OPTEK OP224ESA-B1, OP224ESA-B3, OP224SCC-B3, OP224SCC-C1, OP224SCC-C3 Datasheet

...

Fea tures

• Processed to Optek’s Military

screening program patterned after

ESA/SCC Generic Specification No.

5000

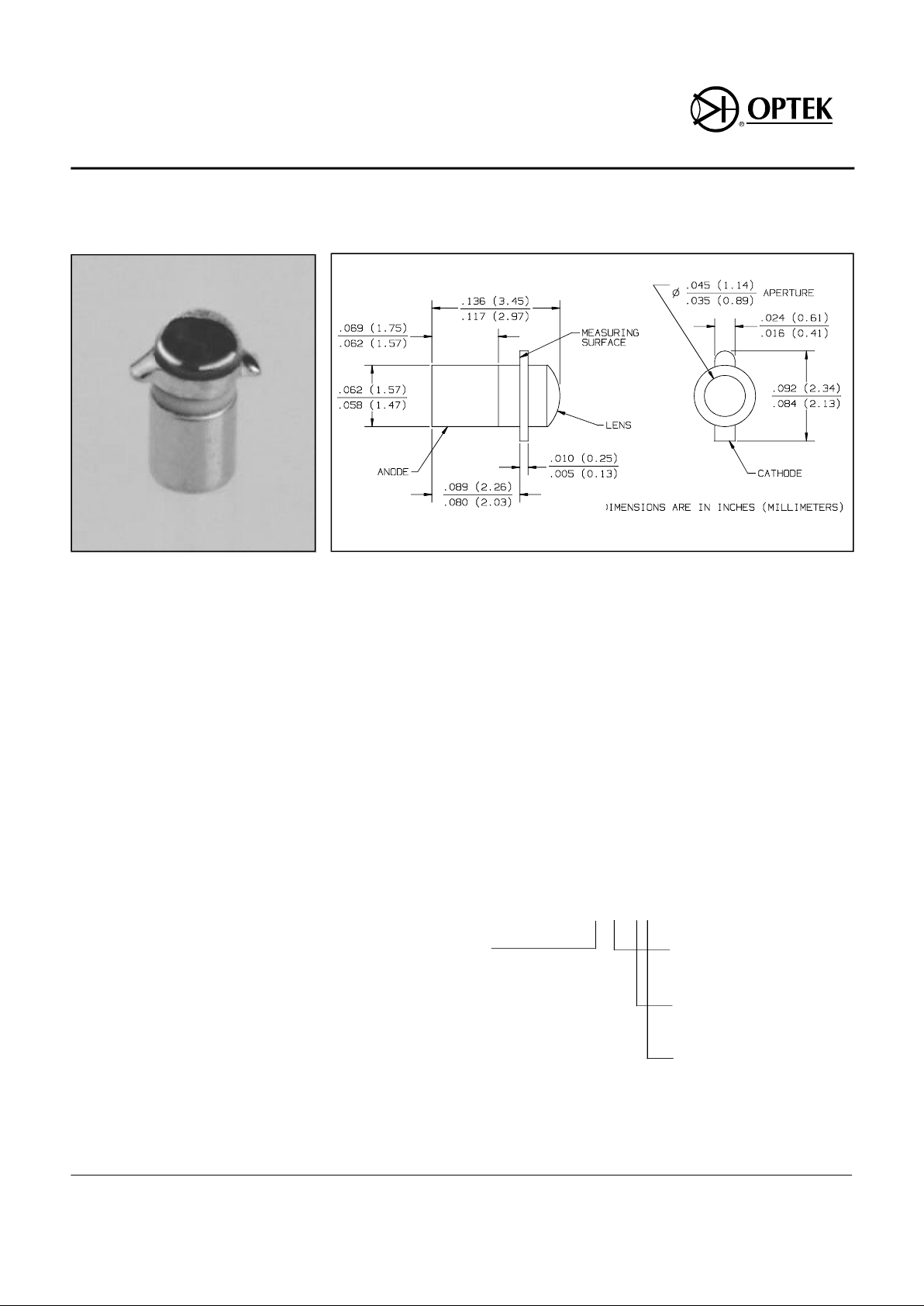

• Miniature hermetically sealed “pill”

package

• Twice the power output of GaAs at the

same drive current

• Mechanically and spectrally matched

to the OP600 series phototransistor

De scrip tion

The OP224ESA is a high reliability

gallium aluminum arsenide infrared

emitting diode mounted in miniature “pill”

type hermetically sealed package. This

package style is intended for direct

mounting into PC boards.

All devices are processed to Optek’s 100

percent screening program patterned

after ESA/SCC Generic Specification No.

5000. See page 13-4 for details.

Gallium aluminum arsenide features

twice the radiated output of gallium

arsenide at the same forward current.

With a wavelength centered at 890

nanometers, it closely matches the

spectral response of silicon

phototransistors, such as Optek’s OP600

high reliability series.

Ab so lute Maxi mum Rat ings (TA = 25o C un less oth er wise noted)

Stor age Tem pera ture Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65o C to +150o C

Op er at ing Tem pera ture Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . -55o C to +125o C

Sol der ing Tem pera ture (for 5 sec. with sol der ing iron). . . . . . . . . . . . . . . . . 240o C

(1)

Re verse Volt age . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 V

Con tinu ous Fow ard Cur rent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mA

Power Dis si pa tion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mW

(2)

Notes:

(1) No-clean or low solids, RMA flux is recommended. Duration can be extended to 10 seconds

max. when flow soldering.

(2) Derate linearly 1.00 mW/o C above 25o C.

(3) X defines the Testing Level per ESA/SCC 5000 Generic Specification Chart III. X will be

either “B” (full processing) or “C” (reduced processing).

N defines Lot Acceptance Tests per ESA/SCC Generic Specification 5000 Chart V. N will be

either 1, 2, or 3. See Generic Processing Table for details.

Prod uct Bul le tin OP224ESA

Sep tem ber 1996

High Re li abil ity GaA lAs In fra red Emit ting Di ode

Type OP224ESA- XN

(3)

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972) 323- 2200 Fax (972) 323- 2396

Part Num ber Guide

OP224ESA- XN

Op tek

High Re li abil ity

Part Num ber

ESA/SCC Speci fi ca tion

No. 5000

“B” - Full Proc ess ing

“C” - Re duced Proc ess ing

Level ”1” En vi ron men tal/Me chani cal plus Level

2 & 3

Level “2” Life Test ing

plus Level 3

Level “3" Elec tri cal In spec tion

13-26

Type OP224ESA-XN

Op tek re serves the right to make changes at any time in or der to im prove de sign and to sup ply the best pos si ble prod uct.

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972) 323- 2200 Fax (972) 323- 2396

Elec tri cal Char ac ter is tics (TA = 25o C un less oth er wise noted)

Sym bol Pa rame ter Min Typ Max Units Test Con di tions

I

R

Reverse Current (High Temperature)

100

µA

VR = 2 V, TA = 125o C

I

R

Reverse Current (Low Temperature)

10

µA

VR = 2 V, TA = -55o C

P

O

Radiant Power Output 1.50 mW IF = 50 mA

V

F

Forward Voltage 0.80 1.80 V IF = 50 mA

I

R

Reverse Current

100

µA

VR = 2.0 V

λp

Wavelength at Peak Emission

850 910 nm

IF = 50 mA

B Spectral Bandwidth Between Half Power Points 80 nm IF = 50 mA

∆λp/∆T

Spectral Shift with Temperature

0.18 nm/oC

IF = Constant

θ

HP

Emission Angle at Half Power Points

18 Deg.

IF = 50 mA

V

F

Forward Voltage (High Temperature) 0.70 1.70 V IF = 50 mA, TA = 100o C

V

F

Forward Voltage (Low Temperature) 1.20 2.00 V IF = 50 mA, TA = -55o C

E

e(APT)

Apertured Radiant Incidence 3.50 mW/cm2IF = 50 mA

(6)

I

e

Radiant Intensity 5.64 mw/Sr IF = 50 mA

(6)(7)

tr, t

f

Rise and Fall Time

800 ns

IF = 50 mA, PW = 10 µS, dc = 10%

(4) Vis ual in spec tion based upon Op tek’s in ter pre ta tion of pre- cap in spec tion as speci fied in MIL- S- 19500/548 as ap pli ca ble for LED’s.

(5) E

e(APT)

is meas ured us ing a 0.031 inches (0.78 mm) di ame ter ap er tured sen sor placed 0.50 inches (12.7 mm) from the mount ing plane.

(6) Ie is cal cu lated from the meas ured value of E

e(APT)

as sum ing the source to be lo cated at the mount ing plane. The con ver sion for this ap er ture

and dis tance is Ie(mW/Sr) = E

e(APT)

(mW/cm2) x 1.61.

13-27

Loading...

Loading...