Orenco Systems SB1, SB2, SB3, SB4, SB5 Installation Manual

...

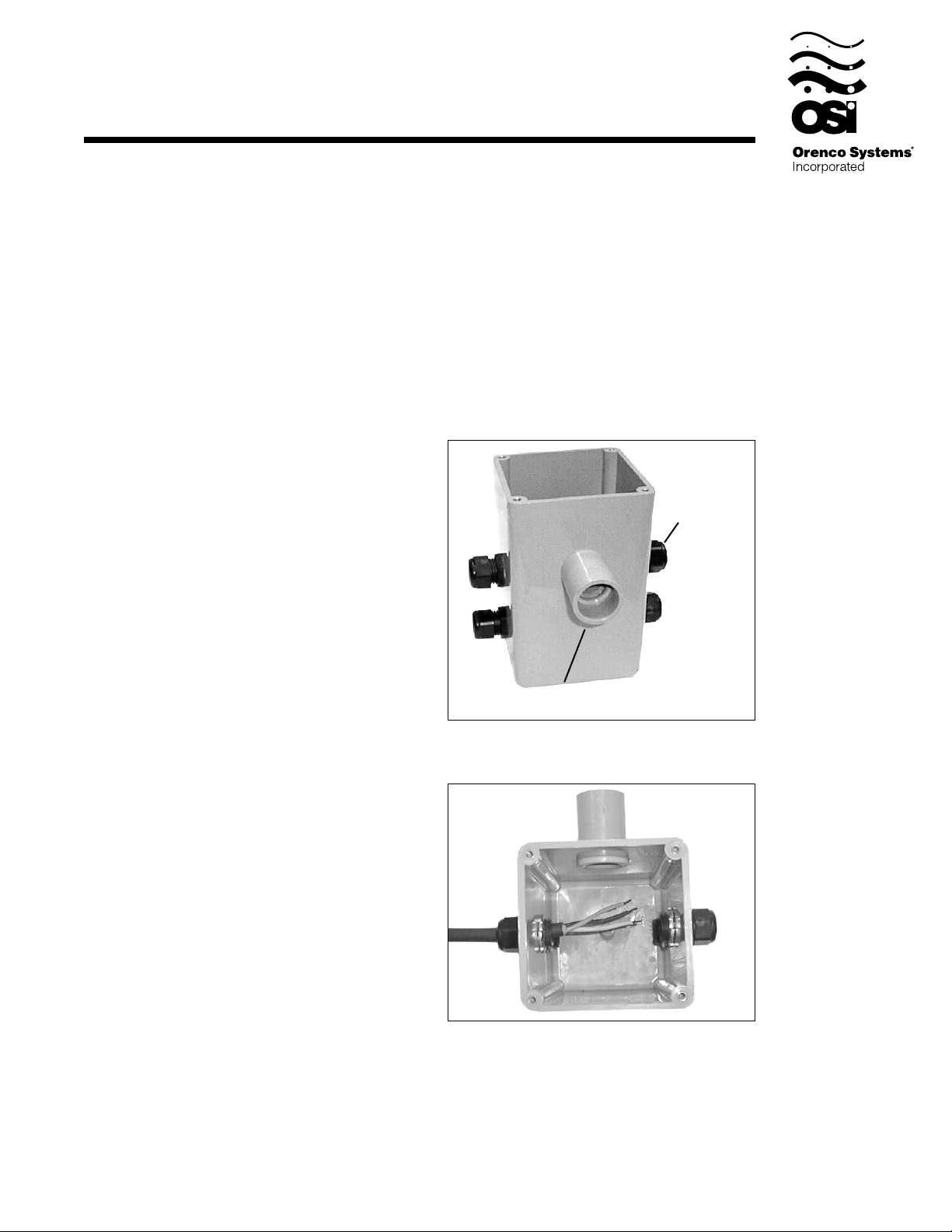

Splice Boxes

814 AIRWAY AVENUE

SUTHERLIN, OREGON

97479

TELEPHONE:

(541) 459-4449

(800) 348-9843

FACSIMILE:

(541) 459-2884

The electrical splice box provides a safe and legal space for splicing cables, typically from

pumps or float switches. It should be mounted inside the access riser, over the pump or filter

unit, where the components being spliced are within sight of the installer. For explosion proof

(Class 1, Div. 1) splice boxes, please see document EIN-SB-SBX-1.

The splice box is provided with heat shrink/ butt connectors and waterproof wire nut(s)

necessary to splice the appropriate floats and pumps.

Installation, Operation and Maintenance

Model SB__

2. Push the appropriate pump and level

control wires through the watertight

cord grips into the electrical splice box.

Leave an adequate length of electrical

cable coiled inside the riser to allow for

easy removal of the pump and float

assembly. Do not remove the colored

markers or the paper tags from the float

cables, and do not try to thread the

markers and tag through the cord grip.

Tighten the cord grips

by hand, not by

tool

, then test the tightness of the cord

grips by tugging on each cable. A cable

is secure when the cord grip is tight

enough to prevent slippage. Adequate

lengths of cable should be left within

the splice box to allow easy removal for

future disconnecting and re-splicing.

1. The splice box should be mounted inside

the access riser. The access riser is

typically supplied with a grommet for

installation of the splice box. If a grommet

is not installed, please refer to riser, lid, and

accessary instructionsdocument EIN-RLARLA-1 for grommet installation

instructions.

Lubricate both the outside of the conduit

coupling and the grommet. Slide the

coupling through the grommet in the

access riser wall. Make sure the box is

pushed snug against the wall, allowing for

removal of any pumping equipment.

Installation Instructions:

Cord Grip

Conduit Coupling

EIN-SB-SB-1

Rev 2.2 12/10/99

Page 1

3. Run properly sized wires from the control panel to the splice box. The wires can

be brought through a conduit, or can be direct buried using suitable direct-burial

wire. Conduit that enters the splice box must be sealed with a conduit seal or

acceptable watertight cord connection, to prevent the infiltration of water into the

splice box. The number of wires required depends on the control panel and the

number of floats and pumps used. This can be determined by consulting the

Splice Box Wiring diagram provided for the control panel and float arrangement

being used.

Installation Instructions cont.

If the floats do not carry direct pump current, the wire should be sized at 14 AWG. Refer

to Chart 1 to determine the proper size for the pump wire and any float wire required to

carry direct pump current. When calculating wire size, you need to take the length and

size of your branch circuit wires from the

service entrance panel to the pump control

panel

into account. Wire that is too small can cause an excessive voltage drop and poor

pump performance.

Chart 1. Recommended Breaker & Wire Size

Pump Motor Size Breaker size Wire Size Max Distance*

115 VAC 1/3 hp 20 amp 12 AWG 210 ft

1/2 hp 20 amp 12 AWG 160 ft

230 VAC 1/2 hp 15 amp 14 AWG 400 ft

1 hp 20 amp 12 AWG 400 ft

1 1/2 hp 20 amp 12 AWG 310 ft

* load center to motor.

Wires should be color coded or otherwise marked to aid in wiring the control panel. The

following chart lists common colors recommended for each of the wires. Colors may

refer to either the color of the wire’s insulating jacket or the color of an electrical tape

marker.

Chart 2. Recommended Field Wire Colors

Float Cables

Float Function Float Marker Wire Color

High Water Alarm Yellow Yellow

Lag Pump On (Duplex) Purple Purple

Lead Pump On (Duplex) Blue Blue

Lead Pump Off (Duplex) Red Red

On / Off Green Blue

Redundant Off / Low Level Alarm White Orange

Float Common Wire - Brown

Pump Cable(s)

Pump Wire (L1) Black

Pump Wire (Neutral, 115vpumps) White

Pump Wire (L2, 230vpumps) Red

Ground Green

EIN-SB-SB-1

Rev 2.2 12/10/99

Page 2

Loading...

Loading...