Page 1

+

RCS Pylons

Support structures designed for low RCS measurements

+

Unique ogival

shape = extremely

low backscatter

Page 2

A broad selection of pylons, combined with the choice of rotator types allows for a custom fi t

between pylon and DUT (Device under test). As a result of the unique ogival shape, front and

rear sharp edges, and structure surface accuracy, ORBIT/FR pylons demonstrate extremely low

backscatter, essential for RCS measurements.

Our pylons can be installed on a concrete base, adapter plate, ORBIT/FR positioner, linear slide,

elevator or any combination of the above.

SOLUTION FOR

• RCS measurements

• R&D applications

• Far-fi eld measurements

Key Features

• Ogive ratio: 1:4 standard, 1:6 and 1:7

available for most models

• Pylons for multiple applications

(RCS, Antenna measurement)

• Height: standard from 3 to 70 feet

(1 to 21 meters), or custom order

• Interchangeable tips (Optional)

• Three types of rotator heads: two AZ/EL

and one AZ only

• Load capacity: From 500 - 80,000 lbs.

• Sharp edges: 0.004 - 0.008 inch

• Surface fi nish – 63 microinch

• Optimal power-to volume ratio

• Position feedback readout: synchro or rotary

encoders

AZ/EL

"HAT" TYPE

Pylon structure

AZ/EL

LOW PROFILE

AZIMUTH

ONLY

System Confi guration

• Pylon structure: steel, aluminum or combination

of steel and aluminum

• Rotators: AZ/EL and AZ only

• Environment: indoor (standard), outdoor (optional)

• Mini model tower (optional)

• Storage fi xture

• Cover and edges protection kit

• Lifting device for installation

Storage fi xture Lifting device Edges protection kit

2

ORBIT/FR offers three types of DUT rotation mechanisms

(heads): two Azimuth-over-Elevation (AZ/EL) rotators and

one Azimuth (AZ) - only rotator.

Page 3

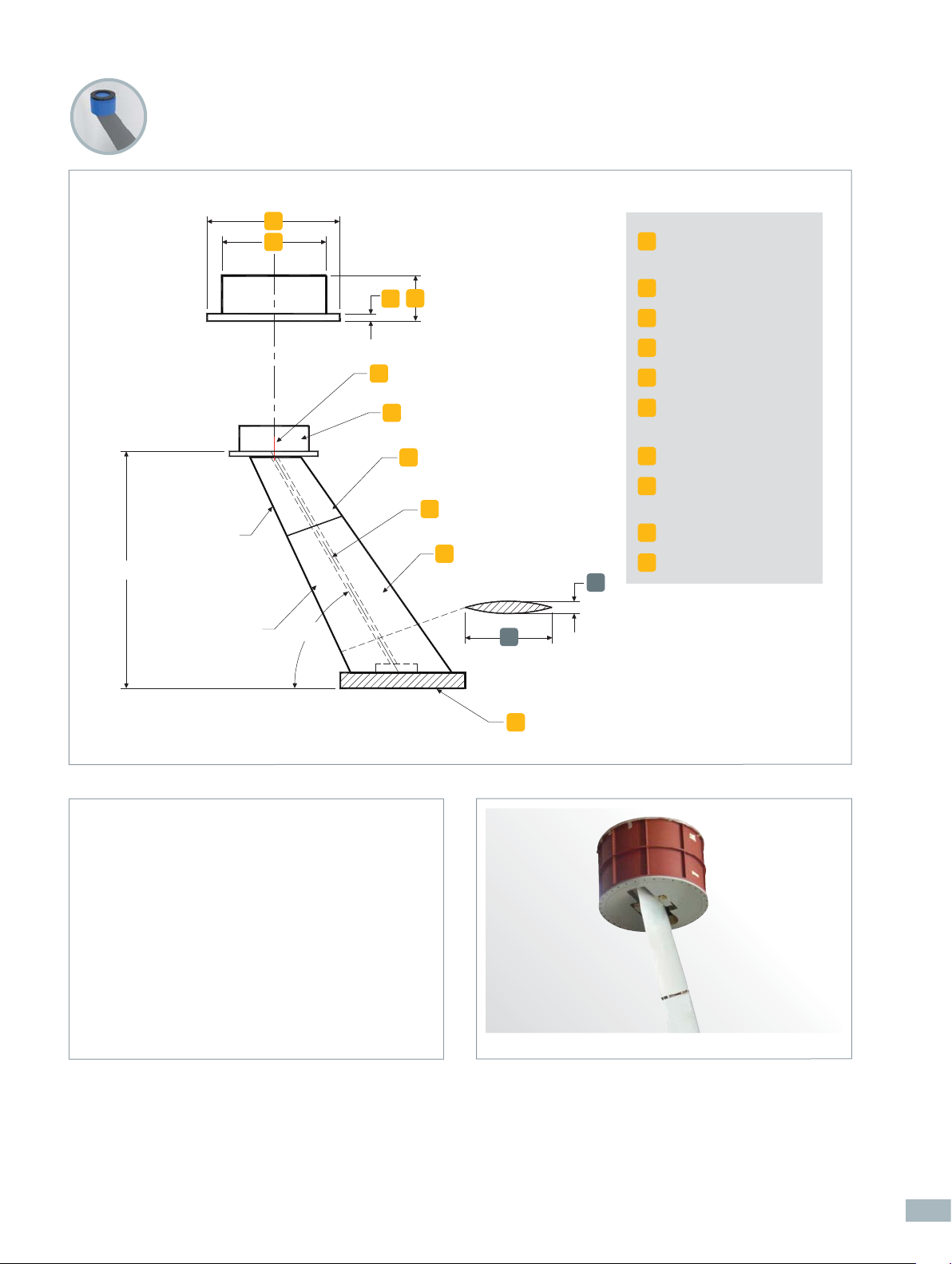

Rotators / AZIMUTH - OVER - ELEVATION (AZ/EL)

"HAT" type rotator with pylon

d1

d2

EDGE SHARPNESS

0.004-0.008 INCH

HEIGHT

d1

Rotator turntable

diameter (flange)

d2

h

t

A

B

C

D

E

OGIVE

w

Rotator base diameter

h

Rotator height

t

Flange thickness

A

Rotator (head)

B

AZ & EL drive and

control system

Tip

C

Through hole

D

for cables

Pylon structure

E

Support base

F

SURFACE FINISH

63 MICROINCH

60°

The “HAT” type pylon rotators are used for heavy

duty DUT measurement.

This unique hat-shaped rotator is positioned on top

of the pylon and provides a mounting interface on its

bottom fl ange to allow the rotator to fi t inside the DUT.

Fitting the rotator inside the DUT minimizes the

rotator’s interference in the measurement results.

Above a 20 ton DUT load, the mounting interface is on

top of the rotator.

l

OGIVE RATIO

w/l=1/4, 1/6, 1/7

F

Pylon with "HAT" type rotator

3

Page 4

AZ/EL Rotator “HAT” Type and Pylon Specifi cations

COMPLETE PYLON

ASSEMBLY MODEL

TIP & ROTATOR

(1)

ONLY

AL-28007-150

AL-28207-150

AL-28010-300

AL-28210-300

AL-28013-600

AL-28213-600

AL-28014-1200

AL-28214-1200

AL-28014-2000

AL-28214-2000

AL-28015-2750

AL-28215-2750

AL-28015-3000

AL-28215-3000

AL-28016-5000

AL-28216-5000

AL-28017-8000

AL-28217-8000

DUT Weight kg 681 1,362 2,724 5,448 9,080 12,485 13,620 22,700 36,300

(max) lbs 1,500 3,000 6,000 12,000 20,000 27,500 30,000 50,000 80,000

Delivered Torque kg-m 104 415 1,078 1,659 3,042 9,678 9,678 20,738 29,034

(EL) ft-lbs 750 3,000 7,800 12,000 22,000 70,000 70,000 150,000 210,000

Delivered Torque kg-m 36 100 173 207 691 4,148 4,148 5,530 6,913

(AZ) ft-lbs 260 720 1,250 1,500 5,000 30,000 30,000 40,000 50,000

Side Bending kg-m 51 142 346 346 1,383 4,148 4,148 5,530 8,295

Moment ft-lbs 370 1,030 2,500 2,500 10,000 30,000 30,000 40,000 60,000

Travel (EL) deg + 5, - 45 + 5, - 45 + 5, - 30 + 5, - 30 + 5, - 30 + 10, - 30 + 10, - 30 + 10, - 30 + 10, - 30

Travel (AZ) deg 360 Continuous

(2)

Accuracy (EL)

Accuracy (AZ)

deg ± 0.05 ± 0.05 ± 0.05 ± 0.05 ± 0.05 ± 0.05 ± 0.05 ± 0.05 ± 0.05

(2)

deg ± 0.03 ± 0.03 ± 0.03 ± 0.03 ± 0.03 ± 0.03 ± 0.03 ± 0.03 ± 0.03

Readout Resolution (EL) deg 0.01 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001

Readout Resolution (AZ) deg 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001

Backlash (EL)

Backlash (AZ)

Rotation Speed (EL)

(± 20 %)

Rotation Speed(AZ)

(± 20 %)

(2)

deg 0.07 0.07 0.07 0.07 0.07 0.04 0.04 0.04 0.04

(2)

deg 0.04 0.04 0.04 0.05 0.05 0.04 0.04 0.04 0.04

(2)

(3)

(3)

deg/min 10 4 4 4 4 20 20 20 2

(2)

deg/min 36 30 30 30 50 30 30 20 12

Rotator Height (h) mm 152 183 305 508 635 584 851 1219 1422

in 6 7.2 12 20 25 23 33.5 48 56

Turntable Diameter (d1) mm 327 406 660 559 864 1524 1524 1880 2413

(Flange) in 12.9 16 26 22 34 60 60 74 95

Base Diameter (d2) mm 279 358 597 508 813 1394 1397 1778 2311

in 11 14.1 23.5 20 32 54.9 55 70 91

Flange Thickness (t) mm 8.1 8.1 15.9 25.4 25.4 30 30.0 38.1

in 0.32 0.32 0.63 1 1 1.2 1.2 1.5

(1) Possible to order a tip and rotator only

(2) Data is based on testing in “No Load” position

(3) (+/-20%) refl ects a speed deviation

* Encoder / synchro are applicable for standard models (Optional: Absolute encoder for 6,000 lbs and above)

4

Page 5

Rotators / AZIMUTH - OVER - ELEVATION (AZ/EL)

Low profi le rotator with pylon

h

d1

d2

Rotator base diameter

d1

Rotator turntable

d2

diameter

Rotator height

h

Rotator (head)

A

A

B

C

EDGE SHARPNESS

0.004-0.008 INCH

HEIGHT

SURFACE FINISH

63 MICROINCH

60°

The Low profi le pylon rotators are used for overall

small size and light weight DUT measurement.

The rotator’s drive and position feedback components

(i.e. synchro and encoder) are installed inside the tip

structure and only the “small” head protrudes from the

top.

AZ & EL drive and

B

control system

Tip

C

Through hole

D

for cables

D

E

OGIVE

w

Pylon structure

E

Support base

F

l

OGIVE RATIO

w/l=1/4,1/6

F

The DUT is secured to the top of the rotator.

Pylon with low profi le rotator

5

Page 6

AZ/EL Rotator Low Profi le Type and Pylon Specifi cations

COMPLETE PYLON ASSEMBLY MODEL

(1)

TIP & ROTATOR ONLY

AL-28063-60

AL-28263-60

AL-28062-110

AL-28262-110

AL-28061-220

AL-28261-220

AL-28060-600

AL-28260-600

DUT Weight (max) kg 270 500 1,000 2,724

lbs 600 1,100 2,200 6,000

Delivered Torque (EL) kg-m 50 44 120 830

ft-lbs 360 320 865 6,000

Delivered Torque (AZ) kg-m 5 12 25 97

ft-lbs 33 87 181 700

Side Bending Moment kg-m 7 17 35 140

ft-lbs 50 123 253 1,020

(2)

Travel (EL)

deg 0,-40 0,-40 0,-40 0,-40

Travel (AZ) deg 360 Continuous

(3)

Readout Accuracy (EL)

Readout Accuracy (AZ)

deg ± 0.13 ± 0.13 ± 0.13 ± 0.12

(3)

deg ± 0.05 ± 0.06 ± 0.06 ± 0.06

Readout Resolution (EL) deg 0.02 0.02 0.02 0.02

Readout Resolution (AZ) deg 0.001 0.001 0.001 0.001

Backlash (EL)

Backlash (AZ)

Rotation Speed (EL)

(± 20 %)

Rotation Speed (AZ)

(± 20 %)

(3)

deg 0.06 0.06 0.06 0.06

(3)

deg 0.03 0.06 0.03 0.03

(3)

(4)

deg/min 1 2 1 1

(3)

(4)

deg/min 22 44 22 22

Rotator Height (h) mm 119 140 140 234

in 4.7 5.5 5.5 9.2

Base Diameter (d1) mm 90 116 116 201

in 3.6 4.6 4.6 7.9

Turntable Diameter (d2) mm 60 88 88 136

in 2.36 3.46 3.46 5.36

(1) For orders concerning tip & rotator only, contact our specialists with interface details.

(2) Typical elevation travel is from 0-40 degrees. For other standard travel options, consult our specialists.

(3) Data is based on testing in “No Load” position.

(4) (+/-20%) refl ects a speed deviation

6

Page 7

Rotators / AZIMUTH ONLY

Azimuth only rotator with pylon

A

B

d1

C

D

EDGE SHARPNESS

0.004-0.008 INCH

HEIGHT

SURFACE FINISH

63 MICROINCH

60°

The Azimuth only pylon rotators are used for an

overall small size and light weight DUT in single axis

measurement. They incorporate a positioner located

in the tip of the pylon. The rotator seamlessly

mates with the device under test, preserving the

integrity of the DUT’s test evaluation. DUT elevation adjustments can be implemented manually or

via a motorized elevation positioner/leveling device at

the base of the pylon.

E

OGIVE

w

l

OGIVE RATIO

w/l=1/4,1/6

F

Pylon with azimuth only rotator

Rotator turntable

d1

diameter

Turntable

A

AZ & EL drive and

B

control system

Tip

C

Through hole

D

for cables

Pylon structure

E

Support base

F

AZ only Rotator and Pylon Specifi cations

COMPLETE PYLON ASSEMBLY MODEL

(1)

TIP & ROTATOR ONLY

DUT Weight (max) kg 227 454 1,000

lbs 500 1,000 2,200

Delivered Torque (max) kg-m 2.8 4.1 6.9

ft-lbs 20 30 50

Bending Moment (max) kg-m 41.5 138.3 248.9

ft-lbs 300 1,000 1,800

(2)

Backlash

Readout Accuracy

Readout Resolution deg 0.001 0.001 0.001

Speed deg/min 30 15 12

Azimuth Travel deg 360 continuous

Turntable Diameter (d1) mm 70 70 159

in 2.75 2.75 6.25

(1) For orders concerning tip & rotator only, contact our specialists with interface details

(2) Data is based on testing in “No Load” position

deg 0.03 0.03 0.03

(2)

deg +/- 0.05 +/- 0.05 +/- 0.05

AL-28053-50

AL-28253-50

AL-28055-100

AL-28255-100

AL-28057-220

AL-28257-220

7

Page 8

Pylon ordering information

Pylons can be ordered from our selection of standard models or can be customized to suit customer

specifi c requirements.

To order a complete pylon assembly follow the example in the

table below.

Note the series number of the pylon model, the number

representing the ogive aspect ratio, and the number of feet for

the height of the pylon.

Options

• Slip rings with up to 30 contacts on the azimuth

axis (depends on rotator’s size)

• Rotary joints for “HAT” type rotators: 12 GHz,

18 GHz, 26 GHz and 40 GHz

• Service connector with static cover on top

of the "HAT" type rotators

• Special mounting holes and interfaces

are available upon request

• Special tilting device for installation or

removal of the pylon

Basic models:

• 28xxx-xxx – complete pylon

assembly, hat type

• 282xx-xxx – tip and rotator

only, hat type

• 2806x-xxx – complete low

profi le pylon rotator

• 2826x-xxx – tip and rotator

only, low profi le

Basic model series Aspect ratio Pylon height

AL-28007-150 7 11

Aspect ratios:

• 4 – 1:4 ogive ratio

• 6 – 1:6 ogive ratio

• 7 – 1:7 ogive ratio

Example: AL-28007-150-7-11

Pylon heights:

• Pylon heights from 3 ft to

70 ft are available in standard

sizes in 1 ft increments.

• Pylon heights requiring ½ ft

increments start from 3 ft are

available upon request

www.microwavevision.com / Contact us at: sales@microwavevision.com

8

Product speci cations and descriptions in this document are subject to change without notice.

Actual products may differ in appearance from images shown.

© MICROWAVE VISION 2012

Loading...

Loading...