Prod uct Bul le tin OPB702

Oc to ber 2000

Re flec tive Ob ject Sensors

Type OPB702, OPB702D, OPB702R

Fea tures

Focused for maximum sensitivity

•

Phototransistor (OPB702) or

•

Photodarlington (OPB702D) or

Phototransistor with base-emitter

resistor (OPB702R)

•

Low cost plastic housing

De scrip tion

The OPB702 family consists of an

infrared emitting diode and a choice of

NPN silicon phototransistor (OPB702),

photodarlington (OPB702D), or

base-emitter resistor for low light

suppresion (OPB702R). The IR LED

and phototransistor are mounted

side-by-side on converging optical axes,

in a black plastic housing.

Both parts are constructed using either

OP165 or OP265 series LEDs. The

OPB702 uses and OP505 type. The

OPB702D uses an OP535 type. The

OPB702R uses an OP705.

Ab so lute Maxi mum Rat ings (TA = 25o C un less oth er wise noted)

Stor age and Op er ating Tem per a ture Range.................... -40° C to +85° C

Lead sol der ing tem per a ture (1/16 inch [1.6 mm] from case for 5 sec. with sol der ing

iron) ......................................................... 240° C

In put Di ode

Re verse Volt age .................................................. 2.0 V

Peak For ward Cur rent............................................. 50 mA

Power Dis si pa tion............................................. 100 mW

Out put Photosensor

Col lec tor-Emitter Volt age - OPB702 & OPB702R ......................... 30 V

OPB702D .................................. 15 V

Emit ter-Collector Volt age - OPB702 & OPB702D......................... 5.0 V

Power Dis si pa tion - OPB702 & OPB702D & OPB702R ................ 100 mW

NOTES:

(1) Derate linearly 1.67 mW/° C above 25° C.

(2) RMA flux is recommended. Duration can be extended to 10 sec. max. when flow soldering.

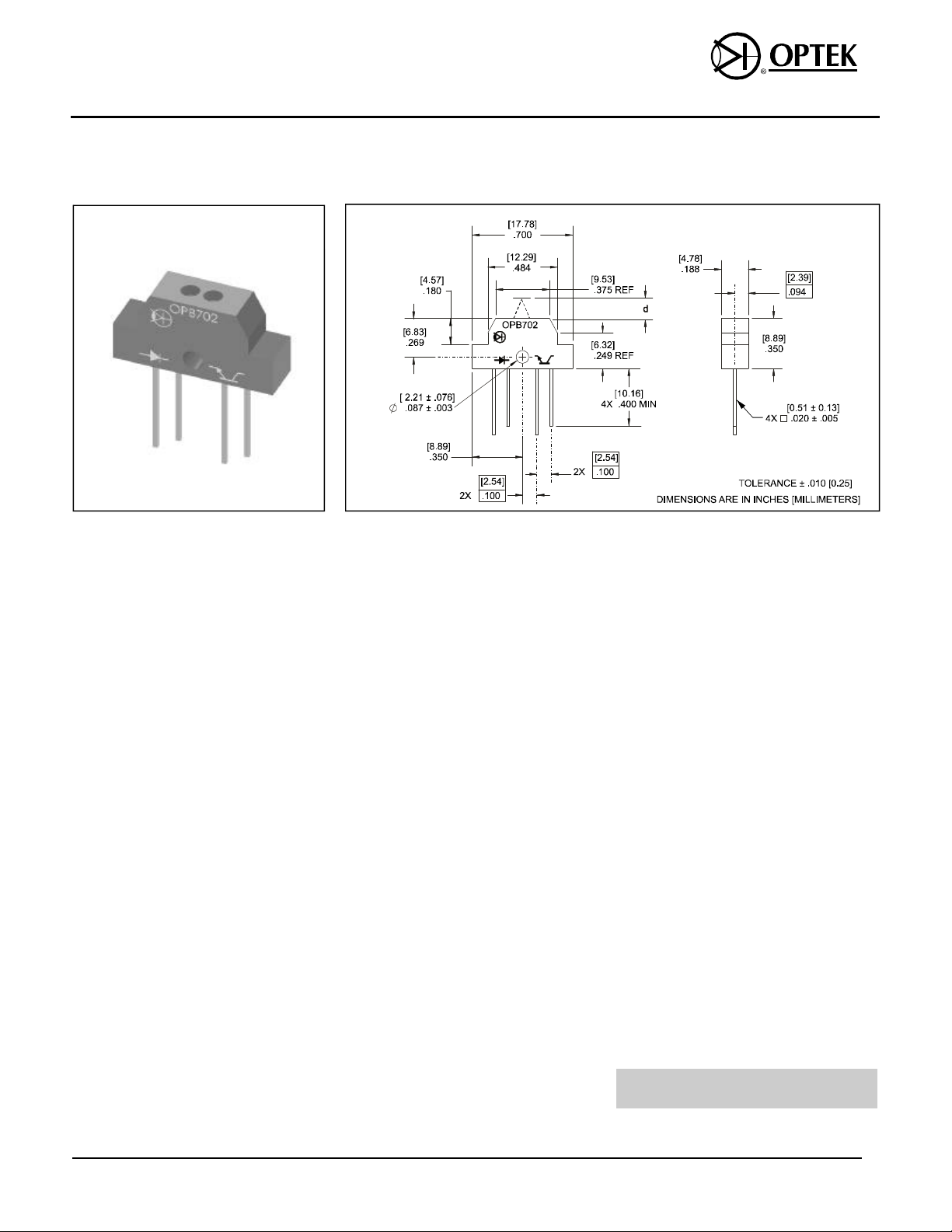

(3) d is the distance from the assembly face to the reflective surface.

(4) Measured using Eastman Kodak gray card. The white side of the card is used as a 90%

diffuse reflectance surface. Reference Eastman Kodak, Catalog #E152 7795.

(5) All parameters tested using pulse techniques.

(6) Lead spacing controlled at body egress.

PRECAUTIONS: Exposure of the plastic body to chlorinated hydrocarbons and ketones such

as thread lock and instant adhesive products will degrade the plastic body. Cleaning agents

methanol and isopropanol are recommended. Spray or wipe do not submerge.

(2)

(1)

(1)

Custom electrical, wire or cabling is

available. Contact your local

representative or Optek for more

information.

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972) 323- 2200 Fax (972) 323- 2396

Visit our website at www.optekinc.com

or email us at sensors@optekinc.com

Type OPB702

Electrical Characteristics (TA = 25° C unless otherwise noted)

SYM BOL PA RAME TER MIN MAX UNITS TEST CON DI TIONS

In put Di ode

V

I

R

Out put Phototransistor

V

(BR)CEO

V

(BR)ECO

I

CEO

Cou pled

I

C(ON)

V

CE(SAT)

Forward Voltage 1.8 V IF = 20 mA

F

Reverse Current

Collector-Emitter Breakdown Voltage

Emitter-Collector Breakdown Voltage

100

30 V

5.0 V

VR = 2.0 V

µA

IC = 100 µA, IF = 0, Ee = 0

IE = 100 µA, IF = 0, Ee = 0

Collector-Emitter Leakage Current 100 nA VCE = 10 V, IF = 0, Ee = 0

On-State Collector Current

Collector-Emitter Saturation Voltage

50

0.40 V

VCE = 5.0 V, IF = 40 mA,

µA

d = 0.150” (3.81 mm)

IC = 250 µA, IF = 40 mA,

d = 0.150” (3.81 mm)

(3)(4)

(3)(4)

Op tek re serves the right to make changes at any time in or der to im prove de sign and to sup ply the best prod uct pos si ble

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972)323- 2200 Fax (972)323- 2396

Type OPB702D

Electrical Characteristics (TA = 25° C unless otherwise noted)

SYM BOL PA RAME TER MIN MAX UNITS TEST CON DI TIONS

In put Di ode

V

I

R

Out put Phototransistor

V

(BR)CEO

V

(BR)ECO

I

CEO

Cou pled

I

C(ON)

V

CE(SAT)

Forward Voltage 1.8 V IF = 20 mA

F

Reverse Current

100

µA

VR = 2.0 V

Collector-Emitter Breakdown Voltage 15.0 V IC = 1 mA, IF = 0 , Ee = 0

Emitter-Collector Breakdown Voltage

5.0 V

IE = 100 µA, IF = 0, Ee = 0

Collector-Emitter Leakage Current 250 nA VCE = 10.0 V, IF = 0, Ee = 0

On-State Collector Current

Collector-Emitter Saturation Voltage

2.0 mA

1.10 V

VCE = 5.0 V, IF = 40 mA,

d = 0.150” (3.81 mm)

IC = 400 µA, IF = 40 mA,

d = 0.150” (3.81 mm)

(3)(4)

(3)(4)

Type OPB702R

Elec tri cal Char ac ter is tics (TA = 25o C un less oth er wise noted)

SYM BOL PA RAME TER MIN MAX UNITS TEST CON DI TIONS

In put Di ode

V

I

R

Out put Phototransistor

V

(BR)CEO

I

ECO

I

CEO

Cou pled

I

C(ON)

V

CE(SAT)

Forward Voltage 1.8 V IF = 20 mA

F

Reverse Current

Collector-Emitter Breakdown Voltage

Emitter-Reverse Current

100

30 V

100 µA

VR = 2.0 V

µA

IC = 100 µA, IF = 0, Ee = 0

VEC = 0.4 V, IF = 0, Ee = 0

Collector-Emitter Leakage Current 100 nA VCE = 10.0 V, IF = 0, Ee = 0

On-State Collector Current

Collector-Emitter Saturation Voltage

50

0.40 V

VCE = 5.0 V, IF = 40 mA,

µA

d = 0.150” (3.81 mm)

IC = 250 µA, IF = 40 mA,

d = 0.150” (3.81 mm)

(3)(4)

(3)(4)

Loading...

Loading...