becomes "1"

NETC01-M2

NETC01-M2

or RS-485

or RS-485

21

Page 22

Details of command

WDT/RWDT

When synchronization has been established, the watchdog timer (WDT) executes checking. Updating the WDT can be

refreshed even if synchronization has not been established.

zWDT

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

SN: Copy of RSN in RWDT

zRWDT

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

RSN: Incremented by 1 each communication cycle

(Slave station WDT count)

9-2 Read ID command (ID_RD: 03h)

This command is used to read the product information as ID data. Select ID data by specifying the DEVICE_CODE.

Refer to the “DEVICE_CODE list” on p.23 for details.

MN: Incremented by 1 each communication cycle

(Master station WDT count)

RMN: Copy of MN in WDT

Data format

Byte

1 ID_RD (03h) ID_RD (03h)

2

3

4

5 DEVICE_CODE DEVICE_CODE

6 OFFSET OFFSET

7 SIZE SIZE

8 to 15 Reserved (0h) ID

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

(

NETC01-M2

Explanation of command

Device group Common command group

Function group Data communication command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=ID_RD (=03h), STATUS.CMDRDY=1, DEVICE_CODE,

OFFSET and SIZE.

DEVICE_CODE: Device code

OFFSET: Read oset

Size: Read data size (byte)

Response

to master)

ALARM

STATUS

22

Page 23

DEVICE_CODE list

RC

Details of command

DEVICE_

CODE

00h

01h

Description Data size Data type

Product model 32 char ASCII

This is a code to specify the product model.

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

NETC01-M200

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

* Data end delimiter: Null code (00h) is added at the end of each

character string.

Manufacture serial 32 char ASCII

This is a manufacture serial number.

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

* Data end delimiter: Null code (00h) is added at the end of each

character string.

Device version 32 char ASCII

This is a code to specify the device version.

02h

0Fh

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

0 1.0000

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

* Data end delimiter: Null code (00h) is added at the end of each

character string.

Vendor code 48 byte BIN/ASCII

This is a code to specify the vendor.

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

05 00

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

OR IENTAL MO TO

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

o. ,LTD .00

* Data end delimiter: Null code (00h) is added at the end of each

character string.

23

Page 24

Details of command

9-3 Read alarm or warning command (ALM_RD: 05h)

This command is used to read the alarm code, warning code or MECHATROLINK-II communication error code that is

currently occurred.

Data format

Byte

1 ALM_RD (05h) ALM_RD (05h)

2

3

4

5 ALM_RD_MODE ALM_RD_MODE

6 to 15 Reserved (0h) ALM_DATA

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

(

NETC01-M2

Explanation of command

Device group Common command group

Function group Control command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=ALM_RD (=05h) and STATUS.CMDRDY=1.

ALM_RD_MODE

0: Reads the present alarm or warning status.

Response

to master)

ALARM

STATUS

9-4 Clear alarm or warning command (ALM_CLR: 06h)

This command is used to reset the MECHATROLINK-II communication error that is currently occurred.

Only the MECHATROLINK-II communication error can be reset by the "clear alarm or warning

command." To reset the alarm and warning of the

NETC01-M2

Data format

Byte

1 ALM_CLR (06h) ALM_CLR (06h)

2

3

4

5 ALM_CLR_MODE ALM_CLR_MODE

6 to 15 Reserved (0h) Reserved (0h)

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

(

NETC01-M2

Response

ALARM

STATUS

, cycle the power.

to master)

24

Page 25

Explanation of command

Device group Common command group

Function group Control command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=ALM_CLR (=06h) and STATUS.CMDRDY=1.

ALM_CLR_MODE

0: Resets the MECHATROLINK-II communication error that is currently occurred.

9-5 Establish connection command (CONNECT: 0Eh)

This command is used to establish the MECHATROLINK-II communication connection.

Data format

Details of command

Byte

1 CONNECT (0Eh) CONNECT (0Eh)

2

3 STATUS

4 Reserved (0h)

5 VER (21h) VER (21h)

6 COM_MODE COM_MODE

7 COM_TIME COM_TIME

8 to 15 Reserved (0h) Reserved (0h)

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

(

NETC01-M2

Explanation of command

Device group Common command group

Function group Network command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=CONNECT (=0Eh), STATUS.CMDRDY=1, VER,

COM_MODE and COM_TIME.

•VER: Version number in the application layer

•COM_MODE: Communication mode

Response

to master)

ALARM

25

Page 26

Details of command

COM_MODE bit allocations

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

DATA_EXP 0 0 0 DTMOD SYNCMOD 0

Explanation of bit eld

Item Description

Data area extension

DATA_EXP

DTMODE

SYNCMODE

0: Padded with zero (0) for the byte 17 to byte 31

1: The byte 17 to byte 31 are extended areas (eective with 32-byte mode)

Communication mode

00: Single transmission

01: Consecutive transmission (Not used in the

10, 11: Reserved

Synchronous setting

0: Asynchronous communication (Detecting the watchdog data error is disabled and

synchronous command cannot be used.)

1: Synchronous command (Not used in the

NETC01-M2

NETC01-M2

)

)

9-6 Release connection command (DISCONNECT: 0Fh)

This command is used to release a connection of MECHATROLINK-II communication.

This command is given priority over other commands. When the DISCONNECT command is received while processing

the other command, the current command is stopped processing and the connection is released.

Data format

Byte

1 DISCONNECT (0Fh) DISCONNECT (0Fh)

2

3

4

5 to 15 Reserved (0h)

16 WDT RWDT

17 to 31 Reserved (0h) Reserved (0h)

Command

(Master to

Reserved (0h)

NETC01-M2

)

Response

(

NETC01-M2

ALARM

STATUS

to master)

Explanation of command

Device group Common command group

Function group Network command group

Communication type Asynchronous command

Completion of command

operation

Controls the command transmitting time of the mater station as at least two

communication cycles.

26

Page 27

9-7 Data READ/WRITE_A command (DATA_RWA: 50h)

Operation commands to the RS-485 communication compatible product, reading and writing parameters, and

monitoring can be executed via remote I/O or remote register.

zRemote I/O

Remote I/O is one of the data used in communication between the master station and RS-485 communication

compatible product. The control like the ON-OFF switching of I/O signals can be executed using serial

communication.

When remote I/O of the

remote I/O via the

•Controls the ON-OFF status of the input signal to the RS-485 communication compatible product.

•Checks the output signal from the RS-485 communication compatible product.

NETC01-M2

NETC01-M2

zRemote register

Remote register is one of the data used in communication between the master station and RS-485 communication

compatible product. Reading and writing the numerical number can be executed using serial communication.

When remote register of the

using remote register via the

•Reads the parameters from the RS-485 communication compatible product.

•Writes the parameters to the RS-485 communication compatible product.

•Monitors the status of the RS-485 communication compatible product.

NETC01-M2

NETC01-M2

Data format

is assigned to the register of the master station, it is possible to control using

. The following functions can be executed using remote I/O.

is assigned to the register of the master station, it is possible to control

. The following functions can be executed using remote register.

Details of command

Byte

1 DATA_RWA (50h) DATA_RWA (50h)

2

3

4

5 to 16 OUTPUT INPUT

17 to 31 OUTPUT INPUT

Command

(Master to

NETC01-M2

OPTION

)

(

NETC01-M2

Explanation of command

Device group I/O command group

Function group Data communication command group

Communication type Asynchronous command

Completion of command

operation

Note

Conrms by the response byte 1=DATA_RWA (=50h) and STATUS.

CMDRDY=1.

•This command can be used in the phase 2 and 3.

•OUTPUT: Output data

•INPUT: Input data

•Refer to the "I/O data."

Response

to master)

ALARM

STATUS

Connection status

The connection status with the RS-485 communication compatible product can be monitored by the response of the

DATA_RWA command. For the connection status shown in the next section “I/O data,” when the master station

properly communicates with the RS-485 communication compatible product, the bit corresponding to the address

number shown in the table next becomes “1.” If the connection setting is disabled or if the communication error has

occurred, the bit becomes “0.”

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Address

number 7

Address

number 15

Address

number 6

Address

number 14

Address

number 5

Address

number 13

Address

number 4

Address

number 12

Address

number 3

Address

number 11

Address

number 2

Address

number 10

Address

number 1

Address

number 9

Address

number 0

Address

number 8

27

Page 28

Details of command

I/O data

The OUTPUT and INPUT respectively correspond to the command and response of the data eld as shown below.

Controlling the I/O signal of the RS-485 communication compatible product, reading and writing operation data or

parameters, and monitoring can be executed.

In the following cases, the most signicant bit of the register address number response becomes “1.”

•When “Communication (address number)” parameter species the address number of “0: Disabled”

•When the power supply of the RS-485 communication compatible product is not turned on

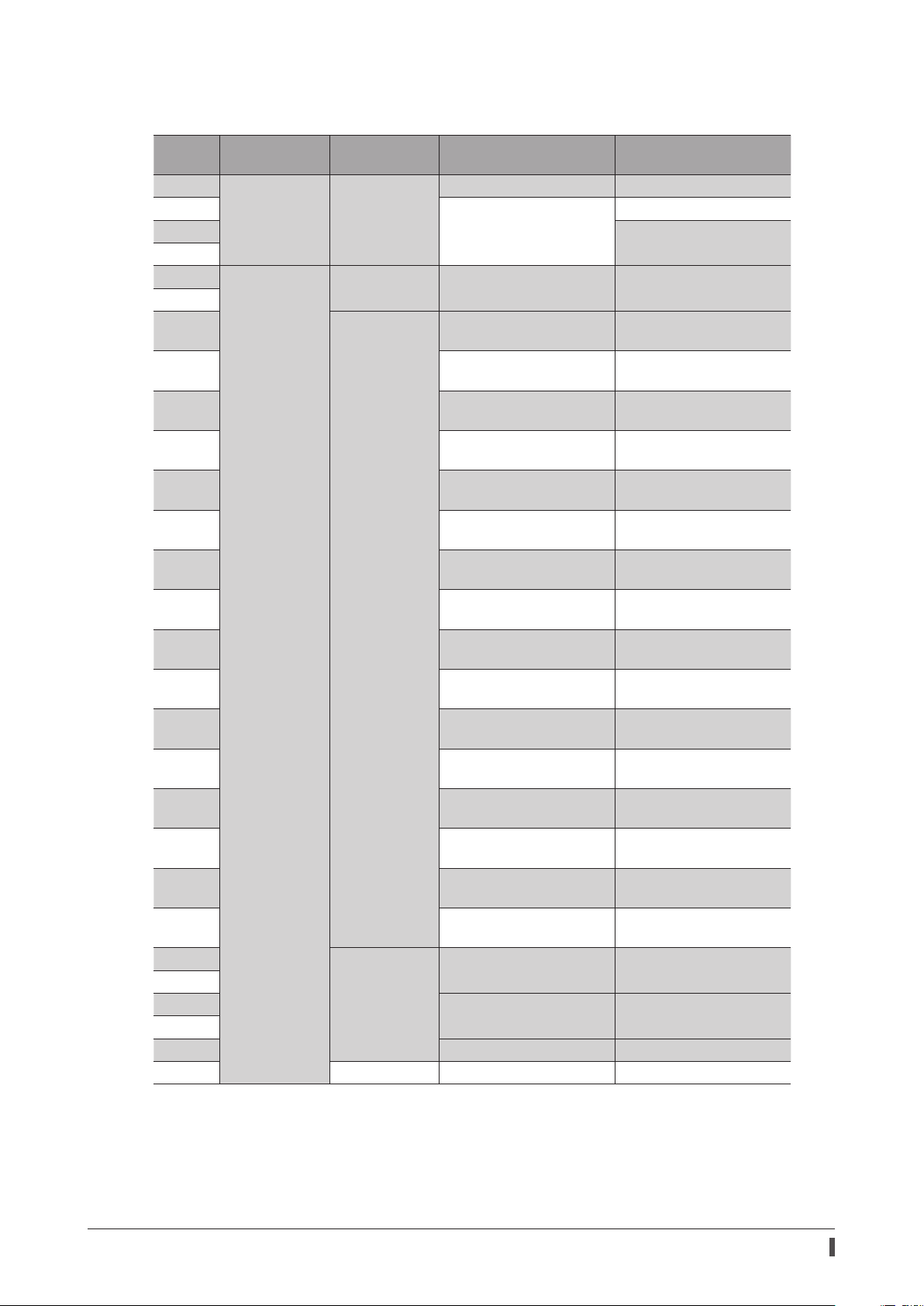

zRemote I/O occupied size: 16-bit mode

Number of transmission bytes: 17-byte mode

Byte Part Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Header eld −

Data eld

Remote I/O

− Reserved Connection status

− Reserved Reserved

Command

(Master to

NETC01-M2

DATA_RWA (50h) DATA_RWA (50h)

OPTION

Address number "0"

remote I/O input

Address number "1"

remote I/O input

Address number "2"

remote I/O input

Address number "3"

remote I/O input

)

Response

(

NETC01-M2

ALARM

STATUS

Address number "0"

remote I/O output

Address number "1"

remote I/O output

Address number "2"

remote I/O output

Address number "3"

remote I/O output

to master)

28

Page 29

zRemote I/O occupied size: 16-bit mode

Number of transmission bytes: 32-byte mode

Details of command

Byte Part Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 to 30 DATA DATA response

31 − Reserved Reserved

Header eld −

− Reserved Connection status

RemoteI/O

Data eld

Remote register

Command

(Master to

Address number "7"

Register address number

Command code + TRIG

NETC01-M2

DATA_RWA (50h) DATA_RWA (50h)

OPTION

Address number "0"

remote I/O input

Address number "1"

remote I/O input

Address number "2"

remote I/O input

Address number "3"

remote I/O input

Address number "4"

remote I/O input

Address number "5"

remote I/O input

Address number "6"

remote I/O input

remote I/O input

)

Command code response +

Response

(

NETC01-M2

Address number "0"

remote I/O output

Address number "1"

remote I/O output

Address number "2"

remote I/O output

Address number "3"

remote I/O output

Address number "4"

remote I/O output

Address number "5"

remote I/O output

Address number "6"

remote I/O output

Address number "7"

remote I/O output

Register address number

TRIG response + STATUS

to master)

ALARM

STATUS

response

29

Page 30

Details of command

zRemote I/O occupied size: 8-bit mode

Number of transmission bytes: 17-byte mode

Byte Part Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 − Reserved Reserved

Header eld −

Data eld

Remote I/O

− Reserved Connection status

Command

(Master to

NETC01-M2

DATA_RWA (50h) DATA_RWA (50h)

OPTION

Address number "0"

remote I/O input

Address number "1"

remote I/O input

Address number "2"

remote I/O input

Address number "3"

remote I/O input

Address number "4"

remote I/O input

Address number "5"

remote I/O input

Address number "6"

remote I/O input

Address number "7"

remote I/O input

)

Response

(

NETC01-M2

ALARM

STATUS

Address number "0"

remote I/O output

Address number "1"

remote I/O output

Address number "2"

remote I/O output

Address number "3"

remote I/O output

Address number "4"

remote I/O output

Address number "5"

remote I/O output

Address number "6"

remote I/O output

Address number "7"

remote I/O output

to master)

30

Page 31

zRemote I/O occupied size: 8-bit mode

Number of transmission bytes: 32-byte mode

Details of command

Byte Part Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 to 30 DATA DATA response

31 − Reserved Reserved

Header eld −

− Reserved Connection status

RemoteI/O

Data eld

Remote register

Command

(Master to

Address number "8"

Address number "9"

Address number "10"

Address number "11"

Address number "12"

Address number "13"

Address number "14"

Address number "15"

Register address number

Command code + TRIG

NETC01-M2

DATA_RWA (50h) DATA_RWA (50h)

OPTION

Address number "0"

remote I/O input

Address number "1"

remote I/O input

Address number "2"

remote I/O input

Address number "3"

remote I/O input

Address number "4"

remote I/O input

Address number "5"

remote I/O input

Address number "6"

remote I/O input

Address number "7"

remote I/O input

remote I/O input

remote I/O input

remote I/O input

remote I/O input

remote I/O input

remote I/O input

remote I/O input

remote I/O input

)

Command code response +

Response

(

NETC01-M2

Address number "0"

remote I/O output

Address number "1"

remote I/O output

Address number "2"

remote I/O output

Address number "3"

remote I/O output

Address number "4"

remote I/O output

Address number "5"

remote I/O output

Address number "6"

remote I/O output

Address number "7"

remote I/O output

Address number "8"

remote I/O output

Address number "9"

remote I/O output

Address number "10"

remote I/O output

Address number "11"

remote I/O output

Address number "12"

remote I/O output

Address number "13"

remote I/O output

Address number "14"

remote I/O output

Address number "15"

remote I/O output

Register address number

TRIG_R + STATUS

to master)

ALARM

STATUS

response

31

Page 32

Details of command

dO

RS-485 communication

[

[Master to

[Power supply input]

9-8 Timing chart of the data READ/WRITE_A command

The command codes in the following timing charts are examples of the AR Series FLEX DC power input Built-in

controller type.

TM: Communication cycle between the master station and

TS: Communication cycle between the

NETC01-M2

When the power supply is turned on (remote I/O)

NETC01-M2

and RS-485 communication compatible product.

1. Turn on the power supply of the

2. Turn on the power supply of the RS-485 communication compatible product.

3. Check the connection status is turned from OFF to ON.

compatible product

NETC01-M2 to master]

Connection status

* When the connection status is OFF, turn the signals to start operation (START, HOME etc.) to OFF.

NETC01-M2

NETC01-M2

NETC01-M2]

Remote I/O input Input disabled

Remote I/O output Output not specied Output update

ON

OFF

ON

OFF

ON

OFF

.

TM+TS TM+TS

Input enabled

(can be accepted)

(TM+TS)×2 (TM+TS)×2

Input disabled *

Input enabled

(can be accepted)

utput updatedOutput maintained

32

Page 33

When the power supply is turned on (remote register)

RS-485 communication

[

[Master to

[Power supply input]

Details of command

1. Turn on the power supply of the

2. Turn on the power supply of the RS-485 communication compatible product.

3. Check the connection status is turned from OFF to ON. For the next step, refer to the next section “read parameter

and operation data (remote register).”

NETC01-M2

compatible product

NETC01-M2]

Register address number

TRIG

Command code

DATA

NETC01-M2 to master]

Connection status

Register address number

response

TRIG_R

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

NETC01-M2

.

0001h

*1*1

0000h *10000h *1 1201h1200h

1,000 (03E8h)

2,000 (07D0h)

TM+TSTM+TS

0000h 0001h 0001h

8001h *2

Command code response

DATA response

0000h

0000h 0000h

1,000 (03E8h) 2,000 (07D0h)

0000h

1201h1200h

*1 When the connection status is OFF, set the command code to “0000h” and turn the TRIG to OFF.

*2 When the power supply of the RS-485 communication compatible product is OFF, the most signicant bit of the

register address number response becomes “1.”

33

Page 34

Details of command

(TM+TS)×2

e

C

[

[Master to

Read parameters and operation data (remote register)

1. Specify the register address number.

2. Check the register address number response.

3. Turn the TRIG from OFF to ON. The selected parameter or operation data is started reading.

4. After checking the TRIG_R was turned from OFF to ON, check the command code response and DATA response.

5. Turn the TRIG from ON to OFF, and check that the TRIG_R was turned from ON to OFF.

When reading the “position (1,000)” of the operation data No.0

NETC01-M2]

Register address number

0 s or more

ON

TRIG

OFF

Command code

response

TRIG_R

DATA

(TM+TS)×2

ON

OFF

NETC01-M2 to master]

Register address number

ommand code response

DATA response

0001h

0 s or more

0200h

(TM+TS)×2

0 s or mor

0001h

0200h

1,000 (03E8h)

34

Page 35

Details of command

(TM+TS)×2

C

[

[Master to

Write parameters and operation data (remote register)

1. Specify the register address number.

2. Check the register address number response.

3. Turn the TRIG from OFF to ON. The selected parameter or operation data is started writing.

4. After checking the TRIG_R was turned from OFF to ON, check the command code response and DATA response.

5. Turn the TRIG from ON to OFF, and check that the TRIG_R was turned from ON to OFF.

When writing 1,000 to the “position” of the operation data No.0

NETC01-M2]

Register address number

0 s or more0 s or more

ON

TRIG

OFF

Command code

response

TRIG_R

DATA

(TM+TS)×2

ON

OFF

NETC01-M2 to master]

Register address number

ommand code response

DATA response

1200h

0001h

(TM+TS)×2

0 s or more

1,000 (03E8h)

0001h

1200h

1,000 (03E8h)

35

Page 36

Details of command

(TM+TS)×2

C

[

[Master to

Maintenance (remote register)

1. Specify the register address number.

2. Check the register address number response.

3. Turn the TRIG from OFF to ON. The selected maintenance command is executed.

4. After checking the TRIG_R was turned from OFF to ON, check the command code response and DATA response.

5. Turn the TRIG from ON to OFF, and check that the TRIG_R was turned from ON to OFF.

When executing “batch NV memory write”

NETC01-M2]

Register address number

0 s or more 0 s or more

ON

TRIG

OFF

Command code

response

TRIG_R

DATA

*

ON

OFF

NETC01-M2 to master]

Register address number

ommand code response

DATA response

* It varies depending on the type of the RS-485 communication compatible products or commands.

0001h

(TM+TS)×2

0 s or more

30C9h

1 (0001h)

0001h

30C9h

1 (0001h)

36

Page 37

Details of command

(TM+TS)×2

C

[

[Master to

Monitor (remote register)

1. Specify the register address number.

2. Check the register address number response.

3. Turn the TRIG from OFF to ON. The selected monitor command is executed.

4. After checking the TRIG_R was turned from OFF to ON, check the command code response and DATA response.

The DATA response value is updated while the TRIG is ON.

5. Turn the TRIG from ON to OFF, and check that the TRIG_R was turned from ON to OFF.

When monitoring the “command position”

NETC01-M2]

Register address number

0 s or more

ON

TRIG

OFF

Command code

response

TRIG_R

DATA

ON

OFF

(TM+TS)×2

TM+TS TM+TS

NETC01-M2 to master]

Register address number

ommand code response

DATA response

0001h

2063h

(TM+TS)×2

0001h

100 (0064h)0 (0000h)

0 s or more

2063h

200 (00C8h)

37

Page 38

Details of command

C

[

[Master to

(TM+TS)×2

When an error has occurred (remote register)

1. Specify the register address number.

2. Check the register address number response.

3. Turn the TRIG from OFF to ON. The selected parameter or operation data is started writing.

4. When the written value is an error, the STATUS is turned from OFF to ON. Check the command code and DATA.

5. Turn the TRIG from ON to OFF, and reset the error status.

When specifying data that is outside the setting range (write 1,000 to the “STOP input action”

parameter)

If an error has occurred in data transfer, the STATUS is turned ON.

NETC01-M2]

Register address number

0 s or more0 s or more

ON

TRIG

OFF

Command code

DATA

NETC01-M2 to master]

Register address number

response

STATUS

TRIG_R

ommand code response

DATA response

ON

OFF

ON

OFF

(TM+TS)×2

0001h

(TM+TS)×2

0 s or more

1100h

1,000 (03E8h)

0001h

1100h

1,000 (03E8h)

38

Page 39

Troubleshooting and remedial actions

ALARM LED (Red)

T

an alarm generates

-II

Approximately

Approximately

Approximately

10 Troubleshooting and remedial actions

The

NETC01-M2

operation, etc. (protective functions), as well as warnings that are output before the corresponding alarms generate

(warning functions).

provides alarms that are designed to protect the

NETC01-M2

from poor connection, error in

10-1 Alarms and MECHATROLINK-II communication error

If an alarm has generated, the ALARM LED of the

When the MECHATROLINK-II communication error has occurred, the ERR LED blinks.

his LED will blink when

.

When an alarm in the

If an alarm in the

The present alarm can be checked by counting the number of times the ALARM LED blinks. The present alarm can be

also checked using the

You can check the records of up to 10 most recent alarms starting from the latest one, or clear the alarm records.

NETC01-M2

NETC01-M2

unit has generated, RS-485 communication is stopped and the ALARM LED blinks.

MEXE02

or

OPX-2A

NETC01-M2

unit was generated

.

zALARM LED status (Example: RS-485 communication error)

blinks.

ERR LED (Red)

This LED is blink when an error

has occurred via MECHATROLINK

communication.

200 ms

If an alarm is generated, the communication between the

compatible product is stopped. When RS-485 communication is stopped, the parameter command,

maintenance command and monitor command of the RS-485 communication compatible product

cannot be used.

200 ms

1.4 s

Interval

NETC01-M2

and RS-485 communication

zAlarm reset

Before resetting an alarm to cycle the power, always remove the cause of the alarm and ensure safety.

The alarm in the

II communication.

NETC01-M2

unit cannot be reset by the

MEXE02, OPX-2A

or via MECHATROLINK-

When the MECHATROLINK-II communication error has occurred

If the MECHATROLINK-II communication error has occurred, the ERR LED blinks.

The motor operation is stopped but RS-485 communication is continued.

How to reset the MECHATROLINK-II communication error

Perform one of the reset operations specied below. Before resetting the MECHATROLINK-II communication error to

cycle the power, always remove the cause of the error and ensure safety.

•Execute the alarm reset for the

OPX-2A

•Cycle the power of the

•Execute the clear alarm or warning command (ALM_CLR: 06h) of MECHATROLINK-II communication.

.

NETC01-M2

NETC01-M2

or master device.

or RS-485 communication compatible product using the

MEXE02

or

39

Page 40

Troubleshooting and remedial actions

ALARM blink

POWER only lit

ALARM blink

d

ALARM blinking

POWER only lit

ALARM blink

C-D

ALARM blink

POWER only lit

POWER only lit

C-D

C-D

ALARM blink

POWER only lit

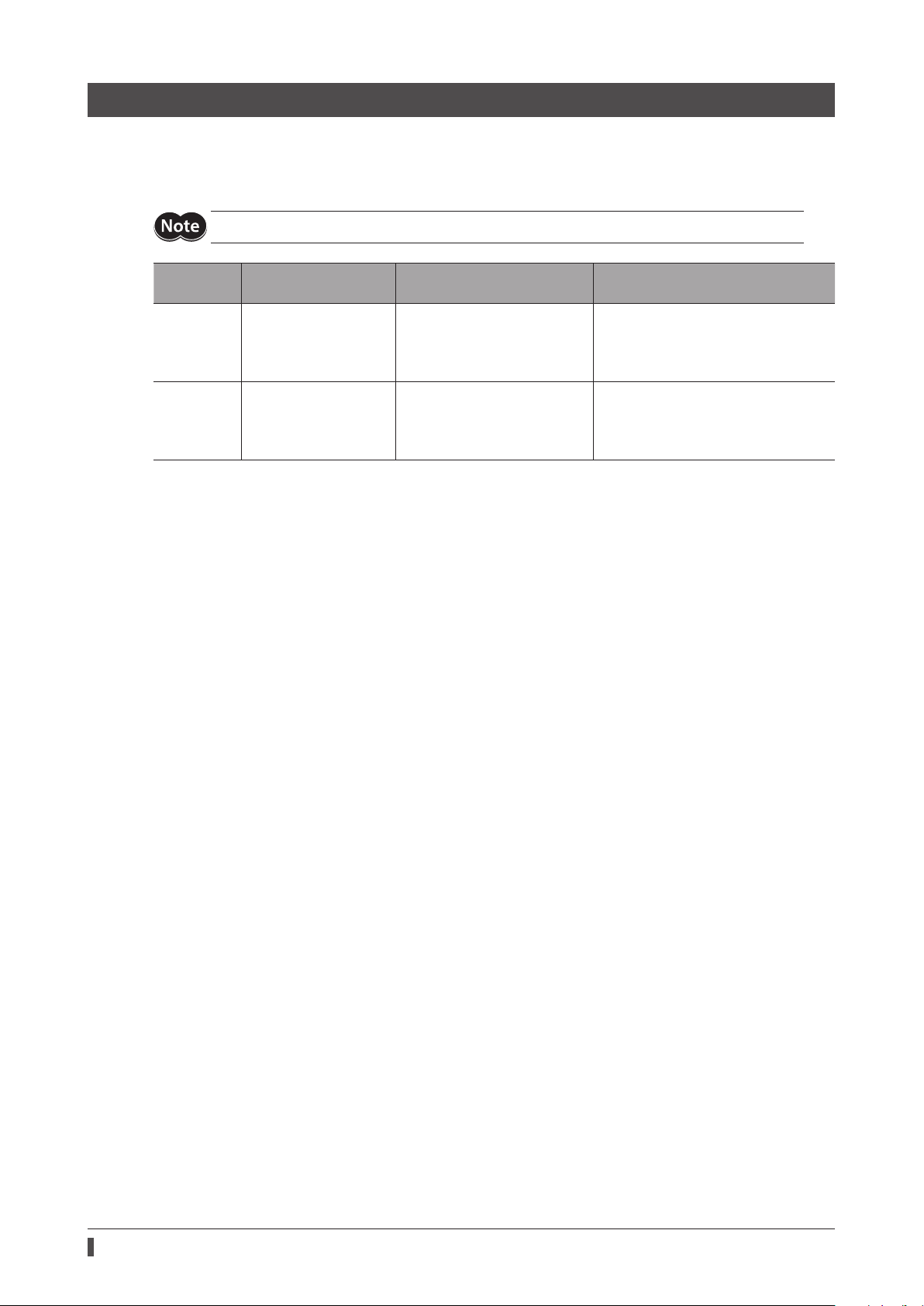

List of alarm and MECHATROLINK-II communication error

Product Type

NETC01-M2

unit Alarm

Between master and

NETC01-M2

MECHATROLINK-II

communication

error

NETC01-M2

ing

9 times

ing

7 times

C-ERR lit red

ERR lit re

LED status

C-DAT lit green

RS-485 communication

compatible product

7 times

Alarm

code

A1h EEPROM error

E3h

E4h

E6h

01h Unsupported command

02h

Between

NETC01-M2

and RS-485

communication

compatible product

MECHATROLINK-II

communication

error

AT lit green

C-ERR lit red

AT lit green

C-ERR lit red

03h

ing

7 times

ing

7 times

C-ERR lit red

− −

AT lit green

ing

7 times

40

Page 41

Troubleshooting and remedial actions

Alarm type System status Cause Remedial action

Communication switch

setting error

RS-485 communication

error

Network connection

product error

Command execution

condition error

Outside the range of

command data

Communication between

the

NETC01-M2

RS-485 communication

compatible product cannot

be performed.

Communication between

the

NETC01-M2

master station cannot be

performed.

and

and

The stored data of the

NETC01-M2

The transmission rate setting switch

(SW1) of RS-485 communication

was set outside the range (8 and

above).

The RS-485 communication error

has been detected three times

consecutively.

The "Communication (address

number)" parameter is outside the

setting range.

The command that was not

implemented was executed.

•The order (sequence) of the

command that has been sent is

not correct.

•The command not being

permitted in the current phase

was executed.

The data in the command was not

correct.

The power supply of the

NETC01-M2

communicating via RS-485

communication.

The setting of the SW1 of the

NETC01-M2

that of the transmission rate of

RS-485 communication compatible

product.

was damaged.

was shut o while

is not the same as

Initialize data using any of the

maintenance command,

MEXE02

Set the transmission rate

setting switch (SW1) to "7."

•Check the transmission rate of

•Check the connector or cable

Set either of "0: Disable" or "1:

Enable."

Re-examine the command

sending sequence of the master

station.

Re-examine the command data

content that the master station

sends.

Check the power supply of the

NETC01-M2

Check the setting of the switch.

or

OPX-2A

RS-485 communication.

of RS-485 communication.

.

.

Communication between

the

NETC01-M2

RS-485 communication

compatible product cannot

be performed.

and

The "Communication (address

number)" parameter is set to "0:

Disable."

The RS-485 communication

compatible product corresponding

to the "Communication (address

number)" parameter does not exist.

The communication of the RS-485

communication compatible

product was shut o while

communicating.

When the RS-485 communication

cable was connected incompletely