Oranier Polar Neo Aqua I Operating And Installation Instructions

EN

Operating and Installation

EN

Instructions for

Wood Burning Stoves

with water heat exchanger

ORANIER

Polar Neo Aqua I

292 9929 000 · 1069

EN

Table of Contents

Welcome 3

Spare parts and service call-out 3

1. Description 5

2. General 5

2.1 External combustion air supply 5

2.2 Design 6

3. Flue tube connection and

setup of th e wood burning stove 6

3.1 Connection of the ue tube 6

3.2 Setup of th e wood burning st ove 7

4. Technical data 8

5. Operating the wood burning sto ve 9

5.1 General safety instructions 9

5.2 Air control 9

5.3 Suitable fuels 10

6. Connection of the water circuit to t h e

heating system 13

6.1 Connection of the sup p ly and

return pipe 14

6.2 Bleeding the system 14

6.3 Installation instructions 15

7. Connection diagram 16

8. Maintenance schedule 17

Connections 18

ORANIER factory guarantee 19

Dimensions 20

Energy label and product data sheet

21

Declaration of performance 22

CE mark 23

Appliance parameters* Rear cover

5.4 Commissioning 10

5.5 Heating with lignite briquettes 11

5.6 Heating during the t ransitional period 11

5.7 Maximum input quantity and air

adjustment with NHO 11

5.8 Emptying ashes 12

5.9 Cleaning and maintenance 12

5.10 Chimney re 12

This replace must not be operated without properly and correctly designed water connections and/or without water lling!

2

EN

Dear Customer,

Congratulations on the purchase of this ORANIER

wood burning stove!

ORANIER wood burning stoves offer you sophisticated and reliable technology, functionality and an

attractive design.

If, despite our careful quality checks, you find

anything yo u are not h app y with, ple ase contact ou r

central custom er service team who wi ll be h ap p y t o

assist yo u.

ORANIER Heiztechnik GmbH

Oranier Straße 1

35708 Haiger / Sechshelden

Telefon: +49 (0) 27 71 / 2630- 0

Kundenservice / Ersatzteile

email customer

service: service-ht@oranier.com

email spare parts: ersatzteil-ht@oranier.com

Telephone: +49 (0) 27 71 / 2630-360

All services can be contacted

Mon - Thu: 8.00 - 17.00 h

Fri.: 8.00 - 15.00 h

*Please note:

Outside of German y , plea se contact yo ur

local distributor for customer service and

requests related to spare parts.

You can nd our ofcial distribution partners on our webs i te www.oranier.com.

If you would like to enter a customer service

order, please have the following information

ready:

Type and serial number

Fabrication number / Inspection stamp, date:

(see the back of these operating instructions)

Identification Code

Date of purchase

A photo of the back of this manual or of the

nameplate

A photo of the fault

With this information, the customer service

order can be processed very quickly!

If you would like to contact us by email or

telephone, please have the above information

ready, so the processing of your request can

be carried out quickly and easily.

*Please note:

When ordering spare parts and in the

event of any service call-outs, please

always specify the model number of

your appliance.

It is worth noting down the version of

your new wood burning stove now in the

circular eld provided in the table on the

page listing the “Appliance parameters”.

Thank you!

3

EN

This replace must not be altered in any way! The purchaser and operator

of this wood burning stove is obliged to learn how to handle it correctly by

reading these instructions. Our guarantee of fault-free function shall immediately be rendered void if the following guidelines and instructions are

not complied with. Thank you for your understanding.

Please note:

Before setting up and operating this appliance, check for any transport

damage to the functional parts (air slide, lining, seals, rebox door, pipe

supports, etc.).

If any such defects are found, please contact our customer service team.

These operating instructions familiarise you with the function and handling of the stove and are part of the replace package. Keep the operating instructions in a safe place so that you can remind yourself of the

correct operating procedures when starting a new period of heating.

Directives and standards that must be complied with:

EN 12828 Heating systems in buildings

DIN 13384 Thermal and uid calculation methods

for chimneys

DIN 18160 Domestic chimneys, requirements, planning & design

VDI 2035 Prevention of d a m age caused by corrosion an d s cale formation

in water heating systems (only for appliances t ransporting water)

1. BImSchV Ordinance on Small Firing Installations

FeuVo Firing Directive

Boiler room guidelines

Regional building regulations

If applicable: Electrical connections must be carried out by specialist electricians as

specied by VDE

Type tested in accordance with

EN 13240

Section 15a B- VG Austria

Model 1

The degree of efciency and

emission values can be found

in the Declaration of Conformity

included in these instructions.

4

EN

1. Description

The wood burning stove is made of a welded

steel construction. The central section feat ures

the rebox, which is lined with safety panels.

The ash box is l ocated below a s turdy cast i ron

trivet. Belo w this is a space for st o rin g wood.

Wood burnin g sto v es of t his des ign work us ing

convection, i.e. the surrounding air is sucked

in by the convection shafts built into the stove,

heated to a high temperature and then blown

back out into the living are a.

This stove also has a powerful water heat exchanger , f or the integ ration of the s tov e in a hot

water heating system.

Note:

For the in t egr a tion o f th e st ove

in a hot wate r heating system

further on-site components

are necessary.

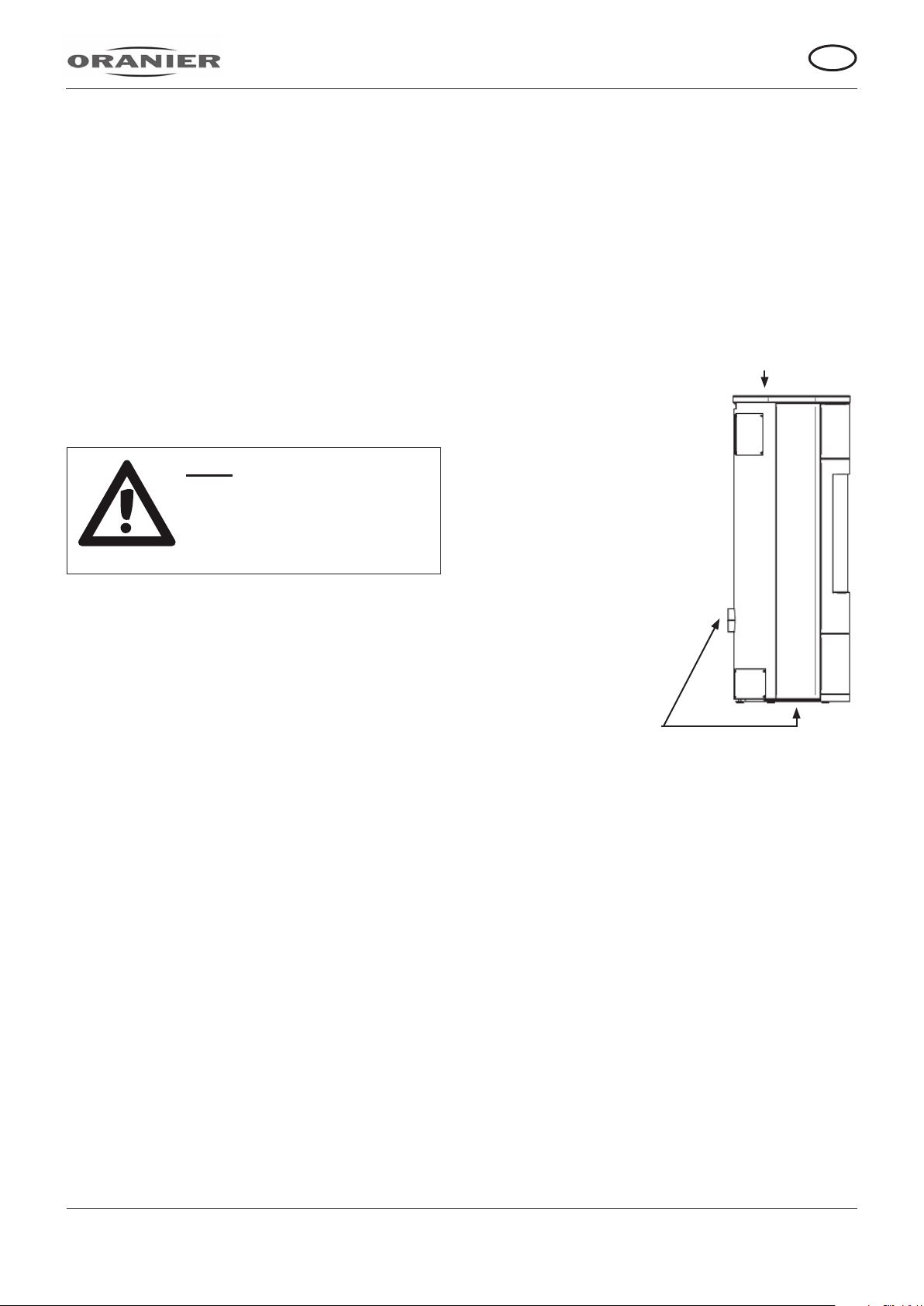

2.1 External combustion air supply

If necessary, the wood burning stove can

be equipped with a connection for an external combustion air supply (See Fig. 1):

For especially well-insulated rooms, an air supply from outside can be connected. The connection pipe requ ir ed f or th is is avail abl e as a n

accessory

Fig. 1

Flue tube opening

2. General

Your wood burning stove must be set up with

strict adherence to the relevant regional building regulations and following consultation with

the local profession al chimney s weep.

Once installed, he will also check that the replace is connected correctly.

During operation, a replace will draw oxygen

from the room in which it is set up. It is therefore absolutely essential to ensure an adequate supply of fresh ai r to this room.

If the stove is set up in rooms with particularly

tightly-closing windows and doors, malfunctions cannot be excluded.

If you are uncertain whether there is sufcient

air available for the stove in the room in which

you plan to set it up, ask your chimney sweep

for advice.

.

Wood burnin g stove

Connections for

external combustion

air supply

When attaching an external combustion

air supply, ensure that the pipes are tightly

sealed!

The combustion air is supplied exclusively via

a supply pipe with a ND of 100 mm, tted during installation. The air pipe should be made

from smooth ste e l or p lastic (drainag e p i p e).

The full length of the pipe should be no longer

than 6 m, have no reductions in the bore diameter and include no more than 3 90° elbow

pieces.

A safety grille attached in front of the external air supply opening must not be able to

accidentally restrict or occlude the supply air

cross-section.

It can be connected to a suitable air exhaust

chimney.

5

EN

In every case, care must be taken to ensure

that the combustion air requirement of around

30 m3/h is met at a feed pr e ssure of 4 Pa .

When not in use, all air slides should be kept

closed to ensure that no cold air is able to circulate via the chimney. The potential build-up

of condensation can be avoided

by insulating the air pipe.

The chimney draught must be able to overcome the additional resistances of a ring

system equipped with this setup.

2.2 Design

The wood burning stove series described in

these instructions a r e of “Design 1”.

The wood burning stove has a self-closing

rebox door and is approv ed onl y for use with

the rebox closed. Wood burning stoves of this

design may be connected to chimneys with

multiple ues, provided the dimensions of the

chimney permit this.

3. Flue tube connection and

setup of the wood burning sto ve

3.1 Connection of the ue tube

Your wood burning stove is connected up-

wards. To connect it to the chimney, a ue tube

made from 2 mm-thick sheet steel should be

used.

All of the connections between the stove and

the chimney must be stable, solid, tight and

free from tension. Use a temperature-resist-

ant sealing paste (e.g. boiler putty) to seal

off the stove outlets.

Ensure that the ue tube does not protrude into

the clear cross-section of the chimney.

We recommend using a liner.

The ue tube should run towards the chimney

in a slight up wa rds i ncline , b ut at th e v ery least

horizontally.

If the stove is connected to a chimney with

multiple ues, the hydraulic closure springs of

the rebox door must be removed under no cir-

cumstances.

The rebox door must be able to close inde-

pendently once fuel has been added so that

any inuence from the draught (feed pressure)

and associated risks and impairments of other

connected replaces can be avoided.

The design and condition of the chimney to

which the stove is to be connected plays a

key part in the fault-free operation of the wood

burning stove.

In all cases, have the suitability of the

chimney you intend to use checked by a

specialist.

This wood burning stove has been tested in

accordance with EN 13240.

Note:

The connection pieces required for a connection on the

ue gas side are not included

in the scope of delivery.

Caution!

If the feed pressure is too

low, or also too high

(draught), malfunctions can

occur.

If the value i s m ore than 25%

higher than the value listed

under Point 4 (Technical da ta:

"Feed pressur e at NHO"), corresponding measures must be

carried out on the chimne y.

6

EN

3.2 Setup of the wood burning stove

Fire safety regulations according to FeuVo

(mi nimum distances; see Fig . 2) must be complied with when setting up the applian ce.

FeuVo ("O rdinance on Firing Installations an d

Fuel Storage", or: Firing Ordinance for short)

is the legal basis for setting up and operating

ring installations.

Fig. 2

Caution!

For your own safety, you

must comply with the minimum distances specied to

installation walls, ammable

furnishings and objects and

for protection of the ooring!

Note:

Before heating the system for

the rst time, please remove

all documents a n d accessory

parts from the rebox and ash

box.

Remove all stick ers so there

is no residue from the v i ewing

pane.

Minimum distances that must be maintained:

A: 80 cm in the radia nt range of the pa n e

B1: 20 cm distance from th e wall at the rea r

B2: 30 cm distance from the wall at th e s i d e

C: 30 cm oor protection on the side of the

ller opening

D: 50 cm oor protection in front of the

ller opening

The rear (B1) and side (B2) minimum distances are also lis ted on your stove's type plate .

Caution!

Ensure before setup that the

oor (setup surface)

is able to support the weight

of the stove.

If necessary, use a suitable

supporting plate to distribute

the weight.

7

EN

4. Technical data

Wood burning stove type: POLAR NEO AQU A I

Design: 1

Nominal heat output: 10,0 kW

Water heat output: 6,0 kW

Energieefzienzklasse: A+

Energy efciency index

EEI: 111

Room heating capacity

DIN 18893 max.: 200 m

Height

incl. cover plate: 1320 mm

Width: 595 mm

Depth: 505 mm

Max. supply temp.: 95°C

Max. boiler pressure : 3,0 bar

Firebox H / W / D: 380 / 430 / 350 mm

Filler opening H / W: 530 / 480 mm

Max. rewood length: 35 cm

Weight steel / stone: 210 / 250 kg

Suitable for constant

operation and constant

ring: yes

Tested and approv ed

according to standard: EN 13240

1. BlmSchV-Stage 2: yes

Regensburger Standard: yes

Münchner Standard: yes

§15a B-VG Austria: yes

VKF Switzerland: yes

Ext. combustion

air supply: yes

Emissions and efciency values

(13% 0

; wood / BB7):

2

Efciency

(wood / BB7):: 83,6 / 84,1 %

CO: 1022 / 808 mg/m

NOx: 129 / 142 mg/m

CnHm: 70 / 73 mg/m

Particulate matter: 35 / 32 mg/m

3

3

3

3

3

Exhaust mass ow: 8,1 g/s

Feed pressure for NHO: 12,0 Pa

Exhaust temperature

at outlet: 227 °C

Approved fuels: - Firewood < 25% moisture

content (preferred fuel)

- Wood briquettes < 12%

moisture content,

- Lignite briquettes

Diameter of pipe outlet: 150 mm

Diameter of ue: 150 mm

Top outlet

(Base - LB outlet): 1305 mm

Top outlet

(FB - central outlet): 178 mm

Rear outlet

(Floor - LB outlet): -

Safety distance

At rear: 200 mm

At the side:: 200 mm

In the radiant range

of the viewing pane: 800 mm

Firebox lining:

Flat trivet: yes

Locking of the

Firebox door: hydraulic

Primary air control: yes

Secondary air control

Slider ventilation

Tertiary air control: yes

Water connections: 3/4“

Recommended content

buffer store: 300-500 l

Diameter of outlet of

external combustion air

supply (2x): 100 mm

Floor to centre

outlet: 351 mm

Front edge t o centra l

outlet: 283 mm

Vermiculite

: yes

8

Loading...

Loading...