Opticom Technologies Inc.

SAE J1455 and MIL-STD-810F

Vibration Testing of

Model CC-02-4.3

CCTV Camera

Prepared by: Weir-Jones Engineering Consultants Ltd.

2040 West 10th Avenue

Vancouver, B.C.

V6J 2B3

Tel: 604 732-8821

Fax: 604 732-4801

E-mail: wjgroup@weir-jones.com

Web: www.weir-jones.com

ISO 9001:2000 Registered

June 17 , 2005

th

AUTHORIZATION

The work described in this report was authorized by David Boyd of Opticom Technologies

Inc. on June10 , 2005. The report was prepared by Paul Chong, P.Eng.

th

Paul Chong, P.Eng.

Project Engineer

Dated at Vancouver, June 17 , 2005.

th

Weir-Jones Engineering Consultants Ltd. 30144-REP-001-0.wp9

TABLE OF CONTENTS

1.0 INTRODUCTION .......................................................1

2.0 VIBRATION PROFILES .................................................1

3.0 VIBRATION TEST EQUIPMENT ..........................................3

4 . 0 R E S UL T S .............................................................5

4.1 Sinusoidal Vibration Test ...........................................5

4.2 Random Vibration Test .............................................5

APPENDIX 1: Calibration Certificates ............................................7

APPENDIX 2: Sinusoidal Test Results ...........................................12

APPENDIX 3: Random Test Results .............................................14

Weir-Jones Engineering Consultants Ltd. 30144-REP-001-0.wp9

1.0 INTRODUCTION

On June 10 , 2005 Weir-Jones Engineering Consultants Ltd. (WJEC) was retained by

th

Opticom Technologies Inc. to perform a set of vibration tests on its Model CC-02-4.3 CCTV camera.

The primary objective in testing the camera was to verify its structural integrity. This was done by

subjecting the unit to the worst-case vibrational stresses expected in its application environment.

The testing consisted of vibrating the Model CC-02-4.3 CCTV camera in the two mutually

perpendicular axes in accordance with the profiles defined in Sections 4.9 of the SAE J1455 (August

1994) Standard and Method 514.5 of the MIL-STD-810F (January 2000) Standard. The testing of

the camera was performed on June 14 and 15 , 2005.

th th

2.0 VIBRATION PROFILES

The vibration testing of the Model CC-02-4.3 CCTV camera comprised of subjecting the unit

to the Sinusoidal profile as defined in Section 4.9 of the SAE J1455 (August 1994) Standard and to

the Random profile as defined in Method 514.5 of the MIL-STD-810F (January 2000) Standard. The

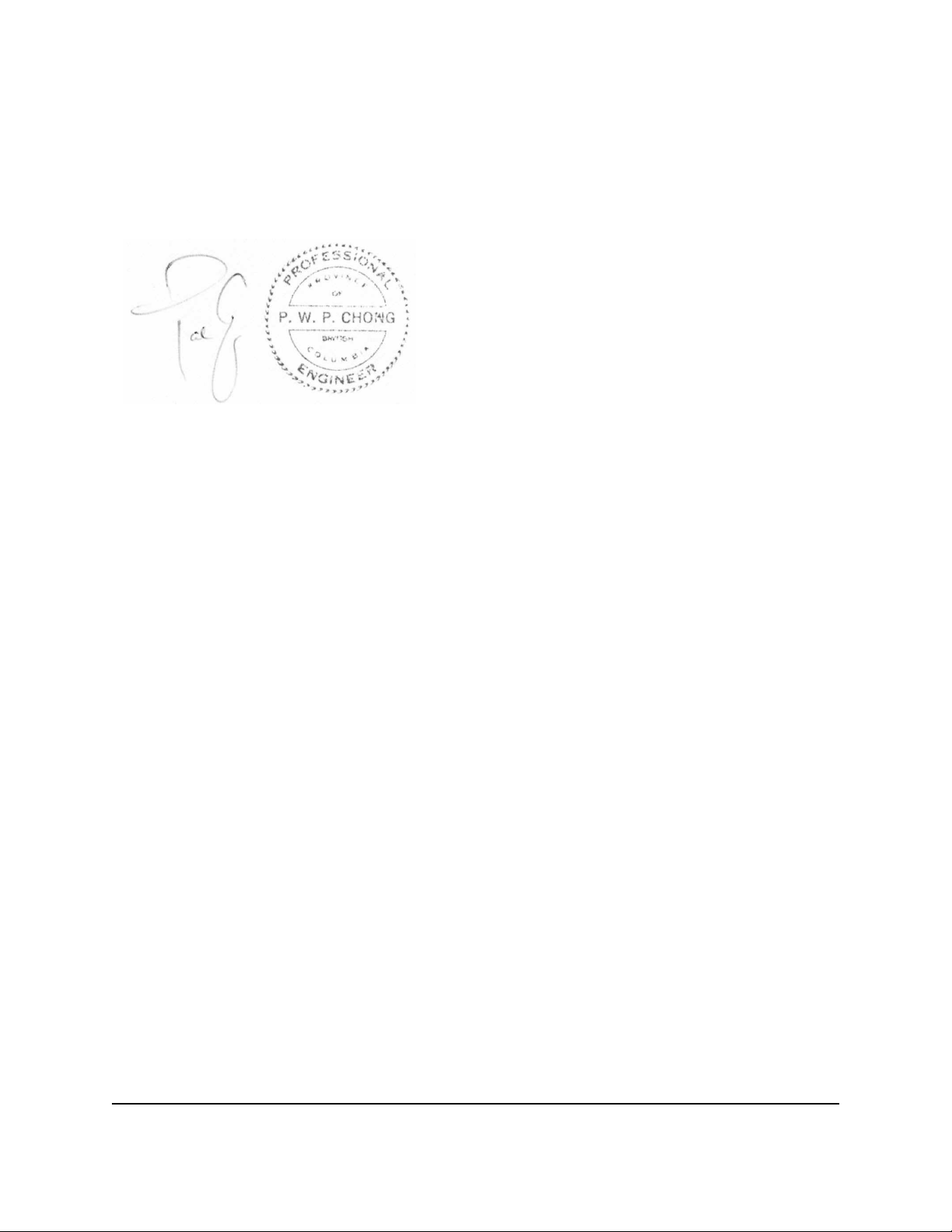

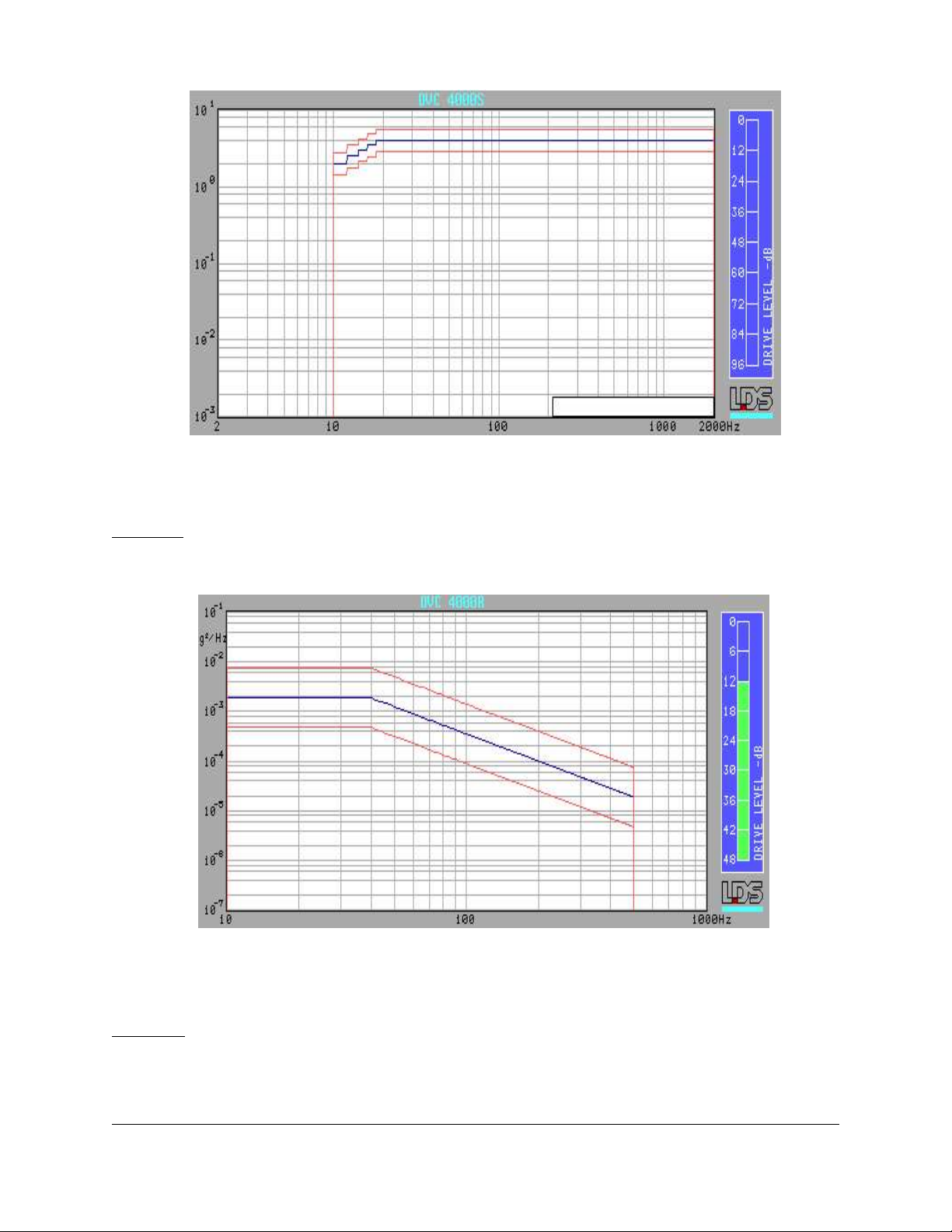

parameters of the Sinusoidal and Random profiles are summarized below with the graphical

representation of the Sinusoidal profile shown in Figure 1 and that of the Random profile shown in

Figure 2.

Sinusoidal (truck chassis-mounted)

Amplitude* - 2 G’s from 10 to 12 Hz

2.5 G’s from 12 to 14 Hz

3 G’s from 14 to 16 Hz

3.5 G’s from 16 to 18 Hz

4 G’s from 18 to 2,000 Hz

Sweep rate - 0.5 octave per minute

Duration - 180 minutes per axis for each axis. Unit to be operational as

intended during testing.

* the step function is intended to simulate the ramp-up from 10 to 20 Hz.

Random (Basic Transportation for U.S. Highway Truck)

Breakpoints - as per Figure 514.5C-1

10 Hz ÿ 0.015 G /Hz

40 Hz ÿ 0.015 G /Hz

500 Hz ÿ 0.00015 G /Hz

Overall G level of 1.04

RMS

2

2

2

Duration - 60 minutes is equivalent to 1,000 miles of travel. Unit is

recommended to be operational as intended during testing.

Weir-Jones Engineering Consultants Ltd. 1 30144-REP-001-0.wp9

Blue - Vibration profile

Red - Upper and lower limits of frequency and acceleration (equivalent to ±3dB)

Figure 1: Graphical plot of the SAE J1455 Sinusoidal vibration profile intended for equipment

to be mounted on truck chassis.

Blue - Vibration profile

Red - Upper and lower limits of frequency and amplitude (equivalent to ±6dB)

Figure 2: Graphical plot of the MIL-STD-801F Random vibration profile (U.S. Highway

Truck). It should be noted that the amplitude shown in the plot has been reduced by

-9dB.

Weir-Jones Engineering Consultants Ltd. 2 30144-REP-001-0.wp9

3.0 VIBRATION TEST EQUIPMENT

The equipment required for the vibration tests was a shaker, a vibration controller and two

feedback accelerometers (see Figure 3). The specifications of the equipment used are as follows.

Shaker: Manufacturer: Ling Dynamic Systems (LDS)

Model: V722

Rated Force: 750 lbf. rms (Random)

Frequency: 5 Hz - 4000 Hz

Maximum Displacement: 1 inch peak-to-peak

Maximum Velocity: 40 inch/sec peak

Maximum Acceleration: 50g rms (Random)

Maximum Payload: 220 lbs (total weight)

Driven by: LDS PA2000 2kW power amplifier

Controlled by: LDS DVC 4000 Mk3

Accelerometer: Manufacturer: PCB

Model: J357B01 (charge capacitance type)

Serial: 8968, 8969

Range: ±1800 g

The vibration controller and feedback accelerometers were calibrated on March 21 , 2005 by

st

Ralco Inc. in North Haven, Connecticut, in compliance with ANSI/NCSL Z540-1 and traceable to

NIST. The calibration certificates of the controller and accelerometers are provided in Appendix 1.

Power amplifier

Vibration controller

Vibration shaker

Figure 3: Weir-Jones Engineering Consultants Ltd. vibration testing equipment. Note that the

direction of shaker movement is vertical.

Weir-Jones Engineering Consultants Ltd. 3 30144-REP-001-0.wp9

Loading...

Loading...