Orbit OD80H, OD80LH, OD80LLH, OD110H, OD110LH Installation Instructions Manual

...

Orbit Industries, Inc. 2100 S. Figueroa St. Los Angeles, CA 90007 Tel: (213) 745-8884 Fax: (213) 745-2015 1-800-90-ORBIT

WARRANTY OWNER: Orbit Industries, Inc., warrants to the original consumer purchaser that

it’s products will be free from defects in materials or workmanship for a period of one year from

the date of original consumer purchase.

THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

During this one year period, Orbit, will at its option, repair or replace , without charge, any

products or part which is found to be defective under normal use and service. THIS

WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS OR TUBES,

FILTERS, DUCT, ROOF CAPS, and OTHER ACCESSORIES FOR DUCTING.

This warranty does not cover (a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance of repair

(other than by Orbit), faulty installation or installation contrary to recommended installation

WARN ING - TO RE DUC E THE RIS K OF FIRE , ELECT RIC SHO CK, OR IN JURY TO

PER SON, OB SERVE T HE FO LLOWI NG:

a) Us e this un it only i n the man ner int ended b y the man ufact urer. If y ou have q uesti ons, co ntact t he manu factu rer.

b) Be fore se rvici ng or cle aning u nit, sw itch po wer off at s ervic e panel a nd lock t he serv ice dis conne cting m eans

to pr event p ower fr om bein g switc hed on ac ciden tally. Wh en the se rvice d iscon necti ng mean s canno t be

loc ked, se curel y faste n a promi nent wa rning d evice , such as a t ag, to th e servi ce pane l.

"CAUTION - For General Ventilating Use Only. Do Not Use To Exhaust Hazardous Or Explosive Materials And Vapors."

" Do Not Mount In A Ceiling Thermally Insulated To A Value Greater Than R40"

WARN ING - TO RE DUC E THE RIS K OF FIRE , ELECT RIC SHO CK, OR IN JURY TO

PER SON, OB SERVE T HE FO LLOWI NG:

a) In stall ation w ork and e lectr ical wi ring mu st be don e by qual ified p erson (s) in ac corda nce wit h all app licab le

cod es and st andar ds, inc ludin g fire- rated c onstr uctio n.

b) Wh en cutt ing or dr illin g into wa ll or cei ling, d o not dam age ele ctric al wiri ng and ot her hid den uti litie s.

c) Du cted fa ns must a lways b e vente d to the ou tdoor s.

d) If t his uni t is to be in stall ed over a t ub or sho wer, it mu st be mar ked as ap propr iate fo r the app licat ion and b e

con necte d to a GFCI ( Groun d Fault C ircui t Inter rupte r) - prot ected b ranch c ircui t.

WARN ING:

a) "Do not install fan above or inside a 45-degree

angle projected outwards from the cooking equip ment element closest to the fan. See instruction

sheet for clarification;" or

b) "Not for use in cooking area - see installation

instructions;"

ROOF CAP*

(with built-in

damper)

ROUND

DUCT*

WALL CAP*

(with built-in

* Purchase

damper)

separately

POWER

CABLE*

INSULATION*

(Place around and

over Fan Housing.)

Seal gaps

around

Housing.

FAN

HOUSING

ROUND

ELBOW(S) *

Seal duct

joints with

tape.

Keep duct

runs short

Recommended to put insulation around and the fan housing to

minimize the building heat loss. Seal all the gaps around the

housing with caulk or other similar material to inhibit air leakage

to the exterior of the thermal envelope of the building. Rigid sheet

metal duct and the shortest path to the outside will minimize

static pressure losses and promote adequate flow.

Deluxe

“ODH” Series

REA D AND S AVE TH ESE INS TRUCT IONS

“WAR NING - To Re duc e The Ris k Of Elec tric Sh ock,

Do No t Use Thi s Fan Wit h Any S oli d-S tate Sp eed Con trol De vice. ”

OD80H

OD80LH

OD80LLH

OD110H

OD110LH

OD110LLH

ODU814H

ODU814LH

ODU814LLH

1

INSTALL GRILLE

Install ceiling material to complete the ceiling construction. Then cut the opening

around the fan housing.

Insert the sensor connector into the base connector in the unit and then install the

Insert the light connector from the grille assembly into the base connector in the unit and then install the grille.

To attach the grille assembly to the fan housing, pinch the grille springs on the sides of the grille assembly and

position the grille into the housing with the grille springs in the appropriate slots. Push the grille assembly

towards the ceiling to secure.

Removing Lens:

Carefully pryout the light lens by inserting a small, flathead screwdriver between the grille and lens.

Installing Light Bulbs:

Install the 23W, GU24 Flourescent lamp or 10W LED lamp and 4W Incandescent Lamp for Night Light.

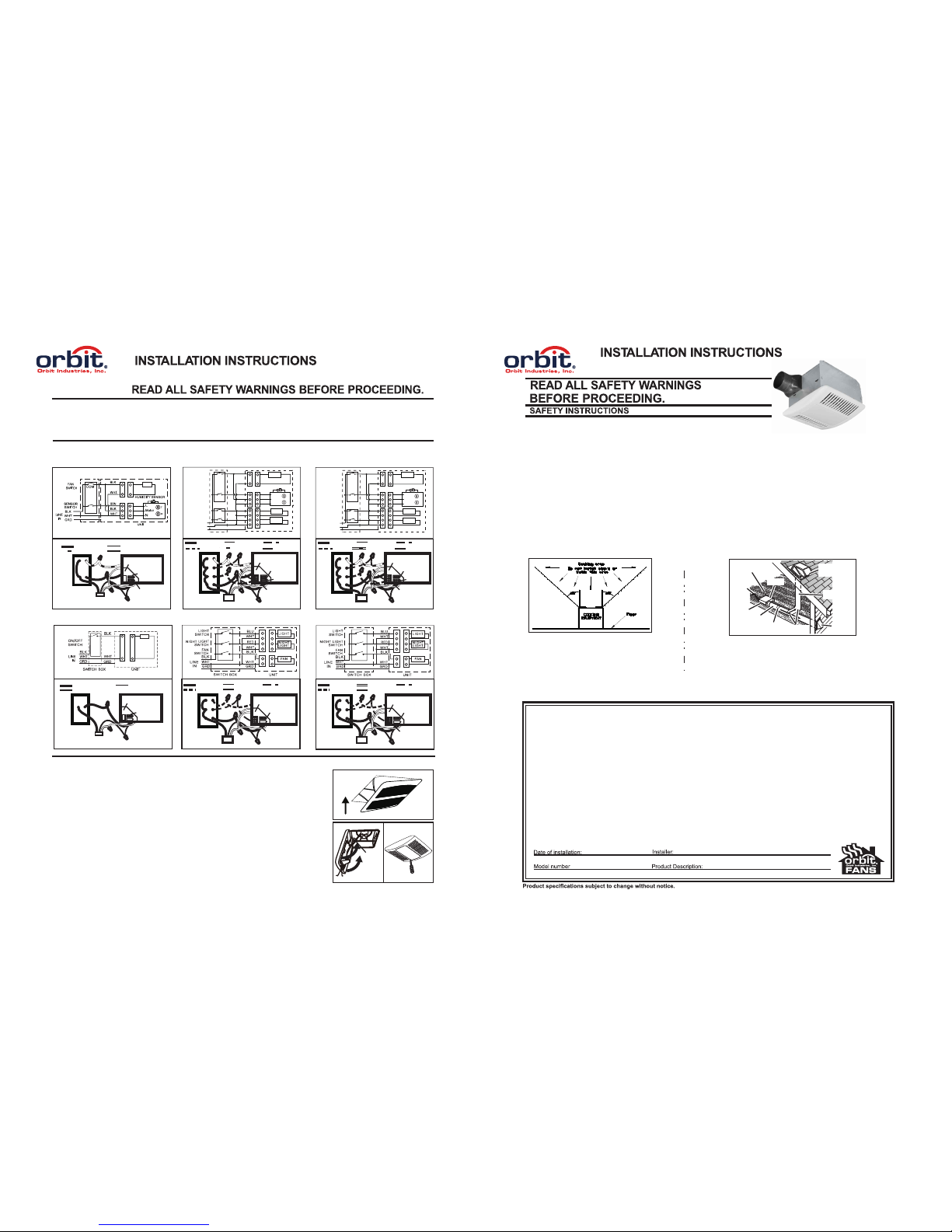

Wire panel

Model OD80H OD110H ODU814H

Model OD80LH OD80LLH OD110LH OD110LLH ODU814LH ODU814LLH

ODU814H

FAN

WIRE

PANEL

UNIT

BLACK (BLK)

SWITCH BOX

FAN

POWER SUPPLY

120V AC

GROUND (GRD)

WHITE(WHT)

FAN

CONNECTOR

UNIT

BLACK (BLK)

NIGHT

LIGHT

LIGHT

SWITCH BOX

FAN

120V AC LINE IN

GROUND (GRD)

RED

WHITE (WHT)

BLUE (BLU)

FAN

CONNECTOR

LIGHT

CONNECTOR

WIRE

PANEL

ODU814LH

OD80H

OD110H

WIRE

PANEL

UNIT

BLACK(BLK)

SENSOR

SWITCH BOX

FAN

POWER SUPPLY

120V AC

GROUND (GRD)

BROWN(BRN)

WHITE(WHT)

FAN

CONNECTOR

FAN

SWITCH BOX

HUMIDITY

HUMIDITY

HUMIDITY

SENSOR

CONNECTOR

OD80LH

OD110LH

UNIT

SENSOR

LIGHT

NIGHT

LIGHT

SWITCH BOX

FAN

120V AC LINE IN

GROUND (GRD)

BROWN (BRN)

FAN

CONNECTOR

SENSOR

CONNECTOR

LIGHT

CONNECTOR

RED

BLACK (BLK)

WHITE (WHT)

BLUE (BLU)

Humidity Sensor

UNIT

Motor

N

GRD

GRD

SWITCH BOX

BLK

BLK

WHT

BLK

WHT

FAN

SWITCH

SENSOR

SWITCH

LINE

IN

C

O

M

L

WHT

TT

HH

LIGHT

SWITCH

WHT

WHT

NIGHT LIGHT

SWITCH

BLU

RED

LIGHT

NIGHT

LIGHT

BRN

FAN

WIRE

PANEL

WIR ING DIA GRAMS :

Deluxe

“ODH” Series

WIR ING: Po wer mus t be disc onnec ted dur ing ins talla tion.

1. Run e lectr ical as d irect ly as pos sible f rom the w all swi tch to th e unit.

2. Usi ng appr oved co nnect ors, co nnect c ables w ires ac cordi ng to the m odel a nd diag ram bel ow to the j uncti on box.

3. Do no t allow c able to t ouch si de of uni t after i nstal latio n.

4

OD80LLH

OD110LLH

UNIT

SENSOR

LIGHT

NIGHT

LIGHT

SWITCH BOX

FAN

120V AC LINE IN

GROUND (GRD)

BROWN (BRN)

FAN

CONNECTOR

SENSOR

CONNECTOR

LIGHT

CONNECTOR

RED

BLACK (BLK)

WHITE (WHT)

BLUE (BLU)

Humidity Sensor

UNIT

Motor

N

GRD

GRD

SWITCH BOX

BLK

BLK

WHT

BLK

WHT

FAN

SWITCH

SENSOR

SWITCH

LINE

IN

C

O

M

L

WHT

TT

HH

LIGHT

SWITCH

WHT

WHT

NIGHT LIGHT

SWITCH

BLU

RED

LIGHT

NIGHT

LIGHT

BRN

FAN

WIRE

PANEL

UNIT

BLACK (BLK)

NIGHT

LIGHT

LIGHT

SWITCH BOX

FAN

120V AC LINE IN

GROUND (GRD)

RED

WHITE (WHT)

BLUE (BLU)

FAN

CONNECTOR

LIGHT

CONNECTOR

WIRE

PANEL

ODU814LLH

VER 2

Deluxe

“ODH” Series

4” & 6” Ter minat ion (du ct)

Rou gh Open ing:

11-1 /4” L X 10-1 /2” W

Hou sing Di mensi on:

11-1 /4” L X 10-1 /2” W X 7-5 /8” H

Car efull y posit ion fan

for s horte st duct r un and

few est elb ows to ac hieve

max imum pe rform ance

1. Re move gr ille fr om hous ing bef ore ins talla tion.

2. In sert pa ir of sli ding br acket s in each b racke t mount .

3. Lo cate ho using b etwee n ceili ng jois ts and tr uss so bo ttom

fla nge wil l fit flu sh to the c eilin g joist .

4. Lo osely s crew to j oist th rough t he moun ting br acket

KEY HOLE sl ots (scr ews not p rovid ed).

5. Op tiona l side mo unt to ce iling j oist an d use one s ide of th e

bra cket for m ore sta ble su pport .

1. Fo r new fan i nstal latio n posit ion the h ousin g in the

att ic next to t he ceil ing jo ist or tru ss.

2. Tra ce hous ing bot tom edg e on ceil ing mat erial f or cuto ut.

3. Co nfirm t he open ing, th en cut ho le 11-1/4 ” X 10-1/ 2” of the

hou sing in side ed ge.

4. Pl ace hou sing in side op ening ( attic ) of the ce iling .

5. To atta ch foll ow step s 3, 4, 5 for N ew Cons truct ion.

HUMIDITY SENSOR OPERATION

The humidity sensing fan uses a sophisticated humidity sensor that responds to: (a) rapid to moderate (user adjustable)

increases in humidity or (b) humidity above a user adjustable set point (50%-100% relative humidity). The humidity sensor

may occasionally turn the fan ON when environmental conditions change. If the fan continuously responds to changing

environmental conditions, adjustment “H” (humidity) may be required. The fan is factory set for about 75% (ambient

temperature of 77 F).

OPERATION

o

2

Deluxe

“ODH” Series

SENSITIVITY ADJUSTMENT

The “H” has been factory set for most shower applications. However, if the fan is in a tub area or is being used for dampness

H “+” may need to adjust to maximum setting. If the control is responding too often to changing environmental conditions,

adjust H “-” to lower the setting.

To adjust the “H”:

1. Disconnect power at service entrance.

2. Through the grille, locate the slot marked “H”.

3. Carefully rotate the “H” adjustment toward “+” or “-”.

4. Turn on power and check operation by turning on the shower or other humidity source until the fan turns ON.

5. Repeat above steps if necessary.

Humidity sensor has a deviation values when the temperature changes.

TIMER ADJUSTMENT (For model OD80H OD110H OD80LH OD110LH OD80LLH and OD110LLH )

The humidity sensing fan has a timer “T” that can be adjusted from 5 to 60 minutes (factory setting is 20 minutes). This “T”

controls the length of time that the fan remains ON after the sensor has stopped sensing a rise in humidity and the humidity

level is below the user adjusted set point.

To adjust Timer “T”:

1. Disconnect power at service entrance;

2. Through the grille, locate the slot marked “T”;

3. Carefully rotate the “T” and adjust to desired setting (from 5 to 60 minutes).

4. Check by turning ON the Humidity switch until the fan turn ON.

5. Turn the Humidity Switch OFF and time the unit.

The control box, located inside the fan housing, has three separate adjustments:

(1) The Low Airflow Knob adjusts the airflow from 30CFM up to the air flow rate of

the high fan speed determined by the dip switch setting.

(2) The Humidity Sensor Knob set user adjustable setpoint.

(3) The Dip Switch will adjust the fan speed setting from 80 to 120 CFM using a

4" duct or 90 to 140 CFM using a 6" duct.

Note: Both 4" & 6" duct adaptors are included.

Fan run continuously at a low speed(adjustable by low airflow knob) and automatically

boost up to high speed when humidity above a user adjustable setpoint

(50%-100% relative humidity).

After delay timer (20 minutes) returns fan to the default low speed.

Model ODU814H ODU814LH ODU814LLH

-

+

-

+

1 2 3

1

Dip Switch

Power box

Low Airflow

Knob

Humidity

Sensor Knob

80 90 110 120 90 110 120 140

1

6"

Switch

position

Duct

diameter

(inches)

Airflow

(CFM)

6"

6"

6"4"4"4"4"

80 90 110120 90 110 120 140

12312312 312

3123123

123123

6"

Switch

position

Duct

diameter

(inches)

Air deliver

(CFM)

6"

6"

6"4"4"4"4"

Other airflow reference performance based on HVI Procedures

915, 916, and 920.

Factory setting: 110CFM ( )

HVI Certified performance based on HVI Procedures 915, 916,

and 920.

with 6" duct

2 3

2 3

1 2 3

1 2 3

1 2 3 1 2 3 1 23 1 2 3 1 2 3

Dip Switch Position

* Blower Assembly includes part 6, 5, d, 4, c, b, a.

Replacement installation:

Remove the screw (part c), then take out the motor plate (part 4) from the housing (part 9) by pushing

down the rib in the plate while pulling out on the side of the housing. Replace the broken parts.

5

6

d

e

a

1a

2

3

4

b

c

1b

12

7

9

8

10

10

11

PART PART NAME Qty.

1b

2

3

4

5

6

7

8

9

10

11

12

a

b

c

d

e

Housing

Damper / Duct Connector

Lens

Wiring plate

Screw

Blower Wheel

Wire Panel / Harness Assembly

Motor

1

2

1

1

1

1

1

1

1

4

1

1

4

4

1

4

1

Isolator

Motor Plate

Washer

Nut, Hex Lock

Grille Assembly (includes part 2)

1a

Grille Spring

Bar Hanger Kit

Screw

Power box

Model OD80H OD110H ODU814H

Model OD80LH OD80LLH OD110LH

OD110LLH ODU814LH ODU814LLH

SERVICE PARTS

WARNING: Power must be disconnected before servicing.

Grille Assembly (includes part 2)

1

3

Loading...

Loading...