Optex RN4-10-25. ChA, RN4-10-25. ChB, RN4-25-75. ChA, RN4-25-75. ChB, RN4-75-150. ChA Installation

...Page 1

REDNET

®

INFRARED BEAM SET TYPE RN4/10-25, RN4/25-75 & RN4/75-150

INSTALLATION AND SET UP INSTRUCTIONS

DESCRIPTION

REDNET® is an extemal beam system that may be used for outdoor ranges between 10 and 150 metres.

The electronics for the beams are supplied with 4 transmitter and 4 receiver heads pre-wired to their

respective electronic control modules. The electronics can then be mounted into either free standing or wall

mounted tower enclosures.

OPERATION

The operating system for the beams uses sequential transmission starting from the top (A Head) and

sequencing down to the bottom (D Head). Synchronisation is achieved electronically eliminating the need for

synchronising cables between transmitters and receivers. All receiving heads will be in the field of view of all

transmitting heads and vice versa creating 16 beam paths.

Beam sets are normally supplied pre-set to code channel number “A” and cannot be changed in the field.

Other channels can be supplied to special order, but, are only used in exceptional circumstances.

Beam heads have integral heating elements to direct warm air onto the tower front covers to prevent the

build up of frost. The heaters are powered via a thermostatic switch (supplied with beam sets) this switches

when the temperature drops to below 15 degrees C.

The system provides three alarm responses as follows:

1) FAST RESPONSE of 40mSec, if two adjacent heads are blocked simultaneously.

2) SLOW RESPONSE, adjustable between 120mSec and 1500mSec if any one beam head is blocked.

3) NO RESPONSE if ANY ONE head is blocked (switch selectable).

A FAST RESPONSE is initiated only when the network is blocked by an object bigger than the distance

between adjacent beam heads. (See Fig. 6)

OUTPUTS

Alarm and fog outputs are via a changeover (Form C) contact. To avoid spurious operation, the fog detection

circuit output is delayed by 10 seconds. To cater for all security requirements the fog detection output is

adjustable.

MOUNTING

Beam sets can be mounted onto the beam head brackets inside the free standing or wall mountable towers.

These brackets are pre-fitted to the towers and may be adjusted vertically as required. The control modules

may be fitted close to the base with the 4 heads stacked above, or, alternatively fitted between the lower two

heads using the locking clips provided. (See Fig. 1A, 1B)

Page 2

A tamper switch (supplied with each tower) operates when the top cover of the tower is removed. Free

standing towers can be fitted with an anti-climb top tamper system type RNTT, to detect attempts to climb

over the tower.

Wall mount towers must be fixed to a stable surface, such as brick, by means of suitable wall fixings.

WARNING: ensure that tower extrusion is not bent by bumps in the wall surface, use spacers if required. A

pole mount kit RNPK (accessory) may be used for fixing to scaffold poles.

Whenever possible, use the rear hole for cable access. If the bottom end cap (with the drain holes) is to be

used for cable entry, remove from tower before drilling.

Remove the control electronics covers, keeping the two screws safe and fit to the tower extrusion using

the swivel locking clips. The unit may be located either between heads ‘C’ and ‘D’ or close to the bottom

of the tower with the heads stacked above. The choice will depend upon the type and flatness of the

ground surface. To avoid confusion when setting or re-alignment, it is recommended that both receiver and

transmitter heads are fitted with ‘A’ at the top and ‘B’ - ‘D’ below. The signals received by head ‘D’ are used

for fog detection and must be nearest the ground.

Ensure that all the transmitter and receiver heads are within sight of each other and that the bottom ‘D’ heads

are not obscured by rising ground, see Fig. 1B. Locate the head cables into the cut-outs on the brackets, run

any other cables behind the brackets.

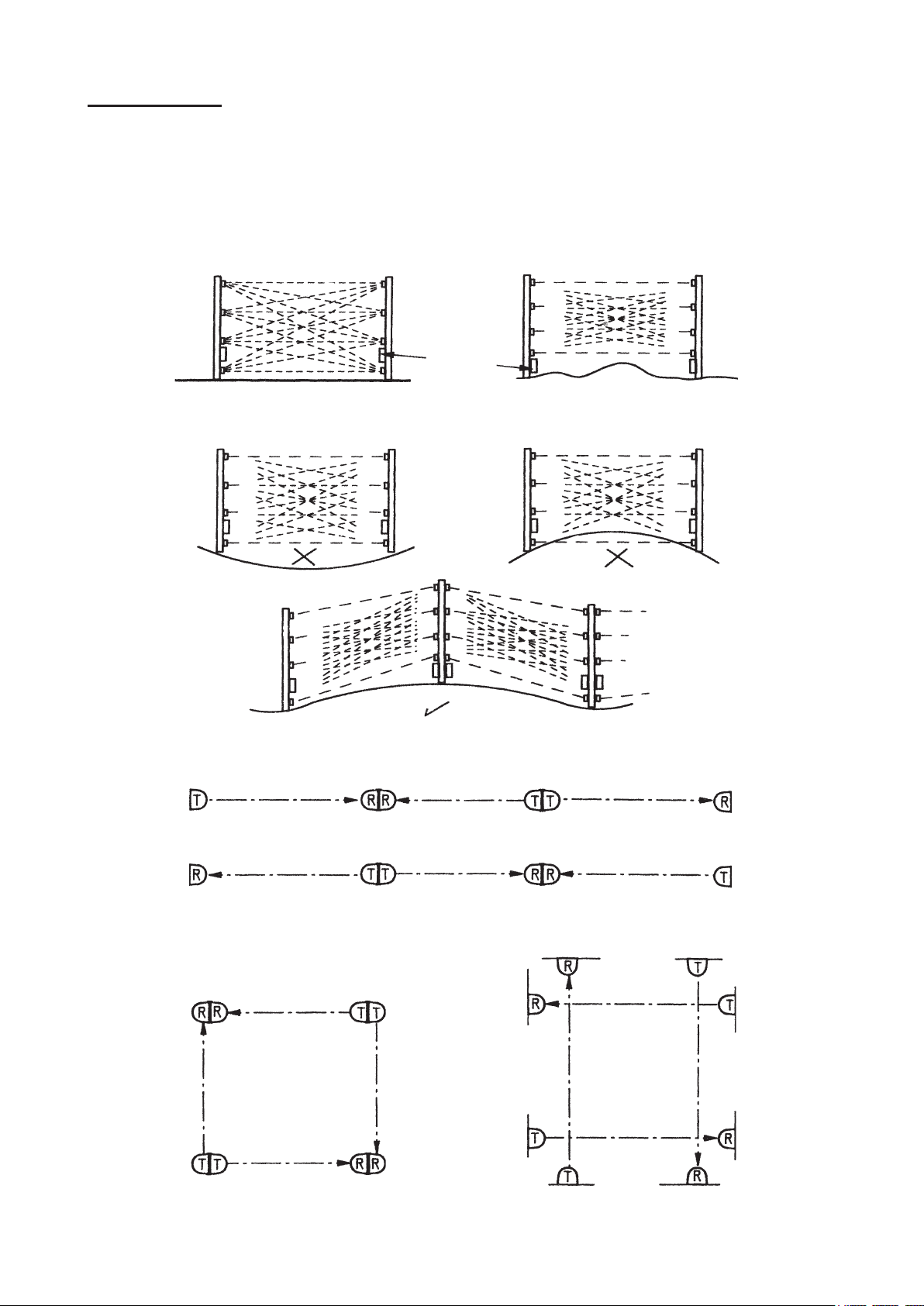

When planning the system layout, ensure that the receiver heads only see their respective transmitters.

Figures 1-4 illustrate preferred layouts. It is strongly recommended that towers contain either all

transmitters or all receivers as shown.

ELECTRICAL CONNECTIONS

Terminal connections are shown on the controller covers. The transmitter has 3 terminals.

H: 12VDC nominal heater supply via thermostat

The receiver has 10 terminals, two heater terminals located towards the top of the circuit board. The other 8

terminals are split for the fog and alarm relay and power. See Fig. 5 for connection. With heaters operating,

each tower will require a total of typically 450mA. (Assume 0.5 Amp. for cable voltage drop calculations.)

+: 12VDC nominal transmitter supply

- : Common ground both supply

Page 3

INSTALLATION

The towers must be mounted firmly. Free-standing towers should be bolted to a solid surface using the

expansion bolts provided. When the free-standing towers are to be fitted into soft earth, it is essential to

provide a concrete pad. Anchor plate, type RNBB (accessory) may be cast into wet concrete to provide 4

projecting studs to which the tower base may be firmly bolted.

A

B

C

D

A

B

C

CONTROLLER

D

A

B

C

D

A

B

C

D

Fig. 1A

Fig. 1B

PERIMETER

(TOWERS)

Fig. 3

LINEAR OR PATH

Fig. 2

PERIMETER

(WALL-MOUNT)

Fig. 4

Page 4

CONTROLS AND INDICATORS

The transmitter (Tx) control unit has a 4 way selector switch used to switch off each Tx head. These can be

used during alignment if the head blanking plates, supplied, are missing. The red LED confirms power is

applied to the Tx control unit.

WARNING: DO NOT ADJUST ANY POTS ON Tx or Rx BOARDS

WITHOUT REFERENCE TO INSTRUCTIONS

The receiver (Rx) control unit also contains a similar 4 way switch which is used to route the head signal

pulse outputs to the signal strength LED, test point and fog detection circuit. The test point produces a

voltage output proportional to the signal strength of the received pulses and can be used for alignment if the

RN TEST (normally supplied) is not available.

The voltage at the test point varies between 0 Volt with no signal and 3.5 Volts with a strong signal.

The REDNET® system provides the option of controlling the single beam or small object response by means

of a switch and potentiometer. (See Fig. 5)

With the switch up, “SINGLE”, the response to a single head blockage or small object can be set between

120mSec and 1500mSec (1.5Sec) by means of the alarm RESPONSE pot.

With the switch down, “DUAL”, there will be no alarm if any one head is blocked or an object enters the beam

network which is smaller than the distance between two adjacent heads. (See Fig. 6)

If the blockage is bigger than the distance between two adjacent heads, then the alarm will be fast

(approximately 40mSec) irrespective of the switch or pot settings.

NOTE: Blockage of the bottom ‘D’ receiver head for more than 10 seconds will activate the fog relay and LED.

The fog level pot, FOG , controls the point at which the fog relay operates. For most installations a midway

setting is recommended. For high security installations, where only a small reduction in signal strength

is acceptable, set the pot clockwise. The fog relay response is delayed by 10 seconds to avoid spurious

operation.

ALIGNMENT PROCEDURE

For reliable operation it is essential that the heads are accurately aligned. Although it is possible to set the

system up using only the signal strength LED, it is not recommended. For trouble-free operation it is essential

that the alignment viewer, the RN TEST pulse detector and the 8 head blanking plates are used and that the

multi-step procedure is followed exactly.

Before any alignment is carried out, it is essential that the beam towers are rigidly fixed. Any movement will

swing the beams away from the optimum alignment and may cause false alarms during bright sunlight or

misty conditions.

RN TEST

The RN TEST is a combination tester that includes four LED’s inside the lens window for receiver alignment

and a high intensity flashing light and bleeper for transmitter alignment.

Page 5

Tx

HEAD SELECT

TRANSMITTER

Rx

HEAD SELECT

RECEIVER

TOP A

BOTTOM D

B

C

“POWER”

SUPPLY

TOP A

BOTTOM D

B

C

“SIGNAL”

STRENGTH

120mSec 1500mSec

“TEST”

POINT

HEAVY LIGHT

“FOG”

“ALARM”

12VDC SUPPLY

-

+

THERMOSTAT THERMOSTAT

12VAC SUPPLY

~

~

Fig. 5

OBJECT SMALLER THAN X

SWITCH UP, “SINGLE” 120mSec TO 1.5Sec RESPONSE.

SWITCH DOWN, “DUAL” NO ALARM

OBJECT BIGGER THAN X

FAST RESPONSE / 40mSec

Fig. 6

Page 6

ALIGNMENT USING THE RN TEST

At the Transmitter

Step 1. Fit the viewer into the Tx lens holes (Fig. 8) and align all Tx heads to the centre of the Rx tower.

Lightly lock the heads, but do not over tighten.

Step 2. At the 4-way switch on the Tx board switch heads A, B & D off, (1,2 & 4 switches to the right).

Switch 3 ON (to the left). Fit blanking plates to front of all Tx heads and leave all fully open.

At the Receiver

Step 3. Fit the viewer into the Rx lens holes (Fig. 8) and align all Rx heads to the centre of the Tx tower.

Lightly lock the heads but do not over tighten.

Step 4. At the 4-way switch on the Rx board deselect heads A, B & D, (1,2 & 4 switches to the left). Select

3 (to the right). Fit blanking plates to front of all Rx heads and leave all fully open. Check that the

single beam response switch is in the “SINGLE” (up) position.

Step 5. Switch the RN TEST tester to the flash and bleep mode (TOGGLE UP) and connect yellow lead to

signal-stength test point. Use alignment viewer to aim RN TEST at the Tx tower. Adjust Rx C to

give maximum flash/bleep rate. Progressively block lens with blanking plate (Fig. 10), adjusting to

maintain fastest flash/bleep rate. When alignment is completed, fully open blanking plate on Rx C.

At the Transmitter

Step 6. Align transmitter head C to give maximum flash/bleep rate. Progressively block lens with blanking

plate (Fig. 10) adjusting to maintain fastest flash/bleep rate. When fully adjusted leave blanking plate

in position. When alignment is completed, fully tighten hex head bolts to lock head.

Step 7. To align head D, switch 4 ON (to the left) and 1,2 & 3 OFF (to the right). Align as Step 6.

To align head A, switch 1 ON (to the left) and 2,3 & 4 OFF (to the right). Align as Step 6.

To align head B, switch 2 ON (to the left) and 1,3 & 4 OFF (to the right). Align as Step 6.

Compare blanking plates to ensure similar levels of blanking on all heads. If unequal repeat Step 6.

Step 8. Remove all blanking plates from Tx heads and move all Tx head switches, ON (1,2,3 & 4, to the

left).

At the Receiver

Step 9. Deselect all Rx head switches, 1,2,3, & 4 (to the left) and switch RN TEST to pulse detect mode.

(TOGGLE DOWN).

Step 10.

Step 11.

observe the 4 LED’s. If they are flickering, carefully adjust head A until there are four solid LED’s. If

one or more LED’s are out, check for beam blockage or re-align the transmitters. Progressively

block lens with blanking plate adjusting to maintain four solid LED’s. When maximum achieved, fully

tighten hex head bolts to lock head.

Connect pulse detector yellow lead to top head, test point (A).

Swivel the RN TEST alignment tester or remove it from its bracket so that the lens faces you and

Page 7

Step 12.

To align head B, connect pulse detector yellow lead to head test point (B). Align as per Step 11.

To align head C, connect pulse detector yellow lead to head test point (C). Align as per Step 11.

To align head D, connect pulse detector yellow lead to head test point (D). Align as per Step 11.

Compare blanking plates to ensure similar levels of blanking on all heads. If unequal repeat Step 11.

Alarm LED should now be off.

Remove all blanking plates and check for correct operation.

ENSURE ALL FOUR RECEIVER SWITCHES ARE TO THE LEFT (DESELECT)

Remove and disconnect the alignment head clip and leads.

The complete system should be working. The signal strength LED should be lit and the alarm relay energised

with the alarm and fog LED’s out.

Blocking any one head should produce a SLOW RESPONSE alarm, blocking any two adjacent heads should

give a FAST RESPONSE alarm. Refer to the main installation instructions for response and fog level setting

details.

Handle the alignment head with care, it contains fragile optical components.

Fig. 7

HEAD SWITCH A

HEAD SWITCH B

HEAD SWITCH C

HEAD SWITCH D

FIXING FOR RN TEST

120mSec 1500mSec

SIGNAL

STRENGTH

TEST POINT

SIGNAL

STRENGTH

LED

HEAVY LIGHT

FOG LED

RED BLACK

HEADS TEST POINTS

SINGLE BEAM

RESPONSE

SWITCH

ALARM

LED

YELLOW

Fig. 8

VIEWER OPERATION

Fig. 10

BLANKING PLATE OPERATION

Fig. 9

12V+

-VE

Page 8

MAINTENANCE

Periodically remove the acrylic covers. Remove any dirt, BY WASHING, not by dry rubbing or scraping since

this may scratch the polished surfaces and reduce performance margins.

Inspect the head lenses for insects, taking care not to move the heads. Remove the receiver control box lid

and check for insects, corrosion or water ingress. Check signal level by observing the signal level LED or

by connecting a meter to the test terminal. If the system produces un-explained activities, check the ground

and adjacent area for excessive grass or foliage growth. Always re-check the alignment using the procedure

here. Do not try to re-align individual heads without using the RN TEST. Always follow the procedure.

Before replacing covers, check that wall mount back extrusion is still firmly fixed. (Some wall fixings may

become loose with time.)

SPECIFICATIONS

Model RN4/10-25 RN4/25-75 RN4/75-150

Range 10-25m 25-75m 75-150m

Power Input 11-15VDC

Current Draw

Power Input (Heater) 10-15VAC/DC

Current Draw

(Heater)

Synchronisation no synchronisation wiring required

Operating Temperature

Heating System Integral thermostat below +15 deg. C.

User Controls

System Alarm Response

(Interruption Period)

Alarm Output Form C (change-over) relay contacts. 24VDC 1A

Fog Output Form C relay contacts. 24VDC 1A

Indication Signal strength, alarm & fog LEDs.

Tamper Switch

Accessories Supplied Reflex viewer, locking spanner, blanking plates (8) and RN TEST.

Transmitter 40mA (max) at 12VDC

Receiver 60mA (max) at 12VDC

Transmitter 400mA nominal (450mA (max)) at 12VDC

Receiver 400mA nominal (450mA (max)) at 12VDC

-25 to +60 °C

SINGLE BEAM RESPONSE SWITCH

RESPONSE CONTROL POTENTIOMETER

FOG LEVEL CONTROL POTENTIOMETER

(Other controls factory sealed)

1) 40mSec any 2 blocked.

2) 120mSec to 1,500mSec any 1 blocked.

3) No alarm, any 1 blocked.

N.C opens when tower cover removed 28VDC 0.1A

SINGLE / DUAL

120mSec - 1500mSec

LIGHT - HEAVY

ACCESSORIES

RNT175 Free-standing tower

RNW175 Wall mount tower

RNBB Base Bracket for RNT175

RNTT Anti-Climb Top Tamper for RNT175

RNTEST Rednet Electronic Alignment Tester

RNPK Pole Mount Bracket for RNW175(48mm dia)

IR2000 B8/L Replacement Acryllic Cover

NOTE

These units are designed to detect movement of an intruder and activate an alarm control panel.

Being only part of a complete alarm system,we cannot accept responsibility for any damages or other

consequences resulting from an intrusion.These products conform to the EMC Directive 89/336 EEC.

OPTEX CO., LTD.

(JAPAN)

(ISO 9001 Certified by LRQA)

(ISO 14001 Certified by JET)

5-8-12 Ogoto

Otsu,Shiga, 520-0101

Japan

Tel :+81-77-579-8670

Fax:+81-77-579-8190

URL http://www.optex.co.jp/e

OPTEX INCORPORATED

(USA)

13661 Benson Ave., Bldg. C

Chino, CA 91710-5266

U.S.A.

Tel: (909)993-5770

Fax:(090)628-5560

URL http://www.optexamerica.com

OPTEX (EUROPE) LTD.

(UK)

(ISO 9001 Certified by NQA)

Clivemont Road, Maidenhead,

Berkshire, SL6 7BU

UK

Tel:+44-1628-631000

Fax:+44-1628-636311

http://www.optexeurope.com

OPTEX SECURITY SAS

(FRANCE)

475, Rue Piani

69780 Amberieux d’Azergues

France

Tel:+33.4.37.55.50.50

Fax:+33.4.37.55.50.59

http://www.optex-security.com

OPTEX SECURITY SP.Z.O.O.

(POLAND)

ul. Bitwy Warszawskiej 1920 r.

7B 02-366 Warszawa

POLAND

main:+48-22- 598-06-60

Fax:+48-22-598-06-61

No.59-1292-1 06,10-20

Loading...

Loading...