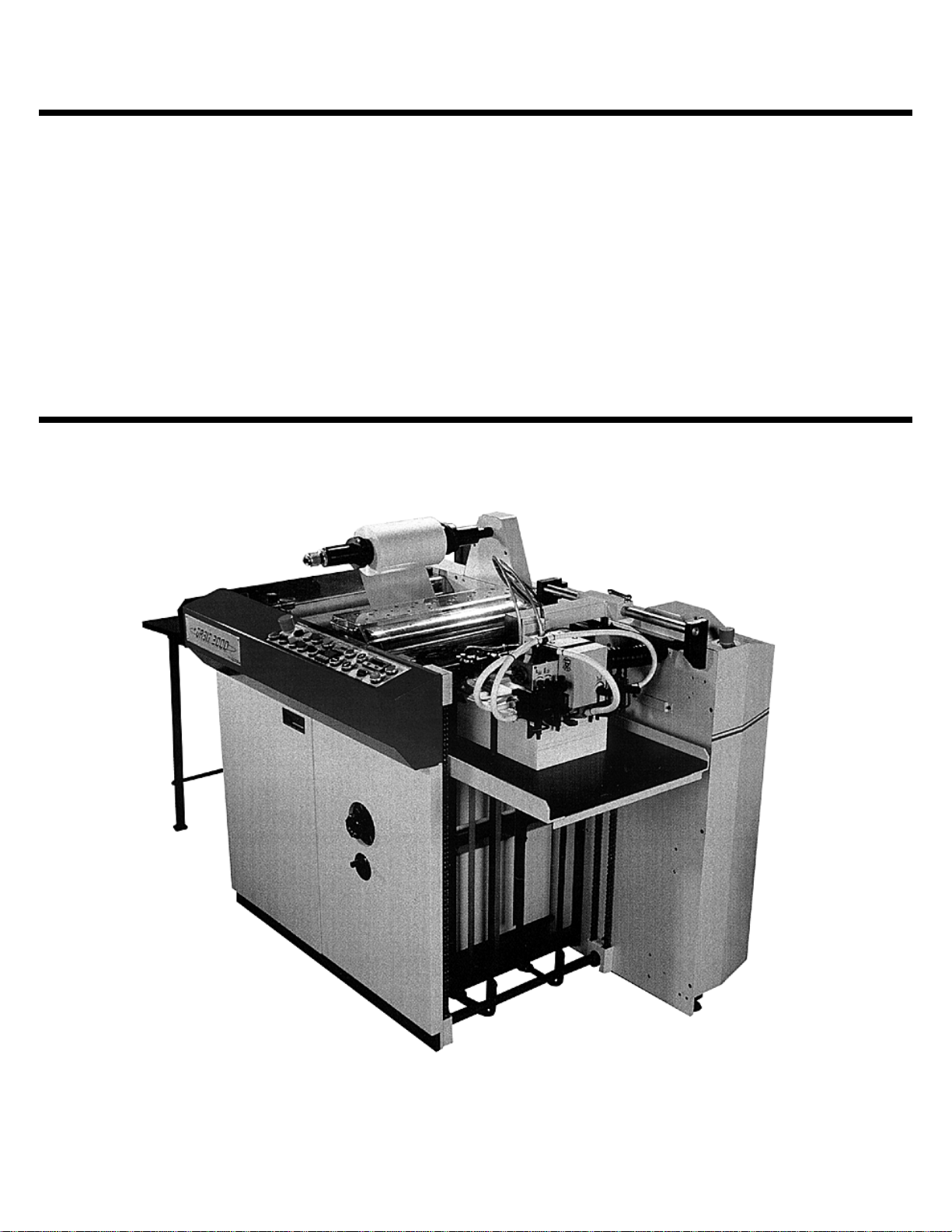

ORBIT ™ 2000 OPERATION &

MAINTENANCE MANUAL

© January 2001 GBC Films Group

Do not duplicate without written permission.

GBC Pro - T ech

4151 Anderson Road

DeForest, WI 53532

Revision : Ph: ( 608 ) 246 - 8844

Part number : 930 - 051

Fx: ( 608 ) 246 - 8645

Read me fileOrbit™ 2000 Operation and Maintenance Manual

Read Me File . . . . . . . . .

The information in this publication is provided for reference and is believed to be accurate and complete. GBC Films Group is not liable for errors in this publication or for incidental

or consequential damage in connection with the furnishing or use of the information in this

publication, including, but not limited to, any implied warranty of fitness or merchantability for

any particular use.

GBC Films Group reserves the right to make changes to this publication and to the

products described in it without notice. All specifications and information concerning products

are subject to change without notice.

Reference in this publication to information or products protected by copyright or patent

does not convey any license under the rights of GBC Films Group or others. GBC Films

Group assumes no liability arising from infringements of patents or any other rights of third

parties.

This publication is copyrighted © 2000 by GBC Films Group. All rights reserved. The

information contained in this publication is proprietary and may not be reproduced, stored,

transmitted, or transferred, in whole or in part, in any form without the prior and express written

permission of GBC Films Group.

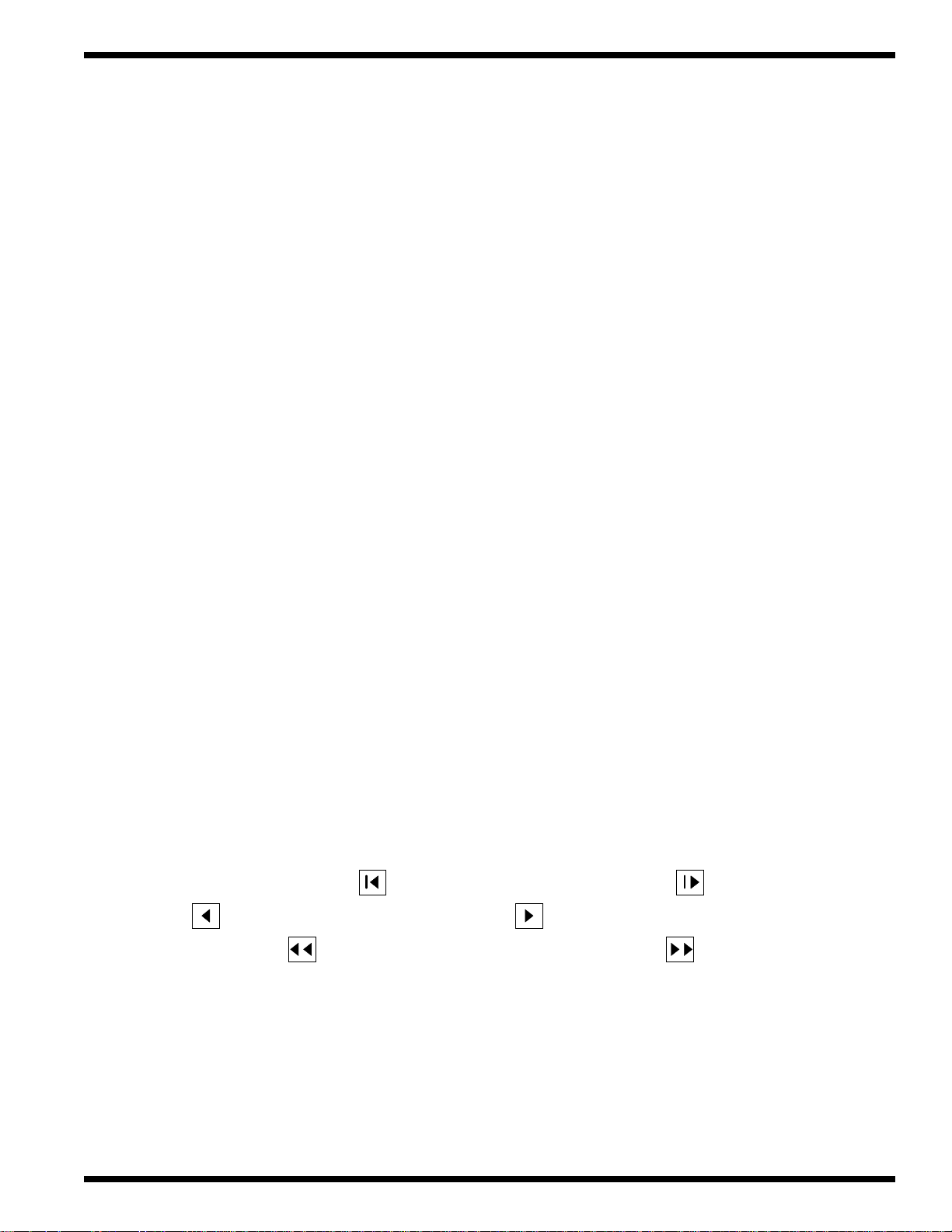

The following information will explain how to move around within the electronic version

of this publication. The hand will change to a pointer finger identifying hyperlinked areas. When

moving from page to page, use

PAGE, use

from view to view, use

VIEW.

Should you find an error within this publication or would like to make a suggestion,

please utilize the fax correspondence sheet following this read me file and fax it to the number

provided. Your comments and help will ensure up to date information. Thank you.

to go back one PAGE and use to advance one PAGE. When moving

to return to a previous VIEW and use to advance to the next

to return to the first PAGE, use to advance to the last

© GBC Films Group January 2001

Read me file Orbit™ 2000 Operation and Maintenance Manual

This page intentionally left blank.

© GBC Films Group January 2001

Fax Correspondence

Fax number : ( 608 ) 246 - 8645 Date :

To : Sean Flood at GBC Pro-Tech

4151 Anderson Road

DeForest, WI 53532

From :

Company :

Address :

Phone number : ( ) Fax number : ( )

Read me fileOrbit™ 2000 Operation and Maintenance Manual

Re : Orbit™ 2000 Operations and Maintenance Manual ( 930051 )

Section #: Page #:

Correction (s):

Additional comments:

© GBC Films Group January 2001

Read me file Orbit™ 2000 Operation and Maintenance Manual

This page intentionally left blank.

© GBC Films Group January 2001

Section 1: Safety

1.1 Safety - Complete equipment......................................................................1 - 1

1.2 Safety - Rules for loading paper .................................................................1 - 4

1.3 Safety - Rules for handling the feeding head ..............................................1 - 5

1.4 Safety - Rules for setting up the rollers and the hinged stops .....................1 - 7

T able of ContentsOrbit™ 2000 Operation and Maintenance Manual

Table of Contents

1.5 Safety - Rules for set-up of the adjustable guide plates ..............................1 - 9

1.6 Safety - Rules for the chrome and pressure rollers ..................................1 - 10

1.7 Safety - Rules for the snap roller area ......................................................1 - 14

1.8 Safety - Rules for the use of the twin knife ...............................................1 - 17

1.9 Safety - Rules for the position adjustment of the decurling bar ................1 - 19

1.10 Safety - Rules for electrical installation .................................................1 - 20

1.11 Safety - Rules for machine cleaning .......................................................1 - 22

1.12 Safety - Rules for machine maintenance and adjustments .....................1 - 24

1.13 Safety - Rules for the feeder table ..........................................................1 - 26

© GBC Films Group January 2001

Page I

T able of Contents Orbit™ 2000 Operation and Maintenance Manual

1.14 Safety - Rules for the central drive maintenance ....................................1 - 27

1.15 Safety - Rules for snapping assembly/ chain/ belt drive maintnenance ..1 - 28

1.16 Safety - Rules for maintenance/ replacement of the twin knife ..............1 - 29

Section 2: Warranty

2.1 Terms and conditions .................................................................................2 - 1

2.2 Limited period of warranty ........................................................................2 - 2

2.3 Limited warranty conditions ......................................................................2 - 2

Section 3: Specifications

3.0 Specific dimensions and weight of the equipment illustration ...................3 - 1

Page II

3.1 Dimensions and weight of the equipment ....................................................3 -1

3.2 Shipping crate dimensions ..........................................................................3 - 2

3.3 Basic technical data ...................................................................................3 - 2

© GBC Films Group January 2001

Section 4: Installation

4.0 Installation precautions ..............................................................................4 - 1

4.1 Pre-installation check list ...........................................................................4 - 2

4.2 Suggested floor layout ................................................................................4 - 4

4.3 Shipping damage inspection .......................................................................4 - 5

4.4 Transporting of the machine ......................................................................4 - 6

T able of ContentsOrbit™ 2000 Operation and Maintenance Manual

4.5 Electrical installation .................................................................................4 - 7

4.6 Becker T4.25 DSK compressor installation ..............................................4 - 8

4.7 Initial inspection .........................................................................................4 - 9

Section 5: Operations

5.0 Operations ..................................................................................................5 - 1

5.1 General information ...................................................................................5 - 2

5.1.1 Main and secondary operator position ..........................................5 - 2

© GBC Films Group January 2001

Page III

T able of Contents Orbit™ 2000 Operation and Maintenance Manual

5.1.2 The control panel ...........................................................................5 - 3

Original overlay illustration ..........................................................5 - 4

New overlay illustration ................................................................5 - 5

5.2 Feeder section ............................................................................................5 - 6

5.2.1 Sheet stacking ................................................................................5 - 7

5.2.2 Feeder table positioning ................................................................5 - 9

5.2.3 The feeding head ..........................................................................5 - 10

5.2.4 First Gate ......................................................................................5 - 15

5.2.5 Feed roller assembly ....................................................................5 - 16

5.2.6 Second gate ...................................................................................5 - 21

5.2.7 Adjustable guide plates ................................................................5 - 22

5.3 Lamination section ....................................................................................5 - 23

Page IV

5.3.1 Film roll positioning .....................................................................5 - 23

5.3.2 Heating ...........................................................................................5 - 27

© GBC Films Group January 2001

T able of ContentsOrbit™ 2000 Operation and Maintenance Manual

5.3.3 Laminating rollers .........................................................................5 - 29

5.3.4 Spreader roller ( option ) .............................................................5 - 32

5.4 Separator Section ....................................................................................5 - 33

5.4.1 The decurling bar .........................................................................5 - 33

5.4.2 Pull rollers ....................................................................................5 - 37

5.4.3 Twin knife .....................................................................................5 - 40

5.4.4 Snapping assembly .......................................................................5 - 42

5.4.5 Stacking table ...............................................................................5 - 45

Section 6: Applications

6.1 Recommended film types ............................................................................6 - 1

6.2 General threading procedure .....................................................................6 - 2

6.3 Film threading diagram ..............................................................................6 - 5

© GBC Films Group January 2001

Page V

T able of Contents Orbit™ 2000 Operation and Maintenance Manual

Section 7: Troubleshooting

7.1 Lamination troubleshooting ......................................................................7 - 2

7.2 Wave pattern troubleshooting ...................................................................7 - 4

7.3 Feeder troubleshooting ..............................................................................7 - 9

7.4 Misfed sheets troubleshooting ..................................................................7 - 10

7.5 Web troubleshooting ..................................................................................7 - 11

7.6 Machine troubleshooting ...........................................................................7 - 12

Section 8: Maintenance

8.1 Maintenance schedule ...............................................................................8 - 2

8.2 Operators Maintenance .............................................................................8 - 5

8.2.1 Safety - Rules for machine cleaning ...............................................8 - 5

Page VI

8.2.2 Safety - Rules for maintenance/ replacement of the twin knife ......8 - 7

8.2.3 Feed table chain tensioning ...........................................................8 - 9

© GBC Films Group January 2001

1.0 Safety regulations

1.1 Safety - Complete equipment

ATTENTION

SafetyOrbit™ 2000 Operation and Maintenance Manual

1/

2/

Do not operate this equipment unless you have read and understand this

operator manual and have been fully trained in its operation by a

qualified GBC service technician.

ATTENTION

The operator may use the Orbit 2000 only for the lamination of paper sheets.

The equipment may not be used for any other type of work. The type of paper

and film must comply with conditions of Section 2 of the Technical Specifications.

The equipment is provided with means to control lamination functions. The

controls as set up by the factory may not be modified or altered.

3/

Do not operate , adjust, service or repair the Orbit 2000 if you are under the

influence of alcohol, drugs, or medication.

4/

Do not operate the Orbit 2000 if you are ill or tired.

© GBC Films Group January 2001

ATTENTION

ATTENTION

Page 1 - 1

Safety Orbit™ 2000 Operation and Maintenance Manual

ATTENTION

5/

6/

All safety covers must be in place during operation. The equipment must not be started

and used, if all covers are not in place, and safety switches are not operational.

ATTENTION

Test all three interlocked safety g ua rd s each d ay ( the ch ro m e roller gu ard ,

snap roller guard and the guard under the laminating and snap ARGA s ) and

the two em ergen cy stop sw itches ( one on the co ntrol p an el and on e on th e

drive side of th e feeder ) and the p ile up safety switch ( on the feeder ta b le

guide ra ils )to ensure tha t they fu nction p rop erly.

7/

8/

ATTENTION

Exercise extreme caution when working with sheets to avoid paper cuts.

ATTENTION

Never clean any rollers while the equipment is running. If needed, turn the rollers for

cleaning or testing by using the slow forward or slow reverse push buttons.

ATTENTION

9/

Page 1 - 2

When using the slow forward and slow reverse push buttons, push and

release the buttons and wait for the machine to stop before cleaning

the exposed area of the rollers.

© GBC Films Group January 2001

ATTENTION

SafetyOrbit™ 2000 Operation and Maintenance Manual

10/

11/

Never p erfo rm ad ju stm en ts w hile the m a ch ine is run n ing. T h e m ach in e m u st first be

stopped , ad justed a nd th en restarted. ( Ex cep t When A d justing Lap For S h eet Size ! )

ATTENTION

Excercise caution when working around the feeder table, control panel and

stacking tray to avoid bumping you head.

ATTENTION

12/

13/

14/

The equipment must be fixed/ positioned on a firm and even floor. The

working station of the operator must be at the same level.

ATTENTION

The operator shall provide adequate lighting suitable for the given task.

ELECTRICAL

SHOCK

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

Page 1 - 3

Safety Orbit™ 2000 Operation and Maintenance Manual

1.2 Safety - Rules for loading paper

The normal function of the equipment is to insert paper and laminate it. For a safe loading of paper

it is necessary to follow these safety rules:

ATTENTION

1/

2/

3/

Do not attempt to load paper while the machine is running. Your fingers

couldbe hurt during the automatic insertion of paper.

WARNING

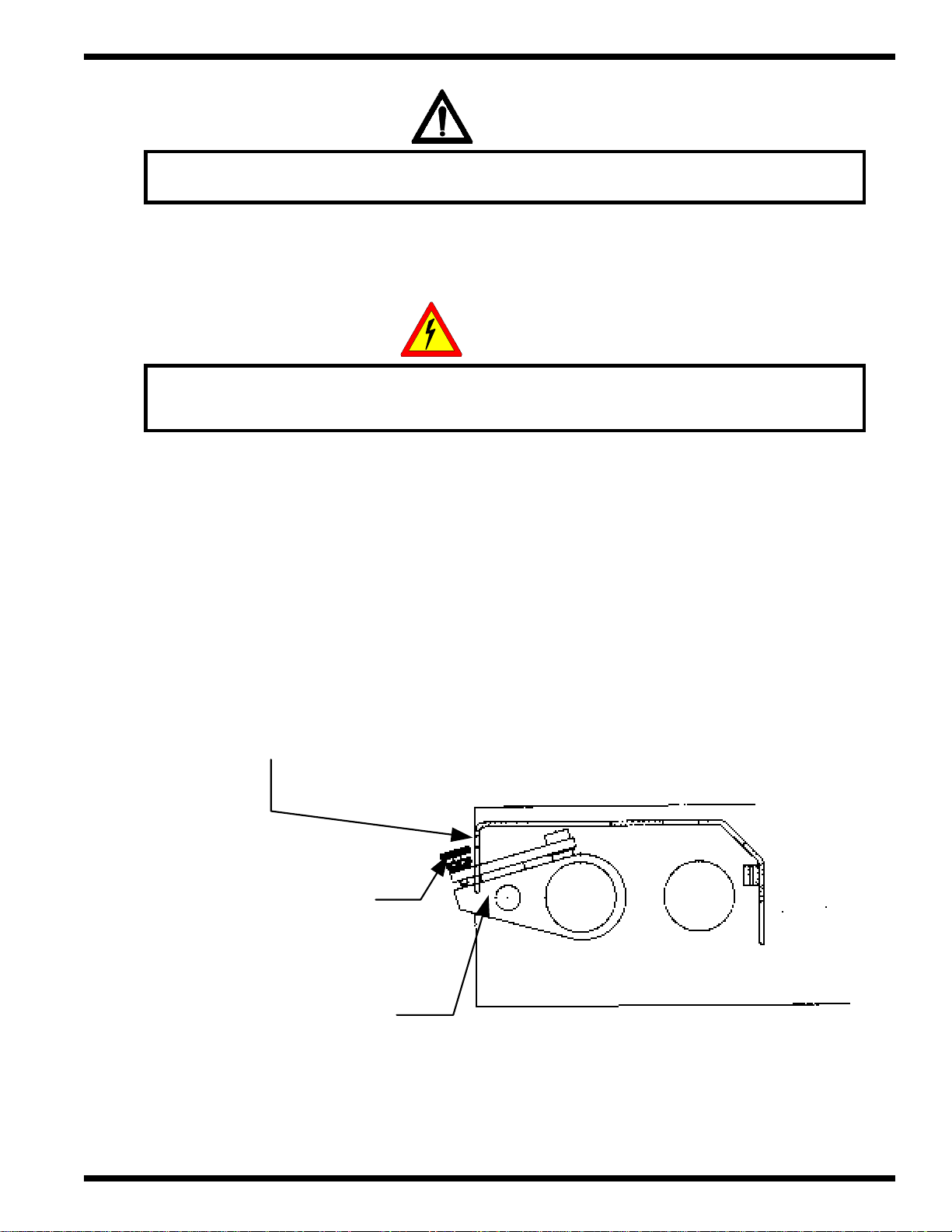

Ensure the feeder stack/ pile is in the bottom position before loading paper. To move

into that position, press the Pile/ Stack down push button.

CAUTION: Avoid bumping your head on the feeder when loading paper.

WARNING

Do not touch the stack/ pile, table or chains with your fingers or other body

parts when the table is moving or the laminator is running.

Page 1 - 4

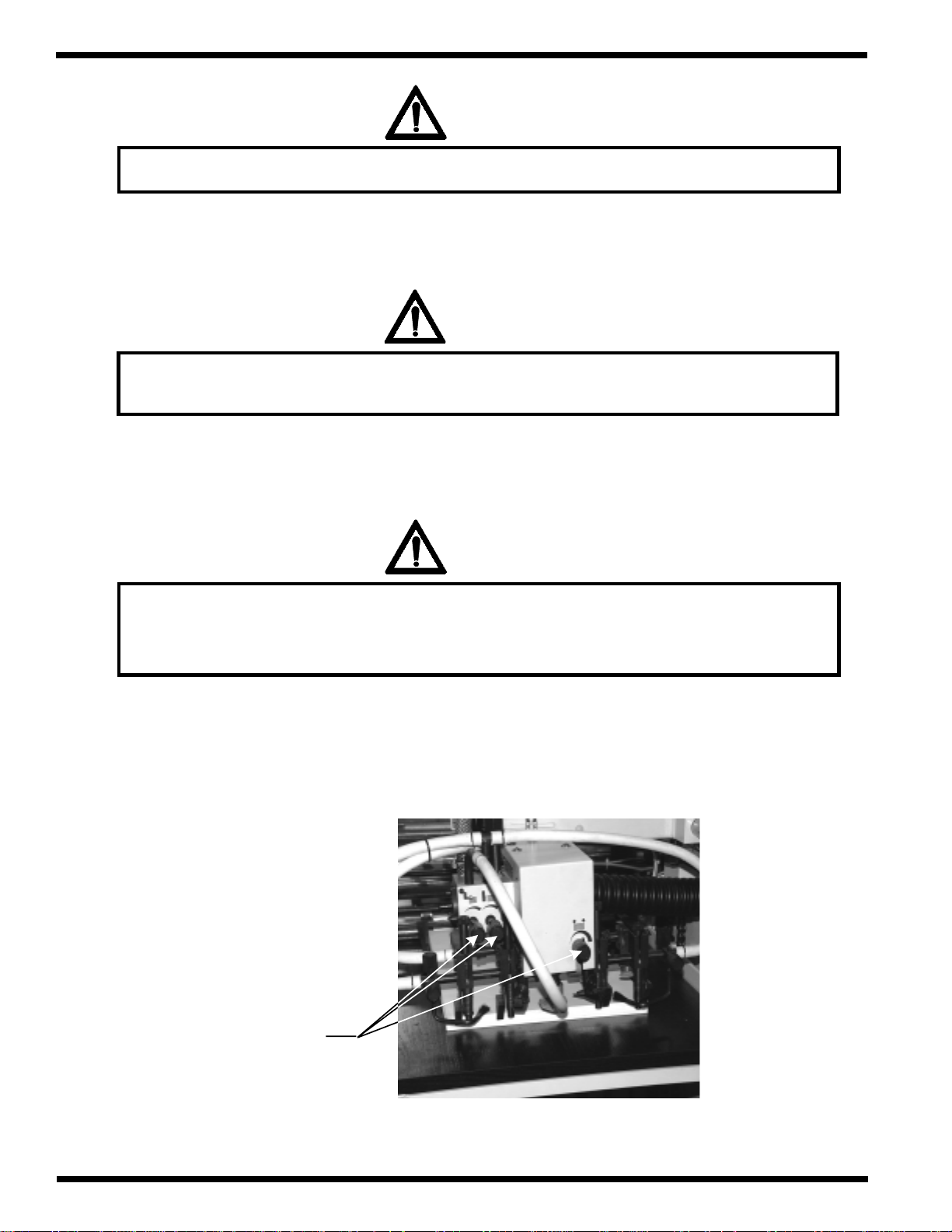

Feeder Stack/ Pile

Feeder Table

Chains

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.3 Safety - Rules for handling the feeding head

The feeding head grabs the paper sheet and inserts it into the pull rollers. When changing paper

size, the position of the feeding head must also be changed. For safe adjustments, the following safety rules

apply:

WARNING

1/

2/

3/

Do not touch the feeder head while the machine is running. The moving

suction cups may hurt your hands or fingers.

ATTENTION

Do not adjust the feeding head while the machine is running with the

exception of the control buttons described in Section 5.0

ATTENTION

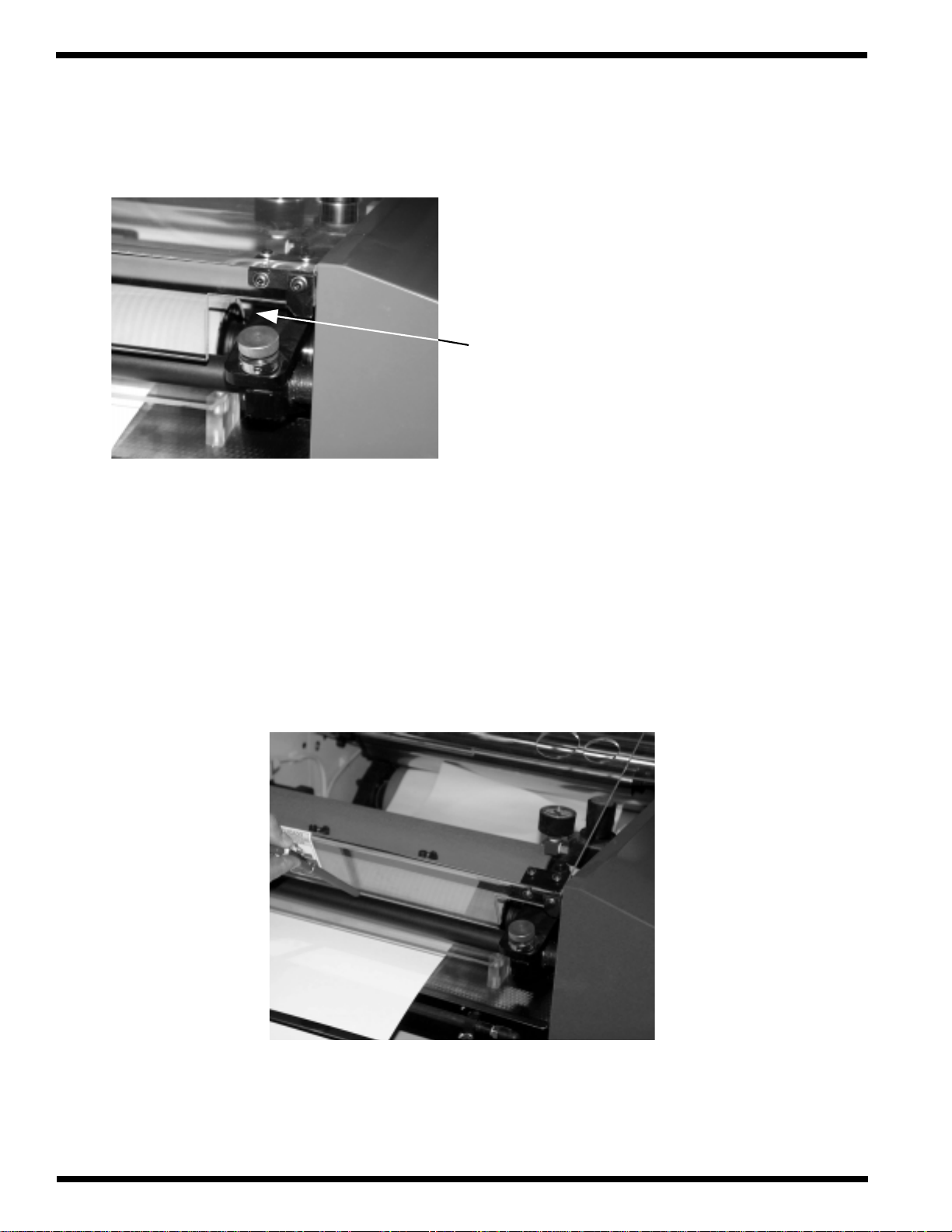

To move the head, loosen the clamp on the locating bar, then slide the head

by grabbing the upper handle bar and gently pull or push.

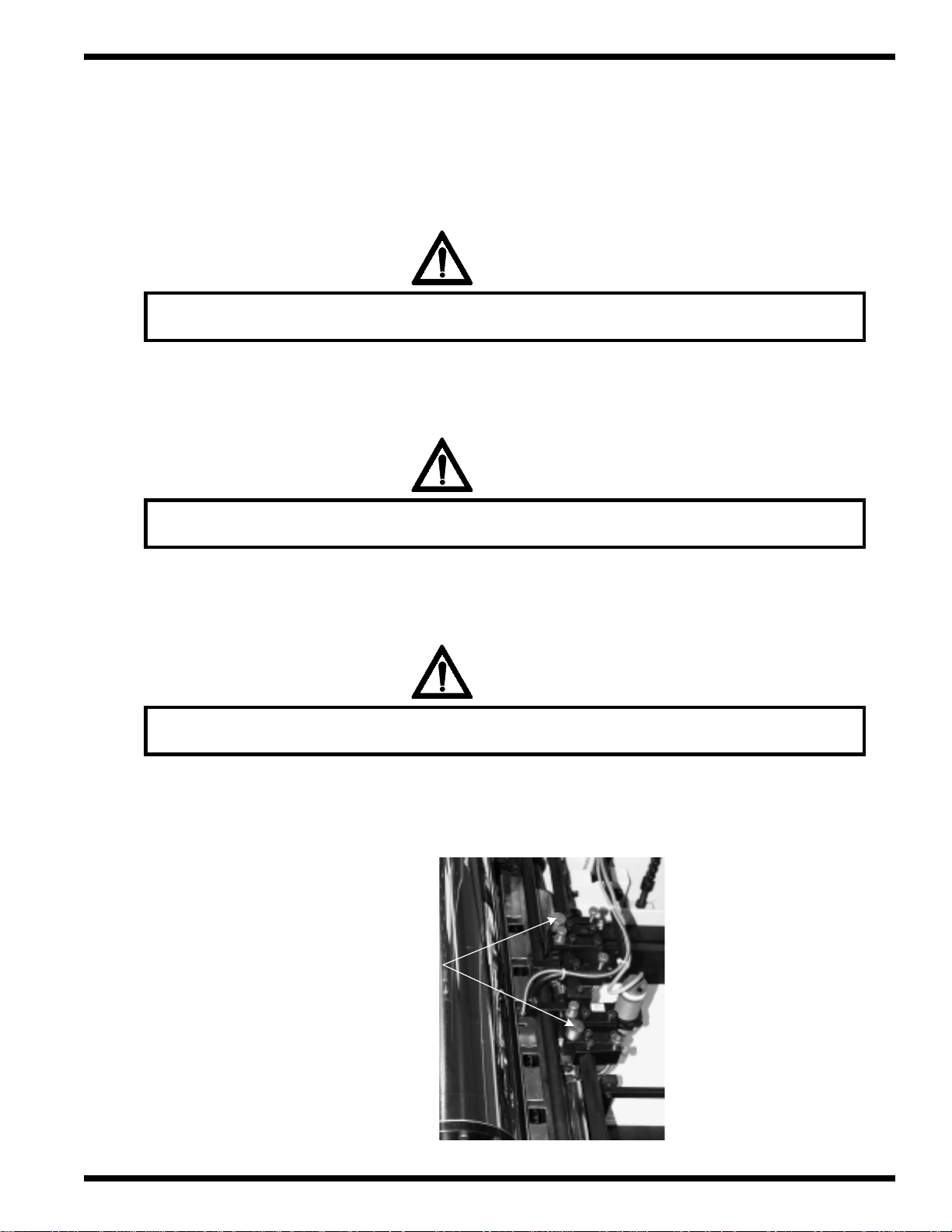

Handle bar

Clamp

© GBC Films Group January 2001

Locating bar

Page 1 - 5

Safety Orbit™ 2000 Operation and Maintenance Manual

ATTENTION

4/

Do n ot p lace an y o bjects on the u p p er su rface of th e feed ing h ead or f eeder tab le.

ATTENTION

5/

6/

Do not remove covers, fixed cover of the feeding head

and/ or the protective rubber cover.

ATTENTION

Op erate th e turn ing k n ob s carefu lly an d w ith on ly on e h an d w h ile the

machine is running. Only trained operators may use the machine. Do not wear

ties, loose fit clothing or dangling jew elry while operating the machine.

Page 1 - 6

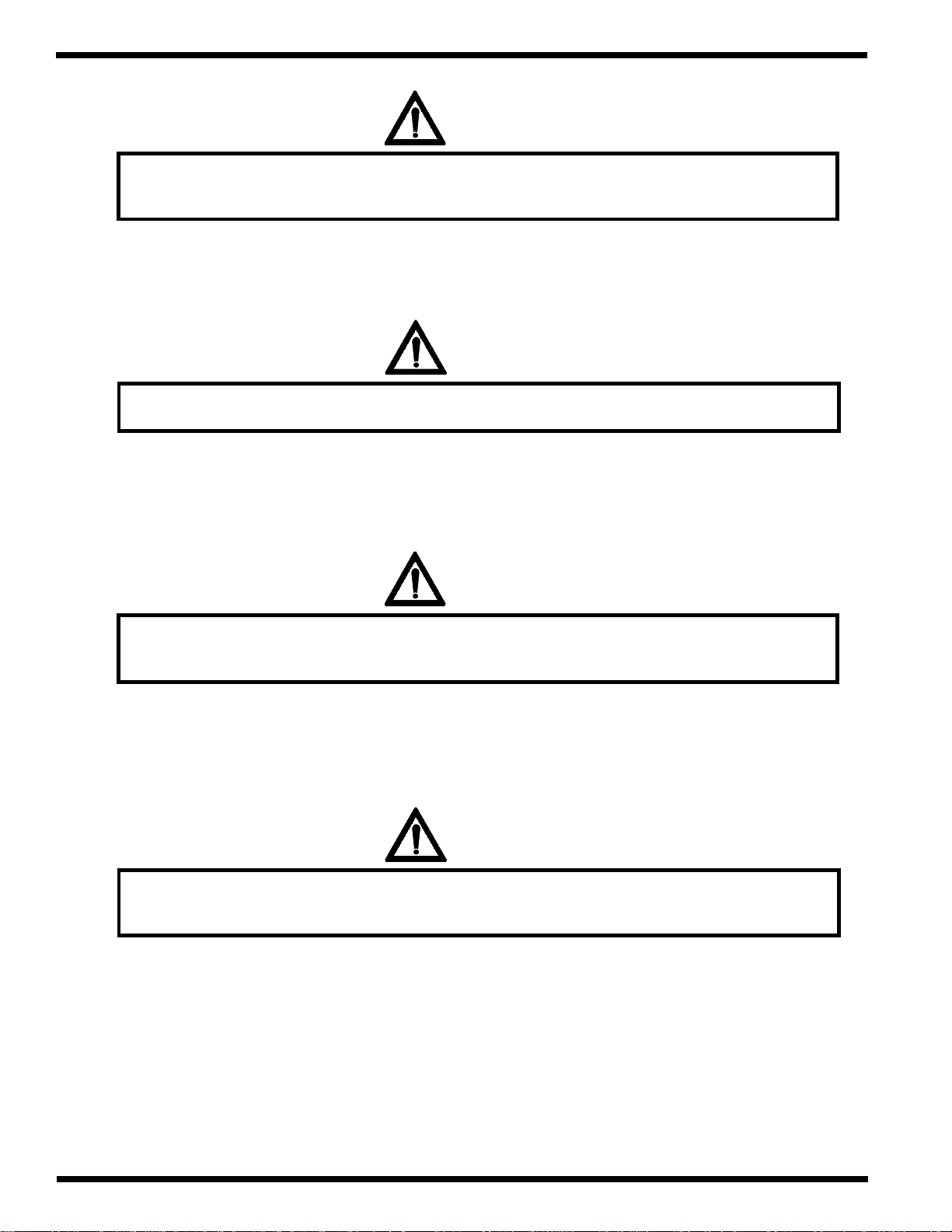

Turning

knobs

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.4 Safety - Rules for setting up the rollers and the hinged

stops

ATTENTION

1/

2/

3/

Do not touch the rollers or hinged stops while the machine is running.

WARNING

WARNING: The chrome roller may be hot. Contact will result in severe burns!

ATTENTION

The insertion or removal of any weights is permissable only when the machine is idle.

Counter weights

© GBC Films Group January 2001

Page 1 - 7

Safety Orbit™ 2000 Operation and Maintenance Manual

WARNING

4/

5/

Caution: Excercise extreme caution when adjusting the rollers

to avoid pinching by the loading roller.

ATTENTION

Ha nd le the ro llers only w h en the P lexi-glass cover of th e ch rom e ro ller is closed.

ATTENTION

6/

7/

Keep fingers, hands and clothing clear away from the rollers

while the machine is in operation.

WARNING

WARNING: Do not be startled by the pressure roller dropping

approximately two minutes after the laminator has been stopped.

Page 1 - 8

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.5 Safety - Rules for setup of the adjustable guide plates

The guiding plates form paper before it enters into the chrome roller . Their position must be adjusted

for different paper weights. For a safe adjustment of plates follow these safety rules:

ATTENTION

1/

2/

3/

The plate's position may be adjusted while the equipment is running by using

the set-up screw. This may only be performed by a trained operator.

WARNING

CAUTION: Do not wear ties, loose fit clothing or dangling jewelry. These items

can get caught by the hinged stops or the feed rollers.

ATTENTION

Th e ch rom e ro ller gua rd must be in the fu lly closed p osition.

Se t-u p s c re w

© GBC Films Group January 2001

Chro m e ro ller guard

Chro m e ro ller

Pa p e r & f ilm s to c k

Pressure roller

Page 1 - 9

Safety Orbit™ 2000 Operation and Maintenance Manual

1.6 Safety - Rules for the chrome and pressure rollers

The working temperature of the chrome roller is 120 to 135 deg C. Because of the machine function

it is not possible to cover the area around the chrome and pr essur e rollers completely. Near the contact

area of the rollers, there is a very dangerous zone. Because of that and the high temperature, the following

safety rules must be complied with:

WARNING

1/

2/

WARNING: The chrome roller may be hot. Contact will result in severe burns!

WARNING

WARNING: Keep fingers, hands and other body parts away from the rollers.

WARNING

3/

4/

Page 1 - 10

CAUTION: Never clean the surface of the rollers while the machine is running.

Use the Slow FWD and Slow Reverse to change the exposed area for cleaning.

WARNING

CAUTION: Do not wear ties, loose fit clothing or dangling jewelry. These items

can get caught the rollers while working around or loading film.

© GBC Films Group January 2001

WARNING

SafetyOrbit™ 2000 Operation and Maintenance Manual

5/

6/

CAUTION: Do not use any tools for cleaning or removing remnants of films

from the rollers while the machine is in operation.

ELECTRICAL

SHOCK

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

WARNING

7/

8/

CAUTION: Do not cover the chrome roller guard ventilation holes.

ATTENTION

When cleaning, follow the rules for Safety - Rules for cleaning in Section 3.10

WARNING

9/

WARNING: Keep hands and fingers away from the pressure/ chrome roller when

using Pressure Roll Up/ Close and Down/ Open push buttons.

© GBC Films Group January 2001

Page 1 - 11

Safety Orbit™ 2000 Operation and Maintenance Manual

WARNING

10/

11/

WARNING: Depress the laminator Stop button before attempting to

perform any web up procedure on the laminator.

ATTENTION

Alw ay s ensu re the ad h esive is facing away from the ch rom e ro ller wh en load ing film.

WARNING

12/

13/

CAUTION: Open the plastic chrome roller guard fully to prevent to

accidental closing onto your hands and fingers.

WARNING

WARNING: Hot surface. Ensure the chrome roller is below 122

O

F ( 50 OC )

before servicing or adjusting. Check the temperature on the temperature

control display or by using an external temperature sensor or wait

60 minutes from the time the machine has been turned off.

Page 1 - 12

© GBC Films Group January 2001

WARNING

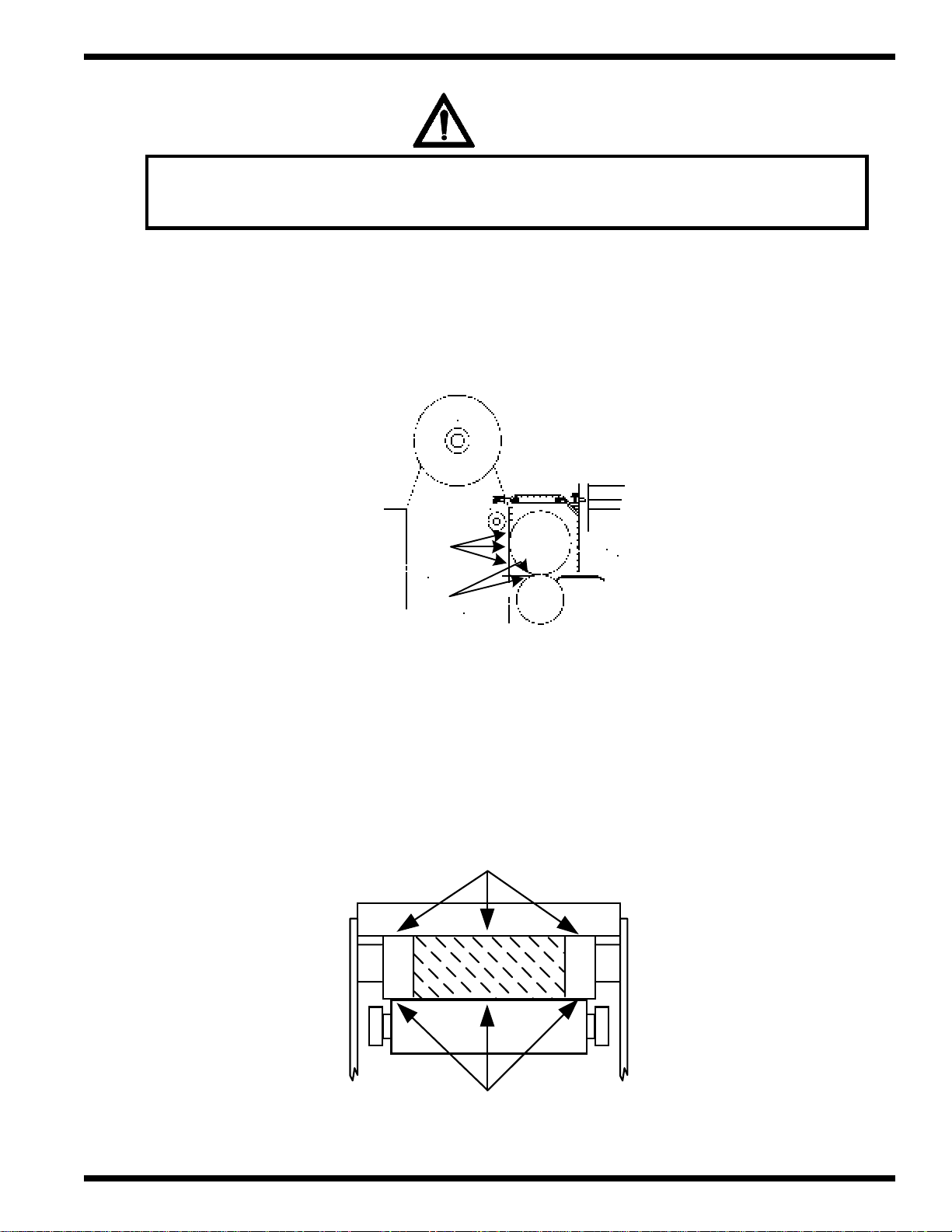

SafetyOrbit™ 2000 Operation and Maintenance Manual

14/

WARNING: Avoid making contact with any of the hot surface areas. Avoid all

pin ch points an d cr u sh h a za rd a r ea s a s illu str a ted b e lo w.

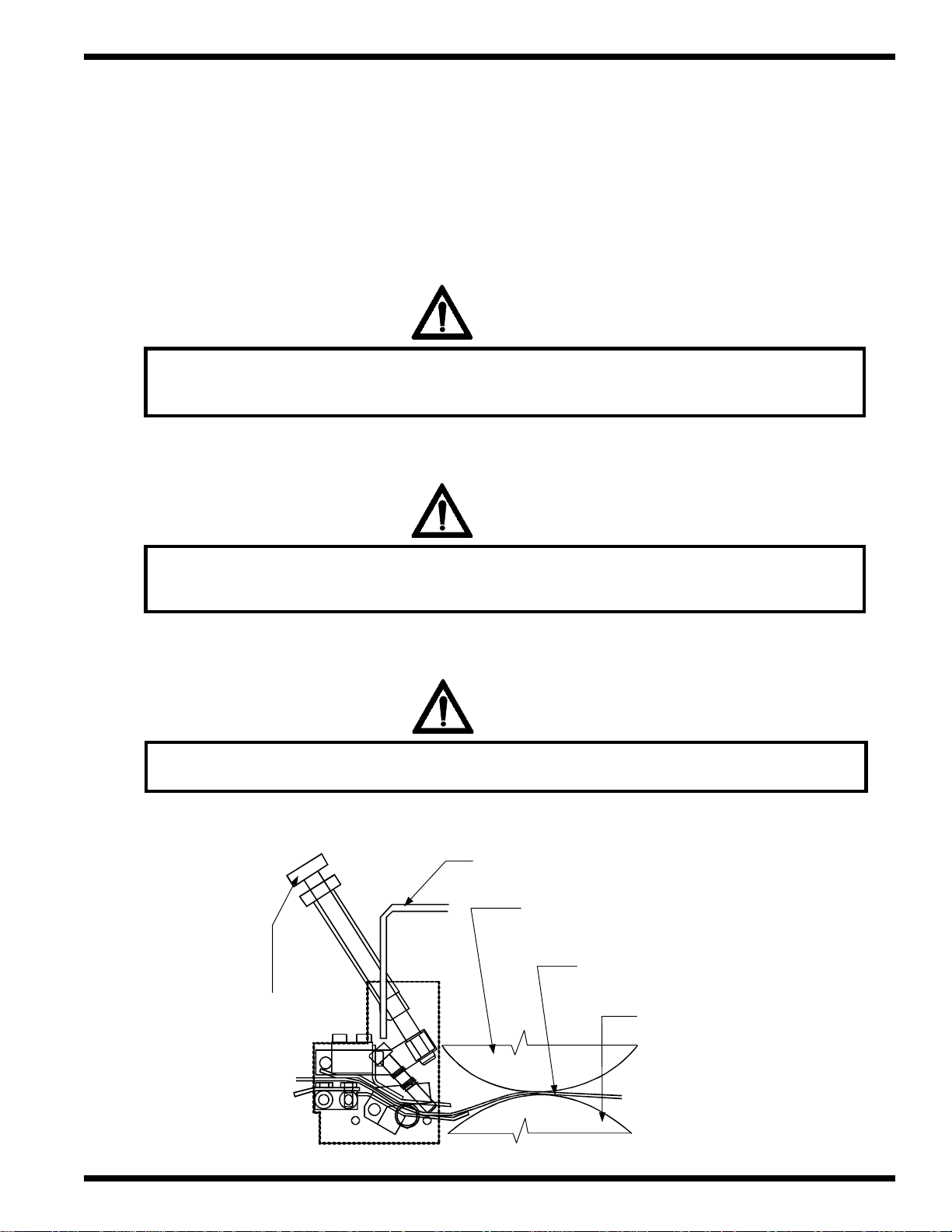

Side view

a - DANGER: High temperature

roller surface area.

b - DANGER: Pinch/ Crush

point area.

a

b

© GBC Films Group January 2001

Rear view

WARNING: Hot surface area

WARNING: Crush hazard area

Page 1 - 13

Safety Orbit™ 2000 Operation and Maintenance Manual

1.7 Safety - Rules for the snap roller area

It is not possible to cover the entire zone around the snapping roller because of the operation of the

machine. It is therefore necessary to observe the following safety rules:

WARNING

1/

2/

CAUTION: Do not adjust the regulating screws of the sn a pp ing roller w h ile the

lamina tor is in opera tion. D u ring op era tion the reg ulating screw h an d le is mov ing a n d

your fin gers may be cru shed b etw een the reg u lating screws and the P lexi-Glass co ver.

WARNING

CAUTION: Do not place your fingers or any other part of your body near the contact

point between the upper and lower snap rollers.

ATTEN TION

3/

4/

Page 1 - 14

Du ring o peration, the plastic cover mu st rem ain in the fu lly closed position.

WARNING

CAUTION: Open the plastic snap roller guard fully to prevent accidental

closing onto your hands or fingers.

© GBC Films Group January 2001

WARNING

SafetyOrbit™ 2000 Operation and Maintenance Manual

5/

CAUTION: Do not place any objects on the plastic snap roller guard.

6/

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

The snap roller side view

ELECTRICAL

SHOCK

CAUTION: Keep fingers clear during

machine operation

Adjusting regulating screws

W ARNING: Pinch hazard area

DANGER: Crush point by

Regulating Screws

Top

Bottom

© GBC Films Group January 2001

Page 1 - 15

Safety Orbit™ 2000 Operation and Maintenance Manual

Regulating screw view from the stacking table

CAUTION: Finger Crush hazard area

Rear view of the Snap Roller Guard Cover

Page 1 - 16

© GBC Films Group January 2001

1.8 Safety - Rules for the use of the twin knife

The cutting knives are covered by plastic guards from the top and side. Because of the sharpness

and speed with which the knives move it is necessary to observe the following safety rules:

WARNING

SafetyOrbit™ 2000 Operation and Maintenance Manual

1/

2/

CAUTION: Do not place your fingers or any other part of your body near

the plastic guard while the machine is running.

WARNING

WARNING: Do not place your fingers or objects under the plastic guard,

unless the equipment is disconnected from the power supply and the

emergency stop switch is depressed.

WARNING: Sharp knife can cut you!

Remove power and depress

emergency stop switch before

woking in this vicinity.

© GBC Films Group January 2001

Page 1 - 17

Safety Orbit™ 2000 Operation and Maintenance Manual

WARNING

3/

4/

WARNING: For safe knife adjustment, use a 4 mm allen wrench only. The allen

wrench can be inserted through the oval shaped openings in the upper

section of the plastic guard of the twin knife.

WARNING

WARNING: Disconnect power to the equipment before performing any task in the

vicinity of the twin knife requiring the removal of the cover

ATTEN TION

5/

6/

7/

Do not operate the laminator unless the plastic guard is in place above the twin knife.

WARNING

CAUTION: Do not place any objects on the plastic knife guard.

ELECTRICAL

SHOCK

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

Page 1 - 18

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.9 Safety - Rules for the position adjustment of the decurling bar

During lamination internal stress develops between paper and the chrome roller. The decurling

bar straightens the sheets before they exit the lamination section. During adjustment of the bar , the

following safety rules must be observed:

WARNING

1/

2/

CAUTION: Exercise caution while loosening the decurling bar handle.

The securing screw and the edge of the groove on the regulating

wheel may collide during sudden loosening.

WARNING

CAUTION: Exercise caution while adjusting the control lever position.

During sudden change in the position of the control lever, the set-up

lever of the decurling bar may be hit.

WARNING

3/

4/

CAUTION: Do not place your fingers near the groove on the regulating

wheel while changing the position of the decurling bar.

CAUTION: Due to heat eminating from the chrome roller and pressure

roller area, avoid contact with the decurling bar.

© GBC Films Group January 2001

WARNING

Page 1 - 19

Safety Orbit™ 2000 Operation and Maintenance Manual

1.10 Safety - Rules for electrical installation

WARNING

1/

CAUTION: Repairs, adjustments and/ or maintenance may be performed

by a qualified technician ( excludes any operator maintenance and operator

adjustments ). The word "qualified" is decribed below.

Qualified

• Any engineer that has experience with electrical and mechanical design of lamination equipment.

The engineers should be fully aware of all aspects of safety with regards to lamination equipment.

• Any commissioning or service engineer must be of competent nature, trained and qualified to GBC

Pro-T ech standards to fulfill that job. This person will have completed and passed the full service training

course from GBC Pro-T ech.

• Any GBC T echnician, GBC Specialist, and / or GBC Pro-Tech T echnician that has been through

the GBC Pro-T ech service training course.

2/

Page 1 - 20

WARNING: Operator maintenance and operator adjustments may be performed

only by person(s) trained in all aspects of the equipment.

WARNING

© GBC Films Group January 2001

WARNING

SafetyOrbit™ 2000 Operation and Maintenance Manual

3/

4/

5/

WARNING: At no time should you attempt to overide/ by pass and safety shield,

safety switches or safety device located on this equipment.

ELECTRICAL

SHOCK

WARNING: Do not modify any part of the circuitry at any time or for any reason!

WARNING

WARNING: All guards and covers must be returned to their original position after any

repairs, adjustments and/ or maintenance has been completed.

6/

7/

WARNING: At least 1 ft. ( 1 meter ) of free space is required in front of the machine to

allow for safe access for work on the machine electrical system.

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

WARNING

ELECTRICAL

SHOCK

Page 1 - 21

Safety Orbit™ 2000 Operation and Maintenance Manual

1.11 Safety - Rules for machine cleaning

WARNING

1/

2/

WARNING: Do not clean any part of the machine while the laminator is in operation.

WARNING

CAUTION: Never clean the surface of the rollers while the machine is running.

Use the Slow FWD and Slow Reverse to change the exposed area for cleaning.

Use the sequence described below.

a/ Press and hold the Inch/ Slow FWD or Reverse/ Slow Reverse push button.

b/ Release the perspective push button and wait for the machine to stop.

c/ Clean the exposed area of the rollers.

d/ Repeat as necessary.

Page 1 - 22

WARNING

WARNING: The chrome roller is hot. Contact will result in severe burns!

© GBC Films Group January 2001

WARNING

SafetyOrbit™ 2000 Operation and Maintenance Manual

3/

4/

5/

WARNING: Hot surface. Exercise extreme caution when cleaning the chrome roller.

Surface temperatures may be upwards of 248

ATTENTION

Always use cotton or Nomex gloves when cleaning the chrome roller.

CAUTION: Do not use aggressive solvents that could cause damage to

the rubber rollers. Use only Mineral Spirits.

TM

WARNING

O

F to 275 OF ( 120 - 135 OC ).

6/

7/

WARNING: Crush hazard exists near any rollers. Do not press Pressure Up/ Pressure

Roll Close switch when your hands or fingers are near the pressure roller arms.

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

WARNING

ELECTRICAL

SHOCK

Page 1 - 23

Safety Orbit™ 2000 Operation and Maintenance Manual

1.12 Safety - Rules for machine maintenance and adjustments

WARNING

1/

2/

WARNING: Do not remove any covers or guards while the machine is in operation.

WARNING

WARNING: Do not start the machine with the guards or covers removed.

3/

4/

WARNING

WARNING: Shut off and lock the electric supply circuit breaker before performing

any operator maintenance or operator adjustments.

WARNING

WARNING: Hot surface! Ensure the chrome roller temperature is below

122 OF ( 50 OC ) before servicing or adjusting.

Page 1 - 24

© GBC Films Group January 2001

5/

SafetyOrbit™ 2000 Operation and Maintenance Manual

WARNING

WARNING: Check the temperature on the temperature control display if power

is "ON" or by using an external temperature sensor or wait 60 minutes from

the time the machine has been turned off before performing any

operator maintenance, operator adjustments or set-up.

WARNING

6/

7/

8/

CAUTION: Do not wear ties, loose fit clothing or dangling jewelry. These items

can get caught by moving parts while performing tasks.

WARNING

CAUTION: Always wear safety glasses when changing the springs.

Uncontrolled springs can damage your eyes.

WARNING

WARNING: Operator maintenance and operator adjustments may be performed

only by person(s) trained in all aspects of the equipment.

9/

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

ELECTRICAL

SHOCK

Page 1 - 25

Safety Orbit™ 2000 Operation and Maintenance Manual

1.13 Safety - Rules for the feeder table

During the automated run the feeder table moves upward in steps. When a new ream of paper is

loaded, the table must be moved down. T o ensure your safety , the following safety rules should be followed:

WARNING

1/

2/

WARNING: Operation of the feeder table may be performed only by

person(s) trained in all aspects of the equipment.

ATTEN TION

Use the Pile/ Stack Up or Pile/ Stack Down push buttons to move the feeder table.

3/

Page 1 - 26

ELECTRICAL

SHOCK

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.14 Safety - Rules for the central drive maintenance

The main motor drives the feeding head, the feeding roller , and the chrome roller. It is located on the

opposite side from the operator, and protected by a fixed cover. For safe work, the following safety rules

should be followed:

1/

2/

WARNING

WARNING: Shut off the compressed air intake before setting up the

second hinged end-stops and pressure rollers.

WARNING

WARNING: Only person(s) trained in all aspects of the equipment may

operate the central drive.

ELECTRICAL

SHOCK

3/

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

Page 1 - 27

Safety Orbit™ 2000 Operation and Maintenance Manual

1.15 Safety - Rules for Snapping assembly/ chain/ belt drive maintenance

The chain and belt drives are protected by a fixed cover and is located on the opposite side from the

operator . For safe work, the following safety rules should be followed:

WARNING

1/

2/

WARNING: Turn power off at the main breaker before tentioning the chains or belts.

ATTEN TION

O p er a tor m a in te n ance for th e c h a in s a n d b elts ar e limited to lu b r ica tion an d

tentioning. All other work must be performed by a qualified technician.

3/

Page 1 - 28

ELECTRICAL

SHOCK

Do not modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

© GBC Films Group January 2001

SafetyOrbit™ 2000 Operation and Maintenance Manual

1.16 Safety - Rules for maintenance/ replacement of the twin knife

The twin knife is very sharp and extreme caution should be exercised when working in its vicinity .

For safe work, the following safety rules should be followed:

WARNING

1/

2/

3/

WARNING: Knife has sharp edges! Do not touch the sharp edges of the knives.

WARNING

WARNING: For safe knife adjustment, use a 4 mm allen wrench only. The allen

wrench can be inserted through the oval shaped openings in the upper

section of the plastic guard of the twin knife.

WARNING

WARNING: Do not place your fingers or objects under the plastic guard,

unless the equipment is disconnected from the power supply and the

emergency stop switch is depressed.

4/

© GBC Films Group January 2001

Do not remove or modify any guards, covers or enclosures. Contact with any

moving parts or/ and electrical voltage can result in injury or death!

ELECTRICAL

SHOCK

Page 1 - 29

Safety Orbit™ 2000 Operation and Maintenance Manual

This page intentionally left blank.

Page 1 - 30

© GBC Films Group January 2001

Orbit™ 2000 Operation and Maintenance Manual

Warranty

2.0 Warranty

GBC Films Group’s sole and exclusive liability and the customer’ s sole and exclusive remedy under

this warranty shall be, at GBC Films Group’s option, to r epair or replace any such defective part or product.

These remedies are only available if GBC Films Group’s examination of the product discloses to GBC

Films Group’s satisfaction that such defects actually exist and wer e not caused by misuse, neglect, attempt

to repair , unauthorized alteration or modification, incorrect line voltage, fir e, accident, flood or other hazards.

2.1 Terms and conditions

2.1.1 GBC Films Group warrants that the laminating machine ORBIT™ 2000, except as noted

below, is fr ee from defects in material and workmanship for a period of ( 3 ) three months from the date of

installation.

2.1.2 The warranty shall be limited to repairs, adjustments and/ or replacement as deemed

necessary by GBC Films Group.

2.1.3 THE WARRANTY MADE HEREIN IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OR MERCHANTABILITY OR FITNESS

FOR A P AR TICULAR PURPOSE. GBC FILMS GROUP WILL NOT BE LIABLE FOR PROPERTY

DAMAGE OR PERSONAL INJURY ( UNLESS PRIMARIL Y CAUSED BY ITS NEGLIGENCE ), LOSS

OF PROFIT OR OTHER INCIDENT AL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE

USE OR INABILITY TO USE THE EQUIPMENT .

© GBC Films Group January 2001

Page 2 - 1

Warranty Orbit™ 2000 Operation and Maintenance Manual

2.2 Limited period of warranty

Consumption replacement parts are warranted to be free from defects and workmanship for a period

of ( 60 ) sixty days from date of installation and include:

• Nip rollers, Snapping rollers and Pull rollers

• All rubber made rollers

• All belts

• Feeder suction cups

Warranty r epair or replacement does not extend the warranty beyond the initial ( 60 ) day period

from the date of installation.

2.3 Limited warranty conditions

The warranty becomes void in the event of mishandling, tampering, incorrect use of films not

compatible with our equipment or use contrary to the applicable instruction materials, shipping damage or

repair performed by other than a qualified service personnel authorized by GBC. Routine maintenance,

cleaning, adjustments, normal cosmetic and mechanical wear or deterioration due to extreme conditions

are not covered by this warranty .

Page 2 - 2 © GBC Films Group January 2001

Orbit™ 2000 Operation and Maintenance Manual

Warranty

2.3.1 Warranty is not applicable to the following conditions:

1/ Damage to the chrome laminating roller , rubberized feeding r ollers, pressure r ollers, pull rollers

and snapping rollers if caused by knives, razor blades or any other type of sharp tool.

2/ Damage to the chrome laminating roller , rubberized feeding r ollers, pressure r ollers, pull rollers

and snapping rollers if caused by:

– any object falling into the working area of the machine.

– cleaning the rollers using solutions or material that could harm the surface. Refer to Section 8

Maintenance under cleaning the rollers for suitable cleaners.

3/ Damage to the Plexi-Glass panels or air regulator glass caused:

– mechanically

– by using cleaners that would harm the Plexi-Glass covers

4/ Damage to the exterior finish caused:

– mechanically

– by using cleaning solvents that would harm the finish. Refer to Section 8 Maintenance under

cleaning the exterior for suitable cleaners.

5/ Damage to the feeding head by incompetent handling or adjusting.

6/ Damage to the machine caused by:

– moving

– installation performed by any person other than a qualified GBC service technician

– Operation of the equipment by person(s) not fully trained in all aspects of the machine.

© GBC Films Group January 2001

Page 2 - 3

Warranty Orbit™ 2000 Operation and Maintenance Manual

This page intentionally left blank.

Page 2 - 4 © GBC Films Group January 2001

SpecificationsOrbit™ 2000 Operation and Maintenance Manual

3.0 Specific dimensions and weight of the equipment

1956 mm

1325 mm

1010 mm

718 mm

1025 mm

1010 mm

1210 mm

3.1 DIMENSIONS AND WEIGHT OF THE EQUIPMENT

US VERSION EU VERSION

Machine dimensions 77" x 39.76" x 47.64" 1956 x 1010 x 1210 mm

(length x width x height) (length x width x height)

Base dimensions 3.3' x 6.4' 1.01 x 1.96 m

Floor area 21.3 ft

Weight of the Machine 1543 Ib 700 kg

2

1.98 m

© GBC Films Group January 2001

2

Page 3 - 1

Specifications

Orbit™ 2000 Operation and Maintenance Manual

3.2 SHIPPING CRATE DIMENSIONS AND WEIGHT

US VERSION EU VERSION

Dimensions of the crate with machine 59.1" x 47.3" x 56.7" 1500 x 1200 x 1440 mm

(length x width x height) (length x width x height)

W eight of the Machine with the crate 1676 lb 760 kg

3.3 BASIC TECHNICAL DATA

1. P APER SPECIFICATION

Max. paper size 14" x 20" 360 x 520 mm

Min. paper size 8" x 8" 200 x 200 mm

Smallest paper size 70 lb - 24 pt 115 - 350 g/m

2. FILM SPECIFICATIONS

T ypes of useable films Polypropylene, Polyester , Nylon film

Film gauge 1.0 - 1.7 mil. 1.0 - 1.7 mil.

Inside film roll diameter 21/4" - 3" 57 - 77 mm

Outside film roll diameter 7.4" 190 mm

Length of rolled film 1700 ft520 m

3. MACHINE PARAMETER

Speed 65 ft/min. 20 m/min.

Feeder pile height 25" 635 mm

US VERSION EU VERSION

2

4. ACOUSTIC NOISE DAT A

Equivalent noise level L AEG 75.3 dB (A) 75.3 dB (A)

Maximum noise level L Aeg (max) 79.8 dB (A) 79.8 dB (A)

Level of the acoustic output L W A 87.7 dB (A) 87.7 dB (A)

Page 3 - 2

© GBC Films Group January 2001

5. ELECTRICAL CIRCUIT

Power input 5 kV A +/- 10 % 5 kVA +/- 10 %

Basic voltage requirements 3 phase 230 V 60 Hz 3 phase 400 V 50

Nominal current 30 A 30 A

6. PNEUMATIC CIRCUIT

Pressure in the machine circuit 90 psi @ 4 CFM 0,6 MPa @ 113 l/min.

The feeder pneumatic circuit

- vacuum - 0.6 Bar - 0.6 Bar

- pressure +0.6 Bar +0.6 Bar

SpecificationsOrbit™ 2000 Operation and Maintenance Manual

US VERSION EU VERSION

with ground Hz with ground

7. MIN/ MAX 1ft./ min / 65 ft./ min .3 m/ min. / 20 m./ min

Slow Forward V ariable speed V ariable speed

Slow Reverse V ariable speed V ariable speed

© GBC Films Group January 2001

Page 3 - 3

Specifications

This page intentionally left blank.

Orbit™ 2000 Operation and Maintenance Manual

Page 3 - 4

© GBC Films Group January 2001

InstallationOrbit™ 2000 Operation and Maintenance Manual

4.0 Installation Precautions

WARNING

WARNING: To avoid injury to yourself or damage to the equipment, please

read and understand the instructions in this manual before you

attempt to install, operate or service the laminator!

1. The GBC Orbit™ 2000 System may be installed only by a qualified ( as defined below ) GBC employed technician.

2. Any moving or un-installing of the equipment may also, only be done by a qualified ( as defined below ) GBC

employed technician.

3. Once the machine is installed, all cables remaining on the floor from the electrical cabinet to the machine must be

covered, to avoid any accidents.

Qualified

• Any engineer that has experience with electrical and mechanical design of lamination equipment. The engineers

should be fully aware of all aspects of safety with regards to lamination equipment.

• Any commissioning or service engineer must be of competent nature, trained and qualified to GBC Pro-T ech

standards to fulfill that job. This person will have completed and passed the full service training course from GBC ProT ech.

• Any GBC T echnician, GBC Specialist, and / or GBC Pro-T ech T echnician that has been through the GBC

Pro-T ech service training course.

© GBC Films Group January 2001

Page 4 - 1

Installation

Orbit™ 2000 Operation and Maintenance Manual

4.1 Pre-installation checklist

The installation of the machine, the start-up of operation, and training must be provided by a qualified

GBC Films Group service technician, or another authorized organization.

Prior to the machine installation it is necessary to provide:

– an even floor of 2500 kg/ sq. meter minimal load factor ( 36.165 lb/ sq.ft ).

– a connection to air pressure of 0.6 Mpa @ 1 13L/ min. ( 90 PSI @ 4 CFM ) for the pneumatic

circuit.

– a fused dicconnect

– a connection of 3 phase with ground, 400/ 230VAC+/- 10 %, 50 Hz, 30 amps ( EU V ersion )

for the electrical circuit.

– a connection of 3 phase with ground 230VAC +/- 10 %, 60Hz, 30 amps ( US V ersion ) for

the electrical circuit.

Becker Compressor

The Becker compressor supplies air to the feeding assembly , and is connected by means of

a plug to the machine.

Machine position

The machine must be placed so that

Page 4 - 2

– space of at least 40 cm (1.3 ft) is available between the stacking table and the wall or any

other fixed object

– space of at least 80 cm (2.6 ft) is available on the drive side between the covers and the wall

or any other fixed object (another machine, etc.)

© GBC Films Group January 2001

InstallationOrbit™ 2000 Operation and Maintenance Manual

The Floor

The machine must be placed on a firm and reasonably even floor capable of supporting a

load of 2500 kg/ square meter ( 36165 lb/ sq.ft. ).

Note

The machine is also provided with a terminal to connect an additional conductor for the interconnection, since the value of leakage currents from noise suppression elements is higher than 3.5

mA AC. This terminal for the additional interconnection can be located on the bar between the side

plates, when the lower cover on the operator's side has been opened. The additional interconnecting

conductor is to be attached to this terminal.

ELECTRICAL

SHOCK

Only a qualified electrician should connect power to the laminator. You can be severely

shocked, electrocuted or cause a fire if power is improperly applied.

ELECTRICAL

SHOCK

Do not allow anything to rest on the power cord. Do not locate the cord where people

can walk on it. You or others can be severely shocked, electrocuted or cause a fire.

© GBC Films Group January 2001

Page 4 - 3

Installation

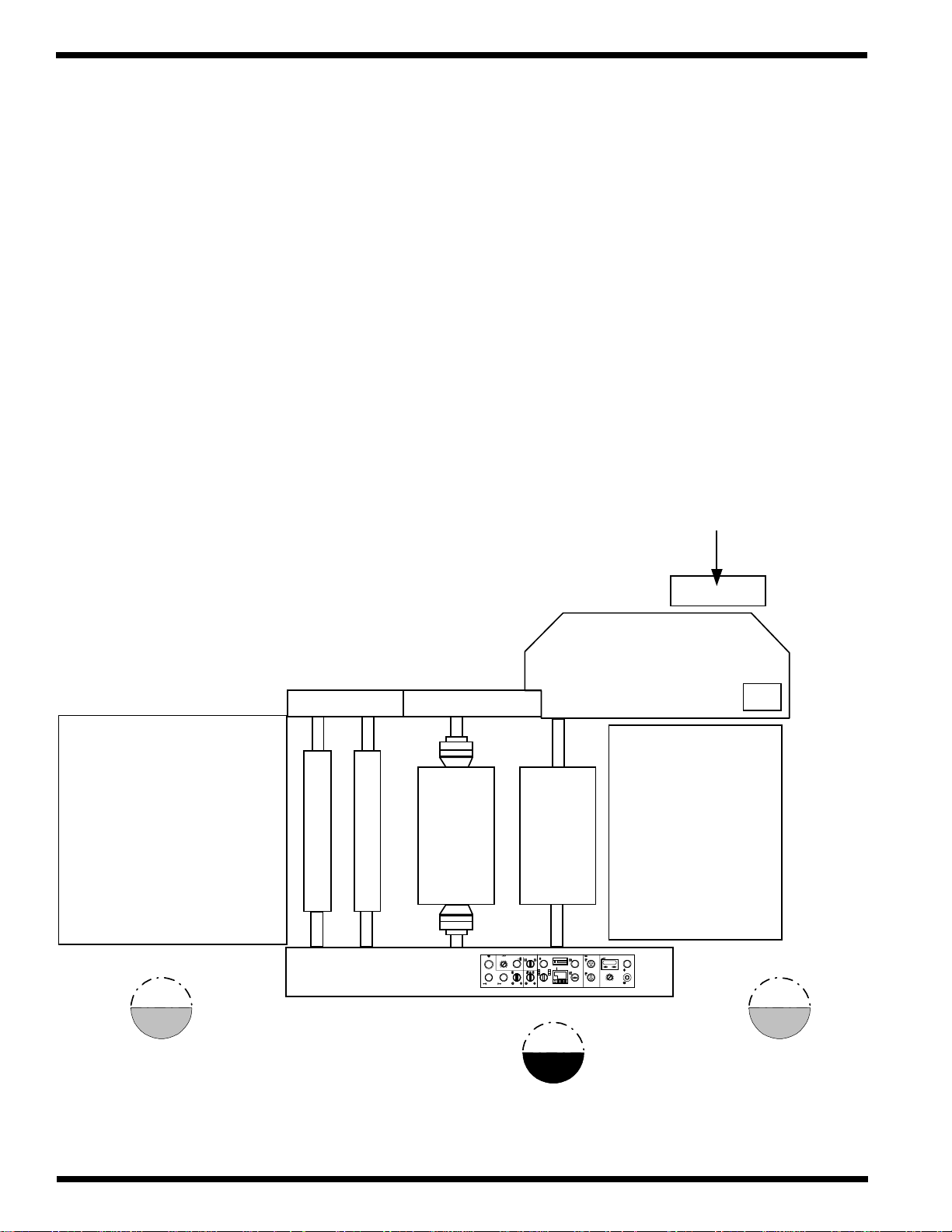

4.2 Suggested floor layout

T4.25DSK

Becker Compressor

Orbit™ 2000 Operation and Maintenance Manual

Operation

Secondary

Min. 0.8 m

( Min. 2.6 ft. )

Main

Operation

Operation

Secondary

Page 4 - 4

Min. 0.4 m

( Min. 1.3 ft. )

© GBC Films Group January 2001

4.3 Shipping damage inspection

INFORMATION

Before signing the Bill of Lading, youshould inspect the crate and / or palletfor signs

of damage or missing items; ifapplicable, make note of this on theBill of Lading.

INFORMATION

InstallationOrbit™ 2000 Operation and Maintenance Manual

ALL SHIPMENTS ARE EX-WORKS. At ourdock, title passes to the buyer. Please

review your insurance coverage prior to shipment, as you are responsible for all

subsequent freight charges and risks.

WARNING

The Orbit™ 2000 is a large and heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to move the machine. The machine is not

designed to be tipped up or sideways in any way. Such action disturbs the exact

alignment of moving parts on the machine and requires extensive realignment.

You can be crushedor seriously injured.

GBC Pro-Tech's warranty does not cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films Group bears no responsibility for

personal injury or damage due to moving the machine improperly.

© GBC Films Group January 2001

WARNING

Page 4 - 5

Installation

Orbit™ 2000 Operation and Maintenance Manual

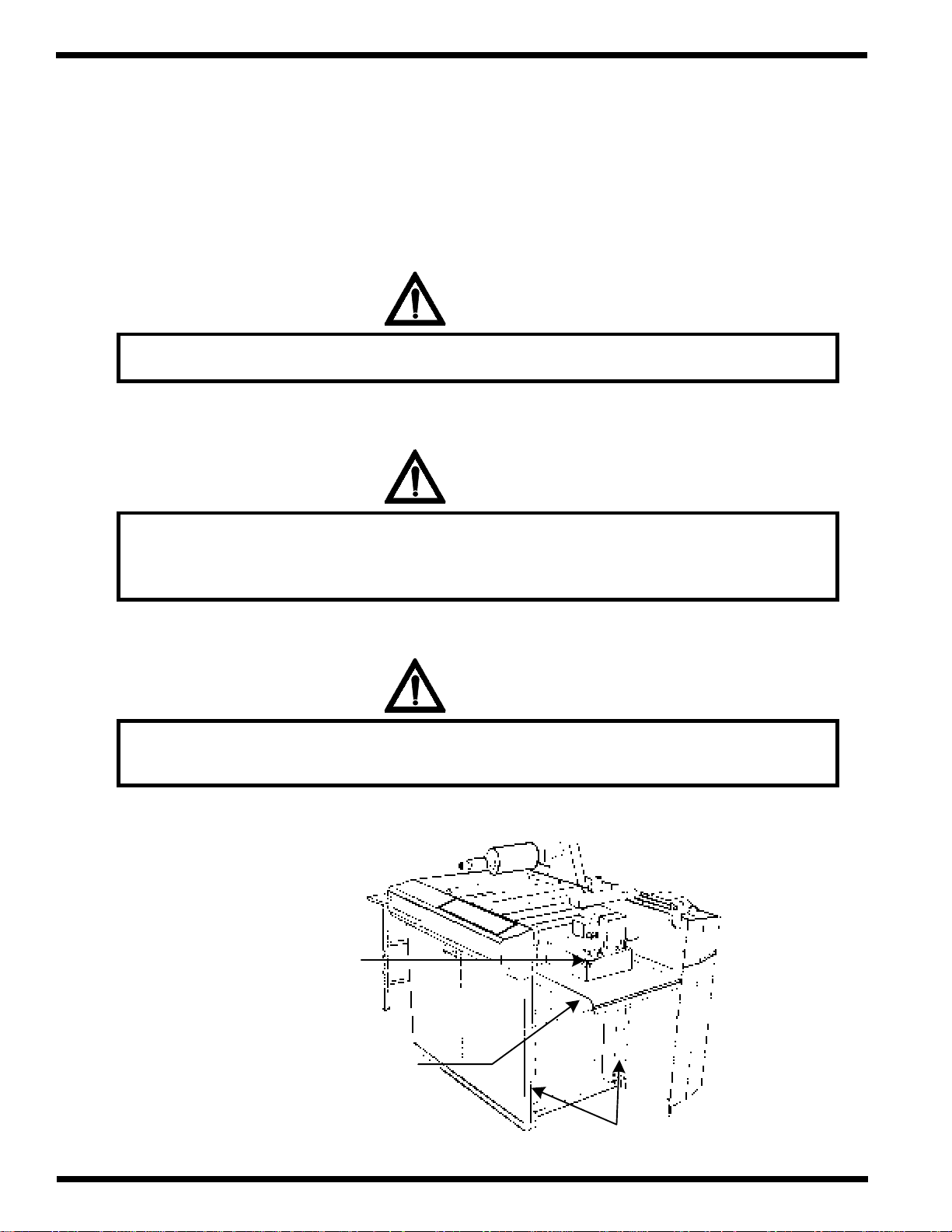

4.4 Transporting of the machine

The machine is shipped from the factory bolted to

a wooden shipping pallet/ frame.

Note the position of the machine on the pallet/

frame as illustrated to the right.

Moving the machine on the pallet/ frame

can only be accomplished with a lift truck

or a pallet wagon.

The forks of the lift truck/ pallet wagon

must be long enough to reach past the

transport supports on the farthest side

from the lift truck/ pallet wagon.

T o remove the machine fr om the pallet/ frame:

– remove the shipping bolts

– drive the lift truck/ pallet wagon between the

pallet/ frame and the machine frame

– slowly raise the machine from the pallet/ frame

– Replace the shipping angle irons with the leveling

feet before final placement.

The shift of the machine from the frame to

the floor is shown on the picture.

Page 4 - 6

© GBC Films Group January 2001

InstallationOrbit™ 2000 Operation and Maintenance Manual

4.5 Electrical installation

The main plug may be inserted only into a fixed electrical distribution socket, regularly inspected

according to appropriate national standards. Prior to the start-up, the initial inspection of the machine

electrical equipment must be done according to IEC 364-6-61 standard, which includes the fixed power

input if the machine is not connected by a flexible cable. The machine may be started only when all electrical

requirements have been complied with according to appropriate national standards for printing machines.

During the entire time of operation the user is obligated to comply with the requirements of applicable

national standards for printing machines, and their electrical wiring.

EU VERSION US VERSION

Nominal voltage 3 NPE 400 V/230 V 50 Hz 3 Phase with ground

230+/- 10% VAC 60 Hz

Operating voltage 24 VDC 24 VDC

Power input 5 kVA 5 kVA

Nominal current 30 Amps 30 Amps

Recommended fuses 25 A gTF 500V 25 A gTF 500V

Electrical installation has been designed, manufactured and tested according to EN 60204-1, 1992

Standard, and is shown on electrical installation schematic diagram BJ-41-1 10 to BJ-41-1 18, description

BJ-41-211 to BJ-41-212, and lay-out BJ-41-200- to BJ-41-203.

The manufacturer of ORBIT 2000 guarantees that the machine complies with interference elimination

to a level specified by EN 500081-1 part 1, in residential, business, and light industry zones.

Repairs, setup, and maintenance may be performed by a technically trained or sufficiently experienced

person, who knows how to avoid dangers involved in manipulations with electricity, as stated in EN 602041, article 3.55.

© GBC Films Group January 2001

Page 4 - 7

Installation

Orbit™ 2000 Operation and Maintenance Manual

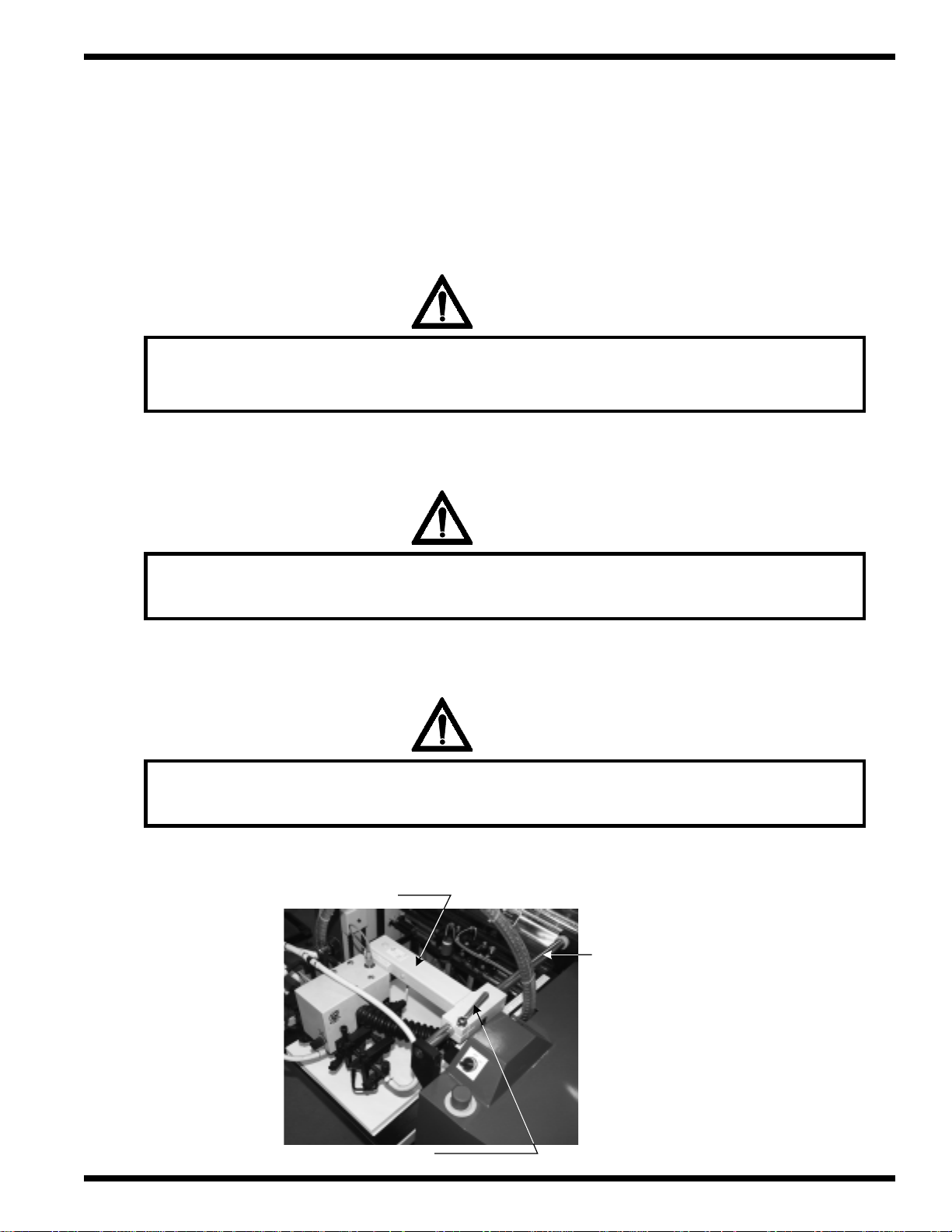

4.6 Becker T4.25 DSK Compressor installation

WARNING

WARNING: Do not place the compressor near machines that have

exhaust air containing oil.

The machine includes a compressor with its own original technical description. It is the rotary wing

type Becker T4.25 DSK compressor , operating without the use of oil. It may not suck in any moistur e, oil,

or any other fluid.

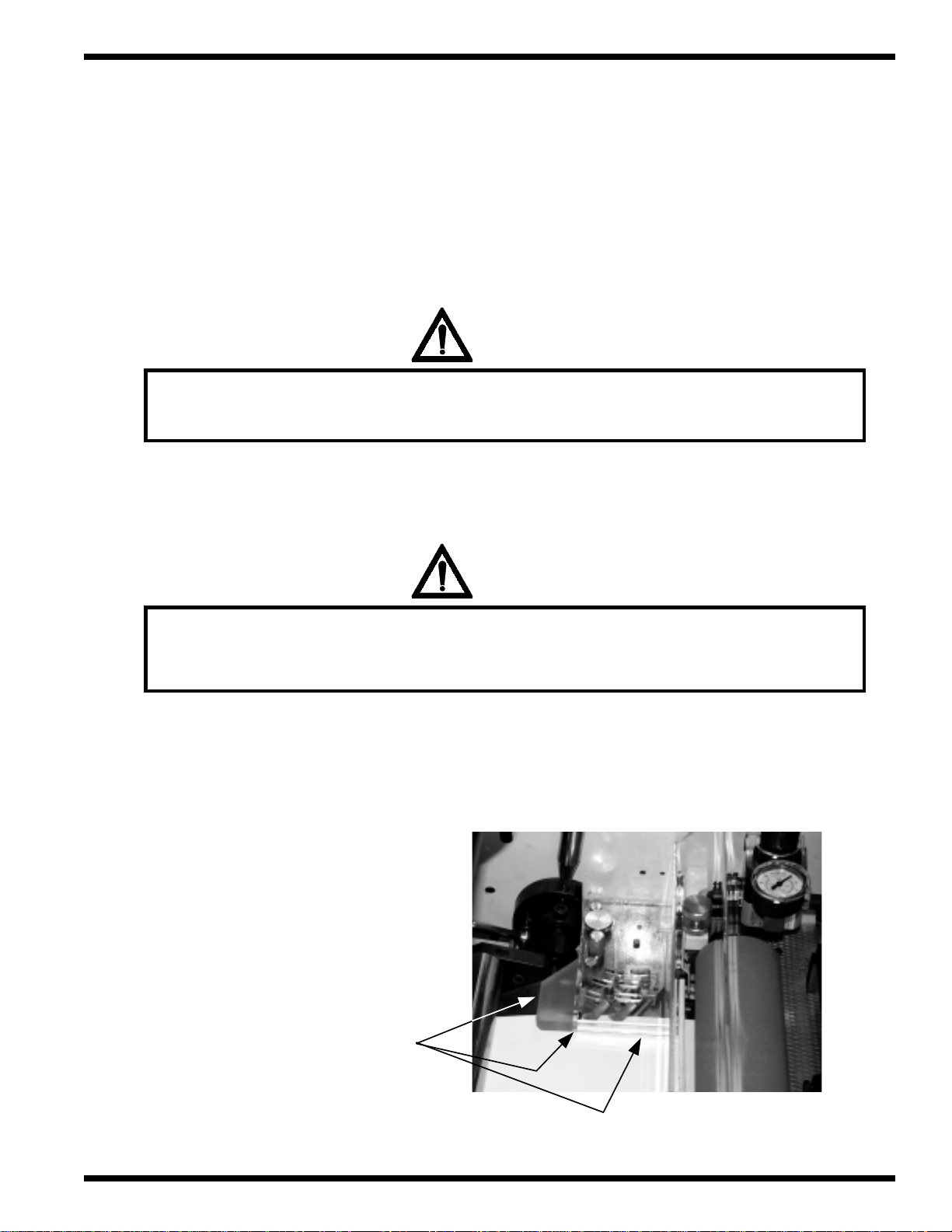

When the compressor has been attached to the machine, check the vacuum, which should be 0.4 Bar

( 1 1.81 inHg ). Adjust the compressor for correct vacuum gauge ( a ) indication. The compr essor may be

switched on and off by means of the switch ( b ), while the machine is being adjusted.

a

b

The pressure and the vacuum valves are adjusted as needed for the operation. When the valves are

completely closed, the compressor has the highest output, electric power is unnecessarily wasted, and wear

and tear are increased.

Page 4 - 8

© GBC Films Group January 2001

4.7 Initial inspection

Remove power to the laminator before performing step ( a ) below. Contact with

electrical components while power is supplied can result in injury or death!

a/ Electrical assembly inspection

– Component mounting

InstallationOrbit™ 2000 Operation and Maintenance Manual

ELECTRICAL

SHOCK

– T erminal security

– Wire tightness

– Circuit breaker wires

ELECTRICAL

SHOCK

Electrical troubleshooting should be left to qualified GBC service technicians!

Electrical shock hazard!

b/ Protective circuit inspection

– The safety of protective circuits may be checked by feeding a current of at least 10 A (50

Hz) from the PEL V source for at least 10 seconds. The test is done between the PE terminal

and various points that are part of the protective circuit. See EN 60204-1, article 20.2.

© GBC Films Group January 2001

Page 4 - 9

Installation

– The voltage measured between the terminal PE and the test points may not exceed

c/ Voltage checks

– from fused disconnect - 240 VAC +/- 10% 3 phase with ground.

– Check each leg, A,B nad C, to ground for proper voltage drop.

Orbit™ 2000 Operation and Maintenance Manual

U =3.3V fo r S= 1.0 square millimeters

U = 2.6V f or S= 1.5 sq. millimeters

U = 1.9V f o r S = 2.5 sq. millimeters

( U ) is the largest drop in voltage and ( S ) is the smallest effective diameter

of the protective conductor in the tested branch of the protective circuit.

– Check main line voltage to locking plug connection on the Orbit™2000.

– Connect plug from Orbit™2000 to electrical supply .

d/ Perform a safety check of all emergency stops, safety latches and lockouts.

– Emergency stop buttons

– Safety shields

– Power on/ off lockout

– T able limit switches

– Feeder head protect from pile-up table

e/ Power-up the Orbit™2000 and confirm that the temperature contoller is illuminated.

If the temperature controller is not illuminated, check the E-Stops, safety latches or lockouts

for activation.

f/ Check all roatations of motors: Feeder Pile-up, Feeder pile-down, main drive and

compressor/ feeder

Page 4 - 10

© GBC Films Group January 2001

g/ Perform a function check of the control panel switches.

h/ Ensure all guides move corr ectly.

i/ Install the stacking table.

InstallationOrbit™ 2000 Operation and Maintenance Manual

© GBC Films Group January 2001

Page 4 - 11

Installation

This page intentionally left blank.

Orbit™ 2000 Operation and Maintenance Manual

Page 4 - 12

© GBC Films Group January 2001

5.0 Operation

WARNING: Only person(s) trained in all aspects of safety and operations

CAUTION: Do not wear ties, loose fit clothing or dangling jewelry. These items

OperationsOrbit™ 2000 Operation and Maintenance Manual

WARNING

may use this equipment.

WARNING

can get caught by the hinged stops or the feed rollers.

This section describes in detail each part of the four areas on the Orbit™ 2000. The four areas

consist of;

( 1 ) 5.1 General information

( 2 ) 5.2 The Feeder Section

( 3 ) 5.3 The Lamination Section

( 4 ) 5.4 The Separator Section.

ATTENTION

Do not operate this equipment unless you have read and understand this

operator manual and have been fully trained in its operation by a

qua lified GB C service technician.

© GBC Films Group January 2001

Page 5 - 1

Operations

Orbit™ 2000 Operation and Maintenance Manual

5.1 General information

Under this section you will find an illustration of the main and secondary operator positions, the

control panel legend and an illustration of the control panel (with the original overlay and the new

overlay).

5.1.1 The main and secondary operator positions

Becker Compressor

T4.25DSK

Secondary

Operation

Page 5 - 2

Secondary

Operation

Main

Operation

© GBC Films Group January 2001

5.1.2 The control panel

Legend

1. Push button - start

2. Push button - stop

3. Speed indicator

4. Potentiometer - speed adjustment by means of the main motor

5. Push button - feeder table UP

6. Push button - feeder table DOWN

7. Push button - pressure roller UP

8. Push button - pressure roller DOWN

OperationsOrbit™ 2000 Operation and Maintenance Manual

9. Laminated sheets counter

10. Temperature regulator of the chrome roller deg C/ deg. F

11. Indicator of missing sheets

12. Switch for changing heating zones on the chrome roller

13. The pulling roller switch, UP/DOWN

14. The cutter drive switch ON/OFF

15. Push button for pulsing the snapping assembly

16. Snapping drive switch

17. Potentiometer - snapping drive speed adjustment

18. Push button - r everse drive

19. Push button - emergency stop

20. Push button - stepping run (slow drive for equipment cleaning)

Please refer to the control panel diagram that r esembles your machine on pages 4 and 5.

The overlay has changed but the functions have remain the same.

© GBC Films Group January 2001

INFORMATION

Page 5 - 3

Operations

Original overlay

Orbit™ 2000 Operation and Maintenance Manual

MACHINE START

1

SPEED

3579

R00

UP

PILE

MACHINE STOP

24

80

90

70

60

50

40

DOWN

100

0

30

10

20

68101214161820

F E E D E R

TEMPERATURE

DOWN

120.0

120.0

UP

PRESSURE ROLL

9999

1113151719

L A M I N A T I N G S E C T I O N

S E P A R A T O R

EMERGENCY

MISSING SHEETS

PULL ROLLERSNAP IMPULSE

50

SEP. SPEED

8"-14"8"-11"

OFF

HEATER

UPDOWN

80

90

70

60

40

30

10

20

ONOFFONOFF

KNIFESEP. MOTOR

100

REVERSEMACHINE INCH

0

Page 5 - 4

© GBC Films Group January 2001

New overlay

OperationsOrbit™ 2000 Operation and Maintenance Manual

START

1

357

SPEED

R00

UP

70

60

50

40

30

DOWN

STOP

24

80

90

100

%

0

10

20

68101214161820

F E E D E R L A M I N A T O RL A M I N A T O R

TEMPERATURE

DOWN

120.0

120.0

UP

9999

9

1113151719

S E P A R A T O R

MISFEED

CLOSEOPEN

50

SNAP SPEED

EMERGENCY STOP

STOP

HEATERS

STARTSTOP

PULL ROLLER

STARTSTOP

SNAP MOTOR

SNAP IMPULSE

80

90

70

60

40

100

%

0

30

10

20

SLOW REV

SLOW FWD

© GBC Films Group January 2001

Page 5 - 5

Operations

Orbit™ 2000 Operation and Maintenance Manual

5.2 Feeder Section

The feeding mechanism consists mainly of the assembly for the lowering and lifting of the feeding

table. In addition, there are the feeding table, the feeding head, fixed face stops, first gate, side stackers,

feeding roller, and the second gate.

The feeder serves the purpose of stacking paper sheets, and is operated by roller chains guided

by two leading spindles. The sheets are taken from the table and inserted into the machine by means of

the feeding head. During lamination the paper is removed from the pile.

The feeding head feeler controls the height of the pile and the lifting of the table. The feed table is

lifted automatically as the paper is removed. One step of lift equals 2 to 3 mm, independently of the

amount of paper . The table lift is either automatically contr olled by the feeding head feeler, or manually

by means of push buttons on the control panel.

"PILE UP” (5) the table lifts

"PILE DOWN” (6) the table lowers

New overlay Oroginal overlay

5

6

Page 5 - 6

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

5.2.1 Sheet stacking

Face stacking

The correct face position of the paper stack on the feeding table is provided by the face stackers

( a ), and the first gate ( b ). The sheets must be pushed tight against the surface of the face stackers. One

should make sure that the paper doesn't bend, which can cause problems in the feeding process.

b

a

© GBC Films Group January 2001

Page 5 - 7

Operations

Orbit™ 2000 Operation and Maintenance Manual

Side stacking

The collation of paper pile on the sides is done by side stackers ( c ), which are placed symmetrically .

A slight play must be allowed between the ledges and the paper pile to prevent damage to the paper and

improper feeding. The side stackers are controlled by the knob ( d ) on the operator's side. The arrow

indicates ( e ) the direction of turning for the changing of sheet size. Smaller size in the “ - “ direction,

larger size in the “ + “ direction.

e

d

WARNING

CAUTION: Ensure the path of the side stackers are

clear before making any adjustments.

Page 5 - 8

c

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

5.2.2 Feeder table positioning

When the paper pile has been loaded, press the “ FEEDER ST ACK/ PILE UP ” button. The table

( f) starts lifting, and its top position is determined by the Paper Pile Height Sensor ( g ), adjust so that

the first gate exceeds the height of the paper by 6 mm.

ATTENTION

The capacity sensor may be adjusted by a qualified service technician only.

First gate

g

6 mm

f

© GBC Films Group January 2001

Page 5 - 9

Operations

5.2.3 The feeding head

WARNING: Press the stop button before performing the following set-up procedure!

Feeding head setup

Orbit™ 2000 Operation and Maintenance Manual

WARNING

Loosen the clamp ( a ) using the handle bar ( b ). Push the head to its back position, away from the

machine. Press the button FEEDER ST ACK/ PILE UP until the paper pile stops at the Paper Pile Height

Sensor ( d ). The feeder foot ( e ) now assumes control and lift the table with paper stack on to its working

position. Move the head so that the rear stops ( c ) touch gently the rear side of the paper stack, and

tighten the clamp.

b

a

Page 5 - 10

c

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

The separating elements setup

1/ The foot of the ( d ) feeler touches the top of the paper stack. Move the strip ( e ) to the stack so

that its front edge is 5 to 7 mm within the paper and 4 to 6 mm above it. For various paper

weights ( e ) must be set to provide for correct paper sheets separation.

5 - 7 mm

d

e

4 - 6 mm

2/ Brushes ( f ) should overlap the paper edge by 2 to 3 mm, and touch the paper very lightly, and

not interfere with paper sheets feathering. For heavier paper use only brushes instead of strips.

ff

© GBC Films Group January 2001

Page 5 - 11

Operations

Orbit™ 2000 Operation and Maintenance Manual

3/ Set up the center suction cups ( g ) by adjusting strips ( e ) so the paper sheets between the cups

are tight.

gg

e

4/ Depending on the paper type, adjust vacuum as needed to lift the sheets via the transport suction

cups by turning the regulator on the Becker compressor. The amount of vacuum can be observed

on the manometer ( h ).

h

5/ The proper air pressure required to feather the paper is set up by means of regulators ( i ) and

( j ).

ij

Page 5 - 12

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

6/ Adjust air blowing tubes ( k ) by turning the nut ( l ) so that 10 - 20 sheets at the top of the stack

are feathered.

l

k

7/ Regulator ( m ) sets up the stack height.

m

© GBC Films Group January 2001

Page 5 - 13

Operations

Orbit™ 2000 Operation and Maintenance Manual

Feeding small sheet sizes

WARNING

WARNING: Press the stop button before performing the following set-up procedure!

To feed small sizes of paper sheets, less than the distance between the outside suction cups ( n ),

you must loosen the screw ( o ) and rotate the two outside suction cups ( n ) 90 degrees forward then

secure in place by tightening the screws ( o ). This is necessary to prevent the outside suction cups ( n )

from colliding with the side stacker guides and to not waste vacuum power on suction cups not in contact

with the paper pile.

o

n

n

Page 5 - 14

90

o

© GBC Films Group January 2001

5.2.4 First gate

WARNING

CAUTION: Only a qualified service technician may adjust the first gate.

The first gate assembly is calibrated at the factory and may be field calibrated by a qualified

service technician only. Refer to Section 8 Maintenance.

OperationsOrbit™ 2000 Operation and Maintenance Manual

Function of the first gate

The first gate ( a ) positions the paper ream so that the front is always vertical. While the head is

moving forward, the first gate will tip so as to not interfere with the paper feeding.

© GBC Films Group January 2001

a

Page 5 - 15

Operations

5.2.5 Feed roller assembly

The assembly consists of gravity rollers ( a), accelerating rollers ( b ), plate holders ( c ) and the

sheet overlap sensor ( d ).

d

Orbit™ 2000 Operation and Maintenance Manual

c

a

c

b

Gravity rollers

The gravity rollers are always touching the

paper pressing it against the feed rollers. The position

is factory set, and remains unchanged for all sizes of

paper. For higher paper weights the pressure has to be

increased. For this purpose, a set of weights ( e ) is

supplied as accessories. The weight is simply pulled

out or inserted.

a

b

e

Page 5 - 16

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

Accelerating rollers

WARNING

CAUTION: The position of the rollers are set at the factory and does not

require changing, regardless of sheet size.

Accelerating rollers increase the pressure on the feeding roller at the moment the second gate

drops out of the way . Allowing equal pressure to feed paper stock evenly to the chr ome roller and pressure

roller area. The moment of pressure is controlled by the control system and has been factory set. The

spring ( g) determines the pressure.

g

© GBC Films Group January 2001

Page 5 - 17

Operations

Orbit™ 2000 Operation and Maintenance Manual

Plate holders

The plate holders keeps the paper sheet on the lower guiding plate to prevent it from jumping

over the second gate.

Positioning: The machine has three hold-down fingers in total. The position of the middle one does not

change and is factory set. The position of the extreme two change with respect to the size of sheet, and is

adjusted to be about 10 mm distant from the edge of paper, after the screw ( h ) has been loosened. Be

sure to tighten the screw ( h ) after positioning the hold down fingers.

10 10

Adjusting: Pressure is adjusted by moving the holder ( i ) , which is held by screw ( j ). Follow the

procedure below.

j

1/ Loosen the screw ( h ).

h

2/ Insert one sheet of paper ( of the same

specific weight ) to be laminated.

i

Pressure area

3/ Adjust the holders so the finger ( k )

touches the paper without bending.

k

Feeder

4/ Tighten the screw ( h ).

Page 5 - 18

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

Sheet misfeed sensor

The sheet misfeed sensor protects the supporting laminating roller from the laminating adhesive.

Check its function daily.

To check the sensor, follow the procedure below.

1/ Take a single sheet of paper, insert it under the sensor ( l ).

2/ Block the sensor repeatedly by sliding the sheet of paper in and out from under the sensor.

3/ The proper function is signaled by the sensor LED, which lights up accordingly.

l

CAUTION: Only a qualified service technician may repair the sheet overlap sensor.

© GBC Films Group January 2001

WARNING

Page 5 - 19

Operations

Overlap adjustment

WARNING: Only person(s) trained in all aspects of the equipment may

CAUTION: NEVER TURN THE DIAL ( t ) WHEN THE MACHINE IS STOPPED!

Orbit™ 2000 Operation and Maintenance Manual

WARNING

perform any operator adjustments.

WARNING

For each paper size, the speed of the feeding head must be adjusted. This is done by manually

turning the dial pointer ( u ) located below the control panel.

Steps

1/ Set the machine to its lowest running speed.

2/ Start the machine.

u

3/ Set the dial pointer ( u ) to a value

just short of the sheet length. ( ie. a 17 in.

sheet, set the dial to 16.5 in. )

4/ Check the overlap.

5/ Should you require a shorter overlap, turn the dial pointer ( u ) slightly toward the “larger sheet

size” direction.

6/ Should you require a longer overlap, turn the dial pointer ( u ) slightly toward the “shorter sheet

size” direction.

7/ After turning the dial pointer ( u ), always wait for 2 to 4 sheets, before continuing with the

adjustments. The variator has a slight delay.

Page 5 - 20

© GBC Films Group January 2001

5.2.6 Second gate

WARNING

CAUTION: Only a qualified service technician may adjust the second gate.

The second gate ( a ) rigisters the sheet and drops out of the way releasing the sheet so that the

overlap of the individual sheets are within the required limits of +/- 1.5 mm.

OperationsOrbit™ 2000 Operation and Maintenance Manual

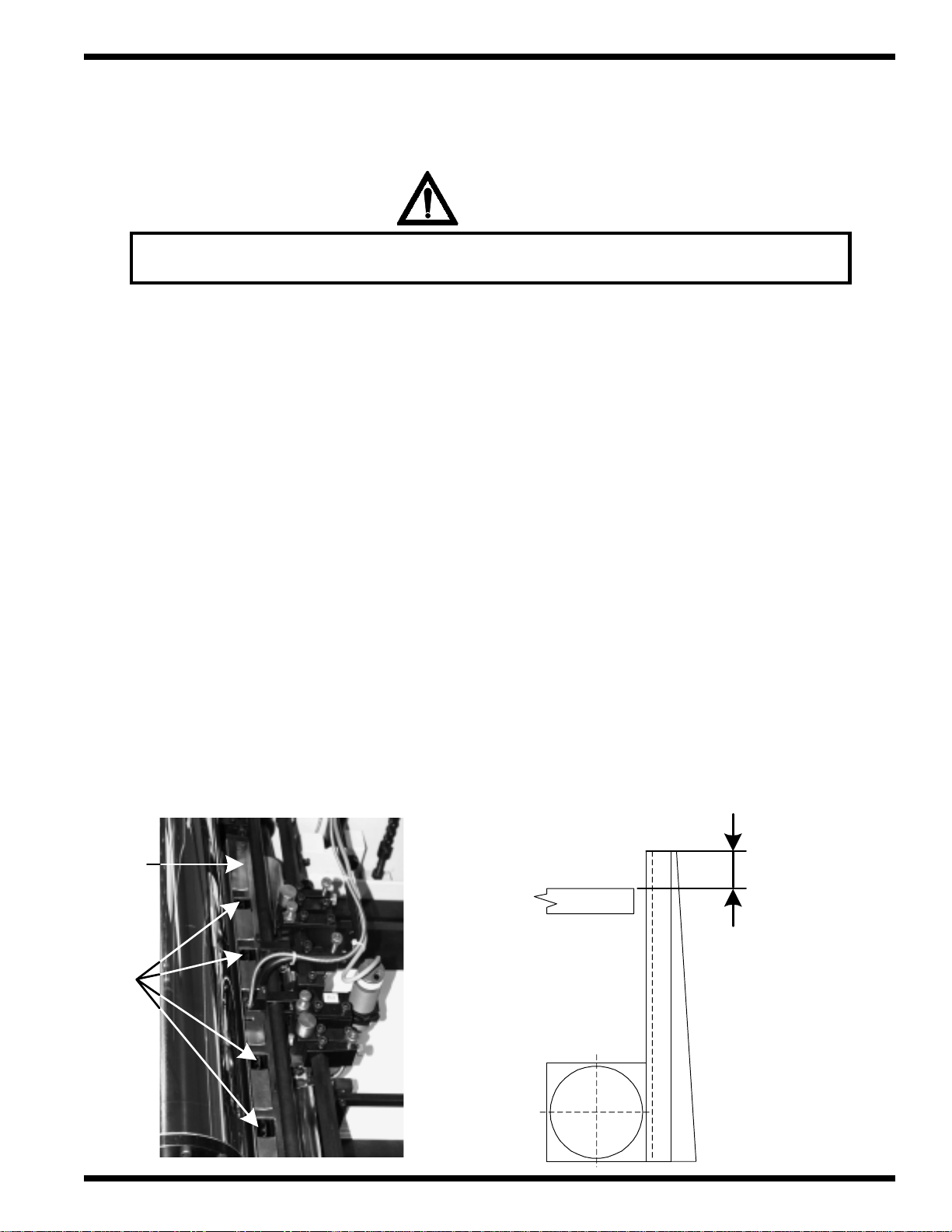

Position of the second gate

The top edge of the second gate ( a ) must exceed the height of the guide plate ( b ) by 2.3 to 2.7

mm.

b

a

2.3 - 2.7

mm

© GBC Films Group January 2001

Page 5 - 21

Operations

Orbit™ 2000 Operation and Maintenance Manual

5.2.7 Adjustable guide plates

Sliding plates ( a ) guide the sheets into the pressure area helping to minimize wrinkles of the

sheets. They form the sheet before it enters the laminating rollers. The plates position is adjusted by

turning screw ( b ) and nut ( c ).

When working with heavy paper, adjust the plates so the sheet is guided into roller 1/8 in. ( 3.17 mm )

below chrome roller and pressure roller nip.

b

a

c

When working with light paper,adjust the plates so the sheet is guided into roller 1/4 in. ( 6.35 mm )

below chrome roller and pressure roller nip.

b

c

Page 5 - 22

a

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

5.3 Lamination section

The lamination section consists mainly of the spool arbor, heating controls, laminating rollers

and the spreader roller.

The laminator serves the purpose of unwind the spool of film via the spool arbor, activating the

thermal adhesive via the chrome roller , laying it on the fed sheets via the laminating r ollers and decurling

the sheets for flat separation via the decurling bar.

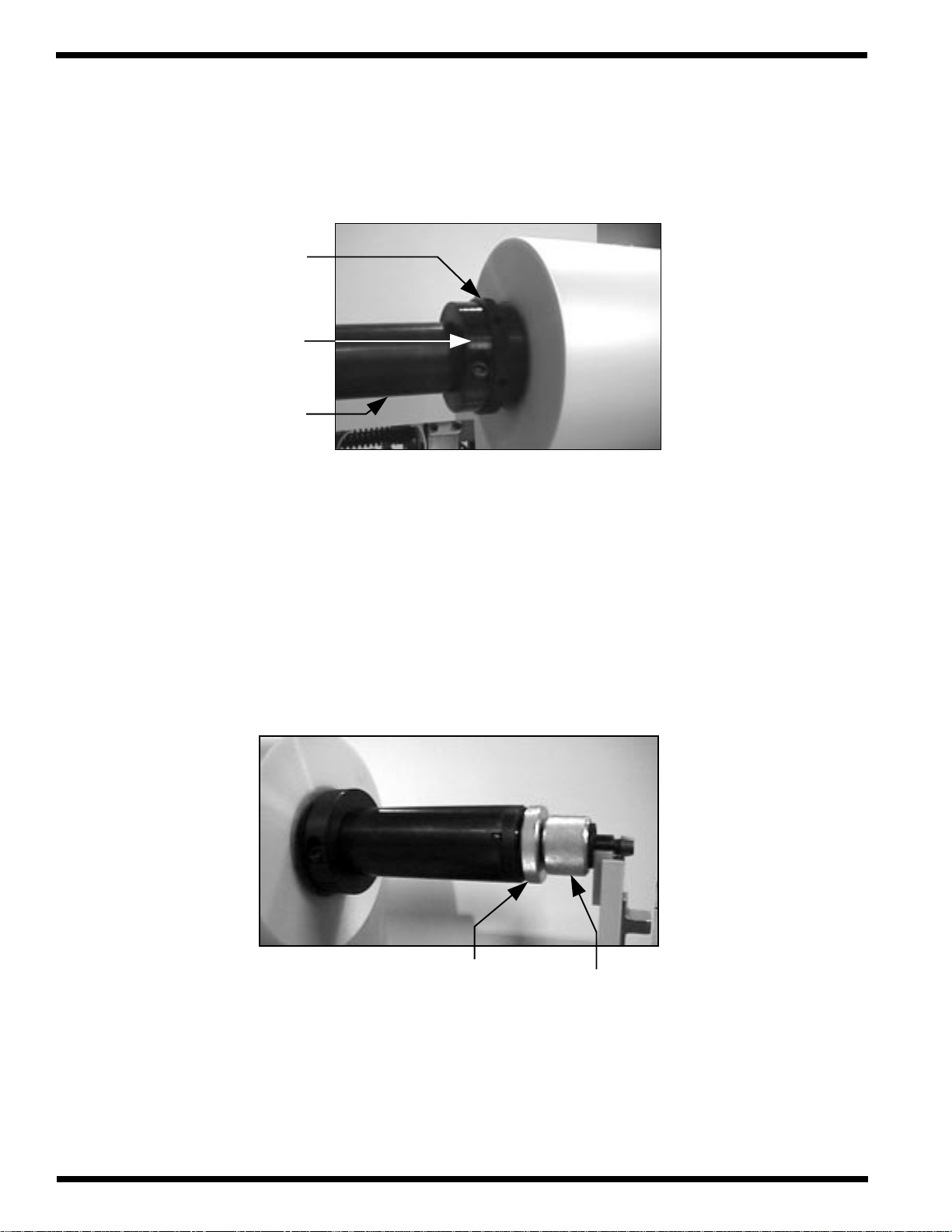

5.3.1 Film roll positioning

WARNING

CAUTION: Do not wear ties, loose fit clothing or dangling jewelry. These items

can get caught the rollers while working around or loading film.

Use the following instructions to load a roll of film and to properly position it:

1/ Set the lateral film adjust nut ( a ) so that the face is in line with the marker ( b ) on the thread of

the spool arbor ( c ). This provides acenter point in which you can adjust the film shaft left or

right to fine tune the film lay down on the sheets.

ab

© GBC Films Group January 2001

c

Page 5 - 23

Operations

g

Orbit™ 2000 Operation and Maintenance Manual

2/ Lower the spool arbor support arm ( d ) by pressing down on the latch ( e ) and pull towards you

from the control side.

e

YOUR MACHINE MAY OR

*

MAY NOT HAVE A

SUPPORT ARM.

d

3/ Loosen the 8 mm screw to the control side conical cone ( f ) and slide it off of the spool arbor

( c ).

c

f

4/ Loosen the nut ( g ) on the drive side conical cone ( h ) and leave loose measurement purposes.

Page 5 - 24

h

© GBC Films Group January 2001

OperationsOrbit™ 2000 Operation and Maintenance Manual

5/ Position the roll of film on the spool arbor ( c ) with respect to the adhesive side (Poly-in or Poly-

out). Refer to Section 6 Applications.

c

f

6/ Replace the control side conical cone ( f ) on the operator’s side and leave the 8 mm screw

loose for movemt.

7/ Measure from operators side/ side frame to paper pile left margin ( a ). Always add 1/8 in.

( 3.17 mm ) to this measurement. Use the measurement just obtained, with the 1/8 in ( 3.17 mm )

addition, to measure the edge of the film ( b ) on the spool arbor to the operators side/ side frame.

X

X + 10 mm

X + 3/8 in.

© GBC Films Group January 2001

b

a

5 mm

Page 5 - 25

Operations

g

Orbit™ 2000 Operation and Maintenance Manual

8/ Tighten the 8 mm screws on both conical cones and tighten the nut ( g ) on the drive side conical

cone ( h ) to secure the roll of film to the spool arbor ( c ).

h

c

9/ Use the lateral film adjust nut ( a ) to fine tune the positioning of the spool arbor with respect to

the pile stack and use the unwind brake nut ( i ) to apply tension to film roll on shaft.

ai

Page 5 - 26

© GBC Films Group January 2001

5.3.2 Heating

WARNING: Keep fingers, hands and other body parts away from the rollers.

OperationsOrbit™ 2000 Operation and Maintenance Manual

WARNING

WARNING: The chrome roller can become extremely hot.

Contact will result in severe burns!

WARNING

Heating is controlled by two means. ( 1 ) by using the temperature controller and ( 2 ) by using

the heat width selection. Heat is delivered from the chrome roll of the laminating rollers.

Temperature adjustment

Adjust the chrome roller temperature for good lamination by pressing or on the

temperature controller.

Actual temperature

( Green numbers )

120.0

120.0

Set temperature

( Red numbers )

Decrease set point

© GBC Films Group January 2001

Increase set point

Page 5 - 27

Operations

Orbit™ 2000 Operation and Maintenance Manual

Heat width selection

For sheet width size between 8 - 11 in. ( 200-280 mm ), set the heater switch ( a ) to 8-11”.

HEATERS

STOP

a

HEATER

OFF

12"-14"8"-11"

New

overlay

Original

overlay

Chrome

roller

12-14 in.

( 305-356 mm )

For sheet width size between 12 - 14 in. ( 305-356 mm ), set the heater switch ( a ) to 12-14”.

HEATERS

STOP

New

overlay

a

HEATER

OFF

12"-14"8"-11"

Original

overlay

Chrome

roller

( 200-280 mm )

8-11 in.

Page 5 - 28

© GBC Films Group January 2001