Optris OPTCSV2MLSFV, OPTCSV3MHSFV, OPTCSV2MHSFV, OPTCSV3MHCFV, OPTCSV2MHCFV User manual

...Page 1

Operator’s Manual

optris

®

CSvideo

Infrared-thermometer

2M, 3M

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Table of Contents 3-

Table of Contents

Table of Contents ............................................................................................................................................. 3

1 General Information ................................................................................................................................. 6

1.1 Description ....................................................................................................................................... 6

1.2 Warranty ........................................................................................................................................... 7

1.3 Scope of Supply ............................................................................................................................... 7

1.4 Maintenance ..................................................................................................................................... 8

1.5 Model Overview ................................................................................................................................ 8

1.6 Factory Default Settings ................................................................................................................... 9

2 Technical Data ........................................................................................................................................ 10

2.1 General Specifications ................................................................................................................... 10

2.2 Electrical Specifications .................................................................................................................. 11

2.3 Measurement Specifications .......................................................................................................... 12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

-4 -

2.4 Optics ............................................................................................................................................. 14

3 Mechanical Installation .......................................................................................................................... 17

4 Accessories ............................................................................................................................................ 18

4.1 Mounting Brackets .......................................................................................................................... 18

4.2 Air Purge Collar .............................................................................................................................. 19

4.3 Water Cooled Housing ................................................................................................................... 20

5 Electrical Installation ............................................................................................................................. 21

5.1 Cable Connections ......................................................................................................................... 21

5.2 Power supply .................................................................................................................................. 21

5.3 Analog Mode .................................................................................................................................. 23

5.4 Digital Mode ................................................................................................................................... 24

5.5 Maximum Loop Impedance ............................................................................................................ 25

6 Sighting ................................................................................................................................................... 26

6.1 Focusing and Video Sighting ......................................................................................................... 27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Table of Contents 5-

7 IRmobile app ........................................................................................................................................... 28

8 Software CompactConnect ................................................................................................................... 30

8.1 Installation ...................................................................................................................................... 30

8.2 Communication Settings ................................................................................................................ 32

8.3 Digital Command Set ..................................................................................................................... 33

9 Basics of Infrared Thermometry........................................................................................................... 34

10 Emissivity ............................................................................................................................................... 35

10.1 Definition......................................................................................................................................... 35

10.2 Determination of unknown Emissivities .......................................................................................... 35

10.3 Characteristic Emissivities.............................................................................................................. 36

Appendix A – Emissivity Table Metals ......................................................................................................... 37

Appendix B – Emissivity Table Non Metals ................................................................................................. 39

Appendix C – Smart Averaging ..................................................................................................................... 40

Appendix D – Declaration of Conformity ..................................................................................................... 41

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

-6 -

1 General Information

1.1 Description

Thank you for choosing the optris® CSvideo infrared thermometer.

The sensors of the optris CSvideo series are noncontact infrared temperature sensors.

They calculate the surface temperature based on the emitted infrared energy of objects [►9 Basics of

Infrared Thermometry]. The alignment of the sensor can be done with the integrated video sighting and

cross laser aiming.

The sensor housing of the CSvideo head is made of stainless steel (IP65/ NEMA-4 rating).

The CSvideo sensing head is a sensitive optical system. Please use only the thread for

mechanical installation.

• Avoid abrupt changes of the ambient temperature.

• Avoid mechanical violence on the head – this may destroy the system (expiry of warranty).

• If you have any problems or questions, please contact our service department.

Read the manual carefully before the initial start-up. The producer reserves the right to change

the herein described specifications in case of technical advance of the product.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

General Information 7-

► All accessories can be ordered according to the referred part numbers in brackets [ ].

1.2 Warranty

Each single product passes through a quality process. Nevertheless, if failures occur please contact the

customer service at once. The warranty period covers 24 months starting on the delivery date. After the

warranty is expired the manufacturer guarantees additional 6 months warranty for all repaired or substituted

product components. Warranty does not apply to damages, which result from misuse or neglect. The

warranty also expires if you open the product. The manufacturer is not liable for consequential damage or in

case of a non-intended use of the product.

If a failure occurs during the warranty period the product will be replaced, calibrated or repaired without

further charges. The freight costs will be paid by the sender. The manufacturer reserves the right to

exchange components of the product instead of repairing it. If the failure results from misuse or neglect the

user has to pay for the repair. In that case you may ask for a cost estimate beforehand.

1.3 Scope of Supply

▪ CSvideo

▪ Mounting nut and mounting bracket (fixed)

▪ 5 m USB cable

▪ Software CompactConnect (as a download)

▪ Operators manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

-8 -

1.4 Maintenance

Lens cleaning: Blow off loose particles using clean compressed air. The lens surface can be cleaned with a

soft, humid tissue (moistened with water) or a lens cleaner (e.g. Purosol or B+W Lens Cleaner).

Never use cleaning compounds which contain solvents (neither for the lens nor for the housing).

1.5 Model Overview

The sensors of the CSvideo series are available in the following basic versions:

Model

Model code

Measurement range

Spectral

response

Typical applications

CSvideo 2M

2ML

250 to 800 °C

1,6 µm

Metals and ceramic surfaces

2MH

385 to 1600 °C

CSvideo 3M

3ML

50 to 400 °C

2,3 µm

3MH

100 to 600 °C

In the following chapters of this manual you will find only the short model codes.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

General Information 9-

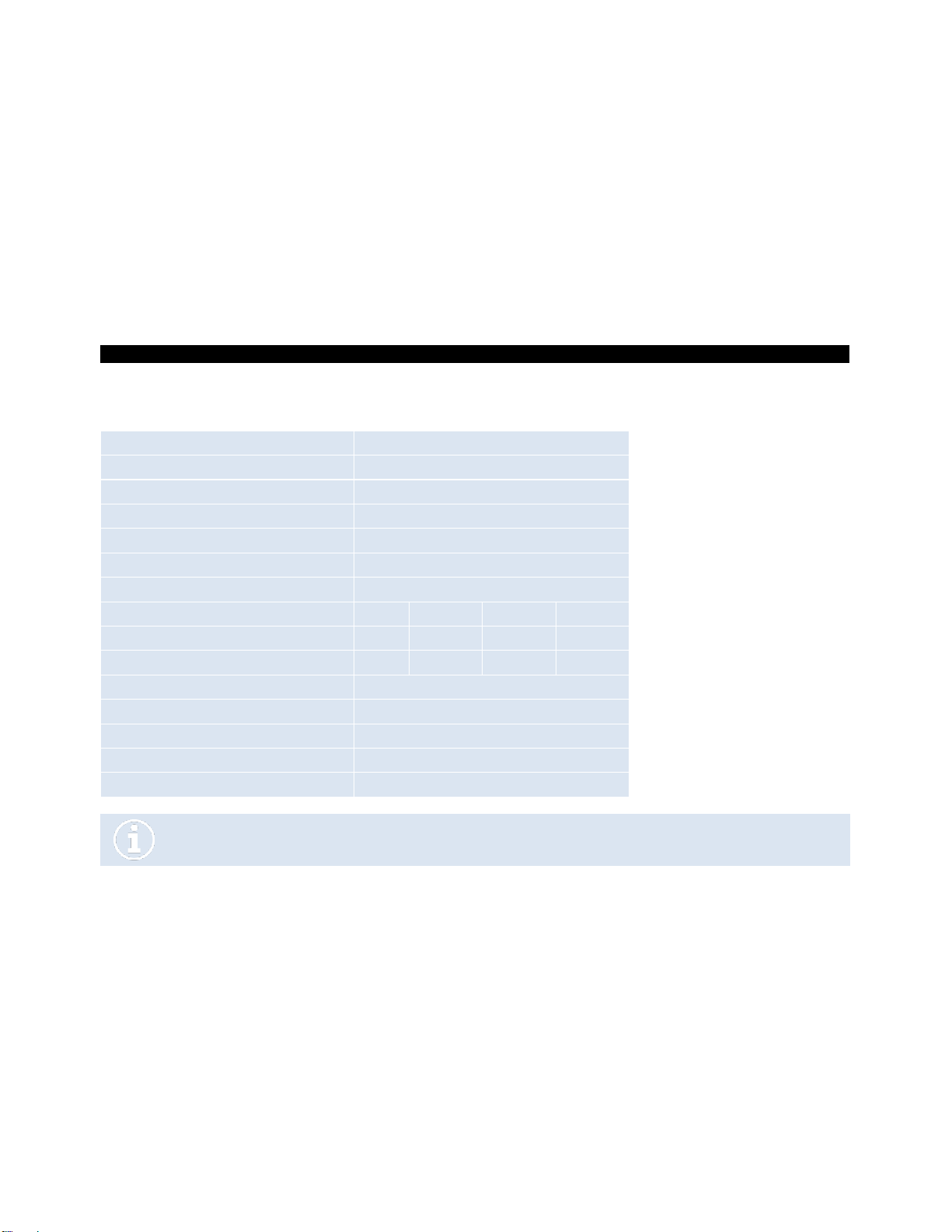

1.6 Factory Default Settings

The unit has the following pre-setting at time of delivery:

Signal output object temperature

4-20 mA

Emissivity

1,000

Transmissivity

1,000

Average time (AVG)

0,1 s

Smart Averaging

active

Peak hold

inactive

Valley hold

Inactive

2ML

2MH

3ML

3MH

Lower limit temperature range [°C]

250

385

50

100

Upper limit temperature range [°C]

800

1600

400

600

Lower limit signal output

4 mA

Upper limit signal output

20 mA

Temperature unit

°C

Ambient temperature compensation

internal head temperature probe

Laser

active

Smart Averaging means a dynamic average adaptation at high signal edges.[Activation via software

only].►Appendix C – Smart Averaging

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

-10 -

2 Technical Data

2.1 General Specifications

Environmental rating

IP65 (NEMA-4)

Ambient temperature 1)

-20…70 °C

Storage temperature

-40...85 °C

Relative humidity

10...95 %, non-condensing

Material

stainless steel

Dimensions

118,5 mm x 50 mm, M48x1,5

Weight

600 g

Cable length (analog+alarm)

3 m, 8 m, 15 m

Cable length (USB)

5 m (incl.), 10 m, 20 m

Cable diameter

5 mm

Ambient temperature cable

80 °C max. [High temperature cable (optional): 180 °C]

Vibration

IEC 68-2-6: 3G, 11 – 200 Hz, any axis

Shock

IEC 68-2-27: 50G, 11 ms, any axis

Software / App (optional)

CompactConnect / IRmobile

1)

The lasers will turn off automatically at ambient temperatures >50 °C.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Technical Data 11-

2.2 Electrical Specifications

Power Supply

5–30 VDC

Current draw (laser)

45 mA @ 5 V

20 mA @ 12 V

12 mA @ 24 V

Aiming laser

Crosshair laser, 635 nm, 1 mW, On/ Off via external switch (needs to be installed by user before

start-up) or software

Video sighting

Digital (USB 2.0), 640 x 480 px, FOV 3.1° x 2.4°

Output/ analog

4–20 mA current loop

Alarm output

Programmable open collector output at RxD pin [0-30 V/ 500 mA]

Output impedance

max. loop resistance 1000 Ω (in dependence on supply voltage)

Output/ digital

USB 2.0

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

-12 -

2.3 Measurement Specifications

2ML

2MH

Temperature range (scalable)

250...800 °C

385...1600 °C

Spectral range

1,6 µm

Optical resolution

150:1

300:1

System accuracy

1), 2)

±(0,3 % of reading +2 °C)

Repeatability

1), 2)

±(0,1 % of reading +1 °C)

Temperature resolution

0,1 K

Response time (90% signal)

10 ms

Emissivity/ Gain

0,100…1,100 (adjustable via switches on sensor or via software)

IR window correction

0,100…1,000 (adjustable via software)

Signal processing

Average, peak hold, valley hold, extended hold functions with threshold

and hysteresis (adjustable via software)

1)

at ambient temperature 235 °C

2)

= 1/ Response time 1 s

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Technical Data 13-

3ML

3MH

Temperature range (scalable) 1)

50...400 °C

100...600 °C

Spectral range

2,3 µm

Optical resolution

60:1

100:1

System accuracy

2), 3)

±(0,3 % of reading +2 °C)

Repeatability

2), 3)

±(0,1 % of reading +1 °C)

Temperature resolution

0,1 K

Response time (90% signal) 4)

20 ms

Emissivity/ Gain

0,100…1,100 (adjustable via switches on sensor or via software)

IR window correction

0,100…1,000 (adjustable via software)

Signal processing

Average, peak hold, valley hold, extended hold functions with threshold

and hysteresis (adjustable via software)

1)

T

Object>TSensor head

+25 °C

2)

at ambient temperature 235 °C

3)

= 1/ response time 1 s

4)

with dynamic adaption at low signal levels

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

-14 -

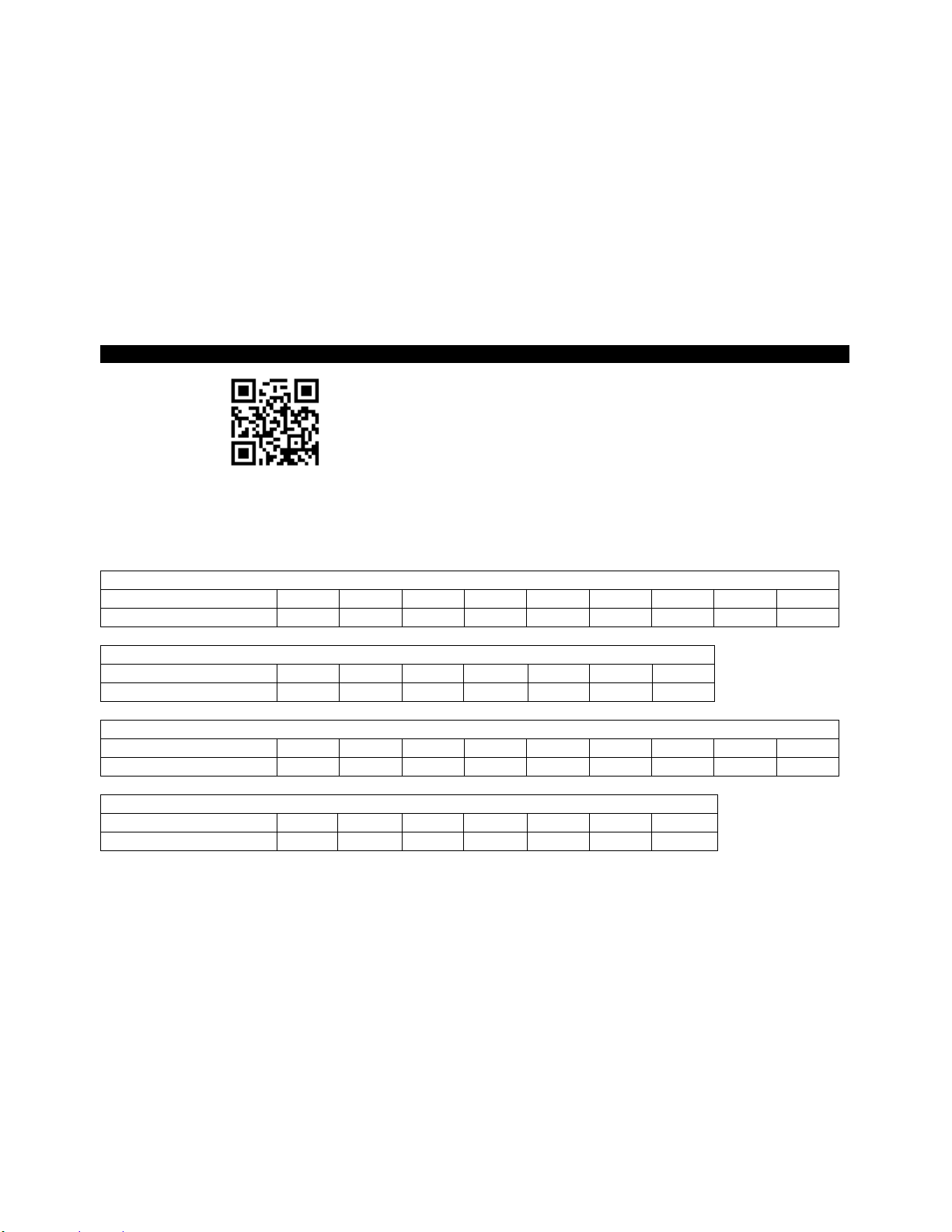

2.4 Optics

The vario optics of the CSvideo allows a smooth focusing of the optics to the desired distance. The sensors

are available in two optic versions:

Optics

Focus adjustable in the range

SFV

200 mm till infinity

CFV

90 mm till 250 mm

The size of the measuring object and the optical resolution of the infrared thermometer

determine the maximum distance between sensing head and measuring object.

In order to prevent measuring errors the object should fill out the field of view of the optics

completely.

Consequently, the spot should at all times have at least the same size like the object or should

be smaller than that.

The following tables show the diameter of the measuring spot for some selected distances. The spot size

refers to 90 % of the radiation energy.

The distance is always measured from the front edge of the sensing head.

As an alternative to the optical diagrams, the spot size calculator can also be used on the Optris website

or the Optris calculator app. The app can be downloaded for free from the Google Play store (see QR

code).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Technical Data 15-

D = Distance from front of the sensing head to the object

S = Spot size

2ML SF optics (D:S=150:1)

Spot size

mm

1,3

2,0

3,0

4,7

7,3

10,7

16,7

33,3

Measurement distance

mm

200

300

450

700

1100

1600

2500

5000

2ML CF optics (D:S=150:1)

Spot size

mm

0,6

0,8

1,0

1,2

1,4

1,7

Measurement distance

mm

90

120

150

180

210

250

2MH SF optics (D:S=300:1)

Spot size

mm

0,7

1,0

1,5

2,3

3,7

5,3

8,3

16,7

Measurement distance

mm

200

300

450

700

1100

1600

2500

5000

2MH CF optics (D:S=300:1)

Spot size

mm

0,3

0,4

0,5

0,6

0,7

0,8

Measurement distance

mm

90

120

150

180

210

250

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

-16 -

3ML SF optics (D:S=60:1)

Spot size

mm

3,3

5,0

7,5

11,7

18,3

26,7

41,7

83,3

Measurement distance

mm

200

300

450

700

1100

1600

2500

5000

3ML CF optics (D:S=60:1)

Spot size

mm

1,5

2,0

2,5

3,0

3,5

4,2

Measurement distance

mm

90

120

150

180

210

250

3MH SF optics (D:S=100:1)

Spot size

mm

2,0

3,0

4,5

7,0

11,0

16,0

25,0

50,0

Measurement distance

mm

200

300

450

700

1100

1600

2500

5000

3MH CF optics (D:S=100:1)

Spot size

mm

0,9

1,2

1,5

1,8

2,1

2,5

Measurement distance

mm

90

120

150

180

210

250

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Mechanical Installation 17-

3 Mechanical Installation

The CSvideo is equipped with a metric M48x1,5 thread and can be installed either directly via the sensor

thread or with help of the supplied mounting nut (standard) and fixed mounting bracket (standard) to a

mounting device available.

CSvideo sensing head

Make sure to keep the optical path clear of any obstacles.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

-18 -

4 Accessories

4.1 Mounting Brackets

Mounting bracket, adjustable in two axes [ACCTLAB]

Mounting bracket, adjustable in one axis [ACCTLFB]

For an exact sensor alignment to the object please

activate the integrated video and/ or cross laser

sighting.

[►6 Sighting]

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Accessories 19-

4.2 Air Purge Collar

The lens must be kept clean at all times from dust, smoke, fumes and other contaminants in order to avoid

reading errors. These effects can be reduced by using an air purge collar. Make sure to use oil-free,

technically clean air, only.

Air purge collar [ACCTLAP]

Hose connection: 6x8 mm

Thread (fitting): G 1/8 inch

The needed amount of air (approx. 2...10 l/

min.) depends on the application and the

installation conditions on-site.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

-20 -

4.3 Water Cooled Housing

Water cooled housing [ACCTLW]

Hose connection: 6x8 mm

Thread (fitting): G 1/8 inch

The CSvideo can be used at ambient temperatures up to 70 °C without cooling. For applications, where the

ambient temperature can reach higher values, the usage of the optional water cooled housing is

recommended (operating temperature up to 175 °C). The sensor should be equipped with the optional high

temperature cables (operating temperature up to 180 °C).

Water flow rate: approx. 2 l/ min

(Cooling water temperature should not exceed

30 °C)

To avoid condensation on the optics an air

purge collar is recommended.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Electrical Installation 21-

5 Electrical Installation

5.1 Cable Connections

The CSvideo has two connector plugs integrated in the sensor backplane.

Therefore, an opening of the sensor for cable assembling is not

necessary. For connection to a PC you can use the supplied 5 m USB

cable with a 4-pin sensor connector (lengths of 10 m and 20 m are

optional available).

For the analog connection (4-20 mA current loop, alarm, laser) a cable

with a 7-pin plug is needed. This cable is not included in the scope of

supply and has to be ordered separately.

Lengths of 3, 8 and 15 m are available.

Please use the original ready-made, fitting connection cables.

5.2 Power supply

Please use a separate, stabilized power supply unit with an output voltage of 5–30 VDC which can supply

100 mA. The ripple should be max. 200 mV.

Please use shielded cables only for all power and data lines.

The sensor shield has to be grounded.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

-22 -

Pin assignment of 7-pin connector (current loop/ alarm/ laser)

PIN

Designation

Wire color (original sensor cable)

1 – yellow

2

LOOP –

brown

3

LOOP +

white

4

Alarm

green

5

LASER –

grey

6

LASER +

pink

7

–

Pin assignment of 4-pin connector (USB)

PIN

Designation

1

VCC

2

GND

3

D-

4

D+

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Electrical Installation 23-

5.3 Analog Mode

If the CSvideo is used as analog device the sensor provides beside the 4-20 mA signal in addition an alarm

output (open-collector). To activate the alarm output and set the alarm threshold value the software is

needed.

The supply line for the sighting laser must be led via a switch or pushbutton, which has to be

installed max. 2 m away from installation site of the sensor.

With a laptop or tablet PC, the sensor parameterization and alignment can be carried out on site. The USB

cable can be plugged into the sensor during operation (hot plug & play).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

-24 -

5.4 Digital Mode

In the digital mode the sensor and the laser will be powered via the 5 V from USB interface. The activation/

deactivation of the laser has to be made via the software.

The sensor is offering two ways of digital communication:

▪ bidirectional communication (sending and receiving data)

▪ unidirectional communication (burst mode – the sensor is sending data only)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Electrical Installation 25-

5.5 Maximum Loop Impedance

The maximum impedance of the current loop depends on the supply voltage level:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

-26 -

6 Sighting

The CSvideo has an integrated video camera which is using the same optical channel than the IR detector.

In addition, the sensor has a cross laser aiming which marks the center of the measurement spot at any

distance. The combination of video and laser sighting enables a perfect alignment of the sensor to the

object.

The supply line for the sighting laser must be led via a switch or pushbutton, which has to be

installed max. 2 m away from installation site of the sensor.

The laser can be activated/ deactivated via this switch (which needs to be installed by the user) or via the

software.

At ambient temperatures >50 °C the laser will be switched off automatically.

The laser should only be used for sighting and positioning of the sensor. A permanent use of the laser can

reduce the lifetime of the laser diodes and also the measurement accuracy can be affected.

WARNING: Do not point the laser directly

at the eyes of persons or animals!

Do not stare into the laser beam. Avoid

indirect exposure via reflective surfaces!

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Sighting 27-

6.1 Focusing and Video Sighting

On the back plane of the sensor you will find a rotary button for focusing of

the optics.

To set the focus to the desired measurement distance you have to connect

the sensor with a PC using the USB cable. Please start the CompactConnect

software. You will see the video beside the temperature-time diagram. The

position of the measurement spot is indicated by a circle inside the video

picture. The size of this circle is equivalent to the IR spot size.

By turning the rotary button clockwise you will change the focus in direction far. By turning

counterclockwise you will change the focus in direction close.

After a successful focusing please enter the

measurement distance (distance sensor front

– object) in the according field in the software

(underneath the video picture).

You will find a detailed description of the video

settings in the software description which you

can call via the menu [?/ Help...].

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

-28 -

7 IRmobile app

The CSvideo sensor has a direct connection to an Android smartphone or tablet. All you

have to do is download the IRmobile app for free in the Google Play store. This can also be

done via the QR code. An IRmobile app connector is recommended for connection to the

device (Part-No.: ACPIIAC).

With IRmobile you are able to monitor and analyse your infrared temperature measurement on a connected

smartphone or tablet. This app works on most Android devices running 5.0 or higher with a micro USB or

USB-C port supporting USB-OTG (On The Go). It is easy to operate: after you plug your CSvideo device to

your phone or tablet, the app will start automatically. The device is powered by your phone. Different digital

temperature values can be displayed in the temperature time diagram. You can easily zoom-in the diagram

to see more details and small signal changes.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

IRmobile app 29-

IRmobile app features:

➢ Temperature time diagram with zoom function

➢ Aligning the sensor via live video with integrated simultaneous temperature

display (CSvideo/CTvideo)

➢ Setup of emissivity, transmissivity and other parameters

➢ Scaling of the analog output and setting of the alarm output

➢ Change of temperature unit: Celsius or Fahrenheit

➢ Saving/loading of configurations and T/t diagrams

➢ Restore factory default sensor settings

➢ Integrated simulator

Supported for:

➢ Optris pyrometers: Compact series, high performance series and video thermometers

➢ Optris IR cameras: PI and Xi series

➢ For android devices running 5.0 or higher with a micro USB or USB-C port supporting USB-OTG (On

The Go)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

-30 -

8 Software CompactConnect

The installation wizard will place a launch icon on the desktop and in the start menu:

[Start]\Programs\CompactConnect.

If you want to uninstall the software from your system, please use the uninstall icon in the start menu.

A detailed description is provided in the software manual on the downloaded software package.

Min. system requirements:

▪ Windows 7, 8, 10

▪ USB interface

▪ Hard disc with at least 30 MByte free space

▪ At least 128 MByte RAM

8.1 Installation

The software can be downloaded under

Unzip and open the program and start the

CDsetup.exe. Follow the instructions of the

wizard until the installation is finished.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Software CompactConnect 31-

Main Features:

▪ Alignment of the sensor

▪ Graphic display for temperature trends and

automatic data logging for analysis and

documentation

▪ Complete sensor setup and remote controlling

▪ Adjustment of signal processing functions

▪ Programming of outputs and functional inputs

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

-32 -

8.2 Communication Settings

Serial Interface

Baud rate:

9600 baud

Data bits:

8

Parity:

none

Stop bits:

1

Flow control:

off

Protocol

All sensors of the CSvideo series are using a binary protocol. To get a fast communication the protocol has

no additional overhead with CR, LR or ACK bytes.

To power the sensor the control signal ”DTR“ has to be reset.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Software CompactConnect 33-

8.3 Digital Command Set

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

-34 -

9 Basics of Infrared Thermometry

Depending on the temperature each object emits a certain amount of infrared radiation. A change in the

temperature of the object is accompanied by a change in the intensity of the radiation. For the measurement

of “thermal radiation” infrared thermometry uses a wave-length ranging between 1 µm and 20 µm.

The intensity of the emitted radiation depends on the material. This material contingent constant is described

with the help of the emissivity which is a known value for most materials (►10 Emissivity).

Infrared thermometers are optoelectronic sensors. They calculate the surface temperature on the basis of

the emitted infrared radiation from an object. The most important feature of infrared thermometers is that

they enable the user to measure objects contactless. Consequently, these products help to measure the

temperature of inaccessible or moving objects without difficulties. Infrared thermometers basically consist of

the following components:

▪ lens

▪ spectral filter

▪ detector

▪ electronics (amplifier/ linearization/ signal processing)

The specifications of the lens decisively determine the optical path of the infrared thermometer, which is

characterized by the ratio Distance to Spot size.

The spectral filter selects the wavelength range, which is relevant for the temperature measurement. The

detector in cooperation with the processing electronics transforms the emitted infrared radiation into electrical

signals.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Emissivity 35-

10 Emissivity

10.1 Definition

The intensity of infrared radiation, which is emitted by each body, depends on the temperature as well as on

the radiation features of the surface material of the measuring object. The emissivity (ε – Epsilon) is used as

a material constant factor to describe the ability of the body to emit infrared energy. It can range between 0

and 100 %. A “blackbody” is the ideal radiation source with an emissivity of 1,0 whereas a mirror shows an

emissivity of 0,1.

If the emissivity chosen is too high, the infrared thermometer may display a temperature value which is much

lower than the real temperature – assuming the measuring object is warmer than its surroundings. A low

emissivity (reflective surfaces) carries the risk of inaccurate measuring results by interfering infrared radiation

emitted by background objects (flames, heating systems, chamottes). To minimize measuring errors in such

cases, the handling should be performed very carefully and the unit should be protected against reflecting

radiation sources.

10.2 Determination of unknown Emissivities

► First, determine the actual temperature of the measuring object with a thermocouple or contact sensor.

Second, measure the temperature with the infrared thermometer and modify the emissivity until the

displayed result corresponds to the actual temperature.

► If you monitor temperatures of up to 380 °C you may place a special plastic sticker (emissivity dots – part

number: ACLSED) onto the measuring object, which covers it completely. Now set the emissivity to 0,95

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

-36 -

and take the temperature of the sticker. Afterwards, determine the temperature of the adjacent area on

the measuring object and adjust the emissivity according to the value of the temperature of the sticker.

► Cove a part of the surface of the measuring object with a black, flat paint with an emissivity of 0,98. Adjust

the emissivity of your infrared thermometer to 0,98 and take the temperature of the colored surface.

Afterwards, determine the temperature of a directly adjacent area and modify the emissivity until the

measured value corresponds to the temperature of the colored surface.

CAUTION: On all three methods the object temperature must be different from ambient temperature.

10.3 Characteristic Emissivities

In case none of the methods mentioned above help to determine the emissivity you may use the emissivity

tables ►Appendix A – Emissivity Table Metals and Appendix B – Emissivity Table Non Metals. These

are average values, only. The actual emissivity of a material depends on the following factors:

▪ temperature

▪ measuring angle

▪ geometry of the surface

▪ thickness of the material

▪ constitution of the surface (polished, oxidized, rough, sandblast)

▪ spectral range of the measurement

▪ transmissivity (e.g. with thin films)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Appendix A – Emissivity Table Metals 37-

Appendix A – Emissivity Table Metals

1,0 µm 1,6 µm 5,1 µm 8-14 µm

Aluminium non oxidized 0,1-0,2 0,02-0,2 0,02-0,2 0,02-0,1

polished 0,1-0,2 0,02-0,1 0,02-0,1 0,02-0,1

roughened 0,2-0,8 0,2-0,6 0,1-0,4 0,1-0,3

oxidized 0,4 0,4 0,2-0,4 0,2-0,4

Brass polished 0,35 0,01-0,05 0,01-0,05 0,01-0,05

roughened 0,65 0,4 0,3 0,3

oxidized 0,6 0,6 0,5 0,5

Copper polished 0,05 0,03 0,03 0,03

roughened 0,05-0,2 0,05-0,2 0,05-0,15 0,05-0,1

oxidized 0,2-0,8 0,2-0,9 0,5-0,8 0,4-0,8

Chrome 0,4 0,4 0,03-0,3 0,02-0,2

Gold 0,3 0,01-0,1 0,01-0,1 0,01-0,1

Haynes alloy 0,5-0,9 0,6-0,9 0,3-0,8 0,3-0,8

Inconel electro polished 0,2-0,5 0,25 0,15 0,15

sandblast 0,3-0,4 0,3-0,6 0,3-0,6 0,3-0,6

oxidized 0,4-0,9 0,6-0,9 0,6-0,9 0,7-0,95

Iron non oxidized 0,35 0,1-0,3 0,05-0,25 0,05-0,2

rusted 0,6-0,9 0,5-0,8 0,5-0,7

oxidized 0,7-0,9 0,5-0,9 0,6-0,9 0,5-0,9

forged, blunt 0,9 0,9 0,9 0,9

molten 0,35 0,4-0,6

Iron, casted non oxidized 0,35 0,3 0,25 0,2

oxidized 0,9 0,7-0,9 0,65-0,95 0,6-0,95

Material

typical Emissivity

Spectral response

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

-38 -

1,0 µm 1,6 µm 5,1 µm 8-14 µm

Lead polished 0,35 0,05-0,2 0,05-0,2 0,05-0,1

roughened 0,65 0,6 0,4 0,4

oxidized 0,3-0,7 0,2-0,7 0,2-0,6

Magnesium 0,3-0,8 0,05-0,3 0,03-0,15 0,02-0,1

Mercury 0,05-0,15 0,05-0,15 0,05-0,15

Molybdenum non oxidized 0,25-0,35 0,1-0,3 0,1-0,15 0,1

oxidized 0,5-0,9 0,4-0,9 0,3-0,7 0,2-0,6

Monel (Ni-Cu) 0,3 0,2-0,6 0,1-0,5 0,1-0,14

Nickel electrolytic 0,2-0,4 0,1-0,3 0,1-0,15 0,05-0,15

oxidized 0,8-0,9 0,4-0,7 0,3-0,6 0,2-0,5

Platinum black 0,95 0,9 0,9

Silver 0,04 0,02 0,02 0,02

Steel polished plate 0,35 0,25 0,1 0,1

rustless 0,35 0,2-0,9 0,15-0,8 0,1-0,8

heavy plate 0,5-0,7 0,4-0,6

cold-rolled 0,8-0,9 0,8-0,9 0,8-0,9 0,7-0,9

oxidized 0,8-0,9 0,8-0,9 0,7-0,9 0,7-0,9

Tin non oxidized 0,25 0,1-0,3 0,05 0,05

Titanium polished 0,5-0,75 0,3-0,5 0,1-0,3 0,05-0,2

oxidized 0,6-0,8 0,5-0,7 0,5-0,6

Wolfram polished 0,35-0,4 0,1-0,3 0,05-0,25 0,03-0,1

Zinc polished 0,5 0,05 0,03 0,02

oxidized 0,6 0,15 0,1 0,1

Spectral response

Material

typical Emissivity

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Appendix B – Emissivity Table Non Metals 39-

Appendix B – Emissivity Table Non Metals

1,0 µm 2,2 µm 5,1 µm 8-14 µm

Asbestos 0,9 0,8 0,9 0,95

Asphalt 0,95 0,95

Basalt 0,7 0,7

Carbon non oxidized 0,8-0,9 0,8-0,9 0,8-0,9

graphite 0,8-0,9 0,7-0,9 0,7-0,8

Carborundum 0,95 0,9 0,9

Ceramic 0,4 0,8-0,95 0,8-0,95 0,95

Concrete 0,65 0,9 0,9 0,95

Glass plate 0,2 0,98 0,85

melt 0,4-0,9 0,9

Grit 0,95 0,95

Gypsum 0,4-0,97 0,8-0,95

Ice 0,98

Limestone 0,4-0,98 0,98

Paint non alkaline 0,9-0,95

Paper any color 0,95 0,95

Plastic >50 µm non transparent 0,95 0,95

Rubber 0,9 0,95

Sand 0,9 0,9

Snow 0,9

Soil 0,9-0,98

Textiles 0,95 0,95

Water 0,93

Wood natural 0,9-0,95 0,9-0,95

Material

typical Emissivity

Spectral response

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

-40 -

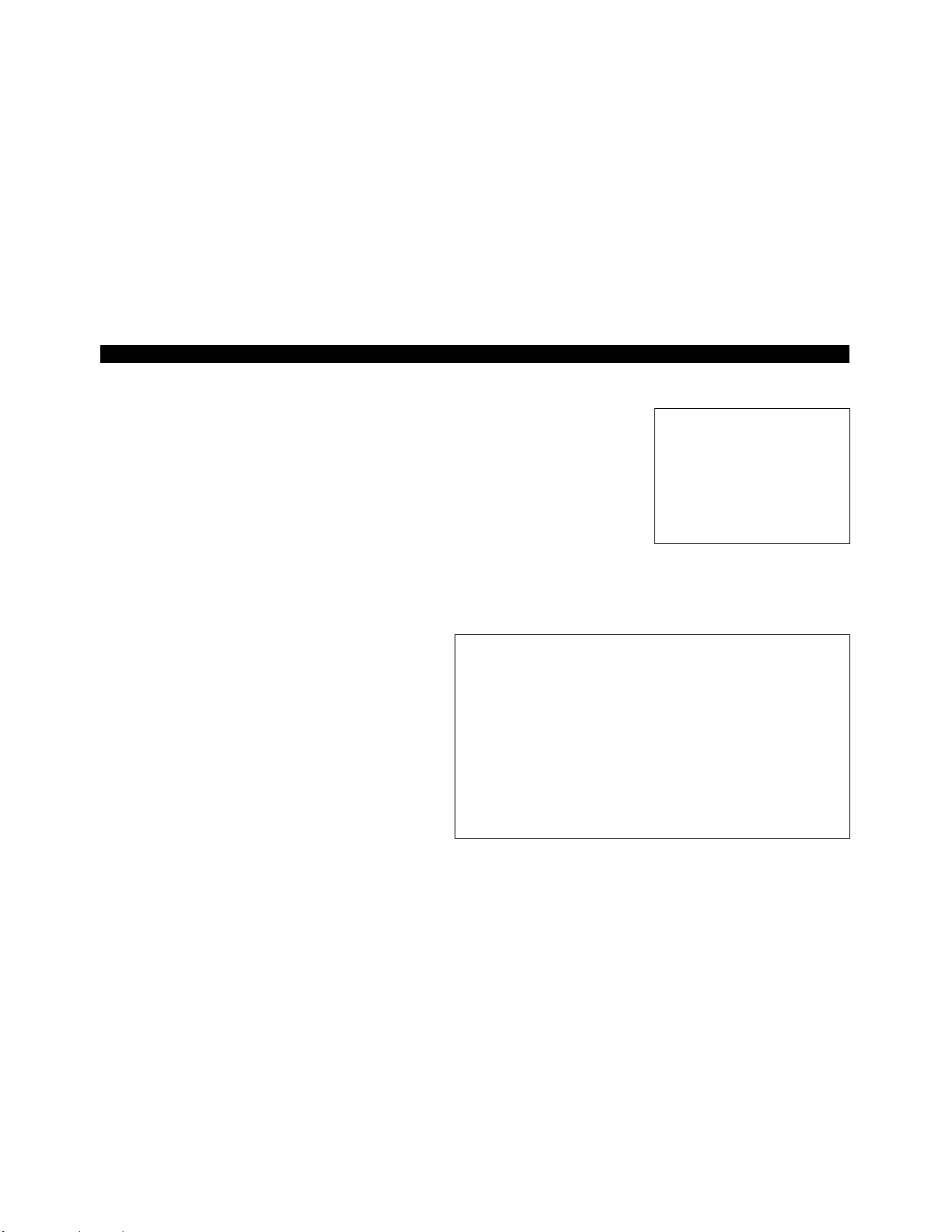

Appendix C – Smart Averaging

The average function is generally used to smoothen the output signal. With the adjustable parameter time

this function can be optimal adjusted to the respective application. One disadvantage of the average function

is that fast temperature peaks which are caused by dynamic events are subjected to the same averaging

time. Therefore those peaks can only be seen with a delay on the signal output.

The function Smart Averaging eliminates this disadvantage by passing those fast events without averaging

directly through to the signal output.

Signal graph with Smart Averaging function

Signal graph without Smart Averaging function

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Appendix D – Declaration of Conformity 41-

Appendix D – Declaration of Conformity

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

-42 -

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...