Page 1

- 1 -

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

INTRODUCTION

1

1 INTRODUCTION

1-1

BEFORE OPERATION ............................................................. 1

1-2

PRECAUTIONS ........................................................................ 2

1-3

PARTS IDENTIFICATION ......................................................... 2

2 TYPES OF INSTALLATION METHOD AND DETECTION AREAS

2-1

TYPES OF INSTALLATION METHOD ..................................... 2

2-2

TYPES OF DETECTION METHOD .......................................... 3

2-3

AREA SETTING PROCEDURE ................................................ 3

3 INSTALLATION AND ANGLE ADJUSTMENT

3-1

INSTALLING TO WALL AND ANGLE ADJUSTMENT .............. 4

3-2

INSTALLING TO CEILING PLANE AND ANGLE

ADJUSTMENT .......................................................................... 5

3-3

INSTALLING TO POLE ............................................................. 6

3-4

INSTALLING AT AN ANGLE TO WALL OR CEILING

PLANE ...................................................................................... 6

3-5

INSTALLING AT AN ANGLE TO POLE ..................................... 7

4 PARTS LAYOUT INSIDE THE COVER AND THEIR FUNCTIONS

4-1

WIRING ..................................................................................... 7

4-2

RESET SWITCH ....................................................................... 7

4-3

SIGNAL OUTPUT ..................................................................... 7

4-4

CONNECTING WALK TESTER ................................................ 8

4-5

POWERING ON ........................................................................ 8

4-6

SWITCH LAYOUT ..................................................................... 8

4-7

LED FUNCTIONS ..................................................................... 8

5 SETTING HORIZONTAL DETECTION AREAS 1 AND 2

5-1

SELECTOR SWITCH OPERATION ......................................... 8

5-2

MANUAL SETTING OF HORIZONTAL DETECTION

AREA ........................................................................................ 9

5-3

STARTING SECURITY PROTECTION IN MANUAL

MODE ....................................................................................... 9

5-4

AUTO SETTING OF HORIZONTAL DETECTION AREA ......... 9

6 SETTING VERTICAL DETECTION AREA

6-1

SELECTOR SWITCH OPERATION ....................................... 10

6-2

SETTING DETECTION AREA IN VERTICAL

DETECTION AREA .................................................................

10

6-3

AUTO SETTING OF VERTICAL DETECTION AREA ..............11

7 AREA CHECKUPS

7-1

WALK TEST .............................................................................11

7-2

CHANGING THE SETTINGS DURING SECURITY

PROTECTION .........................................................................11

7-3

SYSTEM FUNCTION AFTER POWER FAILURE .................. 12

8 SPECIFICATIONS

8-1

SPECIFICATIONS OF THE MAIN UNIT ................................. 12

8-2

DIMENSIONAL DRAWING ..................................................... 12

8-3

OPTIONS ................................................................................ 12

1-1

BEFORE OPERATION

Read this instruction manual carefully prior to installation.

This manual uses the following warning indications to provide

information regarding correct usage of the product to prevent

you and other people from being harmed, and your assets

from being damaged. These warning indications are described

below.

Ensure you understand these precautions before reading the

rest of this manual.

Warning

Failure to follow the instructions provided by

this warning and improper handling may cause

death or serious injury.

Caution

Failure to follow the instructions provided by

this caution and improper handling may cause

injury and/or property damage.

This symbol indicates prohibition.

The specic prohibited action is provided in and/or around

the gure.

This symbol requires an action or gives an instruction.

Warning

Do not use the product for purposes other than the

detection of moving objects such as people and

vehicles.

Do not use the product to activate a shutter, etc.,

which may cause an accident.

Do not touch the unit base or power terminals of

the product with a wet hand (do not touch when the

product is wet with rain, etc.). It may cause electric

shock.

Never attempt to disassemble or repair the product. It

may cause re or damage to the devices.

Do not exceed the voltage or current rating specied

for any of the terminals, doing so may cause re or

damage to the devices.

Ensure the power is turned off before connecting

wiring.

Conrm the signal name of every terminal to ensure

wiring is carried out correctly.

Whenever a commercial switching regulator is used,

be sure to connect PE (Protective Earth Terminal).

Hold the main unit securely when you install or

service it. Exercise care not to bump the product

against nearby objects or drop it inadvertently.

This product is not capable of detecting objects in the

dead zone of the laser scan.

Do not use this product for an application where it is

not capable of covering the detection area required

by the task.

Please note that the product can malfunction,

including producing an irregular output and

committing a detection error, if it is exposed to

unfavorable environmental conditions such as

strong ambient light, electronic noises or mechanical

vibrations.

Caution

Use of controls or adjustments or performance of

procedures other than those specied herein may

result in hazardous radiation exposure.

Clean and check the product periodically for safe use.

If any problem is found, do not attempt to use the

product as it is.

When disposing of this product, be sure to follow the

waste-disposal regulations of the country or region

where it is used.

This product is intended to detect an intruder(s)

and is not designed to prevent theft, disasters or

accidents. The manufacturer shall not be held liable

for any damage to user’s property resulting from

theft, disasters or accidents.

•

•

FEATURES

* 30 m (Approx. 100 ft.) radius for 190 degrees

* Vertical and horizontal mounting

* Unique detection algorithm

* Four independently adjustable detection areas for PTZ camera

control

* Four independent N.O. outputs

* Form C master alarm outputs

* Automatic area setting function

* Environmental disqualification (EDQ) circuit

* Trouble output

* Tamper output

REDSCAN is an area sensor that configures a fan-like detection

area of 30 m (Approx.100 ft.) radius over 190 degrees arc. using

laser beams.

REDSCAN detects target objects by emitting laser beams at the

target and measuring the time required for the emitted beams to

be reflected and returned to the detector.

There are 3 modes for detecting an intruder. Horizontal Detection

Area1, Horizontal Detection Area2 and Vertical Detection Area.

Each one is configured with an independent detection algorithm.

CONTENTS

No.591555-0 2009.3

INSTALLATION INSTRUCTIONS

RLS-3060

RLS-3060

Laser Scan Detector

Laser Scan Detector

Page 2

- 2 -

- 3 -

TYPES OF INSTALLATION METHOD AND DETECTION AREAS

2

1-2

PRECAUTIONS

Install the product only on a

solid surface.

In the Horizontal Detection

Area, this product must

normally be used within the

recommended installation

height in order to detect an

intruder.

Install the product so that the

detection area is not inuenced

by interference from tall grass

or tree branches waving in the

wind.

Do not install or leave the

product in a location exposed

to heat, vibrations or impacts

beyond the noted rating.

Do not use the product in an

environment where solvent

fumes or corrosive gases are

present.

Do not use this product in

environments where there

may be oil mist particles which

may contaminate the window

of the detector; thus causing

detection errors and possible

corrosion which may lead to

product failure.

The symbol “Í” indicates prohibited actions.

Cleaning the Product

Clean the front window on a regular basis

using a wet cloth.

A smeared front window can limit the

detection area due to the reduced laser

sensitivity. In addition, heavy soiling of the

window can induce detection errors.

On Safety of Laser

This product is categorized as a Class 1 product in terms of the

Safety Standard.

Average Power : Max. 0.015 mW (AEL)

Wavelength : 905 nm

Pulse With : 4 ns

Emission period : 36 μs

Standard : IEC60825-1

Class 1 of the Laser Safety Standard means that the safety

of laser products belonging to this class is warranted under

normal operating conditions (reasonably predictable operating

conditions). The user is simply required to indicate that this

product is laser equipment. No additional safety measures are

necessary.

Certied to FDA (21 CFR part 1040.10 and 1040.11)

Class 1 laser product

Do not expose your eyes directly to the laser beam.

1-3

PARTS IDENTIFICATION

Accessories>>

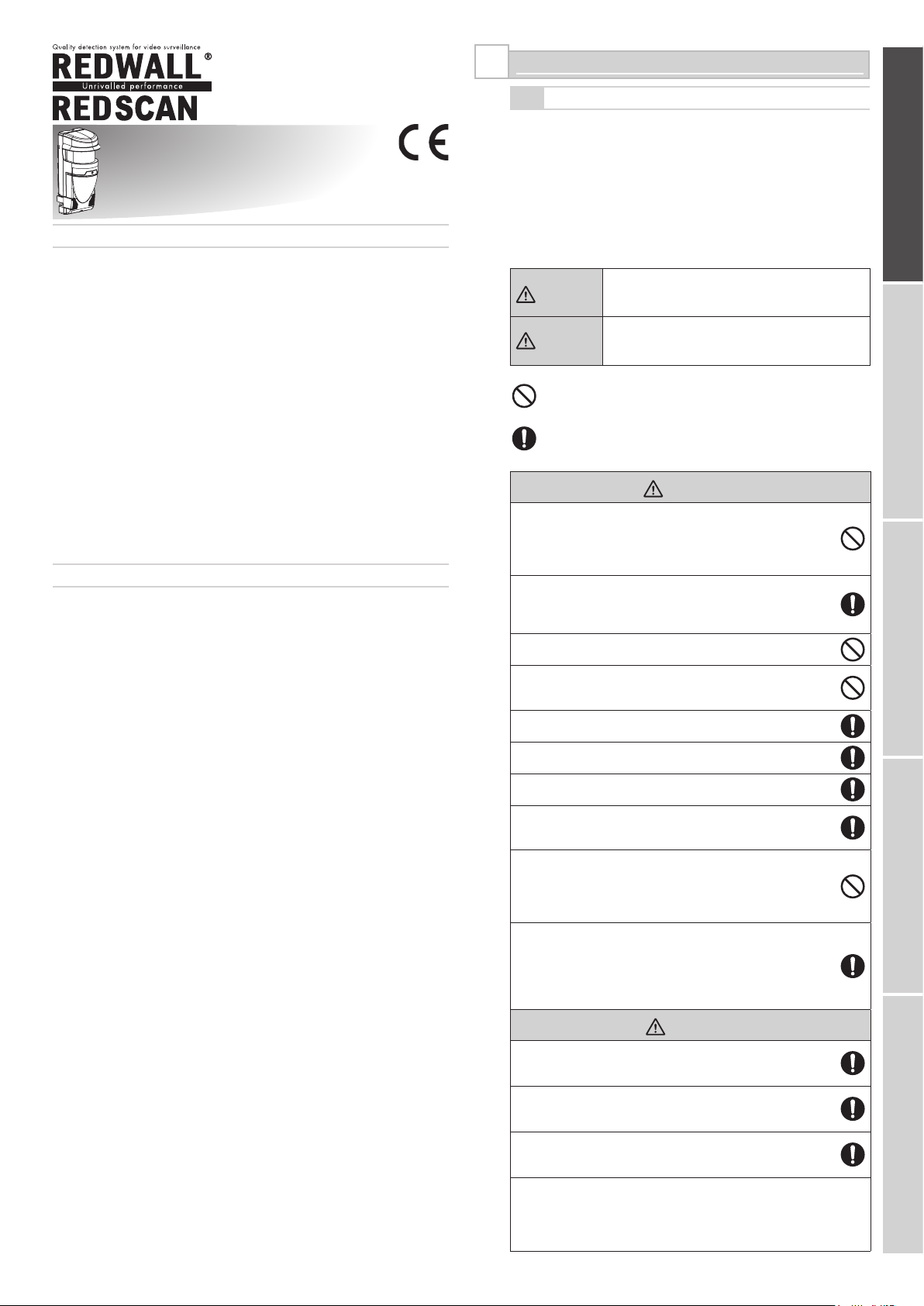

2-1

TYPES OF INSTALLATION METHOD

Installing to a wall Installing to a pole

Installing at an angle to a wall Installing at an angle to a pole

Installing to a ceiling plane

Installing at an angle to a

ceiling plane

Installation height:

0.7 m to 1 m

(2.3 ft. to 3.3 ft.)

Front window

Mounting bracket Main unit

Cover

Cover mounting screw

Main unit mounting screw

Angle adjustment screw

4 screws

(For locking the

mounting bracket)

4 anchors

for the board

1 paper template 2 cable glands

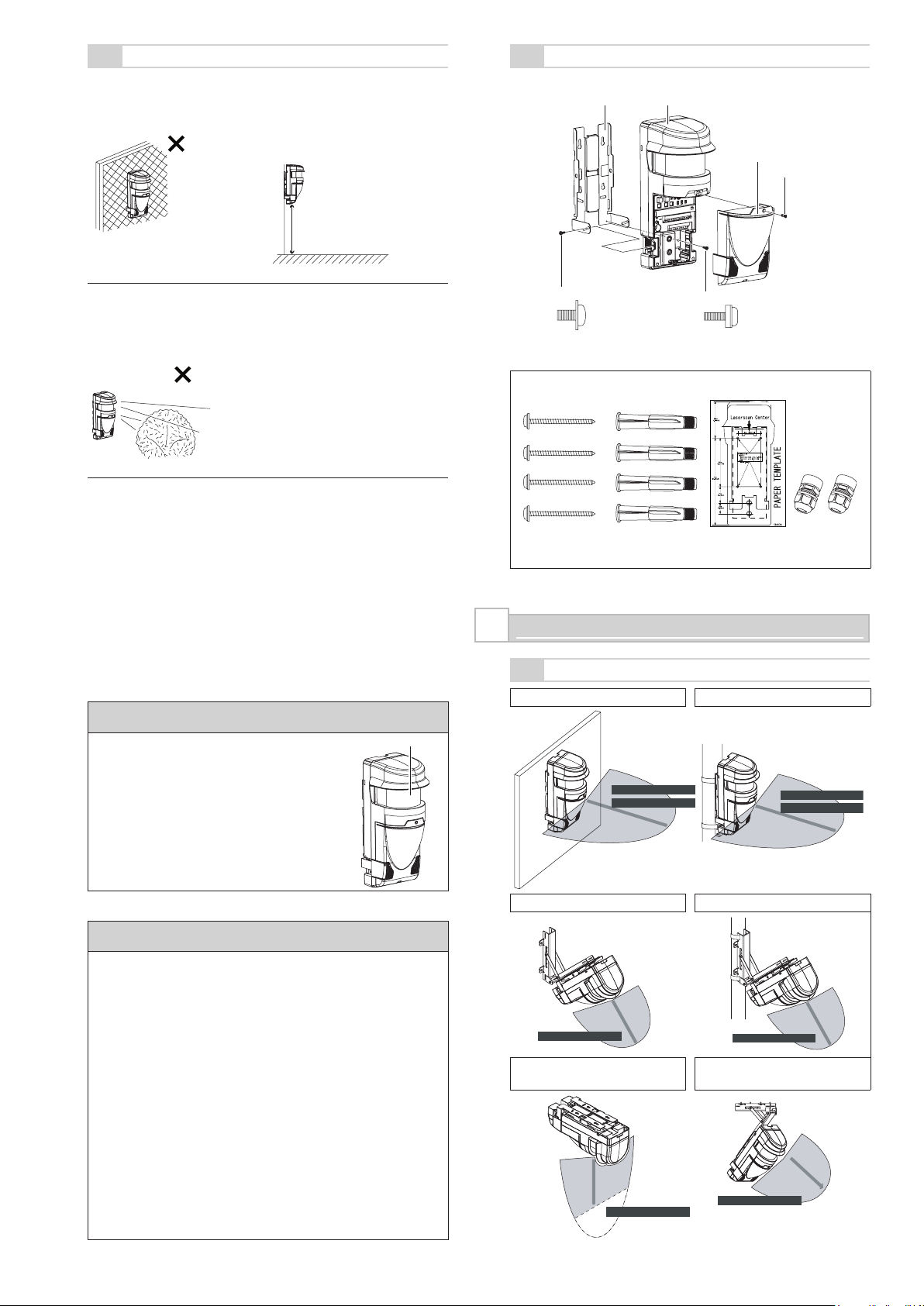

Detection method

Detection method

Horizontal Detection Area 1

Horizontal Detection Area 2

Horizontal Detection Area 1

Horizontal Detection Area 2

Detection method

Detection method

Vertical Detection Area

Vertical Detection Area

Laser beam

Laser beam

Laser beam

Laser beam

Detection method

Detection method

Vertical Detection Area

Vertical Detection Area

Laser beam

Laser beam

Bracket is optional item.

Bracket is optional item. Bracket is optional item.

Bracket is

optional item.

Page 3

- 3 -

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

2-2

TYPES OF DETECTION METHOD

The detection method comprises the three modes of Horizontal

Detection Area 1, Horizontal Detection Area 2 and Vertical

Detection Area.

-Horizontal Detection Area 1

H1 H2 V

This mode allows setting of a fan-like detection area in

the horizontal direction with a maximum radius of 30 m

(Approx.100 ft.), a spread angle of 180 degrees, and a width of

1 m (3.3 ft.).

This mode detects intrusion of an object that appears from the

rear side of the sensor or in a position within 1 m (3.3 ft.) from

the sensor installation line and that moves toward the front of the

sensor.

Cautions>>

This mode does not detect an object that appears in a

position more than 1 m (3.3 ft.) away from the sensor

installation line.

-Horizontal Detection Area 2

H1 H2 V

This mode allows setting of a fan-like detection area in the

horizontal direction with a maximum radius of 30 m (Approx.

100 ft.), a spread angle of 190 degrees.

This mode detects intrusion into the detection area from any

direction.

-Vertical Detection Area H1 H2 V

This mode allows setting of a fan-like detection area in the

vertical direction with a maximum radius of 30 m (Approx. 100 ft.),

a spread angle of

190 degrees and a maximum recommended

height above the ground of 15 m (Approx. 50 ft.).

This mode detects an object that traverses the detection area.

2-3

AREA SETTING PROCEDURE

The Manual and Auto modes are available for setting the area.

The Auto setting procedure comprises the two options of P1 and

P2.

The setting procedure in each mode varies depending on which

detection method of either H1, H2 or Vertical detection Area is

selected.

-Horizontal Detection Area 1/Horizontal Detection Area 2

Manual

In this mode, set up a detection area by specifying a radius of

the fan-like detection area.

The rough alignment rotary switch can specify the radius in the

range of 0 to 30 m in 2 m steps.

Using the ne adjustment potentiometer the area setting can be

increased or decreased by up to +/- 1 m.

The detection area is divided into Area A and Area B, allowing

you to specify a different radius for each. Each of Areas A and B

is halved to A1, A2, B1 and B2 areas.

-

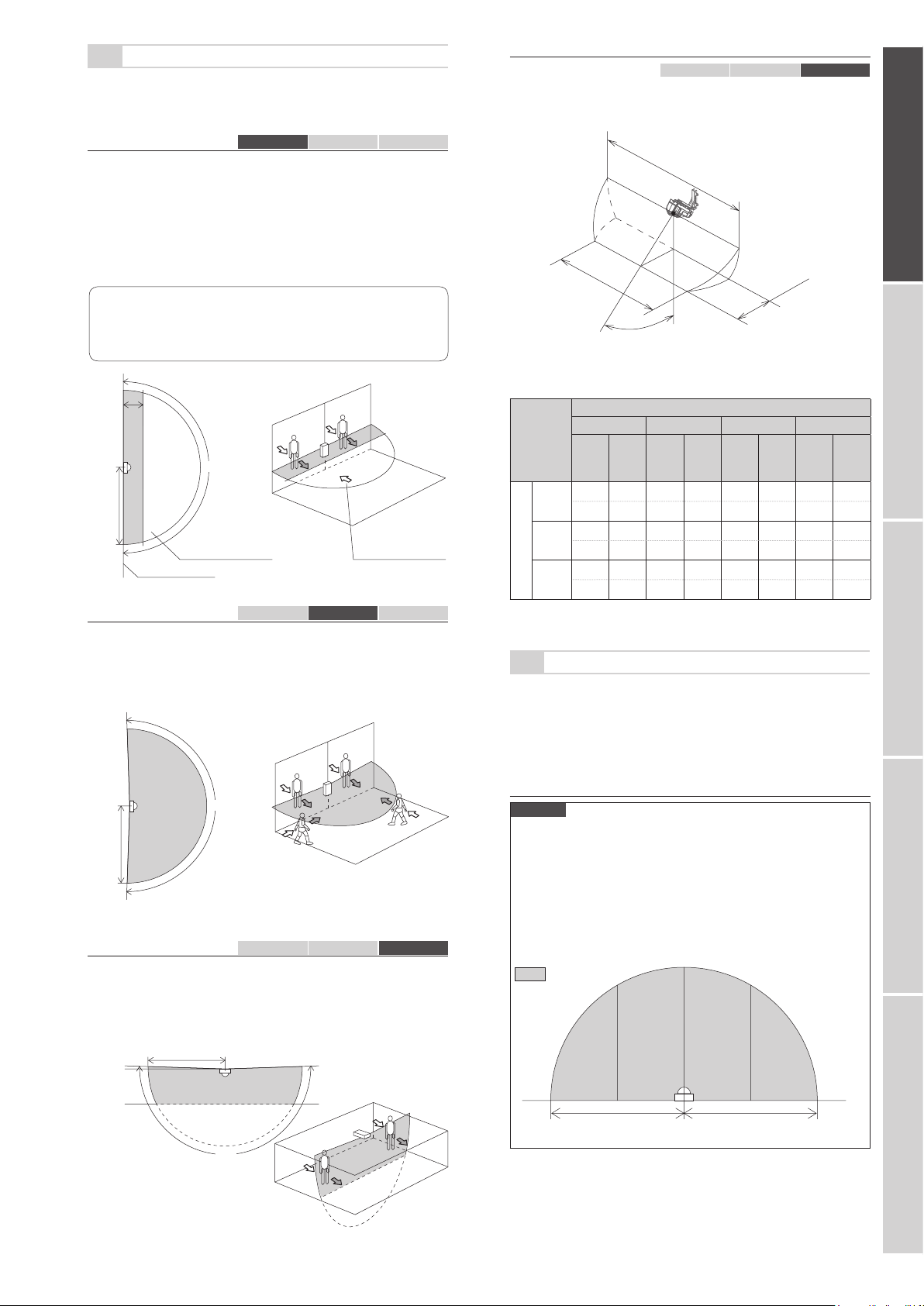

Vertical Detection Area when the product is installed at an angle

H1 H2 V

When you have installed this product at an angle with the optional

adjustable angle mounting bracket, the detection area varies as

shown below depending on the installation height and angle.

Width of laser optical axis and positional dimension (Laser

center standard)

Mounting angle

0° 20° 30° 45°

Width of

optical

axis

Position

Width of

optical

axis

Position

Width of

optical

axis

Position

Width of

optical

axis

Position

Installation height

4 m

(13 ft.)

59 0 59 1.5 59 2.3 59 4.0

195

0 195 4.8 195 7.6 193 13.1

10 m

(33 ft.)

57 0 56 3.6 55 5.8 53 10.0

186

0 184 11.9 182 18.9 174 32.8

15 m

(49 ft.)

52 0 51 5.5 49 8.7 42 15.0

170

0 167 17.9 161 28.4 139 49.2

[Upper row: m/Lower row: ft.]

180°

1 m

(3.3 ft.)

30 m

(Approx.

100 ft.)

An object that appears in

this area is not detected.

An object that intrudes

from this direction is

not detected.

Sensor

installation line

30 m

(Approx.

100 ft.

)

190°

Mounting

height

Ground

surface

30 m (Approx. 100 ft.

)

Mounting angle

Position

60 m (Approx. 200 ft.)

Width of optical axis

30 m (Approx. 100 ft.) 30 m (Approx. 100 ft.)

Area

B2

Area

B1

Area

A1

Area

A2

: Detection area

Page 4

- 4 -

- 5 -

a

dc

b

INSTALLATION AND ANGLE ADJUSTMENT

3

Auto

P1 Auto Learning

The area automatically learnt by the sensor within the boundary

dened by the rough alignment rotary switches and ne

adjustment potentiometers.

P2 Auto Tracing

The area automatically learnt by tracing a person walking a

boundary within the area set by the rough alignment rotary

switches and ne adjustment potentiometers.

-Vertical Detection Area

Manual

Vertical Detection Area is not available in Manual mode.

Turn on the Auto mode to use it.

Auto

P1 Fix

The area being automatically recognized by the sensor scanner

within the fan-like area set by the rough alignment rotary

switches and the ne adjustment potentiometers.

P2 Refresh

The area being detected is automatically adapted every hour to

compensate for objects blocking the areas.

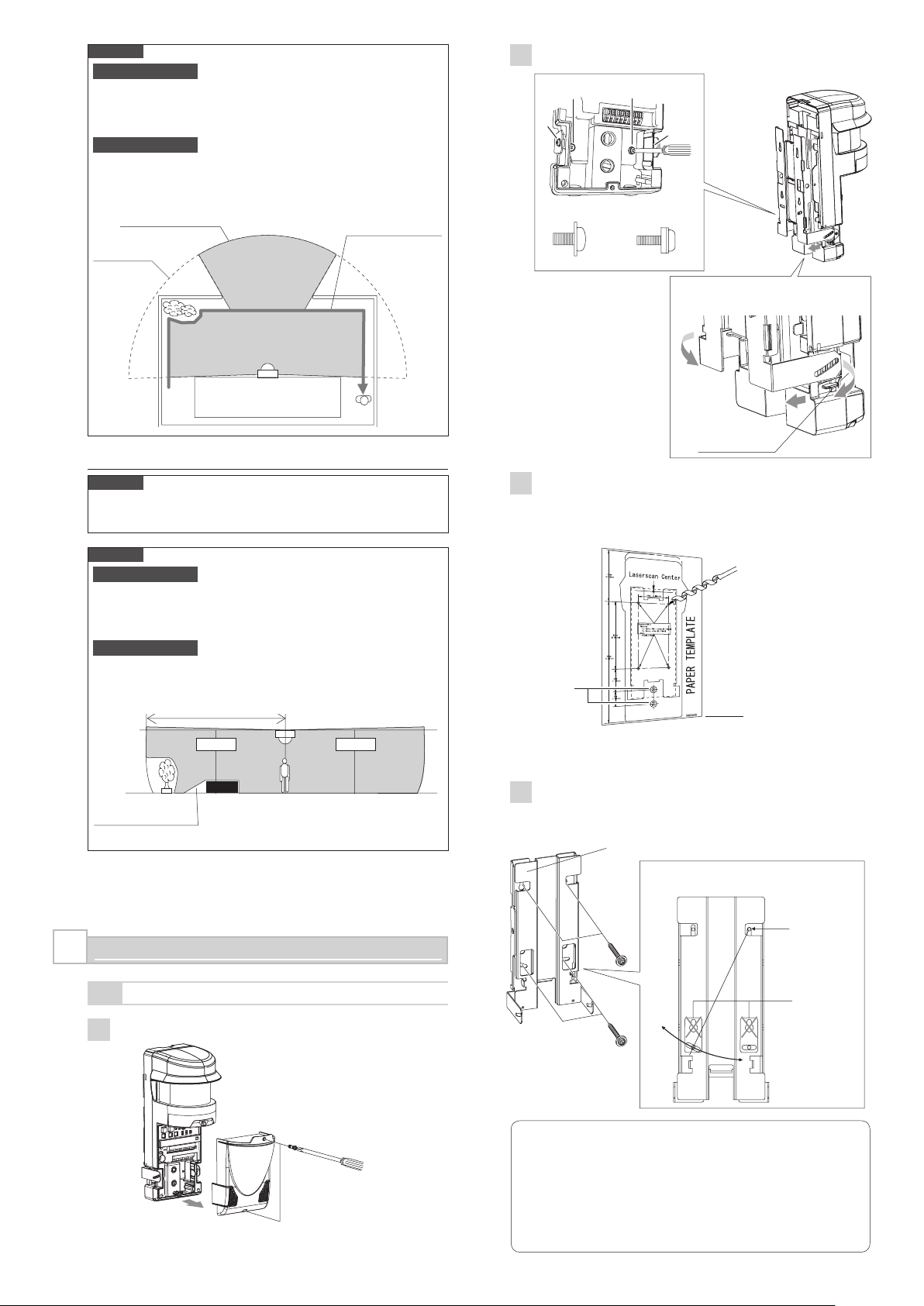

3-1

INSTALLING TO WALL AND ANGLE ADJUSTMENT

1 Remove the cover from the main unit.

2 Remove the mounting bracket from the main unit.

3 Attach the paper template (an accessory) onto the wall, and

drill 4 mounting holes in it. Drill 2 wiring holes as required.

Insert the anchor bolt (an accessory) into the board

mounting holes.

4 Fix the mounting bracket on the wall. Adjust the angle so

that the inclination in the horizontal plane becomes parallel

to the ground.

Cautions>>

When installing the product to the wall, fix the mounting

bracket parallel to the ground. If the mounting bracket is

set at an angle, the laser beam will not be emitted parallel

to the ground, which may result in the non-detection of

an intruder. An inclination of 1 degree varies the shape

of the detection area of 30 m (Approx.

100 ft.) ahead by

approximately 0.5 m (1.6 ft.).

Auto P1 (Auto Learning)

Auto P2 (Auto Tracing)

Manual

Area

A2

Area

A1

Area

B1

Area

B2

30 m maximum (Approx. 100 ft.)

Auto P1 (Fix)

Installation

height

Ground

surface

1

Loosen 2 lock screws.

Main unit fallprotection stopper

(Washer without rubber)

1 Loosen 4 lock screws.

2 Move the

mounting

bracket

3 Remove the mounting bracket by moving it

over the stopper while opening the bottom

of the mounting bracket slightly outward.

They are not

used

A

Mounting hole in 4 locations

Diameter 6 mm (0.24 inches)

Depth

60 mm (2.36 inches)

Set the lower end of the

paper template at a position

at least 0.7 m (28 in.) above

the ground.

Wiring hole

Tighten 4 lock screws for the mounting bracket (accessories).

Adjust the angle along the slot while setting screw

hole A at the center. After the adjustment, tighten

the screws.

Angle adjustment

screws a and b

Main unit mounting

screws c and d

Area A Area B

2

Remove the cover.

(Washer with rubber)

Page 5

- 5 -

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

a

dc

b

a

dc

b

5 Install the cable gland.

6 Install the main unit and fix it to the mounting bracket.

Adjust the angle so that the inclination in the vertical

direction becomes parallel to the ground.

7 See section “4-1” and connect the wires to the terminal

block.

Cautions>>

When the indicators (A1, A2, B1, B2, Status and Power)

light after the power turns on, this signifies that the system

is warming up. Wait for approximately 30 seconds until the

indicators go out.

8 See Chapters 5, 6 and 7, make various settings and confirm

that the equipment operates correctly.

9 The installation work is complete when the various settings

and operational check are finished. Mount the cover.

3-2

INSTALLING TO CEILING PLANE

AND ANGLE ADJUSTMENT

When you have selected the Vertical Detection Area for detection

purposes, install the product to the ceiling plane.

1 Implement steps 1 and 2 in “3-1” to remove the cover and

mounting bracket.

2 Attach the paper template (an accessory) to the ceiling

plane and drill 4 mounting holes in it. Drill 2 wiring holes as

required.

Insert the anchor bolt (an accessory) into the board

mounting holes.

3 Fix the mounting bracket to the ceiling plane.

4 Install the main unit and fix it to the mounting bracket. Adjust

the angle so that the inclination in the vertical direction

becomes parallel to the ground.

5 Take steps 6 through 9 in “3-1” to do wiring, check the

setup and operation, and then install the cover.

1 Install the main unit by moving it over the

stopper while opening the bottom of the

mounting bracket slightly outward.

Ensure that any unused

wiring holes are covered

securely with a wiring

hole cap.

Cable gland

Main unit fallprotection stopper

3

Tighten 4 lock screws.

Angle adjustment

screws a and b

Main unit mounting

screws c and d

(Washer without

rubber)

2

Insert the top portion

When tightening screws a and b,

adjust the angle referencing the

slot.

2

Tighten 2 lock screws.

1

Install the cover.

Wiring hole

Peel off the paper template from the portion indicated

with the dotted line when using its inner portion alone.

Mounting hole in 4 locations

Diameter 6 mm (0.24 inches)

Depth

60 mm (2.36 inches)

Tighten 4 lock screws

for the mounting

bracket (accessories).

They are not

used

Main unit fallprotection stopper

1 Install the main unit by moving it over the

stopper while opening the bottom of the

mounting bracket slightly outward.

2

Insert the top portion.

3

Tighten 4 lock screws.

(Washer without

rubber)

(Washer with rubber)

Angle adjustment

screws a and b

When tightening screws a and b,

adjust the angle along the slot.

5°

5°

5°

5°

(Washer with rubber)

Main unit mounting

screws c and d

Page 6

- 6 -

- 7 -

3-3

INSTALLING TO POLE

When installing the product to a pole, use the optional pole

mounting bracket (RLS-PB).

1 Take steps 1 and 2 in “3-1” to remove the cover and

mounting bracket.

2 Fix the pole mounting bracket (optional) to the pole using 2

stainless belts (included in the pole mounting bracket).

Points >>

For detailed handling procedures, see the manual attached

to the pole mounting bracket.

3 Fix the mounting bracket to the pole mounting bracket.

For the fixing, use the screw with the washer attached to

the pole mounting bracket. Adjust the angle so that the

inclination in the horizontal plane becomes parallel to the

ground.

4 Take step 6 in “3-1” to install and fix the main unit to the

mounting bracket.

5 Take steps 7 through 9 in “3-1” to do wiring, check the

setup and operation, and then install the cover.

3-4

INSTALLING AT AN ANGLE TO WALL

OR CEILING PLANE

When installing the product at an angle to a wall or ceiling plane,

use the optional adjustable angle mounting bracket (RLS-SB).

1 Take steps 1 and 2 in “3-1” to remove the cover and

mounting bracket.

2 When installing the product at an angle to a wall, attach the

paper template (attached to the main unit) to the wall and

drill 4 mounting holes in it in the same way as described

in “3-1

3

.” For the ceiling plane, follow the procedures

described in “3-2 2.”

Points >>

The mounting holes for the adjustable angle mounting

bracket must be provided in the same position, diameter

and depth as that for the main unit mounting holes

indicated on the paper template.

3 Fix the optional adjustable angle mounting bracket to the

wall or ceiling plane using 4 screws attached to the main

unit.

Wall Ceiling plane

Points >>

For detailed handling procedures, see the manual attached

to the adjustable angle mounting bracket.

4 Fix the mounting bracket with 4 lock screws with the washer

attached to the optional adjustable angle mounting bracket.

Wall Ceiling plane

5 Take step 6 in “3-1” to install and fix the main unit to the

mounting bracket.

Wall Ceiling plane

6 Take steps 7 through 9 in “3-1” to carry out wiring, check

the setup and operation, and then install the cover.

Stainless belt

(included in the

pole mounting

bracket)

Pole mounting

bracket (optional)

The angle varies according to the bolt

insertion position.

The angle varies according to the bolt

insertion position.

45°

40°

30°

20°

30°

45°

40°30°20°10°

10

°

0°

45°

Page 7

3-5

INSTALLING AT AN ANGLE TO POLE

When installing the product at an angle to a pole, use the optional

adjustable angle mounting bracket for pole (RLS-SB).

1 Take steps 1 and 2 in “3-1” to remove the cover and

mounting bracket.

2 Fix the optional adjustable angle mounting bracket to the

pole using 2 stainless belts (included in the adjustable angle

mounting bracket).

Stainless belt

(included in the

pole mounting

bracket)

Power wires should not exceed the following lengths.

WIRE

SIZE

AWG20

(0.52 mm2)

AWG18

(0.83 mm2)

4-2

24V DC 24V AC

120

(394)

200

(656)

60

(197)

100

(328)

m (ft.)

RESET SWITCH

Stripped wire length

Wires must be stripped back 9 mm.

Use the gauge on the panel for

correct measurement.

This switch is used for restarting the system.

Do not touch it during normal operation.

4-3

SIGNAL OUTPUT

9 mm

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

Adjustable angle

mounting bracket

3 Fix the mounting bracket with 4 lock screws with the washer

attached to the optional adjustable angle mounting bracket.

4 Take step 6 in “3-1” to install and fix the main unit to the

mounting bracket.

5 Take steps 7 through 9 in “3-1” to do wiring, check the

setup and operation, and then install the cover.

-D.Q. output

The algorithm specific to REDSCAN allows

detecting an intrusion amid the fog. However,

during severe conditions such as heavy rain,

dense fog or snow storms the Environmental

DisQualification (EDQ) output is activated.

-Alarm output

Upon detecting an intruder, this product outputs the alarm specific

to the area (Area A1, Area A2, Area B1 or Area B2) where the

intrusion happened.

When combined with an area monitoring system using a PTZ

camera, this product works efficiently to provide early detection of

intruders.

-Tamper output

This output is enabled when the terminal cover is

removed.

-Trouble output

It is generated when an error has occurred on the

sensor.

Name Function

4

PARTS LAYOUT INSIDE THE COVER AND THEIR FUNCTIONS

4-1

WIRING

RESET

Switch

D.Q OUTPUT (N.C.)

D.Q OUTPUT (N.O.)

A2 area ALARM OUTPUT (N.O.)

A1 area ALARM OUTPUT (N.O.)

B1 area ALARM OUTPUT (N.O.)

B2 area ALARM OUTPUT (N.O.)

TAMPER OUTPUT (N.C.)

A

r

e

a

A

A

r

e

a

B

A

u

to

F

u

n

c

1

6

1

6

1

2

1

2

2

0

2

0

7

H1

7

Rang

e

P1

2

4

2

4

8

8

H2

P2

V

4

2

8

4

2

8

0

0

O

f

f

s

e

t

Fine

adj

.

-1 +

1

-1 +

1

-1 0

TROUBLE OUTPUT (N.O.)

MAINTENANCE

CONNECTOR

WALK TESTER

CONNECTOR

POWER INPUT

TROUBLE OUTPUT (N.C.)

ALARM OUTPUT (N.O.)

ALARM OUTPUT (N.C.)

*1: TAMPER terminals to be connected to a 24 hour supervisory loop.

It is activated when an obstacle

has been placed in front of the

sensor in order to block the

Anti-masking

detection area. It is reset after

such obstacles are removed.

Heavy soiling of the front

window can also activate this

function.

This function is activated

when the area being scanned

changes by a signicant

Anti-rotation

amount as a result of the unit

being rotated from its original

settings. Not applicable in

Manual mode.

.

S

A1

e

t

A2

B

1

B

2

Status

Powe

r

S

e

n

s

.

S

iz

e

M

o

d

e

H

S

M

M

M

A

L

L

5

7

3

1

2

4

0

Sensor error

It is activated when the sensor

has detected an internal self

check error.

-Alarm output

The alarm output is generated if an intruder is

detected in one or more of the divided areas (Area

A1, Area A2, Area B1 and Area B2).

- 7 -

Page 8

- 8 -

- 9 -

REDWAVE

REDWAVE

MICROWAVE

REDWAVE

ALARM OUTPUT

CELL BATTERY

POWER

SUPPLY

FROM

SENSOR

POWER OFF

REDWAVE

PIR NEAR

REDWAVE

PIR FAR

MEGARED

FAR

MEGARED

NEAR

REDWALL

REDWIDE

WALKTESTER

REDWALL

REDWIDE

MEGARED

CONNECTION

SELECT

SWITCH

MODE

SELECT

SWITCH

POWER

SELECT

SWITCH

OPM-WT

Set A2

Power

A1

B1 B2

Status

Set A2

Powe

r

A1

B1 B2

Status

F

in

e

adj.

A

u

t

o F

u

n

c

.

S

e

t

P1

P2

H1

V

H2

O

f

f

s

e

t

S

e

n

s

.

H

M

L

S

i

z

e

S

M

L

A

r

e

a

A

A2

Powe

r

-1 +

1

-1 +

1

-1 0

A1

B

1

B

2

A

r

e

a

B

5

7

3

1

2

4

0

Status

Range

M

o

d

e

M

A

0

8

1

6

2

4

4

1

2

2

0

2

8

0

4

8

1

2

1

6

2

0

2

4

2

8

7

7

Fine

adj.

Auto Func. Set

P1

P2

H1

V

H2

Offset

Sens.

H

M

L

Size

S

M

L

Area A

A2

Power

-1 +1 -1 +1 -1 0

A1

B1 B2

Area B

5731240

Status

Range

Mode

M

A

0

8

16

24

4

12

20

2804

8

12

16

20

24

28

7

7

Set A2

Powe

r

A1

B1 B2

Status

SETTING HORIZONTAL DETECTION AREAS 1 AND 2

5

4-4

CONNECTING WALK TESTER

1 Turning on the power selector switch after plugging

the cable into the Walk Tester Connector generates a

continuous beep at a constant sound level.

2 The beep sound becomes stronger and continues for a

longer period if an object is detected.

4-5

POWERING ON

Connect 24 VAC/DC to the power input terminal to

turn power on.

As power is turned on, the indicators (A1, A2, B1,

B2, Status and Power) light for about 30 seconds

and then go out.

During this period, REDSCAN initializes itself.

Indicator Power remains lit as long as power is

turned on.

Legend OFF Light Blink

4-6

SWITCH LAYOUT

4-7

LED FUNCTIONS

-In the normal operation

Symbol Color DETECTOR STATUS

A2 Red

Area A2 alarm output

A1

Red

Area A1 alarm output

B1

Red

Area B1 alarm output

B2 Red Area B2 alarm output

Status Yellow

Lit during auto setup of the unit.

(Turned off during normal operation.)

Power Green Lit when power is turned on

-When an abnormality occurs

Status

A2 A1 B1 B2

Status

Power

D.Q.

Anti-masking

Anti-rotation

Sensor

error

Error 1

Error 2

Error 3

Error 4

Error 5

Legend OFF Light Blink

5-1

SELECTOR SWITCH OPERATION

-Detection method selection

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select the desired method using the detection

method selector switch.

Func.

H1

V

H2

SELECTOR

POSITION

FUNCTION

H1

It selects Horizontal Detection Area 1.

H2

It selects Horizontal Detection Area 2.

V

—

-Selection of the area setting method

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select the desired method using the mode

selector switch.

Mode

M

A

SELECTOR

POSITION

FUNCTION

M

Selects the Manual setting.

A

Selects the Auto setting.

-Selecting the Auto mode

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select it using the Auto mode selector switch.

Auto

P1

P2

SELECTOR

POSITION

FUNCTION

P1

Turns on the Auto Learning.

P2

Turns on the Auto Tracing.

Area A2 alarm output

Area A1 alarm output

Area B1 alarm output

Area B2 alarm output

Power selector

switch

Use at “REDWALL”

position.

WALK TESTER <OPM-WT>

REDSCAN

Approximately

30 seconds

(Initialization is

turned on)

Auto mode selection

Detection method selection

Detection area setting button

Operation Indicator

Tamper switch

Mode selection

Detection sensitivity setting (Size.)

Detection sensitivity setting (Sens.)

Offset adjustment

Area A ne alignment

potentiometer

Area B

ne alignment

potentiometer

Area A rough

alignment

Area B rough

alignment

Page 9

- 9 -

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

Area B Area A

0

8

16

24

4

12

20

28

0

4

8

12

16

20

24

28

7

F

Fine

adj.

Area A

-1 +1 -1 +1

Area B

Range

0

8

16

24

4

12

20

2804

8

12

16

20

24

28

7

F

Offset

-1 0

Set A2

Set A2

Power

A1

B1 B2

Status

REDWAVE

REDWAVE

MICROWAVE

REDWAVE

ALARM OUTPUT

CELL BATTERY

POWER

SUPPLY

FROM

SENSOR

POWER OFF

REDWAVE

PIR NEAR

REDWAVE

PIR FAR

MEGARED

FAR

MEGARED

NEAR

REDWALL

REDWIDE

WALKTESTER

REDWALL

REDWIDE

MEGARED

CONNECTION

SELECT

SWITCH

MODE

SELECT

SWITCH

POWER

SELECT

SWITCH

OPM-WT

1

2

Auto

P1

P2

-Selecting the detection sensitivity

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Set the detection sensitivity using the Size selector switch and

Sens. selector switch. You can set the detection sensitivity in the

horizontal area with the size of the target object and its move

distance within the detection area.

H

M

L

S

M

L

Size

Sens.

SELECTOR

POSITION

FUNCTION

S

Approx. 150 mm

(0.5 ft.) or above

This switch

species

the width of

the target

object to be

detected.

M

Approx. 300 mm

(1 ft.) or above

L

Approx. 1000 mm

(3.3 ft.) or above

H

Approx. 500 mm

(1.6 ft.) or above

This switch

species

the move

distance of an

object in the

detection area

above which

it is judged as

an intruder.

M

Approx. 1000 mm

(3.3 ft.) or above

L

Approx. 2000 mm

(6.6 ft.) or above

5-2

MANUAL SETTING OF HORIZONTAL DETECTION AREA

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Set a fan-like detection area using the rough alignment rotary

switch and fine alignment potentiometer.

-Rough alignment rotary switch

You can specify the radius in the range of 0 to 30 m in 2 m steps.

Setting the rough alignment rotary switch to 0 m deletes the area.

Example: if you specify “Detection distance in Area A: 30 m”

and “Detection distance in Area B: 14 m” in a location where the

radius is 30 m or more without a reflector, the following detection

areas will result.

SELECTOR

POSITION (m)

[ft.]

0 0

4 13

8 26

12

39

16

52

20 65

24 79

28 92

-Fine alignment potentiometer

This potentiometer can fine tune the value set with the rough

alignment rotary switch by +/- 1 m. within the range of 0 m

minimum and 30 m maximum.

Setting done in rough

alignment

Range available for fine alignment

When 0 m is set

0 to +1 m (From -1 to 0 m on the scale

is not usable)

When 2 to 28 m is set ±1 m

When 30

m is set

-

1 to 0 m (From 0 to +1 m on the scale

is not usable)

-Offset adjustment

You can reduce a set detection area using the offset

potentiometer. Use this adjusting function when windblown grass

or tree branches interfere with the currently set detection area.

You can adjust the boundary of a given detection area inward

(toward the sensor) in the range of 0 to -1 m.

5-3

STARTING SECURITY PROTECTION IN MANUAL MODE

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

When “Manual” is chosen from the mode selector

switch, turning the power on starts the security

protection in manual mode.

5-4

AUTO SETTING OF HORIZONTAL DETECTION AREA

-Function of the detection area setting button

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

This button starts the auto function of either P1 or

P2 whichever has been selected.

-Setting P1 (Auto Learning)

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Sequence of

operation

Status

indicator

Time

Action of REDSCAN/

Response of Walk Tester

1

Hold down the

detection area setting

button for 1 second.

Flashing

starts

For

1 second

Pitch of Walk Tester

sound changes for

2 seconds

2

Evacuation from

the area

Flashing (*1)

For

15 seconds

—

—

Fast flashing

(*2)

For

10 seconds

Scan of the detection

area is executed

—

ON

For

15 seconds

Scan of the detection

area is completed and

the data are saved

—

Flashing

For

3 seconds

—

—

OFF

—

Security protection of the

detection area is started

*1: Flashes once a second

*2: Flashes twice a second

Cautions >>

Do not enter the area while the area scan is being carried

out.

An unwanted object in the area interferes with the correct

scanning of the target area.

Offset

Offset

Auto P1 (Auto Learning)

Manual Mode

AreaB2AreaB1Area

A1

Area

A2

15 m

7 m

30 m14 m

: Detection area

Page 10

- 10 -

- 11 -

Auto

P1

P2

2

3

Set A2

Power

A1

B1 B2

Status

REDWAVE

REDWAVE

MICROWAVE

REDWAVE

ALARM OUTPUT

CELL BATTERY

POWER

SUPPLY

FROM

SENSOR

POWER OFF

REDWAVE

PIR NEAR

REDWAVE

PIR FAR

MEGARED

FAR

MEGARED

NEAR

REDWALL

REDWIDE

WALKTESTER

REDWALL

REDWIDE

MEGARED

CONNECTION

SELECT

SWITCH

MODE

SELECT

SWITCH

POWER

SELECT

SWITCH

OPM-WT

1

Area BArea A

0

8

16

24

4

12

20

28

0

4

8

12

16

20

24

28

7

F

SETTING VERTICAL DETECTION AREA

6

-Setting P2 (Auto Tracing)

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Sequence of

operation

Status

indicator

Time

Action of REDSCAN/

Response of Walk Tester

1

Hold down the

detection area setting

button for 1 second.

Flashing

starts

For

1 second

Pitch of Walk Tester

sound changes for

2 seconds

2

Evacuation from

the area

Flashing

(*2)

For

15 seconds

—

—

Fast flashing

(*3)

For

10 seconds

Scan of the detection

area is executed

3

Walking along the

boundary of the area

(*1)

Flash

(*4)

For

5 minutes

Tracing started

Pitch of the Walk Tester

sound changes in

3-second cycles

(Last

30 seconds)

Pitch of the Walk Tester

sound changes in

1-second cycles

—

ON

For

15 seconds

Tracing is completed and

the data are saved

—

Flashing

For

3 seconds

—

—

OFF

—

Security protection of the

detection area is started

*1: The tracing is automatically ended after 5 minutes. When

movement of the target object along the area boundary has

finished before this time, you can terminate the tracing without

waiting for 5 minutes by holding down the detection area

setting button for 3 seconds.

*2: Flashes once a second

*3:

Flashes twice a second

*4: A flashin g sequen ce of flashing twice a second and n ot

flashing for a second is repeated

Cautions >>

Do not enter the area while the area scan is being carried

out. An unwanted object in the area interferes with the

correct scanning of the target area.

Note >>

Any area left untraced will revert to the Auto learning area

settings.

6-1

SELECTOR SWITCH OPERATION

-Detection method selection

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select the desired method using the detection

method selector switch.

Func.

H1

V

H2

SELECTOR

POSITION

FUNCTION

H1

—

H2 —

V

Selects the vertical detection area.

-Selection of the area setting method

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select the desired method using the mode

selector switch.

Mode

M

A

SELECTOR

POSITION

FUNCTION

M

NOT APPLICABLE

A

Selects the Auto setting.

-Selecting the Auto mode

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Select it using the Auto mode selector switch.

Auto

P1

P2

SELECTOR

POSITION

FUNCTION

P1

Fixes the detection area.

P2

Periodically refreshes the detection

area.

-Setting the detection sensitivity

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Set the detection sensitivity using the Size selector switch and

Sens. selector switch. You can set the detection sensitivity in the

vertical area with the size of the target object and the time it takes

to traverse the detection area.

H

M

L

S

M

L

Size

Sens.

SELECTOR

POSITION

FUNCTION

S

Approx. 300 mm

(1 ft.) or above

This switch

species the

height from

offset position

of the target

object to be

detected.

M

Approx. 500 mm

(1.6 ft.) or above

L

Approx. 1000 mm

(3.3 ft.) or above

H

100 ms or longer. This

setting is recommended

when the target object

can run through the

detection area.

This switch

species

the duration

during which

the target

object stays in

the detection

area.

M 150 ms or longer

L

200 ms or longer. This

setting is recommended

when detecting large

objects such as a car.

6-2

SETTING DETECTION AREA IN

VERTICAL DETECTION AREA

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Set a fan-like detection area using the rough alignment rotary

switch and fine alignment potentiometer.

-Rough alignment rotary switch

It can specify the radius in the range of 0 to 30 m in 2 m steps.

Setting the rough alignment rotary switch to 0 m deletes the area.

SELECTOR

POSITION (m)

[ft.]

0 0

4 13

8 26

12

39

16

52

20 65

24 79

28 92

Auto P1 (Auto Learning)

Manual Mode

Area

B2

Area

B1

Area

A1

Area

A2

: Detection area

Installation

height

Ground surface

15 m

7 m

30 m 14 m

Page 11

- 11 -

ENGLISH FRANÇAIS DEUTSCH ITALIANO ESPAÑOL

Fine

adj.

Area A

-1 +1 -1 +1

Area B

Range

0

8

16

24

4

12

20

2804

8

12

16

20

24

28

7

F

Offset

-1 0

2

Set A2

Power

A1

B1 B2

Status

REDWAVE

REDWAVE

MICROWAVE

REDWAVE

ALARM OUTPUT

CELL BATTERY

POWER

SUPPLY

FROM

SENSOR

POWER OFF

REDWAVE

PIR NEAR

REDWAVE

PIR FAR

MEGARED

FAR

MEGARED

NEAR

REDWALL

REDWIDE

WALKTESTER

REDWALL

REDWIDE

MEGARED

CONNECTION

SELECT

SWITCH

MODE

SELECT

SWITCH

POWER

SELECT

SWITCH

OPM-WT

1

Set A2

Power

A1

B1 B2

Status

REDWAVE

REDWAVE

MICROWAVE

REDWAVE

ALARM OUTPUT

CELL BATTERY

POWER

SUPPLY

FROM

SENSOR

POWER OFF

REDWAVE

PIR NEAR

REDWAVE

PIR FAR

MEGARED

FAR

MEGARED

NEAR

REDWALL

REDWIDE

WALKTESTER

REDWALL

REDWIDE

MEGARED

CONNECTION

SELECT

SWITCH

MODE

SELECT

SWITCH

POWER

SELECT

SWITCH

OPM-WT

-Fine alignment potentiometer

This potentiometer can fine tune the value set with the rough

alignment rotary switch by +/- 1 m. within the range of 0 m

minimum and 30

m maximum.

Setting carried out in

rough alignment

Range available for fine alignment

When 0 m is set

0 to +1 m (From -1 to 0 m on the scale

is not usable)

When 2 to 28 m is set

±1 m

When 30 m is set

-1 to 0 m (From 0 to +1 m on the scale

is not usable)

-Offset adjustment

You can reduce a set detection area using the offset

potentiometer. Use this adjusting function when windblown

grasses or tree branches interfere with the currently set detection

area.

You can adjust the dead zone from the ground in the range of 0

to -1 m.

6-3

AUTO SETTING OF VERTICAL DETECTION AREA

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Sequence of

operation

Status

indicator

Time

Action of REDSCAN/

Response of Walk Tester

1

Hold down the

detection area setting

button for 1 second.

Flashing

starts

For

1 second

Pitch of Walk Tester

sound changes for

2 seconds

2

Evacuation from

the area

Flashing

(*1)

For

15 seconds

—

—

Fast

flashing (*2)

For

10 seconds

Scan of the detection

area is executed

—

ON

For

15 seconds

Scan of the detection

area is completed and

the data are saved

—

Flashing

For

3 seconds

—

—

OFF

—

Security protection of

the detection area is

started

*1: Flashes once a second

*2: Flashes twice a second

Cautions >>

Do not enter the area while the area scan is being carried

out. An unwanted object in the area interferes with the

correct scanning of the target area.

7-1

WALK TEST

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Ensure that the detection area has been correctly set referencing

the red indicator and changes in the pitch of Walk Tester sound.

-When a detection area has not been correctly set

1 Before pressing the detection area setting button, ensure

that the detection method switch and the detection mode

switch are set to the correct position, respectively.

2 Set the detection again with reference to “5-4” for the

horizontal detection area and “6-3” for the vertical detection

area.

7-2

CHANGING THE SETTINGS DURING SECURITY PROTECTION

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

You can change the following settings as required during the

security protection.

It is not necessary to press the detection area setting button after

conducting a change.

SELECTOR

NAME

Manual (M) Auto (A) <P1/P2>

Mode selector

Object size

Object movement

Rough alignment

Fine alignment

Offset

—

If you shift the mode selector switch from Manual (M) to Auto (A),

the area that has been specified previously in Auto (A) is selected

as the detection area. When the area is not set in Auto, set it with

reference to the procedure described in “5-4” or “6-3.”

Summary of detection area switch settings

Function

AUTO MODE

(Press Detection area setting button to initiate)

MANUAL MODE

P1

P2

H1

Automatically learns

the detection area

within 1 m x area set by

Rough alignment rotary

switches and Fine adj.

potentiometers

N/A

Detection area

is 1 m x Area

set by Rough

alignment

rotary switches

and Fine adj.

potentiometers

H2 Automatically learns

the detection area

within the area set by

Rough alignment rotary

switches and Fine adj.

potentiometers

Automatically learns the

detection area by tracing

a person walking a

boundary within the area

set by Rough alignment

rotary switches and Fine

adj. potentiometers

Detection area is

the Area set by

Rough alignment

rotary switches

and Fine adj.

potentiometers

V Automatically learns

the detection area

within the area set by

Rough alignment rotary

switches and Fine adj.

potentiometers

Automatically updates the

detection area every hour

within the area set by

Rough alignment rotary

switches and Fine adj.

potentiometers

N/A

AREA CHECKUPS

7

Offset

Ceiling

Ground

surface

Installation

height

Area

B2

Area

B1

Area

A1

Area

A2

Installation

height

Ground surface

Manual

Auto P1 (Fix)

Area A Area B

Area

A1

Area

B1

Area

B2

Area

A2

Ensure that the action of walking into an area causes

the corresponding red indicator to turn on.

30 m

Page 12

- 12 -

OPTEX CO., LTD. (JAPAN)

(ISO 9001 Certified)

(ISO 14001 Certified)

5-8-12 Ogoto Otsu

Shiga 520-0

101

JAPAN

TEL:+81-77-579-8670

FAX:+8

1-77-579-8190

URL:http://www.optex.co.jp/e/

OPTEX INCORPORATED (USA)

TEL:+1-909-993-5770

Tech:(800)966-7839

URL:http://www.optexamerica.com

OPTEX (EUROPE) LTD. (UK)

TEL:+44-1628-631000

URL:http://www.optexeurope.com

OPTEX SECURITY SAS (FRANCE)

TEL:+33-437-55-50-50

URL:http://www.optex-security.com

OPTEX SECURITY Sp.z o.o. (POLAND)

TEL:+48-22-598-06-55

URL:http://www.optex.com.pl

8-1

SPECIFICATIONS OF THE MAIN UNIT

Model RLS-3060

Detection method Infrared Laser Scan

Laser protection

class

Class 1

Wavelength of laser

emission

905 nm (infrared laser)

Coverage for vertical

mounting

Radius: 30 m (Approx. 100 ft.), Arc: 190

°

Coverage for

horizontal mounting

MAX. 60 m (Approx. 200 ft.)

Detection resolution 0.25°

Power input 24V AC/DC ± 10%

Power consumption 400 mA (24VDC) 600 mA (24VAC)

Vertical mounting

height

15 m (Approx. 50 ft.) max

Horizontal mounting

height

0.7 m (28 in.) (recommended)

Indicator

A2 alarm

Red LED

A1 alarm

B1 alarm

B2 alarm

Status Yellow LED

Power Green LED

Area alarm output N.O. 28V DC, 0.2A × 4outputs

Master alarm output Form C, 28V DC, 0.2A max.

Trouble output Form C, 28V DC, 0.2A max.

Tamper output N.C. 28V DC, 0.1A max.

Environmental

disqualication

circuit

Form C, 28V DC, 0.2A max.

Alarm period Approx. 2 sec. Off delay timer

Warm-up period Approx. 30 sec.

Operating

temperature

-20 – +60 °C (-4 – +140 °F)

IP rating IP65

Dimensions

(H × W × D)

334 × 144 × 155 mm

(13.2

× 5.7 × 6.1 in.)

Weight 3 kg (106 oz.)

Accessories

Mounting screw, anchor bolt for board,

paper template, waterproof plug and

Installation Instructions

* Specifications and design are subject to change without prior

notice.

8-2

DIMENSIONAL DRAWING

8-3

OPTIONS

OPM-WT : Audio Walk Tester

RLS-PB : Pole mount bracket

RLS-SB

: Adjustable angle mounting bracket

SPECIFICATIONS

8

7-3 SYSTEM FUNCTION AFTER POWER FAILURE

H1 Manual H1 Auto H2 Manual H2 Auto V Auto

Even if the power is shut down during the security protection

process (detection area is specified) due to reasons including

power failure, the specified detection area is saved on this

product. After power is restored, the product resumes intruder

detection normally in the detection area that was specified prior

to the power failure.

144

(5.7)

155

(6.1)

64

(2.5)

18

(0.7)

334

(13.2)

135

(5.3)

92

(3.6)

107

(4.3)

Unit:mm (inch)

Loading...

Loading...