Page 1

OP-900 SERIES INDICATOR

USER’S MANUAL

(OP-900A, OP-900B Series)

optimascale.com

Page 2

TABLE OF CONTENTS

Safety Precautions 1

Preparations and Set Up 1

Features 2

Specications 3

Power Supply 4

Displays 5

Display and Key Descriptions 6

Operating Instructions 7

Calibration 9

Indicator Parameter Settings 11

Connectors 16

RS232 Serial Output Format 18

4-20 mA Analog Output 22

Relay Output 23

Troubleshooting 24

Q&A 25

Contact Us 26

Page 3

SAFETY PRECAUTIONS

For safe operation of the weighing indicator, please follow these

instructions:

● Calibration inspection and maintenance of the indicator are prohibited by non-pro-

fessional staff

● Please ensure that the indicator rests on a stable surface

● The indicator is a piece of static sensitive equipment; Please cut off power during

electrical connections

● Touching the internal components by hand is prohibited

● DO NOT exceed the rated load limit of the unit

● DO NOT step on the unit

● DO NOT jump on the scale

● DO NOT use this product if any of the components are cracked

● DO NOT use for purposes other then weight taking

● To avoid damaging the battery do not keep charger plugged in once battery is fully

charged

● Make sure the weight is not over the Max capacity as it could damage the load cell

inside

● Material that has a static electric charge could inuence the weighing. Discharge

the static electricity of the samples, if possible. Another

solution to the problem is to wipe both sides of the pan and the top of the case with

an anti-static agent

Please take anti-static prevention measures

Any accumulated charge on the body of the human operator should be discharged rst

before opening the protective container with ESDS devices inside. The discharge can

be accomplished by:

● Putting a hand on a grounded surface or, ideally, by wearing a grounded Anti-static

Wrist Strap and an Anti-static Mat

PREPARATION & SET UP

● Plug into a wall outlet to avoid interference with other wirings

● Turn on the balance while there is no load

● We suggest to warm-up the balance by powering on 5 minutes before use for

accurate weighing

● Calibration may be required before weighing when the balance is initially installed

or moved from a location

Page 4

FEATURES

● Multiple weighing units: (kg/g/lb/oz/lb:oz)

● Gross/Tare/Zero

● Count weighing

● Accumulation weighing

● Overload / Underload indication

● Print

● Splash proof keyboard and display

● Can connect to a secondary large display/scoreboard

● Relay output (optional)

● 4-20mA analog output (optional)

● Can connect to a PC or printer for data logging (optional)

● Wireless capability (optional)

Indicator Model Options

The OP-900 series consists of the OP-900A (LED) series and OP-900B (LCD)

series. Options for rechargeable battery, stainless steel enclosure, computer connection,

relay output and analog output can be added.

Please contact sales@optimascale.com for a list of possible options.

Technical Parameters

● Accuracy class: 5000 e

● Resolution - Display: 30,000 ; ADC: 2,000,000

● Zero stability error: TK0 < 0.1μV//K

● Span stability error: TKspn < ± 6 ppm//K

● Sensitivity (internal): 0.3 μV / d

● Input voltage: -30 to +30mV DC

● Excitation circuit: 5 VDC, 4 wire connection, 6 load cell of 350ohm max

● AC power: AC 100-250V (use only the included 9V adapter supplied)

● Operation temperature: -10 °C ~ +40 °C

● Operation humidity: ≤90%RH

● Storage temperature: -40 °C ~ +70 °C (32-104°F)

Page 5

SPECIFICATIONS

FIGURE 1: INDICATOR MEASUREMENTS

Page 6

POWER SUPPLY

AC Adapter

If the indicator is powered by an adapter, plug the adapter directly into the “DC” pin

located at the bottom of the indicator. We recommend to plug into a wall outlet to avoid

interference with other wirings.

Battery (Optional)

If you have an indicator with the rechargeable battery option, please charge the

internal battery fully before rst time use. A 110 to 220V AC adapter should be

provided with your indicator. Please use only the AC adapter provided to prevent damage to your indicator. To keep the battery in best condition, fully discharge the battery

every month by leaving the indicator on until the indicator powers off, and then recharge

fully. If the battery is not going to be used for a long period of time it is recommended to

remove it to avoid leakage.

On OP-900A

● When the Battery is low the battery indicator light ashes red

● During charging the red light will stay lit

● The light will turn green once fully charged

ON OP-900B

●

●

symbol will indicate battery’s charge

symbol indicates that the battery needs to be charged

Page 7

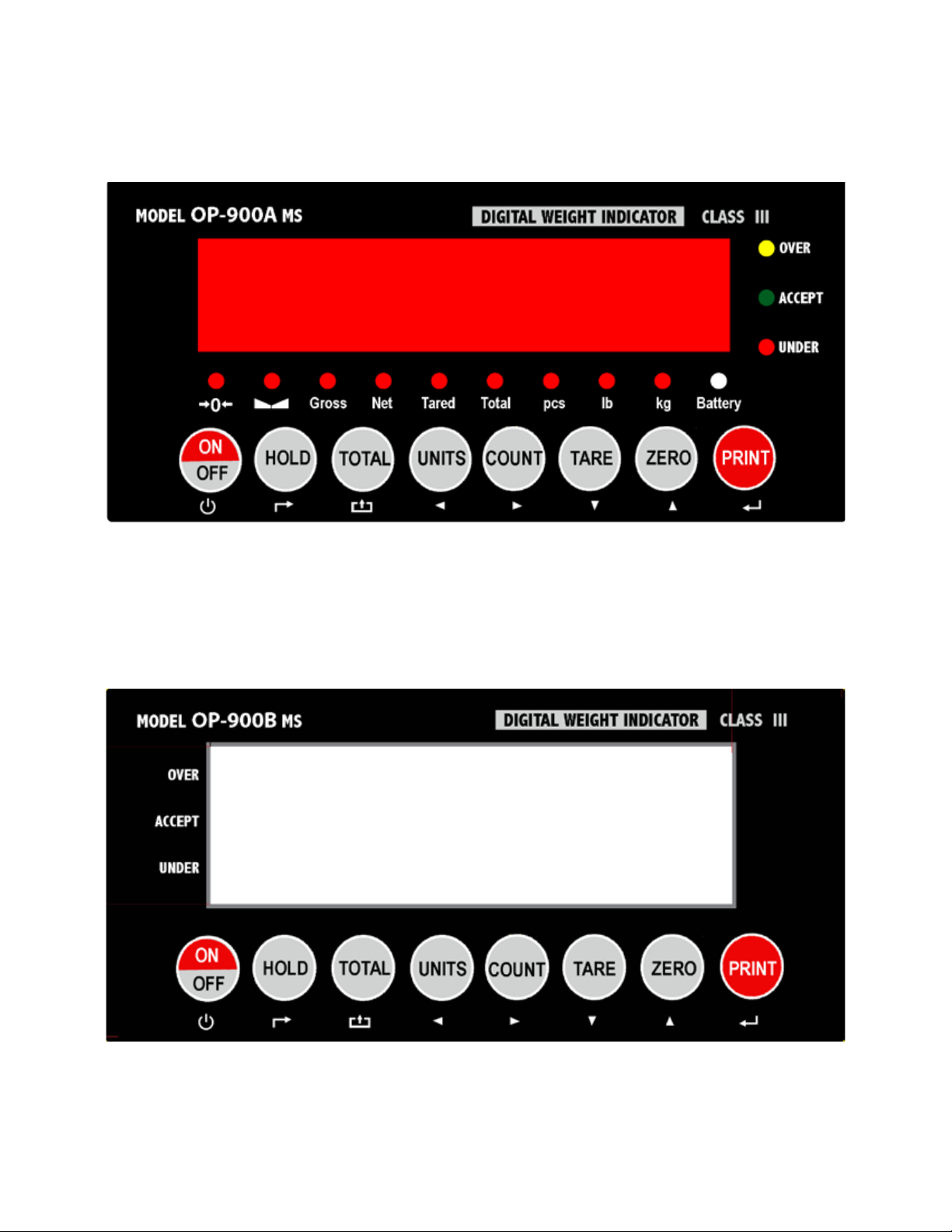

OP-900A (LED)

OP 900B (LCD)

Page 8

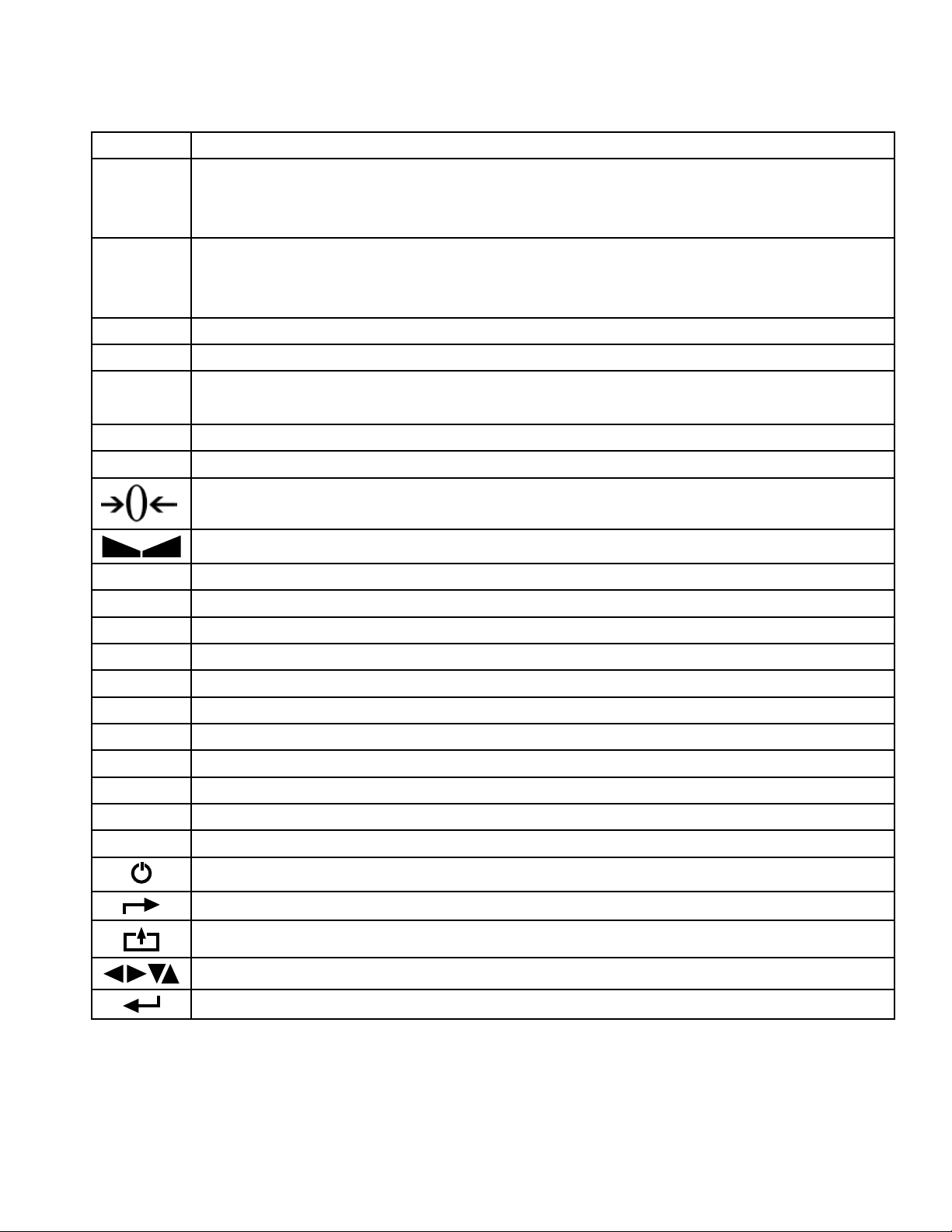

DISPLAY AND KEY DESCRIPTION

ON/OFF Powers the Indicator On or Off if held for 2 seconds

Hold 1. Peak hold - Grabs the highest weight (for tension and pulling force)

2. Data hold - Holds the current weight value (ex. for use with weighing

moving animals)

TOTAL 1. Accumulates weights

2. Works with “Print” to perform the accumulation function and check the

accumulation result

UNITS Shifts between weighing units (kg/lb)

COUNT Use the scale to count product based on a sample weight

TARE 1. Zero’s the scale. Used when using a container to hold objects

2. Clears the tare to see the gross weight

ZERO Zero’s the scale

PRINT Print data

The scale is at zero

The scale is stable

Gross Shows you are in Gross weight mode (includes tare); default mode

Net Shows you are in Net weight mode (without tare)

pcs Shows you are in Counting mode

total Shows you are in Accumulation mode

hold Shows you are in Hold mode

lb The weight is shown in pounds

kg The weight is shown in kilograms

battery Flashes red = low battery, Solid red = charging, Green = fully charged

Over Flashes when weight is higher than set alarm parameter

Accept Flashes when weight is within the set alarm parameters

Under Flashes when weight is lower than set alarm parameter

Power

Back

Save and Exit

Arrow keys

Return/Enter

Page 9

OPERATING INSTRUCTIONS

Power On

● Turn on the power by pressing the power button for 2 seconds. Once on, the scale

will ash the voltage and then begin to auto-check and count down from 0-9

sequentially before entering the weighing mode

Note: Anything on the scale before powering on will automatically be tared out.

Zeroing

● When indicator is turned on the screen should read 0

● If the screen reads any number other than 0 before weighing, press the ZERO key

to set to 0

Unit Selection

● To switch between measuring units (kg, lb, oz) press the UNITS key

Tare Function

● When the indicator is in gross mode (gross light is shown) pressing the TARE key

will Tare the current weight on the scale and enter the net mode (net light shown)

● For example if you are using a container add the container to the scale, press tare

and the display will show the tare symbol

● Add your sample to the scale to weigh without the weight of the container

● To exit Tare mode press the TARE key again to enter gross mode

Note: If you remove the container the scale will show the minus weight of the container

To use a pre-set tare weight

● Press and hold the tare key for 2 seconds

● Input the tare weight using the arrow keys

● Press print key to conrm

and reset back to 0

Counting Function

● In weighing mode: Put a sample weight on the scale

● Then press the COUNT key to go to the counting mode (“pcs” will light up)

● It will then display the sample number (ex. PCS 0) which you can change using the

up or down arrows (Sample options are 5, 10, 20, 50, 100, 200, 500)

● Press the PRINT key to conrm your sample number

● The scale is now ready to start counting, load your product on the scale and the

indicator will show the quantity

● To exit counting mode press the COUNT key

● If you want to count a different product hold the PRINT and COUNT key together

and the sample pieces will reset back to zero

Page 10

Accumulation

● In weighing mode load the rst weight, once stable press the ACCUM key to enter

the accumulation mode. The “total” light will display.

● Remove weight and press ZERO key before adding the second weight to the scale

● Once stable press ACCUM key to add the weight to the accumulated total

● Press ZERO Key before adding the next weight to the scale

● Repeat previous step until all desired weights have been added to the total (max 999

times)

● When you are done and want to display the accumulated total, press the ACCUM

and PRINT key together. The accumulated number “n###” (the number of weights

you are adding together) will ash on the display followed by the total. The total will

display by ashing between 2 sets of numbers

● There are 8 digits in total, the display will ash 4 at a time, the rst 4 on the left and

the last 4 on the right. For example if the rst 4 digits are “0012” and the last 4 digits

are “3456” the actual weight is 001234.56 or 1234.56 lbs/kg

● If you want to print the accumulated total, hold the PRINT key while the last 4

digits of the total are shown

● To exit accumulation mode, wait for the last 4 digits to the right of the screen to

appear, and then press and hold the ACCUM key. “CLr n” will be displayed, asking you if

you want to keep the data?

● If NO you do not want to clear the accumulated total, then keep “CLr n”.

● If YES you do want to clear the accumulated total, then use the arrow key to change

to “CLr y”.

● Finally, press the PRINT key to select exit accumulation mode

Print

● If the indicator is connected to a printer and the weight on the scale is stable press the

PRINT key to print the current weight

● In accumulation mode press the PRINT key when the last 4 digits of the total weight

are shown to print the total weight

Note: In tare mode the printer can not print if negative weight is shown

Hold

There are 2 different hold functions

Peak Hold: Grabs the highest weight

force)

Data Hold: Grabs the current weight and holds it so it will not change/uctuate (ex. for

use with weighing moving animals)

(for materials testing, such as tension and pulling

Page 11

CALIBRATION PROCEDURE

1. Turn on the scale by holding the ON/OFF key. (If the scale does not turn on, plug in

the ac adapter because the battery is low.)

2. Press the HOLD key and the PRINT key simultaneously to access the setup menu.

3. If done correctly, the display should now show C01.

4. Press the PRINT key to access the C1 channel. The display should show [C1 X].

5. Press the ZERO key to change the value of C1 to 2. (The value of 2 sets the scale

6. up in pounds.)

7. Press the PRINT key to set the value. The display will now show C02.

8. Press the PRINT key to access the C2 channel. The display should show [C2 X].

9. Press the ZERO key to change the setting to the decimal places desired. (The C2

channel is used to adjust the decimal point on the scale. A value of 1 means there is

one digit behind the decimal point.)

10. Press the PRINT key to set the value. The display will now show C03.

11. Press the PRINT key to access the C3 channel. The display should show [C3 X].

12. Press the ZERO key to cycle through the values until the desired graduation appears.

(The C3 channel adjusts the divisions on the scale. A value of 1 selected and C2 set

to 1, the scale will read in 0.1 lb. increments.)

13. Press the PRINT key to set the value. The display will now show C04.

14. Press the PRINT key to access the C4 channel. The display will show [XXXXXX].

15. Enter in the maximum capacity you want to use for this scale by using the UNIT and

GROSS keys to move the cursor left and right, and the TARE and ZERO keys move

the values down and up. (The C4 channel is used to enter in the max capacity of the

scale; Make sure this doesn’t exceed the max capacity of the scale; Max capacity

divided by the increment set in C02 and C03 above cannot exceed 5000)

16. Press the PRINT key to set the value. The display will now show C05.

17. Press the PRINT key to access the C5 channel. The display should show [C5 0].

18. The C5 channel calibrates zero on the scale. Make sure the scale is empty.

19. Press the ZERO key to change the value to 1.

20. Press the PRINT key. The display will count down from 10 while the scale is calibrating zero. When the display shows 0 the zero calibration is complete.

21. Press the PRINT key to continue. The display will now show C06.

22. Press the PRINT key to access the C06 channel. The display will show [C6 0].

23. The C6 channel is used to calibrate the scale with a known weight. Press the ZERO

key to set the value of C6 to 1. Press the PRINT key. The display will ash SPAN, and

then show [XXXXXX].

24. Enter the calibration weight value you will use (at least 10% of max capacity you set

in C04 by using the UNIT and GROSS keys to move the cursor left and right, and the

TARE and ZERO keys move the values down and up.

25. Place the calibration weight you have on the empty scale and press the PRINT key.

Page 12

26. The scale will count down from 10 to 0. Once 0 has been reached, the display will

show CALEnd.

27. Press the PRINT key to continue. The display will now show C07.

28. Press the ACCUM/TOTAL key to save and exit the setup menu.

29. The scale has now been calibrated. The display will show the value of the calibration

weight on the scale.

30. If the scale does not show the value of the calibration weight, check that the feet on

the platform are not screwed in too tightly, and verify that the platform is level.

31. Unload the scale; the display should read 000000.

32. If the scale does not display 00000, check that the feet on the platform are not

screwed in too tightly, and verify that the platform is level.

Page 13

INDICATOR PARAMETER SETTINGS

The parameter settings menu has a calibration section (C01 to C07 explained above) and a

parameter settings section (C08 and up).

To access the calibration section the seal switch (located at one corner of the PCB) must be

OFF. This will allow access to all C01 and up settings. If the seal switch is ON, then only C08 and up

can be accessed by the user. If you break the ofcial seal by opening the back of the indicator to

access the seal switch, you may need to have the indicator recertied. Be sure to adjust the seal

switch back to the original setting after calibration/conguration has been performed.

To enter calibration/parameter settings, follow the procedure below:

1. Press and hold the HOLD and PRINT key at the same time for 2 seconds

2. Navigate through the settings (C01 to C45) as shown in the table 4 below by using the arrow

keys and return keys as labeled under each indicator button

3. Press the PRINT

Press the ACCUM key to save and exit settings at any time

Table 1. Indicator Parameter Settings

key to enter/edit the parameter setting

Function Parameter Settings/Options

Weighing Unit C01 1 = kg

2 = lb

3 = gram

4 = oz

Note: for calibration only kg or lb are allowed

Decimal Setting C02 0 = no decimal

1 = #.#

2 = #.##

3 = #.###

4 = #.####

Graduation Setting

(readability of the least

signicant digit)

Maximum Capacity C04 set max capacity ex. 100kg = 0100.00

Zero Calibration C05 0 = zero calibration

Calibration C06 0 = calibration not needed

Restore Default

Settings

C03 options: 1/2/4/10/20/50

Example with no decimal places (ie C02=0)

1 = 1 lb

2 = 2 lb

5 = 5 lb

10 = 10 lb

20 = 20 lb

50 = 50 lb

1 = set the zero calibration (Please ensure scale is empty and the

stable light is on)

1 = ready to calibrate with calibration weight

C07 0 = do not restore

1 = restore to default settings

Page 14

Function Parameter Settings/Options

Warning Tone C08 0 = turn off warning tone

1 = turn on warning tone

Automatic

Power Off

Power Saving Mode C10 LED Version OP900A:

Hold Function C11 0 = turn off hold function

Unit Conversion C12 * See table 2

Upper Limit Alarm C13 Set upper limit within the max. capacity

Lower Limit Alarm C14 Set lower limit within the max. capacity

Inner Code Display C15 check the inner code (raw data)

Set Date C16 Set date from left to right: month/day/year

Set Time C17 Set the time from left to right: hour/minute/second

Communication

Setting

C09 0 = turn off auto power off

10 = power off automatically if no change within 10 minutes

30 = power off automatically if no change within 30 minutes

60 = power off automatically if no change within 60 minutes

0 = turn off power saving setting

3 = turn off display if no change within 3 minutes

5 = turn off display if no change within 5 minutes

LCD Version OP900B:

0 = turn off the backlight

1 = backlight only when the weight changes or keyboard is pressed

2 = constant backlight

1 = Peak hold

2 = Data hold

3 = Reserved

Peak hold - Grabs the highest weight (for tension and pulling force)

Data hold - Holds the current weight value (ex. for use with

weighing moving animals)

C18 Set the serial interface data output method:

0 = Turn off serial interface data output

1 = Continuous sending, connect big display

2 = Print method, connect printer

3 = Command request method, connect computer.

4 = PC continuous sending format, connect computer

5 = PC/big display, continuous sending format

6 = Print to adhesive label printer

Baud Rate C19

0=1200

1=2400

2=4800

3=9600

Manual

Zero Range

C20 0 = turn off manually zero setting

1 = ±1% max capacity

2 = ±2% max capacity

4 = ±4% max capacity

10 = ±10% max capacity

20 = ±20% max capacity

100 = ±100% max capacity

Page 15

Function Parameter Settings/Options

Initial Zero Range C21 0 = no initial zero setting

1 = ±1% max capacity

2 = ±2% max capacity

5 = ±5% max capacity

10 = ±10% max capacity

20 = ±20% max capacity

Zero Tracking C22

0= turn off zero tracking

0.5 = ±0.5d d = division

1.0 = ±1.0d

2.0 = ±2.0d

3.0 = ±3.0d

4.0 = ±4.0d

5.0 = ±5.0d

Note: the zero tracking range can not be bigger than manual

zero range

Zero Tracking Time C23 0 = turn off zero tracking time

1 = 1 second

2 = 2 seconds

3 = 3 seconds

Overload Range C24 00 = turn off overload range

01-99d = overload range setting d = division

Negative Display C25 0 = -9d

10 = 10% max. capacity

20 = 20% max. capacity

50 = 50% max. capacity

100 = 100% max. capacity

Standstill Time C26 0 = quick

1 = medium

2 = slow

Standstill Range C27

Digital Filter

(for ltering moving

weight such as

animals)

C28 0 = turn off dynamic lter

1 = 1d

2 = 2d

5 = 5d

10 = 10d

1 = 1 digital lter strength

2 = 2 digital lter strength

3 = 3 digital lter strength

4 = 4 digital lter strength

5 = 5 digital lter strength

6 = 6 digital lter strength

Note: The higher the number, the higher the lter strength

Noise Filter C29 0 = turn off noise lter

1 = 1 digital lter strength

2 = 2 digital lter strength

3 = 3 digital lter strength

Print Time and Date C30 0 = yy.mm.dd

1 = mm.dd.yy

2 = dd.mm.yy

3 = yy.mm.dd

Analog Output Setting C31 0 = 0 - 5V ouput

1 = 4 - 20mA output

Calibrate Current C32 4 - 20mA current

d= division

Page 16

Function Parameter Settings/Options

Relay Output Setting C33 0 = turn off relay output

1 = turn on relay output function 1

2 = turn on relay output function 2

3 = Reserved menu

Multi-connection add. C34

Wireless Communication

Gravity of Calibration

Location

Gravity of Destination C37

Version No. C38

Preserved Menu C39

Print Mode C41 0 = auto mode

Print Carriage Return C42 0 - 9

Space Print C43 0 - 9

Date Print C44 0 = do not print the date

Time Print C45 0 = do not print the time

C35

C36

0 - 99 Add. Code

0 - 99 signal

9.7000 - 9.9999

9.7000 - 9.9999

1 = gross mode

2 = tare mode

1 = print the date

1 = print the time

Table 2. Unit Conversion Parameter Settings

Parameter Settings Units Available

C01= 3 & C12= 0 gram only

C01= 4 & C12= 0 oz only

C01= 1 & C12= 0 kg only

C01= 1 & C12= 1 kg/lb

C01= 1 & C12= 2 kg/lb/oz

C01= 1 & C12= 3 kg/lb/lb:oz/oz

C01= 1 & C12= 4 kg only

C01= 2 & C12= 0 lb only

C01= 2 & C12= 1 lb/kg

C01= 2 & C12= 2 kg/lb/oz

C01= 2 & C12= 3 kg/lb/lb:oz/oz

C01= 3 & C12= 4 lb only

Page 17

Table 3. Default Parameter Settings

Function Parameter Default Setting

Weighing Unit C01 1

Decimal Setting C02 0

Graduation Setting C03 1

Maximum Capacity C04 1000

Zero Calibration C05 0

Calibration C06 0

Restore Default C07 0

Warning Tone C08 1

Automatic

Power Off

Power Saving Mode C10 0

Hold Function C11 0

Unit Conversion C12 1

Upper Limit Alarm C13 000000

Lower Limit Alarm C14 000000

Inner Code Display C15

Set Date C16

Set Time C17

Communication Setting C18 0

Baud Rate C19 3 (9600)

Manual Zero Range C20 10

Initial Zero Range C21 10

C09 0

Zero Tracking C22 0.5

Zero Tracking Time C23 1

Overload Range C24 9

Negative Display C25 10

Standstill Time C26 1

Standstill Range C27 2

Digital Filter C28 0

Noise Filter C29 2

Print Time and Date C30 0

Analog Output Setting C31 1

Calibrate Current C32 4

Relay Output Setting C33 1

Multi-connection add. C34 0

Wireless Communication

Gravity of Calibration

Location

Gravity of Destination C37 9.7936

C35 6

C36 9.7936

Page 18

CONNECTORS

Connecting load cells to the indicator

● The indicator can connect with 6 load cells of 350Ω at most

● 4 wire or 6 wire load cell connections are both okay

● Please contact us directly if you have other special needs for your application.

● There are two connection methods between the load cell and indicator

Quick Disconnect as shown below:

FIGURE 2: QUICK DISCONNECT CONNECTION DIAGRAM

Hardwire (Using Inner Terminal Block Connection:

Note: Make sure you follow all the anti-static rules to avoid damage to your indicator

● Excitation voltage: 5V DC

● Largest output current: 120 mA

● Excitation circuit: 5 VDC, 4 wire connection, 6 load cell of 350ohm maximum

● Open the back cover of the weighing indicator, and insert signal cable to the

terminal block (see gure 3); Make sure the screw on terminal block is xed tightly

Page 19

FIGURE 3: INNER TERMINAL BLOCK CONNECTION DIAGRAM

Table 4. Wiring Color Code

Signal Name Color Code Description

+Exe/ +EX RED Positive excitation voltage to load cell

+IN / +SIG GREEN Positive output signal from load cell

HD / SHLD YELLOW/THICK BLACK Shield Wire

-IN / -SIG WHITE Negative output signal from load cell

-EXC / -EX BLACK Negative excitation voltage to load cell

DB9 Connection (9 pin Serial Connector)

The DB9 9 pin serial connector is used for different purposes depending on the

indicator model

● Figure 4 shows the pin assignment on the DB9 9 pin connector

FIGURE 4: DB9 SERIAL CONNECTOR PINOUT

There are 3 Output formats to choose from

1. RS232 Serial Output Format (Standard)

2. 4-20 mA Analog Output (Optional)

3. Relay Output (Optional)

Page 20

RS232 SERIAL OUTPUT FORMAT

Follow the pin out of Table 5 below to connect the indicator the RS-232 Serial device

Table 5. DP9 Pin Description

DP9 Pin Denition Function

2 TXT Transmit Data

3 RXD Receive Data

5 GND Ground Interface

The serial output format depends on the settings for parameter C18. The serial output

consists of a string of ASCII characters. Here is a list of the serial parameters

● 8 data bits

● 1 stop bits

● No parity

● No handshaking

Below are the formats of the serial output

● 2nd Display Continuous Output Format (C18=1)

● RS232 Output Formats

● Computer Continuous Output Format (C18=2)

● Serial Command Mode (C18=3)

● Print Format (C18 = 4)

● PC or 2nd Display Continuous Format (C18=5)

Note: With the RS232 Output option we have data logging software available as seen in

Figure 5.

FIGURE 5. DATA LOGGING SOFTWARE

Page 21

2nd Display Continuous Output Format (C18=1)

Output Continuous Format

S

T

X

1 2 3 4 5 6

S

S

S

W

W

W

A

B

0 1 2 Decimal point position

1 0 0 XXXXXX0

0 1 0 XXXXXXX

1 1 0 XXXXX.X

0 0 1 XXXX.XX

1 0 1 XXX.XXX

0 1 X1

1 0 X2

X X X X X X X X X X X X

C

State A

Bits0,1,2

Bits3,4 Division

C

R

C

K

S

State B

BitsS function

Bits0 gross=0, net=1

Bits1 Symbol: positive=0, negative=1

Bits2 Overload (or under zero)=1

Bits3 dynamic=1

Bits4 unit: lb=0, kg=1

Bits5 Constant 1

Bits6 Constant 0

State C

Bit2 Bit1 Bit0 unit

0 0 0 Kg or lb

0 0 1 g

0 1 0 t

Bit 3 printing=1

Bit 4 Extend display=1

Bit 5 Constant 1

Bit 6 Constant 0

Page 22

Computer Continuous Ouput Format (C18=2)

, , CR LF

{

S 1 S 2 S 3 Data S 4

S1: weight status, ST=standstill, US=not standstill, OL=overload

S2: weight mode, GS=gross mode, NT=net mode

S3: weight of positive and negative, “+” or “-”

S4: “kg” or “lb”

Data: weight value, including decimal point

CR: carriage return

LF: line feed

{

{

Serial Command Mode (C18=3)

In this mode, the indicator can recieve ASCII commands as listed below

Command Name Function

T Tare Save and clear tare

Z Zero Zero gross weight

P Print Print the weight

R G.W/N.W Read gross weight or net weight

C Kg/lb Kg/lb conversion

G G.W Check gross weight at net weight mode

The R command will trigger the indicator to output the followind data format:

<STX> <POL> XXXXX.XX <SP> <LB/KG> <SP> <GR/NT> <CR> <LF>

Start

Transmission

Polarity:

<SP> = Positive

“-” = Negative

Weight Data Space Units:

lb = punt

kg = kilogram

pcs = pieces*

Space

Gross/Net:

GR = Gross

NT = Net

Carriage

Return

Line Feed

Page 23

Print Format (C18 = 4)

ID.NO. 004 (Serial No.)

Date: XX.XX. XX (yy.mm.dd)

Time: XX.XX.XX (hh.mm.ss)

GROSS 8.88kg (gross weight)

TARE 2.88kg (tare)

NET 6.00kg (net weight)

PC or 2nd Display Continuous Format (C18=5)

<STX> <POL> XXXXX.XX <L/K> <G/N> <STAT> <CR> <LF>

Start

Transmission

Polarity:

<SP> = Positive

“-” = Negative

Weight Data

Units:

lb = punt

kg = kilogram

pcs = pieces*

Gross/Net:

GR = Gross

NT = Net

Carriage

Status:

<SP> = Valid

M = Motion

O = Over/under range

Return

Line Feed

Page 24

4-20 mA ANALOG OUTPUT (OPTIONAL)

The 4-20 mA analog output of the OP-900

scale is a voltage sourcing sensor that will

output current which is proportional to the

calibrated scale’s weight range (i.e. 4 mA = 0

LBS and 20 mA = 10,000 LBS). It is

important to note, that this is a sourcing

output sensor (i.e. the sensor will source

9VDC with an output current range of 4-20

mA). Unlike many other “loop powered” type 4-20 mA

sensors, an external supply voltage should not be connected

to the unit’s 4-20 mA circuit, however, the ground connection

(pin 6) of the DB-9 connector will need to be connected to

the same ground as the data acquisition device which will be

responsible for interoperating the 4-20 mA signal. This ground

connection is imperative, as both the data acquisition device’s

power supply and the scale’s internal 9VDC power supply will

need to be on the same ground plane for the output current to

FIGURE 6. CONNECTION DIAGRAM

be synced and measured correctly. Please reference Figure 6 as a visual clarication on

how to connect your scales 4-20 mA output to a data acquisition device.

Below is a list of important notes when using the indicator with the 4-20 mA option

● Resolution: 1/1000

● Outside Load: 100-350ohms

● Inside connection: load input port pin “1” of J2, ground port pin “GND” of J2

● Outside connection: load input port pin 1 of DB9, ground port pin 6 of DB9

● To test the connection, connect a 250 ohm load; Locate a volt meter, and probe

across the 250 ohm load. As the weight input to the indicator varies, the voltage of

the volt meter will change accordingly

● Pressing the TARE key will reset to output current to 4mA

● 0-20mA output can be set by setting parameter C31 to 0

● Please note that this option will disable the RS232 weigh data output (serial ASCII

data) that comes in the standard indicator

Calibration:

● Press PRINT and HOLD key to go into conguration mode

● Go to C32 and press PRINT key

● The display should show [out-4] and output should be at 4mA

● Press the up/down arrow keys and the [out-#] will increase/decrease

Note: X corresponds to the output current. For example if out-12 is displayed, then

12mA should be the output. If not, press the left and right arrow key to adjust/calibrate

Page 25

RELAY OUTPUT (OPTIONAL)

● The indicator can output 4 signals, which when connected to outside equipment,

can perform an automatic control function and an upper/lower limit alarm function.

● Change parameter setting C33 following Table 6 below:

Table 6: Relay Output Parameter Setting

Output Port Port Denition Function

Out1 Turn off output function No Output Signal

C33=0

C33=1

C33=2,3 Preserved, no function

Out2 Turn off output function No Output Signal

Out3 Turn off output function No Output Signal

Out4 Turn off output function No Output Signal

Out1 Turn on overload control function Output overload control signal

Out2 Turn on compliance control function Output compliance control signal

Out3 Turn on under-load control function Output under-load control signal

Out4 Turn on stable control function Output stable control signal

Table 7 below shows the DB9 port pinout for the relay output option. Please note that

this is optional and only available for the OP-900 indicator ordered with this option.

The relay output option will disable the RS232 weigh data output (serial ASCII data) that

comes in the standard indicator.

Table 7: Relay Output Pin Denition

DP9 Pin Denition Port

1 1st output signal pin Out1

st

6 1

2 2

7 2

3 3

8 3

4 4

9 4

output signal pin Out1

nd

output signal pin Out2

nd

output signal pin Out2

rd

output signal pin Out3

rd

output signal pin Out3

th

output signal pin Out4

th

output signal pin Out4

Page 26

Error Codes

Error Reason Solution

UUUUUU

nnnnnnn

ERR1 During calibration, weight is not used or

ERR2

ERR3 During calibration, the input signal is

ERR4 During calibration signal is unstable After the platform is stable, start calibration

ERR5 EEPROM Error Change PCB

ERR6 Exceed Zero Range See Q&A section

TROUBLESHOOTING

1. Overload

2. Wrong connection with load cell

3. Load cell has quality problem

1. Calibration is no good

2. Wrong connection with load cell

3. Load cell has quality problem

the weight is above the max. capacity

During calibration, the weight is below

the minimum required weight

negative

1. Reduce the weight

2. Check load cell connection

3. Inspect load cell; Check the input/output

4. See Q&A section

1. Make sure scale is level

2. Check load cell connection

3. Check load cell input and output resistance

4. See Q&A section

Use correct weight within the dened range

The calibration weight minimum is 10% of

the max. capacity set in C04.

Recommended to use 60%-80% of max.

capacity if possible

1. Check all wire connections

2. Check load cell

3. Recalibrate

4. PCB replacement needed if steps 1-3 fail

Page 27

Q&A

Q: The scale does not turn on

A: Make sure the power cord is plugged in, and that there is power. One easy way to

test this is by connecting another appliance to the same outlet and see if it’s

operational

Q: The reading goes negative when a load is applied

A: Try interchanging the Sig+ and Sig- wiring connected to the load cell and/or

junction box (if one is used)

Q: How do I resolve ERR6 error?

A: Please follow the procedure below:

1) Turn on the indicator and make sure nothing is on the scale, and that the scale

is level and not wobbling

2) Press and hold the “PRINT and HOLD” key simultaneously for a few of seconds

3) The screen will read “C01”

4) Using the arrow keys, change C01 to C20. You have to change the 1st digit

from 0 to 2 rst before you can change the 2nd digit 1 to a 0.

5) Press “PRINT” key to enter C20 parameter

6) Change the value of C20 on the right to 100 if possible using the up arrow key.

If 100 is not available change to 20

7) Press “PRINT” key to enter your selection

8) The screen will read “C21” now

9) Press “PRINT” key to enter C21 parameter

10) Change the value on the right of C21 to 100 if available, 20 if not

11) Press “PRINT” key to enter your selection

12) he screen will read “C22” now

13) Press “TOTAL” key to save and exit

14) Power the indicator off and then on, and see if this resolves the ERR 6 issue.

If not, then following the Q&A answers below for resolving “nnnnnn”and “uuuuuu”

errors

Q: How do I resolve “nnnnnn” and “uuuuuu” error?

A: 1) Check to see if the cable that runs from the indicator to the junction box is

damaged. If it is, replace the cable.

2) Open up the junction box (if available) and check to see if there is any water

damage. If so, replace the junction box

3) Make sure all the wires on all 5 terminal blocks (5 wires on each terminal block)

are not loose. Re-tighten the screws even if the wires seem to be connected

4) Recalibrate

5) If steps 1-4 do not work, there is a possibility one or more load cells are

defective (consult with support@optimascale.com for further instructions)

Page 28

CONTACT US

Please e-mail sales@optimascale.com for any sales related question

Please e-mail support@optimascale.com for any support related questions

Don’t forget to visit our website at:

optimascale.com

Loading...

Loading...