Page 1

fixed mount laser scanner

User’s Manual DFM 1000

Page 2

U

SER’S MANUAL

DFM1000

Limited warranty and disclaimers

By opening the package of this product you agree to

become bound by the liability and warranty conditions

as described below.

Under all circumstances this manual should be read

attentively, before installing and or using the product.

In no event, Opticon Sensors Europe will be liable for

any direct, indirect, consequential or incidental

damages arising out of use or inability to use both

the hardware and software, even if Opticon has been

informed about the possibility of such damages.

CAUTION:This user’s manual may be revised or

withdrawn at any time without prior notice.

Copyright 2002, Opticon Sensors Europe B.V.

All rights reserved.

This manual may not, in whole or in part, be copied,

photocopied, reproduced, translated or converted to

any electronic or machine readable form without

prior written consent of Opticon Sensors Europe.

DFM-ver2 / printed 02-02

A serial number appears on all Opticon products.

This official registration number is strictly related to

the device purchased. Make sure that the serial

number appearing on your Opticon device has not

been removed.Servicing by our Repair Depar tment

can only be carried out under warranty.

All Opticon products are warranted for a period of

one year after purchase, covering defects in material

and workmanship.Opticon will repair or, at its opinion,

replace products that prove to be defective in material

or workmanship under proper use during the warranty

period.

Opticon will not be liable in case modifications are

made by the customer.In such case the standard

repair charge will be applicable.The standard charge

for repair will also be applicable in case no defect is

found at all.These rules also apply for products that

are still under warranty. Therefore, you are advised to

have the product specifications always at hand.

Trademarks used are property of their respective

owners

Page 3

CONTENTS

page

U

SER’S MANUAL

DFM1000

page

1 INTRODUCTION 4

2 INSTALLATION 4

2.1 UNPACKING 4

2.2 DETAILED VIEW

2.2.1 Dimensions of the scanner 5

2.2.2 Details of the scanner 5

2.3 H

ANDLING PRECAUTIONS 6

2.4 MOUNTING 7

2.4.1 Place for mounting 7

2.4.2 Scanning distance and angles 7

2.4.3 Mounting suggestions 8

2.5 POWER CONNECTION 8

2.5.1 Power supply and connection

to the host 9

2.5.2 Grounding 9

3 OPERATION OF THE TERMINAL 10

3.1 F

3.2 C

UNCTIONING 10

HARACTERISTICS 10

3.2.1 Automatic triggering 10

3.2.2 Adjustable scan width 10

3.2.3 Read modes 10

3.2.4 Check mode 11

3.2.5 Formatting the bar code data 11

3.2.6 LED indicator 11

3.2.7 Buzzer signal 11

3.2.8 Serial communication 11

3.2.9 Bar code polarity 11

3.2.10 (No) Decode signal 11

3.2.11 (No) Decode message 11

3.2.12 Trigger signal 11

3.2.13 Trigger message 11

3.2.14 Data formatting options 11

5 PIN OUT 13

6 SPECIFICATIONS 14

6.1. Electrical specifications 14

6.2 Optical specifications 14

6.3 Supported symbologies 14

5

6.4 Functionality 14

6.5 Environmental specifications 15

6.6 Physical specifications 15

7 TROUBLESHOOTING 16

8 PRODUCT ORDERING

INFORMATION 18

9 TEST LABELS 19

4 WORKING WITH THE SCANNER 12

4.1 Scan position 12

4.2 Reading the bar codes 12

3

Page 4

U

Double

Sided

SER’S MANUAL

DFM1000

1

The DFM1000 bar code laser scanner has

been specifically developed for industrial use.

The rugged metal housing can easily be fixed

through an adapter on a DIN rail.

The high scan rate makes the scanner

extremely suitable for mounting on a conveyor

belt.

When the DFM1000 is connected to the host,

it will operate as a self supporting scanner.To

integrate the scanner to many industrial applications and other devices, it is provided with

several I/O lines which can be configured by

the user .

The general use and functioning of the scanner will be described in this manual. For

instructions about applications please consult

the documentation of that software.

Read this manual carefully before using

the terminal, to maximise the efficiency of

this scanner.

Do not remove the scanner label.

includes information about the power supply

to the scanner and a serial number.Do not

remove it.

INTRODUCTION

On the back housing

of every scanner you

will find a label.The

label is attached by

the manufacturer and

2

INSTALLATION

2.1 UNPACKING

When you remove the packing, please check

for any physical damage. We recommend that

you save all packing material, as it should be

used whenever you need to ship your terminal

(eg. for service). Damage due to improper

repacking is not covered by the warranty.

Make sure that all of the items shown below are

present. If there are any missing parts please

contact your supplier.

DFM1000:

Laser scanner:

including

DB25 male connector

+ 1,5 m cable

OPTIONAL:

Configuration kit:

including

configuration disc with

configuration software

RS232 adapter

RS232 DB9 cable

12V power supply

4

Page 5

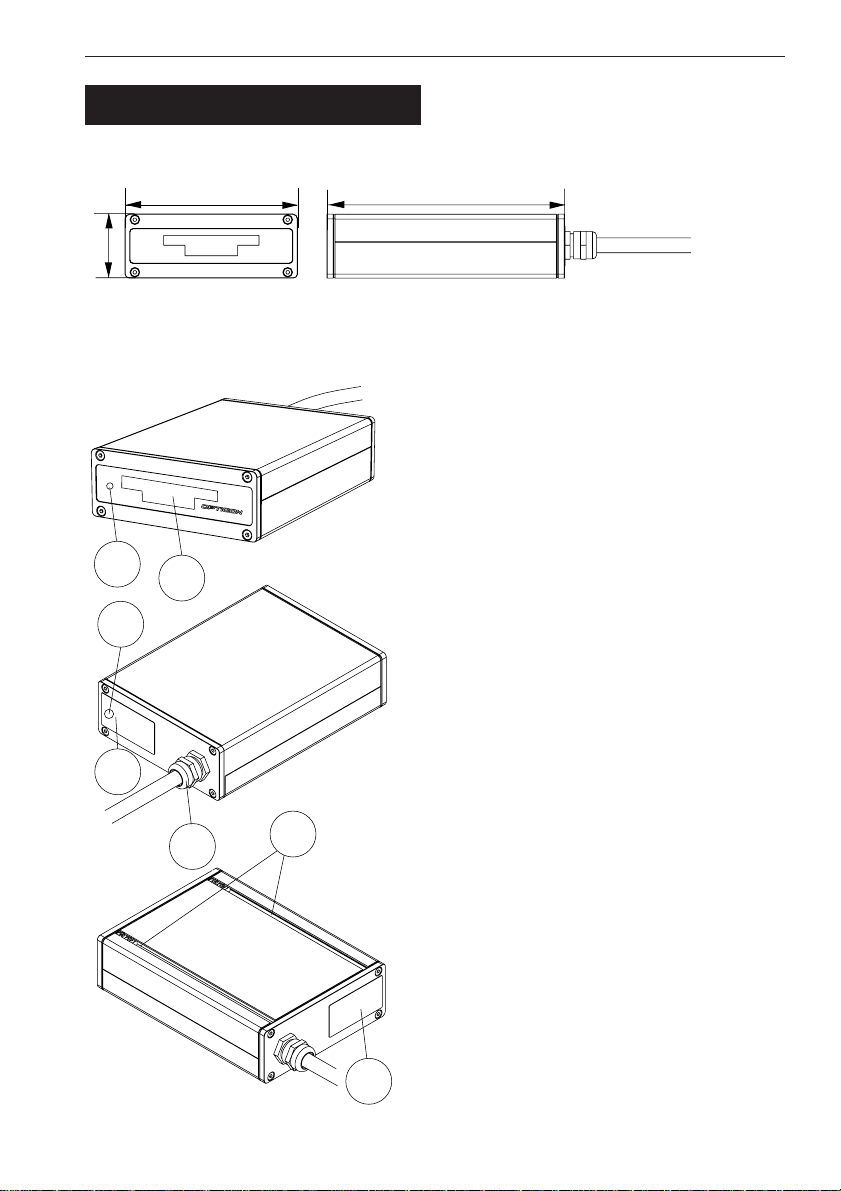

39 mm

105 mm

143 mm

1

2

3

4

5

6

7

2.2 DETAILED VIEW

2.2.1

Dimensions of the scanner

2.2.2

Details of the scanner

U

SER’S MANUAL

1. Reading window

Reads bar codes

Never obstruct this window.

2. Autotrigger aperture

It is very important that the autotrigger

aperture always can operate free.

Never obstruct this part of the window.

3. LED indicator

Power LED orange (default)

Good Read LED green (default)

4. Buzzer/Beeper

A single tone beep indicates results as

defined by the user.

DFM1000

5. Connector

For RS 232 and RS 485 connection,

power supply and configurable I/O lines

6. Mounting slot

Slot for fixed mounting or for DIN-rail

adapter, with adjustable bolts and nuts.

7. Scanner label

Do not remove it

5

Page 6

U

!

COMPUTER:

- RS 232 port

- parallel port

DFM1000:

DB25 male

connector

!

SER’S MANUAL

DFM1000

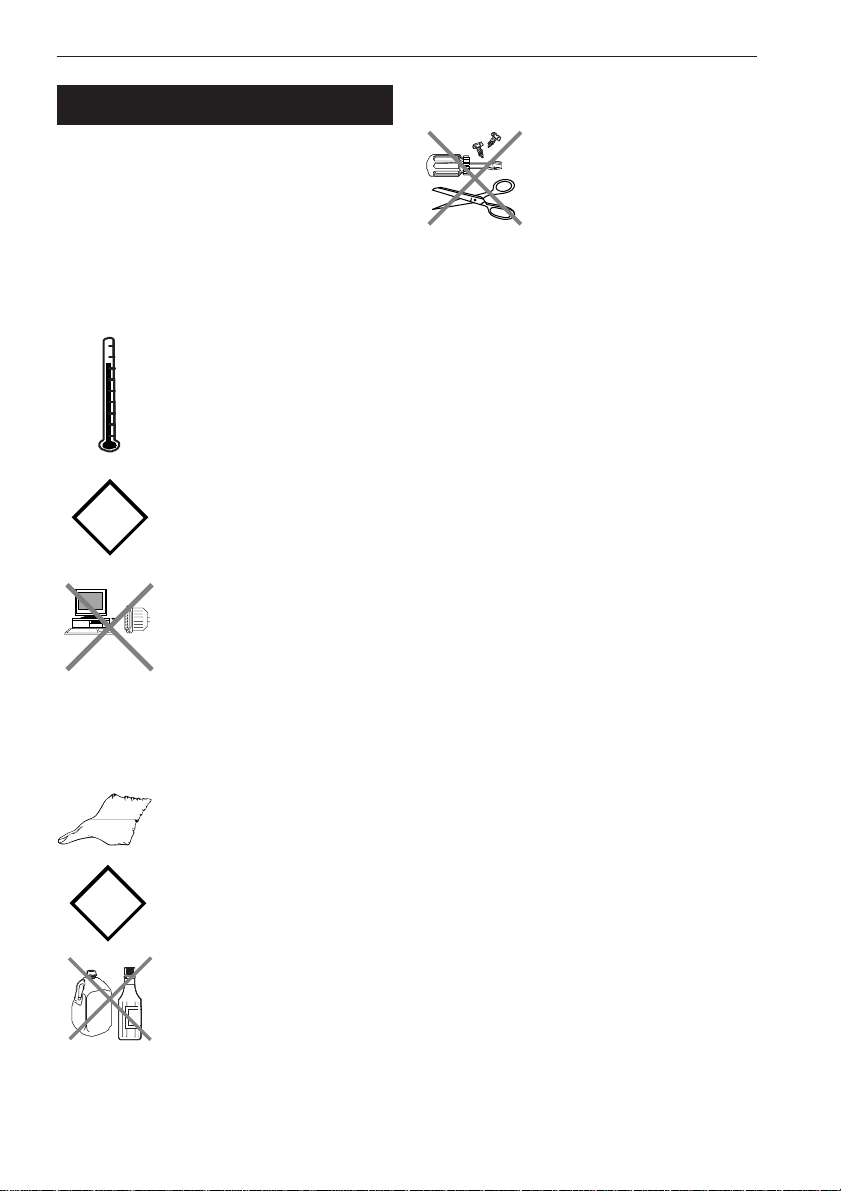

2.3 HANDLING PRECAUTIONS

The DFM1000 is water-, dust- and schock

resistant according to the specifications in the

appendix, but the scanner consists of minute

electronic parts. To avoid malfunctioning and

to ensure years of trouble free operation, we

want tot state you the precautions below. Pay

attention to the following:

Use of the DFM1000

For long periods, do not use

or leave the scanner in area’s

that are exposed to extreme

heat that is higher than 50 oC

- like direct sunlight, or near a

heater.Also do not expose

the scanner to freezing area’s.

Do not subject the scanner to

very strong impact, do not

throw or drop the scanner

from large heights.

Do not plug the DB25 male

connector of the scanner

directly into the RS232 or

parallel port from computer

(or printer). The pinout is not

compatible and will cause

damage without using an

adapter.

Maintenance/Troubles

There are no user-serviceable

parts inside the terminal or

the cradle. So do not try to

take it apart. Opticon will not

be liable for any damage

caused by the customer.

In case of malfunction that can not be solved

by the trouble-shooting instruction in the

appendix, please consult our service

department.

Cleaning of the DFM1000

Clean the exterior by wiping it

with a soft, lightly moist cloth.

Do not use a high pressure

cleaning method.

To clean the window use nonabresive liquids.

6

Page 7

U

!

!

5 mm

75 mm

90 mm

130 mm

155 mm

270 mm

360 mm

425 mm

520 mm

750 mm

0.15 (6

mil)

0.127 (5

mil)

0.25 (10 mil)

0.33 (13 mil)

0.39 (15.6 mil)

0.5 (20 mil)

1.0 (40 mil)

Resolution

at PCS 0.9

Reading width and reading distance of DFM1000

DFM1000

Reading

distance

Scan width (mm)

050100

150

200

250

300

50

100

150

200

250

300

0 - 60

0

0 - 50

0

3 - 80

0

5 - 85

0

Reading angles of DFM1000

Pitch angle

Skew angle

= Reading area

= NO reading

SER’S MANUAL

DFM1000

2.4 MOUNTING

Follow the next steps to make your scanner

ready for installation in a system.

2.4.1.

Place for mounting

Avoid sunlight and/or bright light or

aser light from other devices.

Place the scanner in such a way that

the reading window and the autotrigger

aperture can operate free.

Wall mounting instructions

To ensure optimum reading capacity,

estimate the scan distance of the scanner,

as described in this chapter.

Pay attention to the pitch and skew angles,

as described in this chapter.

Avoid excessive angles.

2.4.2.

Scanning distance and angles

Use the diagram below to see which reading

distance should be used related to the bar

code resolution.

Use the other diagram to adjust your scanner

to the right angle.

7

Page 8

!!!!!

U

!!!

KEEP THE

BOLTS

LOCKED

NON-MOUNTING

1

2

BEFORE

MOUNTING

SER’S MANUAL

2.4.3.

The DFM1000 can be placed on a flat surface

or can be permanently mounted (fixed).

The bottom of the scanner is provided with 2

slots with adjustable bolts and nuts for mounting

on e.g. a DIN-rail.

In every mounting situtation make

sure that the bottom of the scanner

is positioned under straight angle.

When you do not fix the scanner,do

not loosen the

bolts.

To mount

the scanner on a DIN-rail, we

recommend you to use a DIN-rail

adapter. (as shown in example below)

DFM1000

Mounting suggestions

2.5 POWER CONNECTION

Exercise caution at all times when

working with AC and DC-powered

equipment.

Turn off your devices before

installation.

We advise you to connect the

DFM1000 to your host as shown in the

figures in this chapter.

Before connecting the additional

communication cables, take notice of

the pin-out specifications (chapter 5)

Do not plug the DB25 male connector of

the scanner directly into the RS232 or

parallel port from computer (or printer).

The pinout is not compatible and will

cause damage without using an adapter.

Follow the next instructions to mount the

scanner.

First remove the bolts.(ref. 1)

When an adapter for mounting is used,

take the adapter to fix the scanner.

Adjust the nuts to the position that is

needed for mounting. (ref. 2)

Screw the bolts into the nuts until

the scanner is secured.

8

Minimize noise interference and

ground loops.Therefore pay attention

to the grounding diagram.

Page 9

U

COMPUTER:

- RS 232 port

- parallel port

DFM1000:

DB25 male

connector

9-33 V DC

DB25 MALE

(from scanner)

6P6

MOD.

JACK

TO PARALLEL

PORT OF PC

TO HOST

DB25

FEMALE

RS 232

ADAPTER

ALTERNATIVE

CONFIGURATION

MODE

DFM1000 Wiring Diagram

CONFIGURATION

ADAPTOR

DB25 MALE

(from scanner)

COMMUNICATION

AND CONFIGURATION

MODE

POWER

SUPPLY

9-33 V DC

POWER

SUPPLY

8P8

MOD.

JACK

DB9

FEMALE

EARTH GROUND

SHIELDING

COMMUNICATION CABLE

DFM1000 Grounding Diagram

SCANNER HOST

SER’S MANUAL

DFM1000

For configuration of the DFM100 an additional

configuration kit is available.You are strictly

recommended to use this kit for optimalization.

The scanner should work according to the

default options.Other options have to be set

by the user, through the optional configuration

kit.

2.5.1

Power supply and

connection to the host.

The wiring diagram on this page gives some

suggestions to connect the scanner correctly.

Do not plug the DB25 male

connector of the scanner

directly into the RS232 or

parallel port from computer

(or printer). The pinout is not

compatible and will cause

damage without using an

adapter.

Connect the scanner to the host.

Connect power supply to the scanner

(9-33V DC unregulated + 5%)

Connect power to the host.

Scanner beeps.

Default setting; Power LED(back side

scanner) should light up in orange colour.

Scan an EAN/UPC bar code label from the

test labels in chapter 9.

Scanner beeps.

Default setting;Good Read LED (back side

scanner) flash green shortly.

Data is sent to the host.

Default communication settings:

RS232 (9600,N,8,1)

Check data at the host.

2.5.2

Grounding

See grounding diagram.

Make sure the shielding is grounded only

to earth ground at the host. The shielding

connection to the scanner from the host

should not be connected ot the shielding

of the scanner.

Make sure that the frame ground of the

scanner is connected to the earth ground.

Make sure that the host, the scanner and

their power supplies are connected to a

common earth ground.

9

Page 10

U

SER’S MANUAL

3

DFM1000

OPERATION OF

THE TERMINAL

3.2 CHARACTERISTICS

The DFM1000 is equipped with different characteristics. Some characteristics are already

preset by Opticon and have a function.A number of characteristics can be enabled or disabled by the user through configuration software and the configuration cable.In this chapter we give you some examaples of the scanners many functions.

3.2.1.

Automatic triggering

3.1 FUNCTIONING

The DFM1000 will detect the bar code with a

single line laser beam.The reflected light will

be picked up and converted by the sensor to

an electric signal, which is representing the

bar code label.The decoder will recognise the

bar code symbology and extract teh information.The resulting dta is sent to the host that

is connected to the scanner.

The presence of a bar code will be recognised

by the autotrigger function of the scanner,

meaning that the laser beam is activated as

soon as an object moves towards the reding

window of the laser scanner.When the user

prefers to use an external trigger, it is possible

to switch off the autotrigger function and connect an external trigger to the scanner.

Automatic triggering is a default function of the

scanner.When the user prefers to use an

external trigger, it is possible to switch off the

autotrigger funcation and connect an external

trigger to the scanner.

3.2.2.

Adjustable scan width

If another scan width than the default scan

width is needed, it is possible to adjust the

reading width of the scan pattern settings.

3.2.3.

Read modes

By setting an other read mode the use has

the ability to activate the read operation in the

that way that is the most convenient. the scanner is provided with 3 read modes, which can

be enabled or disabled by the user;

Single read mode:

After a bar code is successfully decoded, the

laser is switched off, and the user has to

retrigger the scanner in order to scan the next

label.

Multiple read mode:

After a bar code is decoded successfully the

laser stays on, allowing the user to read

another bar code. A bar code is only transmitted once, regardless the number of times the

scanner reads it. Only when the scanner could

not decode a bar code for a selected time, the

laser is shut off.

10

Continous read mode:

This is a test mode, in which every decoded

bar code is transmitted whether it is the same

or not.

Page 11

3.2.4.

Check mode

3.2.9.

Bar code polarity

U

SER’S MANUAL

DFM1000

To ensure the bar code is correctly decoded,

there are 2 options, to be enabled by the user.

Redundant reading:

A bar code is transmitted only when it is

decoded successfully for a selected number of

times.This number can be set by the user.

Check digit calucation:

A calculation of the digits of the bar code

should correspond with the check digit.

3.2.5.

Formatting the bar code data

When reading a bar code, some formatting

can be done by the scanner.the user can

configure this. Some examples are:

Some of the options many not be valid for all symbologies.

Enable required symbologies, disable all others

Transmit start/stop characters on/off

Transmit check digit on/off

Case conversion

Add character(s) as prefix and suffix

Translate bar codes, like full ASCII code 39,

ISBN, EAN etc.

3.2.6.

LED indicator

The LED indicator can light up red or green.

They can light up as a separate colour or

together (shown as orange light).

As a default setting the indicator is defined as

a Power LED (orange) and as a Good Read

LED (green). The duration that it lights after a

successful decode or an other definition of the

setting can be configured by the user.

3.2.7.

Buzzer signal

The buzzer signal, i.e.single tone beepe can

be used for a good read bar code or as an

error signal for a failed transmission.The

definition of use, frequency and duration of the

beeper can be adjusted by the user.

3.2.8.

Serial communication

For direct communication between the

scanner and the host the scanner is provided

with RS232 interface.Other interfaces are

available on request.

The laser scanner is able to red positive and

negative labels, for both black or coloured

labels.The following bar code reading options

are available:

Black on white

White on black

3.2.10.

(No) Decode signal

Except for the Good Read LED, its is possible

to indicate the results of bar code reading and

decoding by a pulse signal to the host.

Dedoce pulse: the bar code is read and

decoded correctly

No Decode pulse: during the read time no

bar code is detected or could not be

decoded

3.2.11.

(No) Decode message

When the read time expires and the scanner

did not detect or decode a bar code, a

configurable string of max. 50 characters can

be transmitted to the host.

(supported from software version DCCV0103 or higher)

3.2.12.

Trigger signal

If internal trigger is activated, a positive or

negative pulse is generated.This option can

be set for each symbology separately or for all

symbologies.

(supported from software version DCCV0103 or higher)

3.2.13.

Trigger message

A configurable string of max. 50 characters

can be sent to the host when the scanner is

triggered.

(supported from software version DCCV0104 or higher)

3.2.14.

Data formatting options

Data can be manipulated before the data is

transmitted to the host.The data manipulation

is performed unconditionally. See configuration

disc for the specifications.

(supported from software version DCCV0110 or higher)

11

Page 12

U

!

!

SER’S MANUAL

DFM1000

WORKING WITH

4

The DFM1000 laser scanner is a Class I laser

product conforming to strictest laser safety

standards. However, we recommend that you

avoid looking directly into the laser beam emitter, or pointing the laser beam directly into

someone’s eyes.

THE SCANNER

Take care of the handling precautions.

Make sure that the scanner is installed

according to the installation

instructions.

4.1

Scan Position

The bar code label of the product should be

visible in the field of the scanner pattern.

When the scanner is not able to decode the

bar code label of the product, it is possible to

change some settings through configuration

software to achieve a better scan width.

4.2

Reading the bar codes

Depending on the bar code size and bar

code resolution we recommend you the

scan distances as described in the

diagram of chapter 2.4. of this manual.

Take care that the bar code side of the

product appears in the front of the reading

window.

Pay attention to the reading angles of the

scanner, as shown in chapter 2.4.of this

manual.The scanner should read the bar

codes in the reading area.

If you have problems with the read operation,

pay attention to the following:

Check if the scanner is not oblique

mounted.

Check if the scanner is able to decode the

bar code, referring to the reading angles.

Check if the position of the bar code label

is correct.

Scan one of the test labels of chapter 9. If

the test label is read correctly, check the

readability of the bar code used.

12

Page 13

U

!

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

COLOR

BROWN

RED

ORANGE

PINK

PIN 1 - 4 : RS485 INTERFACE

YELLOW

GREEN

LIGHT GREEN

BLUE

LIGHT BLUE

PIN 6 - 9 : RS232 INTERFACE

PURPLE

GREY

WHITE

BLACK

BROWN - BLACK

RED - BLACK

PIN 14 : FOR FUTURE EXPANSION

ORANGE - BLACK

PINK - BLACK

YELLOW - BLACK

GREEN - BLACK

PIN 16 - 19 : FOR FUTURE EXPANSION

LIGHT GREEN - BLACK

BLUE - BLACK

LIGHT BLUE - BLACK

PURPLE - BLACK

GREY - BLACK

WHITE - BLACK

FUNCTION

TRTR+

TT+

not connected

RTS

CTS

RxD

TxD

SUPPLY VOLTAGE

9-33 V DC

UNREGULATED

(< 1 V

SIGNAL GROUND

(NO)READ OUTPUT

TTL - sink or source

max. 4mA

TRIGGER INPUT

High level voltage: 2-15 V

Low level voltage : 0-0.8 V

I/O 1

TRIGGER OUTPUT

TTL - sink or source

max. 4mA

I/O 2

I/O 3

I/O 4

I/O 5

I/OE 1

I/OE 2

I/OE 3

not connected

+5 V DC OUTPUT

(MAX. 100mA)

FRAME GROUND

p-p

ripple)

SER’S MANUAL

DFM1000

5

PIN-OUT

The pinout description mentioned in this chapter must be used to connect the DFM1000

scanner to the host.

The pinout of the DB25 male

connector is NOT compatible with

standards for RS232.

Do not plug the DB25 male connector of the

scanner directly into the RS232 or parallel

port from computer (or printer). The pinout is

not compatible and will cause damage without

using an adapter.

13

Page 14

U

SER’S MANUAL

6

6.1

Electrical specifications

Voltage requirement 9-33V DC unregulated,

Power consumption max.4.5 Watt.

6.2

Optical specifications

Light source 670 nm visible laser diode

Deflection system rotating polygon

Scan rate 1000 scans/sec

Decode rate max. 1000 decodes/sec

DFM1000

SPECIFICATIONS

less than 1V

(10 facets)

p-p

ripple

6.3

Supported symbologies

Codabar incl. ABC, CX

Code 39

Code 93 (version DCCV0111 or higher)

Code 128

EAN 8 incl. +2,+5

EAN 13 incl. +2,+5

IATA

Industrial 2of5

Interleaved 2of5

ISBN

ISSN

Laetus

Matrix 2of5

Italian Pharmaceutical

MSI/ Plessey

UK/ Plessey

S-Code

Telepen

UPC-A incl. +2,+5

UPC-E incl. +2,+5

6.4

Functionality

configurable I/O’s Trigger input

Trigger modes External input

Trigger output

Noread output

Auto trigger

Spot velocity 215 m/sec at 100 mm

Reading width max.140mm at 100mm

max.300mm at 300mm

Min. resolution

at PCS 0,9 0.127 mm (5 mil)

Min PCS values 0.30

Depth of field max. 750 mm

at PCS 0.9 (resolution=1mm)

14

Configuration via download cable

and/or OSEMENU

software

Interfaces RS232

Upgradeability The software can easily

be upgraded using

OSEMENU

Page 15

6.5

Environmental specifications

U

SER’S MANUAL

DFM1000

Temperature 0 - 50 oC in operation

-20 - 60 oC in storage

Humidity 5 - 95 % in operation

(non condensing) 5 - 95 % in storage

Emission According to EN50081,

part 1 & 2

Immunity According to EN50082,

part 1 & 2

Protection against

dust and moisture According to IEC529,IP

54

Safety, Laser class According to IEC825,

Class I laserproduct

6.6

Physical specifications

Dimensions (l x w x h) 143 x 105 x 39

mm

Case material aluminium - anodised

Weight 780g

Standard connector DB25 - male (1.5m cable)

15

Page 16

U

?????

?

?

SER’S MANUAL

DFM1000

Scanner does not function.

The DB25 male connector of the

DFM1000 is not RS232 compatible!

Check if the scanner is connected as

advised in the wiring diagram

(chapter 2.5)

TROUBLE

7

This chapter contains information on solving

problems you may encounter when using the

terminal and/or cradle. If problems occur, first

carry out some general checks, before verifying

the problem with the descriptions in this chapter.

General checks:

Make sure everything is installed properly

Check the power supply of all devices

Is the read window of the scanner clean?

Are the bar code labels readable, eg. not

damaged or poorly printed?

Scan a test label of chapter 9. If the test

label is read correctly, check the readability

of the bar code used.

If the equipment still does not work after these

checks have been performed, please verify if

one of the problems described in this chapter

applies to the problem you have with the

scanner.

It is possible that you may not solve the

problems, despite our descriptions. In this

instance, please contact your dealer or

Opticon.

When the terminal needs to be repaired,

please ensure that the label with the serial

number is still present. If sending the terminal

or cradle, please use the original packing to

minimise the chances of damage.

SHOOTING

Good Read LED is off.

Check the power supply.

If faulty power supply is used, replace the

power supply.

Check the cables.

If faulty cables are used, replace the

cables.

Scanner does not beep at startup.

Motor does not or hardly rotate.

Power LED is on.

The power supply is not capable of

powering the scaner.Replace the power

supply.

Laser goes off.

Motor seems to be slower.

Buzzer keeps beeping.

Motor could not be regulated to its desired

speed. Restart the scanner. If the porblem

persists, contact your local dealer.

Scanner does not read very well anymore.

Scanner window is dirty.

Clean window with clean damp flintfree

cloth. Do not use abrassive liquids.

Autotrigger does not react very well.

Autotrigger aperture is dirty.

Clean the scanner window (autotrigger

aperture) with clean damp flintfree

cloth. Do not use abrassive liquids.

Autotrigger aperture is obstructed.

Take care that the autotrigger aperture

always can operate free.

16

Page 17

Scanner seems to work but the bar code

???

?

?

can not be read.

The bar code symbology to be read is

disabled.

Enable the bar code symbology in the

software.

Of a certain bar code symbology, some bar

codes can be read while other can not be

read.

Some bar codes contain a ‘check digit’.

Disable ‘check digit’ for the involved bar

code symbology.

Fixed length is set for the involved bar

code symbology.

Adjust or remove the fixed length check.

Strange characters are received at host.

Baudrate, databits, stop or parity do not

match.

Compare and match these settings

between host and scanner.

Default communication settings:

9600 baudrate

No parity

8 data bits

1 stop bit

U

SER’S MANUAL

DFM1000

No data is received at host and scanner.

No handshake signals, while

handshaking is selected.

Compare and match handshake settings

for host and scanner.

17

Page 18

U

SER’S MANUAL

DFM1000

PRODUCT

ORDERING

8

Scanner

DFM-1000 laser scanner A15013R0010

including

DB25 male connector

+ 1,5 m cable

Additional

Configuration kit for DFM A83200N0010

including

configuration disc with

configuration software

RS232 adapter

RS232 DB9 cable

12V power supply

INFORMATION

Article Code

18

Page 19

U

!

!

0 071589 812308

9

780123 456786

>

( 0123456789 )

7 376221 357463

12345

*C+O+D+E 39*

( Code 39 )

*V2GZD9*

( 908557705 )

SER’S MANUAL

UPC A [default]

DFM1000

TEST

9

LABELS

Default labels

In the default mode the scanner

will only read the UPC and EAN labels

without add-on.

Other labels

Before testing one of the other labels,

first activate the right bar code symbology

in the configuration software of the

DFM1000.

EAN 13 [default]

( ISBN)

EAN 13 ADDON 5

Code 39

( Code 39 FULL ASCII )

( Italian Pharmaceutical )

Code 39

19

Page 20

U

0123456789

0123456784

Telepen

( 57748174857483 )

0123456789

( ]C10123456789 )

SER’S MANUAL

DFM1000

Industrial 2 of 5 (without CD)

Interleaved 2 of 5 (with CD)

with bearer bars

Telepen ASCII

( Telepen numeric )

Code 128 Code C

( EAN 128 )

Opticon Article Code

O0225000010

20

Loading...

Loading...