Page 1

>

Low Frequency Absorbers - AEP-EM Series

AEP-12-EM

> Applications:

• Low frequency measurement in medium size

chambers

• Multiple refl ection and resonant condition reduction

> Key features:

• High loss at low frequency

• Minimum thickness

• Stackable to build temporary wall

• Allows for greater repeatability

> Shape:

• Pyramidal

> Frequency band:

• From 30 MHz to 1000 MHz

> Standard base size:

• 2’ x 2’ (60.96 cm x 60.96 cm)

> Height:

• 12’’ to 48’’ (30.5 cm to 121.9 cm)

> Operating conditions:

• Temperature: 70º F +/- 10º (21º C +/- 3º)

Relative humidity: 55 % RH +/-15 %

•

> Indoor/outdoor:

• Indoor

> Related certifi cations:

• NRL 8093 – 1, 2, 3

> Ordering code:

• AEP-XX-EM, where XX designates absorber

height in inches

Specialty Absorbers

4141

Page 2

1/ Description

Low Frequency absorbers should be used in order to

reduce the multiple refl ection and resonant conditions

typical in shielded rooms at frequencies from 30 MHz to

1000 MHz. The use of these materials allows for greater repeatability of tests performed within a shielded

room. Due to the extremely long wavelength at 30 MHz,

conventional pyramidal absorbing materials must be extremely thick because the performance of the absorber

drops off rapidly as the material becomes less than one

quarter wavelength in thickness. In order to minimize this

roll off and improve the overall loss characteristics, AEMI

has developed low frequency absorber using special

materials. These materials have proven to be extremely

effective in medium size shielded rooms.

2/ A unique graded dielectric approach

The EM material is essentially a pyramidal front material properly loaded to match successive layers of graded dielectric foam. This design allows for the proper

matching of the material to free space by initially providing a tapered impedance match through the pyramidal

front.

After the energy has entered the material, it is then suc-

cessively passed on to higher and higher dielectrically

loaded layers which enhance the energy dissipation characteristics. It is through this gradual change in dissipation that high loss at low frequencies can be achieved.

The design of this graded dielectric approach provides

the user with 33% more lossy dielectric material than

the use of conventional pyramidal material of equal size.

This added dielectric material provides increased performance at low frequencies. The graded design also

increases the wide angle performance of these products

with respect to conventional pyramidal materials. Typical

performance increases at normal incidence are 3-6 dB

and 6-10 dB at wide angles.

3/ A high fl exibility of use

Another feature of this series is its ability to be stacked.

This allows the engineer to provide a temporary wall of

absorptive material for the elimination of hot spots in a

shielded facility. This mobility also gives the freedom to

alter the test environment whenever conditions and requirements change. Resonance of the shielded cavity

can be altered at will by the proper placement of this

series of absorbers.

4/ Specifi cations

AEP-12-EM AEP-18-EM AEP-24-EM AEP-36-EM AEP-48-EM

Height in 12 18 24 36 48

cm 30.5 45.7 61 91.4 121.9

@ 30 MHz dB 6 9

@ 50 MHz dB 8 12 16

@ 100 MHz dB 9 11 14 21 27

@ 250 MHz dB 19 21 26 30 34

@ 500 MHz dB 26 29 32 36 39

Absorption @

Normal Incidence

@ 1000 MHz dB 32 35 38 41 44

Weight lbs/pc. 10 16.5 17 27 36

kg/pc. 4.5 7.5 7.7 12.2 16.3

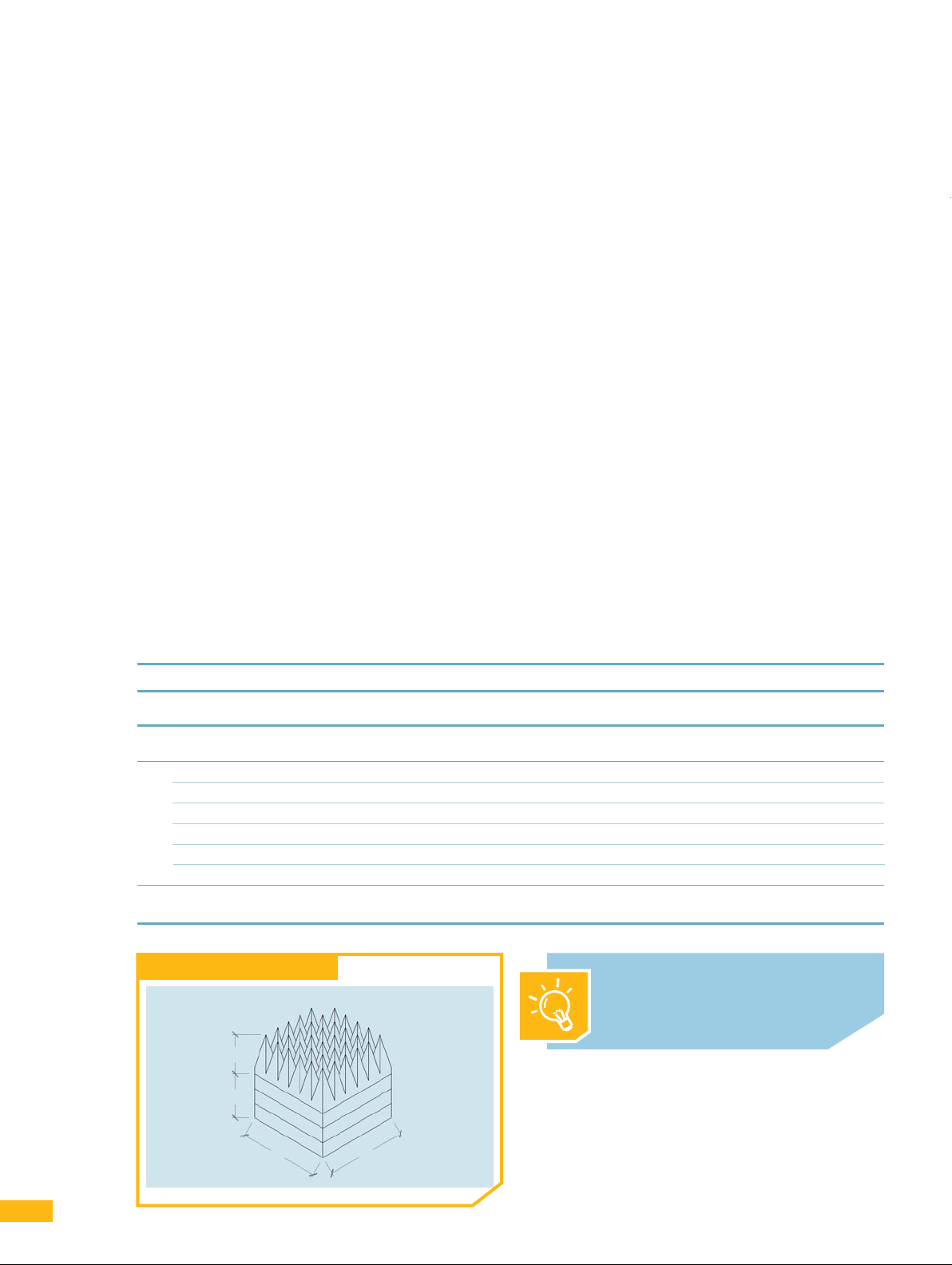

AEP-24 EM mechanical drawing

Increase durability & lifespan

by adding our rubberized coating!

For more information, see page 32

12’’12’’

42

24’’

24’’

Loading...

Loading...