Page 1

Preface

This ma nual is prepared for the maintena nce service f or EP735 Micro Portable XGA

DLP Projector. Maintenance procedures described in this manual are intended to isolate

faulty parts and replace them in the field. It also aims to serve as a guide in procuring

replace ment parts f or this product.

This ma nual is copyrighted and all rights are reserved. This product may not, in

whole or in part, be copied, photocopied, translated or reduced to any electronic or machine

rea dable form without prior written consent except for copies retained by the purcha ser f or

backup purpose.

EzPro735

EzPro735

This ma nual includes system overview, ma jor system assembly, components’

description, and the “Trouble shooting” making explanations on how to detect errors. It also

includes a flow chart for checking or correcting faults.

No warranty or representation, either expressed or implied, is made with respect

to this documentation, its quality, performance, merchantability or fitness for

particular purpose.

No event that the vendor will be liable for direct, indirect, special, incidental or

consequential damages arising out of the user or inability to use this product or

documentation.

✍ NOTICE :

The information found in this manual is subject to change without prior

notice. Any subsequent changes made to the data herein will be incorporated in

further edition.

Copyright 2001, July

All Rights Reserved

Ma nual Version 1.0

Doc.#

834-G04-01A

P/N : 36.83403.001

SERVICE MANUAL

Page 2

EzPro735

EzPro735

4TABLE OF CONTENTS 3

1. Introduction 1-1

1-1 Product Features 1-2

1-2 Technical Specification 1-3

2. Fundamental Principle 2-1

2-1 Block Diagra m 2-2

2-2 Optics 2-6

3. Mechanical Construction 3-1

3-1 Package Overview 3-2

3-2 Exploded Overview 3-4

3-3 Recommendation Spare Parts List 3-10

4. Procedure of Disassembly 4-1

4-1 Disassemble Top Cover and Speaker 4-2

4-2 Disasse mble Main Board and DC-DC Module 4-3

4-3 Disassemble Engine, Formatter Board and Thermal Board 4-5

4-4 Disassemble Ballast Module 4-8

4-5 Disasse mble Fan Modules 4-9

4-6 Disassemble La mp Module 4-11

4-7 Disassemble Base Housing 4-13

5. The Function of Boards 5-1

5-1 Main Board 5-2

5-2 Formatter Board 5-10

5-3 IR Board 5-16

5-4 DC-DC Power 5-17

5-5 Thermal Board 5-19

5-6 Ballast 5-24

SERVICE MANUAL

Page 3

EzPro735

EzPro735

6. Specifications 6-1

6-1 Lamp Specifications 6-2

6-2 DMD Specifications 6-4

6-3 Screen Defects 6-7

6-4 DC-DC Specifications 6-9

6-5 Lam p Driver Specifications 6-10

7. Troubleshooting Procedure 7-1

7-1 Equipment Needed 7-2

7-2 Main Procedure 7-2

8. Function Test and Alignment Procedure 8-1

8-1 Equipment Needed 8-2

8-2 T est Condition 8-2

8-3 T est Display Modes a nd Pattern 8-3

8-4 Inspection Procedure 8-7

9. Firmware Upgrading Procedure 9-1

9-1 Equipment Needed 9-2

9-2 Setup Procdure 9-2

9-3 Upgrading Procdure 9-3

10. DDC Key-In Procedure 10-1

10-1 Equipment Needed 10-2

10-2 Setup Procdure 10-2

10-3 Upgra ding Procdure 10-3

11. Appendix 11-1

11-1 Serial Number Format 11-2

SERVICE MANUAL

Page 4

Chapter 1

EzPro735

EzPro735

INTRODUCTION

This manual is applied to EP735 0.7”*1 DMD XGA Micro Portable

Projector with digital imaging functionality based on Digital Micromirror

Device (DMD) technology. It’s the mode of single panel, 130 watt Compact

P-VIP lamp and 1024*768 resolution. The manual gives you a brief

description of basic technical information to help in service and maintaining

the product.

Your customers will appreciate the quick response time when you

immediately identify problems that occur with our products. We expect your

customers will appreciate the service that you offer them.

This manual is for technicians and people who have an electronic

background. Send the product back to the distributor for repairing and do not

attempt to do anything that is complex or is not mentioned in the

troubleshooting.

SERVICE MANUAL 1 - 1

Page 5

EzPro735

EzPro735

1-1 Product Highlights

u One pa nel 0.7” DMD projection syste m with 820 ANSI lumens (A verage),

75% uniformity (Min.)

u 130-W att Compa ct P-VIP Lamp (user replacea ble)

u High efficiency cooling system with syste m acoustic noise level 38dBA (Average)

u Light weight less than 3.4 lbs

u Manual focus projection zoom lens

u True 1024*768 resolution, True colors

u With up, down, left, and right screen reverse

u Built-in full screen NTSC/PAL/SECAM video capability with S-video/composite/

component a nd HDTV terminals

u SXGA/XGA/SV GA/VGA/MAC/PC98/FM Towns compatibility with XGA

compression/pan

u Auto image re-sizing to 1024*768 full screen

u Auto detection of computer signal input

u Auto image. (Auto-tra cking/frequency/position a djustment)

u Powerful enlarge and freeze function

u Automatically saves a djustments f or furture use

u On-screen menu with 9 la nguages

u On-screen lamp life timer

u One DVI PC-data input (Including Analog and Digital RGA signal)

u Built-in one speaker with 2-Watt amplifier

u Self protect (15 seconds) timer f or hot re-strike of compact P-VIP lam p

u Wireless re mote controller/mouse

u Adaptive voltage control fan speed

SERVICE MANUAL 1 - 2

Page 6

EzPro735

1-2 Technical Specification

1-2.1 Optical Features

Technology Digital Light Processing™ (DLP™) technology

by T exas Instruments

Resolution 1024*768 XGA, True color

Brightness 820 ANSI Lumens (Average)

700 ANSI Lumens (M ini mum)

Contrast Ratio 300:1 (Full White and Black)

EzPro735

Unif ormity 50% (ANSI standard)

60% (3*3)

75% (Japan standard)

Displayable Color 16.7 Milion colors

Color T e mperature 6500oK~9000oK

Projection Lens f =28.51~34.21mm, F/2.2~2.4

Zoom Factor 1.2X , Manual

Projection Screen Size Adjustable from 20.5” to 246” Diagonal

Throw Distance 1.0m to 12m

SERVICE MANUAL 1 - 3

Page 7

EzPro735

EzPro735

Throw Ratio 2.17~2.94(Projection Dista nce/Image Width)

1-2.2 Electrical Features

Horizontal Sca n Rate 15~100 kHz

Vertical Refresh Rate 43~120 Hz

Pixel Frequency 140 MHz

Aspect Ratio 4:3, 16:9 (wide screen) compatible

Video Compati bility Sta ndards : NTSC (M, 4.43 MHz)

PAL ( B, D, G, H, I, M, N )

SECAM (B, D, G, K, K1, L)

HDTV ( 1080i , 720P , 480i/P )

TV Lines : 500 lines

Power Supply Universal AC 100-240V, AC 50/60Hz with PFC input (SRAM)

130W for 130W Compa ct V-VIP Lamp @ normal operation

Vari ance FAN speed control (De pend on te mperature varia nt)

Audio One 8-Ohm, 2W, internal speaker

3-W att amplifier

Input sensitivity 0.3V rms.

SERVICE MANUAL 1 - 4

Page 8

EzPro735

EzPro735

1-2.3 Mechnical Features

Dimension (W x H x D) 8.86*6.93*2.0” / 225*176*52mm

Keystone Correction ± 16 degrees

W eight Approx. 3.46 lbs (1.572 Kg)

Lamp Door Protection Lamp Power Supply shut off automatically when door open

1-2.4 Environmental Features

Temperature Operating : 10°C~40°C / 50°F~104°F

Storage : -20°C~60°C / -4°F~140°F

Humidity Operating : 10°C~40°C, 80%RH (M ax.), non-condensing

Storage : -20°C~60°C, 80%RH (Max.), non-condensing

Acoustic Noise Level 38dBA (Average, under 25oC)

Less tha n 40dBA (M ini mum)

Lamp Life 1,000 hours Min. 70% survival rate

1,500 hours typical, 50% survival rate

Altitude Operating : 10,000 ft

Storage : 40,000 ft

MTBF Operating : more than 10,000 hours (80% confidence level)

1-2.5 Regulation Features

Regulation FCC Part 15 Class B

CE --- Class B

VCC --- Class B

UL

CUL

TUV — GS

SERVICE MANUAL 1 - 5

Page 9

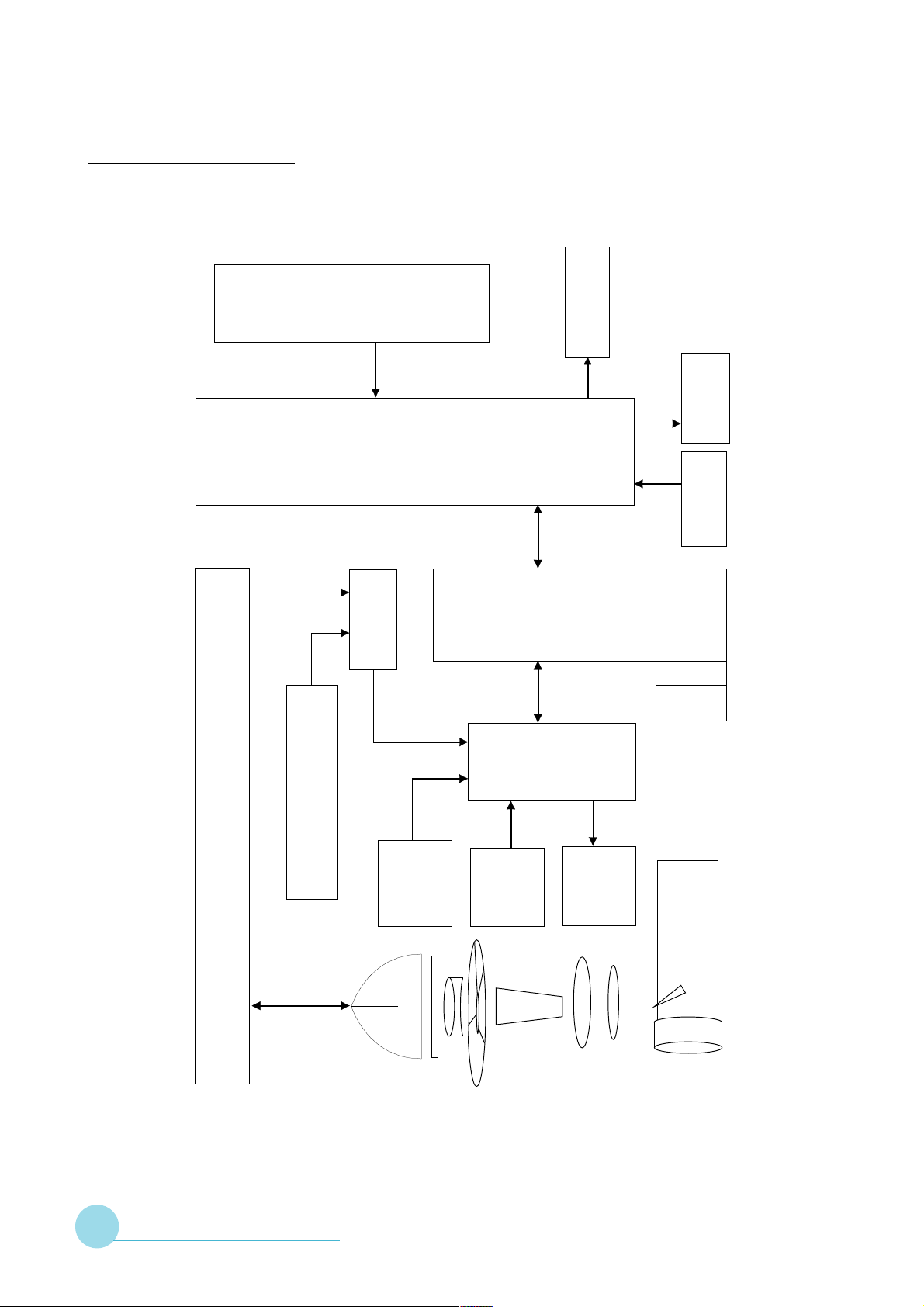

Chapter 2

EzPro735

EzPro735

FUNDAMENTAL PRINCIPLE

This section provides the conceptual drawing about optics of projector.

You can realize optical projection system through the following diagram and

the integral part of configuration, too.

SERVICE MANUAL 2 - 1

Page 10

EzPro735

EzPro735

2-1 Block Diagram

Board

Keypa d

Input

Mouse

DVI

Audio

Board

Main

Video

D-sub Output

S-V ideo

Speaker

IR Receiver

Ballast

DC to DC

Inter Lock Switch

Switch

Thermal

Board

Sensor

Board

Board

Thermal

DMD

Fan

DMD

Mirror

Projection Lens

Mirror

SERVICE MANUAL 2 - 2

Hollow Rod

Lamp

UV -IR L3

Color Wheel

Condenser

Condenser

Page 11

EzPro735

EzPro735

ADC

GCOAST

GVS

GHS

GFBK

GCLK

GBLKSPL

GRE(0..7)

GRO(0..7)

GGE(0..7)

DE

GGO(0..7)

SDA

SCL

GBE(0..7)

GBO(0..7)

Digital Receiver

GCLK

GHS

GVS

GFBK

GRE(0..7)

GGE(0..7)

DE

GBE(0..7)

Switch

Memory

Image Processor

GCOAST

GFBK

GCLK

GBLKSPL

GRE(0..7)

GRO(0..7)

GGE(0..7)

GGO(0..7)

GBE(0..7)

GBO(0..7)

GHS

GVS

Y(0..7)

UV(0..7)

Switch

BOOTWE

A(0..5)

BOOTWE

DRE(0..7)

GGE(0..7)

DBE(0..7)

TEMPER

Sta ndby

RESET

7SEC

A(0..5)

VPPEN

D(0..5)

D(0..5)

VPPEN

ROMOEN

SCL

SDA

TXD

RXD

KEY(1..7)

DCLK

MCLK

ROMOEN

ROMWEN

ROMWEN

DMD Module

DRE(0..7)

GGE(0..7)

DBE(0..7)

TEMPER

SCL

SDA

PWRGOOD

IR-ONOFF

LAMPEN

-RESET

TXD

RXD

SERVICE MANUAL 2 - 3

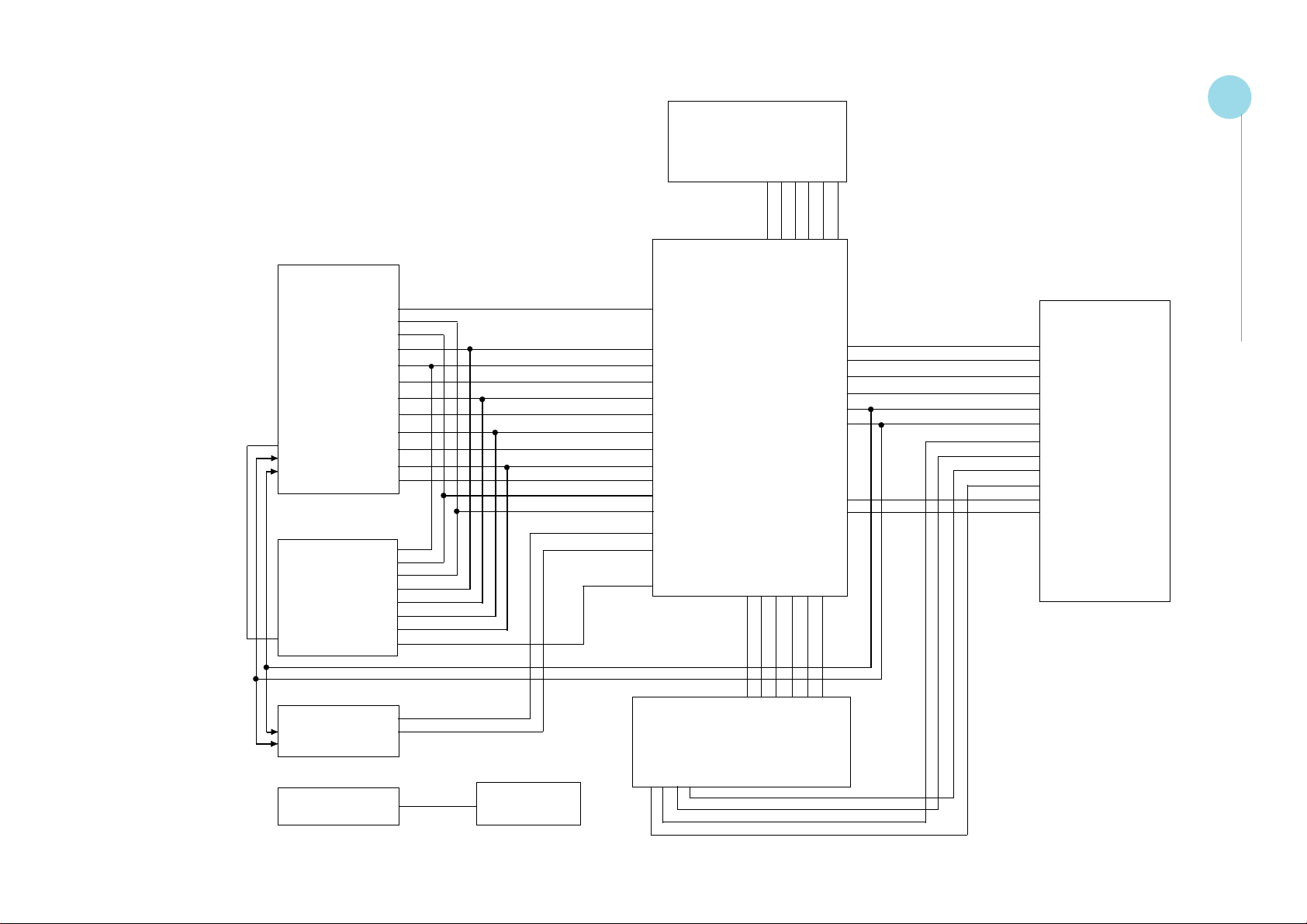

2-1.1 Main Board Block Diagram

Video

SCL

SDA

Audio

Y(0..7)

UV(0..7)

Speaker

±

Speaker

-RESET

PWRGOOD

IR-ONOFF

LAMPEN

RESET

Sta ndby

7SEC

DCLK

KEY(1..7)

MCLK

MIS

Page 12

EzPro735

EzPro735

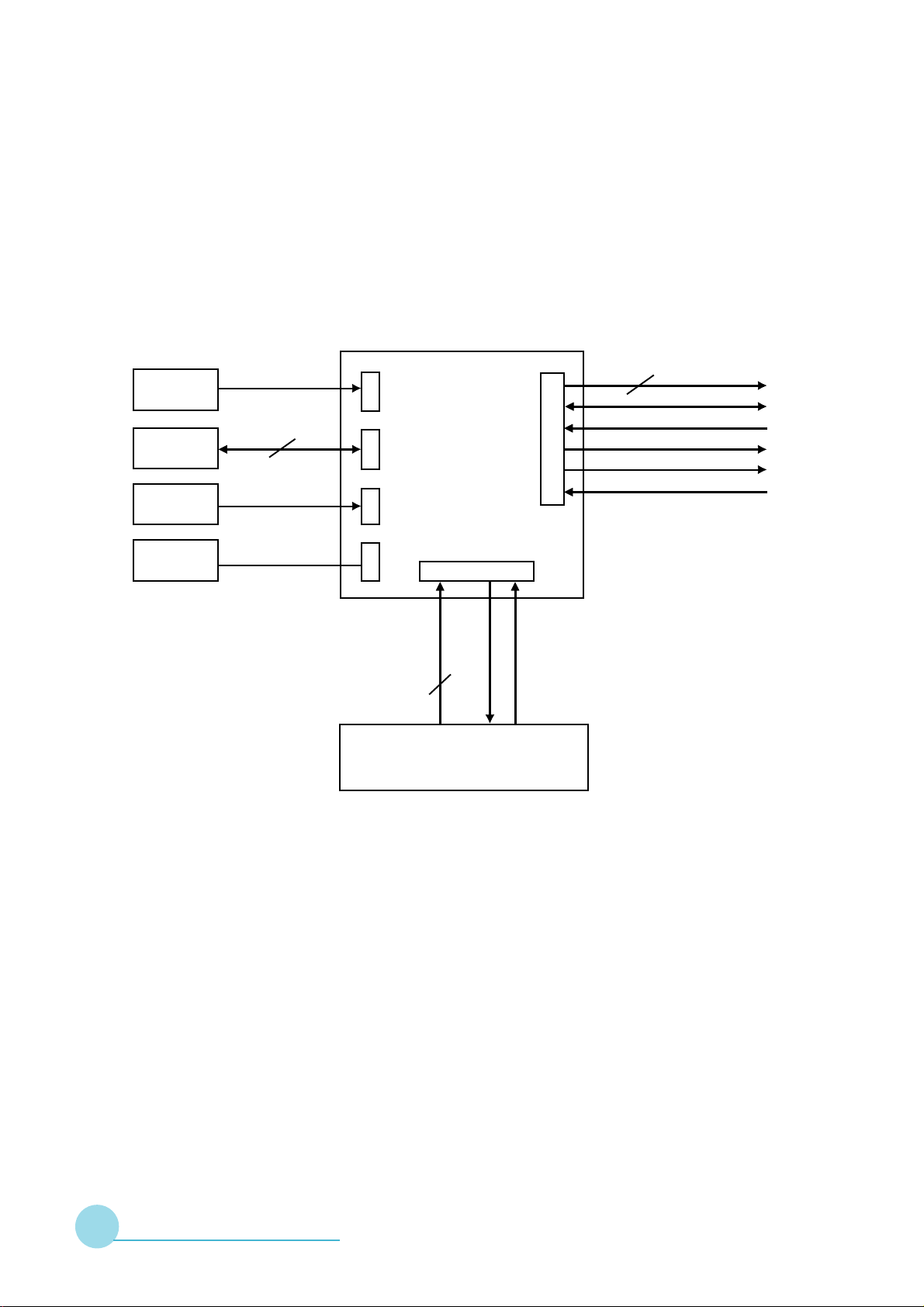

2-1.2 Thermal Board Block Diagram

PHOTO

SENSOR

F AN1-13

THERMAL

SWITCH

THERMAL

SENSOR

THERMAL BOAR D Interface

3P Connector

3P Connector*3

30P Connector

to Formatter

2P Connector

4P Connector*2

14P Connector

+15VSBY

+5VSBY

+3.3VSBY

LAMPEN_OUT

DC TO DC POWER SUPPLY

Board

LAMPLIT_IN

+12V*1

+5V*2

+3.3V*2

GND

LAMPEN (RESETZ)

CWINDEX

LAMPLIT

Power on/off (only 5V, 15V)

SERVICE MANUAL 2 - 4

Page 13

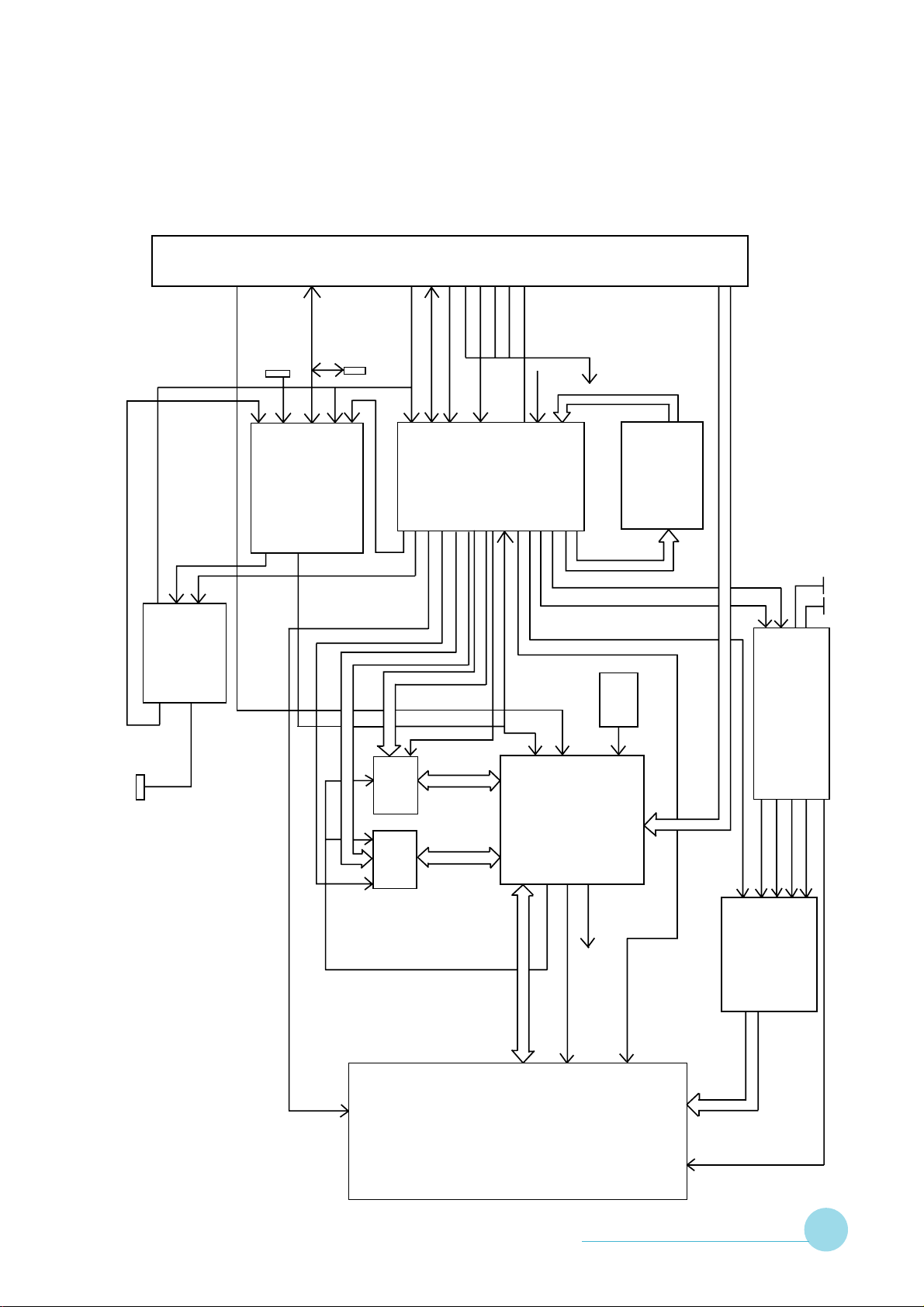

2-1.3 Formatter Board Block Diagram

Customer Interface Connector

HEADER

PROGRAMMING

FLASH

U13

COLOR WHEEL INDEX

VSYNCZ, RESETZ

LAMP CONTROL&STATUS

CWRSTZ

DMD CONTROL

MEMORY CONTROL B

COLOR WHEEL STATUS

CONTROL

WHEEL

COLOR

CLKIN

IIC BUS

HEADER

DOWNLOAD

HITACHI

CONTROLLER

MICRO

SYNCVAL

TFIELD

OLACT

MEMORY ADDRESS B (12)

MEMORY ADD RESS A (12)

ACTDATA

HSYNCZ

VSYNCZ

FPGA

CONTROL

BIAS/RESET CONTROL

DMD CONTROL

PBUS2

MEMORY CONTROL A

EzPro735

EzPro735

DPF2A CONTROL

FPGA CLK

DATA(8)

U504

CONFIG/

BIAS BIN

VOLTAGE ENABLES

U6

ADDRESS(19)

PROM

SEQUENCE

+5V+12V

DRIVE

WHEEL

COLOR

CONTROL

U2

MOTOR

ALLEGRO

A

B

SDRAM

SDRAM

DMD DA T A (0..63)

INPUTCLK

DPF2A

FORMA TTER

SDRAM CLK

DMDCLK

OSC

DAT APA TH

FPGA CLK

CLOCK

VERSET GENERA TION

VCC2, VOFFSET, VBIAS

VRESET

VBIAS

VOFFSET

RESET ASIC

MBIASRST(16)

VCC2(ASIC)

VCC2 (DMD)

DATA (0..63)

0.7”XGA

DMD

SERVICE MANUAL 2 - 5

Page 14

EzPro735

EzPro735

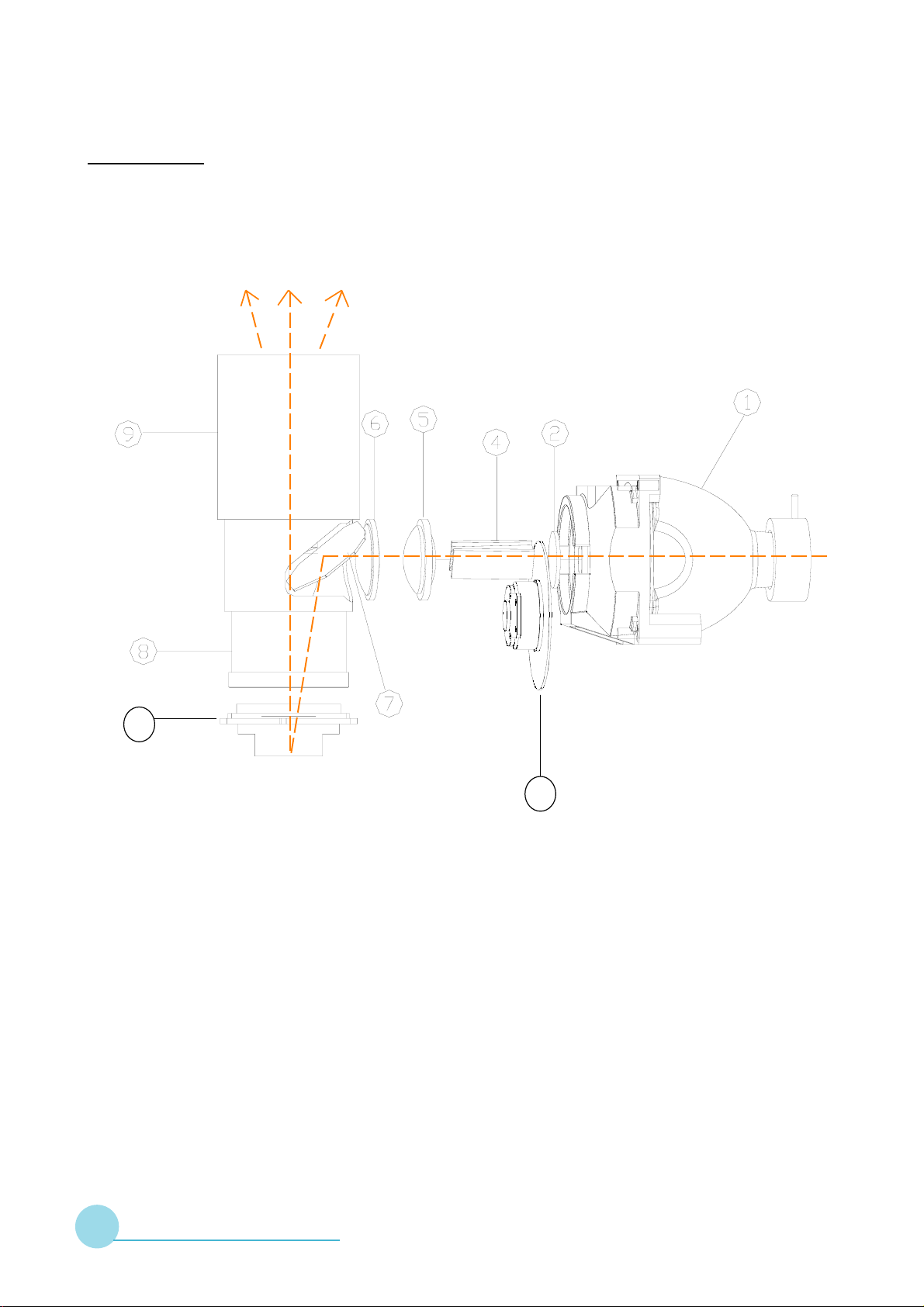

2-2 Optics

2-2.1 Conceptual Drawing

10

3

1. OSRAM Elli ptical Reflector 6. Condenser Lens 2

UHP La mp 120W

7. Enhance M irror

2. UV-IR Filter

8. Field Lens

3. Color Wheel

9. Projection Zoom Lens

4. Hollw Integratin Rod

10. DMD Module

5. Condenser Lens 1

SERVICE MANUAL 2 - 6

Page 15

EzPro735

EzPro735

2-2.2 Basic Functions

◆ Elliptical Reflector The light source.

UHP Lamp 120W

◆ UV-IR Filter Filtering UV -IR out.

◆ Color Wheel Separating the light beam into a nd produce

R.G.B colors.

◆ Hollow Making the light bea m uniform.

Integration Rod

◆ Condenser Lens Condensing the light beam .

◆ Enhance Mirror Folding optical path.

◆ Projection Zoom Lens Projecting i mage on the screen

◆ DMD Module Displaying component.

SERVICE MANUAL 2 - 7

Page 16

Chapter 3

EzPro735

EzPro735

MECHANICAL CONSTRUCTION

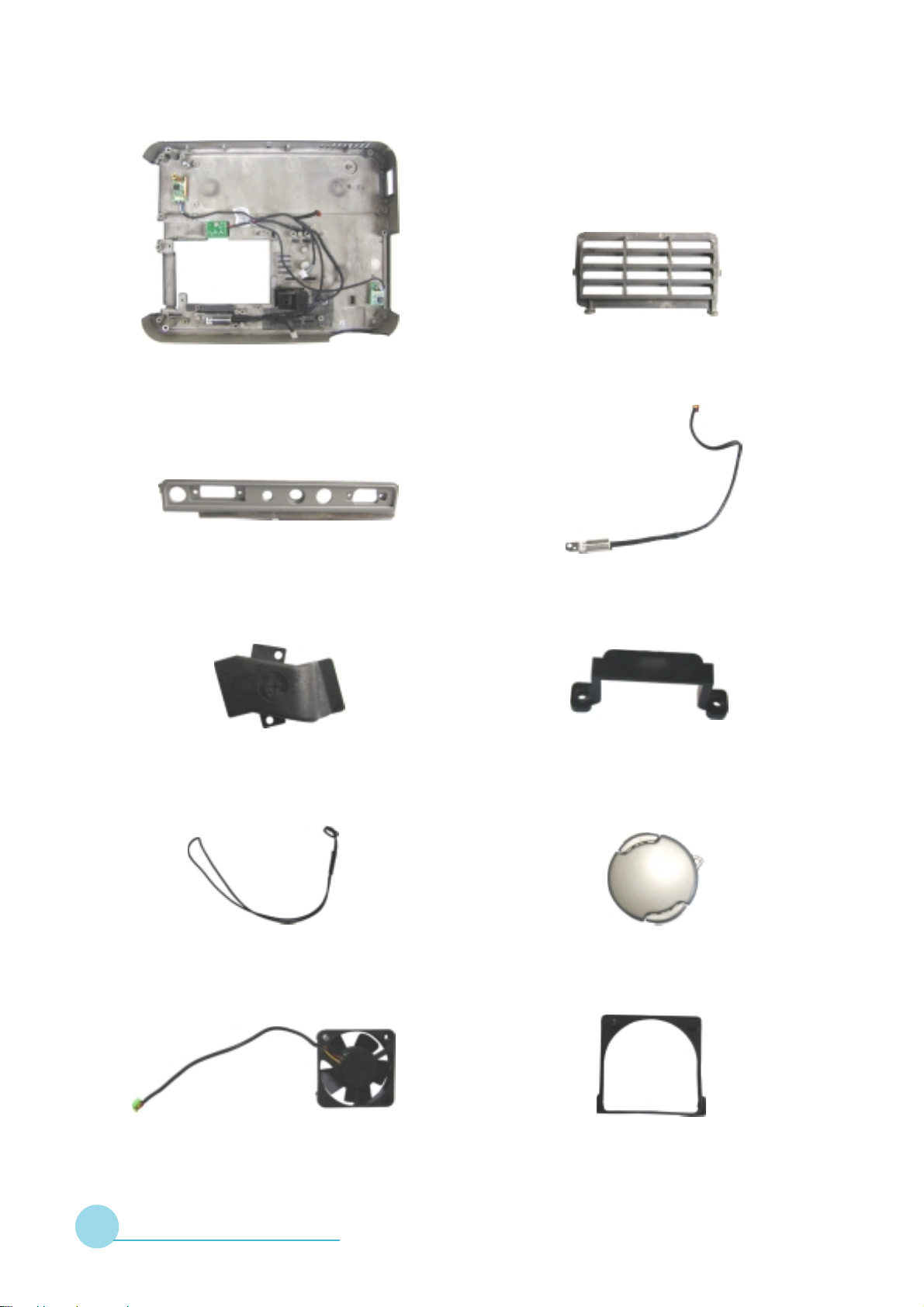

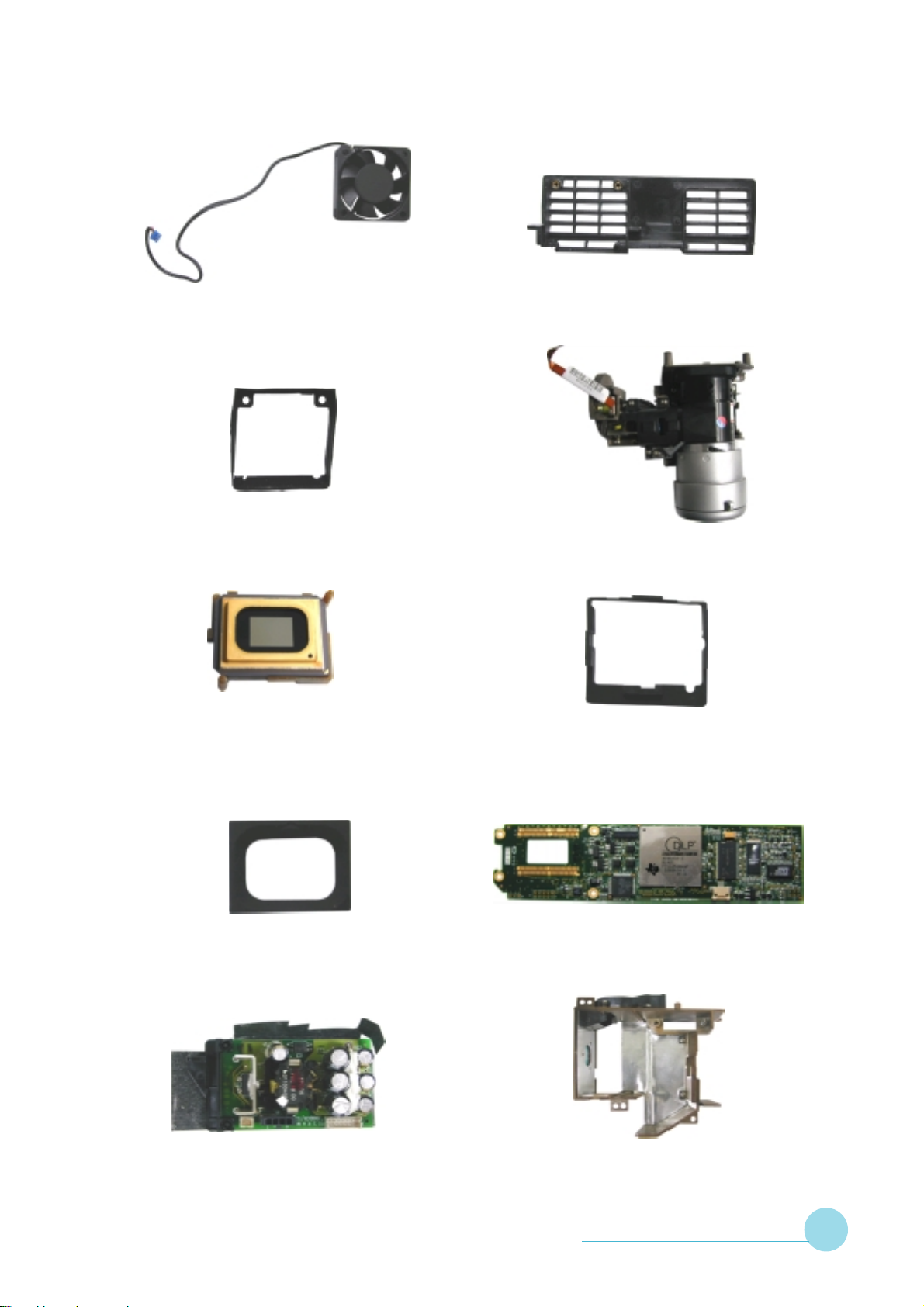

This section provides the package and exploded overview, replaceable

parts list and recommendatiom parts list for the portable projector. You can

place an order for correct parts in the recommendation parts list.

SERVICE MANUAL 3 - 1

Page 17

EzPro735

EzPro735

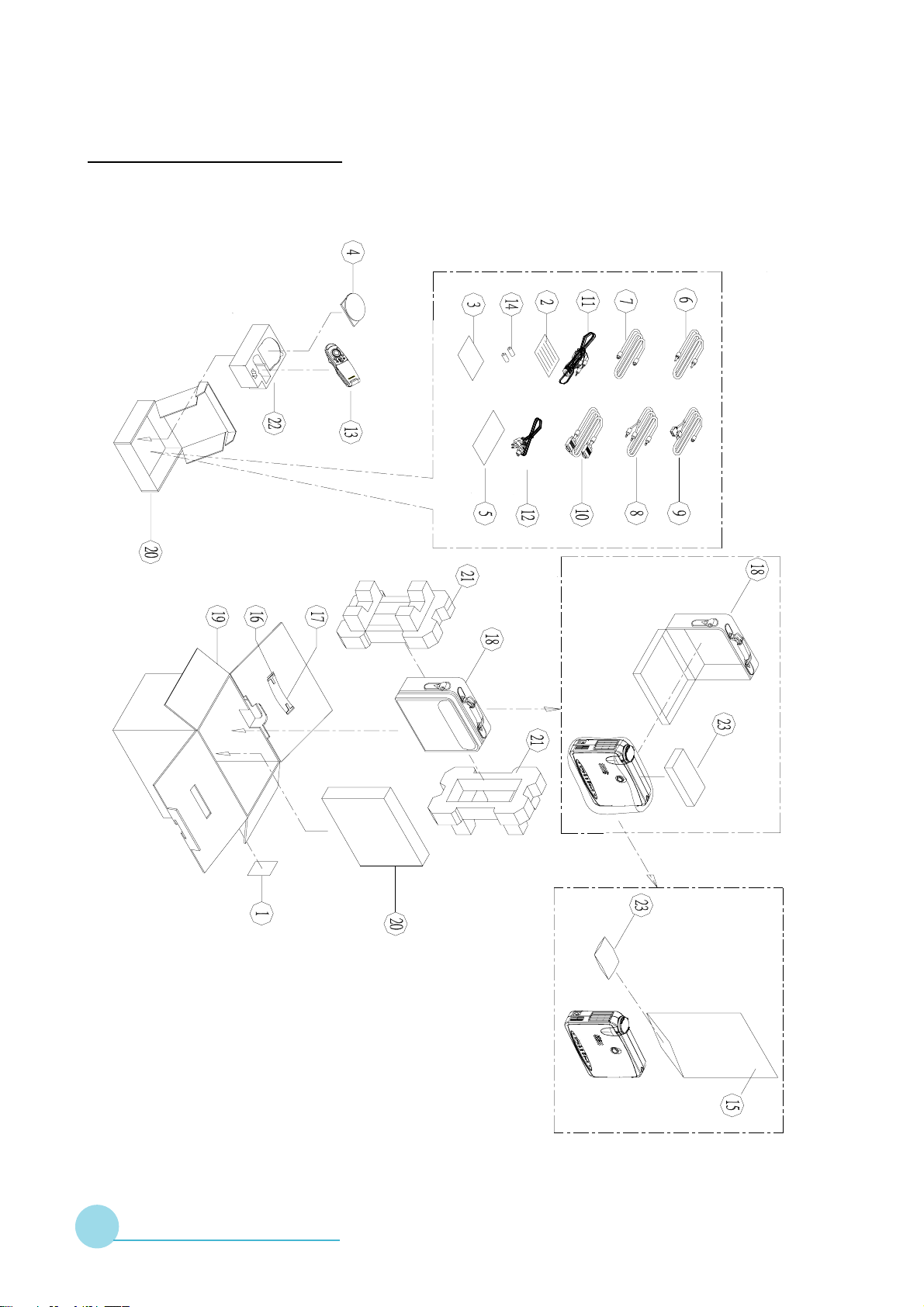

3-1 Package Overview

SERVICE MANUAL 3 - 2

Page 18

EzPro735

EzPro735

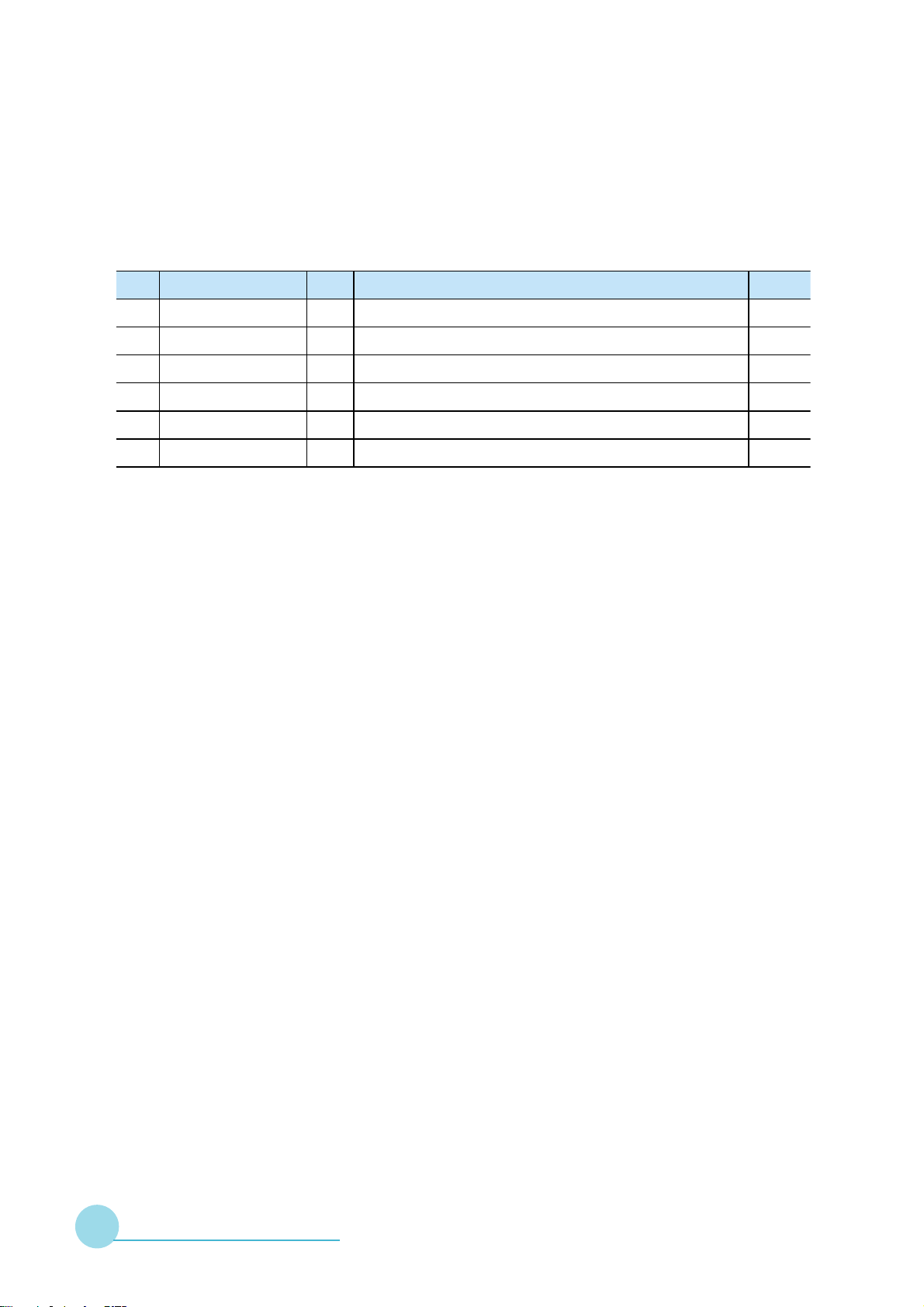

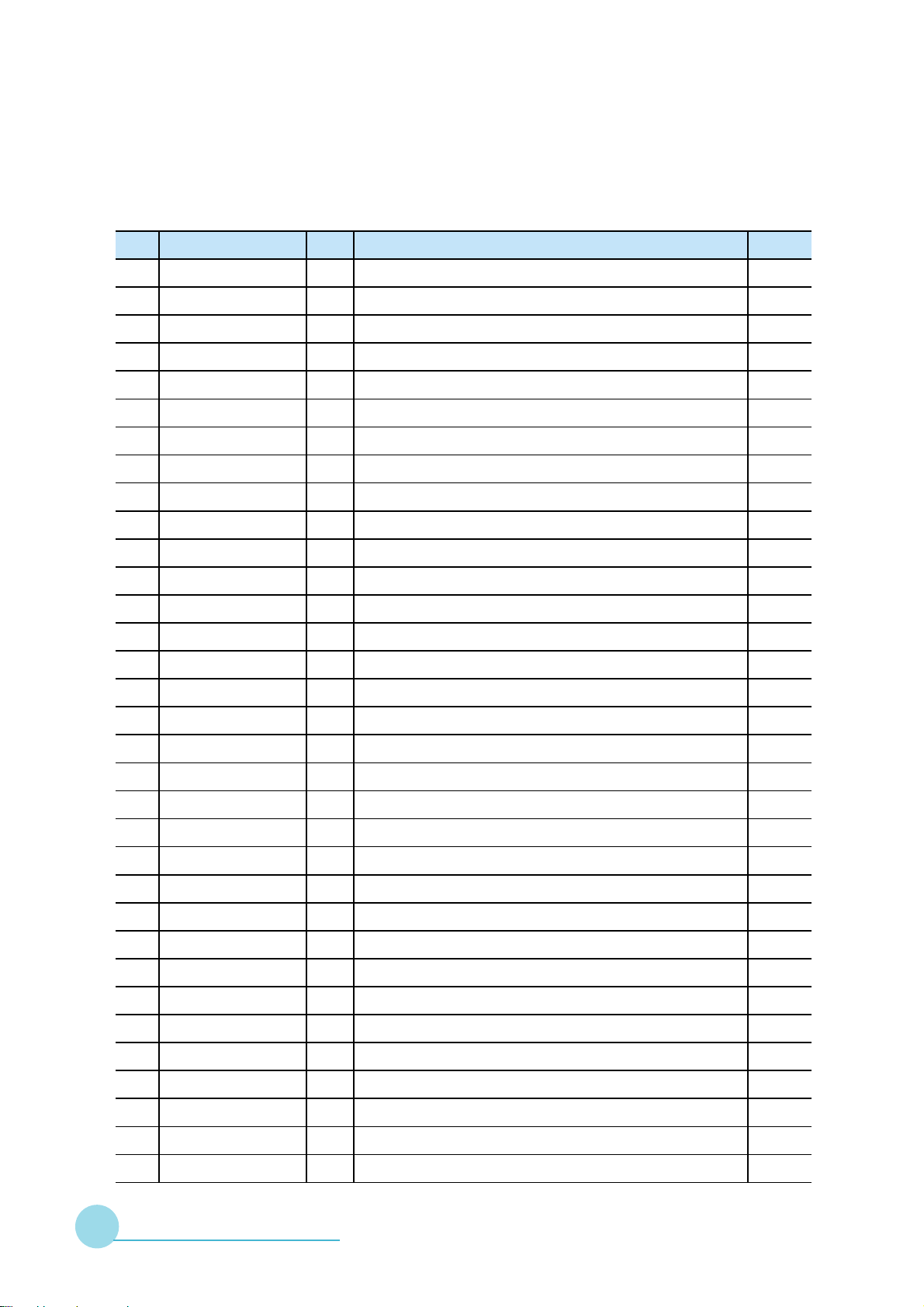

3-1.1 Replacement Parts List

metI N/P .veR noitpircseD krameR

1190.20325.53A knalB29*801notraC,lebaL

1-2200.21000.63B seireSPPLrofSU,draCytnarraW

2-2300.50000.63B NPJ,draCytnarraW

3-2300.60000.63B NWT,draCytnarraW

4-2300.90000.63B KH,draCytnarraW

5-2200.01000.63B KU,draCytnarraW

---100.21000.53B mc4.3*8.7ecivreSKUroflebaL

3100.31000.63B seiresPPLrofSU,mroFnoitartsigeRytnarraWdednetxE

4100.10438.63C 537PElaugnilitluMediuGs'resU

5100.20438.63B 537PElaugnilitluMdraCtratSkciuQ

6200.01105.24B oediV-PPLmm0051ACRelbaC

7110.90205.24BM2SHV-SelbaC

8100.51708.24B mm0081ACRotkcaJiniMelbaC

9100.01918.24B

01100.30438.24B M8.1)eulB(AGVot)etihW(IVDelbaC

11100.40438.24B etihWM8.1ACRotIVDelbaC

1-21100.50438.24B 501M8.1CAdroCrewoPelbaC

2-21100.70438.24B )anihC(kcalBM8.1CAdroCrewoPelbaC

3-21140.21518.24B

4-21100.51138.24B )napaJ(kcalB75/65XM8.1droCCAelbaC

5-21100.61138.24B )eporuE(kcalB75/65XM8.1droCCAelbaC

6-21100.71138.24B )KU(kcalB75/65XM8.1droCCAelbaC

---100.20318.24BTRACSretpadA

3138.54 104 00. 2 ArellortnoCetomeR lebaLADFhtiw

41100.10308.64BV5.14#yrettaB

M8.1BUS-D/epyT"A"BSUotP8niDiniMelbaCY

o

)SU(kcalBC

)dnalaeZweN/ailartsuA(kcalBtf015CCAdroCrewoPelbaC

51100.73518.15A mm1.0*004*003gaBDSE

61100.92518.15A xoB-yrraCreppUeldnaH

71100.03518.15A xoB-yrraCrewoLeldnaH

81100.10338.35AgaBgniyrraCtfoS

91100.10338.55A 037PExoBedistuOnotraC

02100.20338.55A xoByrosseccAnotraC

SERVICE MANUAL 3 - 3

Page 19

EzPro735

EzPro735

metI N/P .veR noitpircseD krameR

12100.10338.65AnoihsuC

22100.20338.65A xoByrosseccArofnoititraP

32100.30438.65A esaCtfoSedisnInoihsuC

42100.10000.75AOiSkcaP2 g02reirD

---200.30438.53A erutarepmeT&egatloVhgiHnoituaClebaL

---100.20438.55A tellaProftroppuSrepaP

Note : Mark --- and in red color mean the added or updated item, and item

in blue color is deleted.

SERVICE MANUAL 3 - 4

Page 20

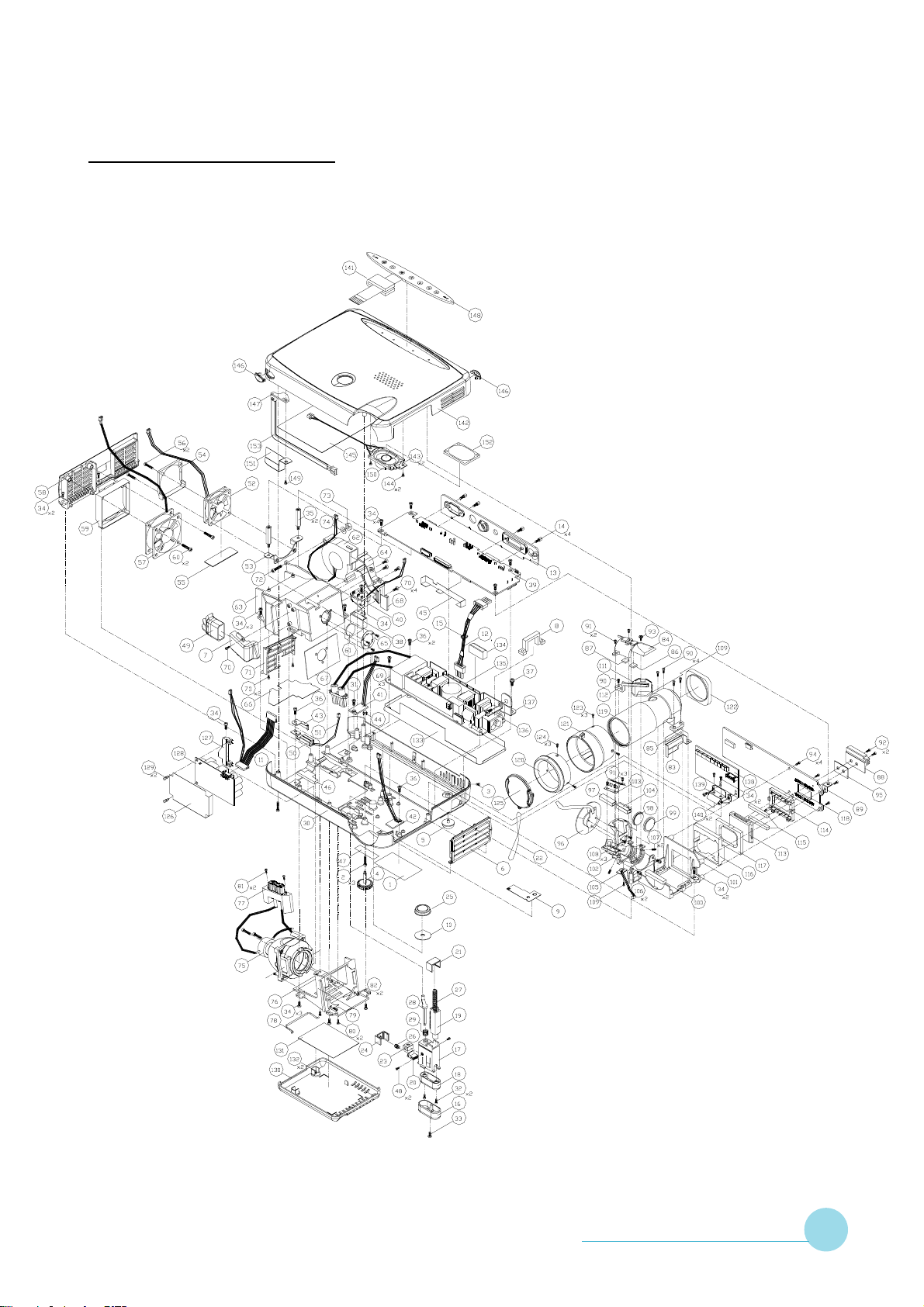

3-2 Exploded Drawing

EzPro735

EzPro735

SERVICE MANUAL 3 - 5

Page 21

EzPro735

EzPro735

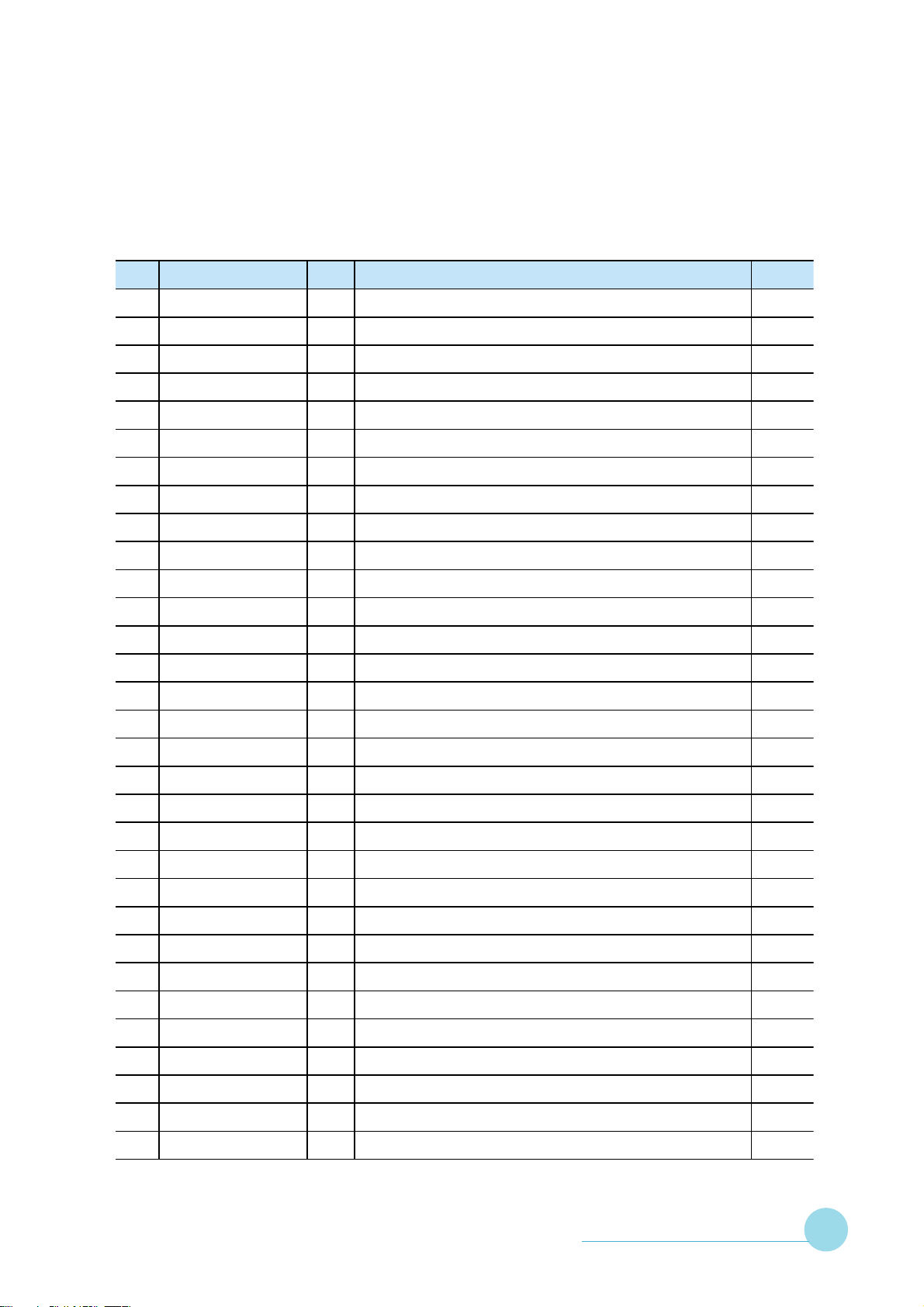

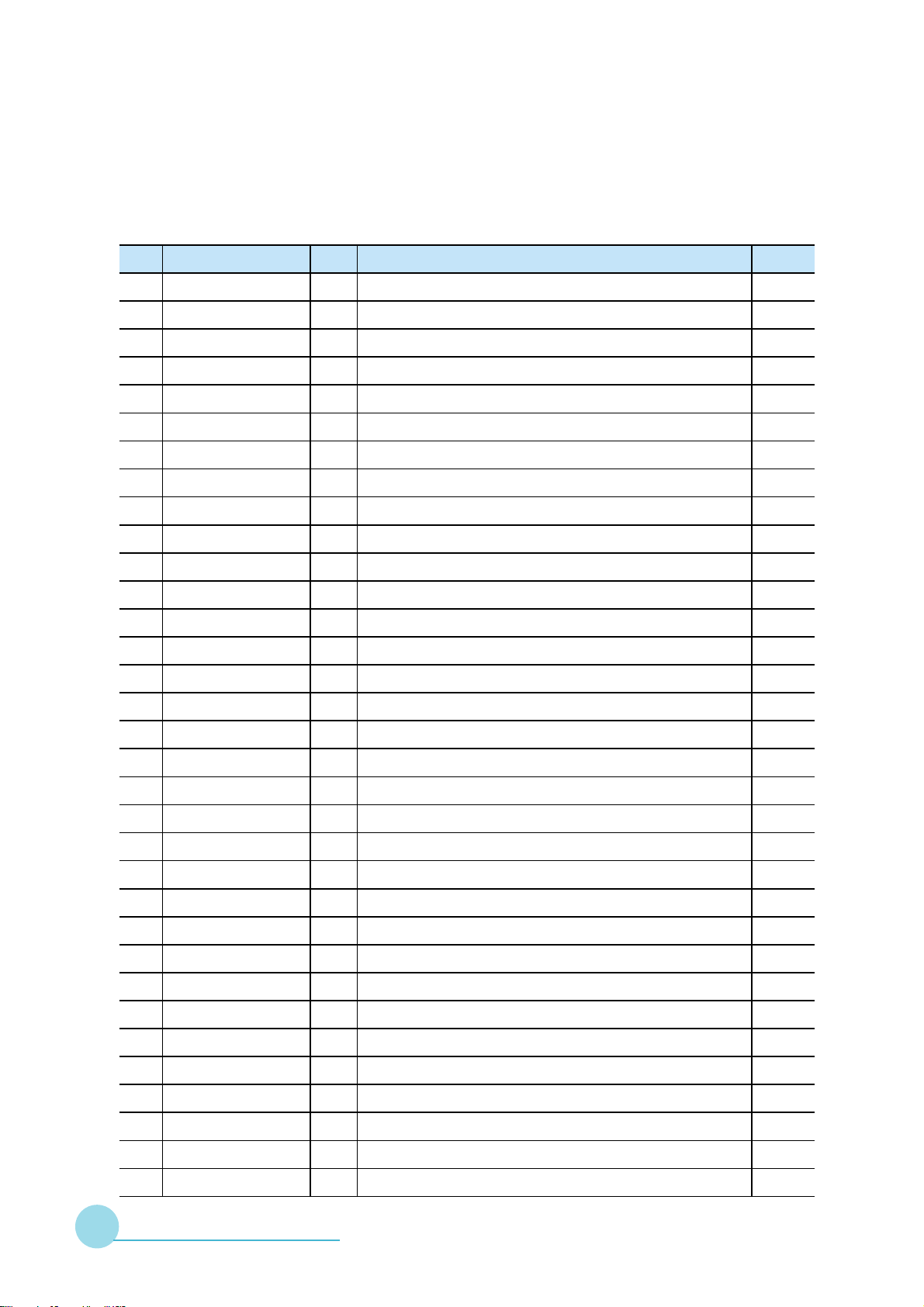

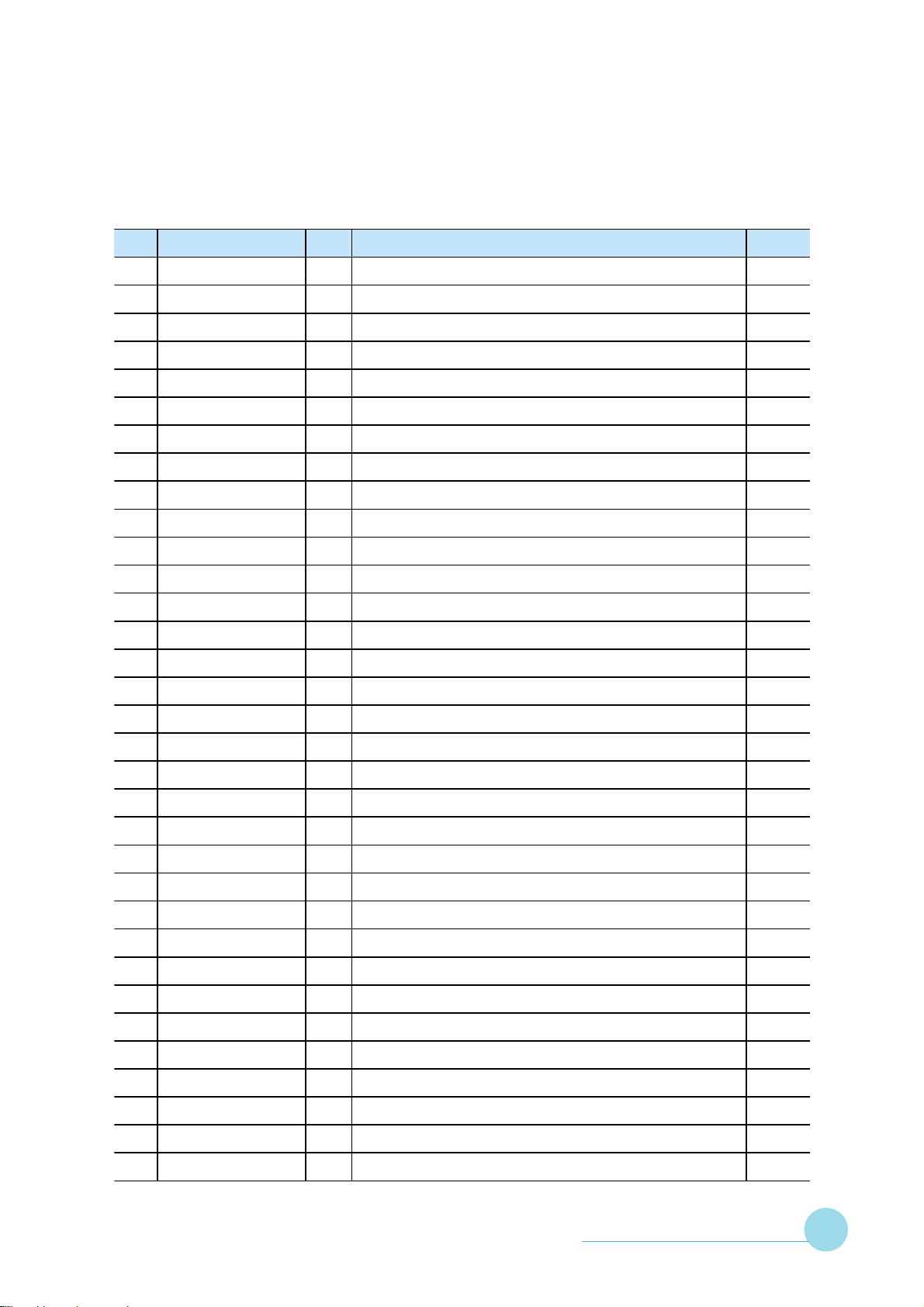

3-2.1 Replacement Parts List

metI N/P .veR noitpircseD krameR

1100.60418.53A knalB601*23cepSlebaL

2003.323A1.58A kcalB03*3MhceMnapwercS

3060.221A4.58A 6*2MhceMtalFwercS

4100.10138.25A evitcAllamSrotavelE

5100.20138.25BtroppuSrebbuR

6100.11338.15A 537PErevoCtupnItneV

7100.73138.15AediuGriAtuptuO

8100.93138.15AxiFedoCrewoP

9100.70438.16A lateMteNfoorperiF

01100.50438.25B P04-S-RSnoroPyeKrotavelEroftuCthgiL

11100.30138.24B )B/TotCD(mm0862#P41.A.W

21100.40138.24B )tsallaBotdraoBCD-CD(mm05242#P4.A.W

31100.70338.15A 037PErevoCxoBOI

41.GA500.58 040 AO/IwercS 5.5L*4H*CNU04-4#leetS

51100.10000.15AeiTelbaC

61.91138.15 200 AesaBrotavelE

71100.02138.15BtekcarBrotavelE

81100.12138.15ASProtavelE

91.22138.15 200 AraeGrotavelE

02100.42138.15AtraPedilS

12100.03138.15A tekcarBpoTrotavelE

22100.05138.15ApartSpaC

32100.45138.15AediuGraBhsuP

42100.55138.15A tekcarBediSrotavelE

52100.50338.15AyeKrotavelE

62100.22138.16A gnirpSediSrotavelE

72100.52138.16A gnirpSraeGrotavelE

82200.82138.16AraBhsuP

92100.65138.16A gnirpSraBhsuProtavelE

03100.20338.16CgnisuoHesaB

13100.40438.16A 5.4LwercS81L3MkcitSreppoCnogaxeH

23080.221A1.58A 8*2MhceMnaPwercS

33.58 321A0 060.A 6*3MhceMF/PwercS

SERVICE MANUAL 3 - 6

Page 22

EzPro735

EzPro735

metI N/P .veR noitpircseD krameR

43060.321A1.58A 6*3MhceMnaPwercS

53100.60438.16A 3.62L3MkcitSreppoCnogaxeH

63040.321A1.58A 4*3MhceMnaPwercS

73060.722C1.58A )rehsaWPS/W(roloC6*5.3MhceMnaPwercS

83100.14138.15A revoCnoitcetorPkcolretnI

93100.10438.08D draoBniaMABCP

04100.80138.08A draoBhctiwSABCP

14100.50438.08C 09=DIdraoBrosneSlamrehTABCP

24100.60438.08D 19=DIdraoBrosneSlamrehTABCP

34100.30438.16A hctiwSlamrehTraeNtuCthgiL

44.68 530.24130 AP7.0*4MstuNdaeHpaCxeH

54100.10438.15B ralyMdraoBniaM

64100.52138.25A rebbuRnoitalusnItaeHesuoHpmaL

74100.40438.53A hctiwSkcolretnIroflebaL

84420.221A4.58A 4.2*2MhceMrefaWwercS

94100.60438.25A rebbuRnociliSepiPriA

05.12138.16 300 AredloHhctiwSlamrehT

15.20138.34 300 AhctiwSlamrehT 07

25100.20138.94A01*04*04naF

35100.91138.16A 01*04*04redloHnaF

45100.10438.25A naFllamSrofrebbuR

55100.10438.53AepaTnaFllamS

65041.323A0.58A 41*3MhceMtalFelbuoDwercS

758.94 8013 100.A 51*05*05naFsselhsurBCDNONUS

85100.01338.15A revoCtuptuOtneV

95100.30438.25A naFgiBrofrebbuR

o

06002.323A1.58A kcalB02*3MhceMnaPwercS

16200.01138.32A retliFRI-VUlacitpO w mn556:05Tmm1.1=T57.61=

26100.30138.94A mm051:Lmm51*15HP21-F50DnaFOCCORICSCEDIN

36.40138.15 200 BgnisuoHpmaL

46100.60138.15A epiPdniWrewolB

56100.71518.16A retliFRI-VUroftekcarB

66100.74138.16B lioFmunimulApoTesuoHpmaL

SERVICE MANUAL 3 - 7

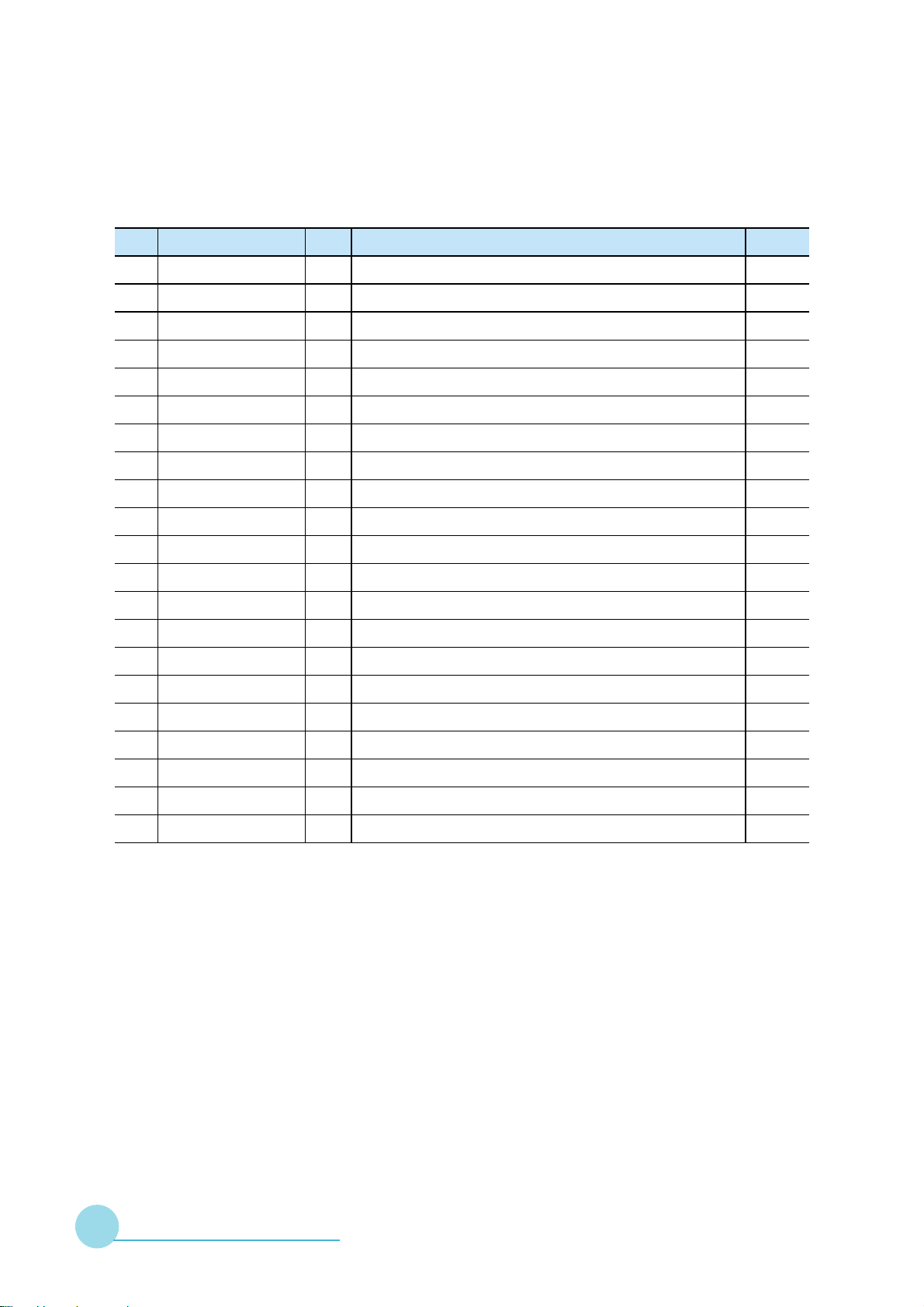

Page 23

EzPro735

EzPro735

metI N/P .veR noitpircseD krameR

76100.44138.16A lioFmunimulAesuoHpmaL

86100.54138.16AdleihSepiPdniW

96520.223AY.58A kcalB5.2*2MpaTdaeHtalFwercS

07AW.58 623 060.A kcalB6*6.2MpaTdaeHnaPwercS

17100.20438.15A keePpmaLroftuCthgiL

27002.323A1.58A kcalB02*3MhceMnaPwercS

37A0.68 420.321 AtuNxeH 4.2LP5.0*3M

47900.031RS.78A t9.0*3MrehsaWgnirpS

57.51918.32 400 Amm3.1W021rotcelfeRlacitipillEMARSO

67100.20138.15AredloHpmaL

77.53138.15 200 AtekcarBrotcennoCpmaL

87100.90138.16A reldnaHegnahcxEpmaL

97060.321A1.58A 6*3MhceMnaPwercS

08.58 106 060.32AwercS tekcoSxeH 6*3MhceM

18060.621AW.58A 6*6.2MpaTdaeHnaPwercS

28420.321A0.68A 4.2LP5.0*3MtuNxeH

38100.40338.16AtuCthgiL

48.10138.15 200 ArevoCenignE

58100.30438.15AralyMtuCthgiL

68100.60138.25A rebbuR1sneL-revoCenignE

78100.12138.25A rebbuR2sneL-revoCenignE

88100.10138.16AkniStaeHDMD

98100.70138.16B )draoBniaMrof(troppuS-LdraoBDMD

09060.321A1.58A 6*3MhceMnaPwercS

19080.221A1.58A 8*2MhceMnaPwercS

29230.FA1A1.58A 4/1x23-6#hceMnaPwercS

39050.221D1.58A rehsaW/W(5*2MhceMnaPwercS & )0.5

49A0.58 321 060.AwercS F/P 6*3MhceM

59100.10138.75A evisehdAnoitcudnoCtaeH

69200.71138.32A mm1.62:L,wolloH,repaT,doRgnitargetnI

79200.91138.32C 301B25W501G001R F leehWroloCmm44

89110.60138.32A 1sneLresnednoClacirehpsA F mm7.6:Tmm12

99100.60338.32A 2sneLresnednoClacirehpsA F mm00.9:Tmm22

SERVICE MANUAL 3 - 8

Page 24

EzPro735

EzPro735

metI N/P .veR noitpircseD krameR

001100.80138.25A rebbuRsneL-1esaBenignE

101100.31138.16AIesaBenignE

201100.41138.16AIIesaBenignE

301100.32138.16A tsujdAdoRrofetalPgnirpS

401100.14138.16AgnirpSdexiFdoR

501200.10138.67A draoBrosneSotohPYSSA

601060.321A1.58A 6*3MhceMnaPwercS

701080.325A3.58A 8*3MhceMdaeHpaCwercS

801050.221D1.58A rehsaW/W(5*2MhceMnaPwercS & )0.5

901050.221A1.58A 5*2MhceMnaPwercS

011200.20138.32A mm7.0:TnogyloProrriMecafruStnorF

111.31138.53 300 A76J-M3mm21.51*02rorriMrofepaTediShtoB

211.81138.16 200 AAGXrofredloHrorriM

31110D.MD818.84A AGX"7.0slexiP867**4201DMD

411100.10238.15A AGX"7.0rofredloHDMD

511100.10718.25AremotsalEarbeZ

611200.40138.25A rebbuRredloHDMD

711300.90138.25A rebbuRkraMDMD

811100.10238.08B draoBrettamroFABCP

911200.10138.32A 4.2:#/FsneLevitcejbOnoitcejorP

021100.60338.15AgniRsucoF

121100.21338.15AgniRmooZ

221100.30138.25A rebbuRsneLtcejorP

321040.10438.16A 3D-4*2MhceMtalFwercS

421030.221A4.58A 3*2MhceMtalFwercS

521100.10438.57A eludoMpaCsneLYSSA

621100.13138.15AralyMCD-CD

721100.83138.15A redloHdraoBCD-CD

821.20138.57 200 AdraoBCD-CDYSSA

921100.16000.15AteviRcitsalP w L3-RS0.3

031110.31138.15A revoCtnemecalpeRpmaL

131100.34138.16A )revoCtnemecalpeR(reppoCkniStaeH

231100.11508.16A kcalB4-8*3MhceMnaPwercS

SERVICE MANUAL 3 - 9

Page 25

EzPro735

EzPro735

metI N/P .veR noitpircseD krameR

331100.50438.15AralyMtsallaB

431200.24138.15A )LU-L1-HF(revoCesuF

531100.10138.57A CPF+tsallaBYSSA

631060.722C1.58A )rehsaWPS/W(6*5.3MhceMnaPwercS

731100.20438.16A etalPdnuorGtsallaB

831100.30438.08F draoBlamrehTABCP

931100.80138.16A troppuSdraoBlamrehT

041050.221A1.58A 5*2MhceMnaPwercS

141100.10138.14A eroCCPFdapyeK

241110.10338.16BrevoCpoT

341100.30338.16AredloHrekaepS

441.621A1.58 030 AMhceMnaPwercS 3*6.2

541100.50338.16A reppoCkniStaeH

641100.31338.15ArevoCsneLRI

741100.50138.08A draoBrevieceRRIABCP

841100.10338.67BdapyeKYSSA

941060.321A1.58A 6*3MhceMnaPwercS

051100.10438.94A mm11*2.82*04mho8W2rekaepS

151100.15138.15AralyMdraoBRI

251100.60438.15BdleihSrekaepS

351100.60438.24A )DBniaMotDBRI(mm08262#P3.A.W

Note : Mark --- and in red color mean the added or updated item, and item

in blue color is deleted.

SERVICE MANUAL 3 - 10

Page 26

EzPro735

EzPro735

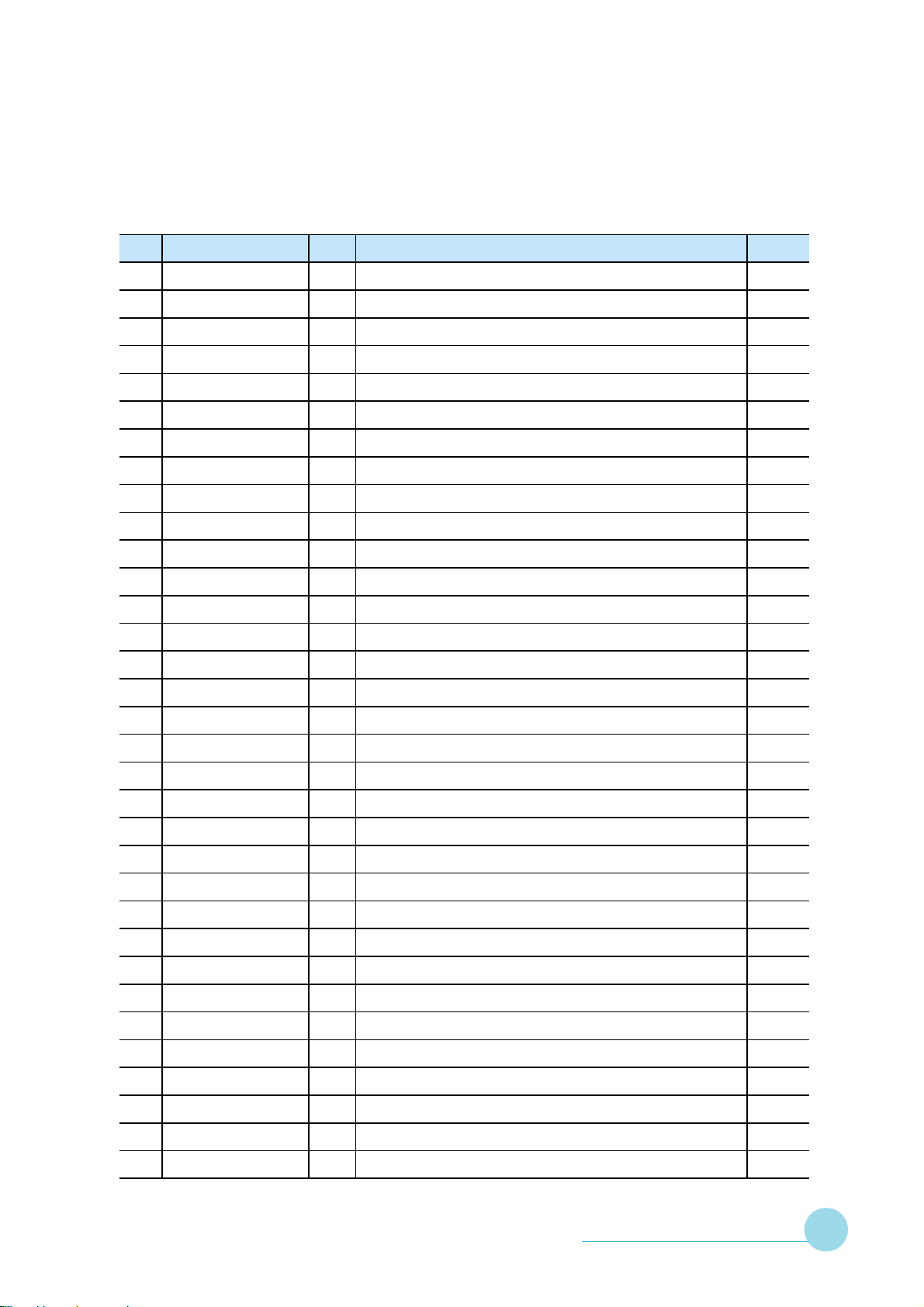

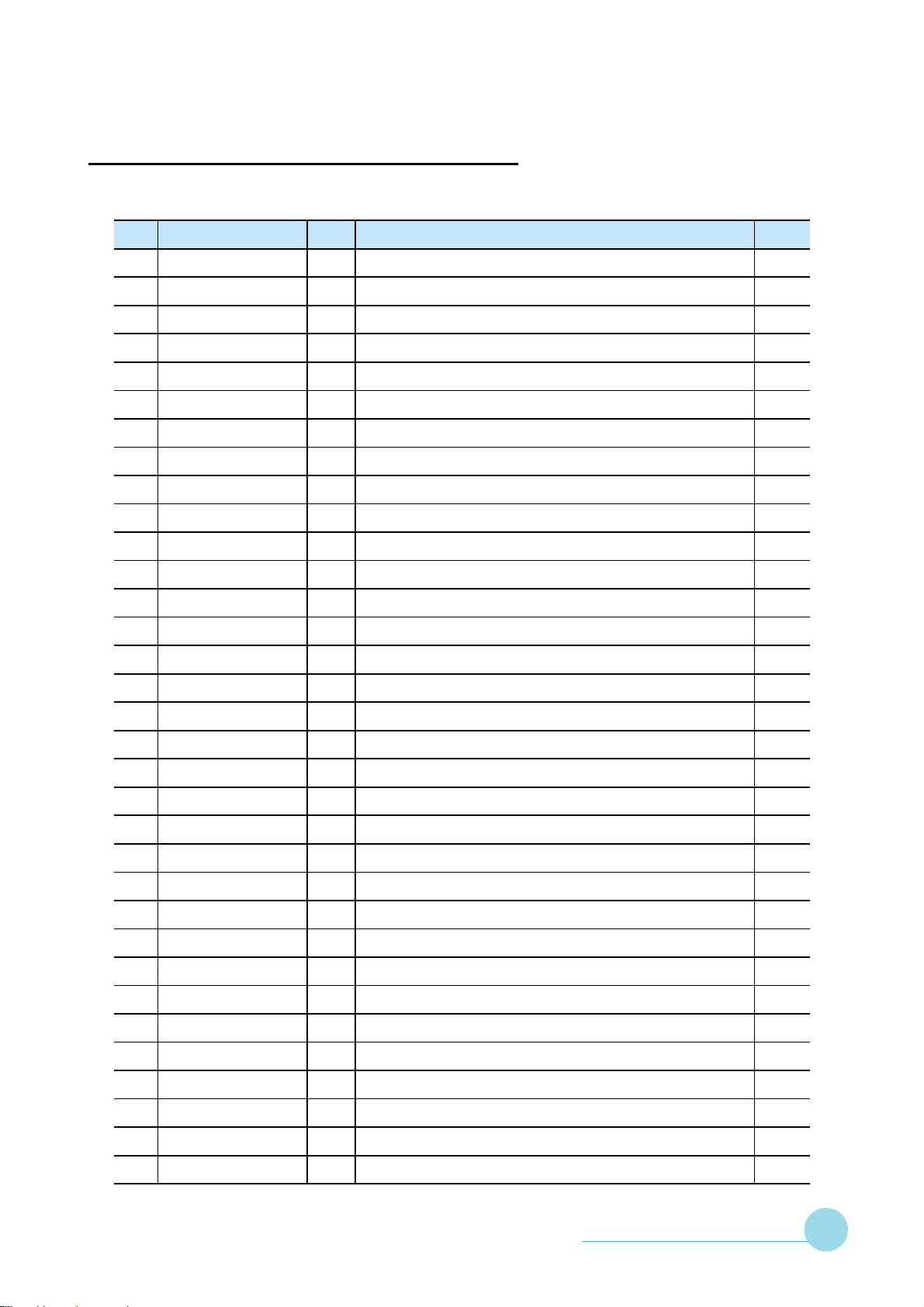

3-3 Recommendation Spare Parts List

metI N/P .veR noitpircseD epyT

1100.72438.07A )AMR(eludoMgnisuoHesaBMC

2100.11338.15ArevoCtupnItneVMC

3100.10000.15AeiTelbaCMC

4100.70338.15ArevoCxoBOIMC

5100.50438.07A eludoMrosneSlamrehTYSSAMC

6100.73138.15AediuGriAtuptuOMC

7100.93138.15AxiFdroCrewoPMC

8100.05138.15ApartSpaCMC

9100.14138.15A revoCnoitcetorPkcolretnIMC

01100.60438.25A rebbuRnociliSepiPriAMC

11100.65138.16A gnirpSraBhsuProtavelEMC

21100.20138.94A01*04*04naFMC

31100.10438.25A naFllamSrofrebbuRMC

4138.94 801 100.A 51*05*05naFMC

51100.01338.15A revoCtuptuOtneVMC

61100.30438.25A naFgiBrofrebbuRMC

71100.30138.94A mm051:Lmm51*15HP21-F50DnaFOCCORICSCEDINMC

81100.92438.07A )AMR(eludoMenignEYSSAWS

91200.10138.67A draoBrosneSotohPYSSAMC

0210D.MD818.84A AGX"7.0slexiP867*4201DMDWS

12200.40138.25A rebbuRredloHDMDMC

22300.90138.25A rebbuRkraMDMDMC

32100.10238.08B draoBrettamroFABCPWS

42100.10438.57A eludoMpaCsneLYSSAMC

52100.10138.75A evisehdAnoitcudnoCtaeHMC

62100.41438.07A eludoMCDotCDYSSAWS

72100.13438.07A )AMR(eludoMgnisuoHpmaLWS

82100.51438.07A revoCtnemecalpeRpmaLYSSAMC

92100.50438.15AralyMtsallaBMC

03100.03438.07A )AMR(eludoMtsallaBYSSAWS

13100.62438.07A )AMR(eludoMdraoBniaMYSSAWS

23100.80138.08A draoBhctiwSABCPWS

33100.30438.16A hctiwSlamrehTraeNtuCthgiLMC

SERVICE MANUAL 3 - 11

Page 27

EzPro735

EzPro735

metI N/P .veR noitpircseD epyT

43100.82438.07A )AMR(eludoMrevoCpoTYSSAMC

53100.10438.94A mm11*2.82*04mho8W2rekaepSMC

63100.60438.15BdleihSkaepSMC

73100.15138.15AralyMdraoBRIMC

83100.31338.15ArevoCsneLRIMC

93100.50138.08A draoBrevieceRRIABCPWS

04100.60438.24A )draoBniaMotRI(mm08262#P3.A.WMC

14100.30438.08F draoBlamrehTABCPWS

24100.50438.08C 09=DIdraoBrosneSlamrehTABCPWS

34100.60438.08D 19=DIdraoBrosneSlamrehTABCPWS

44100.10438.PSA )AMR(eludoMpmaLMC

54100.11508.16A kcalB4-8*3MhceMnaPwercSMC

64040.10438.16A 3D-4*2MhceMtalFwercSMC

74100.40438.16A 5.4LwercS81L3MkcitSreppoCnogaxeHMC

84.GA500.58 040 A*CNU04-4#leetSO/IwercS 5.5L*4H MC

94041.323A0.58A kcalB41*3MhceMF/PwercSMC

05A0.58 321 060.AwercS F/P 6*3MhceMMC

15050.221A1.58A 5*2MhceMnaPwercSMC

25080.221A1.58A 8*2MhceMnaPwercSMC

35040.321A1.58A 4*3MhceMnaPwercSMC

45060.321A1.58A 6*3MhceMnaPwercSMC

55.621A1.58 030 AhceMnaPwercS 3*6.2M MC

65230.FA1A1.58A 4/1*23-6#hceMnaPwercSMC

75002.323A1.58A kcalB02*3MhceMnaPwercSMC

85003.323A1.58A kcalB03*3MhceMnaPwercSMC

95060.722C1.58A )rehsaWS/W(roloC6*5.3MhceMnaPwercSMC

06050.221D1.58A rehsaWS/W(5*2MhceMnaPwercS w )0.5MC

16080.325A3.58A 8*3MhceMdaeHpaCwercSMC

26420.221A4.58A 4.2*2MhceMrefaWwercSMC

36030.221A4.58A 3*2MhceMtalFwercSMC

46060.221A4.58A 6*2MhceMtalFwercSMC

56.58 32106 060.AwercS tekcoSxeH 6*3MhceMMC

66060.621AW.58A 6*6.2MpaTdaeHnaPwercSMC

SERVICE MANUAL 3 - 12

Page 28

EzPro735

EzPro735

metI N/P .veR noitpircseD epyT

76520.223AY.58A kcalB5.2*0.2MepaTdaeHrefaWwercSMC

86530.24130.68A P7.0*4MtuNdaeHpaCxeHMC

96420.321A0.68A 4.2LP5.0*3MtuNxeHMC

07900.031RS.78A t9.0*3MrehsaWgnirpSMC

17100.42438.07A tamroF537PEhtiwlebaLnotraCyssAMC

27110.90205.24BM2SHV-SelbaCMC

37100.51708.24B mm0081ACRotkcaJiniMelbaCMC

47200.01105.24B mm0051ACRelbaCMC

57100.01918.24B M8.1BUS-D/epyT"A"BSUotP8niDiniMelbaCYMC

67100.30438.24B M8.1)eulB(AGVot)etihW(IVDelbaCMC

77100.40438.24B etihWM8.1ACRotIVDelbaCMC

87100.50438.24B 501M8.1CAdroCrewoPelbaC

o

)SU(kcalBCMC

97.10438.54 200 ArellortnoCetomeR lebaLADFhtiw 537PEMC

08100.92518.15A xoB-yrraCreppUeldnaHMC

18100.03518.15A xoB-yrraCrewoLeldnaHMC

28100.73518.15A mm1.0*004*003gaBDSEMC

38100.10338.35A gaBgniyrraCtfoSMC

48100.10338.55A xoBedistuOnotraCMC

58100.20338.55A xoByrosseccAnotraCMC

68100.10338.65AnoihsuCMC

78100.20338.65A xoByrosseccArofnoititraPMC

88.30438.53 200 AerutarepmeT&egatloVhgiHnoituaClebaLMC

98200.21000.63B seireSPPLrofSU,draCytnarraWMC

09100.31000.63B seireSPPLrofSU,mroFnoitartsigeRytnarraWdednetxEMC

19100.10438.63C 537PElaugnilitluMlaunaMs'resUMC

29100.20438.63B 537PElaugnilitluMdraCtratSkciuQMC

Note : SW = Swap Spare Parts, CM = Consume Spare Parts. You can place an order

for swap or consume spare parts to do replacement. Or just return swap spare

parts back for repair, but consume spare parts is not acceptable for repair or

return.

SW is repairable, when its defective please return back the defective but

complete parts to swap for good parts. Regarding CM, its not repairable and you

should give the order to do replacement and discard the defective parts directly.

The recommendation spare parts list is built for the convenience of disassembly

procedure. If there is any comment or recommendatin on the item of SW or CM,

please let us know.

SERVICE MANUAL 3 - 13

Page 29

EzPro735

EzPro735

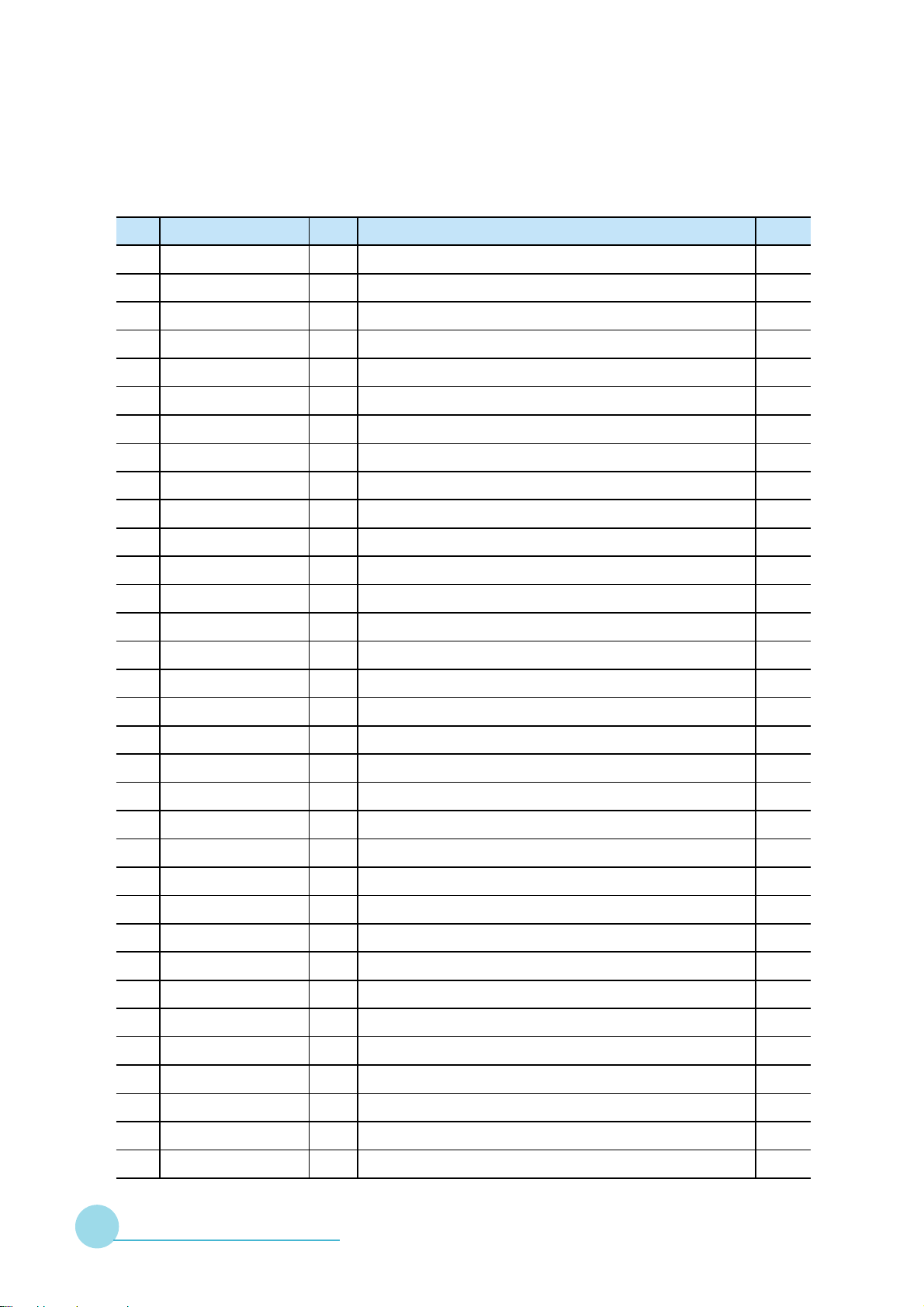

70.83427.001 Base Housing Module (RMA)

51.83307.001 IO Box Cover

51.83137.001 Output Air Guide 51.83139.001 Power Code Fix

51.83311.001 Vent Input Cover

70.83405.001 ASSY Thermal Sensor Module

51.83150.001 Cap Strap

49.83102.001 Fan 40*40*10

SERVICE MANUAL 3 - 14

75.83401.001 ASSY Lens Cap Module

52.83401.001 Rubber for Small Fan

Page 30

EzPro735

EzPro735

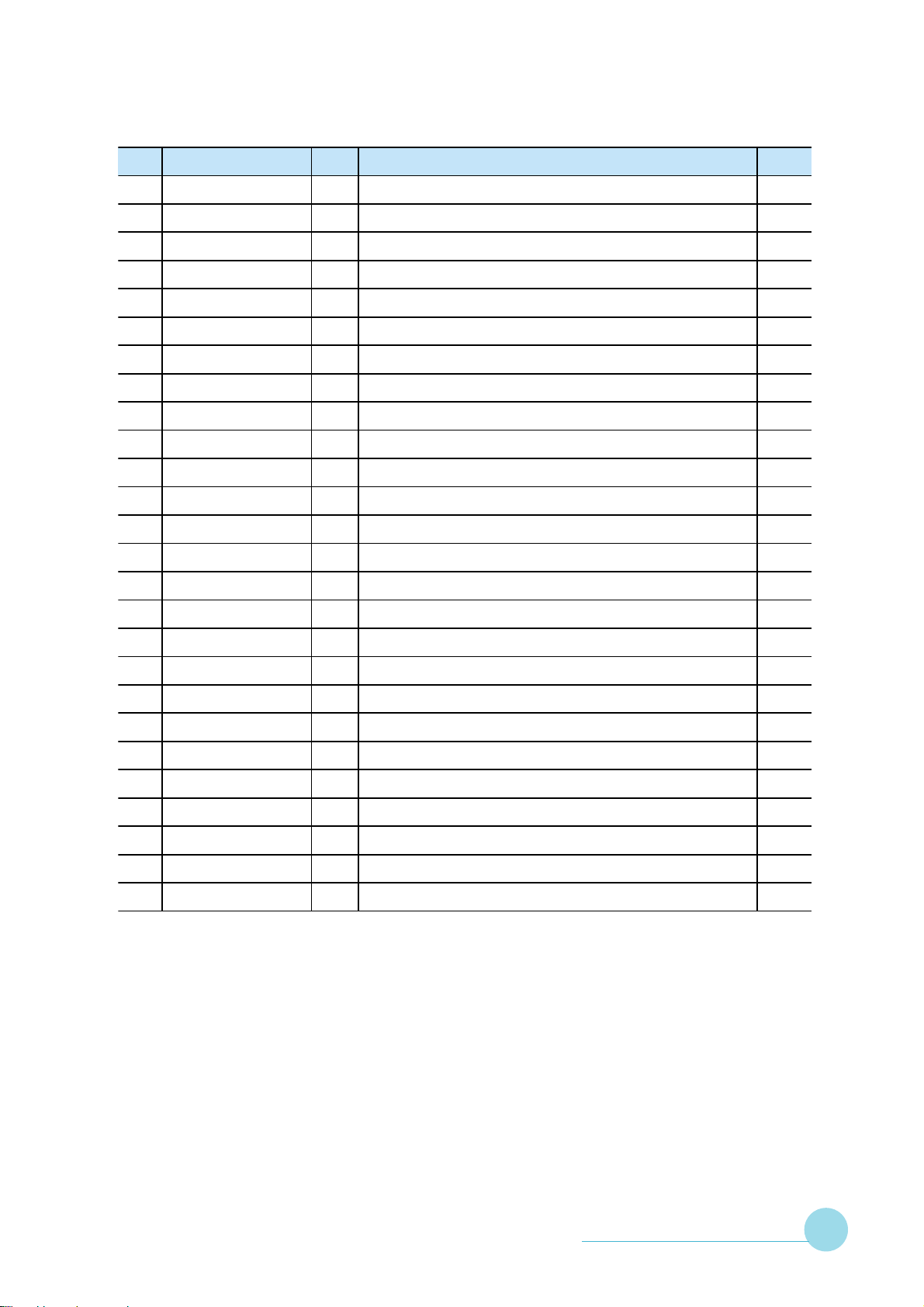

49.83108.001 Fan 50*50*15

52.83403.001 Rubber for Big Fan

48.818DM.D01 DMD 1024*768 Pixels

0.7 XGA

51.83310.001 Vent Output Cover

70.83429.001 Engine Module (RMA)

52.83104.002 DMD Holder Rubber

52.83109.003 DMD Mark Rubber

70.83414.001 ASSY DC to DC Module

80.83201.001 PCBA Formatter Board

70.83431.001 Lamp Holder Module (RMA)

SERVICE MANUAL 3 - 15

Page 31

EzPro735

EzPro735

70.83415.001 ASSY Lamp Replacement Cover

70.83430.001 Ballast Module (RMA)

51.83405.001 Ballast Mylar

70.83426.001 Main Board Module

61.83403.001 Light Cut Near Thermal Switch

80.83108.001 PCBA Switch Board

70.83428.001 ASSY Top Cover Module

(RMA)

SERVICE MANUAL 3 - 16

49.83401.001 Speaker 2W 8ohm 40*28.2*11mm

51.83313.001 IR Lens Cover

Page 32

EzPro735

EzPro735

80.83105.001 PCBA IR Receiver Board

SP.83401.001 Lamp Module (RMA)

42.83406.001 W.A. 3P #26 280mm

80.83403.001 PCBA Thermal Board

80.83405.001 PCBA Thermal Sensor Board

ID=90

49.83103.001 NIDEC SCIROCCO Fan

51*15mm L:150mm

80.83406.001 PCBA Thermal Sensor Board

ID=91

52.83406.001 Air Pipe Silicon Rubber

SERVICE MANUAL 3 - 17

Page 33

EzPro735

EzPro735

61.80511.001 Screw Pan Mech M3*8-4 Black

61.83404.001 Hexagon Copper Stick M3 L18

Screw L4.5

85.0A323.140 Screw P/F Mech M3*14 Black

61.83401.040 Screw Flat Mech M2*4-D3

85.005AG.040 Screw I/O #4-40*H4*L5.5

85.0A123.060 Screw P/F Mech M3*6

85.1A122.050 Screw Pan Mech M2*5

85.1A123.040 Screw Pan Mech M3*4

SERVICE MANUAL 3 - 18

85.1A122.080 Screw Pan Mech M2*8

85.1A123.060 Screw Pan Mech M3*6

Page 34

EzPro735

EzPro735

85.1A126.030 Screw Pan Mech M2.6*3

85.1A323.200 Screw Pan Mech M3*20 (Black)

85.1C227.060 Screw Pan Mech M3.5*6 Color

(W/SP Washer)

85.1A1AF.032 Screw Pan Mech #6-32*1/4

85.1A323.300 Screw Pan Mech M3*30 (Black)

85.1D122.050 Screw Pan Mech M2*5

(W/Washer w5.0)

85.4A122.024 Screw Wafer Mech M2*2.4

85.WA126.060 Screw Pan Head Tap M2.6*6

85.4A122.060 Screw Flat Mech M2*6

85.YA322.025 Screw Wafer Head Tape

M2.0*2.5 Black

SERVICE MANUAL 3 - 19

Page 35

EzPro735

EzPro735

85.0A123.024 Hex Nut M3*0.5P L2.4

42.50209.011 S-VHS Cable

42.50110.002 RCA Cable 1500mm

70.83424.001 Carton Label

42.80715.001 Cable Mini Jack to RCA

1800mm

42.83403.001 Cable DVI(White) to

VGA(Blue) 1.8m

42.83404.001 Cable DVI to RCA 1.8m White

42.83405.001 Cable Power Cord AC

1.8M (US)

SERVICE MANUAL 3 - 20

42.81910.001 Y Cable Mini Din 8P to USB

A Type/D-SUB 1.8m

55.83301.001 Carton Outside Box

Page 36

EzPro735

EzPro735

45.83401.002 Remote Controller

53.83301.001 Soft Carrying Bag

51.81537.001 ESD Bag 300*400*0.1mm

55.83302.001 Carton Accessory Box

56.83301.001 Cushion

35.83403.002 Label Caution High Voltage

& Temperature

36.83402.001 Quick Start Card

Multilingual EP735

36.00012.002 Warranty Card, US for LPP

SERVICE MANUAL 3 - 21

Page 37

EzPro735

EzPro735

36.00013.001 Extended Warranty Registration

Form, US for LPP

36.83401.001 Users Manual

Multilingual EP735

SERVICE MANUAL 3 - 22

Page 38

Chapter 4

EzPro735

EzPro735

PROCEDURE OF DISASSEMBLY

This section provides disassembly procedures for EP735 Micro Portable

XGA DLP Projector. Before you begin a ny of these procedures, be sure to turn

off the power, computer system, and other attached devices; then disconnect

the power cable from the electronically outlet. Moreover, when you disasse mble

the projector, be sure to put the screws in a safe place and separate them

according to grouping.

SERVICE MANUAL 4 - 1

Page 39

EzPro735

EzPro735

Tools Needed :

Long Nose Nipper (Left)

Angle Cutting Ni pper (Right)

Screw Bit (+) : 107, 102, 101 (from top to bottom)

Hex Sleeves 5mm (T op)

Screw Bit (-) 101

SERVICE MANUAL 4 - 2

Page 40

4-1 Disassemble Top Cover and Speaker

1

Base Housing

EzPro735

EzPro735

Lens Cap

1

1

1. Take off Lens Cap. Unscrew three long screws on the rear side of Base Housing and one

screw beside Base Housing.

2. Lift up Top Cover and unplug three wires from Main Board to remove Top Cover.

Mylar

4

IR Receiver Board

5

IR Board W ire

2

Top Cover

2

Speaker

Speaker Holder

3. Unscrew two screws of Speaker Holders to remove Speaker.

4. Unscrew one screw on IR Receiver Board to remove IR Receiver Board and Mylar.

5. Unplug IR Board Wire.

3

SERVICE MANUAL 4 - 3

Page 41

EzPro735

EzPro735

4-2 Disassemble Main Board and DC-DC Module

Main Board

M/B Mylar

2

3

IO Box Cover

1

3

1. Unscrew four screws on Main Board.

2. Disconnect the connector and re move M ain Board with IO Box Cover from

Base Housing.

3. Unscrew four hex screws to remove IO Box Cover from Main Board, and

tear off M ain Board Mylar.

SERVICE MANUAL 4 - 4

Page 42

DC-DC Module

EzPro735

EzPro735

4

4. Unscrew one screw and unplug three wire s to re move DC-DC Module.

DC-DC Board

6

DC-DC Mylar

DC-DC

Board

Holder

5

5. Unscrew two screws a nd two Hex Nuts to remove DC-DC Board Holder.

6. Tear off DC-DC Mylar.

SERVICE MANUAL 4 - 5

Page 43

EzPro735

EzPro735

4-3 Disassemble Engine, Formatter Board and Thermal Board

1

1

2

1. Unplug seven wires.

2. Unscrew four screws on Eengine Module to remove Engine Modulet.

SERVICE MANUAL 4 - 6

Page 44

EzPro735

EzPro735

DMD Holder Rubber

5

DMD Holder

4

3

Thermal Board

DMD

Module

4

Formatter Board

Heat Sink

6

3. Unplug one wire, then push forward a nd take of f Thermal Board.

4. Unscrew four screws of Frmatter Board, a nd unplug FPC to re move Formatter Module.

5. Remove DMD Holder Rubber and DMD Holder.

6. Unscrew two screws on DMD Heat Sink to take of f DMD Module.

SERVICE MANUAL 4 - 7

Page 45

EzPro735

EzPro735

7

7. Unscrew two screws of Thermal Board Support to remove it.

SERVICE MANUAL 4 - 8

Page 46

4-4 Disassemble Ballast Module

5

Ballast

EzPro735

EzPro735

Ballast Mylar

4

2

Base Housing

1

Ballast Wire

1. Unscrew two screws a nd unplug Ballast wire.

2. Unscrew two screws on Ballast, two screws on Power Cord Fix and one screw of

Ground Plate.

2

2

Power Cord

Fix

3. Take off Bala st Module from Ba se Housing.

4. Unscrew one screw to remove Ground Plate from Balla st.

5. Unplug one wire a nd tear of f Ballast Mylar.

SERVICE MANUAL 4 - 9

Page 47

EzPro735

EzPro735

4-5 Disassemble Fan Modules

Small Fa n

1

3

V ent Output

Module

2

1. Unscrew two screws to remove Small Fan Module.

2. Unscrew two screws to remove Vent Output Module.

3. Take off Vent Input Cover a nd Push Bar.

Vent

Input

Cover

3

Push Bar

4. Unscrew two screws to remove Fan Holder from samll Fan.

5. Take of f Rubber.

SERVICE MANUAL 4 - 10

5

Rubber

4

Fan Holder

Page 48

Vent Output Cover

Rubber

EzPro735

EzPro735

6

Brushless Fan

6. Unscrew two screws to remove Brushless Fan a nd Rubber from Vent Output Cover.

SERVICE MANUAL 4 - 11

Page 49

EzPro735

EzPro735

4-6 Disassemble Lamp Module

1

Lamp Holder Module

2

Lamp Repla cement Cover

1. Loose two screws to remove Lamp Repla ce ment Cover.

2. Unscrew three screws to pull out Lamp Holder Module.

Lamp Housing

4

Base Housing

3

Ar Pipe

3. Turn over Base Housing, unscrew two screws and remove Output Air Guide and Air Pipe.

4. Unscrew three screws to remove Lamp Housing.

Output Air Guide

SERVICE MANUAL 4 - 12

Page 50

EzPro735

EzPro735

Lamp Housing

5. Unscrew two screws to remove Light Cut.

Fan

5

Light Cut

Blower Wind Pipe

6

7

6. Unscrew four screws to remove Blower Wind Pipe.

7. Unscrew one screw a nd one Hex Nut to remove Fan.

SERVICE MANUAL 4 - 13

Page 51

EzPro735

EzPro735

4-7 Disassemble Switch Board and Thermal Sensor Board

Switch Board

1

2

Thermal

Sensor Board

Base Housing

Light Cut

Thermal Switch

Thermal Sensor Board

4

3

1. Unscrew one screw to remove Switch Board.

2. Unscrew one screw to remove one Thermal Sensor Board.

3. Unscrew one screw to remove a nother Thermal Sensor Board.

4. Unscrew one screw to remove Light Cut a nd Thermal Switch.

SERVICE MANUAL 4 - 14

Page 52

Chapter 5

EzPro735

EzPro735

FUNCTION OF BOARDS

This section provides each connector location on boards, signal and

function of each board. They will be useful for your detecting the defective

boards.

SERVICE MANUAL 5 - 1

Page 53

EzPro735

EzPro735

5-1 Main Board

5-1.1 The locations of Connectors

JP4

J2

J1

J6

JP6

J5

JP1

J4

CON1

JP2

5-1.2 J6 : Audio-In Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2R_OIDUAtupnIlennahCthgiRoiduA

3L_OIDUAtupnIlennahCtfeLoiduA

4.C.NnoitcennoCoN

5.C.NnoitcennoCoN

SERVICE MANUAL 5 - 2

Page 54

5-1.3 J1 : DVI Input Connector

#niP emaNlangiS noitpircseD

1-2XTataDtimsnarT

2+2XTataDtimsnarT

3dleihS4/2dnuorG

4-4XTnoitcennoCoN

5+4XTnoitcennoCoN

6KLCCDDkcolCCDD

7TADCDDataDCDD

8NICNYSVtupnI.cnySlacitreVgolanA

EzPro735

EzPro735

9-1XTataDtimsnarT

01+1XTataDtimsnarT

11dleihS3/1dnuorG

21-3XTnoitcennoCoN

31+3XTnoitcennoCoN

41CCV_CPrewoPV5+

51DNGdnuorG

61PHV5+

71-0XTataDtimsnarT

81+0XTataDtimsnarT

91dleihS5/0dnuorG

02-5XTV5+

12+5XTataDtimsnarT

22dleihSKLCdnuorG

32+CXTataDlaireS

42-CXTataDlaireS

52R_golanAtupnIlangiSdeRgolanA

62G_golanAtupnIlangiSneerGgolanA

72B_golanAtupnIlangiSeulBgolanA

82NICNYSHtupnI.cnySlatnoziroHgolanA

92DNGdnuorG

SERVICE MANUAL 5 - 3

Page 55

EzPro735

EzPro735

5-1.4 CON1 : VGA-Out Connector

#niP emaNlangiS noitpircseD

1TUO-RtuptuO.cnySdeR

2TUO-GtuptuO.cnySneerG

3TUO-BtuptuO.cnySeulB

4.C.NnoitcennoCoN

5DNGdnuorG

6DNGdnuorG

7DNGdnuorG

8DNGdnuorG

9.C.NnoitcennoCoN

01DNGdnuorG

11.C.NnoitcennoCoN

21.C.NnoitcennoCoN

31TUO_HtuptuO.cnySlatnoziroH

41TUO_VtuptuO.cnySlacitreV

51.C.NnoitcennoCoN

5-1.5 J2 : RS232 Connector

#niP emaNlangiS noitpircseD

1-DBSUlangiS-BSUesuoMetomeR

2+DBSUlangiS+BSUesuoMetomeR

31CRTD

4DNGdnuorG

5CSTRdneSottseuqeR

61CRTD

7CDXTtupnIataDtimsnarTCP

8CDXRataDevieceR

SERVICE MANUAL 5 - 4

Page 56

5-1.6 JP6 : Output Interface Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2BTSV5+rewoPybnatSV5+

3DNGdnuorG

4BTSV5+rewoPybnatSV5+

5DNGdnuorG

6IV3.3+IV3.3+

7DNGdnuorG

8IV3.3+IV3.3+

9DNGdnuorG

EzPro735

EzPro735

01IV3.3+IV3.3+

11DNGdnuorG

21IV3.3+IV3.3+

31DNGdnuorG

41IV3.3+IV3.3+

51DNGdnuorG

61.C.NnoitcennoCoN

71YBDNATS.cnySybdnatS

81RREPMETrorrEerutarepmeT

91FFONO_RIlortnoCybdnatSlortnoCetomeR

02FFONO_DELffO/nODELybdnatS

12DNGdnuorG

22OTESER-.cnySteseR

32DOOGRWPdooGrewoP

42DNGdnuorG

52DLEIFTlangiSdleiF

62XEDNIWCxednIleehWroloC

72ZOCNYSVCNYSlacitreV

82DNGdnuorG

92ATADTCAelbanEataD

03DNGdnuorG

SERVICE MANUAL 5 - 5

Page 57

EzPro735

EzPro735

#niP emaNlangiS noitpircseD

13OKLCDtuptuOkcolCataD

23DNGdnuorG

331DBataDeulB

433DBataDeulB

53DNGdnuorG

635DBataDeulB

737DBataDeulB

83DNGdnuorG

931DRataDdeR

043DRataDdeR

14DNGdnuorG

245DRataDdeR

347DRataDdeR

44DNGdnuorG

540DGataDneerG

642DGataDneerG

74DNGdnuorG

844DGataDneerG

946DGataDneerG

05DNGdnuorG

15IV21+V21+

25DNGdnuorG

35IV21+V21+

45DNGdnuorG

55IV21+V21+

65DNGdnuorG

75IV21+V21+

85DNGdnuorG

95IV5+V5+

06DNGdnuorG

SERVICE MANUAL 5 - 6

Page 58

#niP emaNlangiS noitpircseD

16IV5+V5+

26DNGdnuorG

36IV5+V5+

46DNGdnuorG

56IV5+V5+

66DNGdnuorG

7675X/65XtceteD75Xro65X

86EKOPSsutatSAGPF

96#NWOD_TUHS.cnySnwoD-tuhS

EzPro735

EzPro735

07DNGdnuorG

17ADSataDlaireS

27LCSkcolClaireS

37DNGdnuorG

47CNYSPMAL.cnySpmaL

57TILPMALtiLpmaL

67TSTXEDNIWCtsuahxEleehWroloC

77LAVCNYSV3.3+

87DNGdnuorG

97ZOCNYSHCNYSlatnoziroH

08TCALOlennahCniaM

18DNGdnuorG

28DNGdnuorG

380DBataDeulB

482DBataDeulB

58DNGdnuorG

684DBataDeulB

786DBataDeulB

88DNGdnuorG

980DRataDdeR

092DRataDdeR

SERVICE MANUAL 5 - 7

Page 59

EzPro735

EzPro735

#niP emaNlangiS noitpircseD

194DRataDdeR

296DRataDdeR

39DNGdnuorG

49DNGdnuorG

591DGataDneerG

69DNGdnuorG

793DGataDneerG

895DGataDneerG

99DNGdnuorG

0017DGataDneerG

5-1.7 J4 : S_VHS Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2DNGdnuorG

3AMULtupnIlangiSecnanimuL

4AMORHCtupnIlangiSecnanimorhC

5-1.8 J5 : RCA JACK Connector

#niP emaNlangiS noitpircseD

1PMOCtupnIoediVetisopmoC

2DNGdnuorG

SERVICE MANUAL 5 - 8

Page 60

5-1.9 JP1 : To Keypad

#niP emaNlangiS noitpircseD

1PUlortnoCpUdapyeK

2NWODlortnoCnwoDdapyeK

3YBDNATSlortnoCybdnatSdapyeK

4TFELlortnoCtfeLdapyeK

5THGIRlortnoCthgiRdapyeK

6UNEMlortnoCuneMdapyeK

7RETNElortnoCretnEdapyeK

81PMAL_DELDELpmaL

EzPro735

EzPro735

91YEK_DELffO/nOneerGDEL

011PMET_DELDELerutarepmeT

111FFONO_DELDELybdnatS

21DNGdnuorG

31DNGdnuorG

41DNGdnuorG

5-1.10 JP2 : Speaker

#niP emaNlangiS noitpircseD

1+REKAEPS+rekaepSoT

2-REKAEPS-rekaepSoT

5-1.11 JP4 : IR Receiver Connector

#niP emaNlangiS noitpircseD

1R_RIrevieceRRI

2DNGdnuorG

3BTSV5+rewoPybdnatSV5+

SERVICE MANUAL 5 - 9

Page 61

EzPro735

EzPro735

5-2 Formatter Board

5-2.1 The locations of Connectors

JP5

JP1

5-2.2 J502 : To Color Wheel Connector

#niP emaNlangiS noitpircseD

1RTCWClangiSevirDrotoMleehWroloC

2C1TWClangiSevirDrotoMleehWroloC

3C2TWClangiSevirDrotoMleehWroloC

4C3TWClangiSevirDrotoMleehWroloC

J502

SERVICE MANUAL 5 - 10

Page 62

5-2.3 JP5 : Input Interface Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2BTSV5+rewoPybnatSV5+

3DNGdnuorG

4BTSV5+rewoPybnatSV5+

5DNGdnuorG

6IV3.3+IV3.3+

7DNGdnuorG

8IV3.3+IV3.3+

EzPro735

EzPro735

9DNGdnuorG

01IV3.3+IV3.3+

11DNGdnuorG

21IV3.3+IV3.3+

31DNGdnuorG

41IV3.3+IV3.3+

51DNGdnuorG

61.C.NnoitcennoCoN

71YBDNATSybdnatS

81RREPMETrorrEerutarepmeT

91FFONO_RIlrtnoCybdnatSlortnoCetomeR

02FFONO_DELDELybdnatS

12DNGdnuorG

22OTESER-.cnySteseR

32DOOGRWPdooGrewoP

42DNGdnuorG

52DLEIFTlangiSdleiF

62XEDNIWCxednIleehWroloC

72ZOCNYSVCNYSlacitreV

82DNGdnuorG

92ATADTCAelbanEataD

03DNGdnuorG

SERVICE MANUAL 5 - 11

Page 63

EzPro735

EzPro735

#niP emaNlangiS noitpircseD

13OKLCDtuptuOkcolCataD

23DNGdnuorG

331DBataDeulB

433DBataDeulB

53DNGdnuorG

635DBataDeulB

737DBataDeulB

83DNGdnuorG

931DRataDdeR

043DRataDdeR

14DNGdnuorG

245DRataDdeR

347DRataDdeR

44DNGdnuorG

540DGataDneerG

642DGataDneerG

74DNGdnuorG

844DGataDneerG

946DGataDneerG

05DNGdnuorG

15IV21+V21+

25DNGdnuorG

35IV21+V21+

45DNGdnuorG

55IV21+V21+

65DNGdnuorG

75IV21+V21+

85DNGdnuorG

95IV5+V5+

06DNGdnuorG

SERVICE MANUAL 5 - 12

Page 64

#niP emaNlangiS noitpircseD

16IV5+V5+

26DNGdnuorG

36IV5+V5+

46DNGdnuorG

56IV5+V5+

66DNGdnuorG

7675X/65XtceteD75Xro65X

86EKOPSsutatSAGPF

EzPro735

EzPro735

96#NWOD_TUHSnwoDtuhS

07DNGdnuorG

17ADSataDlaireS

27LCSkcolClaireS

37DNGdnuorG

47CNYSPMALCNYSpmaL

57TILPMALtiLpmaL

67TSTXEDNIWCtsuahxEleehWroloC

77LAVCNYS)AGPF(lortnoCataD

87DNGdnuorG

97ZOCNYSHCNYSlatnoziroH

08TCALOlennahCniaM

18DNGdnuorG

28DNGdnuorG

380DBataDeulB

482DBataDeulB

58DNGdnuorG

684DBataDeulB

786DBataDeulB

88DNGdnuorG

980DRataDdeR

092DRataDdeR

SERVICE MANUAL 5 - 13

Page 65

EzPro735

EzPro735

#niP emaNlangiS noitpircseD

194DRataDdeR

296DRataDdeR

39DNGdnuorG

49DNGdnuorG

591DGataDneerG

69DNGdnuorG

793DGataDneerG

895DGataDneerG

99DNGdnuorG

0017DGataDneerG

5-2.4 JP1 : To Thermal Board Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2DNGdnuorG

3IV5+V5+

4IV5+V5+

5IV5+V5+

6IV5+V5+

7DNGdnuorG

8IV5+V5+

9DNGdnuorG

01DNGdnuorG

11DNGdnuorG

21DNGdnuorG

31V21PV21+

SERVICE MANUAL 5 - 14

Page 66

#niP emaNlangiS noitpircseD

41V21PV21+

51DNGdnuorG

61DNGdnuorG

71V3P3PV3.3+

81V3P3PV3.3+

91V3P3PV3.3+

02V3P3PV3.3+

12DNGdnuorG

EzPro735

EzPro735

22DNGdnuorG

32YBSV5rewoPybdnatSV5+

42YBSV5rewoPybdnatSV5+

52DNGdnuorG

62RORRE_NAFrorrEnaF

72NOCPlortnoCrewoP

82NENAFelbanEnaF

92XEDNIWCxednIleehWroloC

03NEPMALelbanEpmaL

13TILPMALtiLpmaL

23RREPMETrorrEpmeT

33DOOGRWPdooGrewoP

431PMETtceteDerutarepmeT

SERVICE MANUAL 5 - 15

Page 67

EzPro735

EzPro735

5-3 IR Board

5-3.1 The locations of Connectors

JP3

5-3.2 JP3 : IR Receiver Connector

#niP emaNlangiS noitpircseD

1R_RIrevieceRRI

2DNGdnuorG

3BTSV5+rewoPybdnatSV5+

SERVICE MANUAL 5 - 16

Page 68

5-4 DC-DC Board

5-4.1 The locations of Connectors

EzPro735

EzPro735

J4

5-4.2 J2 : Interlock Connector

#niP emaNlangiS noitpircseD

1KCOLRETNIPMALkcolretnIpmaL

J1

J2

2KCOLRETNIPMALkcolretnIpmaL

5-4.3 J1 : To Ballast Connector

#niP emaNlangiS noitpircseD

1REWOPMETSYSV004+

2.C.NnoitcennoCoN

3DNGdnuorG

4REWOPMETSYSV21+

SERVICE MANUAL 5 - 17

Page 69

EzPro735

EzPro735

5-4.4 J4 : To Thermal Board Connector

#niP emaNlangiS noitpircseD

1TUO_NEPMALtuptuOlangiSelbanEpmaL

2YBSV3.3+rewoPybdnatSV3.3+

3YBSV5+rewoPybdnatSV5+

4DNGdnuorG

5DNGdnuorG

6YBSV1.31+rewoPybdnatSV1.31+

7YBSV1.31+rewoPybdnatSV1.31+

8.C.NdnuorG

9DNGdnuorG

01DNGdnuorG

11DNGdnuorG

21YBSV5+rewoPybdnatSV5+

31YBSV3.3+rewoPybdnatSV3.3+

41NI_TILPMALtupnIlangiStiLpmaL

SERVICE MANUAL 5 - 18

Page 70

5-5 Thermal Board

5-5.1 The locations of Connectors

EzPro735

EzPro735

J8 J9 J5 J3 J2 J6 J4

J7

JP2

5-5.2 J8 : Thermal Sensor Connector

#niP emaNlangiS noitpircseD

1YBSV5+rewoPybdnatSV5+

2DNGdnuorG

3ADSataDlaireS

4LCSkcolClaireS

SERVICE MANUAL 5 - 19

Page 71

EzPro735

EzPro735

5-5.3 J9 : Thermal Sensor Connector

#niP emaNlangiS noitpircseD

1YBSV5+rewoPybdnatSV5+

2DNGdnuorG

3ADSataDlaireS

4LCSkcolClaireS

5-5.4 J5 : Fan3 Connector

#niP emaNlangiS noitpircseD

13REWOP_NAFrewoP3naF

2YBSV5+rewoPybdnatSV5+

3DNGdnuorG

5-5.5 J3 : Fan2 Connector

#niP emaNlangiS noitpircseD

12REWOP_NAFrewoP2naF

2YBSV5+rewoPybdnatSV5+

3DNGdnuorG

5-5.6 J2 : Fan Connector

#niP emaNlangiS noitpircseD

11REWOP_NAFrewoP1naF

2YBSV5+rewoPybdnatSV5+

3DNGdnuorG

SERVICE MANUAL 5 - 20

Page 72

5-5.7 J6 :Photo Sensor Input Connector

#niP emaNlangiS noitpircseD

1DNGdnuorG

2NI_OTOHPlangiStupnIrosneSotohP

3V3.3+V3.3+

5-5.8 J4 : Thermal Switch Connector

#niP emaNlangiS noitpircseD

EzPro735

EzPro735

1#RORRE_LAMREHTrorrElamrehT

2DNGdnuorG

5-5.9 J7 : To DC-DC Interface

#niP emaNlangiS noitpircseD

1TUO_NEPMALtuptuOlangiSelbanEpmaL

2YBSV3.3+rewoPybdnatSV3.3+

3YBSV5+rewoPybdnatSV5+

4DNGdnuorG

5DNGdnuorG

6YBSV1.31+rewoPybdnatSV1.31+

7YBSV1.31+rewoPybdnatSV1.31+

8.C.NdnuorG

9DNGdnuorG

01DNGdnuorG

11DNGdnuorG

21YBSV5+rewoPybdnatSV5+

31YBSV3.3+rewoPybdnatSV3.3+

41NI_TILPMALtupnIlangiStiLpmaL

SERVICE MANUAL 5 - 21

Page 73

EzPro735

EzPro735

5-5.10 JP2 : To DMD Board

#niP emaNlangiS noitpircseD

1DNGdnuorG

2DNGdnuorG

3V5+V5+

4V5+V5+

5V5+V5+

6V5+V5+

7DNGdnuorG

8V5+V5+

9DNGdnuorG

01DNGdnuorG

11DNGdnuorG

21DNGdnuorG

31V21+V21+

41V21+V21+

51DNGdnuorG

61DNGdnuorG

71V3.3+V3.3+

81V3.3+V3.3+

91V3.3+V3.3+

02V3.3+V3.3+

12DNGdnuorG

22DNGdnuorG

32YBSV5+rewoPybdnatSV5+

42YBSV5+rewoPybdnatSV5+

52DNGdnuorG

62FFONO_DELDELybdnatS

72FFONO_YEKffO/nOneerGDEL

82FFONO_RI.cnySybdnatSlrtnoCetomeR

92XEDNIWCxednIleehWroloC

03NEPMALelbanEpmaL

SERVICE MANUAL 5 - 22

Page 74

#niP emaNlangiS noitpircseD

13TILPMALtiLpmaL

23#NWOD_TUHS.cnySnwoDtuhS

33DOOGRWPdooGrewoP

43TUO_RREtuptuO.cnySrorrE

EzPro735

EzPro735

SERVICE MANUAL 5 - 23

Page 75

EzPro735

EzPro735

5-6 Ballast

5-6.1 The locations of Connectors

CN1

CN3

5-6.2 CN3 : DC-DC Connector

#niP emaNlangiS noitpircseD

1REWOPMETSYSV004+

2.C.NnoitcennoCoN

3DNGdnuorG

4REWOPMETSYSV21+

5-6.3 CN1 : Control Board Connector

#niP emaNlangiS noitpircseD

1ICStupnIlortnoCtratS

2DNGdnuorG

3TUPTUOGALFtuptuOgalF

SERVICE MANUAL 5 - 24

Page 76

Chapter 6

EzPro735

EzPro735

SPECIFICATIONS

This chapter provides DMD, Screen Defects, Lamp, Lamp Driver an d

DC-DC specifications. All specifications are for your reference.

SERVICE MANUAL 6 - 1

Page 77

EzPro735

EzPro735

6-1 Lamp Specifications

Operating and Measurement Conditions

w Ballast type Test conditions stable at 120W with

OSRAM PT VIP 120 AC/100-240 H ballast

w Rated la mp wattage 120 W (cf. note in item 1. Product Scope)

w Burner position 0° to +20° (0° optical axis horizontal)

w Burning position horizontal

Temperature

w Lamp burner Mo f oil, ba ck < 350°C

w Lamp burner Mo wire < 400°C

w Lamp burner Mo f oil, front < 350°C

Validation of max. permissible temperatures by reference thermocouple mea sure ment ba sed

on a reference lamp housing.

Typical Burner Characteristics (initial)

w UV-output UV A (315-400 nm) 7 W typical

UVB (280-315 nm) < 0,1 W

UVC (248-280 nm) < 0,01 W

w UV-output through dichroic reflector (248-400 nm) 2 W typical

w Total visible flux (400-780 nm) 30 W typical

w I R (780-2500 nm) 30 W typical

Average Lamp Life and Lumen Maintenance

w Switching cycle 3.5 hrs on 0.5 hrs off

w La m p life time 1000 hrs typical

w Lamp life Lamp output >50% of initi al lumen output

Lumens measurement as described in 2.9.

Rise Time

Rise time to 80% of the sta bilized luminous output is < 90 sec without forced convection.

Extensive cooling of the bulb during lamp run-up pha se ha s to be avoided.

Hot Restrike

If the unit has been off f or more than 60 sec. the lamp must restrike.

(Ignition voltage 20 kV +/- 3 kV)

No forced cooling is required following lamp switch-off.

SERVICE MANUAL 6 - 2

Page 78

EzPro735

EzPro735

Light output

w Balla st type Test conditions on electronic power supply

OSRAM PT VIP 120 AC/100-240 H sta ble at 120W

w Stabilization ti m e 5 min, without forced cooling

w Luminous flux throughaperture T yp.: 4000 lm @ 5.0 x 3.8 mm2 rect.

w rectangular aperture Min.: 3600 lm

w Color coordinates

Instructions for use

w For lamp re placement: switch off power, disconnect mains supply, disconnect power

cord, allow lamp to rea ch room te mperature.

w This VIP lamp operates at high pressure a nd at high te mperature and may unexpectedly

shatter.

w This VIP lamp generates ultraviolet ra di ation which may cause skin and eye irritation

with prolonged exposure.

w This VIP lamp must be operated only in suitably designed, enclosed fixtures which

prevent direct observation of the arc a nd will prevent lamp fragments from exiting, in

the unlikely event of a lamp rupture.

w The burning position is 0° to +20° (0° optical axis horizontal).

w Do not touch the lamp with bare hands.

w If necessary, lamp can be cleaned with lint free towel before operation.

w The lamp must be operated with the OSRAM lamp driver PT VIP 120 AC/100-240 H.

w Protect lamp environment against high ignition pulse s (max. 23 kV).

w Avoid direct contact of objects to reflector cover glass.

w Fast on-off-cycles will reduce lamp life.

w Use appropriate spa nner when assembling central connection.

w Visible arc instability ha s to be suppressed by optical system.

w Operate lamp only in accorda nce to UL 1950 regulations.

w This lamp must not be operated with a broken, cracked or loose reflector or cover glass.

1

Typ. x: 0.280 +/- 0.020

Typ. y: 0.290 +/- 0.020

Disposal: For disposal of spent lamps, always consult federal, state, local and provincial

hazardous waste disposal rules and regulations to ensure proper disposal.

Caution: This lamp emits ultra violet (UV) radiation a nd operates at high pre ssure. This lamp

may only be used in enclosed fixtures that comply with UL1572. Due to the high

luminous effica cy, the UV ra di ation which the lamp emits a nd the high pre ssure

within the lamp, P-VIP â lamps may only be operated within enclosed,

purpose-built housings.

SERVICE MANUAL 6 - 3

Page 79

EzPro735

EzPro735

6-2 DMD Specifications

Table 1. Physical, Optical and Thermal Parameters

lacisyhP

snmulocforebmuN4201

sworforebmuN867

retemaraP niM moN xaM tinU

)htdiw(hctiprorriM8.31

]slexip4201[)yarrarorrimevitca(htdiwlatoT-131.41-mm

]slexip867[)yarrarorrimevitca(thgiehlatoT-895.01-mm

lacitpO

)1etoN()elgnaflah(tlitrorriM90111seergeD

tfelrewolotthgirreppu-noitatorfosixA445464seergeD

yarrarorrimlatotrevotneidargssentalF1.0%

)2etoN(ytivitcelferralucepsaeraevitcA0657%

)ngisedyb(rotcafllifaeraevitcA98%

)mn007-024(ytivitcelferralucepslatemrorriM4.98%

)AepyT(noitangisedlairetamwodniW

)CepyT(noitangisedlairetamwodniW

)AepyT(mn545@xednievitcarferwodniW784.1

)CepyT(mn545@xednievitcarferwodniW274.1

gninroC

6507

ttohcS

33taolforoB

mm

lamrehT

)3,2,1T(xaM56

SERVICE MANUAL 6 - 4

,gnitaocRAgnidulcni-ecnattimsnartwodniW

)3etoN(sretemonan007-024@derusaem

)sretemonan055@(ssentalfwodniW

).cte,msitamgitsa(ytiralugerri/rewoplacirehps

ytivitcelfercirtemoidarerutrepawodniW8%

ytivitcelfercipotohperutrepawodniW32%

)6etoN(tneiciffeocnoitprosbaevitcA3353%

)5etoN(esacotaeraevitca,ecnadepmilamrehT7.0

)5&4etoN(esacotretteg,ecnadepmilamrehT7.1

)5etoN(dutslamrehtotesac,ecnadepmilamrehT8.0

)3,2,1T(niM-)3,2,1T(xaM51

79%

21/21segnirf

o

W/C

o

W/C

o

W/C

o

C

o

C

Page 80

EzPro735

EzPro735

Note 1 : Tilt Angle Tolerances

Limits on vari ability of mirror tilt half a ngle are critical in the design of the a ccompanying

optical system. Variations in tilt angle within a device may result in apparent nonuniformities, such a s line pairing and image mottling, across the projected i mage. Variations

in the average tilt a ngle between devices may result in colorimetry a nd syste m contrast

variations. The specified limits represent the tolerances of the tilt angles within a device.

Note 2 : Active Area Reflectivity

The DMD specular reflectivity is defined a s the ratio of the light incident upon the mirror

array to the light specularly reflected from it. The measure ment is made with all mirrors in

the full on state without electronic duty cycle effects (i.e. mea sure using 100% duty cycle).

The specified specular reflectivity applies to any arbitrary point on the DMD active area.

Note 3 : Window Transmittance

Double pass system .

Note 4 : Window Aperture

A shield is utilized on the interior peri meter of the window to improve system contrast and to

expose only the active area of the DMD to the projection optics. Incident light of up to 40

degrees cone half angle shall be supported without interference (active area shading) from

the window aperture. Light that falls outside the window clear aperture or outside the

specified angle will have a detrimental effect on system optical and thermal performance.

Note 5 : Thermal Performance

The DMD is designed to conduct residual heat energy to the ba ck of the package where it ca n

be removed by an appropriate heat sink. A device configured for a particular application can

be ma nufa ctured with a thermal stud de signated f or that a pplication. The heat sink and

cooling system must be capable of maintaining the package within the specified operational

temperatures. The total heat load is largely driven by the incident light a bsorbed by the

active area although other significant contributions that should be considered include light

energy absorbed by the window aperture a nd electrical input power. The portion of incident

light absorbed by the active area is determined from the active area absorption coefficient.

Optical systems should be designed so that no significant light energy falls outside the

window clear aperture as additional thermal load on the case top can damage the device.

SERVICE MANUAL 6 - 5

Page 81

EzPro735

EzPro735

Note 6 : Thermal Performance

The DMD is designed to conduct residual heat energy to the ba ck of the pa ckage where it can

be removed by an appropriate heat sink. A device configured for a particular application can

be ma nufa ctured with a thermal stud de signated f or that a pplication. The heat sink and

cooling system must be capa ble of maintaining the package within the specified operational

temperatures. The total heat load is largely driven by the incident light a bsorbed by the

active area although other significant contributions that should be considered include light

energy absorbed by the window aperture a nd electrical input power. The portion of incident

light absorbed by the active area is determined from the active area absorption coef ficient.

The absorption by the window a perture is the light ne ither spectrally nor dif fusely reflected

according to the window a perture reflectivity parameters. Optical systems should be de

signed so that no significa nt light ener gy falls outside the window clear aperture as any

significa nt additional thermal loa d on the case top ca n damage the device.

P

ARAMETER

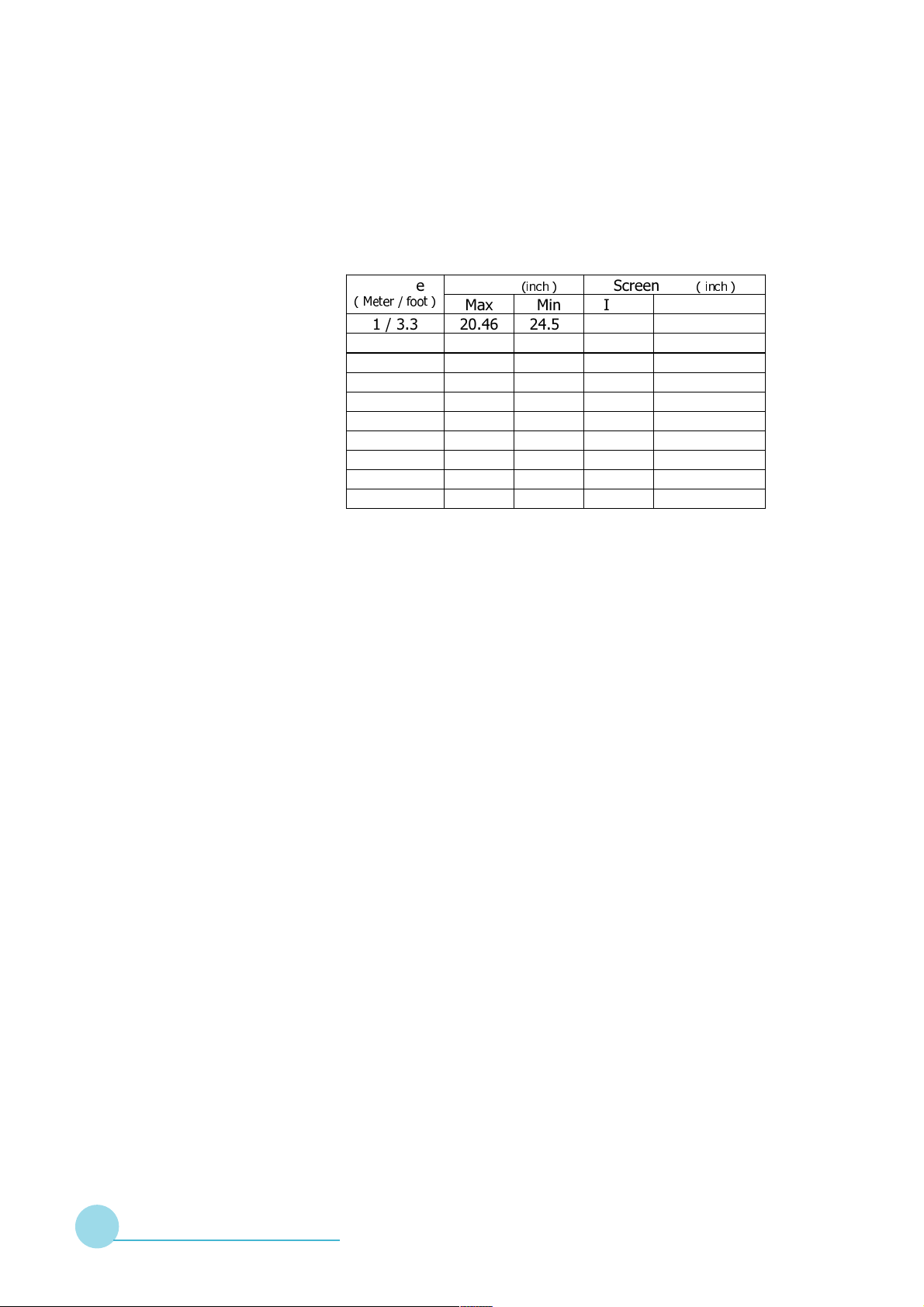

Table 2. Standard DMD Illumination Conditions

I

NPUTCONDITION

ffoelgnayarfeihcmaeB

ralucidneprep

morfgnikcolcyarfeihC

senilretnecaeraevitca

02

o

6 52.0

o61o

54

o

O

UTPUTCONDITION

0o6 52.0

o

N

OTES

metsysotevitaleR

enalpecafretni

otralucidnepreP

sixatlitrorrim

SERVICE MANUAL 6 - 6

Page 82

EzPro735

EzPro735

6-3 Screen Defects

The following are the defect limits f or this product. They include DMD defects and lens

defects where the latter are visible as point or area artifacts.

6-3.1 Image Size

The projector shall be set up in the standard operating position for all evaluations in this

section. Nominal image size is 121.9 cm (48 inches) wide, a nd 91.4 cm (36 inche s) high. The picture

setting of the SOD shall be set for a linear gray scale reproduction.

* Defect Types

There are two types of defects covered in this section, optical blemishes and DMD

defects. DMD defects consist of individual mirrors which do not change state

correctly and do not reproduce the appropriate gray scale.

* DMD Defects

This includes mirrors which are stuck on (bright pixel), stuck off (dark pixel), stuck

at some arbitrary angle (gray pixel) or who change state when they are not supposed

to (twinklers). Observe the screen under a variety of conditions. Enumerate all

single defects.

* Optical Blemishes

These are defects of the lens system, including scratches and specks of dirt, which

result in noticeableor mea surable fixed variations in light intensity on the screen

other tha n the expected light intensity fall of f from the lens axis. Classify blemishes

as e ither major or minor. Minor blemishes are those which are not rea dily

noticeable on screen at a viewing distance equal to the standard setup distance of

2.895 meters.

SERVICE MANUAL 6 - 7

Page 83

EzPro735

EzPro735

6-3.2 DMD Defect Limits

*Unstable Pixels

There shall be no unstable pixels (twinklers).

*Dark Pixels

Using a blue screen, level 180 out of a maximum of 255, look f or pixels and

blemishes darker than this background level. There shall be no more than

4 single dark pixels. No adjacent dark pixels are allowed.

* Bright Pixels

Using a gray screen where each primary color is set to 30 out of a

maximum of 255, look for pixels and blemishes that are brighter tha n this

background level. None are allowed.

* Optical Blemishes

Optical defects must not be large or small and concentrated to the extent

that they are easily visible.

* Minor Blemishes

Using both black and full white screens, count the number of minor

blemishes. There may not be more than 6 of these.

* Major Blemishes

There may not be any major blemishes which are easily visible at the

standard setup dista nce.

SERVICE MANUAL 6 - 8

Page 84

6-4 DC-DC Specifications

Dimensions and Weight

DC-DC Converter Size 70*42*27mm

DC-DC Converter Weight 45g

DC-DC Converter Data

Input W attage 32W 50W

Power Dissipation 7W 1 2 W

EzPro735

EzPro735

Normal Max .

Output V oltage1 3.3V

Output Current1 1.5A 2.0A

Output V oltage2 5V

Output Current2 1.5A 2.5A

Output V oltage3 13V

Output Current3 1.0A 1.5A

SERVICE MANUAL 6 - 9

Page 85

EzPro735

EzPro735

6-5 Lamp Driver Specifications

Dimensions and Weight

Lamp Driver Size 177*50*27mm

Lamp Driver W eight 240g

Lamp Driver Data

Input Voltage, normal 100V to 240V AC, 50/60Hz

Input Current, normal 2.0A to 0.8A

Input W attage, normal 200W

Power Dissipation 16W normal, 23W max.

Output Voltage1 (Lamp) 85V AC rectangular

Output Current1 1.4A

Output Voltage2 (DC-DC) 400V

Output Current2 0.08A

Ignition Pulse 2x max. 10kVpp for max. 4s

Hot Restrike Delay 60s max.

Enable-Dsable-Enable Cycle 15s min.

Switch off Lam p Voltage 115V 1 10-120V

Cooling Method Forced air cooling at 1m/s mini m um

Thermal Protection T1 switch point 90oC +/- 5oC

Electrical Protection Short cut + output /- output for max. 10s

SERVICE MANUAL 6 - 10

no protection for short to GND

Page 86

EzPro735

EzPro735

Environmental Requirements for Lamp and Lamp Driver

Ambient T emperature Operating : 10oC to 40oC

Non-operating : -20oC to 70oC

Humidity Operating : 5% to 95% relative, non-condensing

Non-operating : 5% to 95% relative, non-condensing

Altitude Operating : max. 10,000ft (3,000m) @ 40oC

Non-operating : max. 40,000ft @ 70oC

V ibration Operating : random, standalone 0.015g2/Hz

5Hz to 1000Hz, all primary axis,

30 minutes per orientation

Non-operating : sine, standalone Q[5 1G control,

5Hz to 500Hz, all three primary axis,

5 minutes sweep rate

Shock Operating : standalone 50g 11ms half sine pulse,

all primary axis, three shocks per

orientation

Note : Lamp mounting must ensure the a.m. vibration and shock conditions.

SERVICE MANUAL 6 - 11

Page 87

Chapter 7

EzPro735

EzPro735

TROUBLESHOOTING PROCEDURE

This chapter provides technicians and people who have an electronic

background a primary description about maintaining the product. Moreover,

you can get the appropriate operation to solve some complicated problems

of component repairing and professional problems.

SERVICE MANUAL 7 - 1

Page 88

EzPro735

EzPro735

7-1 Equipment Needed

t EP735

t DVI to VGA Cable, Power Cord

t PC (Personal Computer)

t Audio Input, Video Input

t Screw Drivers

7-2 Main Procedure

Start

Connect Power cord, analog or

digital signal and audio signal,

then turn power on

Is Lamp light on ?

Yes

Is Image OK ?

Yes

Is function ok ?

Yes

No

No

No

A. Power

Troubleshooting

B. Image Performa nce

Troubleshooting

C. Function

Troubleshooting

SERVICE MANUAL 7 - 2

1

Page 89

EzPro735

EzPro735

1

Is Audio OK ?

Yes

Is Remote

Control OK?

Yes

No Fault Found

End

No

No

D. Audio

Troubleshooting

E. Remote Control

Troubleshooting

SERVICE MANUAL 7 - 3

Page 90

EzPro735

EzPro735

7-2.1 A. Power Troubleshooting

Start

Is LED

indicator

OK ?

Yes

Is Fa n working ?

Yes

Is Lamp lit ?

Yes

End

No

No

No

Check

power cord

& input power

voltage

Supply

AC power

Change

DC-DC

Change

Main Board

No

No

No

Yes

Cha nge

Fan

Module

Cha nge

Ballast

Lamp

Housing asse mbly

OK ?

Yes

Cha nge

DC-DC

No

Cha nge

M/B

No

Change

Ballast

No

Reassembly

lamp Housing

SERVICE MANUAL 7 - 4

Page 91

7-2.2 B. Performance Troubleshooting

Start

EzPro735

EzPro735

Have image ?

Yes

Have garbage

pattern ?

No

Uniformity OK ?

Yes

Is color OK ?

Yes

No

Yes

No

No

Cha nge

M/B

Cha nge

M/B

Cha nge

Engine Module

Color Adjust

Procedure

* Note 1

No

No

Change

DMD Module

Change

DMD Module

No

Cha nge

M/B

No

Cha nge

DMD

Module

No

Optical

Engine

Dot defect isn’t

compliant with the

spec.?

No

Have line bar ?

No

Have noise ?

No

End

Yes

Yes

Yes

Change

DMD Module

Adjust

frequency

Adjust

tracking

No

No

Cha nge

M/B

Cha nge

M/B

SERVICE MANUAL 7 - 5

Page 92

EzPro735

EzPro735

Color Adjust Procedure :

Notice : PC shall run R.G.B. gray scale pattern (3:169 pattern) of DMU Program.

1. Press menu button and power on simultaneously. Hold menu button until Optoma logo

shows on the screen.

2. Press menu button again and OSD will appear on the screen.

3. Choose service function.

4. Choose “displaying hours” function.

5. Press “-”, “+” and “-” buttons in turn.

6. Press “+” or “-” button to adjust.

✎ Note 1 : It may need to be used when you replace Main Board or Optical Engine alone.

7-2.3 C. Function Troubleshooting

Start

Does OSD

show up ?

Yes

Ca n function

be a djusted ?

Yes

No

No

Is KeyPad

Board OK ?

No

Cha nge

KeyPa d board

Change

Main board

Yes

Is Remote

Controller

OK ?

No

Cha nge

battery

No

Cha nge

Remote

Controller

Yes

Change

Main board

End

SERVICE MANUAL 7 - 6

Page 93

7-2.4 D. Audio Troubleshooting

Start

EzPro735

EzPro735

Ca n hear

sound ?

Yes

Sound is clear

without noise ?

Yes

End

No

No

Cha nge

Main board

Change

Speaker

7-2.5 E. Remote Control Troubleshooting

Start

No

Cha nge

Speaker

Replace

the battery

No

Cha nge Remote

Controller

No

Cha nge Keypad

No

Cha nge M/B

Yes

Yes

Yes

Yes

End

SERVICE MANUAL 7 - 7

Page 94

Chapter 8

EzPro735

EzPro735

FUNCTION TEST AND ALIGNMENT PROCEDURE

This chapter provides equipment, conditions, patterns, and procedure

needed for Function Test and Alignment. It also includes compatible modes.

All information is for your reference.

SERVICE MANUAL 8 - 1

Page 95

EzPro735

EzPro735

8-1 Equipment Needed

✑ IBM PC with XGA resolution (Color V ideo Signal & Pattern Generator)

✑ VCR with Multi-system(NTSC/PAL/SECAM)

✑ Chroma meter Minolta CL-100

✑ Hi-Pot

VCR with Multi-system

Hi-Pot

(NTSC/PAL/SECAM)

8-2 Test Condition

✑ Circumstance Brightness : Dark room less than 60 lux

✑ Inspection Distance : 2.0m

✑ Screen Size : 60 inches diagonal (wide)

✑ Before function test and alignment, each EP735 should be run-in a nd warmed-up

for at least 30mins with f ollowing conditions.

In room temperature

With cycled display colors (R,G,B,White)

With cycled display mode s

640*350 (H=31.5 KHz, V=70 Hz)

640*400 (H=31.5 KHz, V=70 Hz)

Chroma meter

Minolta CL-100

640*480 (H=37.5 KHz, V=75 Hz)

720*400 (H=31.5 KHz, V=70 Hz)

800*600 (H=53.7 KHz, V=85 Hz)

800*600 (H=37.9 KHz, V=60 Hz)

1024*768 (H=48.4 KHz, V=60 Hz)

1024*768 (H=68.7 KHz, V=85 Hz)

✑ Test Display Mode & Pattern (Ref er to 8-3.1 & 8-3.2)

✑ Function T est a nd Alignment Procedure

SERVICE MANUAL 8 - 2

Page 96

8-3 Test Display Modes and Patterns

8-3.1 Compatible Modes

EzPro735

EzPro735

Analog :

noituloseR )zH(cnyS-V )zHK(cnyS-H ytilibitapmoC

053*046075.13AGV

053*046589.73

004*046075.13

004*046589.73

084*046065.13

084*046279.73

084*046575.73

084*046583.34

004*027075.13

004*027589.73

006*008652.53AGVS

006*008069.73

006*008271.84

006*008579.64

006*008587.35

867*42014.345.53AGX

867*4201064.84

867*4201075.65

867*4201570.06

867*4201587.86

4201*08210689.36AGXS*

4201*08215789.97

468*2511575.76ASEV*

096*08210606ASEV*

096*0821589.58

084*04666.6689.43"31CLCAM

084*04686.6653"31IICAM

426*23855.47527.94"61CAM

867*42015742.06"91CAM

078*251160.5786.86CAM

084*0460653.134GCAM

084*04602130.86

SERVICE MANUAL 8 - 3

Page 97

EzPro735

EzPro735

noituloseR )zH(cnyS-V )zHK(cnyS-H ytilibitapmoC

867*420102190.794GCAM

084*04671106VDcaMi

006*0085906

867*42015706

078*25115749.86

069*08215757

4201*0821589.09

004*04624.6538.4289CP

084*046075.13

084*046065.13

084*04673.5573.42NWOTMF

084*046065.13

* Compressed

Digital :

noituloseR )zH(cnyS-V )zHK(cnyS-H ytilibitapmoC

053*046075.13AGV

053*046589.73

004*046075.13

004*046589.73

084*046065.13

084*046279.73

084*046575.73

084*046583.34

004*027075.13

004*027589.73

006*008652.53AGVS

006*008069.73

SERVICE MANUAL 8 - 4

006*008271.84

006*008579.64

006*008587.35

867*42014.345.53AGX

867*4201064.84

867*4201075.65

867*4201570.06

Page 98

EzPro735

EzPro735

8-3.2 Function Test Display Pattern

metI tnetnoCtseT nrettaP noitacificepS krameR

1gnikcarT&ycneuqerFerioMeniLeniF.esionyvawlausivetanimilE1erugiF

2ssenthgirB/tsartnoCelacSyarG.elbahsiugnitsidebdluohsslevelyarG2erugiF

3

4

5

6

rekcilF

/daeD

yradnuoB

etihWdnaB,G,R

ecnamrofreProloC

&ytimrofinUneercS

hsimelB

lexiP

dnaB,G,R

roloCetihW

etihWlluF.cepsehthtiwtnailpmocebdluohS

,B,G,R

etihW

,081eulB,kraD

03yarG

.lamronebdluohsrolocB,G,RhcaE

F

i

3erug

6~

i

erug

6

F

,

emarFyradnuoB

/daedfosrebmunehT

hsimelb

slexip

.cepsehthtiwtnailpmocebdluohs

ebdluhsoedivfonoitisop.treVdna.zroH

i

F

.emarfneercsehtnihtiwebotelbatsujda

9~3erugiF

erug

01

Fine Line Morie Pattern (Figure 1) Contrast & Brightness (Figure 2)

R. Color Pattern (Figure 3) G. Color Pattern (Figure 4)

SERVICE MANUAL 8 - 5

Page 99

EzPro735

EzPro735

B. Color Pattern (Figure 5) Full White Pattern (Figure 6)

Dark Pattern (Figure 7) Gary 30 Pattern (Figure 8)

Blue 180 Pattern (Figure 9) Boundary Frame (Figure 10)

SERVICE MANUAL 8 - 6

Page 100

EzPro735

EzPro735

8-4 Inspection Procedure

8-4.1 RESET

Please press “Menu” button on the projector panel to enter “Factory Reset” Function

then choose “YES” and press “Enter” to see if it works. This action will allow you to erase