Page 1

-1-

INSTALLATION INSTRUCTIONS

No.59-1881-3 131115UL

No.59-1881-3

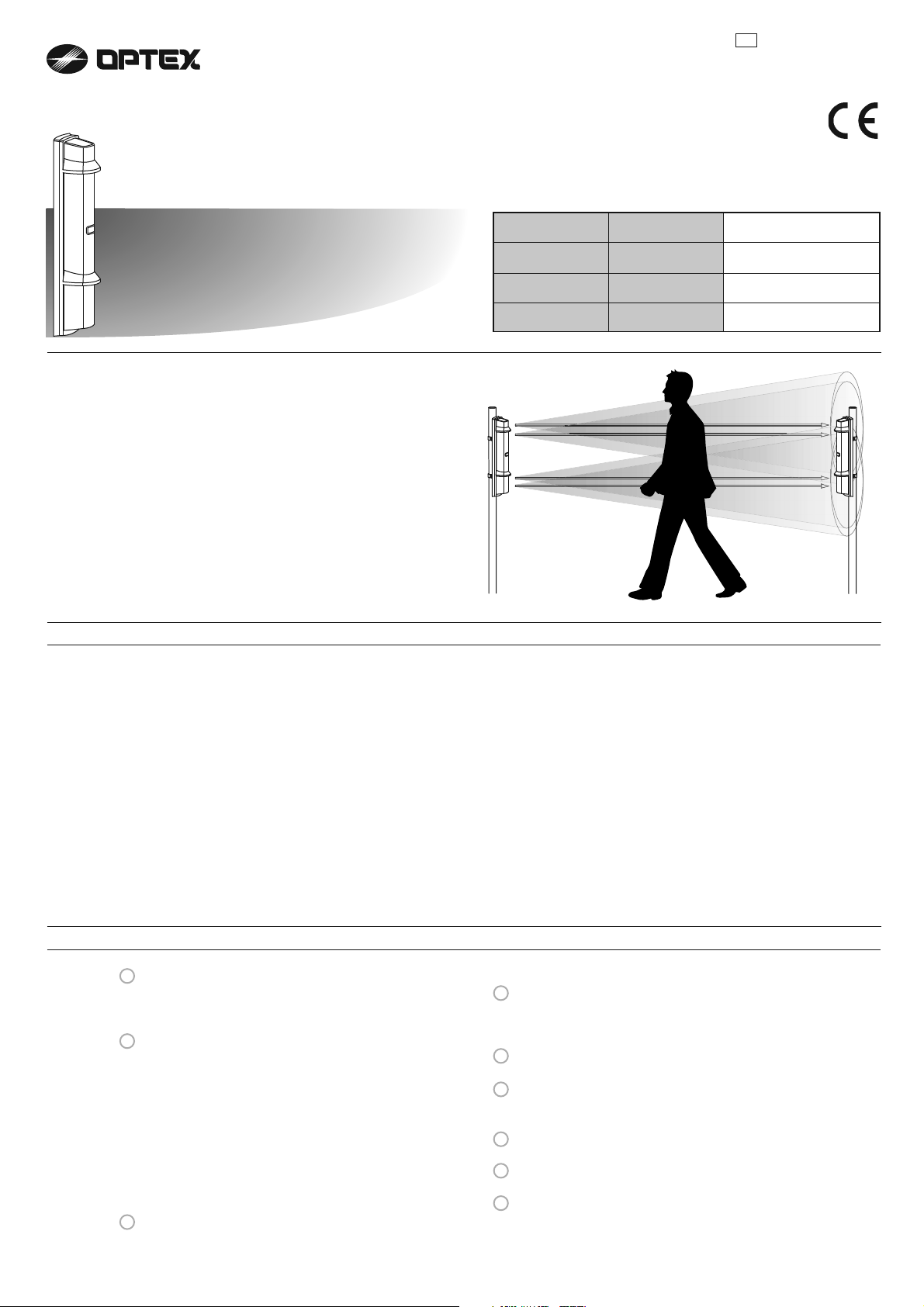

PHOTOELECTRIC DETECTOR

• Quad high power beams

• Double modulated beam

• Smart design

- Slim body design

- Easy-to-see vivid interior color for optical alignment

- IP65*1 waterproof structure

• 4 channel beam frequency selector

• Alignment level indicator

• Viewfinder with 2X magnification

• Various options (refer to page 20)

( HU-3*1, ABC-4*1, BC-4*1, CBR-4, PSC-4*1, BAU-4*1 )

• UL/c-UL Listed

• Beam interruption adjustment function

• D.Q. circuit (environmental disqualification)

• Tamper function

• Beam power control selector

• Alarm memory

• Sound assist function

-

Optical alignment

- Beam reception status

- Walk test

[ SL-QDM only ]

• Auto Transmit Power Control (A.T.P.C*2) to optimize the beam power

• Integrated Alignment Status Communication (I.A.S.C*2) to

communicate the transmitter and receiver

• Re-transmitting circuit function

• Solar Battery Unit SBU-4*1 (option)

PHOTOELECTRIC DETECTOR

A photoelectric detector consists of an infrared light

source that generates IR(Infrared) beams, and an IR

receiver that detects the IR beams. The transmitter

and receiver are installed on opposite sides of the

area to be monitored. The receiver detects when the

IR beams are physically interrupted by an intruder,

and sends an alarm signal to be a control panel.

FEATURES

INTRODUCTION

1-1 BEFORE YOUR OPERATION .......................2

1-2 PRECAUTIONS

.......................................................

2

1-3 PARTS IDENTIFICATION

.....................................

3

INSTALLATION

2-1 SEPARATING................................................. 4

2-2 WIRING.......................................................... 4

2-3 TERMINAL .....................................................5

2-4 WIRING DIAGRAM ........................................ 5

2-5 WIRING DISTANCE BETWEEN POWER

SUPPLY AND DETECTOR ............................ 6

2-6 WALL MOUNTING.........................................6

2-7 POLE MOUNTING ......................................... 8

2-8 MOUNTING IN THE BEAM TOWER..............9

2-9

INSTALLATION EXAMPLE AT PARTICULAR CASE

... 9

FUNCTION SETTING

3-1 DIP SWITCH ................................................. 10

3-2 BEAM POWER CONTROL SELECTOR....... 10

1

2

3

4

6

7

8

9

CONTENTS

3-3 FUNCTION.................................................... 11

OPTICAL ALIGNMENT

4-1 OPTICAL ALIGNMENT FOR UPPER AND

LOWER BEAM.............................................. 15

4-2 OPERATION CHECK.................................... 17

TROUBLESHOOTING

5-1 TROUBLESHOOTING .................................. 17

OPTIONAL SETTING

6-1 HEATER UNIT HU-3 (OPTION) .................... 18

6-2 SOLAR BATTERY UNIT SBU-4 (OPTION)... 18

DIMENSIONS

7-1 DIMENSIONS ............................................... 19

SPECIFICATIONS

8-1 SPECIFICATIONS......................................... 19

OPTIONS

9-1 OPTIONS ...................................................... 20

Detection range

SL-200QDM

SL-350QDM

SL-650QDM

SL-200QDP

SL-350QDP

SL-650QDP

Advanced Standard

5

Transmitter

Receiver

Smart Line series

Smart Line series

™

™

60m/200ft.

100m/350ft.

200m/650ft.

*1 not evaluated by UL

*2 not require any additional tool

Page 2

-2-

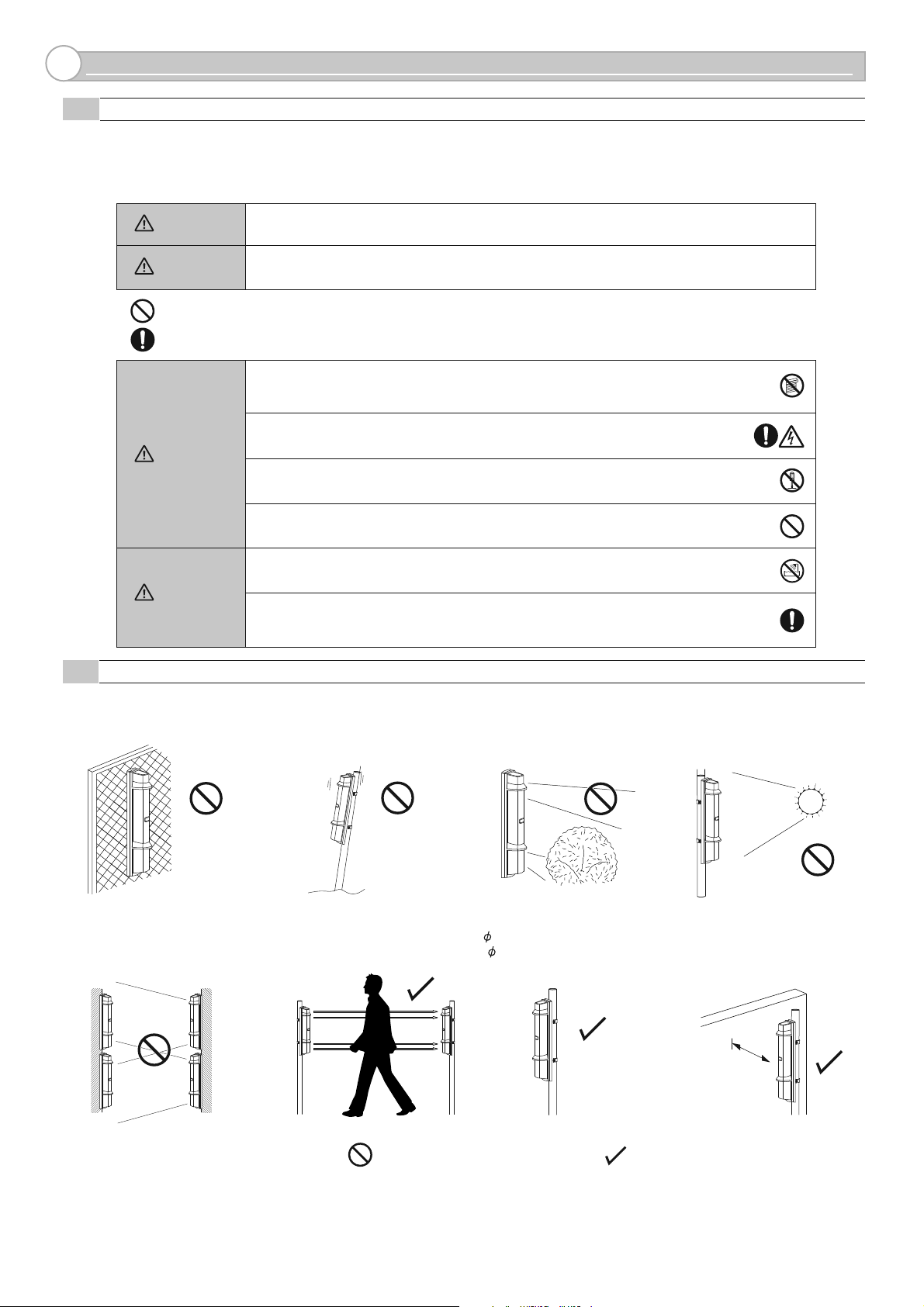

1-2

PRECAUTIONS

This symbol indicates prohibition.

This symbol indicates recommendation.

Receiver

Transmitter

(different

model)

Receiver

(different

model)

Transmitter

At least 1 m (3.3 ft.)

Warning

Caution

• Read this instruction manual carefully prior to installation.

• After reading, store this manual carefully in an easily accessible place for reference.

• This manual uses the following warning indications for correct use of the product, harm to you or other people and damage to your assets, which

are described below. Be sure to understand the description before reading the rest of this manual.

INTRODUCTION

1

1-1

BEFORE YOUR OPERATION

Failure to follow the instructions provided with this indication and improper handling may cause

death or serious injury.

Failure to follow the instructions provided with this indication and improper handling may cause

injury and/or property damage.

This symbol indicates prohibition. The specific prohibited action is provided in and/or around the figure.

This symbol requires an action or gives an instruction.

Do not install the unit on an

unstable surface.

Do not install the pole in a

location where sufficient

stability can not be ensured.

Do not install the unit in a

location where trees, leaves, or

other objects that may swing in

the wind and block the beam.

Do not install the receiver in a

location where it is exposed to

direct sunlight.

Install the unit at a height

where an object can be

detected without fail.

Do not allow the infrared beam

from a different model to reach

the receiver.

Install the unit at least 1 m (3.3

ft.) away from the wall or fence

that may be running parallel to

the beam.

The pole size should be

34 - 48 mm

( 1.34 - 1.89 inch).

Warning

Caution

Do not use the product for purposes other than the detection of moving objects such as

people and vehicles. Do not use the product to activate a shutter, etc., which may

cause an accident.

Do not touch the unit base or power terminals of the product with a wet hand (do not

touch when the product is wet with rain, etc.). It may cause electric shock.

Never attempt to disassemble or repair the product. It may cause fire or damage to the

devices.

Do not exceed the voltage or current rating specified for any of the terminals during

installation, doing so may cause fire or damage to the devices.

Do not pour water over the product with a bucket, hose, etc. The water may enter,

which may cause damage to the devices.

Clean and check the product periodically for safe use. If any problem is found, do not

attempt to use the product as it is and have the product repaired by a professional

engineer or electrician.

[Receiver]

Transmitter

Receiver

For UL/c-UL installations ;

• Reference to UL681, Standard for Installation and Classification of Burglar and Holdup Alarm System.

• Reference to CAN/ULC-S302, ULC Standard for Installation and Classification of Burglar Alarm Systems for Financial and Commercial Premises.

Safes and Vaults, & CAN/ULC-S310, ULC Standards for Installation and Classification of Residential Burglar Alarm.

• Conduit is required for all Outdoor Use Application with Conduit Bracket Kit, Model CBR-4, employing appropriate wiring methods.

• Products to be installed within the protected premises.

Page 3

-3-

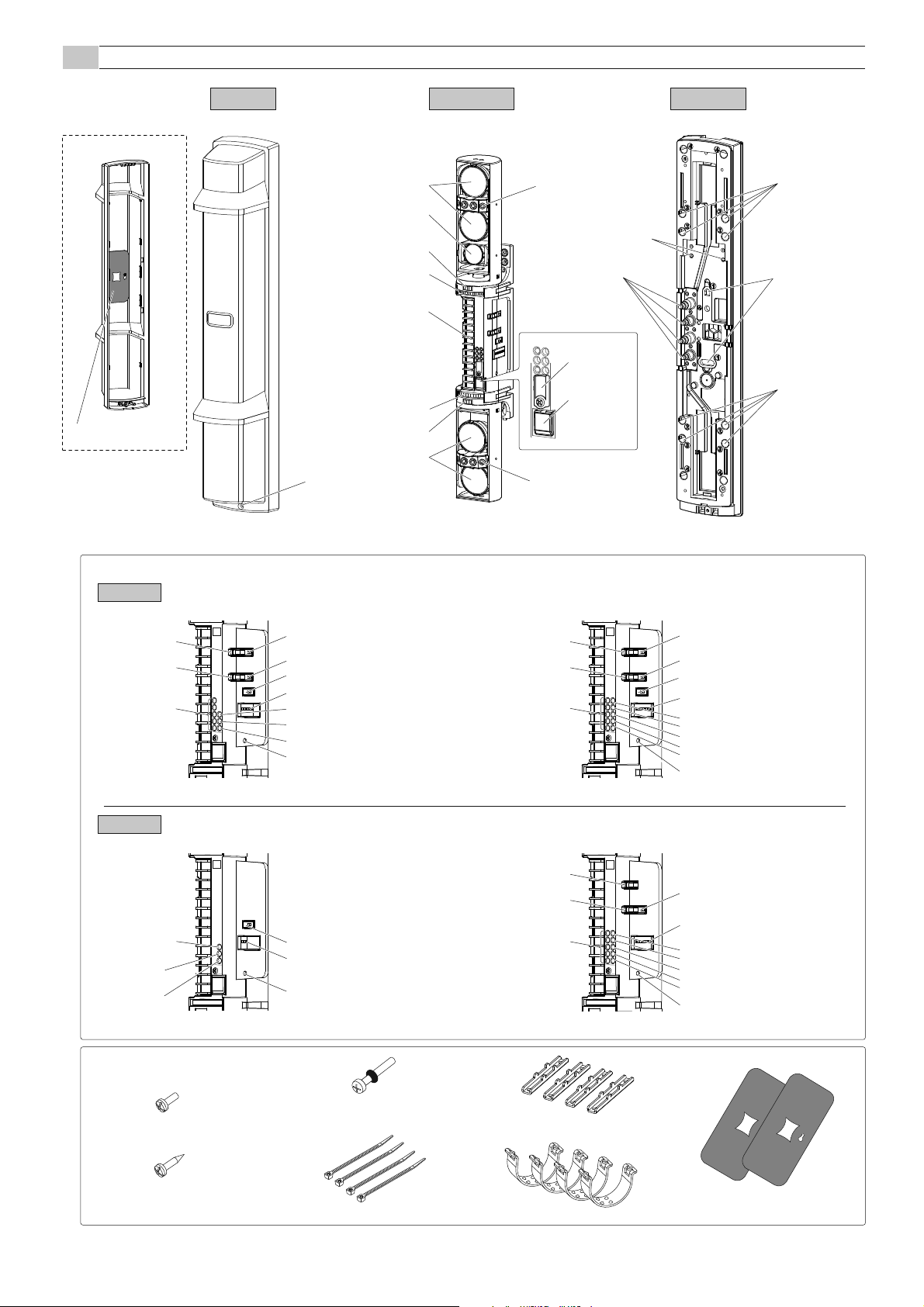

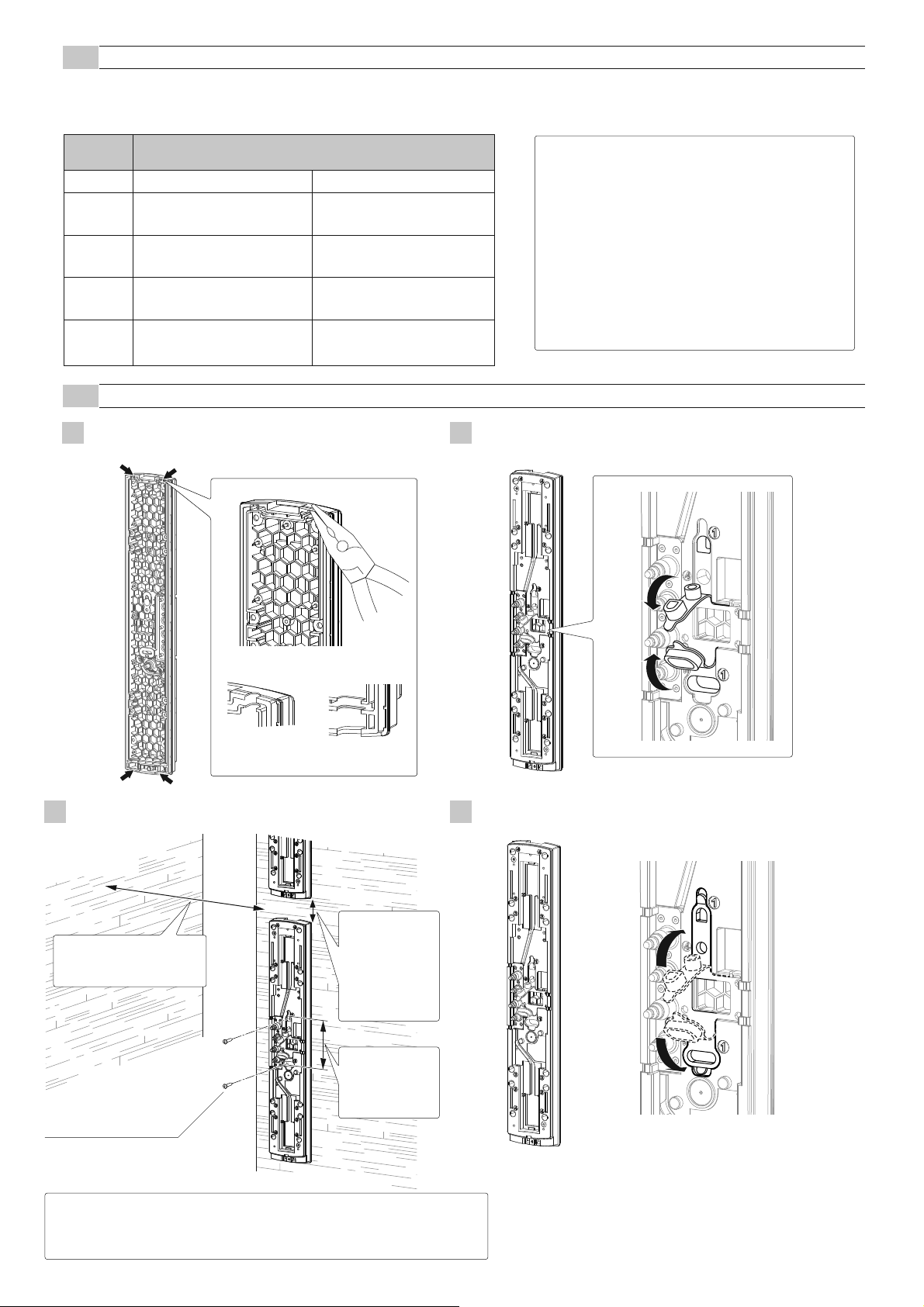

<Transmitter>

U-brackets: 4

Pole brackets: 4

4×20 self tapping for wall mounting: 4

M4×30 screws for pole mounting

(with rubber washer): 8

Beam blocking plate: 2

(attached on the back of the cover)

3×6 self tapping for pole bracket: 4

FUNCTION SETTING SECTION >>

ACCESSORIES >>

SL-QDM

SL-QDP

<Receiver>

<Transmitter> <Receiver>

Banding bands: 4

1-3

PARTS IDENTIFICATION

Cover

Main unit

Chassis

Cover lock screw

View finder

Terminals

Cut bush

for wiring

Main unit base

Mounting screw holes

Pole mounting

screw holes

Pole mounting

screw holes

Wall mounting

screw holes

Vertical alignment dial

Vertical alignment dial

Horizontal alignment dial

Optical lens

I.A.S.C lens

[QDM only]

Horizontal alignment dial

Viewfinder

Beam blocking plate

T R

T

R

Upper/Lower beam selection button

Upper/Lower beam selection button

Upper/Lower beam selection button

Monitor jack (+)

Monitor jack (-)

Power indicator LED

Upper beam indicator LED

Lower beam indicator LED

Power indicator

LED

Upper beam

indicator LED

Lower beam

indicator LED

Power supply selector

Sound assist switch

Beam power control selector

Dip switch

Alignment level

indicator LED

Upper/Lower beam selection button

Power supply selector

Sound assist switch

Dip switch

Alignment level

indicator LED

Beam power control selector

Dip switch

Sound assist switch

Dip switch

Alignment level

indicator LED

Optical lens

Tamper

lock plate

Tamper

button

Power indicator LED

Alarm memory indicator LED

Alarm indicator LED

Upper beam indicator LED

Lower beam indicator LED

Power indicator LED

Alarm memory indicator LED

Alarm indicator LED

Upper beam indicator LED

Lower beam indicator LED

Monitor jack (+)

Monitor jack (-)

Monitor jack (+)

Monitor jack (-)

Beam power control selector

Page 4

-4-

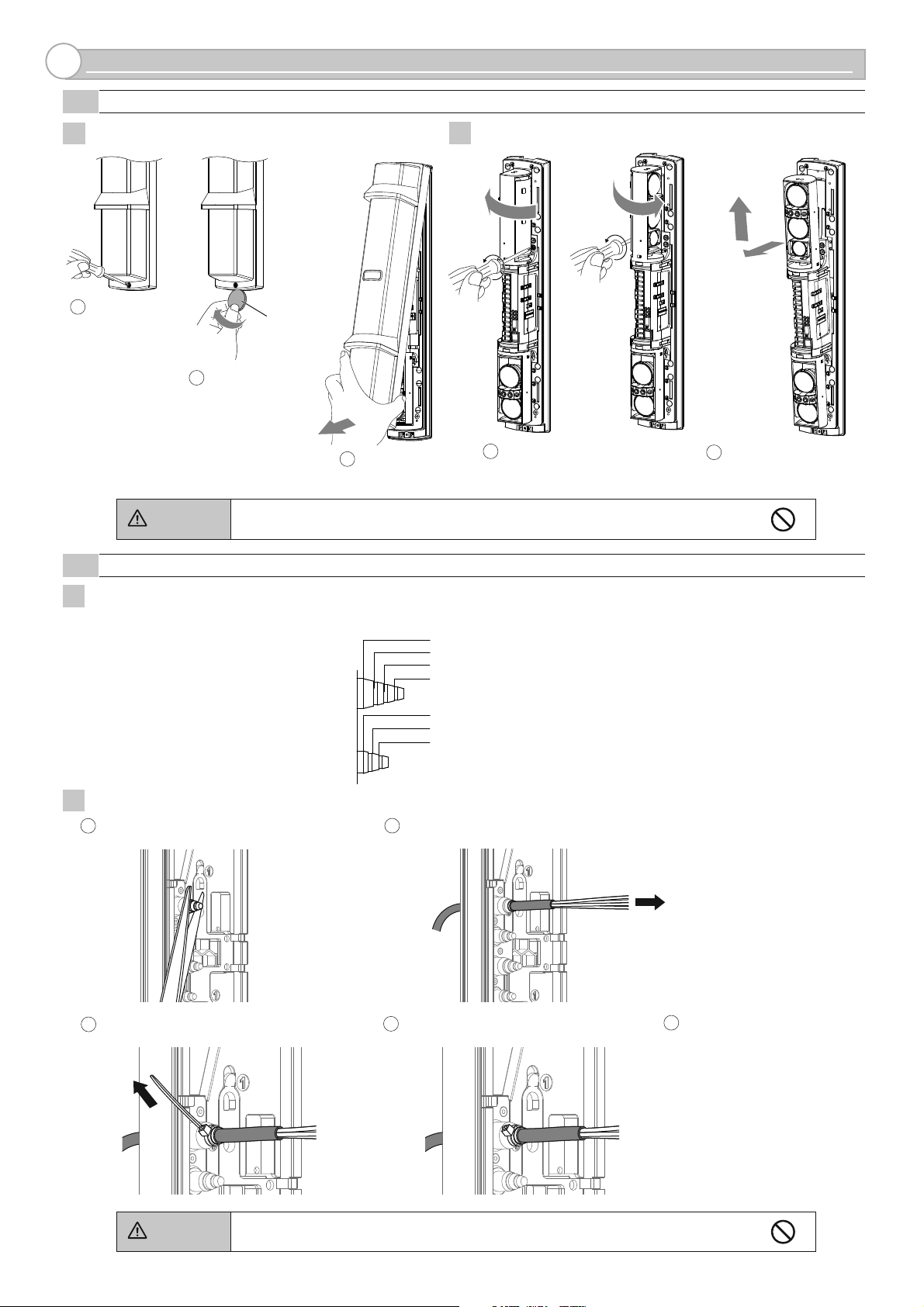

2-1

SEPARATING

INSTALLATION

2

1

Remove the cover.

2

1

2

Remove the main unit from the chassis.

Pull the upper part of

main unit, and raise it to

remove.

Turn the optical unit 90 degrees

and loosen the screws (both

sides).

Do not place the main unit where it allows to incident direct sunlight to its optical lens during

installation. Doing so may cause damage to the product.

Caution

3

4

1

2

5

6

2-2

WIRING

1

Cut off the cut bush according to the cable size.

2

5

3

4

1

Preparing the cut bush

Cut the wiring grommet required according to the wire diameter. Use the lidded grommet for the wiring hole not to be used.

(I.D. : Internal diameter)

Refer to "TERMINAL" on Page

5 to make connections to the

terminals and refer to “OPTICAL ALIGNMENT” on Page 15

to make alignment for the

maximum level of light

reception.

Pass the cable through the cut bush.

Connect to the terminalsCut the excess portion of the banding band.Tighten the cable with the banding band.

2

Threading the wire

Do not exceed the voltage or current rating specified for any of the terminals during

installation, doing so may cause fire or damage to the product.

Caution

Pull

Loosen the

cover lock screw.

2

Twist it lightly.

1

3

A coin

(Not included)

I.D. 10mm (0.39 inch)

I.D. 8mm (0.31 inch)

I.D.

6mm (0.24 inch)

I.D. 4mm (0.16 inch)

I.D. 7mm (0.28 inch)

I.D. 6mm (0.24 inch)

I.D. 4mm (0.16 inch)

Page 5

-5-

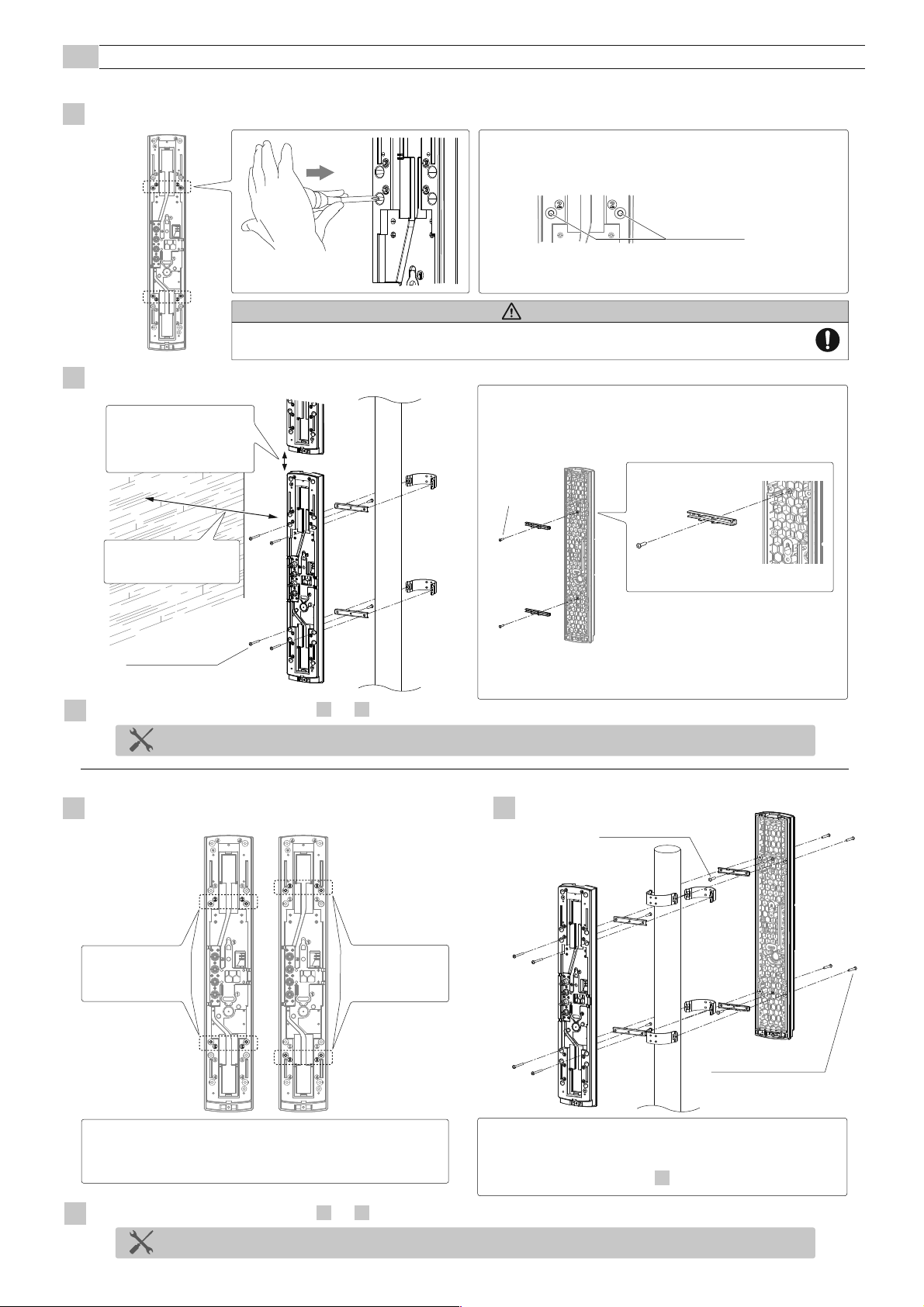

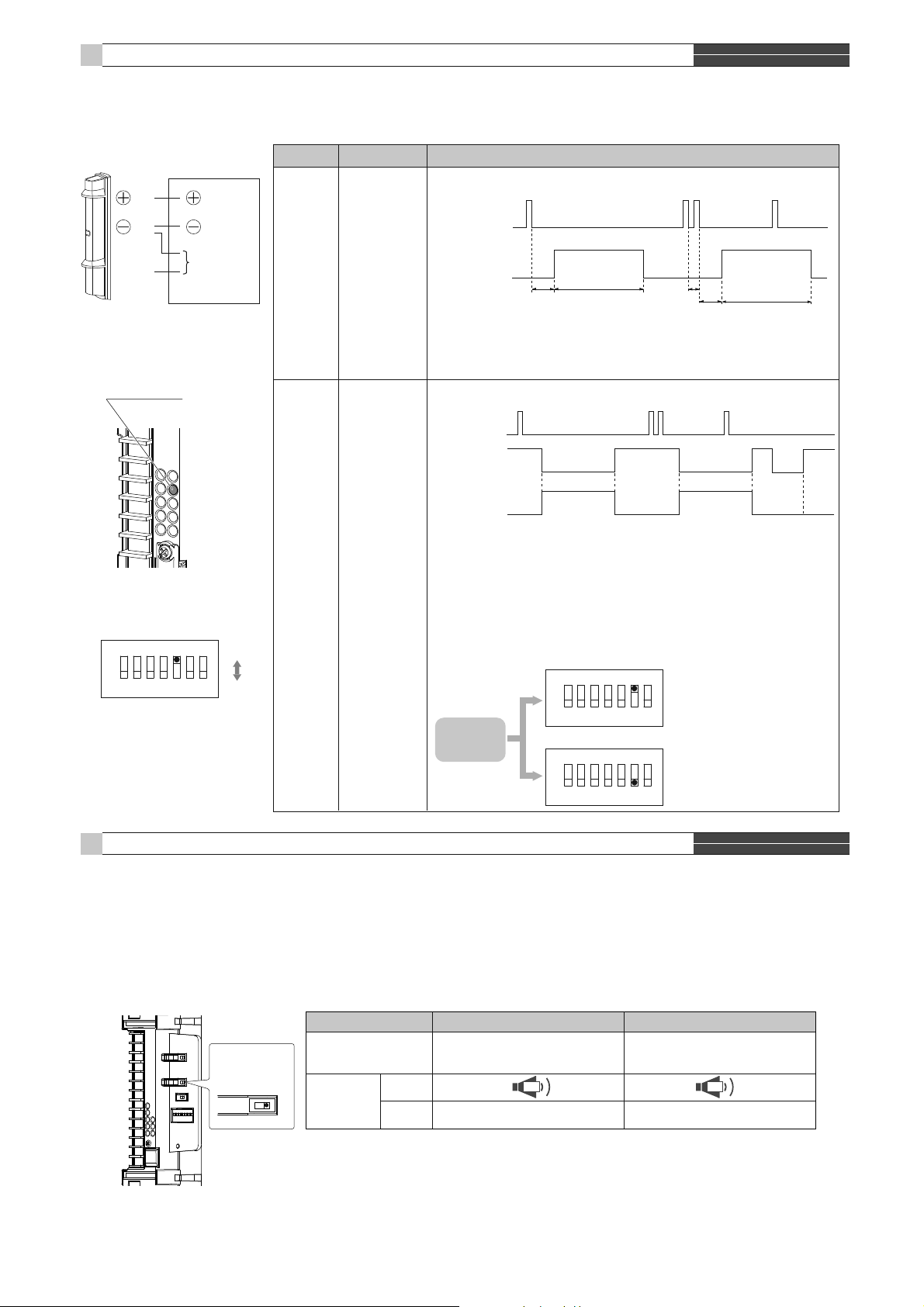

2-4

WIRING DIAGRAM

<Receiver>

<Transmitter>

(1) +

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

<Receiver>

<Transmitter>

SL-QDM SL-QDP

1

1 Set

POWER

CONTROL PANEL

ALARM

N.C.

(1)

(1)(2) (1)(2) (8)(9)

(1) (2)(1) (2) (8)(9)

(1)(2) (2) (8) (9)

(1) (1)(2) (2) (1) (2)(8) (9) (1) (2) (8) (9)

Transmitter Receiver

3

2 Sets in the line

POWER

TransmitterReceiverTransmitter Receiver

Connect the power supply in parallel. Connect the units serially for a normally closed alarm output and in parallel for a normally open output

(the figure below shows an example for a normally closed alarm output).

Connect the power supply in parallel. Connect the units serially for a

normally closed alarm output and in parallel for a normally open

output (the figure below shows an example for a normally closed

alarm output).

Connect the power supplies in parallel.

CONTROL PANEL

2

2 Sets Stacking

POWER

Transmitter Receiver

Ch1 Ch1

Ch3 Ch3

POWER INPUT

10.5-30VDC [ Normal ]

3.6VDC [ SBU-4 ]

*

POWER INPUT

10.5-30VDC [ Normal ]

3.6VDC [ SBU-4 ]

*

SPARE

ALARM INPUT

LOW BATTERY

INPUT

(using with SBU-4)

*

TAMPER

OUTPUT (N.C.)**

(1) +

(2)

(3)

(4)

(5) N.O.

(6) N.C.

(7) COM.

(8) COM.

(9) N.C.

(

10

) N.O.

(

11

)

(

12

)

(

13

)

(

14

)

SPARE

D.Q.

OUTPUT

/

LOW BATTERY

OUTPUT* **

ALARM OUTPUT**

TAMPER OUTPUT**

(N.C.)

ALARM MEMORY INPUT

LOW BATTERY INPUT

(using with SBU-4)*

(1) +

(2)

(3)

(4)

(5)

(6)

POWER INPUT

10.5-30VDC

SPARE

(1) +

(2)

(3)

(4)

(5) N.O.

(6) N.C.

(7) COM.

(8) COM.

(9) N.C.

(

10

) N.O.

(

11

)

(

12

)

(

13

)

(

14

)

POWER INPUT

10.5-30VDC

SPARE

D.Q.

OUTPUT

ALARM OUTPUT**

TAMPER OUTPUT**

(N.C.)

ALARM MEMORY INPUT

SPARE

2-3

TERMINAL

TAMPER

OUTPUT (N.C.)**

Note>>

Connect POWER INPUT - terminal(2) when wiring LOW BATTERY INPUT* terminal(7) of the transmitter,

ALARM MEMORY INPUT terminal(11) and LOW BATTERY INPUT terminal(12) of the receiver.

*

SBU-4 and its low battery input/output function not evaluated by UL ** All outputs are power-limited.

ALARM

N.C.

ALARM

N.C.

*1 CONTROL PANEL = UL/c-UL listed burglar alarm control panel

*2 POWER = power limited output

*2

*2

*1

*2

*1

CONTROL PANEL

*1

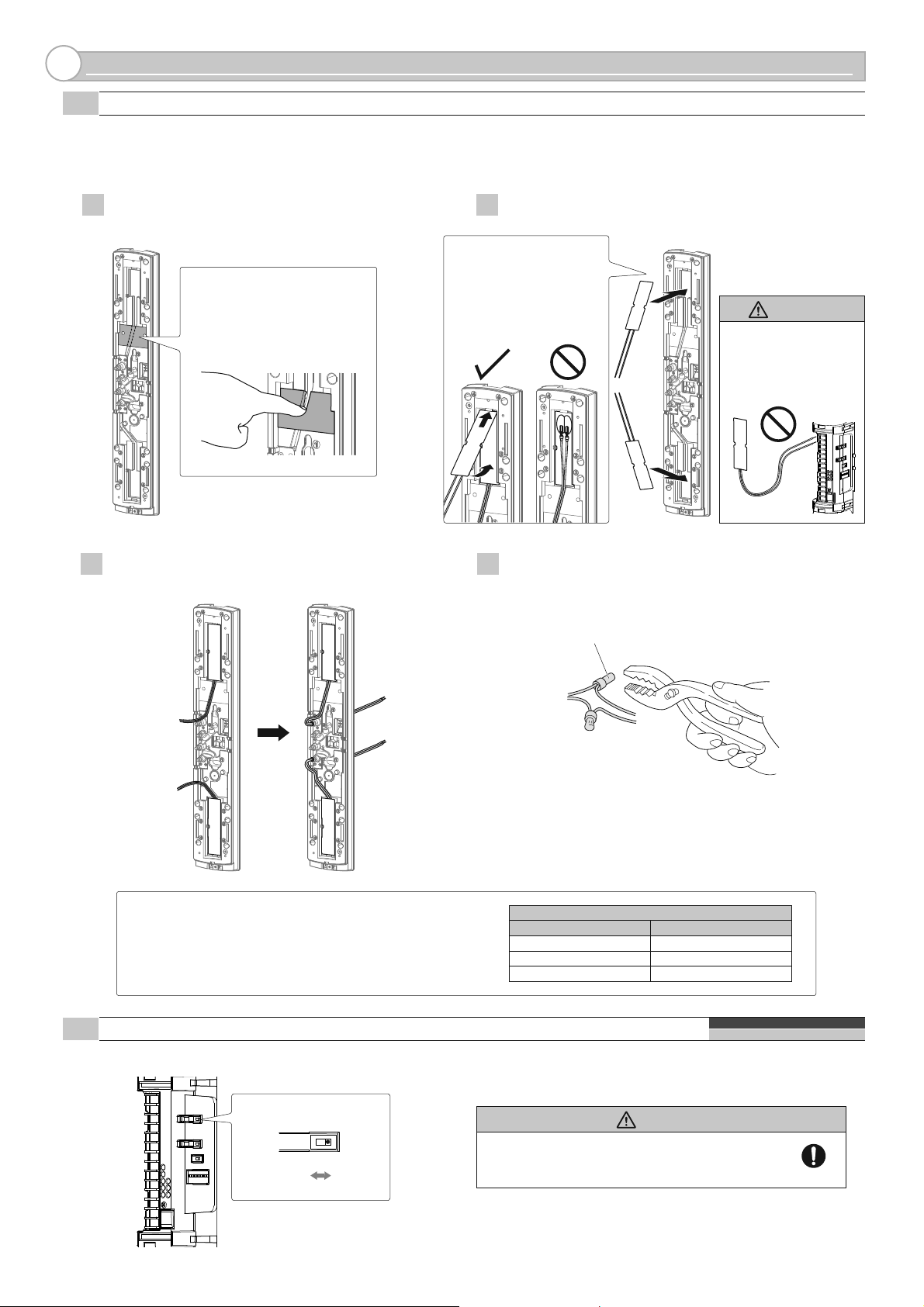

Page 6

-6-

2

Pull the waterproof packing (x2) marked as "①" at the

center of the chassis.

3

Mount the chassis to the wall.

4×20 self tapping

(with rubber washer)

Side wall

Distance from the side wall:

at least 1m

If two detectors

are installed, the

distance between

the upper and

lower detector

should be at least

20 mm.

4

Put the waterproof packing back in place.

2-6

WALL MOUNTING

- Ensure that the wiring distance from the power supply is within the range shown in the table below.

- When using two or more units on one wire, the maximum length is obtained by dividing the wire length listed below by the number

of units used.

2-5

WIRING DISTANCE BETWEEN POWER SUPPLY AND DETECTOR

Note>>

UL/c-UL requires to be connected to a UL/c-UL

Listed burglar alarm power limited power supply of

providing a nominal input of 12 VDC (10.5 to 30

VDC) 30 mA (SL-200/350/650 QDM) or 22 mA

(SL-200/350/650 QDP), and battery standby time of

4 hours.

Wiring method shall be in accordance with the

National Electrical Code (ANSI / NFPA 70),

Canadian Electrical Code, Part 1 (CSA C22.1)

Safety Standard for Electrical Installations, local

codes, and the authorities having jurisdiction.

Pitch: 83.5 mm

For connection

to gang electric

box

1

Open the wiring guide on the back of the chassis using

pliers as shown.

<After the cutting>

[ Upper ] [ Lower ]

MODEL

WIRE SIZE

12 VDC 24 VDC

2,100 m

(7,000 ft.)

3,300 m

(10,000 ft.)

5,300 m

(17,000 ft.)

8,300 m

(27,000 ft.)

0.33 mm

2

(AWG22)

0.52 mm

2

(AWG20)

0.83 mm

2

(AWG18)

1.31 mm

2

(AWG16)

SL-200QDM /

SL-200QDP /

SL-350QDM /

SL-350QDP /

SL-650QDM

SL-650QDP

600 m

(2,000 ft.)

900 m

(3,000 ft.)

1,500 m

(4,900 ft.)

2,500 m

(8,000 ft.)

Note>>

Install the unit vertically at a height where an object can be detected without

fail. In case to be stacked, be careful to cover the detection area totally.

Page 7

-7-

5

Mount the cover and check the operation.

Hook on the upper part of the chassis.

Push the lower part of the cover until it

clicks into position.

1

2

Fasten the cover lock screw.

3

Note>>

Push the middle part of the cover and hide this

orange label completely when in operation.

Do not contact with the optical unit when mounting the cover. Otherwise malfunction

may occur due to the shift of the optical axis, resulting in the need of readjustment.

Caution

Fix the main unit.

4

2

1

Turn the optical unit 90 degrees and tighten the screws (both

sides).

Insert the lower part, and then push the upper part

onto the chassis.

Orange label

A cover must hide this orange label completely when in operation.

Make function settings and optical alignment before mounting the cover.

3

4

1

2

Note>>

Place the tamper lock plate with the face up. Not doing

so may cause damage to the product.

Page 8

-8-

2-7

POLE MOUNTING

< Installing one detector >

< Installing two detectors in opposing directions >

1

Note>>

Caution

Using a screwdriver or similar tool, break the knockout position (x4) in the chassis as shown.

1

Using a screwdriver or similar tool, break the knockout position

(x4) in the chassis as shown.

• When mounting the single set of detectors to the pole, use

a pair of the inside knockouts.

The knockout positions are marked "②" as shown.

• Break the knockout from the direction shown (inside the

chassis). Breaking from the opposite direction (outside of the

chassis), makes a risk of generating burrs scratch the wire.

If you accidentally open an unnecessary knockout, be sure to fill the knockout with rain tight composite

like silicone rubber. Not doing so may result in waterproof failure and malfunction of the product.

Knockout position

2

Fix the chassis on the pole.

Note>>

Side wall

M4×30 screw

(with rubber washer)

Distance from the side wall:

at least 1m

• Before fixing the chassis on the pole, temporarily fix one

point at the center of the pole mounting bracket to the

back of the chassis.

• Install the unit vertically at a height where an object can be

detected without fail. In case to be stacked, be careful to

cover the detection area totally.

3×6 self tapping

3

Perform the wall mounting procedure of 4 to 5 on page 7.

3

2

Fix the chassis on the pole.

Note>>

Note>>

M4×30 screw

(with rubber washer)

• Before fixing the chassis on the pole, temporarily fix one point

at the center of the pole mounting bracket to the back of the

chassis. Refer to procedure 2 of “Installing one detector”.

• Choose a different pair of knockouts.

Pairs of the knockout positions are marked "②" and "③".

3×6 self tapping

Inside pair of

knockouts

marked

"②"

Outside pair of

knockouts

marked

"③"

Perform the wall mounting procedure of 4 to 5 on page 7.

If two detectors are installed,

the distance between the

upper and lower detector

should be at least 20mm.

Make function settings and optical alignment before mounting the cover.

Make function settings and optical alignment before mounting the cover.

Page 9

-9-

2-8

MOUNTING IN THE BEAM TOWER

In accordance with the type of the main unit inside the beam tower, install the detector in the same way as wall mounting or pole mounting.

2

1

When installing the detector without the cover, hold the tamper button with the tamper lock plate on both the transmitter and receiver.

Loosen the screw.

1

Tamper lock plate

Tamper button

Fasten the screw to lock

the tamper button.

3

Rotate the tamper lock plate.

2

< Mounting with the chassis > < Mounting without the chassis >

Caution

The switch selection is not recognized when locking the tamper button.

Release the tamper button before selecting a function using the switch.

After completing the settings, be sure to lock the tamper button to check that all LEDs are

OFF. If the tamper button is not locked, the LEDs are kept ON, which consumes more

battery power.

Monitor jack output become disabled when locking the tamper button.

If you do not close the tamper lock plate, the sensitivity will be reduced as adjustment

mode will not end. Be sure to close the tamper with the tamper lock plate.

Make function settings and optical alignment before mounting the cover.

In case you do this installation, the maximum detection range

shall be half of the original detection range. (This is to prevent

the attenuation of beam by the edge of the cover.)

If possible, avoid installing the transmitter and receiver facing

each other in a slanting direction as shown below.

e.g.) SL-200QDM: 60m/200ft.30m/100ft.

Transmitter Receiver

[ Top view ]

1

2

2-9

INSTALLATION EXAMPLE AT PARTICULAR CASE

Page 10

-10-

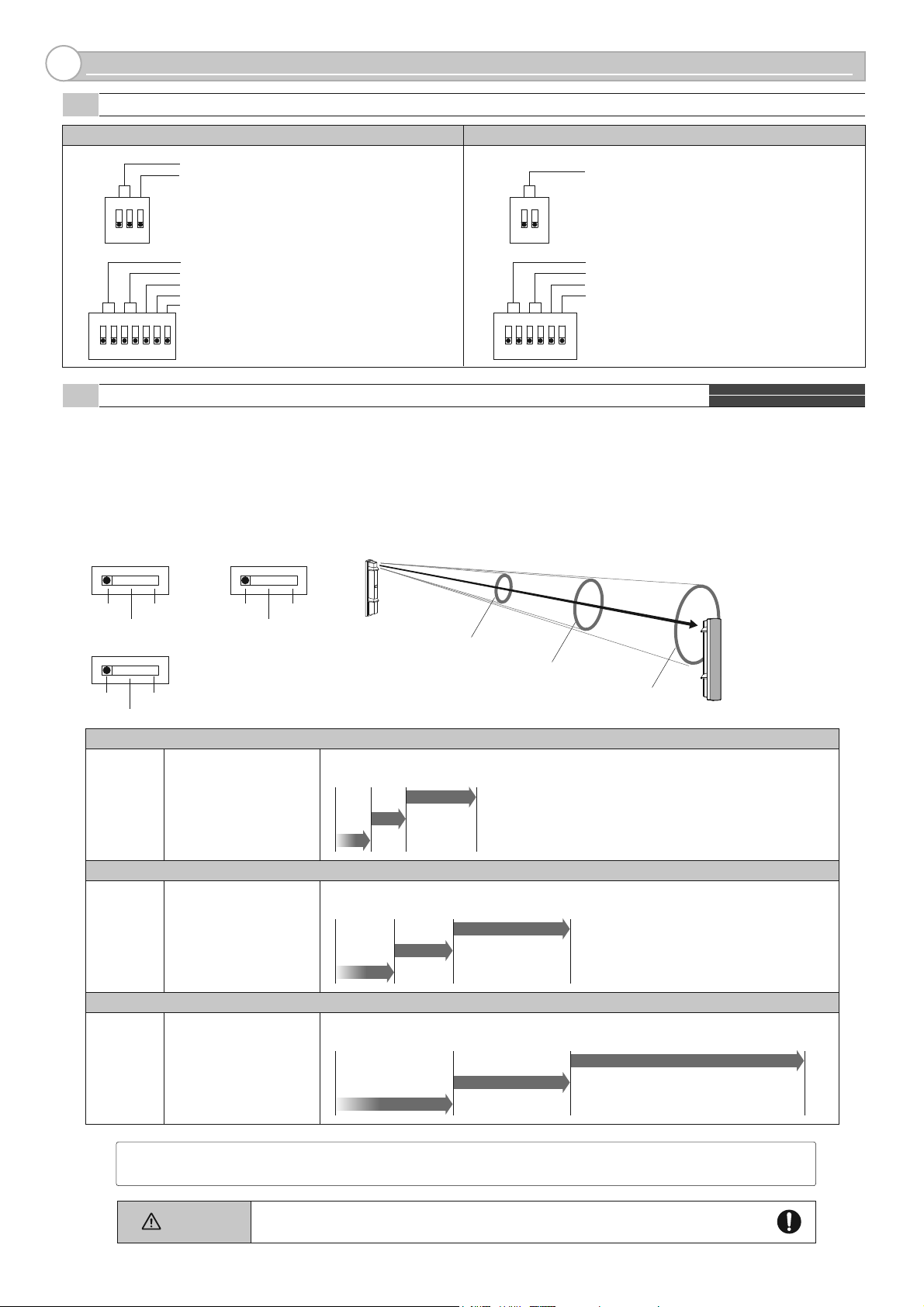

3-1

DIP SWITCH

3-2

BEAM POWER CONTROL SELECTOR

FUNCTION SETTING

3

SL-QDM SL-QDP

4 Channel beam frequency selector switch

Alarm memory switch [Auto/Manual]

Alarm memory switch [Positive/Negative]

D.Q. (environmental disqualification)/Low battery

output switch [D.Q./Low battery]

Interruption time switch [50/100/250/500ms]

ON

1 2 3 4 5 6 7

<Receiver>

4 Channel beam frequency selector switch

Alarm input switch [Positive/Negative]

ON

1 2 3

<Transmitter>

SL-QDM

SL-QDP

The beam power control selector can be used to avoid unwanted crosstalk that can occur when using multiple photo beams for long

distance or beam stacking applications.

The selector allows you to manually adjust beam power from NORMAL to LOW or VERY LOW.

Make sure the selector select to reduce beam power when using the detector for a distance shorter than the rated distance.

This function is also effective for the following purpose.

For countermeasure against crosstalk due to reflection of walls or ground.

For making optical alignment to support peak adjustment when the monitor jack output beams saturated.

< SL-QDM> < SL-QDP>

< Illustration >

Transmitter

Receiver

Transmitter

NORMAL

LOW

VERY LOWNORMAL

LOW

VERY LOW

VERY LOW

LOW

NORMAL

NORMAL

LOW

VERY LOW

SL-200 QDM/QDP

NORMAL

LOW

VERY LOW

SL-350 QDM/QDP

NORMAL

LOW

VERY LOW

60 - 30 m (200 - 100 ft)

30 - 15 m (100 - 50 ft)

Within 15 m (Within 50 ft)

100 - 50 m (350 - 175 ft)

50 - 25 m (175 - 88 ft)

Within 25 m (Within 88 ft)

200 - 100 m (650 - 350 ft)

100 - 50 m (350 - 175 ft)

Within 50 m (Within 175 ft)

SL-650 QDM/QDP

0 m 15 m

(50 ft)

30 m

(100 ft)

60 m

(200 ft)

0 m 25 m

(88 ft)

50 m

(175 ft)

100 m

(350 ft)

0 m 200 m

(650 ft)

50 m

(175 ft)

100 m

(350 ft)

Be sure to set the beam power control selector according to the installation distance.

Not doing so may result in interference with other sets of detectors.

Caution

Make sure the receiver and transmitter that are facing each other are set to the same position (SL-QDM only).

Note>>

NORMAL

LOW

VERY LOW

4 Channel beam frequency selector switch

Alarm memory switch [Auto/Manual]

Alarm memory switch [Positive/Negative]

Interruption time switch [50/100/250/500ms]

ON

1 2 3 4 5 6

<Receiver>

4 Channel beam frequency selector switch

ON

1 2

<Transmitter>

Page 11

-11-

Caution

3-3

FUNCTION

ON

1 2 3 4 5 6 7

ON

1 2 3

Transmitter

Transmitter A

Transmitter B

Receiver A

Receiver B

1

3

1

3

1

3

1

3

1

3

1

3

2

4

2

4

a) Double stacked protection

Since Receiver B may receive the infrared beam from Transmitter

A, select the frequencies as shown in the figure above.

(In the figure, each number in the square indicate a channel numbers.)

Since Receiver C may receive the infrared beam from Transmitter

A, select their frequencies as shown in the figure above.

c) Double stacked long distance protection

Transmitter Receiver

Transmitter Receiver

Receiver Transmitter

Receiver Transmitter

Transmitter Receiver

Transmitter Receiver

4 CHANNEL BEAM FREQUENCY SELECTOR

1 1

1 1 3 3

Transmitter A Receiver A Receiver B Transmitter B Transmitter C Receiver C

b) Long distance protection

The 4 channel beam frequency selector can be used to avoid unwanted crosstalk that can occur when using multiple photo beams for long

distance or beam stacking applications.

7RVHOHFWEHWZHHQVHSDUDWHEHDPIUHTXHQFLHVXVHWKHVZLWFKSURYLGHG

0RUHWKDQGRXEOHVWDFNHGDSSOLFDWLRQLVQRWSRVVLEOH

SL-QDM

SL-QDP

1

More than double stacked application is not possible.

0DNHVXUHWKHUHFHLYHUDQGWUDQVPLWWHUWKDWDUHIDFLQJHDFKRWKHUDUHVHWWRWKHVDPHFKDQQHO

Note>>

ON

ON

ON

ON

Channel 1 Channel 3Channel 2

Channel 4

Receiver

A D

B C

If interference occurs as shown below, use the beam power control selector to reduce beam [A] to less than the specified distance.

Lower the beam power control

selector of transmitter A by one level.

(Refer to 3-2 on page 10.)

Check that the light receiving level

of receiver B is Good or better

without blocking light for both upper

and lower units.

Page 12

-12-

Initial setting is at 50 msec for normal work. According to the speed of a supposed target you select one specific setting out of 4 steps.

Set the beam interruption adjustment switches of the receiver according to the speed of the human object to detect.

(50 msec) (100 msec) (250 msec) (500 msec)

Typical

interruption

time setting

Dip switch

(Receiver)

Running Jogging Walking Slow movement

ON

1 2 3 4 5 6 7ON1 2 3 4 5 6 7ON1 2 3 4 5 6 7ON1 2 3 4 5 6 7

Warning

Do not attempt to install this product with any other photoelectric detector.

It may cause the detector to fail or not respond to movements.

BEAM INTERRUPTION ADJUSTMENT

SL-QDM

SL-QDP

2

d) Perimeter protection

Transmitter 1Transmitter

3

Transmitter

1

Transmitter

3

Receiver

1

Receiver

3

Receiver

3

Receiver

1

e) Perimeter protection in a two-stack configuration

Transmitter

1

Receiver

3

Receiver

3

Transmitter

3

Transmitter

2

Transmitter

4

Transmitter

2

Transmitter

4

Transmitter

1

Transmitter

3

Receiver

2

Receiver

4

Receiver

1

Receiver

2

Receiver

4

Receiver

1

By connecting a alarm output of other detector to the transmitter.

While the alarm input terminal (5) (6) of the transmitter receive the signal

from other detectors, the beam is forced to stop and the receiver sends the alarm signal to the control panel.

< Dip switch >

ON

1 2 3

Transmitter

Dip switch 3: Alarm input

Negative (N.O.)

POSITION MODE

ON

OFF

Positive (N.C.)

CONTROL PANEL

POWER

ALARM

N.C.

Transmitter Receiver

(1)

(2)

(8)

(9)

(1)

(2)

(5)

(6)

< Wiring example >

POWER

ON

OFF

Note>>

Switches Positive/Negative according to the connected device.

Note>>

The detector operates at 100 msec regardless of the switch position during optical alignment.

RE-TRANSMISSION FUNCTION

SL-QDM

SL-QDP

3

*1

*2

*1 CONTROL PANEL = UL/c-UL listed burglar alarm control panel

*2 POWER = power limited output

UL Listed Outdoor

Motion Detector

(Dry contact only)

Connected a motion

sensor to the alarm

input was not

evaluated by UL/c-UL

*2

Page 13

-13-

The difference between SL-QDMandSL-QDP is as follows.

LOW BATTERY mode is used only when SBU-4 is connected. It allows to monitor low battery status of SBU-4* installed to both the

transmitter and receiver at receiver.

The description of D.Q. (environmental disqualification) output is shown below.**

・ The low battery signal from SBU-4* that has been input to the transmitter’s LOW BATTERY INPUT terminal (7) is transmitted to the

receiver and output from the Low battery output terminals (5) to (7).

・ When monitoring low battery status of SBU-4* installed to both the transmitter and receiver at receiver, low battery status cannot be

distinguished between the receiver and transmitter. To distinguish a low battery signal of the receiver and transmitter, output the low

battery signal directly from SBU-4*.

・ When the Power indicator LED of the detector is blinking, SBU-4* is in low battery status so that it can be distinguished which one is in

low battery status.

D.Q. will send a trouble signal when

the beam strength is below acceptable

levels, for more than 20 seconds, due

to rain, snow, or heavy fog.

< Wiring example >

CONTROL PANEL

POWER

ALARM 2

N.C.

Transmitter Receiver

(1)

(2)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(2)

N.O.

N.O.

N.C.

N.C.

COM

COM

DQ

ALARM

ALARM 1

N.C.

CONTROL PANEL

POWER

ALARM 2

N.C.

Transmitter Receiver

(1)

(2)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(2)

N.O.

N.O.

N.C.

N.C.

COM

COM

DQ

ALARM

ALARM 1

N.C.

CONTROL PANEL

POWER

ALARM 1

N.C.

Transmitter Receiver

(1)

(2)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(2)

N.O.

N.O.

N.C.

N.C.

COM

COM

DQ

ALARM

A. Trouble Output + Alarm Output

B. Bypasses Alarm

C. Bypasses Alarm + Trouble Output

< Function >

< Function >

20 sec.

2 sec.

ON

OFF

Reception level

Adverse weather

level

Alarm output level

D.Q. output

D.Q. (environmental disqualification) /LOW BATTERY OUTPUT

SL-QDM

SL-QDP

4

Dip switch 7: D.Q./Low battery

POSITION FUNCTION

ON

OFF

MODE

LOW BATTERY (for Solar Battery Unit SBU-4*)

< Dip switch >

ON

Receiver

ON

OFF

1 2 3 4 5 6 7

D.Q. (environmental disqualification)

SL-QDM series: Available to switch between D.Q. output and Low battery output.

SL-QDP series: Only set D.Q. output.

Refer to 2 below.

Refer to 3 below.

1

2

3

Note>>

If the control panel's input terminals have the same common, the alarm output, sleep and trouble output can be triggered

simultaneously.

* SBU-4 and its low battery input/output are not evaluated by UL.

** D.Q. output was not evaluated by UL/c-UL

Page 14

-14-

When an alarm is activated during alert status, the detector memorizes the alarm activation.

This will allow you to check which detector activated an alarm even when multiple units are installed.

In Remote mode, connect control voltage signal terminal (system arming status voltage output terminal) of control panel to ALARM

MEMORY INPUT terminal (11).

ALARM MEMORY FUNCTION

SL-QDM

SL-QDP

5

SOUND ASSIST FUNCTION

SL-QDM

SL-QDP

6

ON

OFF OFF OFF

POSITION

Walk testOptical alignment

This function informs you of the operation and condition by sounds.

It works well on the two situations below:

< Optical alignment >

The optical alignment level can be checked with sound. The stronger the sensitivity, the faster the sound pattern. It sounds when

the alignment level indicators are illuminated, the tamper button is not pressed.

< Walk test >

Operation check can be performed by the beep sound at interruption for 5 minutes after the tamper button on both the transmitter

and receiver are pressed (after the cover is closed). The sound assist function automatically finishes after 5 minutes.

SOUNDING

DETECTOR

Receiver

SL-QDM: Receiver and transmitter

SL-QDP: Receiver

ONON

Sound assist

[ON/OFF]

ON

Receiver

1 2 3 4 5 6 7

Alarm memory

indicator LED

AUTO

(Timer mode)

ON

OFF

MANUAL

(Remote mode)

Alarm

output

Alarm

memory

indicator

< Operating time chart >

FUNCTIONMODEPOSITION

ON

OFF

Alarm Alarm Alarm

5 min. 55 min.

within

5 min.

5 min. 55 min.

Alarm

output

Alarm

memory

indicator

< Operating time chart >

ON

OFF

Alarm Alarm Alarm

The alarm memory indicator is illuminated after approximately 5 minutes since the

last alarm generated, and kept illuminated for approximately 55 minutes.

The duration of illumination will not be extended even if an alarm generated while

the alarm memory indicator is illuminated. Approximately 55 minutes later, the

indicator will be automatically reset and returned to normal mode.

When an alarm generated, the detector retains it in the memory.

When switching the security system from "System armed" to "System disarmed"

(switching the position), the alarm memory indicator of the detector that

memorizes the alarm memory indicator will be illuminated.

When putting the security system back on (switching the position), the alarm

memory indicator will be turned off and reset.

Once the reset is made, the alarm memory indicator will not be illuminated even if

the security system is switched to "System disarmed" until an alarm outputs again.

Armed

Disarmed

Security

system

System armed: 0~1VDC (grounded)

System disarmed: OPEN or + 5~30VDC

Negative (N.O.)

System armed: OPEN or + 5~30VDC

System disarmed: 0~1VDC (grounded)

Positive (N.C.)

Selectable

Output

ON

Receiver

1 2 3 4 5 6 7

ON

Receiver

1 2 3 4 5 6 7

< Dip switch 6: Alarm memory [Positive/Negative] >

< Dip switch >

< Indicator LED >

< Wiring example >

CONTROL PANEL

POWER

Control

voltage

signal

terminal

Receiver

(1)

(2)

(11)

ON

OFF

Page 15

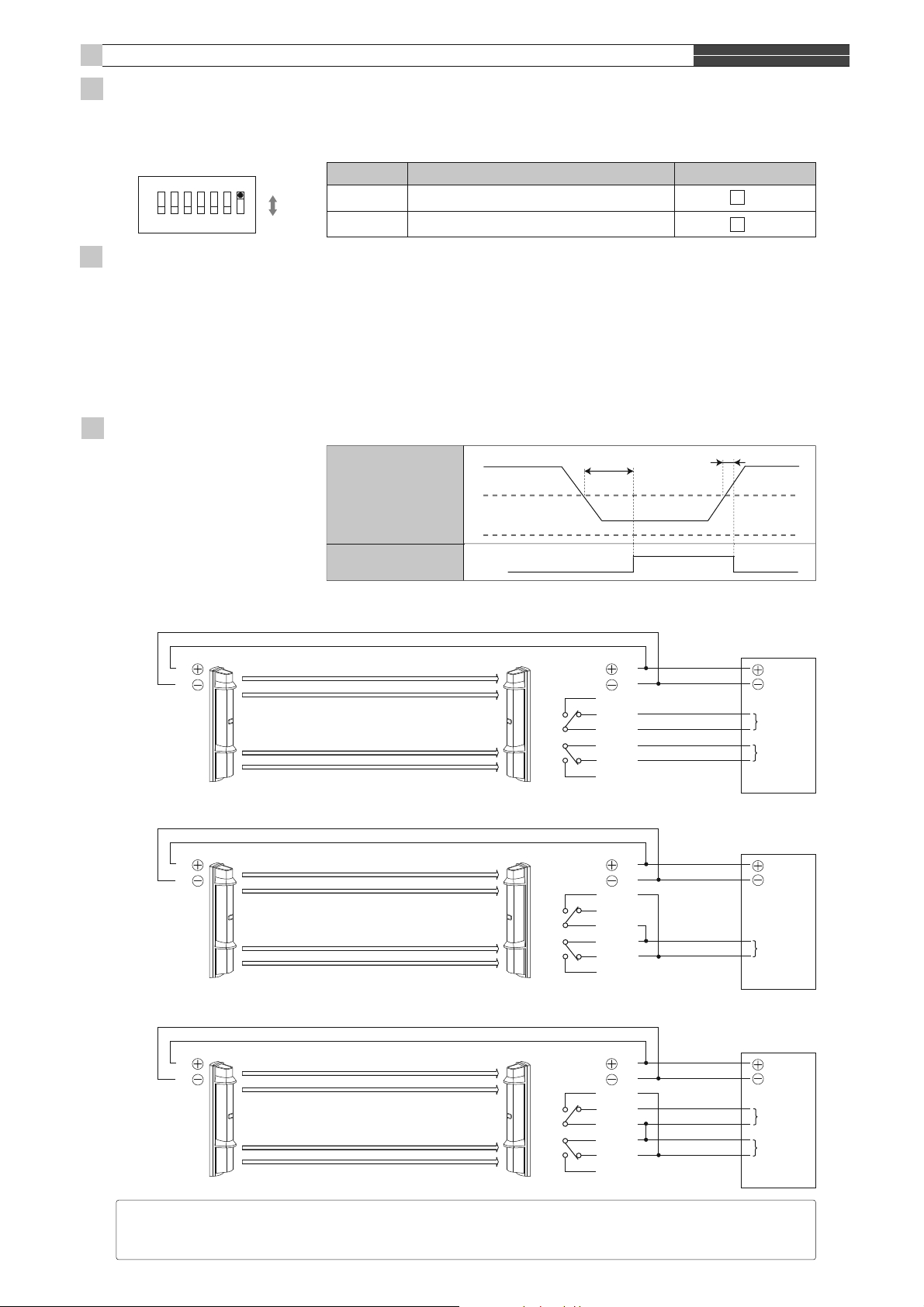

-15-

OPTICAL ALIGNMENT

4

90°

90°

< Horizontal alignment angle > < Vertical alignment angle >

1

Optical alignment is an important adjustment to increase

reliability. Be sure to take adjustment steps 1 through 6

described below to attain the maximum level of the output

through the monitor jack.

See “3-2” on page 10 and set the 4 channel beam

frequency selector.

2

Block lower beam by the beam blocking plate or

Upper/Lower beam selection button.

3

Look into the viewfinder and perform fine alignment of the horizontal and vertical angles using the alignment dial.

Mount a beam blocking plate to the

lower unit and then start optical

alignment from the upper unit.

Beam blocking plate is attached on

the back of the cover.

Put back the beam blocking plate to

the cover after use.

Note>>

Cover

Viewfinder

0DNHWKHVDPHVHWWLQJV

on both the transmitter and

receiver for the same LED

indication patterns.

7KHVHOHFWLRQEXWWRQRIWKH

transmitter and receiver

are not linked.

Note>>

Check the diagram below and perform alignment for

both horizontal alignment and vertical alignment.

Note>>

Turn the small dial for

horizontal alignment.

Turn the large dial for

vertical alignment.

- Clockwise: Upward

- Counterclockwise: Downward

10°

10°

10°

10°

4-1

OPTICAL ALIGNMENT FOR UPPER AND LOWER BEAM

[ TOP VIEW ]

[ SIDE VIEW ]

Beam blocking plate

Beam blocking plate

Caution

Do not touch the lens during optical alignment.

Warning

Do not look at strong light sources such as

sunlight through the viewfinder.

< Using a beam blocking plate >

< Using Upper/Lower beam selection button >

Default Press x1

Press x4

Press x2 Press x3

< How to look into the viewfinder >

Left eye Right eye

From right side From left side

Upper/Lower

beam selection

button

Page 16

-16-

NOTE>>

Pulsed tone

Continuous tone

Poor

View

finder

(image)

Indicator

LED

Excellent

Good

Fair

Re-Align

Poor

—

1.2 V 1.5 V 2.0 V

Sound

assist

function

Monitor

Jack

output

(range

5-10VDC)

Realign Fair Good Excellent

0.5 V

SLOW FAST

The alignment level indicators have 5 LEDs, each LED represents the level of

alignment, ranging from poor to excellent. Each LED will indicate 3 steps of

alignment, slow blink = okay, fast blink = better, continuously on = best, providing

15 graduated stages.

SL-QDM series: Optical alignment can be performed by opening a cover of either the transmitter or receiver.

The optical alignment level can also be checked by sound.

(SL-QDP: Receiver only)

See the following table for operations of LED display and sound.

5

Adjust the horizontal and vertical angle while checking the light receiving status by the alignment level indicator LEDs and sound.

6

Make the settings of 1 to 5 to the lower as well.

Alignment level indicator LED

4

Insert the voltmeter's positive pin

into the positive terminal of the

monitor jack, and the negative pin

into the negative terminal.

After the alignment using the viewfinder, make adjustment with the voltmeter for more accurate optical alignment.

Set the voltmeter range to 5 to 10 VDC.

After checking the receiving level of optical axis by using the alarm indicator, make sure to make fine alignment for both the

transmitter and receiver with voltmeter to achieve a monitor output level of "Excellent".

OFF

Slow blink

Fast blink Continuously

ON

Press the tamper buttons on both the receiver and transmitter (close the covers) after performing

optical alignment for a set of detectors.

Not doing so may result in interference with other sets of detectors and posing a problem on optical

alignment.

Caution

Page 17

-17-

4-2

OPERATION CHECK

TROUBLESHOOTING

5

5-1

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

LEDs are not illuminated

(Transmitter/receiver)

Inappropriate power voltage

Check the voltage and make sure that it is

between 10.5 and 30 VDC

Inappropriate wiring distance or wire diameter

See "2-5 WIRING DISTANCE BETWEEN POWER

SUPPLY AND DETECTOR" on page 6,check the

wiring distance.

Power supply selector setting is incorrect.

See "6-2 SOLAR BATTERY UNIT SBU-4 (OPTION)"

on page 18, check the power supply selector

setting: Normal (left), SBU-4 (right)

"ALARM" LED is not illuminated

even if the beam is blocked

Alignment level indicator LEDs are

not illuminated (Transmitter/

Receiver)

5HÀHFWLRQRIWKHÀRRURUZDOO

Block all four beams at same time

See "4-1 OPTICAL ALIGNMENT" on Page 15 and

make realignment.

See "3-3 1 4 CHANNEL BEAM FREQUENCY

SELECTOR" on Page 11 and set to the same channel.

See"4-1 OPTICAL ALIGNMENT" on Page 15 and

make realignment. If the problem persist,

see "BEAM POWER CONTROL SELECTOR"

on Page 13 and step down the beam power.

Beam has not been blocked.

Optical alignment is not optimized.

The channel setting between the Transmitter

and the Receiver does not match.

Blocking the beam, and

illuminates "ALARM" LED but

does not active the alarm.

Alarm is activated even if the beam

is not blocked

Signal line short-circuited

Alarm contact welded

Check the wiring.

Repair is required. Contact the distributor or us.

Interruption time is too short

See "BEAM INTERRUPTION ADJUSTMENT"

on page 11, set an appropriate interruption time.

Frost, snow or heavy rain causes

false alarm.

Improper output

Alignment level indicator LEDs of

only the Transmitter are not

illuminated.

Optical alignment was not performed properly

Optical alignment is not optimized

The wiring is incorrect

See"4-1 OPTICAL ALIGNMENT" on Page 15 and

make realignment.

See"4-1 OPTICAL ALIGNMENT" on Page 15 and

make realignment.

Inappropriate optical alignment for the upper

beam unit.

Make correct wiring.

See"4-1 OPTICAL ALIGNMENT" on Page 15 and

make realignment.

Surface of the transmitter/receiver cover soiled

Clean the cover (wipe the cover with a soft cloth

dampened with water-diluted neutral detergent)

Channels of the transmitter and receiver are different

Multiple photoelectric detector for long

distance or beam stacking applications.

Set the same channel to both the transmitter and receiver.

Set channels 1-3 or 2-4 or 1-4.

Conduct a walk to check that the alarm indicator LED on the receiver turns ON or the beep sound rings

on the receiver as the walker interrupts the beam.

Be sure to conduct a walk test (to block the infrared beam) at the following three points:

In front of the transmitter

In front of the receiver

At the middle point between the transmitter and the receiver

The detector is installed properly when the Alarm indicator LED turns ON and the

beep sound rings in the tests at all three points.

A B

Transmitter

Receiver

C

Conduct a walk test at least once a year.

2SHUDWLRQFKHFNFDQEHSHUIRUPHGE\WKHEHHSVRXQGDWLQWHUUXSWLRQIRUPLQXWHVRIWKHWDPSHUEXWWRQRQERWKWKHWUDQVPLWWHUDQG

receiver are pressed (the covers are closed).

Note>>

A

B

C

Page 18

SL-QDM

SL-QDP

-18-

OPTION SETTING

6

6-1

HEATER UNIT HU-3 (OPTION)

6-2

SOLAR BATTERY UNIT SBU-4 (OPTION)

When using the Solar Battery Unit SBU-4 together with SL-QDM, set Power Supply Selector from Normal to SBU-4 position.

The heat release effect makes the unit less prone to frost. HU-3 can be mounted to either upper or lower part of the unit.

Use a 24 V power supply to use HU-3.

< Mounting method >

1

Caution

When using SBU-4 (option), be sure to read the

SBU-4 manual.

Tear the wiring groove section of the label that is pasted on

the chassis as shown below.

4

2

3

When connecting the lead wires to the wiring, make the

connection using the included connector or soldering. Insert

the wires into the connector and tighten the connections with

pliers.

Insert HU-3 into the chassis.

Route the cable along the wiring groove and draw the cable

through the cutbush.

NOTE>>

Ensure that the wiring distance from the power supply is within

the range shown in the table on the right. When using 2 or

more units on 1 wire, the maximum wiring distance is obtained

by dividing the wire distance by the number of unit used.

Connector

Power Supply Selector

[Normal/SBU-4]

NOTE>>

NOTE>>

The label can be torn with a

finger.

Insert the tip of HU-3

into the hook of the

chassis to mount HU-3.

Do not mount HU-3 with

the face down.

0.83 mm2 (AWG18)

300 m (1000 ft.)

800 m (2600 ft.)

500 m (1700 ft.)

1.31 mm

2

(AWG16)

2.09 mm

2

(AWG14)

Caution

Do not wire HU-3 to

the main unit. Doing

so may result in

malfunction.

NORMAL

10.5 - 30 V

SOLAR

SBU-4

3.6 V

Wiring distance from power supply

Wire size

Power supply: 24 VAC/DC

* not evaluated by UL

* not evaluated by UL

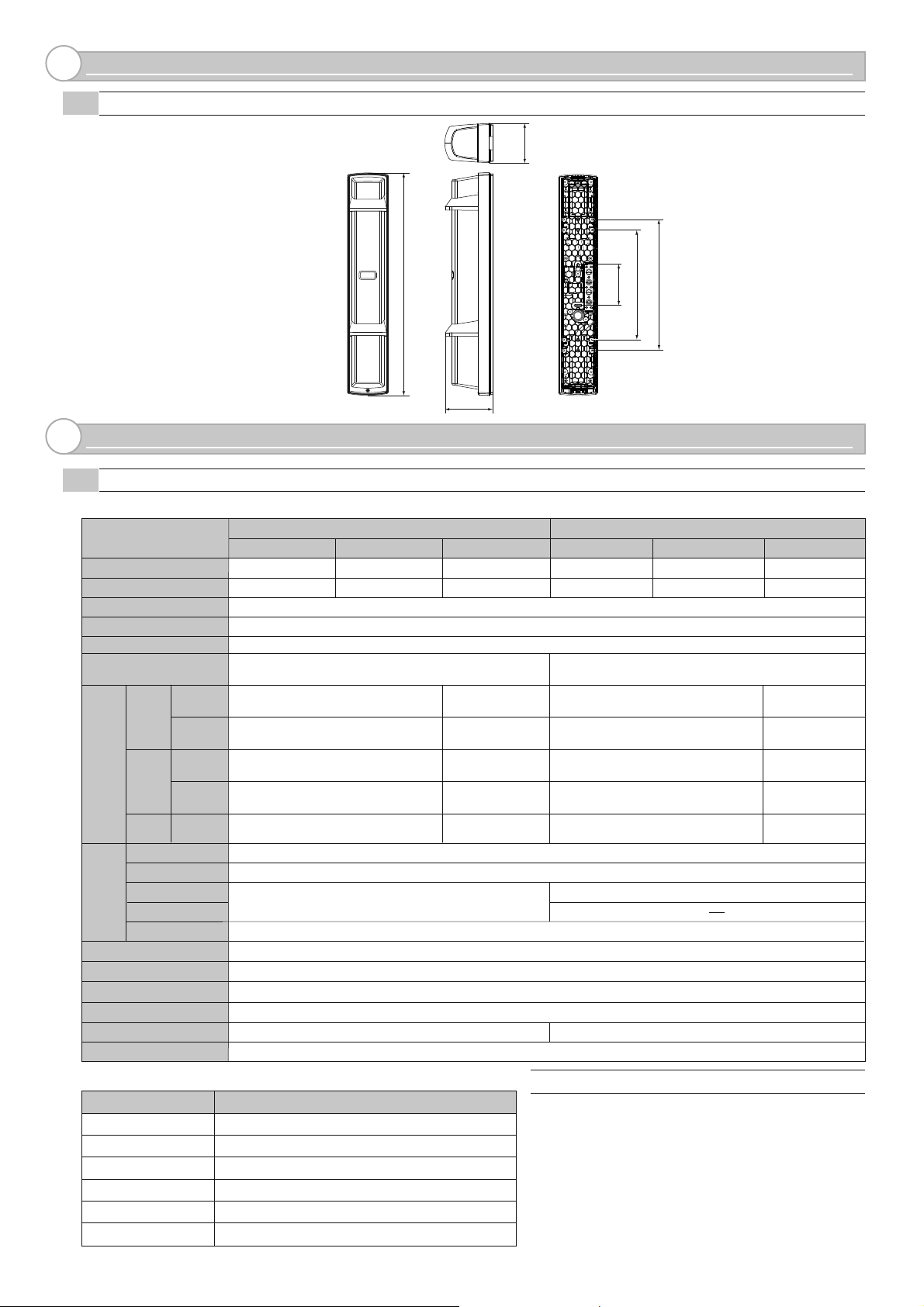

Page 19

-19-

DIMENSIONS

7

SPECIFICATIONS

8

8-1

SPECIFICATIONS

Model HU-3

Power input

24 VAC/DC

Current draw

210 mA max. per 1 piece / 420 mA max. per 1 unit

Thermo switch

60°C (

140

°F)

20 g (0.7oz) (Heater (x2))

Heater (x2), Connector (x4), Waterproof agent

Packages

Operating temperature

Weight

-35°C - +60°C (-31°F - +140°F)

< SL-200QDM, SL-350QDM, SL-650QDM, SL-200QDP, SL-350QDP, SL-650QDP >

< HU-3 (Option) >

*

1

7-1

DIMENSIONS

Unit: mm (inch)

448 (17.6)

96 (3.8)

79 (3.1)

83.5 (3.28)

(WALL)

222 (8.7) (POLE1)

265 (10.4) (POLE2)

These units are designed to detect an intruder and activate

an alarm control panel. Being only a part of a complete

system, we cannot accept responsibility for any damages or

other consequences resulting from an intrusion. These

products conform to the EMC Directive 2004/108/EC.

NOTE

*1 not evaluated by UL

*2 “Maximum Arrival Distance” shows the optical margin for the

detection range.

*3 UL listed power-limited burglar alarm power supply.

*4 All relays are Dry-Contact and all outputs are power-limited.

*5 All interconnecting devices must be UL/c-UL listed.

*6

All inputs and outputs must be connected to power limited circuit only.

Model

Maximum detection range

Maximum arrival distance*1*

2

Detection method

Selectable beam frequency

Interruption time

Power source*

3

Current

draw

Output

*

4

Alarm output

Normal

Peak

10.5-30VDC

SBU-4*

1

10.5-30VDC

10.5-30VDC

(UL evaluated)

SBU-4*

1

Optical

alignment

Alarm period

D.Q. output

*1

Low battery output

Tamper output

Operating temperature

Operating humidity

Alignment angle

Dimension

Weight

International protection

2500 g (Total weight of the transmitter + receiver, excluding accessories)

N.C. (contact output): 30 VDC, 0.1 A Opens when the cover removed.

-35°C - +60°C (-30°F - 140°F)

95 % (max.)

±90° Horizontal, ±10° Vertical

+ɯ:ɯ'PPLQFK[[

2400 g (Total weight of the transmitter + receiver, excluding accessories)

IP65

*1

Form C relay: 30 VDC, 0.2 A

Form C relay: 30 VDC, 0.2 A

(D.Q. and Low battery can be switched.)

ADVANCED

SL-200QDM SL-350QDM SL-650QDM SL-200QDP SL-350QDP SL-650QDP

STANDARD

60 m / 200ft 100 m / 350 ft 200 m / 650 ft 60 m / 200ft 100 m / 350 ft 200 m / 650 ft

600 m / 2,000ft 1,000 m / 3,500 ft 2,000 m / 6,500 ft 600 m / 2,000ft 1,000 m / 3,500 ft

2,000 m / 6,500 ft

Quad infrared beam interruption detection

4 channels

Variable between 50/100/250/500 ms (4 steps)

Normal: 10.5 - 30 VDC

Solar Battery Unit SBU-4*

1

(OPTION): 3.6 VDC

26 mA

(T: 11 mA, R: 15 mA)

26 mA

(T: 9 mA, R: 17 mA)

36 mA

(T: 16 mA, R: 20 mA)

45 mA

(T: 17 mA, R: 28 mA)

30 mA

(T: 15 mA, R: 15 mA)

35 mA

(T: 18 mA, R: 17 mA)

43 mA

(T: 20 mA, R: 23 mA)

60 mA

(T: 26 mA, R: 34 mA)

40 mA

(T: 16 mA, R: 24 mA)

43 mA

(T: 20 mA, R: 23 mA)

17 mA

(T: 6 mA, R: 11 mA)

—

—

—

—

21 mA

(T: 7 mA, R: 14 mA)

22 mA

(T: 11 mA, R: 11 mA)

24 mA

(T: 10 mA, R: 14 mA)

24 mA

(T: 7 mA, R: 17 mA)

33 mA

(T: 10 mA, R: 23 mA)

10.5 - 30 VDC

Form C relay: 30 VDC, 0.2 A

2 sec (±1) (Nominal)

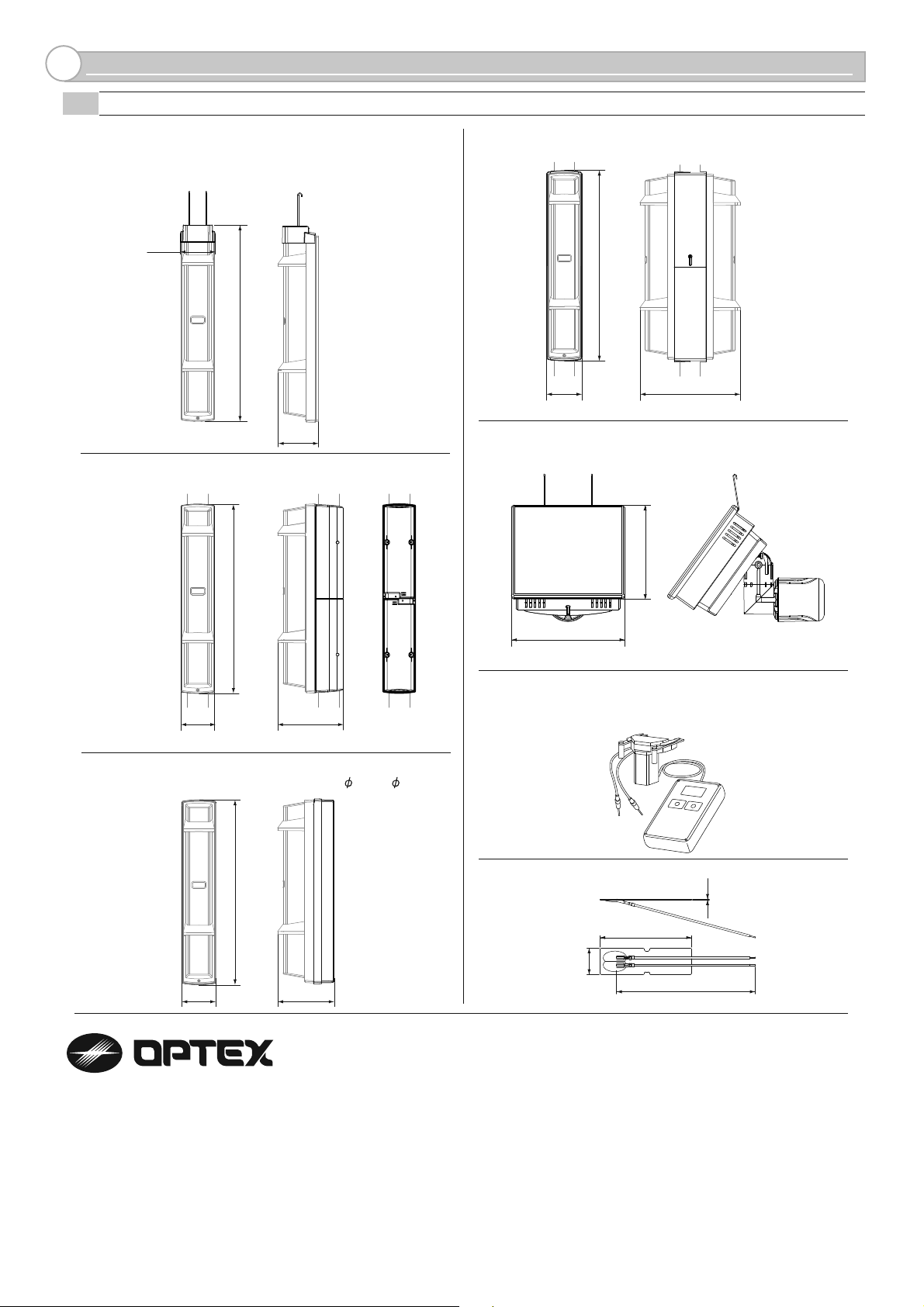

Page 20

-20-

Unit: mm (inch)

Anti Bird Cap ABC-4

Back Cover BC-4

Conduit Bracket CBR-4

Pole Side Cover PSC-4

Unit: mm (inch)

Unit: mm (inch)

Unit: mm (inch)

Unit: mm (inch)

468 (18.4)

96 (3.8)

154 (6.1)

85 (3.3)

448 (18)

79 (3.1)

226〜241 (8.9〜9.5)

84 (3.3)

83 (3.3) 138 (5.4)

Prevent birds and small animals from the detector to reduce the

false alarm.

Prevent streaming rain and snow from the front of the detector to

keep the sensitivity.

Conceal the back side of pole mounted detector.

Conceal the gap of pole mounted detectors back to back.

Solar Battery Unit SBU-4 (SL-QDM only)

Supply power by using solar battery.

Beam Alignment Unit BAU-4

Adjust optical axis automatically.

(SL-QDM: Transmitter/receiver) (SL-QDP: Receiver only)

Heater Unit HU-3

202 (8.0)

202 (8.0)

OPTIONS

9

9-1

OPTIONS

452 (17.8)

0.6 (0.02)

28 (1.1)

97 (3.8)

Actual length 200 (7.9)

Unit: mm (inch)

458 (18)

* Anti Bird Cap ABC-4 not evaluated by UL

* Back Cover BC-4 not evaluated by UL

* Pole Side Cover PSC-4 not evaluated by UL

* Solar Battery Unit SBU-4 not evaluated by UL

* Beam Alignment Unit

BAU-4 not evaluated by UL

* Heater Unit HU-3 not evaluated by UL

This allows for conduit wiring.

(Compatible conduit: 21 mm ( 0.84 inch))

OPTEX CO., LTD. (JAPAN)

URL: http://www.optex.net/

OPTEX INC. (U.S.)

URL: http://www.optexamerica.com/

OPTEX DO BRASIL LTDA. (Brazil)

URL: http://www.optex.net/br/es/sec/

OPTEX (EUROPE) LTD. / EMEA HQ (U.K.)

URL: http://www.optexeurope.com/

OPTEX SECURITY SAS (France)

URL: http://www.optex-security.com/

OPTEX SECURITY Sp.z o.o. (Poland)

URL: http://www.optex.com.pl/

OPTEX (DONGGUAN) CO.,LTD.

SHANGHAI OFFICE (China)

URL: http://www.optexchina.com/

OPTEX KOREA CO.,LTD. (Korea)

URL: http://www.optexkorea.com/

OPTEX PINNACLE INDIA, PVT., LTD. (India)

URL: http://www.optex.net./in/en/sec/

OPTEX TECHNOLOGIES B.V.

(The Netherlands)

URL: http://www.optex.nl/

Loading...

Loading...