Page 1

Network converter EtherCAT compatible

NETC01-ECT

USER MANUAL

HM-60301

Thank you for purchasing an Oriental Motor product.

This manual describes product handling procedures and safety precautions.

•Please read it thoroughly to ensure safe operation.

•Always keep the manual where it is readily available.

Page 2

1 Safety precautions ................................................. 3

2 Overview of the product ...................................... 5

2-1 System conguration ...................................................5

2-2 What is EtherCAT? .........................................................5

3 Introduction ............................................................ 7

4 Preparation ............................................................. 8

4-1 Checking the product ..................................................8

4-2 Names and functions of parts ...................................8

5 Installation ............................................................10

5-1 Location for installation ............................................ 10

5-2 Installation method .................................................... 10

5-3 Installing and wiring in compliance with

EMC Directive ............................................................... 11

6 Connection ............................................................ 13

6-1 Connection example ................................................. 13

6-2 Connecting the power supply and

grounding the

6-3 Connecting the RS-485 communication

cable ................................................................................ 14

6-4 Connecting the EtherCAT communication

cable ................................................................................ 15

6-5 Connecting the data setter ..................................... 15

NETC01-ECT

............................... 13

7 Guidance................................................................16

8 Setting ....................................................................21

8-1 Transmission rate of RS-485 communication ... 21

8-2 Node address of EtherCAT ....................................... 21

9 Basic function .......................................................22

9-1 Remote I/O list.............................................................. 22

9-2 Remote register list ....................................................23

9-3 Remote monitor list ...................................................27

9-4 Objects of the

9-5 Read, write, save of parameters ............................. 33

9-6 Basic operating procedures ....................................34

NETC01-ECT

................................ 30

10 Specications of RS-485 communication ........37

10-1 Operation mode .......................................................... 37

10-2 RS-485 communication conguration ................ 37

10-3 RS-485 communication process and

scan time ........................................................................ 37

10-4 RS-485 communication status ...............................39

11 Troubleshooting................................................... 40

11-1 Alarms .............................................................................40

11-2 EtherCAT communication error ............................. 41

11-3 Warning .......................................................................... 41

11-4 Relationship with the RS-485 communication

compatible product ................................................... 42

12 Inspection ..............................................................43

13 General specications .........................................44

14 Operation using the

14-1 Overview of the

14-2 Names and functions of parts ................................ 46

14-3 How to read the display ............................................46

14-4

OPX-2A

14-5 Screen transitions .......................................................48

14-6 Monitor mode .............................................................. 50

14-7 Parameter mode ..........................................................51

14-8 Copy mode .................................................................... 52

error display ............................................... 47

OPX-2A

OPX-2A

............................ 45

........................................45

15 CoE communication area ...................................53

15-1 CoE communication area ......................................... 53

16 Accessories ............................................................ 61

2

▌

Page 3

1 Safety precautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through safe, correct use

of the product. Use the product only after carefully reading and fully understanding these instructions.

Handling the product without observing the instructions that accompany a "Warning" symbol may

result in serious injury or death.

Handling the product without observing the instructions that accompany a “Caution” symbol may result

in injury or property damage.

General

•Do not use the product in explosive or corrosive environments, in the presence of ammable gases, locations subjected to

splashing water, or near combustibles. This may cause re or injury.

•Assign qualied personnel the task of installing, wiring, operating/controlling, inspecting and troubleshooting the product.

Failure to do so my result in re, injury or damage to equipment.

Connection

•Keep the input power voltage of the

•For the power supply use a DC power supply with reinforced insulation on its primary and secondary sides. Failure to do so may

result in electric shock.

•Connect the cables securely according to the wiring diagram. Failure to do so may result in re.

•Do not forcibly bend, pull or pinch the cable. This may cause re. Applying stress to the connection area of the connectors may

cause damage to the product.

NETC01-ECT

within the specied range. Failure to do so may result in re.

Safety precautions

Operation

•Turn o the

and may cause injury or damage to equipment.

•When an alarm of the

equipment.

NETC01-ECT

power in the event of a power failure. Or the motor may suddenly start when the power is restored

NETC01-ECT

is generated, stop the motor. Failure to do so may result in re, injury or damage to

Repair, disassembly and modication

•Do not disassemble or modify the

branch or sales oce from which you purchased the product.

NETC01-ECT

. Doing so may cause injury. Refer all such internal inspections and repairs to the

General

•Do not use the

•Keep your ngers and objects out of the openings in the

NETC01-ECT

beyond its specications. This may cause injury or damage to equipment.

NETC01-ECT

. Failure to do so may result in re or injury.

Installation

•Install the

•Keep the area around the

•Leave nothing around the

NETC01-ECT

in an enclosure. Failure to do so may result in injury.

NETC01-ECT

NETC01-ECT

free of combustible materials. Failure to do so may result in re or a skin burn(s).

that would obstruct ventilation. Failure to do so may result in damage to equipment.

Connection

•The power supply connector (CN1), EtherCAT communication input port (ECAT IN), EtherCAT communication output port (ECAT

OUT), data edit connector (CN2) and RS-485 communication connector (CN6) of the

When grounding the positive terminal of the power supply, do not connect any equipment (PC, etc.) whose negative terminal is

grounded. Doing so may cause the

NETC01-ECT

and the equipment to short, damaging both.

NETC01-ECT

are not electrically insulated.

Operation

•Use the

•When operating the product, do so after making preparations that an emergency stop can be performed at any time. Failure to

•Set a suitable operation speed and acceleration/deceleration rate. Improper setting may cause loss of the motor synchronism

•Immediately when trouble has occurred, stop running and turn o the

NETC01-ECT

do may result in injury.

and moving the load to an unexpected direction, which may result in injury or damage to equipment.

injury.

in combination with the designated applicable product. Failure to do so may result in re.

NETC01-ECT

power. Failure to do so may result in re or

3

▐

Page 4

Safety precautions

•Static electricity may cause the

is input. Always use an insulated screwdriver to adjust the switches of the

NETC01-ECT

to malfunction or suer damage. Do not touch the

NETC01-ECT

.

Disposal

•To dispose of the

components as industrial waste. Contact your nearest Oriental Motor oce if you have any questions.

NETC01-ECT

, disassemble it into parts and components as much as possible and dispose of individual parts/

NETC01-ECT

while the power

4

▌

Page 5

2 Overview of the product

Overview of the product

The

NETC01-ECT

By converting the EtherCAT communication protocol of the upper level to the RS-485 communication protocol of the lower

level, Oriental Motor RS-485 communication compatible products can be operated via EtherCAT communication. The RS-485

communication protocol of the lower level is Oriental Motor's own RS-485 communication protocol.

Also, using a

When the

and

NETC01-ECT

is a communication converter between EtherCAT and RS-485 communication.

MEXE02

MEXE02

or accessory

is used, a communication cable for data setting software

. Be sure to purchase it.

OPX-2A

The NETC01-ECT

•For details about terms and explanations of EtherCAT communication, refer to the operating manual of the EtherCAT master

device.

•The

NETC01-ECT

perform synchronization control via EtherCAT communication.

is not compatible with the Distributed Clocks of the EtherCAT communication specications, so it cannot

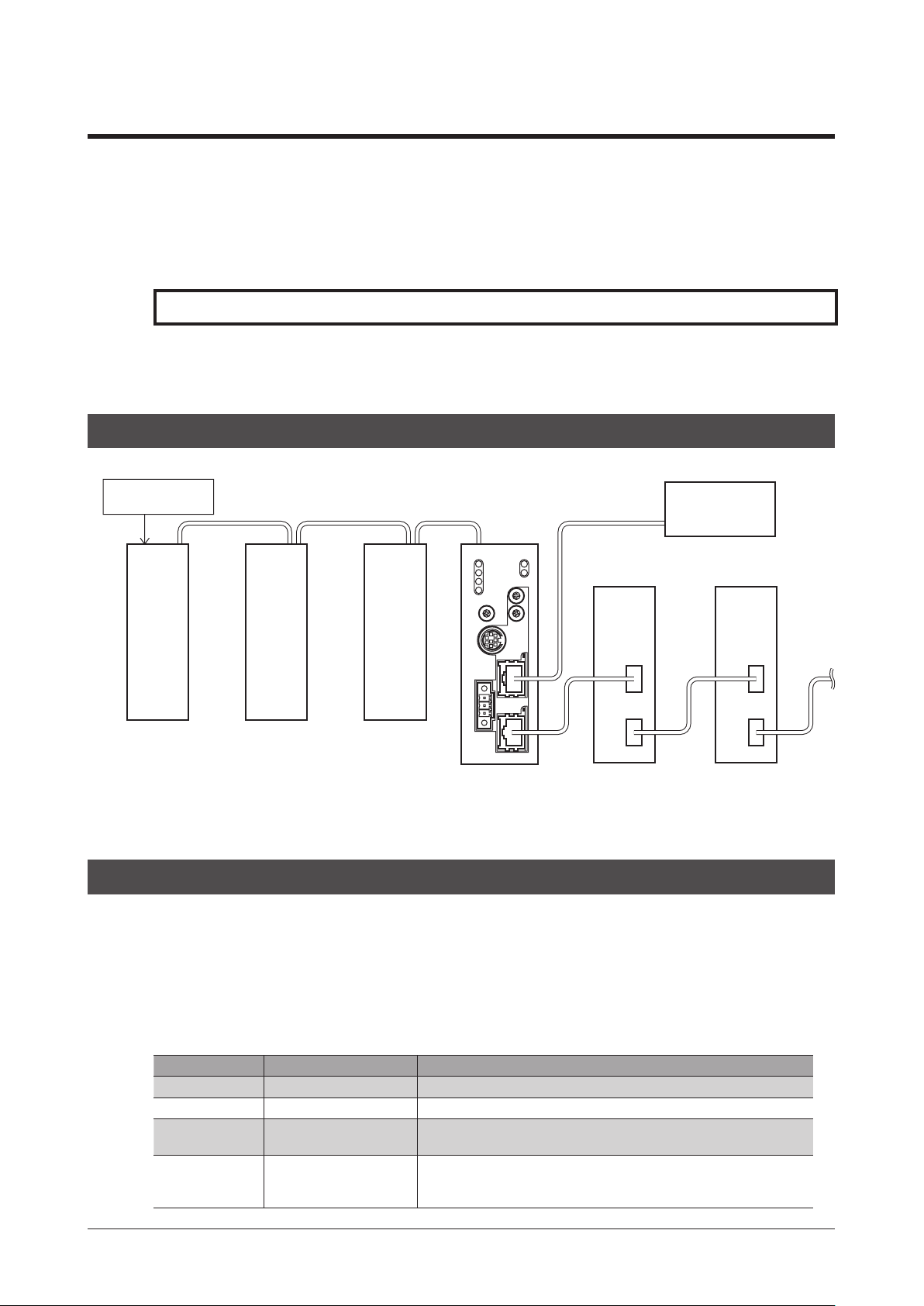

2-1 System conguration

Termination resistor

ON *

RS-485 communication

, the communication time can be monitored.

CC05IF-USB

(accessory) is needed to connect a PC

is operated as an I/O device on EtherCAT communication.

EtherCAT

communication

Master device

RS-485

communication

compatible product

RS-485

communication

compatible product

2-2 What is EtherCAT?

EtherCAT is an open and high-speed industrial network system that conforms to Ethernet (IEEE 802.3).

Since each node transmits Ethernet frames at high speed, it can achieve a short communication cycle time.

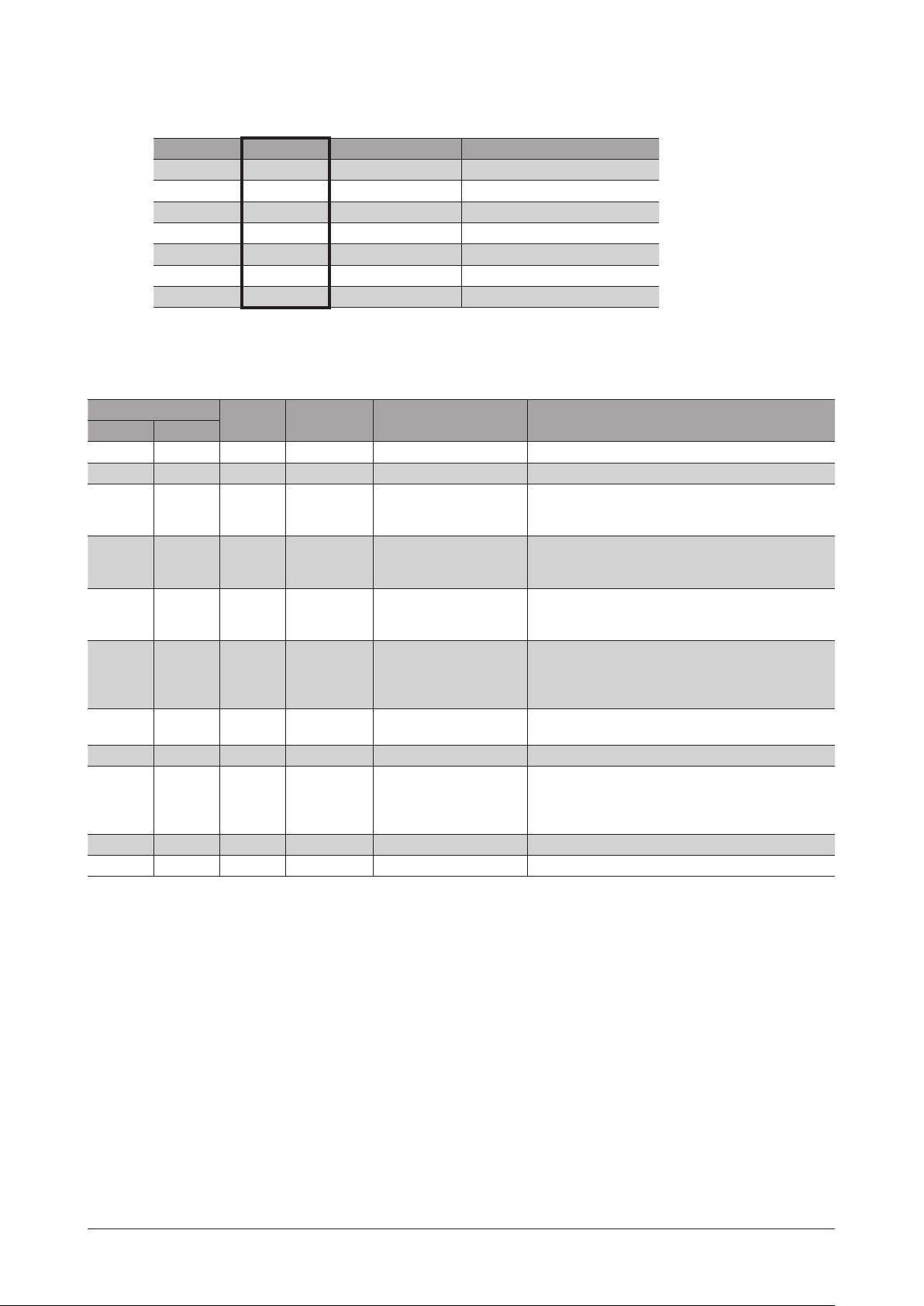

Object dictionary

The object dictionary consists of the data type objects, CoE communication objects, prole objects, and manufacturer-specic

objects.

The objects are assigned indexes of four-digit hexadecimal numbers and consisted of four areas described in the table below.

CoE Index Object dictionary area Description

0000h to 0FFFh Data type area Denition objects of data type.

1000h to 1FFFh CoE communications area Common area for devices to use CoE protocol.

2000h to 5FFFh Manufacturer-specic area

6000h to FFFFh Prole area

RS-485

communication

compatible product

Specic objects for devices that can be assigned freely by manufacturer.

The

Objects dened by each prole.

Example: CiA402 drive protocol, etc.

The

NETC01-ECT

* The termination resistor for RS-485 communication is built into the product.

NETC01-ECT

NETC01-ECT

uses this area.

does not use this area.

EtherCAT

communication

compatible product

EtherCAT

communication

compatible product

5

▐

Page 6

Overview of the product

zAbout description of the type

The type represents the data type of objects. Abbreviations described in the table below are used in this manual.

Data type Abbreviation Description Range of value

Integer8 INT8 8-bit signed data

Integer16 INT16 16-bit signed data

Integer32 INT32 32-bit signed data

Unsigned8 U8 8-bit unsigned data 0 to 255

Unsigned16 U16 16-bit unsigned data 0 to 65,535

Unsigned32 U32 32-bit unsigned data 0 to 4,294,967,295

VisibleString STRING Character string

Manufacturer-specic area list

128 to 127

−

32,768 to 32,767

−

2,147,483,648 to 2,147,483,647

−

−

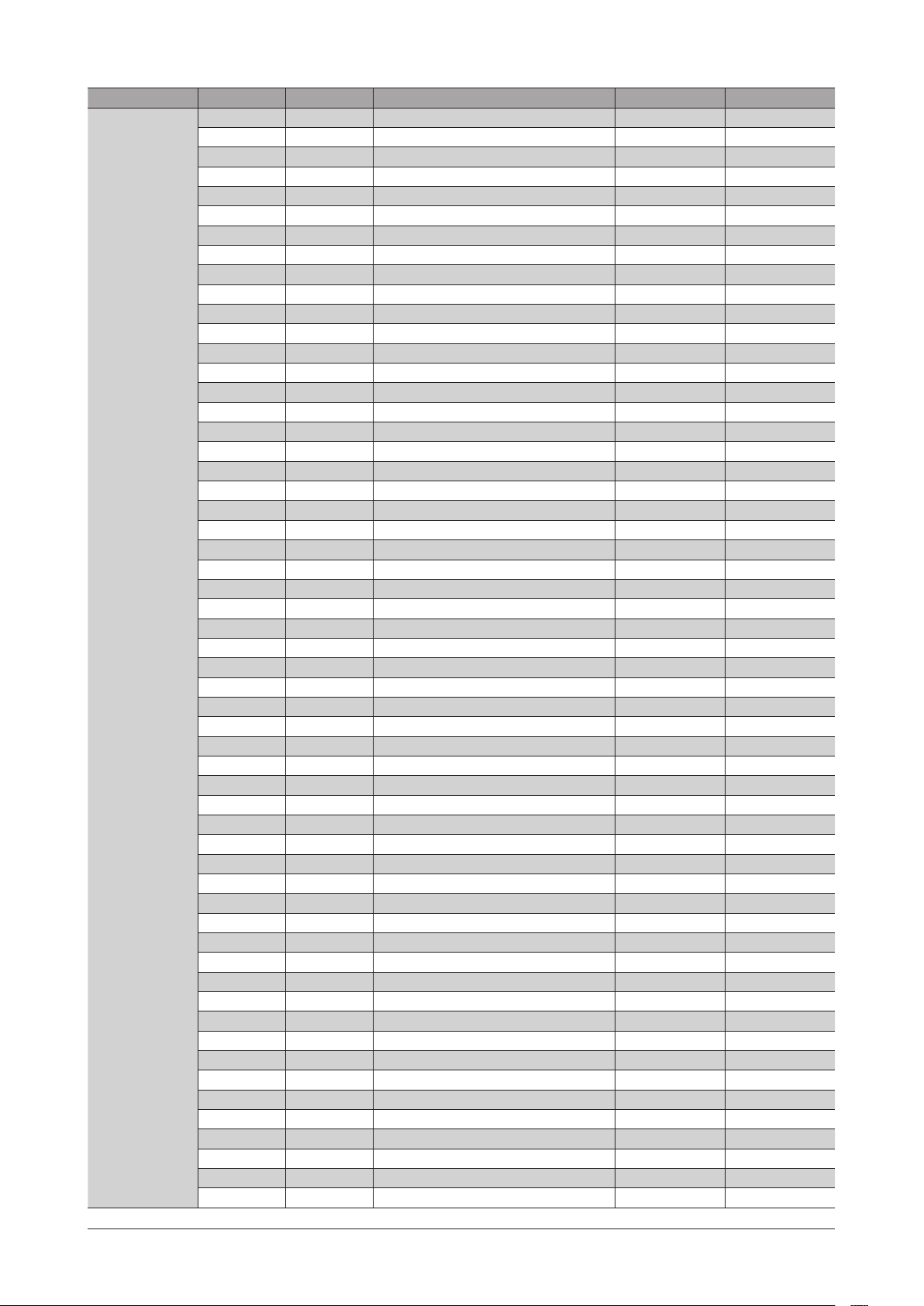

Objects used in the

CoE Index

Start End

2000h 21FFh

2200h 23FFh

2400h 25FFh

2600h 27FFh

2800h 29FFh

2A00h 2BFFh

2C00h 2FFFh

3000h 3BFFh

3C00h 3FFFh

4000h 4FFFh

5000h 5FFFh

NETC01-ECT

Sub-

index

PDO possible/

not possible

− −

− −

−

−

−

−

−

− −

−

− −

− −

are composed as follows.

Area name Description

Reserve This is a reserved area.

Reserve This is a reserved area.

Possible Remote I/O (IN)

Possible Remote I/O (OUT)

Possible Remote register *

Possible Remote monitor *

Possible

Possible

NETC01-ECT

(RW) *

Reserve This is a reserved area.

NETC01-ECT

maintenance (W) *

Reserve This is a reserved area.

Reserve This is a reserved area.

parameter

monitor (R),

This is an input area (

remote I/O. This area is used by NET-OUT of the RS-485

communication compatible product.

This is an output area (Master ->

remote I/O. This area is used by NET-IN of the RS-485

communication compatible product.

This is an area for mapping the remote register area to

the PDO to access the register. There are objects for each

address number.

This is an area for mapping the remote monitor

area to the PDO to monitor the status of the RS-485

communication compatible product. Multiple monitors

can be performed to the same address number.

This is an area (Read/Write) for accessing to parameters

of the

NETC01-ECT

This is an access area for performing monitor and

maintenance of the

command is executed by Read, and the maintenance

command is executed by Write.

NETC01-ECT

.

NETC01-ECT

-> Master) of

NETC01-ECT

. The monitor

) of

* You can access by the SDO when not mapping to the PDO.

Providing the ESI File

The ESI le (EtherCAT Slave Information le) is the one that describes the specic information of the EtherCAT slave products in XML

format. By importing the ESI le to the EtherCAT Congration Tool of the PLC (programmable controller), the settings of EtherCAT

communication can be performed before you receive the

The ESI le can be downloaded from Oriental Motor Website Download Page.

6

▌

NETC01-ECT

.

Page 7

3 Introduction

Before use

Only qualied personnel should work with the product.

Use the product correctly after thoroughly reading the section "1 Safety precautions" on p.8.

The product described in this manual has been designed and manufactured to be incorporated in general industrial equipment.

Do not use for any other purpose. For the power supply of the

its primary and secondary sides. Oriental Motor Co., Ltd. is not responsible for any damage caused through failure to observe this

warning.

NETC01-ECT

Introduction

, use a DC power supply with reinforced insulation on

Operating Manuals for the

Operating manuals for the

After reading the following manuals, keep them in a convenient place so that you can reference them at any time.

zNetwork converter EtherCAT compatible

This manual explains the function, installation and connection of the

For the command code or remote I/O of the RS-485 communication compatible product that can be connected to the

, refer to the USER MANUAL or Function Edition of the corresponding RS-485 communication compatible product.

ECT

The OPERATING MANUAL and Function Edition does not come with the product. For details, contact your nearest Oriental Motor

sales oce or download from Oriental Motor Website Download Page.

zNetwork converter EtherCAT compatible

NETC01-ECT

NETC01-ECT

are listed below.

NETC01-ECT

NETC01-ECT

USER MANUAL (this document)

NETC01-ECT

as well as operating method.

OPERATING MANUAL

NETC01-

(Supplied with the product)

This manual explains safety precautions, connector pin assignments and others.

zData setting software

This manual explains the parameter setting method and monitor function using the

MEXE02

OPERATING MANUAL

MEXE02

.

Notation on operating manual

The items under this heading contain important handling instructions that the user should observe to ensure

safe use of the product.

The items under this heading contain related information and contents to gain a further understanding of the

text in this manual.

CE Marking

Although this product is exempt from the Low Voltage Directive since the input power supply voltage is 24 VDC, perform the

installation and connection as follows.

•This product is designed and manufactured to be incorporated in equipment. Install the product in an enclosure.

•For the power supply of the

•Overvoltage category: I

•Pollution degree: 2

•Degree of protection: IP20

NETC01-ECT

, use a DC power supply with reinforced insulation on its primary and secondary sides.

zEMC Directive

This product has received EMC compliance under the conditions specied in "Example of installation and wiring for the NETC01-ECT"

on p.12.

Since the conformity to the EMC Directive of the customer's equipment will vary depending on such factors as other control-system

devices used together with the

the customer must verify through EMC measurements of the nished equipment after installing all parts including the

.

ECT

NETC01-ECT

, as well as conguration of electrical components, wiring, and installation condition,

NETC01-

Applicable standards

EMI: EN 61000-6-4, EN 55011 group 1 class A

EMS: EN 61000-6-2

Hazardous substances

The products do not contain the substances exceeding the restriction values of RoHS Directive (2011/65/EU).

7

▐

Page 8

Preparation

4 Preparation

This chapter explains the items you should check, as well as the name and function of each part.

4-1 Checking the product

Verify that the items listed below are included. Report any missing or damaged items to the branch or sales oce from which you

purchased the product.

Verify the model number of the purchased product against the number shown on the package label.

NETC01-ECT

•

•CN1 connector (3 pins) .......................1 pc.

•RS-485 communication cable ..........2 pcs. [0.1 m (3.94 in.), 0.25 m (9.84 in.) each 1 pc.]

•OPERATING MANUAL........................... 1 copy

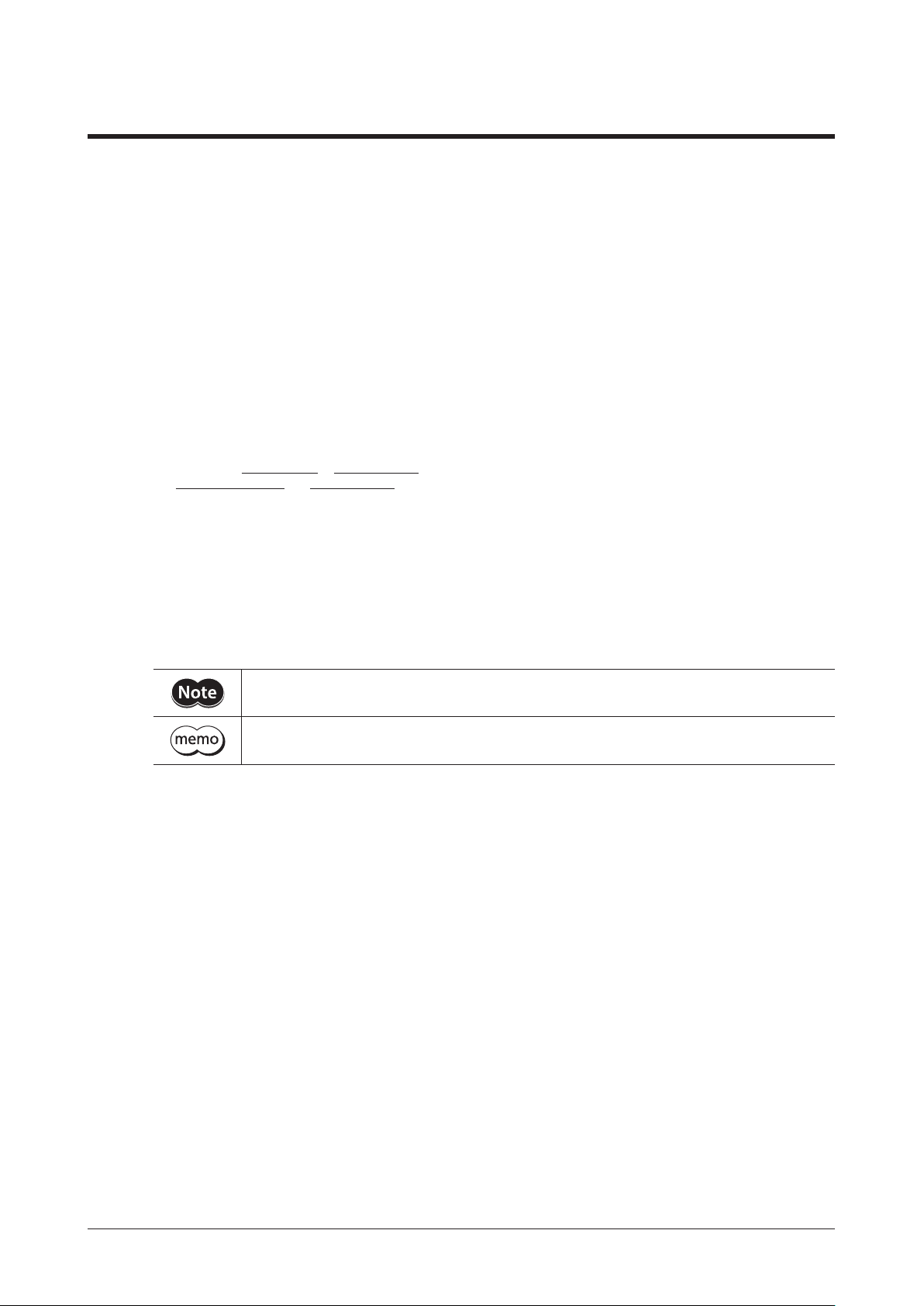

4-2 Names and functions of parts

....................................... 1 unit

RS-485

communication

Connect the RS-485

POWER LED (Green)

ALARM LED (Red)

C-DAT LED (Green)

C-ERR LED (Red)

RS-485 communication transmission

rate setting switch (SW1)

Data edit connector

(CN2)

Power supply input connector

(CN1)

RUN LED (Green)

ERR LED (Red)

Node address setting switches

(ECAT ID ×1, ×10)

L/A LED (Green)

EtherCAT communication input port

(ECAT IN)

L/A LED (Green)

EtherCAT communication output port

(ECAT OUT)

DIN lever

connector (CN6)

communication cable.

8

▌

Page 9

Preparation

Name Description Page

POWER LED (Green) This LED is lit while the power is input.

ALARM LED (Red)

C-DAT LED (Green)

C-ERR LED (Red) This LED is lit when an error was occurred via RS-485 communication.

RUN LED (Green)

ERR LED (Red)

L/A LED (Green)

Power supply connector (CN1) Connects a 24 VDC power supply. p.13

Data edit connector (CN2)

EtherCAT communication input port

(ECAT IN)

EtherCAT communication output port

(ECAT OUT)

RS-485 communication transmission

rate setting switch (SW1)

Node address setting switched

(ECAT ID ×1, ×10)

This LED blinks when an alarm generates. It is possible to check the

generated alarm by counting the number of times the LED blinks.

This LED is lit while transmitting and receiving data via RS-485

communication.

These LEDs indicate the status of EtherCAT communication. p.41

Connects a PC in which the

.

OPX-2A

This is a connector to perform EtherCAT communication. Connect to the

master device.

This is a connector to perform EtherCAT communication. Connect to the

following slave.

Sets the transmission rate of RS-485 communication.

Factory setting: 7

Sets the node address of the EtherCAT communication in the 0 to 255 (00h

to FFh) range.

10: Set the upper

×

1: Set the lower

×

Factory setting: 1 (×10: 0, ×1: 1)

MEXE02

has been installed, or an accessory

−

p.40

−

−

p.15

p.15

p.15

p.14

p.21

9

▐

Page 10

Installation

5 Installation

This chapter explains the installation location and installation method of the

The installation and wiring methods in compliance with the EMC Directive are also explained.

5-1 Location for installation

The

NETC01-ECT

that provides easy access for inspection. The location must also satisfy the following conditions:

•Inside an enclosure that is installed indoors (provide vent holes)

•Operating ambient temperature 0 to +40 °C (+32 to +104 °F) (non-freezing)

•Operating ambient humidity 85% or less (non-condensing)

•Area that is free of explosive atmosphere or toxic gas (such as sulfuric gas) or liquid

•Area not exposed to direct sun

•Area free of excessive amount of dust, iron particles or the like

•Area not subject to splashing water (rain, water droplets), oil (oil droplets) or other liquids

•Area free of excessive salt

•Area not subject to continuous vibration or excessive shocks

•Area free of excessive electromagnetic noise (from welders, power machinery, etc.)

•Area free of radioactive materials, magnetic elds or vacuum

•1000 m (3300 ft.) or lower above sea level

has been designed and manufactured to be incorporated in equipment. Install it in a well-ventilated location

5-2 Installation method

Install the

There must be a clearance of at least 50 mm (1.97 in.) in the horizontal and

vertical directions, between the

equipment within the enclosure.

When installing two or more units of the

to install them closely in the horizontal direction. Provide a minimum clearance

of 50 mm (1.97 in.) in the vertical direction.

NETC01-ECT

Be sure to install the

the

NETC01-ECT

position, its heat radiation eect will deteriorate.

to a 35 mm (1.38 in.) width DIN rail.

NETC01-ECT

NETC01-ECT

NETC01-ECT

is installed in the direction other than vertical

and enclosure or other

in parallel, it is possible

vertically (vertical position). If

NETC01-ECT

.

50 mm (1.97 in.)

or more

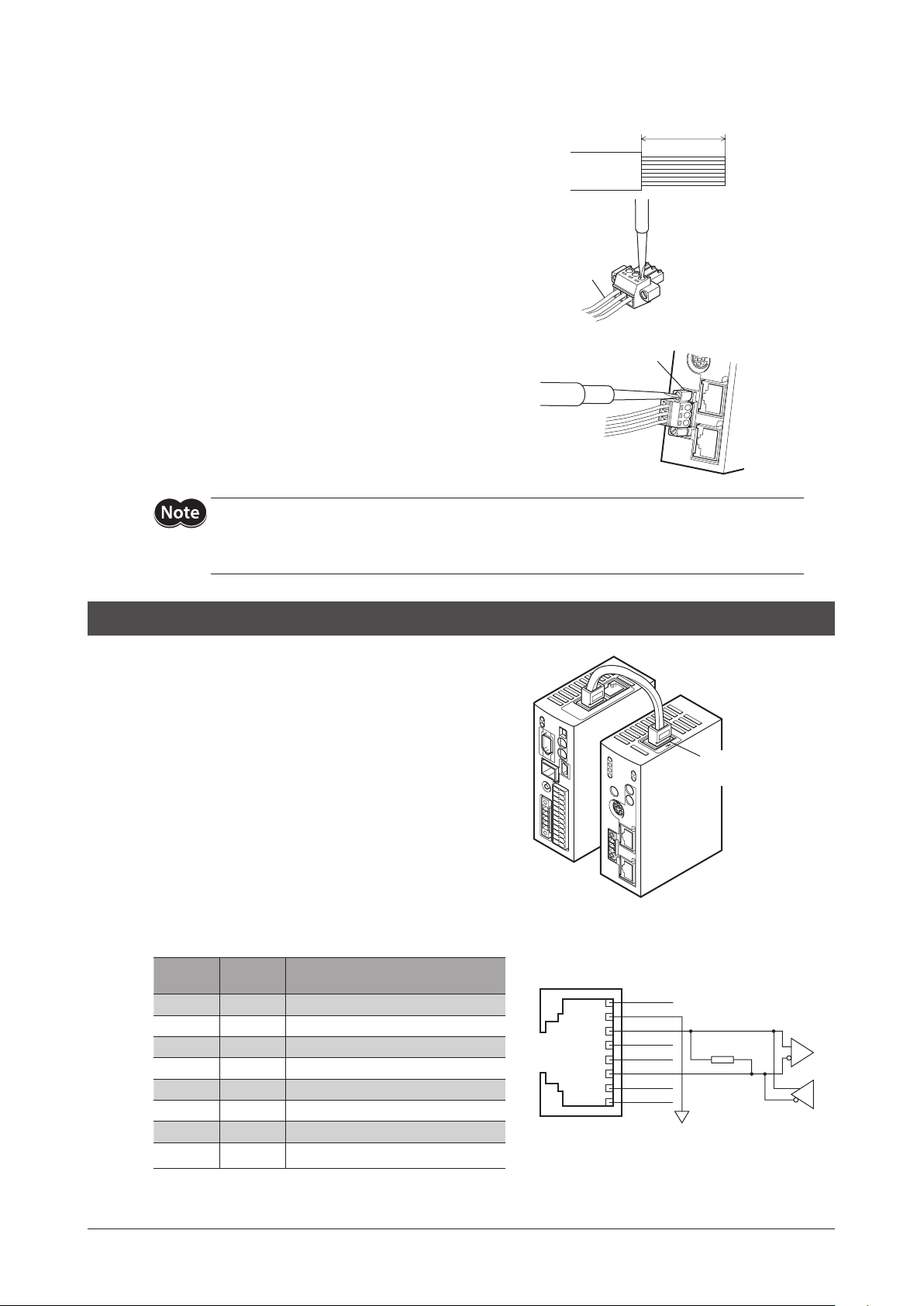

zMounting to DIN rail

1. Pull down the DIN lever of the

2. Hold the

3. Secure both sides of the

DIN rail

NETC01-ECT

Hook

to the DIN rail, and push up the DIN lever to secure.

NETC01-ECT

DIN lever

NETC01-ECT

using end plates.

and lock it. Hang the hook at the rear to the DIN rail.

DIN rail

DIN lever

50 mm (1.97 in.)

or more

End plate

10

▌

Page 11

zRemoving from DIN rail

Pull the DIN lever down until it locks using a at tip screwdriver, and lift

the bottom of the

Use force of about 10 to 20 N (2.2 to 4.5 lb.) to pull the DIN lever to lock

it. Excessive force may damage the DIN lever.

NETC01-ECT

to remove it from the rail.

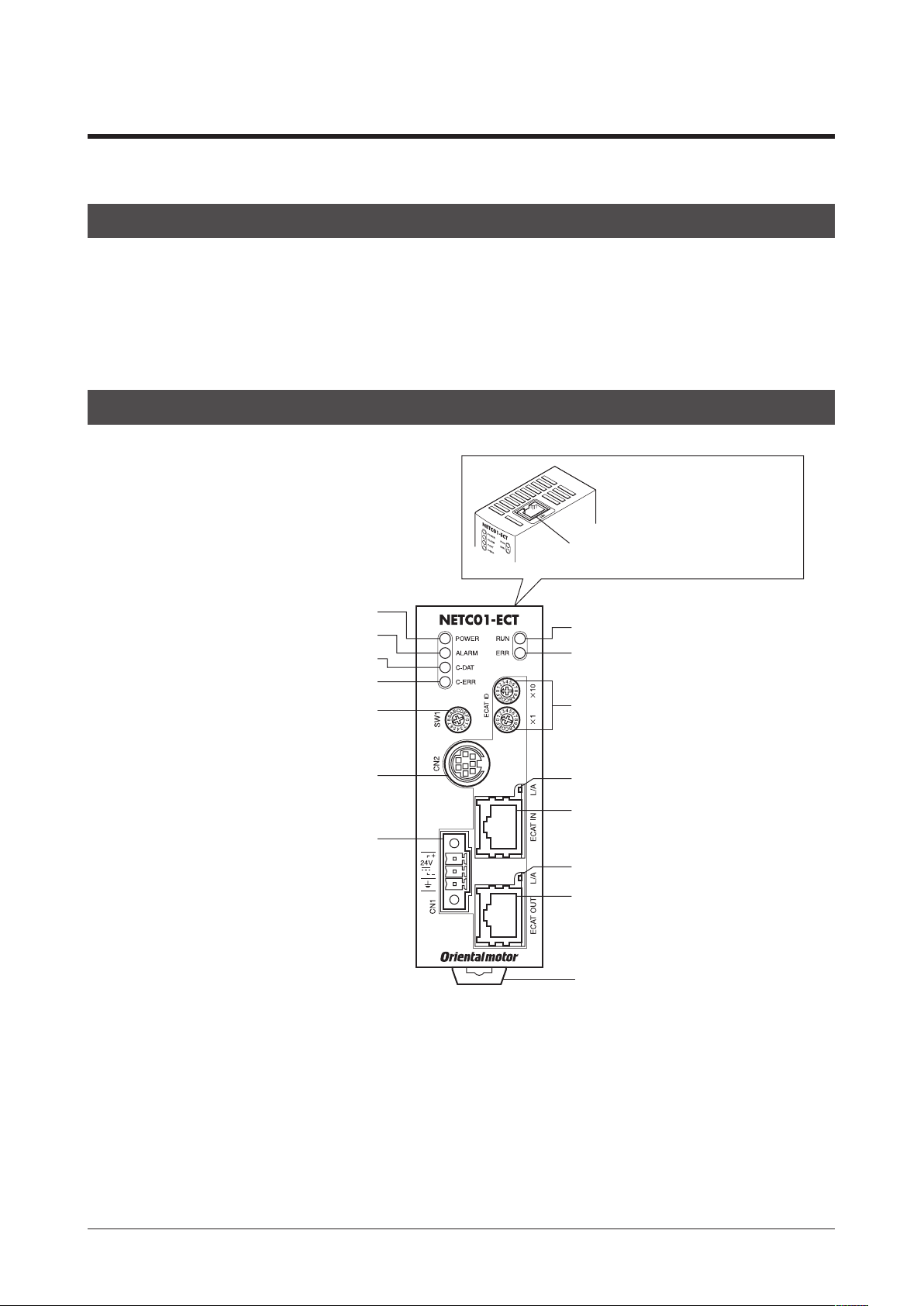

5-3 Installing and wiring in compliance with EMC Directive

Installation

Eective measures must be taken against the EMI that the

the EMS of the

installation and wiring methods will enable the

for the applicable standards.

Oriental Motor conducts EMC measurements on the

NETC01-ECT" on p.12. The user is responsible for ensuring the machine’s compliance with the EMC Directive, based on the installation

and wiring explained below.

NETC01-ECT

itself, in order to prevent a serious functional impediment in the machinery. The use of the following

NETC01-ECT

NETC01-ECT

to be compliant with the EMC directive. Refer to "CE Marking" on p.7

NETC01-ECT

may give to adjacent control-system equipment, as well as

in accordance with "Example of installation and wiring for the

Power supply

This network converter is a product of DC power supply input.

Use a DC power supply (switching power supply etc.) that conforms to the EMC Directive.

Noise lter

•Connect a noise lter to the input side of the DC power supply in order to prevent the noise generated in the

propagating externally through the power supply line.

•When using a power supply transformer, be sure to connect a noise lter to the AC input side of the power supply transformer.

•For a noise lter, use HF2010A-UPF (SOSHIN ELECTRIC CO.,LTD), FN2070-10-06 (Schaner EMC) or equivalent product.

•Install the noise lter as close to the AC input terminal of DC power supply as possible. Use cable clamps and other means to

secure the AC input cables (AWG18: 0.75 mm2 or more) and output cables (AWG18: 0.75 mm2 or more) rmly to the surface of the

enclosure.

•Connect the ground terminal of the noise lter to the grounding point, using as thick and short a wire as possible.

•Do not place the AC input cable parallel with the noise lter output cable. Parallel placement will reduce noise lter eectiveness

if the enclosure's internal noise is directly coupled to the power supply cable by means of stray capacitance.

NETC01-ECT

from

How to ground

The cable used to ground the

generated. Choose a large, thick and uniformly conductive surface for the grounding point.

NETC01-ECT

and noise lter must be as thick and short as possible so that no potential dierence is

Wiring the power supply cable and I/O signal cable

•Use a shielded cable of AWG22 (0.3 mm2) or more for the power supply cable of the

possible.

•To ground the power supply cable, use a metal cable clamp or similar device

that will maintain contact with the entire circumference of the cable. Attach

a cable clamp as close to the end of the cable as possible, and connect it as

shown in the gure.

Shielded cable

NETC01-ECT

, and keep it as short as

Cable clamp

Notes about installation and wiring

•Connect the

dierence from developing between grounds.

•When relays or electromagnetic switches are used together with the system, use noise lters and CR circuits to suppress surges

generated by them.

•Keep cables as short as possible without coiling and bundling extra lengths.

•Place the power cables such as the power supply cables as far apart [100 to 200 mm (3.94 to 7.87 in.)] as possible from the signal

cables. If the power cables and signal cables have to cross, cross them at a right angle. Place the AC input cable and output cable

of a noise lter separately from each other.

NETC01-ECT

and other peripheral control equipment directly to the grounding point so as to prevent a potential

11

▐

Page 12

Installation

OPX-2A

Example of installation and wiring for the

RS-485 communication cable

RS-485 communication

compatible product

Noise

DC power

AC

lter

supply

PEPE

Power supply cable

(Shielded cable)

Ground panel

FG

NETC01-ECT

FG

FG

NETC01-ECT

Shielded cable

EtherCAT communication

cable (Shielded cable)

FG

Master device

Precautions about static electricity

Static electricity may cause the

the

NETC01-ECT

Always use an insulated screwdriver to change the switches of the

with care and do not come near or touch the

The NETC01-ECT uses parts that are sensitive to electrostatic charge. Before touching the NETC01ECT, turn off the power to prevent electrostatic charge from generating. If an electrostatic charge is

impressed on the NETC01-ECT, the NETC01-ECT may be damaged.

NETC01-ECT

to malfunction or suer damage. While the

NETC01-ECT

NETC01-ECT

.

.

NETC01-ECT

is receiving power, handle

12

▌

Page 13

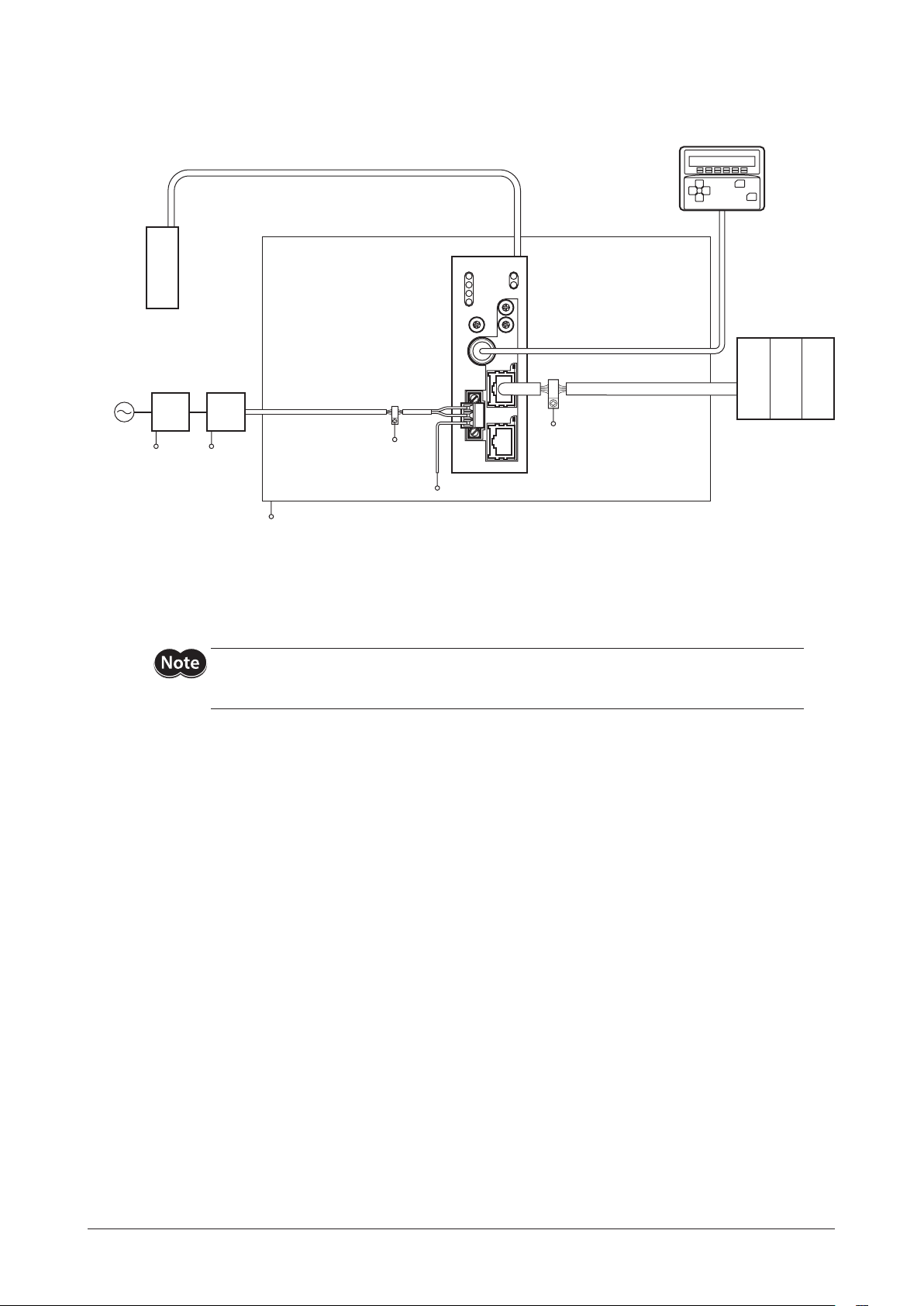

6 Connection

RS-485 communication

Connection

This chapter explains the connection method of the

grounding method.

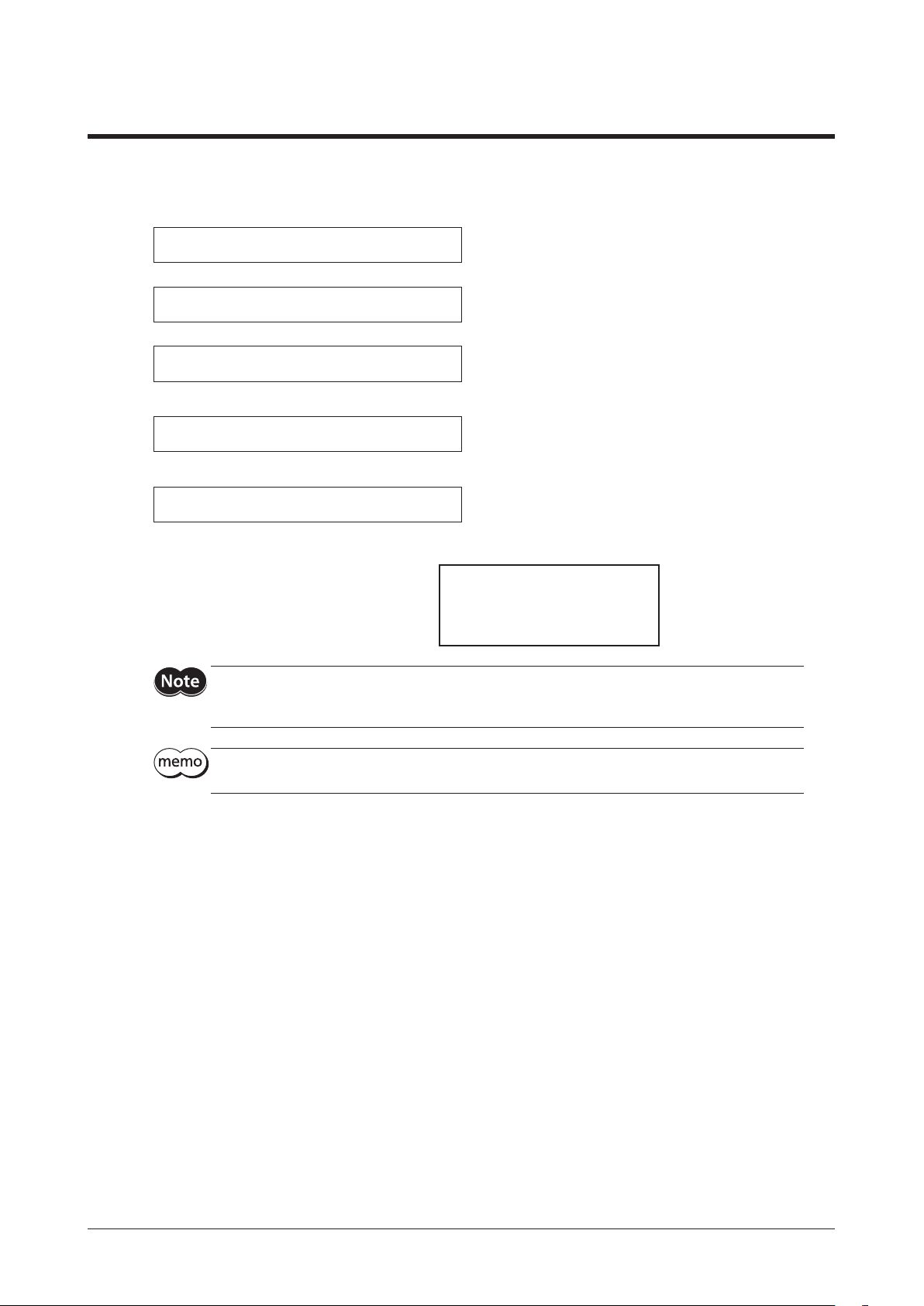

6-1 Connection example

OPX-2A MEXE02

Or

Data edit connector (CN2)

Power supply connector (CN1)

24 VDC

GND

NETC01-ECT

connector (CN6)

and power supply/communication cable, as well as the

RS-485 communication cable

ECAT IN

EtherCAT communication cable

FG

6-2 Connecting the power supply and grounding the

Connecting the power supply

Connect the power supply cable (AWG22: 0.3 mm2) to the power supply connector (CN1) of the

CN1 connector (3 pins).

Grounding the

Ground the Frame Ground terminal (FG) of the

Ground using a wire of AWG24 to 16 (0.2 to 1.25 mm2), and do not share the protective earth terminal with a welder or any other

power equipment.

CN1 connector pin assignments

Pin No. Name Description

1 + +24 VDC±10% 0.2 A or more

2

3

NETC01-ECT

Power supply GND

−

Frame Ground

NETC01-ECT

as necessary.

CN1 connector (supplied)

24 VDC

GND

NETC01-ECT

NETC01-ECT

using the supplied

FG

Power supply connector (CN1)

13

▐

Page 14

Connection

7 mm (0.28 in.)

Power supply input

Connecting method

1. Strip the insulation cover of the lead wire by 7 mm (0.28 in.)

2. Insert each lead wire into the CN1 connector and tighten the screw

using a screwdriver (connector screw size: M2).

Tightening torque: 0.22 to 0.25 N·m (31 to 35 oz-in)

Flap tip screwdriver

Lead wire

CN1 connector

3. Insert the CN1 connector into power supply connector (CN1) and

tighten the screws using a screwdriver (connector screw size: M2.5).

Tightening torque: 0.4 N·m (56 oz-in)

•When connecting, pay attention to the polarity of the power supply. Reverse-polarity connection may cause

damage to the

•Do not wire the power supply cable of the

so may cause malfunction due to noise.

NETC01-ECT

.

NETC01-ECT

in the same cable duct with other power lines. Doing

connector (CN1)

6-3 Connecting the RS-485 communication cable

Connect the

compatible product using the supplied RS-485

communication cable.

Connect the RS-485 communication cable to RS485 communication connector (CN6). Since RS-485

communication cables of two lengths are supplied, use

either one of the two.

You can also use a commercial LAN cable (shielded straight

cable) to link drivers.

NETC01-ECT

and RS-485 communication

RS-485 communication

connector (CN6)

14

▌

CN6 connector pin assignments

Pin No.

1 N.C. Not used (Do not connect anything.)

2 GND GND

3 TR+ RS-485 communication signal (+)

4 N.C. Not used

5 N.C. Not used

6 TR− RS-485 communication signal (−)

7 N.C. Not used

8 N.C. Not used

Signal

name

Description

RS-485 communication

compatible product

NETC01-ECT

•

* The GND line is used in common with CN1 (not insulated)

NETC01-ECT

internal circuit and termination resistor

1 N.C.

2 GND

3 TR+

4 N.C.

5 N.C.

6 TR

7 N.C.

8 N.C.

-

120 Ω

0 V *

Page 15

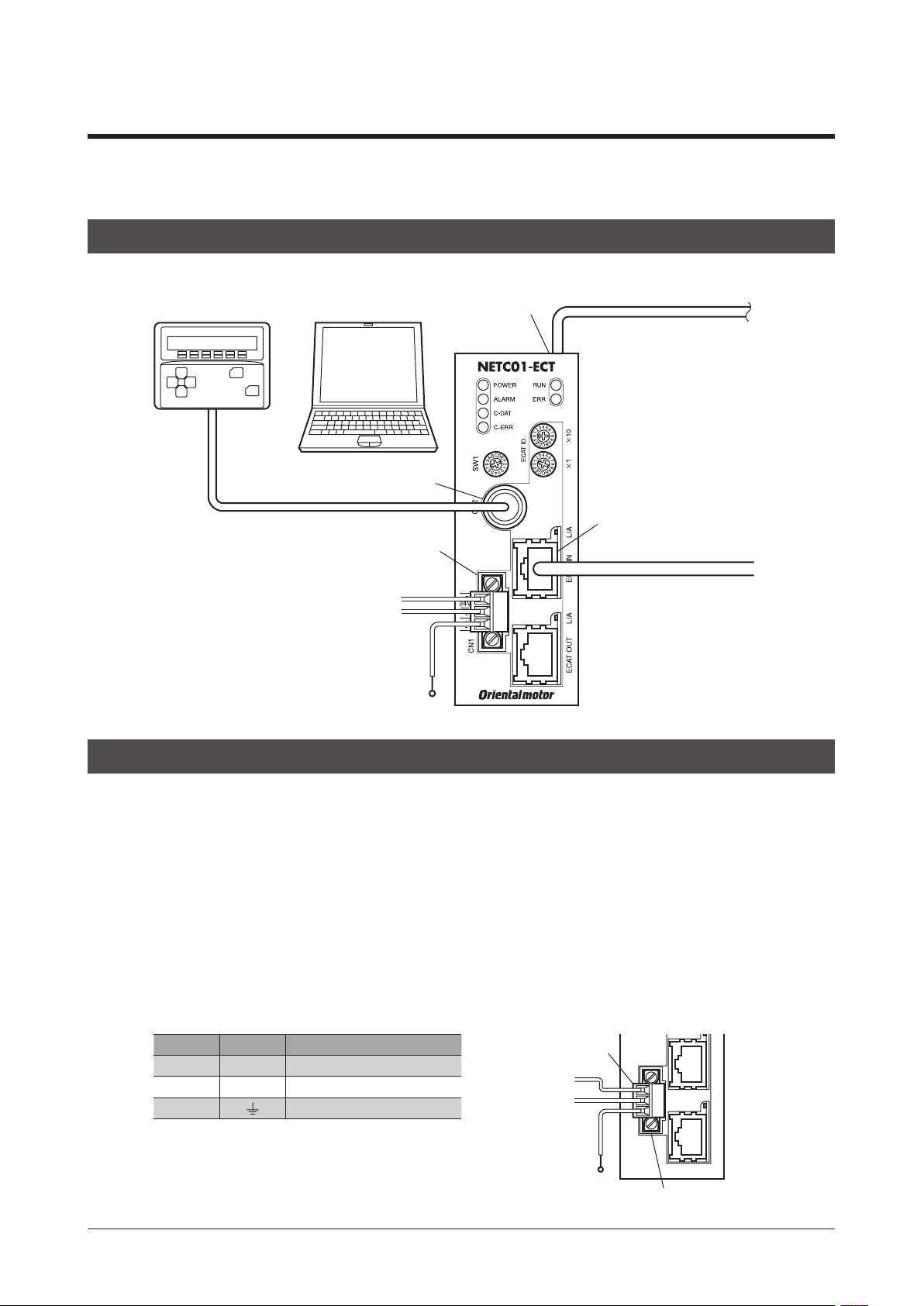

6-4 Connecting the EtherCAT communication cable

NETC01-ECT NETC01-ECT

Connection

Connect the master device and the ECAT IN on the

ECAT IN

EtherCAT

communication

cable *

ECAT OUT

Communication cannot be performed in a wrong connection. When connecting among the

be sure to connect from the ECAT OUT to the ECAT IN.

6-5 Connecting the data setter

Connect the

setting software to the data edit connector (CN2) on the

.

ECT

cable or communication cable for the data

OPX-2A

NETC01-ECT

* Keep the length of the EtherCAT communication cable to 100 m (330 ft.) or less.

NETC01-

using the EtherCAT communication cable.

Master device

ECAT IN

EtherCAT

communication

cable *

ECAT OUT

Data edit connector (CN2)

NETC01-ECT

units,

Cable for OPX-2A or communication

cable for the data setting software

The power supply connector (CN1), EtherCAT communication input port (ECAT IN), EtherCAT communication

output port (ECAT OUT), data edit connector (CN2) and RS-485 communication connector (CN6) of the

NETC01-ECT

do not connect any equipment (PC, etc.) whose negative terminal is grounded. Doing so may cause the

NETC01-ECT

are not electrically insulated. When grounding the positive terminal of the power supply,

and the equipment to short, damaging both.

15

▐

Page 16

Guidance

7 Guidance

If you are new to the

This chapter explains how to perform test operation via EtherCAT communication using the

Series built-in controller type as an example.

AZ

NETC01-ECT

, read this section to understand the operating methods along with the operation ow.

STEP1 Installation and connection

STEP2 Setting of

NETC01-ECT

Parameters are enabled after the power is cycled.

STEP3 Setting of driver

STEP4 Power cycle and check of LED

Parameters are enabled after the power is cycled.

STEP5 Operation of motor

zOperation condition

Here, the motor is supposed to be operated under the

following conditions.

NETC01-ECT

•

•Number of divers connected: One

•Driver address number: 0

•Driver termination resistor: Enabled

node address: 1

NETC01-ECT

in combination with the

•Before operating the motor, check the condition of the surrounding area to ensure safety.

•Before starting guidance, import the ESI le to the EtherCAT Conguration Tool of the PLC and register the PLC

conguration in advance. The ESI le can be downloaded from Oriental Motor Website Download Page.

The termination resistor for the

the termination resistor.

NETC01-ECT

is built into the product. This product can be used without setting

16

▌

Page 17

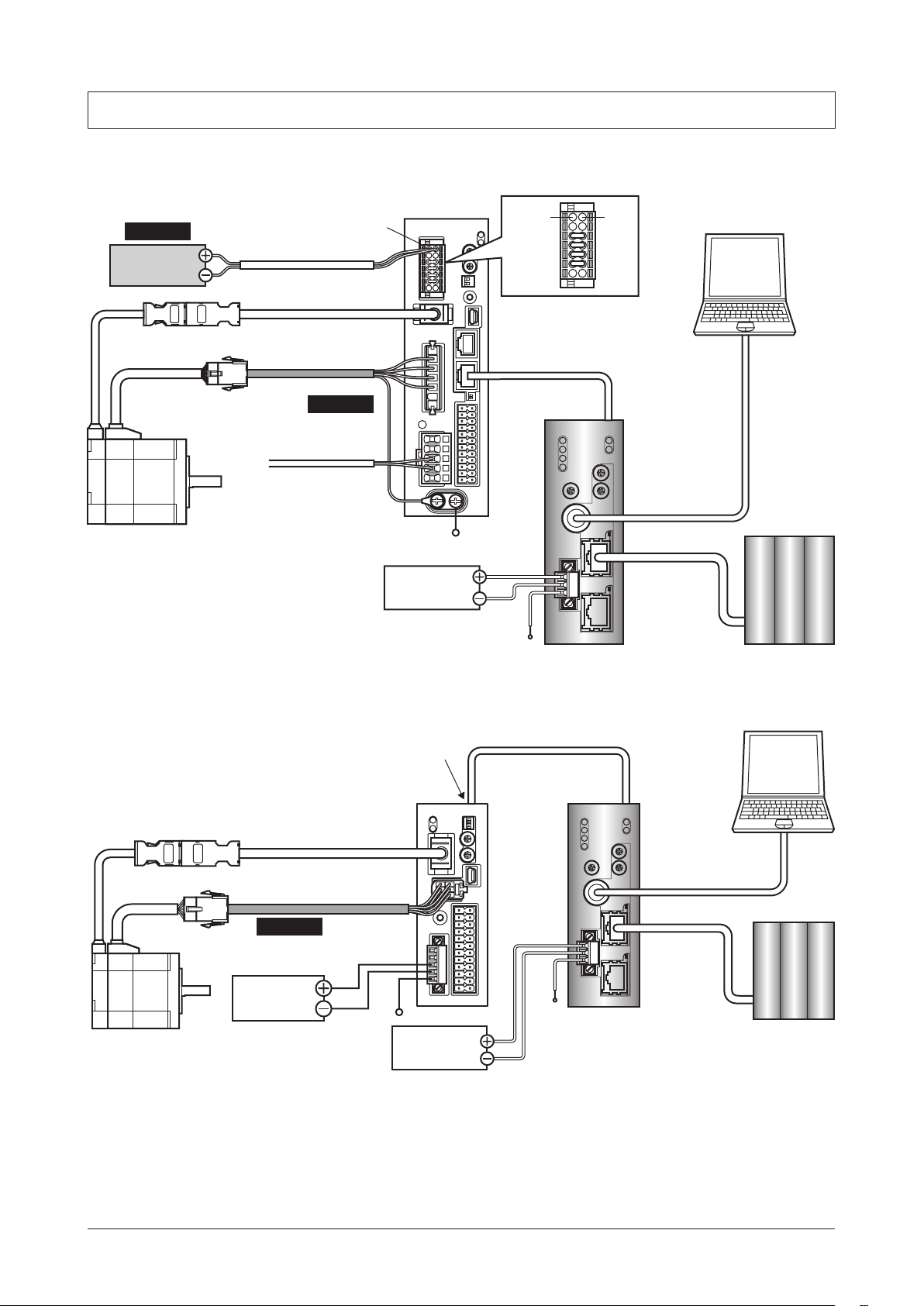

STEP 1 Check the installation and connection

AC power input driver

Guidance

*Necessary

24 VDC

power supply

CN1 connector

Connect to +24 V and 0 V

Connect to ENCODER

Cable for encoder

Connect to MOTOR

Cable for motor

*Necessary

Main power supply

Driver

PE

24 VDC

power supply

+24 V 0 V

Connect to CN6 or CN7

RS-485

communication

cable

FG

NETC01-ECT

Communication

cable for the data

setting software

Connect to CN2

EtherCAT

communication

cable

MEXE02 (PC)

Master device

DC power input driver

Cable for encoder

*Necessary

24 VDC

power supply

Connect to CN6 or CN7

Connect to CN3

Connect to CN2

Cable for motor

PE

24 VDC

power supply

RS-485 communication cable

Driver

FG

NETC01-ECT

Communication

cable for the data

setting software

Connect to CN2

EtherCAT

communication

cable

MEXE02 (PC)

Master device

17

▐

Page 18

Guidance

STEP 2 Set the parameters and switches of the

Set the parameters and switches of the

1. Turn on the power to the

At this time, since parameters and switches are not set, the ALARM LED will be lit.

Move on the next procedure, and set parameters and switches.

2. Start the

Select the

MEXE02

NETC01-ECT

NETC01-ECT

and set the parameters.

.

NETC01-ECT

.

.

NETC01-ECT

3. Set the "Connection (axis #)" parameter of the driver connected to the

The initial value in the "Connection (axis #0)" parameter is set to "Enable." When the connected driver is 1 unit and the address

number of the driver is "0," it is not required to set the "Connection (axis #)" parameter.

MEXE02

tree view Parameter name Description Initial value

Connection (axis #0) Enables the address number of the driver

connected to the

Setting range

Disable

Enable

System

Connection (axis #1)

to

Connection (axis #15)

NETC01-ECT

The initial value is "Enable."

NETC01-ECT

to "Enable" using the

.

Enable

Disable

MEXE02

.

18

▌

Page 19

Guidance

AC input driver

DC input driver

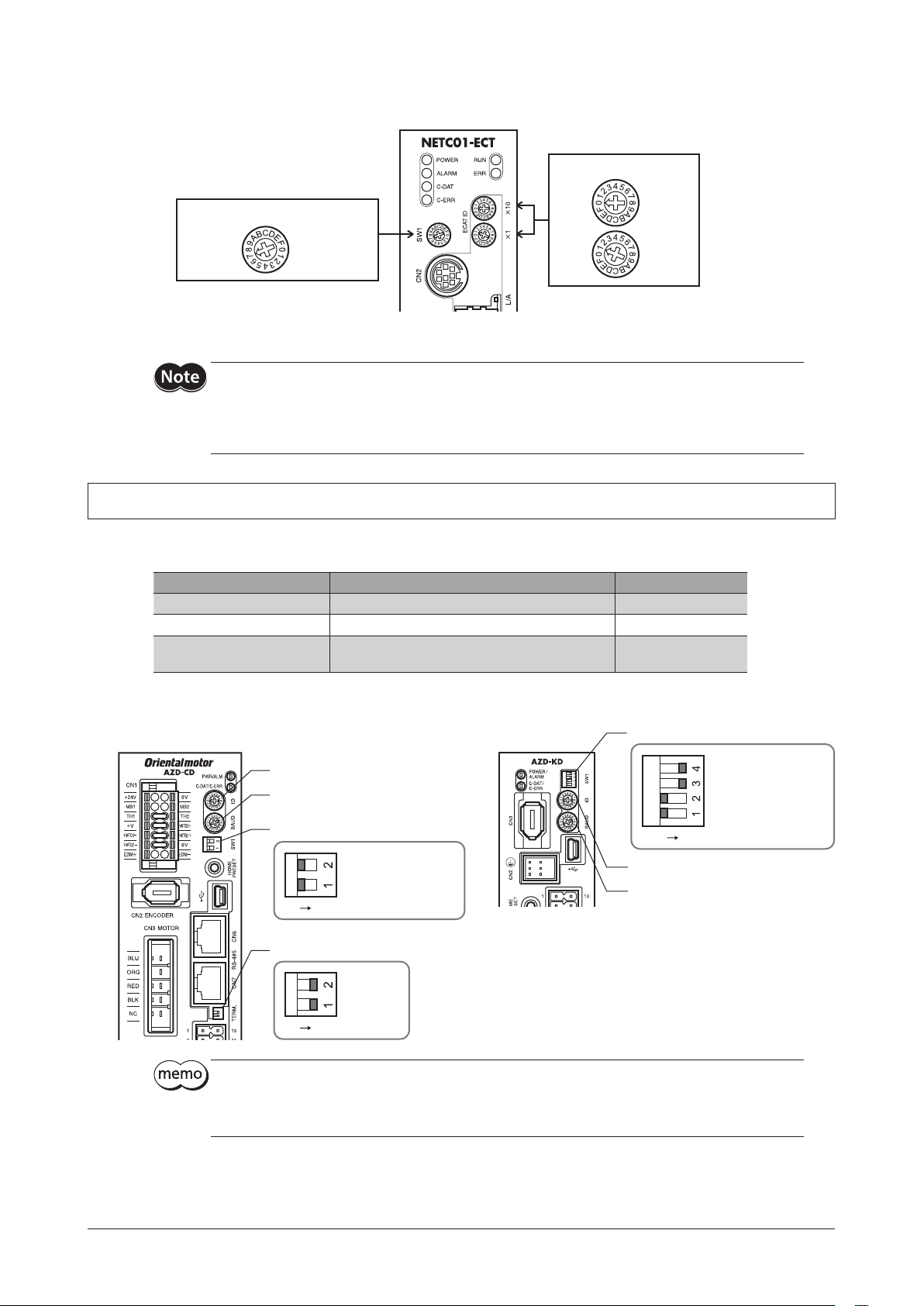

4. Set the switches of the

Set as the illustration below.

RS-485 transmission rate: 625 kbps

5. Turn o the

NETC01-ECT

•When multiple drivers are connected, set connection parameters as many as the drivers.

•To activate the changed "Connection (address number)" parameter, cycling the power supply is required.

•For the SW1, always set to "7." If the switch is set to the dial of "8" or higher, the communication switch setting

error alarm will be generated when turning on the power. And do not set the switch to the dial of "0" to "6"

because they cannot be used. (An alarm will not be generated.)

NETC01-ECT.

SW1: 7

power.

STEP 3 Set the switches of the driver

Set the following with the switches of the driver. For the protocol, select "OFF" (network converter).

The status becomes as shown in the following gures after setting.

EtherCAT node address: 1

×10: 0

×1: 1

Setting contents Switch Factory setting

Protocol: Network converter Turn No.2 of SW1 OFF OFF

Address number: 0 Turn No.1 of SW1 OFF, set ID to 0 No.1: OFF, ID: 0

Termination resistor: ON

AC power input driver: Turn Nos.1 and 2 of TERM ON

DC power input driver: Turn Nos.3 and 4 of SW1 ON

OFF

Function setting switch (SW1)

Address number setting switch (ID)

Transmission rate setting switch

(BAUD)

Function setting switch (SW1)

No.2: Protocol

No.1: Address number

ON

Termination resistor setting switch

(TERM.)

Address number setting switch (ID)

Transmission rate setting switch

(BAUD)

ON

No.2: ON

No.1: ON

ON

No.3, No.4: Termination

resistor

No.2: Protocol

No.1: Address number

•For the address number, set the one with the "Connection (address number)" parameter of the

set to "Enable."

•For the AZ Series, the transmission rate does not require to set. It is xed to 625,000 bps in the

"Baudrate(GWv2)" parameter. The BAUD switch can point anywhere.

NETC01-ECT

19

▐

Page 20

Guidance

NETC01-ECT

AC input driver

DC input driver

STEP 4 Cycle the power and check the LED

Check that the LED of the driver and

NETC01-ECT

are as shown in the gure.

Green lit

Green lit

•When the C-DAT/C-ERR LED (red) of the driver or the C-ERR LED (red) of the

Check the transmission rate of RS-485 communication or the address number.

•When the ERR LED (red) of the

content.

NETC01-ECT

is blink: An EtherCAT communication error has been occurred. Check the error

Perform continuous operation via remote I/O of EtherCAT

STEP 5

communication

OFF

Green lit

OFF

NETC01-ECT

Green litGreen lit

OFF

Green blinking

is lit:

CoE Index

2600h

Turn FW-POS of the address number 0 ON with the remote I/O of EtherCAT communication. Continuous operation for the operation

data No.0 is started at the 1000 Hz of starting speed.

Initial values of the remote I/O are as follows.

zMaster to

Sub-

index

0

1

2

NETC01-ECT

Name Type Access Description

−

I/O

Command

(lower)

I/O

Command

(upper)

U8 R Number of Sub-index: 2

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

U8 RW

U8 RW

NET-IN7 NET-IN6 NET-IN5 NET-IN4 NET-IN3 NET-IN2 NET-IN1 NET-IN0

ALM-RST FREE STOP ZHOME START M2 M1 M0

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

NET-IN15 NET-IN14 NET-IN13 NET-IN12 NET-IN11 NET-IN10 NET-IN9 NET-IN8

RV-POS FW-POS RV-JOG-P FW-JOG-P SSTART D-SEL2 D-SEL1 D-SEL0

STEP 6 Were you able to operate the motor properly?

How did it go? Were you able to operate the motor properly? If the motor does not function, check the following points:

•Is an alarm generated in the driver or

•Are the power supply, motor, and RS-485 communication cable connected securely?

•Are the protocol, address number, transmission rate and termination resistor set correctly?

•Is the "connection (address number)" parameter of the

•Is the C-DAT LED of

•Is the ERR LED of

•Is the L/A LED of

Is the motor excited, or is the setting of the excitation method correct?

•Are the parameters of the driver set correctly?

•Is the operation stop signal input to the driver?

NETC01-ECT

NETC01-ECT

NETC01-ECT

NETC01-ECT

turned o? Or is the C-ERR LED lit in red? (A RS-485 communication error has been occurred.)

blinks in red? (An EtherCAT communication error has been occurred. _p.41)

turnde o? Or is it blinks in green? (An EtherCAT communication error has been occurred. _p.41)

?

NETC01-ECT

set correctly?

20

▌

Page 21

8 Setting

Setting

This chapter explains how to set the functions of the

Be sure to turn o the

still on, the new switch settings will not become eective until the

RS-485 communication

transmission rate

setting switch (SW1)

NETC01-ECT

NETC01-ECT

power before setting the switches. If the switches are set while the power is

.

NETC01-ECT

Node address setting switch

(ECAT ID ×1, ×10)

8-1 Transmission rate of RS-485 communication

Set the transmission rate using the RS-485 communication transmission rate setting switch (SW1).

Factory setting 7 (625 kbps)

For the SW1, always set to "7." If the switch is set to the dial of "8" or higher, the communication switch setting

error alarm will be generated when turning on the power. And do not set the switch to the dial of "0" to "6"

because they cannot be used. (An alarm will not be generated.)

power is cycled.

8-2 Node address of EtherCAT

Set the node address of the

When connecting two or more EtherCAT compatible products, do not set duplicate node address.

Set the upper using the "ECAT ID ×10" and the lower using the "ECAT ID ×1."

NETC01-ECT

Setting range 0 to 255 (00h to FFh)

Factory setting 1 (×10: 0, ×1: 1)

using the two node address setting switches (ECAT ID ×1 and ×10).

21

▐

Page 22

Basic function

9 Basic function

This chapter explains the basic function and signals of the

9-1 Remote I/O list

The PDO mapping is possible for remote I/O. 16 axes of connectable units are assigned.

•Remote I/O status ................................. Mapping to TxPDO is possible.

•Remote I/O command......................... Mapping to RxPDO is possible.

CoE Index Name CoE Index Name

Axis No.

Axis 0 2400h Remote I/O Status (Axis 0) 2600h Remote I/O Command (Axis 0)

Axis 1 2401h Remote I/O Status (Axis 1) 2601h Remote I/O Command (Axis 1)

Axis 2 2402h Remote I/O Status (Axis 2) 2602h Remote I/O Command (Axis 2)

Axis 3 2403h Remote I/O Status (Axis 3) 2603h Remote I/O Command (Axis 3)

Axis 4 2404h Remote I/O Status (Axis 4) 2604h Remote I/O Command (Axis 4)

Axis 5 2405h Remote I/O Status (Axis 5) 2605h Remote I/O Command (Axis 5)

Axis 6 2406h Remote I/O Status (Axis 6) 2606h Remote I/O Command (Axis 6)

Axis 7 2407h Remote I/O Status (Axis 7) 2607h Remote I/O Command (Axis 7)

Axis 8 2408h Remote I/O Status (Axis 8) 2608h Remote I/O Command (Axis 8)

Axis 9 2409h Remote I/O Status (Axis 9) 2609h Remote I/O Command (Axis 9)

Axis 10 240Ah Remote I/O Status (Axis 10) 260Ah Remote I/O Command (Axis 10)

Axis 11 240Bh Remote I/O Status (Axis 11) 260Bh Remote I/O Command (Axis 11)

Axis 12 240Ch Remote I/O Status (Axis 12) 260Ch Remote I/O Command (Axis 12)

Axis 13 240Dh Remote I/O Status (Axis 13) 260Dh Remote I/O Command (Axis 13)

Axis 14 240Eh Remote I/O Status (Axis 14) 260Eh Remote I/O Command (Axis 14)

Axis 15 240Fh Remote I/O Status (Axis 15) 260Fh Remote I/O Command (Axis 15)

Response

(

NETC01-ECT

to master)

Remote I/O status

NETC01-ECT

.

Command

(Master to

NETC01-ECT

Remote I/O command

)

Remote I/O status

zStatus [

CoE Index

2400h

(2400h

to

240Fh)

NETC01-ECT

Sub-

index

0

I/O Status

1

I/O Status

2

to master]

Name Type Access Description

−

(lower)

(upper)

U8 R Number of Sub-index: 2

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

U8 R

U8 R

NET-

OUT7

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

NET-

OUT15

NET-

OUT6

NET-

OUT14

NET-

OUT5

NET-

OUT13

NET-

OUT4

NET-

OUT12

NET-

OUT3

NET-

OUT11

NET-

OUT2

NET-

OUT10

NET-

OUT1

NET-

OUT9

NET-

OUT0

NET-

OUT8

22

▌

Page 23

Remote I/O command

Basic function

zCommand [master to

CoE Index

2600h

(2600h

to

260Fh)

Sub-

index

0

1

2

NETC01-ECT

Name Type Access Description

−

I/O Command

(lower)

I/O Command

(upper)

U8 R Number of Sub-index: 2

U8 RW

U8 RW

]

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

NET-IN7 NET-IN6 NET-IN5 NET-IN4 NET-IN3 NET-IN2 NET-IN1 NET-IN0

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

NET-IN15 NET-IN14 NET-IN13 NET-IN12 NET-IN11 NET-IN10 NET-IN9 NET-IN8

For remote I/O assignment of the RS-485 communication compatible product, check the USER MANUAL or

OPERATING MANUAL Function Edition of each product.

9-2 Remote register list

Remote register is for PDO mapping.

•Remote register command ........................Mapping to RxPDO is possible.

•Remote register response ...........................Mapping to TxPDO is possible.

With remote register, read/write for parameters of the RS-485 communication compatible product that is connected to the

NETC01-ECT

Axis No.

Axis 0 2800h Remote Register Command (Axis 0) 2900h Remote Register Response (Axis 0)

Axis 1 2801h Remote Register Command (Axis 1) 2901h Remote Register Response (Axis 1)

Axis 2 2802h Remote Register Command (Axis 2) 2902h Remote Register Response (Axis 2)

Axis 3 2803h Remote Register Command (Axis 3) 2903h Remote Register Response (Axis 3)

Axis 4 2804h Remote Register Command (Axis 4) 2904h Remote Register Response (Axis 4)

Axis 5 2805h Remote Register Command (Axis 5) 2905h Remote Register Response (Axis 5)

Axis 6 2806h Remote Register Command (Axis 6) 2906h Remote Register Response (Axis 6)

Axis 7 2807h Remote Register Command (Axis 7) 2907h Remote Register Response (Axis 7)

Axis 8 2808h Remote Register Command (Axis 8) 2908h Remote Register Response (Axis 8)

Axis 9 2809h Remote Register Command (Axis 9) 2909h Remote Register Response (Axis 9)

Axis 10 280Ah Remote Register Command (Axis 10) 290Ah Remote Register Response (Axis 10)

Axis 11 280Bh Remote Register Command (Axis 11) 290Bh Remote Register Response (Axis 11)

Axis 12 280Ch Remote Register Command (Axis 12) 290Ch Remote Register Response (Axis 12)

Axis 13 280Dh Remote Register Command (Axis 13) 290Dh Remote Register Response (Axis 13)

Axis 14 280Eh Remote Register Command (Axis 14) 290Eh Remote Register Response (Axis 14)

Axis 15 280Fh Remote Register Command (Axis 15) 290Fh Remote Register Response (Axis 15)

, maintenance command, and monitor can be performed.

CoE Index Name CoE Index Name

Command

(Master to

NETC01-ECT

Remote register command

)

Response

(

NETC01-ECT

to master)

Remote register response

23

▐

Page 24

Basic function

Remote register command

zCommand [master to

CoE Index

2800h

(2800h

to

280Fh)

zDescription of TRIG

Name Description Setting range

TRIG

Remote register response

zResponse [

CoE Index

2900h

(2900h

to

290Fh)

Sub-

index

0

1 Axis U8 R Reserved (not used)

2 Command U16 R Command code response

3 Data INT32 R Data response

4 Status U8 R

NETC01-ECT

Sub-

index

0

1 Axis U8 RW Reserved (not used)

2 Command U16 RW Command code

3 Data INT32 RW Data

4 TRIG U8 RW

This is a trigger to execute a command code.

When TRIG is changed from 0 to 1, the command code is executed.

NETC01-ECT

Name Type Access Description

−

Name Type Access Description

−

to master]

U8 R Number of Sub-index: 4

]

U8 R Number of Sub-index: 4

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

− − − −

0: No action

1: Execute

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

− −

− −

Command Error Axis Error STATUS TRIG_R

− − −

TRIG

zDescription of Status

Name Description Setting range

TRIG_R Indicates a response to the TRIG of the remote register command.

STATUS Detects an error when writing.

Axis Error Indicates an error of the address number.

Command Error Indicates an error of the command code. Reserved (0 xed)

0: TRIG undetected

1: TRIG detected

0: Normal

1: Error

0: Normal

1: Error

24

▌

Page 25

Basic function

Timing chart

zRead (normal time)

This explains how to read the position (travel amount) of the operation data No.0 using the AR Series.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the command code "0200h" of the position (travel amount) of the operation data No.0 to the command code (Command).

3. Turn the transmission request (TRIG) ON.

4. The TRIG response (TRIG_R) is turned ON, and the position (travel amount) of the operation data No.0 is returned to the data

response (Data).

If the command code is read properly, the transmission error (STATUS) remains OFF.

5. Check the TRIG response (TRIG_R) has been turned ON and turn the transmission request (TRIG) OFF.

6. The TRIG response (TRIG_R) is turned OFF.

Continuously, the following command code can be read. The command code "0240h" of the speed of the operation data No.0 is

read in the timing chart below.

Remote

register

CoE

Index

2800h

Command

(address

number 0)

Sub-

index

2

4

4 (bit0)

Description

Command code (Command)

Transmission request (TRIG)

TRIG response (TRIG_R)

ON

OFF

ON

OFF

Timing chart

2

0200h 0240h

3

5

641

2900h

Response

(address

Data response (Data)

3

1000 3000

number 0)

4 (bit1)

Transmission error (STATUS)

ON

OFF

zRead (error)

This explains the case that the undened command code was read using the AR Series.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the undened command code "0001h" to the command code (Command).

3. Turn the transmission request (TRIG) ON.

4. The TRIG response (TRIG_R) is turned ON.

At this time, since the undened command code has been set, the transmission error (STATUS) is turned ON.

The data in error is read because the transmission error was generated.

5. Turn the transmission request (TRIG) OFF in order to release the transmission error (STATUS).

The TRIG response (TRIG_R) and transmission error (STATUS) are turned OFF.

Remote

register

Command

CoE

Index

2800h

(address

number 0)

Sub-

index

2

4

4 (bit0)

Description

Command code (Command)

Transmission request (TRIG)

TRIG response (TRIG_R)

ON

OFF

ON

OFF

Timing chart

2

0001h

3 5

1 4

2900h

Response

(address

Data response (Data)

3

xxxxxxx

number 0)

4 (bit1)

Transmission error (STATUS)

ON

OFF

25

▐

Page 26

Basic function

zWrite (normal time)

This explains how to write the position (travel amount) to the operation data No.0 using the AR Series.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the command code "1200h" of the position (travel amount) of the operation data No.0 to the command code (Command).

3. Set the position (travel amount) "1000 pulses" to the data (Data).

4. Turn the transmission request (TRIG) ON.

5. The TRIG response (TRIG_R) is turned ON.

If the command code is written properly, the transmission error (STATUS) remains OFF.

6. Check the TRIG response (TRIG_R) has been turned ON and turn the transmission request (TRIG) OFF.

7. The TRIG response (TRIG_R) is turned OFF.

Continuously, the following command code can be written. The command code "1240h" of the speed of the operation data No.0

is written in the timing chart below.

Remote

register

Command

Response

CoE

Index

2800h

(address

number 0)

2900h

(address

number 0)

Sub-

index

2

3

4

4 (bit0)

4 (bit1)

Description

Command code (Command)

Data

Transmission request (TRIG)

TRIG response (TRIG_R)

Transmission error (STATUS)

ON

OFF

ON

OFF

ON

OFF

2

3

4

1 5

Timing chart

1200h 1240h

1000 3000

6

7

zWrite (error)

This explains the case that the position (travel amount) that is out of the setting range was written using the AR Series.

The range of the position (travel amount) of the operation data for the AR Series is −8,388,608 to +8,388,607.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the command code "1200h" of the position (travel amount) of the operation data No.0 to the command code (Command).

3. Set the position (travel amount) "9,999,999 pulses" that is out of the setting range to the data (Data).

4. Turn the transmission request (TRIG) ON.

5. The TRIG response (TRIG_R) is turned ON.

At this time, since the position (travel amount) that is out of the setting range has been set, the transmission error (STATUS) is

turned ON.

The position (travel amount) is not written because the transmission error was generated.

6. Turn the transmission request (TRIG) OFF in order to release the transmission error (STATUS).

The TRIG response (TRIG_R) and transmission error (STATUS) are turned OFF.

Remote

register

Command

Response

26

▌

CoE

Index

2800h

(address

number 0)

2900h

(address

number 0)

Sub-

index

2

3

4

4 (bit0)

4 (bit1)

Description

Command code (Command)

Data

Transmission request (TRIG)

TRIG response (TRIG_R)

Transmission error (STATUS)

ON

OFF

ON

OFF

ON

OFF

Timing chart

2

1200h

3

9,999,999

4 6

1 5

Page 27

9-3 Remote monitor list

Remote monitor is an area for PDO mapping.

•Remote monitor command .......................Mapping to RxPDO is possible.

•Remote monitor response ..........................Mapping to TxPDO is possible.

Since 16 dedicated objects for monitor are provided, multiple monitors to one axis can be performed simultaneously.

Refer to the following table for the CoE Index of the object area.

CoE Index Name CoE Index Name

Area

Monitor 0 2A00h Remote Monitor 0 Command 2B00h Remote Monitor 0 Response

Monitor 1 2A01h Remote Monitor 1 Command 2B01h Remote Monitor 1 Response

Monitor 2 2A02h Remote Monitor 2 Command 2B02h Remote Monitor 2 Response

Monitor 3 2A03h Remote Monitor 3 Command 2B03h Remote Monitor 3 Response

Monitor 4 2A04h Remote Monitor 4 Command 2B04h Remote Monitor 4 Response

Monitor 5 2A05h Remote Monitor 5 Command 2B05h Remote Monitor 5 Response

Monitor 6 2A06h Remote Monitor 6 Command 2B06h Remote Monitor 6 Response

Monitor 7 2A07h Remote Monitor 7 Command 2B07h Remote Monitor 7 Response

Monitor 8 2A08h Remote Monitor 8 Command 2B08h Remote Monitor 8 Response

Monitor 9 2A09h Remote Monitor 9 Command 2B09h Remote Monitor 9 Response

Monitor 10 2A0Ah Remote Monitor 10 Command 2B0Ah Remote Monitor 10 Response

Monitor 11 2A0Bh Remote Monitor 11 Command 2B0Bh Remote Monitor 11 Response

Monitor 12 2A0Ch Remote Monitor 12 Command 2B0Ch Remote Monitor 12 Response

Monitor 13 2A0Dh Remote Monitor 13 Command 2B0Dh Remote Monitor 13 Response

Monitor 14 2A0Eh Remote Monitor 14 Command 2B0Eh Remote Monitor 14 Response

Monitor 15 2A0Fh Remote Monitor 15 Command 2B0Fh Remote Monitor 15 Response

Command

(master to

NETC01-ECT

Remote monitor command

)

Response

(

NETC01-ECT

to master)

Remote monitor response

Basic function

Remote monitor command

zCommand [master to

CoE Index

2A00h

(2A00h

to

2A0Fh)

Sub-

index

0

1 Axis U8 RW Address number

2 Command U16 RW Command code

3 Data INT32 RW Reserved (not used)

4 TRIG U8 RW

NETC01-ECT

Name Type Access Description

−

zDescription of TRIG

Name Description Setting range

TRIG

This is a trigger to execute the command code of monitor.

When TRIG is changed from 0 to 1, the command code is executed.

]

U8 R Number of Sub-index: 4

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

− − − − − − −

0: No action

1: Execute

TRIG

27

▐

Page 28

Basic function

Remote monitor response

CoE Index

2B00h

(2B00h

to

2B0Fh)

zResponse [

Sub-

index

0

1 Axis U8 R Address number response

2 Command U16 R Command code response

3 Data INT32 R Monitor data

4 Status U8 R

NETC01-ECT

Name Type Access Description

−

to master]

U8 R Number of Sub-index: 4

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

− − − −

Command Error Axis Error STATUS TRIG_R

zDescription of Status

Name Description Setting range

TRIG_R Indicates a response to the TRIG of the remote monitor command.

STATUS Detects an error when writing.

Axis Error Indicates an error of the address number.

Command Error

Indicates an error of the command code of monitor.

Evaluates as an error if the command code other than monitor was input.

Timing chart

0: TRIG undetected

1: TRIG detected

0: Normal

1: Error

0: Normal

1: Error

0: Normal

1: Error

zMonitor (normal time)

This explains how to monitor the command position of the driver for the address number 2 using the AR Series.

The monitor 0 is used for the monitor number.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the address number "2" of the driver to the address number (Axis).

3. Set the command code "2063h" of the command position to the command code (Command).

4. Turn the monitor request (TRIG) ON.

The monitor is continued while the monitor request (TRIG) is being ON.

5. The TRIG response (TRIG_R) is turned ON, and the monitor value is returned to the monitor value (Data).

At this time, if the command code has been read properly, the transmission error (STATUS) remains OFF.

6. Turn the monitor request (TRIG) OFF.

The TRIG response (TRIG_R) is turned OFF, and the monitor is stopped.

Remote

monitor

Command

CoE

Index

2A00h

(monitor 0)

Sub-

index

1

2

4 (bit0)

4 (bit0)

Description

Address number (Axis)

Command code (Command)

Monitor request (TRIG)

TRIG response (TRIG_R)

ON

OFF

ON

OFF

2

3

4

1 5

Timing chart

2 (dec)

2063h

6

Monitor value (Data)

Response

28

▌

2B00h

(monitor 0)

4 (bit1) Transmission error (STATUS)

4 (bit2)

Address number error

(Axis Error)

ON

OFF

ON

OFF

3

100 101 102 103 104

Page 29

zMonitor (error)

This explains the case that the command code was set to the driver that is not connected using the AR Series.

The monitor 0 is used for the monitor number.

1. Check the TRIG response (TRIG_R) is OFF.

2. Set the address number "5" of the driver that is not connected to the address number (Axis).

3. Set the command code "2063h" of the command position to the command code (Command).

4. Turn the monitor request (TRIG) ON.

5. The TRIG response (TRIG_R) is turned ON.

At this time, since the address number of the driver that is not connected has been set, the transmission error (STATUS) and

address number error (Axis Error) are turned ON.

Since the monitor error is generated, the monitor is not performed properly.

6. Turn the monitor request (TRIG) OFF in order to release the transmission error (STATUS).

TRIG response (TRIG_R), transmission error (STATUS), and address number error (Axis Error) are turned OFF.

Basic function

Remote

monitor

Command

Response

CoE

Index

2A00h

(monitor 0)

2B00h

(monitor 0)

Sub-

index

1

2

4 (bit0)

4 (bit0)

3

Description

Address number (Axis)

Command code (Command)

Monitor request (TRIG)

TRIG response (TRIG_R)

Monitor value (Data)

4 (bit1) Transmission error (STATUS)

4 (bit2)

Address number error

(Axis Error)

ON

OFF

ON

1 5

OFF

ON

OFF

ON

OFF

Timing chart

2

5 (dec)

3

2063h

4

6

xxxxxxx

29

▐

Page 30

Basic function

9-4 Objects of the

Object lists of parameters, monitor, and maintenance for the

NETC01-ECT

Parameter

CoE Index Sub-index Type Access

2CC4h 0

2D80h 0

2D81h 0

2D82h 0

2D83h 0

2D84h 0

2D85h 0

2D86h 0

2D87h 0

2D88h 0

2D89h 0

2D8Ah 0

2D8Bh 0

2D8Ch 0

2D8Dh 0

2D8Eh 0

2D8Fh 0

U8 RW Possible

PDO possible/

not possible

NETC01-ECT

Parameter name Setting range

Data setter edit

(address number 0)

(address number 1)

(address number 2)

(address number 3)

(address number 4)

(address number 5)

(address number 6)

(address number 7)

(address number 8)

(address number 9)

(address number 10)

(address number 11)

(address number 12)

(address number 13)

(address number 14)

(address number 15)

are as follows.

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

Connection

0: Disable

1: Enable

Initial

value

1 A

1 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

0 B

Eective *

* A: Eective immediately, B: Eective after turning the power ON again

If the parameters that enters "B (Eective after turning the power ON again)" in the column of eective are

changed, cycle the power of the

maintenance command.

30

▌

NETC01-ECT

after executing "Batch non-volatile memory write (3E85h)" of the

Page 31

Monitor command

Basic function

CoE Index Sub-index Type Access

3E00h 0 U8 R Tx possible Present alarm

3E01h 0 U8 R Tx possible Alarm record 1

3E02h 0 U8 R Tx possible Alarm record 2

3E03h 0 U8 R Tx possible Alarm record 3

3E04h 0 U8 R Tx possible Alarm record 4

3E05h 0 U8 R Tx possible Alarm record 5

3E06h 0 U8 R Tx possible Alarm record 6

3E07h 0 U8 R Tx possible Alarm record 7

3E08h 0 U8 R Tx possible Alarm record 8

3E09h 0 U8 R Tx possible Alarm record 9

3E0Ah 0 U8 R Tx possible Alarm record 10

3E0Bh 0 U8 R Tx possible Present warning

3E0Ch 0 U8 R Tx possible Warning record 1

3E0Dh 0 U8 R Tx possible Warning record 2

3E0Eh 0 U8 R Tx possible Warning record 3

3E0Fh 0 U8 R Tx possible Warning record 4

3E10h 0 U8 R Tx possible Warning record 5

3E11h 0 U8 R Tx possible Warning record 6

3E12h 0 U8 R Tx possible Warning record 7

3E13h 0 U8 R Tx possible Warning record 8

3E14h 0 U8 R Tx possible Warning record 9

3E15h 0 U8 R Tx possible Warning record 10

3E30h *1 0 U8 R Tx possible Converter status

3E3Bh 0 U16 R Tx possible RS-485 communication scantime

3E3Ch *2 0 U16 R Tx possible RS-485 communication connection request

3E3Dh *3 0 U16 R Tx possible RS-485 communication connection response

3E40h 0 U8 R Tx possible Communication error (remote monitor 0)

3E41h 0 U8 R Tx possible Communication error (remote monitor 1)

3E42h 0 U8 R Tx possible Communication error (remote monitor 2)

3E43h 0 U8 R Tx possible Communication error (remote monitor 3)

3E44h 0 U8 R Tx possible Communication error (remote monitor 4)

3E45h 0 U8 R Tx possible Communication error (remote monitor 5)

3E46h 0 U8 R Tx possible Communication error (remote monitor 6)

3E47h 0 U8 R Tx possible Communication error (remote monitor 7)

3E48h 0 U8 R Tx possible Communication error (remote monitor 8)

3E49h 0 U8 R Tx possible Communication error (remote monitor 9)

3E4Ah 0 U8 R Tx possible Communication error (remote monitor 10)

3E4Bh 0 U8 R Tx possible Communication error (remote monitor 11)

3E4Ch 0 U8 R Tx possible Communication error (remote monitor 12)

3E4Dh 0 U8 R Tx possible Communication error (remote monitor 13)

3E4Eh 0 U8 R Tx possible Communication error (remote monitor 14)

3E4Fh 0 U8 R Tx possible Communication error (remote monitor 15)

3E50h 0 U8 R Tx possible Communication error (remote register 0)

3E51h 0 U8 R Tx possible Communication error (remote register 1)

3E52h 0 U8 R Tx possible Communication error (remote register 2)

3E53h 0 U8 R Tx possible Communication error (remote register 3)

3E54h 0 U8 R Tx possible Communication error (remote register 4)

3E55h 0 U8 R Tx possible Communication error (remote register 5)

3E56h 0 U8 R Tx possible Communication error (remote register 6)

PDO possible/

not possible

Parameter name

31

▐

Page 32

Basic function

CoE Index Sub-index Type Access

3E57h 0 U8 R Tx possible Communication error (remote register 7)

3E58h 0 U8 R Tx possible Communication error (remote register 8)

3E59h 0 U8 R Tx possible Communication error (remote register 9)

3E5Ah 0 U8 R Tx possible Communication error (remote register 10)

3E5Bh 0 U8 R Tx possible Communication error (remote register 11)

3E5Ch 0 U8 R Tx possible Communication error (remote register 12)

3E5Dh 0 U8 R Tx possible Communication error (remote register 13)

3E5Eh 0 U8 R Tx possible Communication error (remote register 14)

3E5Fh 0 U8 R Tx possible Communication error (remote register 15)

*1 CoE Index: 3E30h (Converter stetus)

The status of the

CoE

Index

3E30h 0 U8 R

*2 CoE Index: 3E3Ch (RS-485 communication connection request)

The setting status of the "Connection (address number)" parameter can be monitored.

CoE

Index

3E3Ch 0 U16 R

Sub-

index

Sub-

index

NETC01-ECT

Type Access Description

Type Access Description

can be monitored.

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

− − − − −

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

Axis 7 Axis 6 Axis 5 Axis 4 Axis 3 Axis 2 Axis 1 Axis 0

bit[15] bit[14] bit[13] bit[12] bit[11] bit[10] bit[9] bit[8]

Axis 15 Axis 14 Axis 13 Axis 12 Axis 11 Axis 10 Axis 9 Axis 8

PDO possible/

not possible

Parameter name

S-BSY WNG ALM

*3 CoE Index: 3E3Dh (RS-485 communication connection response)

The communication status of RS-485 communication can be monitored.

CoE

Index

3E3Dh 0 U16 R

Sub-

index

Type Access Description

bit[7] bit[6] bit[5] bit[4] bit[3] bit[2] bit[1] bit[0]

Axis 7 Axis 6 Axis 5 Axis 4 Axis 3 Axis 2 Axis 1 Axis 0

bit[15] bit[14] bit[13] bit[12] bit[11] bit[10] bit[9] bit[8]

Axis 15 Axis 14 Axis 13 Axis 12 Axis 11 Axis 10 Axis 9 Axis 8

1: Communicating properly

0: Communication error, or the "connection (address number)" parameter is set to

"Disable."

zAlarm code list

Code Name Description

00h Alarm not present

47h EEPROM error The stored data in the

83h Communication switch setting error Transmission rate setting switch was out of the specication.

84h RS-485 communication error The RS-485 communication error has been detected three times consecutively.

F0h CPU error CPU malfunctioned.

NETC01-ECT

−

was damaged.

zWarning code list

Code Name Description

00h Warning not present

84h RS-485 communication error RS-485 communication error was detected.

85h RS-485 communication timeout

Even though the receiving cycle of RS-485 communication has passed, the

response frame was not completed receiving.

−

32

▌

Page 33

zCommunication error code list

Code Name Description Note

00h

85h Communication timeout

88h Command not yet dened. The unsupported command code was specied.

89h

8Ch Outside setting range

8Dh Command execute disable STATUS=1 was received from the slave axis.

Communication error not

present

Execution is disabled due to

user I/F communication in

progress

− −

•The non-communication axis was accessed

(TRIG=1) by remote register.

•The non-communication axis was specied to the

Axis of remote monitor.

The command requested by the master could

not be executed because the

communicating with the

The value out of the setting range was specied in

the Axis of remote monitor.

NETC01-ECT

OPX-2A

or

was

MEXE02

.

The factor is recorded in

the communication error

records of the slave.

Maintenance command

Basic function

−

−

−

−

CoE Index Sub-index Type Access

3E80h 0 U8 RW Possible Reset alarm

3E81h 0 U8 RW Possible Clear alarm records 0

3E82h 0 U8 RW Possible Clear warning records 0

3E84h 0 U8 RW Possible

3E85h 0 U8 RW Possible

3E86h 0 U8 RW Possible All data initialization 0

When 1 is written to the data, the command code is executed.

PDO possible/

not possible

9-5 Read, write, save of parameters

Read and write of parameters

When reading or writing the parameters of the

•When operating with the parameter mode or copy mode of the

using the

communication error (communication error code: 89h) occurs.

•When reading or writing parameters via EtherCAT communication, or when executing the maintenance command of the

NETC01-ECT

MEXE02

, you cannot execute read/write of the parameters via EtherCAT communication. If you execute, a

, you cannot read or write parameters using the

NETC01-ECT

Parameter name Setting range

Batch non-volatile

memory read

Batch non-volatile

memory write

, use any of EtherCAT communication,

, or when downloading or initializing the parameters

OPX-2A

OPX-2A

or

MEXE02

.

0: Not reected

1: Reected

OPX-2A

, or

MEXE02

Initial

value

0

0

0

.

Storage for parameters

Parameters are saved in the RAM or non-volatile memory. The parameters saved in the RAM is erased once the 24 VDC power supply

is shut o, but the parameters in non-volatile memory is stored even if the 24 VDC power supply is shut o.

When the 24 VDC power is supplied to the RS-485 communication compatible product, the parameters stored in the non-volatile

memory are sent to the RAM, and the recalculation and setup for the parameters are executed in the RAM.

When the parameters are written to the RS-485 communication compatible product via EtherCAT communication, they are written

in the RAM space. When saving in the non-volatile memory, execute "Batch non-volatile memory write (3E85h)" of the maintenance

command for each EtherCAT communication axis and RS-485 communication axis. Batch non-volatile memory write can be executed

by writing "1."

Do not turn o the 24 VDC power supply while writing in the non-volatile memory, and also do not turn o within

5 seconds after the completion of writing. Doing so may abort writing the data and cause an EEPROM error alarm

to generate.

33

▐

Page 34

Basic function

The non-volatile memory can be rewritten approximately 100,000 times.

9-6 Basic operating procedures

This section explains how to perform positioning operation and monitor function as basic operating procedures.

This is an example of the operating procedure for controlling via EtherCAT communication using the

communication compatible product is explained using the compatible mode of the AZ Series built-in controller type.

Positioning operation

zSetting example

•Driver address number (slave address): 0