Optimum TU2506, TU2506V, TU2807, TU2807V Operating manual

OPTIMUM

M A S C H I N E N - G E R M A N Y

Operating manual

Version 1.0.1

Lathe

GB

OPTIMUM

M A S C H I N E N - G E R M A N Y

Table of contents

1 |

Safety |

|

|

|

1.1 |

Safety warnings (warning notes) .............................................................................................................. |

8 |

|

1.1.1 |

Classification of hazards........................................................................................................................... |

8 |

|

1.1.2 |

Other pictograms ...................................................................................................................................... |

9 |

|

1.2 |

Intended use ............................................................................................................................................. |

9 |

|

1.3 |

Reasonably foreseeable misuse............................................................................................................. |

10 |

|

1.3.1 |

Avoiding misuse...................................................................................................................................... |

10 |

|

1.4 |

Possible dangers caused by the machine .............................................................................................. |

10 |

|

1.5 |

Qualification of the staff .......................................................................................................................... |

11 |

|

1.5.1 |

Target group ........................................................................................................................................... |

11 |

|

1.5.2 |

Authorized persons................................................................................................................................. |

12 |

|

1.5.3 |

Obligations of the operating company .................................................................................................... |

12 |

|

1.5.4 |

Obligations of the operator ..................................................................................................................... |

12 |

|

1.5.5 Additional requirements regarding the qualification................................................................................ |

12 |

|

|

1.6 |

Operator positions .................................................................................................................................. |

12 |

|

1.7 |

Safety measures during operation.......................................................................................................... |

13 |

|

1.8 |

Safety devices ........................................................................................................................................ |

13 |

|

1.9 |

EMERGENCY-STOP button................................................................................................................... |

14 |

|

1.9.1 Lockable main switch (only TU 2506V, TU2807V) ................................................................................. |

15 |

|

|

1.9.2 |

Protective cover with safety switch ......................................................................................................... |

15 |

|

1.9.3 |

Lathe chuck protection with position switch............................................................................................ |

15 |

|

1.9.4 |

Lathe chuck key...................................................................................................................................... |

16 |

|

1.10 |

Safety check ........................................................................................................................................... |

16 |

|

1.11 |

Personnel protective equipment ............................................................................................................. |

17 |

|

1.12 |

For your own safety during operation ..................................................................................................... |

17 |

|

1.13 Disconnecting and securing the lathe..................................................................................................... |

17 |

|

|

1.14 |

Using lifting equipment ........................................................................................................................... |

18 |

|

1.15 |

Mechanical maintenance work ............................................................................................................... |

18 |

2 |

Technical data |

|

|

|

2.1 |

Electrical connection............................................................................................................................... |

19 |

|

2.2 |

Machine data .......................................................................................................................................... |

19 |

|

2.3 |

Working area .......................................................................................................................................... |

19 |

|

2.6 |

Emissions ............................................................................................................................................... |

20 |

|

2.4 |

Environmental conditions........................................................................................................................ |

20 |

|

2.5 |

Operating material .................................................................................................................................. |

20 |

|

2.7 |

Dimensions, installation plan TU2506 .................................................................................................... |

21 |

|

2.8 |

Dimensions, installation plan TU2506V .................................................................................................. |

22 |

|

2.9 |

Dimensions, installation plan TU2807 .................................................................................................... |

23 |

|

2.10 |

Dimensions, installation plan TU2807V .................................................................................................. |

24 |

|

2.11 |

Distance between centres, height of centres TU2506, TU2506V........................................................... |

25 |

|

2.12 |

Distance between centres, height of centres TU2807, TU2807V........................................................... |

26 |

3 |

Assembly |

|

|

|

3.1 |

Scope of delivery .................................................................................................................................... |

27 |

|

3.2 |

Transport ................................................................................................................................................ |

27 |

|

3.3 |

Storage ................................................................................................................................................... |

28 |

|

3.4 |

Installation and assembly ....................................................................................................................... |

29 |

|

3.4.1 |

Requirements to the installation site....................................................................................................... |

29 |

|

3.4.2 |

Load suspension point............................................................................................................................ |

29 |

|

3.4.3 |

Installation............................................................................................................................................... |

29 |

|

3.5 |

Assembly of the synchronous belt and V-belt on the lathe..................................................................... |

30 |

|

3.5.1 Assembly of the synchronous belt on the lathe TU 2506, TU 2807, TU2807 V ..................................... |

30 |

|

|

3.5.2 Assembly of the synchronous belt on the lathe TU 2506 V .................................................................... |

30 |

|

|

|

|

|

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

|

Page 2 |

|

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

|

OPTIMUM |

|

|

|

M A S C H I N E N - G E R M A N Y |

|

|

3.5.3 |

Assembly of the V-belt on the lathe........................................................................................................ |

31 |

|

3.6 |

First commissioning................................................................................................................................ |

31 |

|

3.6.1 |

Warming up the machine ...................................................................................................................... |

31 |

|

3.6.2 |

Cleaning and lubricating......................................................................................................................... |

31 |

|

3.6.3 |

Visual inspection .................................................................................................................................... |

32 |

|

3.6.4 |

Functional test ........................................................................................................................................ |

32 |

|

3.6.5 |

Electrical connection .............................................................................................................................. |

32 |

|

3.6.6 |

Functional check .................................................................................................................................... |

33 |

|

3.7 |

Optional machine accessories ............................................................................................................... |

33 |

|

3.8 |

Mounting instruction ............................................................................................................................... |

34 |

|

3.8.1 |

Mounting instruction chuck flange .......................................................................................................... |

34 |

|

3.8.2 |

Flange for the lathe chuck ...................................................................................................................... |

35 |

|

3.8.3 |

Mounting instruction of collet chuck holder ............................................................................................ |

36 |

|

3.8.4 |

Mounting of follow rest TU 2506 (V)....................................................................................................... |

37 |

|

3.8.5 |

Mounting of follow rest TU 2807 (V)....................................................................................................... |

37 |

|

3.8.6 |

Mounting of steady rest TU 2506 (V) ..................................................................................................... |

38 |

|

3.8.7 |

Mounting of steady rest TU 2807 (V) ..................................................................................................... |

38 |

4 |

Operation |

|

|

|

4.1 |

Operation TU2506 and TU2807 ............................................................................................................. |

39 |

|

4.1.1 |

Control and indicating elements ............................................................................................................. |

39 |

|

4.1.2 |

Switching elements ................................................................................................................................ |

40 |

|

4.1.3 |

Switching on the machine ...................................................................................................................... |

40 |

|

4.1.4 |

Switching off the machine ...................................................................................................................... |

40 |

|

4.2 |

Operation TU2506V ............................................................................................................................... |

41 |

|

4.2.1 |

Control and indicating elements ............................................................................................................. |

41 |

|

4.2.2 |

Switching elements ................................................................................................................................ |

42 |

|

4.2.3 |

Switching on the machine ...................................................................................................................... |

42 |

|

4.2.4 |

Switching off the machine ...................................................................................................................... |

42 |

|

4.3 |

Operation TU2807V ............................................................................................................................... |

43 |

|

4.3.1 |

Control and indicating elements ............................................................................................................. |

43 |

|

4.3.2 |

Switching elements ................................................................................................................................ |

44 |

|

4.3.3 |

Switching on the machine ...................................................................................................................... |

44 |

|

4.3.4 |

Switching off the machine ...................................................................................................................... |

44 |

|

4.4 |

Safety ..................................................................................................................................................... |

45 |

|

4.5 |

Operating elements for feed................................................................................................................... |

45 |

|

4.6 |

Tool holder ............................................................................................................................................. |

45 |

|

4.7 |

Lathe chuck ............................................................................................................................................ |

46 |

|

4.7.1 |

Replacing the clamping jaws on the lathe chuck.................................................................................... |

46 |

|

4.8 |

Speed adjustment .................................................................................................................................. |

47 |

|

4.8.1 |

Changing the speed range ..................................................................................................................... |

48 |

|

4.8.2 |

Speed table TU 2506 ............................................................................................................................. |

48 |

|

4.8.3 |

Speed table TU 2506V ........................................................................................................................... |

49 |

|

4.8.4 |

Speed table TU2807 .............................................................................................................................. |

49 |

|

4.8.5 |

Speed table TU 2807V ........................................................................................................................... |

49 |

|

4.9 |

Feed adjustment..................................................................................................................................... |

50 |

|

4.9.1 |

Selector switch ....................................................................................................................................... |

50 |

|

4.9.2 |

Changing the change gears ................................................................................................................... |

50 |

|

4.9.3 |

Arrangement of change gears................................................................................................................ |

51 |

|

4.9.4 |

Tables for thread-cutting ........................................................................................................................ |

52 |

|

4.9.5 |

Transmission ratio .................................................................................................................................. |

52 |

|

4.9.6 |

Example - assembly of gear wheels for thread 0.75mm 1.5mm 3mm ................................................... |

53 |

|

4.10 |

Feed engaging lever............................................................................................................................... |

53 |

|

4.11 |

Fixing the lathe saddle ........................................................................................................................... |

54 |

|

4.12 |

Turning tapers ........................................................................................................................................ |

55 |

4.12.1 Turning short tapers with the top slide ................................................................................................... |

55 |

||

|

|

|

|

|

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

|

Page 3 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

|

4.12.2 Turning tapers with the tailstock ............................................................................................................. |

55 |

|

|

4.12.3 Turning of cones with high precision ...................................................................................................... |

56 |

|

|

4.13 |

Tailstock sleeve ...................................................................................................................................... |

59 |

|

4.14 |

Clamping a workpiece into the three jaw chuck...................................................................................... |

59 |

|

4.15 |

Standard values for cutting data when turning ....................................................................................... |

60 |

|

4.16 |

Cutting speed table................................................................................................................................. |

61 |

|

4.17 |

Terms for the rotating tool....................................................................................................................... |

62 |

|

4.17.1 |

Cutting edge geometry for turning tools.................................................................................................. |

63 |

|

4.17.2 |

Types of cutting form levels .................................................................................................................... |

63 |

|

4.18 |

Tapping of external and internal threads ................................................................................................ |

65 |

|

4.19 |

Thread types........................................................................................................................................... |

67 |

|

4.19.1 |

Metric threads (60° flank angle).............................................................................................................. |

68 |

|

4.19.2 |

British thread (55° flank angle) ............................................................................................................... |

70 |

|

4.19.3 Indexable inserts..................................................................................................................................... |

71 |

|

|

4.19.4 Examples for thread cutting .................................................................................................................... |

72 |

|

|

4.20 |

Recessing, cutting off and turning off ..................................................................................................... |

74 |

5 |

Maintenance |

|

|

|

5.1 |

Safety...................................................................................................................................................... |

76 |

|

5.1.1 |

Preparation ............................................................................................................................................. |

76 |

|

5.1.2 |

Restarting ............................................................................................................................................... |

76 |

|

5.2 |

Inspection and maintenance................................................................................................................... |

77 |

|

5.3 |

Repair ..................................................................................................................................................... |

79 |

6 |

Ersatzteile - Spare parts TU2807 | TU2807V |

|

|

|

6.1 |

Oberschlitten - Top slide......................................................................................................................... |

80 |

|

6.2 |

PlanschlittenCross slide ....................................................................................................................... |

81 |

|

6.3 |

Bettschlitten - Bed slide .......................................................................................................................... |

82 |

|

6.4 |

Reitstock 2 - Tailstock 2.......................................................................................................................... |

83 |

|

6.5 |

Maschinenbett - Machine bed................................................................................................................. |

84 |

|

6.6 |

Vorschubgetriebe 1 von 2 - Feed gear 1 of 2 ......................................................................................... |

85 |

|

6.7 |

Vorschubgetriebe 2 von 2 - Feed gear 2 of 2 ......................................................................................... |

86 |

|

6.8 |

Spindelstock 1 von 2 - Headstock 1 of 2 ................................................................................................ |

87 |

|

6.9 |

Spindelstock 2 von 2 - Headstock 2 of 2 ................................................................................................ |

88 |

|

6.10 Spindelstock - Headstock TU 2807 V ..................................................................................................... |

89 |

|

|

6.11 |

Wechselradgetriebe - Change gear........................................................................................................ |

90 |

|

6.12 |

Ersatzteilliste - Spare parts list TU 2807................................................................................................. |

91 |

|

6.12.1 Ersatzteilliste TU 2807 V - Spare parts list TU 2807 V ........................................................................... |

96 |

|

|

6.13 Maschinenschilder - Machine labels TU 2807 ........................................................................................ |

97 |

|

|

6.13.1 Maschinenschilder - Machine labels TU 2807 ........................................................................................ |

97 |

|

|

6.14 Maschinenschilder - Machine labels TU 2807 V..................................................................................... |

98 |

|

|

6.14.1 Maschinenschilder - Machine labels TU 2807 V..................................................................................... |

98 |

|

7 |

Ersatzteile - Spare parts TU2506 | TU2506V |

|

|

|

7.1 |

Oberschlitten - Top slide......................................................................................................................... |

99 |

|

7.2 |

PlanschlittenCross slide ..................................................................................................................... |

100 |

|

7.3 |

Bettschlitten - Bed slide ........................................................................................................................ |

101 |

|

7.4 |

Ersatzteilzeichnung Reitstock - Tailstock ............................................................................................. |

102 |

|

7.5 |

Maschinenbett - Machine bed............................................................................................................... |

103 |

|

7.6 |

Vorschubgetriebe 1 von 2 - Feed gear 1 of 2 ....................................................................................... |

104 |

|

7.7 |

Vorschubgetriebe 2 von 2 - Feed gear 2 of 2 ....................................................................................... |

105 |

|

7.8 |

Spindelstock 1 von 2 - Headstock 1 of 2 .............................................................................................. |

106 |

|

7.9 |

Spindelstock 2 von 2 - Headstock 2 of 2 .............................................................................................. |

107 |

|

7.10 Spindelstock - Headstock TU 2506 V ................................................................................................... |

108 |

|

|

7.11 |

Wechselradgetriebe - Change gear...................................................................................................... |

109 |

|

7.12 |

Ersatzteilliste - Spare parts list TU2506................................................................................................ |

110 |

|

|

|

|

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

|

Page 4 |

|

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

|

OPTIMUM |

|

|

M A S C H I N E N - G E R M A N Y |

7.12.1 Ersatzteilliste TU 2506 V - Spare parts list TU 2506 V |

......................................................................... 116 |

|

7.13 |

Maschinenschilder - Machine labels TU 2506...................................................................................... |

117 |

7.13.1 |

Maschinenschilder - Machine labels TU 2506...................................................................................... |

117 |

7.14 |

Maschinenschilder - Machine labels TU 2506 V .................................................................................. |

118 |

7.14.1 |

Maschinenschilder - Machine labels TU2506V .................................................................................... |

118 |

8Malfunctions

9Schaltpläne - Wiring diagrams

9.1 |

Schaltplan - Wiring diagram TU 2506 - 230V...................................................................................... |

120 |

|

9.2 |

Schaltplan - Wiring diagram TU 2506 |

/ TU 2807 - 400V ...................................................................... |

121 |

9.3 |

Schaltplan - Wiring diagram TU 2506 |

V / TU 2807 V........................................................................... |

122 |

10 Appendix

10.1 |

Copyright .............................................................................................................................................. |

123 |

10.2 |

Terminology/Glossary .......................................................................................................................... |

123 |

10.3 |

Change information operating manual ................................................................................................. |

123 |

10.4 |

Product follow-up.................................................................................................................................. |

124 |

10.5 |

Liability claims for defects / warranty.................................................................................................... |

125 |

10.6 |

Note regarding disposal / options to reuse:.......................................................................................... |

125 |

10.6.1 |

Decommissioning ................................................................................................................................. |

126 |

10.6.2 |

Disposal of the packaging of new devices ........................................................................................... |

126 |

10.6.3 Disposing of the old device .................................................................................................................. |

126 |

|

10.6.4 Disposal of electrical and electronic components ................................................................................ |

126 |

|

10.6.5 Disposal of lubricants and coolants...................................................................................................... |

127 |

|

10.7 |

Disposal via municipal collection.......................................................................................................... |

127 |

10.8 |

RoHS , 2002/95/CE.............................................................................................................................. |

127 |

10.9 |

EC Declaration of Conformity TU2506 ................................................................................................. |

128 |

10.10 |

EC Declaration of Conformity TU2807 ................................................................................................. |

129 |

10.11 |

EC Declaration of Conformity TU2506V............................................................................................... |

130 |

10.12 |

EC Declaration of Conformity TU2807V............................................................................................... |

131 |

|

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 5 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

Preface

Dear customer,

Thank you very much for purchasing a product made by OPTIMUM.

OPTIMUM metal working machines offer a maximum of quality, technically optimum solutions and convince by an outstanding price performance ratio. Continuous enhancements and product innovations guarantee state-of-the-art products and safety at any time.

Before commissioning the machine please thoroughly read these operating instructions and get familiar with the machine. Please also make sure that all persons operating the machine have read and understood the operating instructions beforehand.

Keep these operating instructions in a safe place nearby the machine.

Information

The operating instructions include indications for safety-relevant and proper installation, operation and maintenance of the machine. The continuous observance of all notes included in this manual guarantee the safety of persons and of the machine.

The manual determines the intended use of the machine and includes all necessary information for its economic operation as well as its long service life.

In the paragraph "Maintenance" all maintenance works and functional tests are described which the operator must perform in regular intervals.

The illustration and information included in the present manual can possibly deviate from the current state of construction of your machine. Being the manufacturer we are continuously seeking for improvements and renewal of the products. Therefore, changes might be performed without prior notice. The illustrations of the machine may be different from the illustrations in these instructions with regard to a few details. However, this does not have any influence on the operability of the machine.

Therefore, no claims may be derived from the indications and descriptions. Changes and errors are reserved!

Your suggestion with regard to these operating instructions are an important contribution to optimising our work which we offer to our customers. For any questions or suggestions for improvement, please do not hesitate to contact our service department.

If you have any further questions after reading these operating instructions and you are not able to solve your problem with a help of these operating instructions, please contact your specialised dealer or directly the company OPTIMUM.

Optimum Maschinen Germany GmbH Dr.- Robert - Pfleger - Str. 26 D-96103 Hallstadt

Mail: info@optimum-maschinen.de Internet: www.optimum-maschinen.com

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Page 6 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

1 Safety

Glossary of symbols

gives further advice

calls on you to act

enumeration

This part of the operating manual

does explain the meaning and how to use the warning references contained in this operating manual,

defines the intended use of the lathe,

points out the dangers that might arise for you or others if these instructions are not observed,

informs you about how to avoid dangers.

In addition to this operating manual, please note

the applicable laws and regulations,

the legal regulations for accident prevention.

the prohibition, warning and mandatory signs as well as the warning notes on the lathe.

European standards must be kept during installation, operation, maintenance and repair of the lathe.

If European standards are not applied at the national legislation of the country of destination, the specific applicable regulations of each country are to be observed.

If necessary, the required measures must be taken to comply with the specific regulations of each country before the lathe is used for the first time.

ALWAYS KEEP THIS DOCUMENTATION CLOSE TO THE LATHE.

INFORMATION

If you are unable to solve a problem using these operating instructions, please contact us for advice:

Optimum Maschinen Germany GmbH Dr. Robert-Pfleger-Str. 26

D- 96103 Hallstadt

Email: info@optimum-maschinen.de

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 7 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.1Safety warnings (warning notes)

1.1.1 Classification of hazards

We classify the safety warnings into various levels. The table below gives an overview of the classification of symbols (ideogram) and the warning signs for each specific danger and its (possible) consequences.

Ideogram |

Warning alert |

|

Definition / consequence |

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

DANGER! |

Threatening danger that will cause serious injury or death to people. |

||||

|

|

|

|

|

||

|

WARNING! |

A danger that might cause severe injury to the staff or can lead to death. |

||||

|

|

|

|

|

||

|

CAUTION! |

Danger or unsafe procedure that might cause injury to people or damage |

||||

|

to property. |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Situation that could cause damage to the machine and product and other |

||

|

ATTENTION! |

types of damage. |

|

|

||

|

No risk of injury to people. |

|

||||

|

|

|

|

|

||

|

|

|

|

Application tips and other important or useful information and notes. |

||

|

INFORMATION |

No dangerous or harmful consequences for people or objects. |

||||

|

|

|

|

|||

|

|

|

|

|

|

|

In case of specific dangers, we replace the pictogram by |

|

|

||||

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

general danger |

with a warning of |

injuries to hands, |

hazardous electri- |

rotating parts. |

||

|

|

|

|

|

cal voltage, |

|

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 8 |

|

Original operating instructions |

Version 1.0.1 2013-10-31 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.1.2 Other pictograms

Caution slide risk! |

Activation forbidden! |

Pull the main plug! |

Use safety glasses! |

Use ear protection! |

|

|

|

protection |

|

Use protective |

Use protective |

Wear a safety suit! |

Protect the environ- |

Contact address |

gloves! |

boots! |

|

ment! |

|

1.2Intended use

WARNING!

In the event of improper use, the lathe

will endanger personnel,

will endanger the machine and other material property of the operator,

the correct function of the machine may be affected.

The machine is designed and manufactured to be used in environments where there is no potential danger of explosion.

The lathe is designed and manufactured for straight turning and facing round and regular formed three-, sixor twelve-square workpieces in cold metal, castings and plastics or similar materials that do not constitute a health hazard or do not create dust, such as wood, Teflon®.

The lathe must only be installed and operated in a dry and ventilated place. The clamping workpieces in the feed may only be effected with the supplied the special key for chucks.

If the lathe is used in any way other than described above, modified without authorization of Optimum Maschinen Germany GmbH, then the lathe is being used improperly.

We do not take liability for damage caused through improper use.

We would like to stress that any modifications to the construction, or technical or technological modifications that have not been authorized by Optimum Maschinen Germany GmbH will also render the guarantee null and void.

It is also part of proper use that

the operating manual is constantly observed,

inspection and maintenance instructions are observed.

observe the limits of the lathe,

"Technical data“ on page 19

In order to achieve optimum cutting performance, it is essential to choose the right turning tool, feed, tool pressure, cutting speed and coolant.

"Standard values for cutting data when turning“ on page 60

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 9 |

OPTIMUM

M A S C H I N E N - G E R M A N Y

WARNING!

Very serious injury due to improper use.

It is forbidden to make any modifications or alternations to the operation values of the lathe. They could endanger employees and cause damage to the lathe.

INFORMATION

The TU2506V and TU2807V is built according to the standard DIN EN 55011 class A.

WARNING!

The class A (machine tools) is not intended to be used in residential facilities, where the power is supplied via a public low voltage supply system. In these areas it may possibly be difficult to guarantee electromagnetic compatibility due to lead bound aswell as emitted interferences.

ATTENTION!

If the lathe is not used as intended or if the safety directives or the operating instructions are ignored the liability of the manufacturer for any damages to persons or objects resulting hereof is excluded and the claim under guarantee is becoming null and void!

1.3Reasonably foreseeable misuse

Any other use as the one determined under the "Intended use" or any use beyond the described use shall be deemed as not in conformity and is forbidden.

If it is intended to use the device in any other way as described above, it is necessary to consult the manufacturer.

It is only allowed to process metal, cold and non-inflammable materials with the lathe.

In order to avoid misuse, it is necessary to read and understand the operating instructions before the first commissioning.

The operators must be qualified.

1.3.1 Avoiding misuse

Using suitable cutting tools.

Adapting speed settings and feed on the material and on the workpiece.

Clamp the workpiece firmly and vibration-free.

1.4Possible dangers caused by the machine

The lathe has undergone a safety inspection (analysis of danger with assessment of risks). It has been designed and built on the basis of this analysis using the latest technological advances.

Nonetheless, there remains a residual risk, since the machine operates with

high revolutions,

rotating parts,

with electrical voltages and currents.

We have used construction resources and safety techniques to minimize the health risk to persons resulting from these hazards.

If the lathe is used and maintained by the staff who are not duly qualified, there may be a risk resulting from incorrect or unsuitable maintenance of the lathe.

INFORMATION

All staff involved in assembly, commissioning, operation and maintenance, must

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 10 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

be duly qualified,

strictly follow this operating manual.

Always disconnect the machine if cleaning or maintenance work is being carried out.

WARNING !

The lathe may only be used with the safety devices activated.

Disconnect the lathe immediately whenever you detect a failure in the safety devices or when they are not mounted!

All additional installations carried out by the operator must incorporate the prescribed safety devices.

This is your responsibility being the operating company!"Safety measures during operation“ on page 13

1.5Qualification of the staff

1.5.1 Target group

This manual is addressed to

the operating companies,

the users,

the staff for maintenance works.

Therefore, the warning notes refer to both operation and maintenance of the machine.

Always disconnect the machine plug from the mains. This will prevent it from being used by unauthorized persons.

INFORMATION

All staff involved in assembly, commissioning, operation and maintenance, must

be duly qualified,

strictly follow this operating manual.

In the event of intended use

there is a risk for the employee,

the lathe and further property might be endangered,

the correct function of the lathe may be affected.

The qualifications of the staff for the different tasks are mentioned below:

Operator

The operator is instructed by the operating company about the assigned tasks and possible risks in case of improper behaviour. Any tasks which need to be performed beyond the operation in the standard mode must only be performed by the operator if it is indicated in these instructions and if the operating company expressively commissioned the operator.

Electrical specialist

Due to his professional training, knowledge and experience as well as his knowledge of respective standards and regulations the electrical specialist is able to perform works on the electrical system and to recognise and avoid any possible dangers himself.

The electrical specialist is specially trained for the working environment in which he is working and knows the relevant standards and regulations.

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 11 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

Specialist staff

Due to his professional training, knowledge and experience as well as his knowledge of relevant regulations the specialist staff is able to perform the assigned tasks and to recognise and avoid any possible dangers himself.

Instructed persons

Instructed persons were instructed by the operating company about the assigned tasks and any possible risks in case of improper behaviour.

1.5.2 Authorized persons

WARNING!

Inappropriate operation and maintenance of the machine constitutes a danger for the staff, objects and the environment.

Only authorized staff may operate the machine!

Persons authorized to operate and maintain should be trained technical staff and instructed by the ones who are working for the operating company and for the manufacturer.

1.5.3 Obligations of the operating company

The operator must instruct the staff at least once per year regarding

all safety standards that apply to the machine.

the operation,

accredited technical guidelines. The operator must also

check the knowledge of the staff,

document the trainings/instructions,

require staff to confirm participation in training/instructions by means of a signature,

check if the staff is aware of safety rules and dangers in the workplace and that they observe the operating manual.

1.5.4 Obligations of the operator

The operator must

have read and understood the operating manual,

be familiar with all safety devices and regulations,

be able to operate the machine.

1.5.5 Additional requirements regarding the qualification

For work on electrical components or equipment, there are additional requirements:

Must only be performed by a qualified electrician or person working under the instructions and supervision of a qualifiedelectrician.

Before carrying out work on electrical components or operating units, the following measures must be taken, in the order given.

disconnect all poles.

ensure that the lathe cannot be turned on again,

check that there is no voltage.

1.6Operator positions

The operator’s position is in front of the machine.

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 12 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.7Safety measures during operation

CAUTION!

Risk due to inhaling of health hazardous dusts and mist.

Dependent on the material which need to be processed and the used auxiliaries dusts and mist may be caused which might impair you health.

Make sure that the generated health hazardous dusts and mist are safely sucked off at the point of origin and is dissipated or filtered from the working area. To do so, use a suitable extraction unit.

CAUTION!

Risk of fire and explosion by using flammable materials or cooling lubricants.

Before processing inflammable materials (e.g. aluminium, magnesium) or using inflammable auxiliary materials (e.g. spirit) it is necessary to take additional preventive measures in order to safely avoid health risks.

CAUTION!

Risk of winding-up or cutting damages when using hand tools.

The machine is not designed for the use of hand tools (e.g. emery cloth or files). It is forbidden to use any hand tools on this machine.

1.8Safety devices

Use the lathe only with properly functioning safety devices.

Stop the lathe immediately if there is a failure on the safety device or if it is not functioning for any reason.

It is your responsibility!

If a safety device has been activated or has failed, the lathe must only be used if you

the cause of the failure has been removed,

you have made sure that there is no existing danger for persons or objects.

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 13 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

WARNING!

If you bypass, remove or override a safety device in any other way, you are endangering yourself and other persons working on the machine. The possible consequences are

injuries due to components or parts of components flying off at high speed,

contact with rotating parts,

fatal electrocution,

WARNING!

The separating protective equipment which is made available and delivered together with the machine is designed to reduce the risk of workpieces or fractions of them which being expelled, but not to remove them completely. Always work carefully and observe the limits of their machining process.

The lathe includes the following safety devices:

a EMERGENCY STOP button

a protective cover on the headstock,

a special key for the lathe chuck,

a lathe chuck protection with position switch.

1.9EMERGENCY-STOP button

The EMERGENCY-STOP button switches the lathe off.

Knocking on the emergency stop device triggers an emergency stop.

After actuating the switch, turn it to the right, in order to restart the lathe.

EMERGENCYSTOP button TU 2506, TU 2807

EMERGENCYSTOP button

TU 2506 V,

TU 2807 V

Img.1-1: EMERGENCY-STOP button

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 14 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.9.1 Lockable main switch (only TU 2506V, TU2807V)

In the position "0", the lockable main |

|

switch can be secured against accidental |

|

or non-authorized switching-on by means |

Main switch |

of a padlock. |

|

When the main switch is switched off, the |

|

power supply to the machine is com- |

|

pletely interrupted. |

|

Img.1-2: Lockable main switch

1.9.2 Protective cover with safety switch

The headstock of the lathe is equipped with a fixed, separating protective cover.

The locked position is monitored by means of an electrical limit switch.

INFORMATION

It is not possible to start the machine until the protective cover is closed.

integrated  position switch

position switch

Protective cover

Img.1-3: for the protective cover of the headstock

1.9.3 Lathe chuck protection with position switch

The lathe is provided with a lathe chuck protection. The lathe can only be switched on if the lathe chuck protection is closed.

Lathe chuck pro- tection

tection

closed

Lathe chuck pro-  tection

tection

open

integrated position switch

Img.1-4: Lathe chuck protection

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 15 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.9.4 Lathe chuck key

The lathe is equipped with a special key for chucks. Once the lathe chuck key has been released, it is pushed out of the lathe chuck by a spring.

CAUTION!

Only operate the lathe using this key.

Safety lathe chuck key

Lathe chuck key

Img.1-5: Lathe chuck key

1.10 Safety check

Check the lathe regularly. Check all safety devices

before starting work,

once a week,

after every maintenance and repair work.

General check

Equipment |

Check |

OK |

|

|

|

|

|

|

Protective covers, |

Mounted, firmly bolted and not damaged |

|

lathe chuck protection |

|

|

|

|

|

|

|

|

Signs, markings |

installed and legible |

|

|

|

|

|

|

|

Functional check |

|

|

|

|

|

Equipment |

Check |

OK |

|

|

|

|

|

|

EMERGENCY-STOP but- |

When the EMERGENCY STOP push button is activated, the lathe must |

|

ton |

switch off. |

|

|

|

|

Lathe chuck key |

Once the chuck key has been released, it should be automatically pressed |

|

|

out of the lathe chuck. |

|

|

|

|

Lathe chuck protection / |

The lathe shall only run with the lathe chuck protection / protective cover |

|

protective cover head- |

headstock closed. |

|

stock |

|

|

|

|

|

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 16 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.11Personnel protective equipment

For certain work personal protective equipment is required.

Protect your face and your eyes: Wear a safety helmet with facial protection when performing works where your face and eyes are exposed to hazards.

Use protective gloves when handling pieces with sharp edges.

During operation of the lathe, the wearing of gloves is prohibited because of the risk of winding up.

Use safety shoes when you assemble, disassemble or transport heavy components.

Use ear protection if the noise level (emission) in the workplace exceeds 80 dB (A).

Before starting work, make sure that the prescribed personal protective equipment is available at the workplace.

CAUTION!

Dirty or contaminated personnel protective equipment can cause diseases.

Clean it each time after use and once a week.

1.12For your own safety during operation

WARNING!

Before activating the machine assure yourself that this will neither endanger other persons nor cause damage to equipment.

Avoid any risky working practices:

Make sure, your work does not endanger anyone.

Clamp the workpiece tightly before activating the lathe.

For clamping workpieces, only use the special chuck key supplied.

Mind the maximum chuck opening.

Wear safety goggles.

Do not remove the turning chips by hand. Use a chip hook and / or a hand brush to remove turning chips.

Clamp the turning tool at the correct height and with the least possible overhang.

Turn off the lathe before measuring the workpiece.

The instructions mentioned in these operating instructions have to be strictly observed during assembly, operation, maintenance and repair.

Do not work on the lathe, if your concentration is reduced, for example, because you are taking medication.

Observe the accident prevention regulations issued by your Employers Liability Insurance Association or other competent supervisory authority, responsible for your company.

Stay at the lathe until all movements have come to a complete standstill.

Use the prescribed personnel protective equipment. Make sure to wear a well-fitting work suit and, if necessary, a hairnet.

We specially point out the specific dangers when working with and on the machine.

1.13Disconnecting and securing the lathe

Pull the mains plug before beginning any maintenance or repair work or or switch off the supply voltage to the lathe. All machine components and hazardous voltages and movements are disconnected.

Secure the machine using a padlock on the lockable main switch (only TU2506 / TU2807 Vario).

Attach a warning sign on the machine.

Safety |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 17 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

1.14Using lifting equipment

WARNING!

The use of unstable lifting and load suspension gear that might break under load can cause severe injuries or even death.

Check that the lifting equipment and load-suspension gears are of sufficient load capacity and are in perfect condition.

Observe the accident prevention regulations issued by your Employers Liability Insurance Association or other competent supervisory authority, responsible for your company.

Fasten the loads properly.

Never walk under suspended loads!

1.15Mechanical maintenance work

Remove or install protection safety devices before starting any maintenance work and re-install them once the work has been completed.This includes:

covers,

safety indications and warning signs,

earth (ground) connections.

If you remove protection or safety devices, refit them immediately after completing the work. Check if they are working properly!

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Safety |

Page 18 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

2 Technical data

The following information are the dimensions and indications of weight and the manufacturer‘s approved machine data.

2.1 |

Electrical connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TU2506 |

|

|

TU2807 |

|

|

|

|

|

|

|

|

230V 750 W ~ 50 Hz |

|

230V |

850 W ~ 50 Hz |

|

|

|

|

|

|

|

Connection |

|

or |

|

|

|

|

|

|

|

|

|

400V 750 W ~ 50 Hz |

|

400V |

850 W ~ 50 Hz |

|

|

|

|

|||

|

|

|

|

|

|

|

|

TU2506V |

|

|

TU2807V |

|

|

|

|

|

|

|

|

230V 1.2 kW ~ 50 Hz |

|

230V 1.5 kW ~ 50 Hz |

|

|

|

|

|

|

|

2.2 |

Machine data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TU2506 |

|

|

|

|

|

|

|

|

TU2807 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Spindle speeds [min -1] |

|

|

125 - 2000 |

|

|

|

|

|

|

|

|

150 - 2000 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TU2506V |

|

|

|

|

|

|

|

|

TU2807V |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

30 - 4000 |

|

|

|

|

|

|

|

|

30 - 4000 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Spindle taper |

|

|

|

|

|

|

|

|

MT4 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spindle hole, rod opening [mm] |

|

|

|

|

|

|

|

|

|

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bed width [mm] |

|

|

|

135 |

|

|

|

|

|

|

|

|

|

|

180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Travel of top slide [mm] |

|

|

|

70 |

|

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Travel of cross slide [mm] |

|

|

|

110 |

|

|

|

|

|

|

|

|

|

|

160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Tailstock cone |

|

|

|

|

|

|

|

|

MT2 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tailstock sleeve travel [mm] |

|

|

|

65 |

|

|

|

|

|

|

|

|

|

|

85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Longitudinal feed [mm/rev] |

|

|

|

0.07 |

0.10 |

0.14 |

0.20 |

0.28 |

0.4 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

Pitch - Metric [mm/rev] |

|

0.2 |

0.3 |

0.4 |

0.5 |

0.6 |

0.62 |

0.75 |

|

0.8 |

0.88 |

1.0 |

1.2 |

|||||||

|

|

|

|

1.25 |

1.5 |

|

1.75 |

2.0 |

2.5 |

3.0 |

3.5 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Pitch - inch [threads/inch] |

8 |

9 |

9.5 |

10 |

11 |

12 |

|

14 |

16 |

|

18 |

19 |

20 |

22 |

24 |

28 |

36 |

|||

|

|

|

|

|

|

38 |

40 |

44 |

58 |

56 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.3 |

Working area |

|

|

|

|

|

|

|

|

|

|

|

|

TU2506 |

TU2807 |

|

|

|

|

|

|

TU2506V |

TU2807V |

|

|

|

|

|

Height [mm] |

2000 |

2000 |

|

|

|

|

|

Length [mm] |

2200 |

2200 |

|

|

|

|

|

Depth [mm] |

1900 |

1900 |

|

|

|

|

Technical data |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 19 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

2.4 |

Environmental conditions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TU2506 (V) |

|

TU2807 (V) |

|

|

|

|

|

|

Temperature |

|

5 - 35 °C |

|

|

|

|

|

|

|

Humidity |

|

25 - 80 % |

|

|

|

|

|

|

2.5 |

Operating material |

|

|

|

|

|

|

|

|

|

|

|

|

TU2506 (V) |

TU2807 (V) |

|

|

|

|

|

Feed gear |

Mobilgear 627 or a comparable oil |

|

|

|

|

|

|

bright steel parts, guideways, oiler |

e.g. machines oil (Mobil Oil, Fina, ...) |

|

|

|

We recommend the use of weapon oil, weapon oil is acid-, |

|

|

|

stainand resin-free. |

|

|

|

|

|

|

Change gears |

Chain oil (spray box) |

|

|

|

|

|

2.6Emissions

The generation of noise emitted by the lathe is less than 80 dB(A).

INFORMATION

This numerical value was measured on a new machine under proper operating conditions. Depending on the age respectively on the wear of the machine it is possible that the noise behaviour of the machine changes.

Furthermore, the factor of the noise emission is also depending on manufacturing influencing factors, e.g. speed, material and clamping conditions.

INFORMATION

The mentioned numerical value is the emission level and not necessarily a safe working level.

Though there is a dependency between the degree of the noise emission and the degree of the noise disturbance it is not possible to use it reliably to determine if further precaution measures are required or not.

The following factors influence the actual degree of the noise exposure of the operator:

Characteristics of the working area, e.g. size or damping behaviour,

Other noise sources, e.g. the number of machines,

Other processes taking place in the proximity and the period of time during which the operator is exposed to the noise.

Furthermore, it is possible that the admissible exposure level might be different from country to country due to national regulations.

This information about the noise emission shall allow the operator of the machine to more easily evaluate the endangering and risks.

CAUTION!

Depending on the overall noise exposure and the basic limit values the machine operators must wear an appropriate hearing protection.

We generally recommend to use a noise protection and a hearing protection.

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Technical data |

Page 20 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

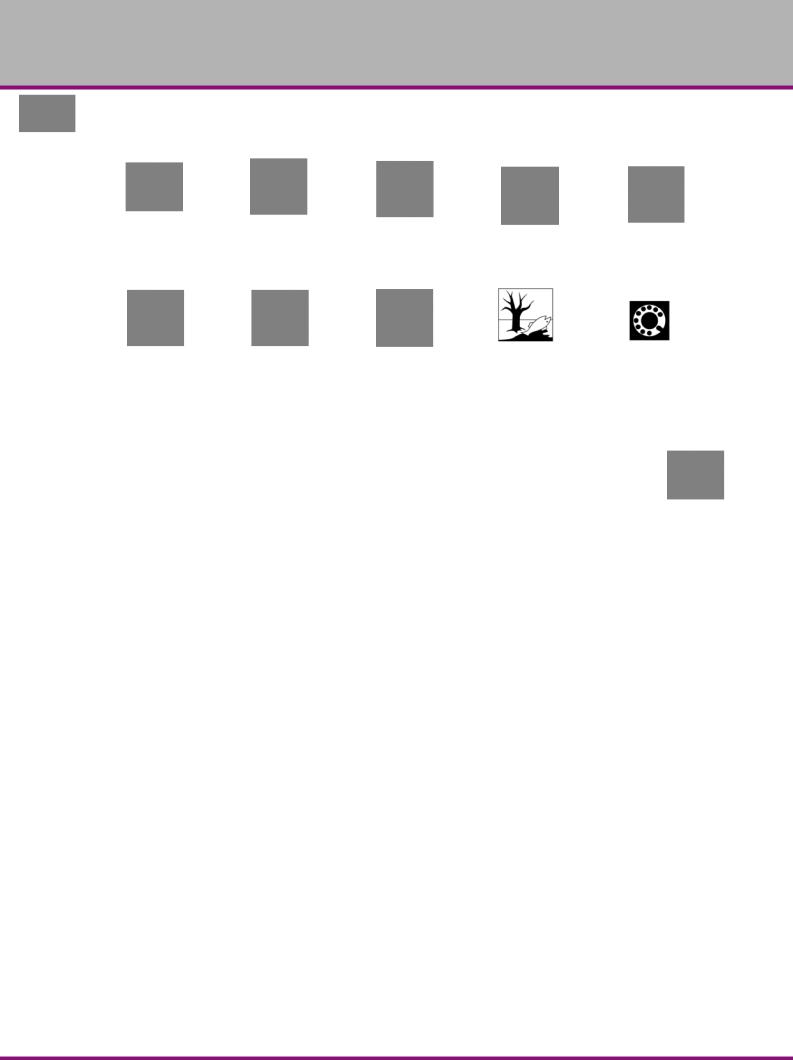

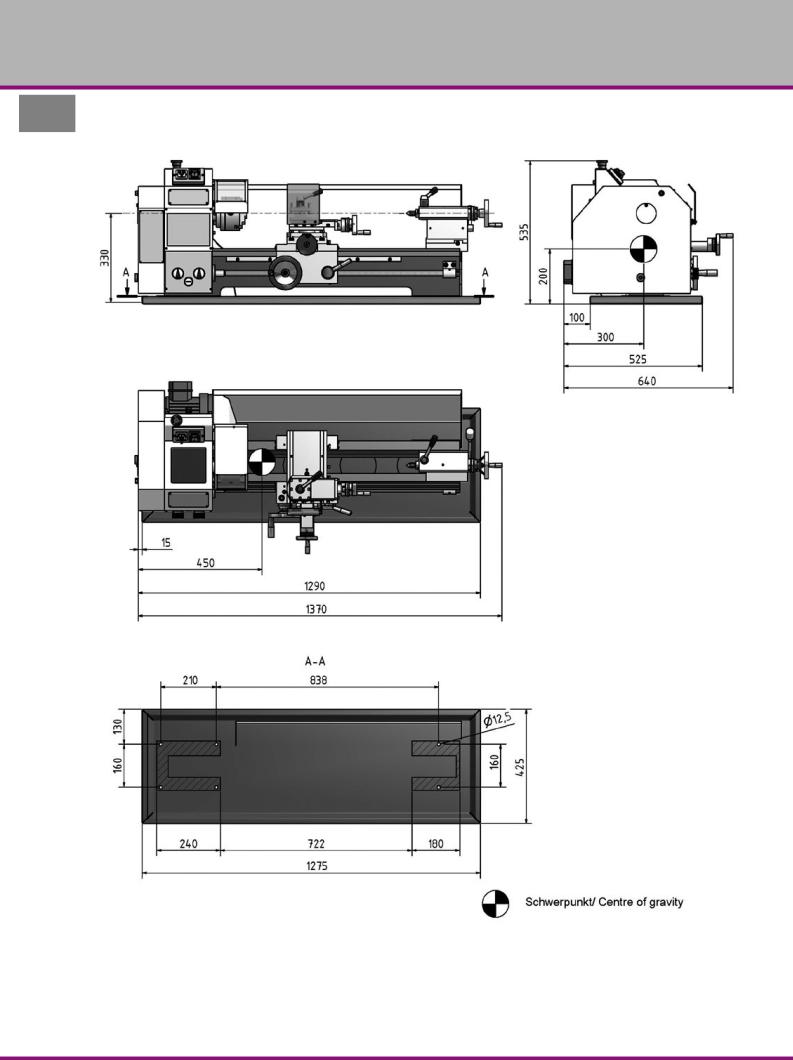

2.7Dimensions, installation plan TU2506

Img.2-1: Dimensions, installation plan TU2506

Technical data |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 21 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

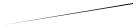

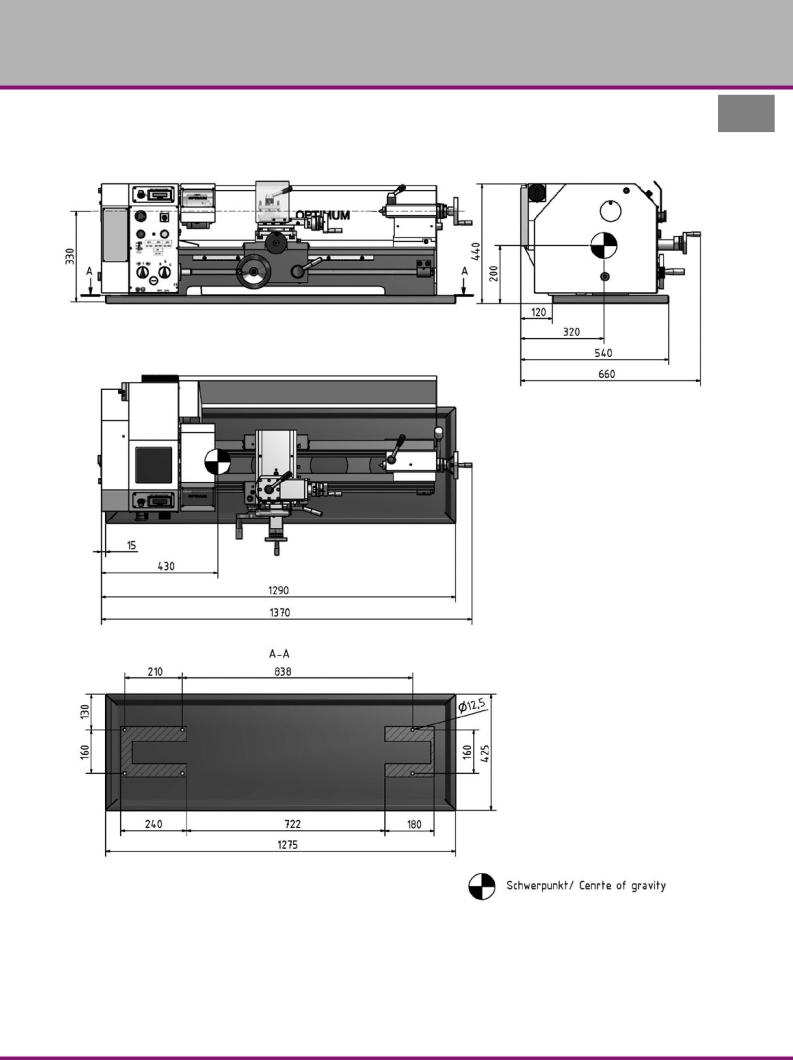

2.8Dimensions, installation plan TU2506V

Img.2-2: Dimensions, installation plan TU2506V

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Technical data |

Page 22 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

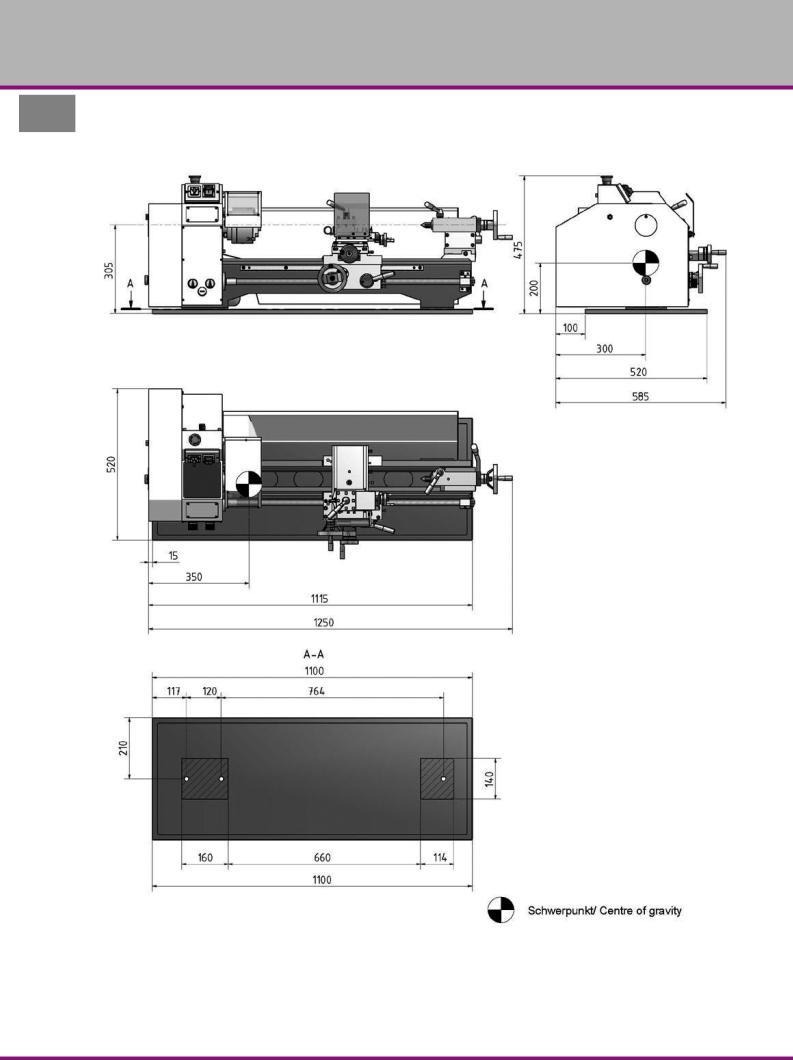

2.9Dimensions, installation plan TU2807

Img.2-3: Dimensions, installation plan TU2807

Technical data |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 23 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

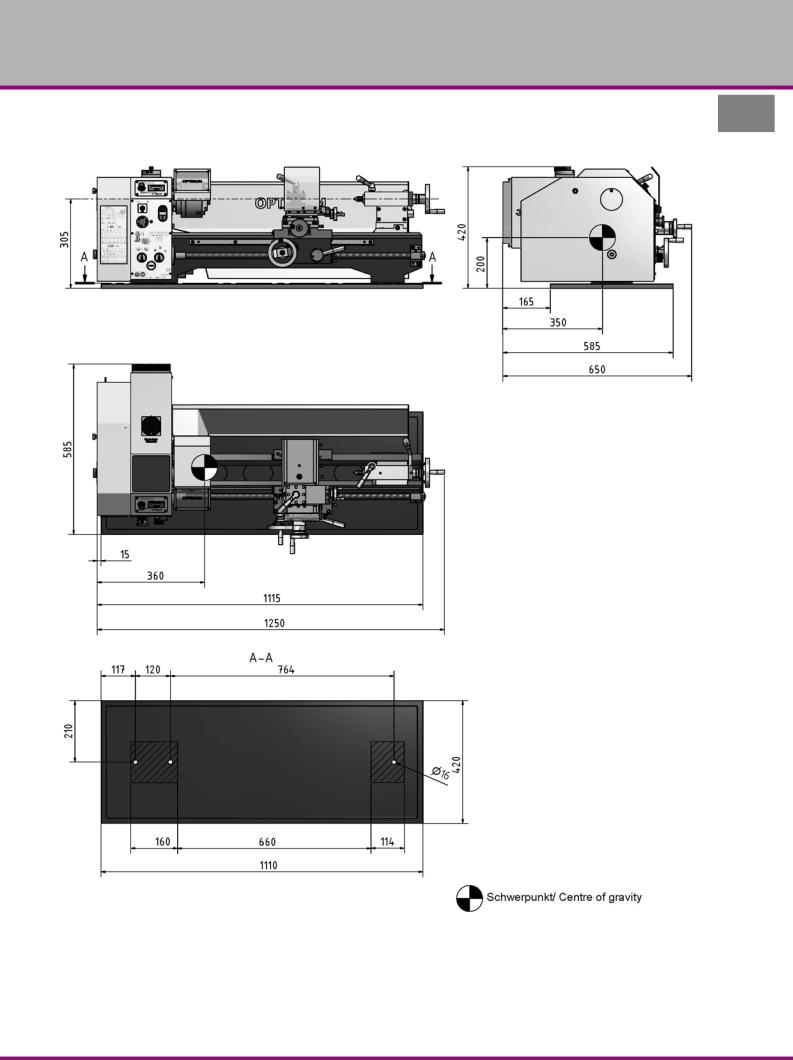

2.10Dimensions, installation plan TU2807V

Img.2-4: Dimensions, installation plan TU2807V

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Technical data |

Page 24 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

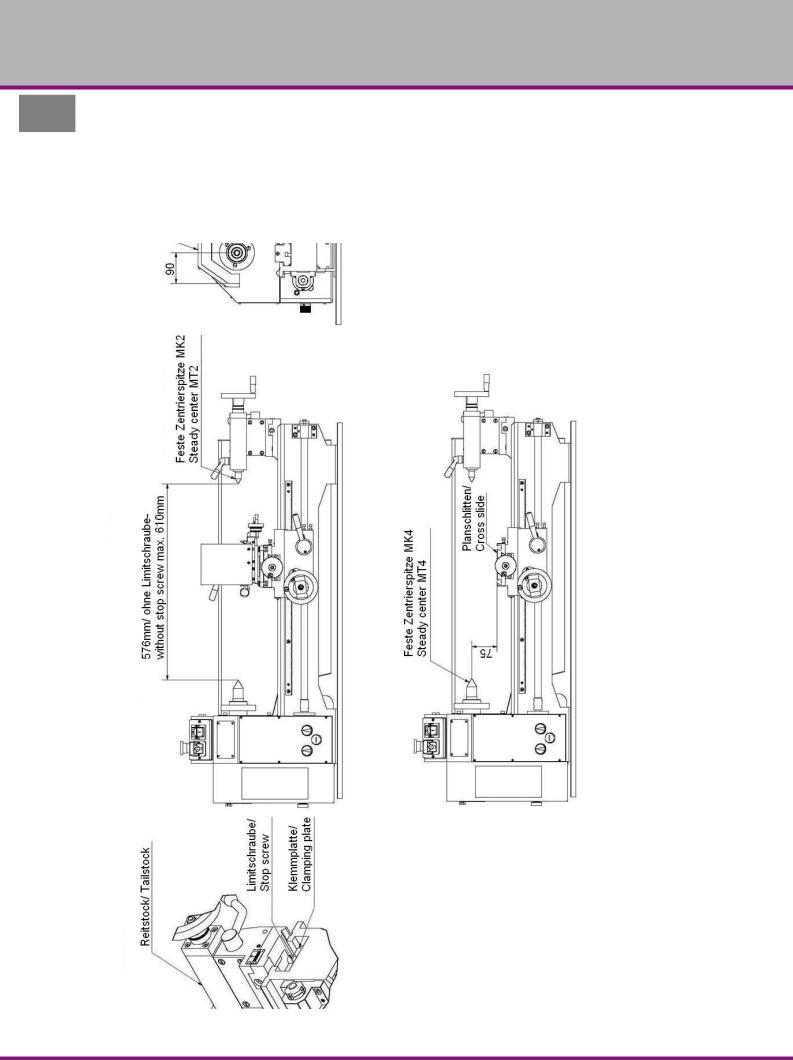

2.11Distance between centres, height of centres TU2506, TU2506V

Img.2-5: Distance between centres, height of centres TU2506, TU2506V

Technical data |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 25 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

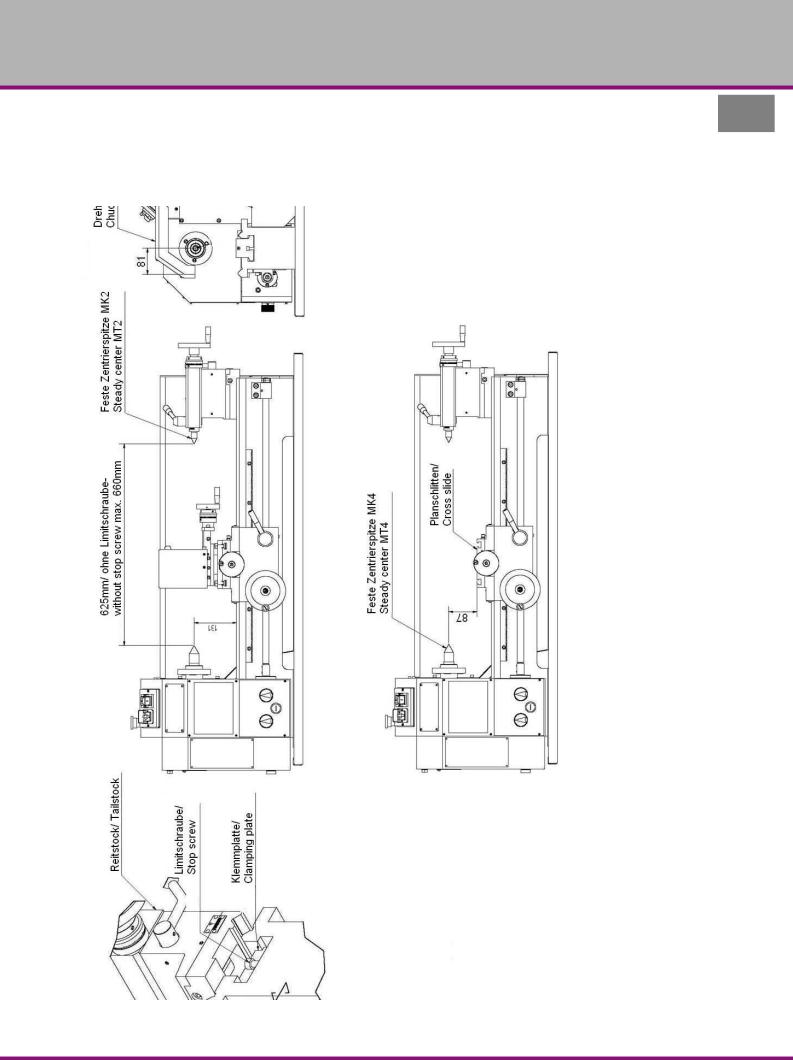

2.12Distance between centres, height of centres TU2807, TU2807V

Img.2-6: Distance between centres, height of centres TU2807, TU2807V

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Technical data |

Page 26 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

3 Assembly

INFORMATION

The lathe is delivered pre-assembled.

3.1Scope of delivery

When the lathe is delivered, please check immediately that it has not been damaged during transport. Also check that no fastening screws have come loose.

Compare the scope of delivery with the attached packing list.

3.2Transport

Centres of gravity

Load suspension point (Marking of the positions for the load suspension gear)

Prescribed transportation position (Marking of the top surface)

Means of transport to be used

Weights

WARNING!

Severe or fatal injuries may occur if parts of the machine tumble or fall down from the forklift truck or from the transport vehicle. Follow the instructions and information on the transport case.

WARNING!

The use of unstable lifting and load suspension gear that might break under load can cause severe injuries or even death.

Check that the lifting and load suspension gear has sufficient load capacity and that it is in perfect condition. Observe the accident prevention regulations issued by your Employers Liability Insurance Association or other competent supervisory authority, responsible for your company.

Fasten the loads properly. Never walk under suspended loads!

Assembly |

TU2506 | TU2506V | TU2807 | TU2807V |

GB |

|

Version 1.0.1 2013-10-31 |

Original operating instructions |

Page 27 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

3.3Storage

ATTENTION!

In case of wrong and improper storage electrical and mechanical machine components might get damaged and destroyed.

Store packed and unpacked parts only under the intended environmental conditions. Follow the instructions and information on the transport case:

Fragile goods

(Goods require careful handling)

Protect against moisture and humid environment"Environmental conditions“ on page 20.

Prescribed position of the packing case

(Marking of the top surface - arrows pointing to the top)

Maximum stacking height

Example:not stackable - do not stack a second packing case

on top of the first packaging case

Consult Optimum Maschinen Germany GmbH if the machine and accessories are stored for more than three months or are stored under different environmental conditions than those given here .

GB |

TU2506 | TU2506V | TU2807 | TU2807V |

|

Assembly |

Page 28 |

Original operating instructions |

Version 1.0.1 2013-10-31 |

|

OPTIMUM

M A S C H I N E N - G E R M A N Y

3.4Installation and assembly

3.4.1 Requirements to the installation site

ATTENTION!

Before you install the machine let the capacity of the floor loading check by an expert. The floor or ceiling of the hall must carry the weight of the machine plus any additional parts and auxiliary equipment, as well as operator and stockpiled materials. If necessary, the floor must strengthened.

INFORMATION

In order to attain good functionality and a high processing accuracy as well as a long durability of the machine the installation site should fulfil certain criteria.

Please observe the following points:

The device must only be installed and operated in a dry and well-ventilated place.

Avoid places nearby machines generating chips or dust.

The installation site must be free from vibrations also at a distance of presses, planing machines, etc.