Page 1

EVBUM2704

VE-Tract Dual EZ Kit

Quickstart Guide

This document is intended to be a guide to explain the

connectivity and usage of the evaluation kit described in the

table below. The evaluation kit is designed to quickly

perform benchmarking or product evaluation at specific

operating conditions in a lab environment. The product

should only be operated and handled by qualified personnel

with sufficient electrical engineering training and

experience.

Applies to the following parts.

Table 1.

NVG800A75L4DSC−EVK 750 V, 800 A based 3−ph

Evaluation kit

Figure 1. NVG800A75L4DSC−EVK

INTRODUCTION

The VE−Trac Dual Evaluation Kit consists of three

VE−Trac Dual power modules (NVG800A75L4DSC)

mounted on dual side cooling heatsink, with a 6−ch Gate

driver board, DC Link capacitor and external hall−effect

current sense feedback for motor control. The kit does not

include a PWM controller. The user must user their on PWM

controller to operate the system. The evaluation kit allows

the customers to evaluate VE−Trac Dual power module

performances in their early stage of inverter development.

The kit can be used as a double pulse tester to measure key

switching parameters or used as a 3−ph inverter for motor

control.

www.onsemi.com

EVAL BOARD USER’S MANUAL

VE−Trac Dual evaluation kit features:

• Inverter evaluation Hardware kit for EV/HEV Traction

Inverter applications (up to 150 kW)

• VE−Trac Dual NVG800A75L4DSC with 800 A, 750 V

Field stop 4 IGBT/Diode chipset

• Automotive Isolated high current and high efficiency

IGBT gate driver with internal galvanic isolation,

NCD57000

• Implementation of Faster and simpler OCP enabled by

On−Chip Current Sensing feature in the power modules

• Implementation of faster and closer to true Tvj OTP with

integrated to On−Chip Temperature Sensing feature in the

power modules

• Custom designed dual side cooler offers low pressure

drop with excellent thermal performance

• Custom Film DC Link capacitor rated up to 500 VDC,

500 mF.

TECHNICAL DETAILS

ON Semiconductor’s latest generation of IGBTs and

Diodes are incorporated into the VE−Trac Dual products.

The 750 V products use the latest 4

IGBTs from ON Semiconductor.

Block Diagram

In this section, we describe the evaluation kit in detail,

including block diagram, operating conditions, key

components, On−chip current/temperature sensing and

protection features.

th

Generation of FS4

© Semiconductor Components Industries, LLC, 2019

July, 2020 − Rev. 1

1 Publication Order Number:

EVBUM2704/D

Page 2

EVBUM2704

Vin

GNDC

Boost

Based on

NCV8870

20 V

Buck

Based on

NCV890100

3.3 V

LDO

1.8 V

Logic

Block

CPLD

5M40ZE64C5N

NCD57000

Flyback NCP 1031

Optical

isolator

15

GND

−9

LDOs

OUTPUTS

Master Fault OC

Temp Fault OC

Over Curr fault OC

Ready OC

HV_fault OC

INPUTS

6x PWM diff

FOD8071

Reset

Halt

ANALOG OUT

Input Voltage

T° IGBT

LEM

Push−Pull

Driver

−5

+5

Sensing

circuit

x3

Q1

Q2

Figure 2. Simplified Block Diagram

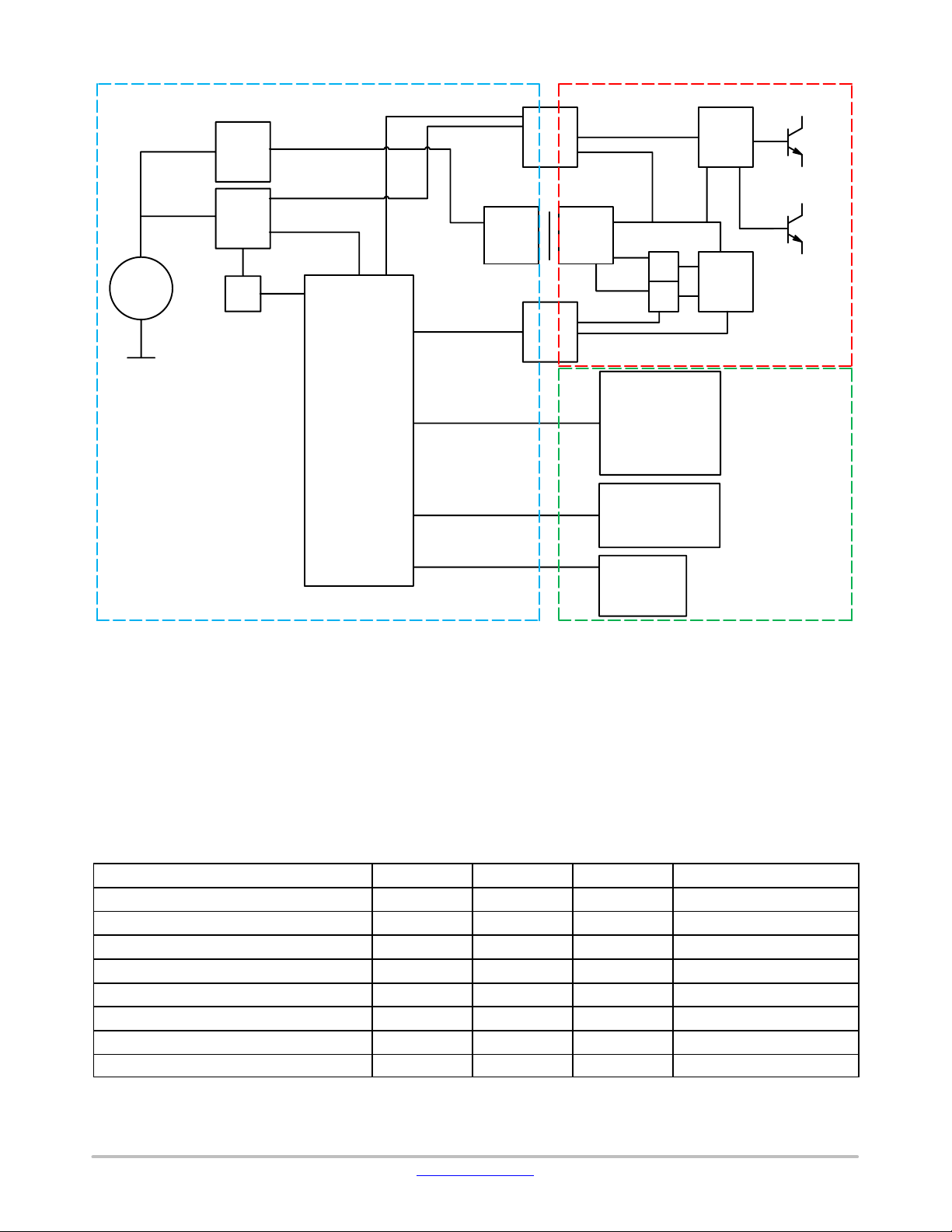

The simplified block diagram gives a quick overview of

the evaluation kit. The dotted lines show the different

isolated sections of the system.

exposed high voltage and high temperatures that when

accidentally contacted can result in electrical shock or

severe burns. Therefore, it should only be handled by

professionals with sufficient electrical engineering training

Maximum Ratings

The VE−Trac Dual Evaluation kit is intended to be

operated in a lab testing environment and should not be

regarded as a protected system. Parts of the design have

Table 2. SUMMARY OF OPERATING CONDITIONS

Parameter Symbol Min Max Conditions

Gate Driver Board Control Power V

DC Link Voltage V

Peak Collector Phase Current (1 ms) I

Maximum IGBT/FWD Junction Temperature T

Wait time after short circuit SC 1 s −

PCB Temperature T

Switching frequency F

Coolant Temperature T

Driv

BUS

CPEAK

VJ_Max

PCB

SW

c

and experience. Moreover, the operating conditions

especially the thermal limits described below should be

followed strictly.

9 V 15 V

0 V 500 V Limited by Capacitor

−1600 A 1600 A Limited by Tvj_Max

−40°C 175°C

− 85°C

− 12 kHz

−40°C 65°C

www.onsemi.com

2

Page 3

EVBUM2704

Key Components

The evaluation kit is shipped in a hard plastic case with the

following contents:

n Full assembled evaluation kit hardware

n USB Drive containing all the required documentation

Figure 3. Shipping Contents in Case

The assembled evaluation kit assembly itself consists of

the following major components.

Figure 4. Major Components that Make Up the Evaluation Kit

www.onsemi.com

3

Page 4

EVBUM2704

Table 3. SUPPLIERS FOR THE MAJOR COMPONENTS OF THE EVALUATION HARDWARE

Part Number Manufacturer Description

NVG800A75L4DSC with reference

heatsink stack

NCD57000 ON Semiconductor Automotive Isolated Gate Driver

Dual side cooler ON Semiconductor ON Semi design with outsourced manufacturing.

700A321 SBE

HAH3DR 900−S00−BB LEM Hall Current Transducer. ±900 A

On−chip Current Sensing and Temperature Sensing

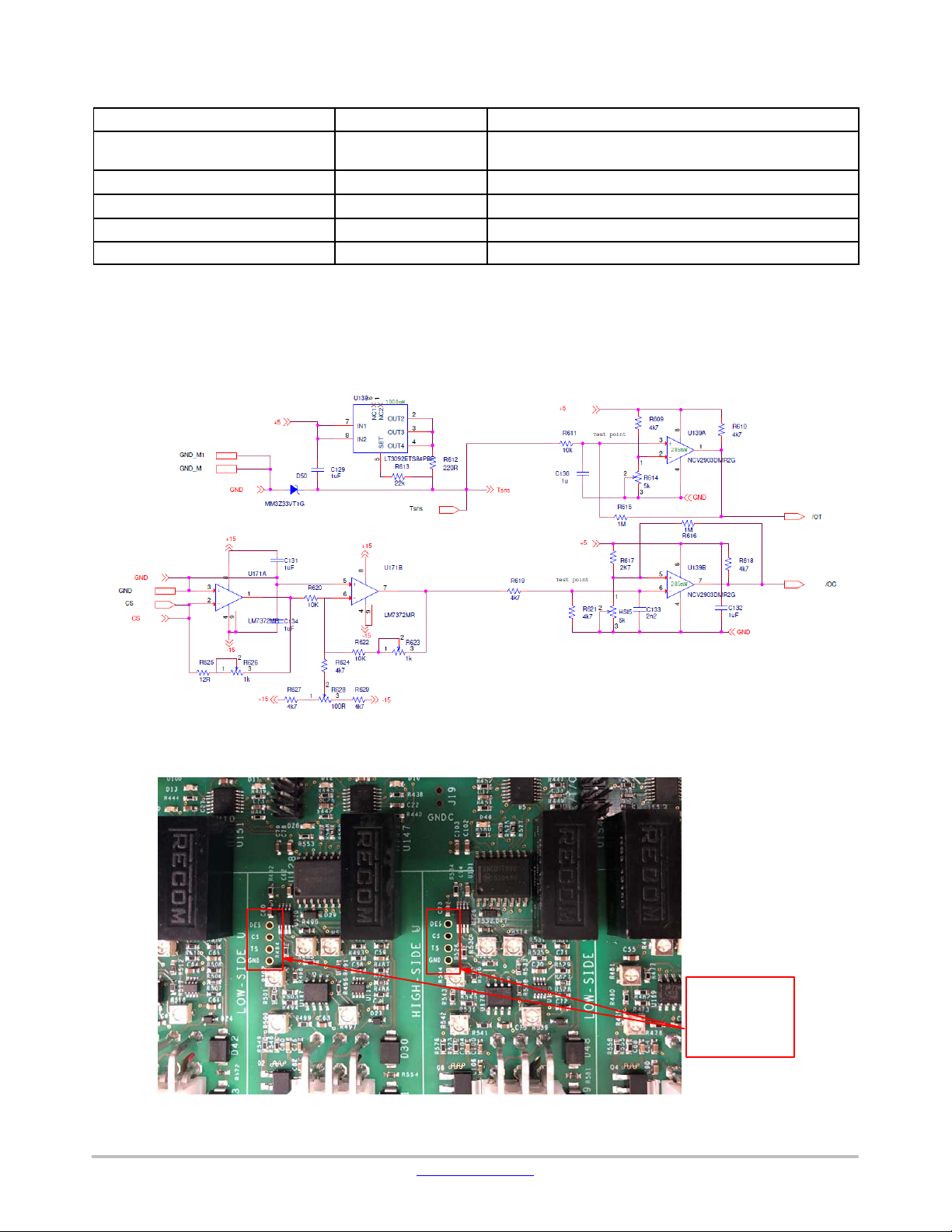

One of the kay advantage of the VE−Trac Dual power

modules is the integrated On−chip current sensing and

On−chip temperature sensing. The Evaluation kit offers

users the option of monitoring the junction temperature and

ON Semiconductor Automotive VE−Trac Dual power module with FS4 750 V 800 A

IGBT and Diode

DC Link Capacitor 500 V, 500 mF

current of all six IGBTs in real time. OCP/OTP protections

is implemented using the on−chip sensors. Below

schematics show how On−chip current sensing is

implemented as well as test points for verification purpose.

Figure 5. Schematics of Implementing On−chip Current Sensing

Figure 6. Test Points for On−chip Current and Temperature Sense

www.onsemi.com

4

Test points for

current/temp

sense, of which

all 6 switches

are available

Page 5

EVBUM2704

Protection Features

Over Current Protection (OCP) and Over Temperature

Protection (OTP) are implemented by sensing the On−chip

current sensor and On−chip temperature sensor respectively.

Besides this, the traditional desaturation protection is also

implemented to allow users to compare it with the On−chip

current sense protection. The protection trigger levels are set

as below:

• Over Current Protection (OCP) for all phases set to

1600 A

Table 4. FAULT INDICATION LED MATRIX

OCP_FAULT_

Phases

Phase_U_HS D12 D10 D28

Phase_U_LS D13 D11 D40

Phase_V_HS D16 D14 D61

Phase_V_LS D17 D15 D64

Phase_W_HS D20 D18 D34

Phase_W_LS D21 D19 D54

LED

• Over Temperature Protection (OTP) for all phases set to

150°C

• DC Link Over Voltage Fault Threshold set to 550 VDC

NOTE: All faults are the latching type and requires a

reset to clear the fault latch to start operating

again. During a fault incident, a LED is lit to

help the user to identify the cause of the fault.

Below is Fault Indication LED Matrix for the

VE−Trac Dual evaluation kit. Normal operation

indication LEDs are off when fault occurs, refer

to Figure 11 for locations of fault LEDs

DRVER_

OTP_FAULT_LED

FAULT_LED

PCBs AND CONNECTORS

There is a total of five (5) PCBs in the evaluation kit

assembly.

1. Power Module interface boards (3)

2. Gate driver board (1)

3. Current sensor board (1)

Power Module Interface boards are not accessible to the

user and is soldered to the signal pins of each of the three

VE−Trac Dual modules. An interface cable with a signal

connector extends from the interface boards to connect to

the gate driver board. The purpose this arrangement is to

make it easy to remove the driver board for replacement or

for trouble shooting purpose.

Gate driver board is the main PCB with several

connectors on it. It interfaces with the user’s Motor Control

Unit (MCU), the hall−effect current sensors, Power modules

and aux. power input.

www.onsemi.com

5

Page 6

EVBUM2704

Table 5. CONNECTOR X1:

Pin# Signal Function Specification

1 POWER_VSS Aux. Power RTN Ground return for External Power Input

2 POWER_VSS Aux. Power RTN Ground return for External Power Input

3 LEM_PHASE_W Analog Output 0 – 10 V LEM Phase W output

4 GND_I/O Ground reference Ground reference for LEM PCB

5 READY Digital I/O 3.3 − 5 V Gate driver ready status

6 GND_RDY Ground reference Ground reference for driver ready status

7 OC I/O_FLT Digital I/O 3.3 V − 5 V Digital output Over Current Fault

8 GND_FLT Ground reference Ground reference for Digital outputs

9 MASTER_FAULT Digital I/O 3.3 V − 5 V Digital output Driver Fault

10 +15_I/O1 Power supply Power supply for LEM PCB

11 HALT_CMD Digital I/O 0 − 3.3 V OR 5V Digital input

12 GND_I/O1 Ground reference Ground reference for LEM PCB

13 PWM_IN−_U_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

14 PWM_IN+_U_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

15 PWM_IN−_V_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

16 PWM_IN+_V_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

17 PWM_IN−_W_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

18 PWM_IN+_W_H Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

19 CGND1 Ground reference Ground reference for digital logic.

20 POWER_VDD Aux. Power IN 9 V to 15 V External Power input

21 POWER_VDD Aux. Power IN 9 V to 15 V External Power input

22 LEM_PHASE_U Analog Output 0 – 10 V LEM Phase U output

23 LEM_PHASE_V Analog Output 0 – 10 V LEM Phase V output

24 RES I/O Digital I/O 0 − 3.3 V OR 5 V external reset input

25 GND RES_I/O Ground reference Ground reference for Reset / Halt−Cmd

26 HV_FAULT_I/O Digital I/O 3.3 V − 5 V Digital output HVDC Fault

27 GND_I/O2 Ground reference Ground reference for DC_LINK+/W_I/O

28 W_I/O Analog Output 0 – 10 V Phase W Temp Sensing

29 DC_LINK+ Analog Output 0 – 10 V DC BUS Voltage Sensing

30 T I/O_FAULT Digital I/O 3.3 V − 5 V Digital output over Temp Fault

31 GND_I/O2 Ground reference Ground reference for DC_LINK+/W_I/O

32 PWM_IN−_U_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

33 PWM_IN+_U_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

34 PWM_IN−_V_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

35 PWM_IN+_V_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

36 PWM_IN−_W_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

37 PWM_IN+_W_L Digital I/O 0 − 3.3 V OR 5 V PWM Logic input

Table 6. CONNECTOR J18

Pin# Signal Function Specification

1 POWER_VDD Aux. Power IN 9 – 15 VDC, 4 A

2 POWER_VSS Aux. Power RTN GND return for Aux. power

www.onsemi.com

6

Page 7

EVBUM2704

Table 7. CONNECTOR LEM1

Pin# Signal Function Specification

1 +15VI/O Power +15 V Power supply for Isolated Signal

2 GND_I/O Ground Ground return for +15 VI/O

3 IU Sensor output LEM Phase U output

4 IV Sensor output LEM Phase V output

5 IW Sensor output LEM Phase W output

6 GND_I/O Ground Ground return for +15 VI/O

Table 8. CONNECTOR J11/J12/J13

Pin# Signal Function Specification

1 FLT−H Protection Gate Driver fault High Side

2 FLT−L Protection Gate Driver fault Low Side

3 OTS_HS Protection Over Temperature High Side

4 OTS_LS Protection Over Temperature Low Side

5 OCS_HS Protection Over Current High Side

6 OCS_LS Protection Over Current Low Side

7 IN+_H PWM Logic PWM Logic High Side

8 IN+_L PWM Logic PWM Logic Low Side

Table 9. CONNECTOR J16

Pin# Signal Function Specification

1 IW Signal LEM Sensor Phase W output

2 NC − −

3 IV Signal LEM Sensor Phase V output

4 NC − −

5 IU Signal LEM Sensor Phase U output

6 NC − −

7 TEMP_IGBTW_I/O Analog output Phase W Low side temperature sensor output

8 GND_I/O Ground Ground return for +15 VI/O

Current Sensor Board conditions the feedback signals

from the hall−effect sensors and interfaces with the gate

driver board via a flat ribbon cable.

Table 10. CONNECTOR J2

Pin# Signal Function Specification

1 +15VI/O Power +15 V Power supply for Isolated Signal

2 GND_I/O Ground Ground return for +15 VI/O

3 IU Sensor output LEM Phase U output

4 IV Sensor output LEM Phase V output

5 IW Sensor output LEM Phase W output

6 GND_I/O Ground Ground return for +15 VI/O

www.onsemi.com

7

Page 8

EVBUM2704

OPEN LOOP OPERATION

This section gives a quick start guide for operating

VE−Trac Dual evaluation kit in open loop operation and

provides a list of equipment needed.

Equipment for Evaluation of VE−Trac Dual Evaluation

Kit

• Power Supply: 9 V − 15 V, 4 A

• HVDC Power Supply: 0 − 500 V 40 A (depends on the

load)

• Load: Passive 3 ph Inductive load or AC Induction

Machine

• Scope: 4 channel digital scope

• HV Differential Probe: 1500 Vpk 200 MHz Bandwidth

• Current Probe: 6000 A 30 MHz Bandwidth

• DVM: General Digital Multi−meter

• MCU or DSP Eval Board: Open loop PWM control

algorithm software

• Cooling System : 50/50 Ethylene Glycol/Water Flow rate

8 − 10 LPM

• Hose: ¾” ID, 1” OD, rated to 100°C, 45 PSI @ 25°C

• Cooling System for Load: Liquid or Air−cooled.

Connections with Control Power and MCU/DSP

Interface

The evaluation kit requires an external MCU or DSP Eval

Board for PWM control signals for open loop operation. The

interface features a standard DB−37 connector. Below

figure and table show the pin out definitions.

Figure 7. Controller Interface

www.onsemi.com

8

Page 9

EVBUM2704

Table 11. CONTROLLER INTERFACE SIGNAL USED

Pin# Signal Function Specification

1 Vss Ground To be connected to ground

2 Vss Ground To be connected to ground

13 PWM_IN−_U_H PWM signal Differential pairs

14 PWM_IN+_U_H PWM signal Differential pairs

15 PWM_IN−_V_H PWM signal Differential pairs

16 PWM_IN+_V_H PWM signal Differential pairs

17 PWM_IN−_W_H PWM signal Differential pairs

18 PWM_IN+_W_H PWM signal Differential pairs

32 PWM_IN−_U_L PWM signal Differential pairs

33 PWM_IN+_U_L PWM signal Differential pairs

34 PWM_IN−_V_L PWM signal Differential pairs

35 PWM_IN+_V_L PWM signal Differential pairs

36 PWM_IN−_W_L PWM signal Differential pairs

37 PWM_IN+_W_L PWM signal Differential pairs

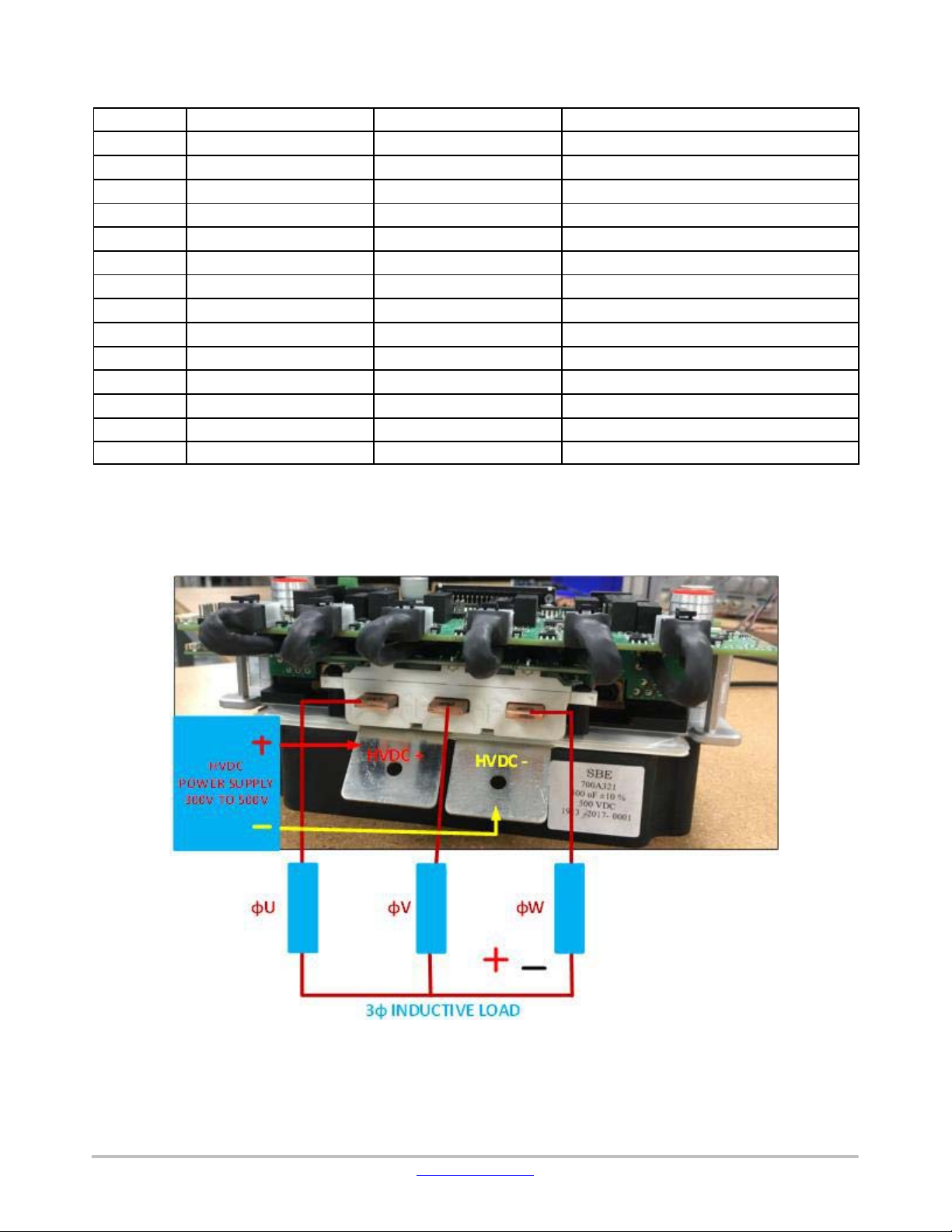

VE−Trac DSC Drive Connection for HVDC and LOAD

Figure 8 shows the right connection of HVDC power

supply and loads. Make sure a good electrical contact

between the power tabs to avoid generating excessive heat.

We recommend monitor the temperature of the power

terminals during operation and take corrective actions when

they are overheated.

Figure 8. Power and Load Connection

VE−Trac Dual Evaluation Kit Cooling System

The cooler can be connected with a ¾ inch Inside

Dimension and 1inch Outside Dimension flexible hose

interface. Use 50% Water/50% Ethylene Glycol as cooling

www.onsemi.com

fluid and make sure that cooling fluid corrosion protection

is compatible with aluminum heatsink. We strongly

recommend not use pure water as cooling fluid because it

might damage the heatsink.

9

Page 10

EVBUM2704

Figure 9. Cooling Interface Appearance

Figure 10. Example with Hose Interface Connected

Run the VE−Trac Dual Evaluation Kit in Open Loop

Configuration

Following are the steps to run the inverter in open loop

operation.

• Turn off all the power supplies

• Connect control power supply to Inverter at connector

J18, refer to Figure 7

• Connect logic PWM signal from DSP/MCU to gate driver

board at DB37 pin connector as shown in Figure 7

• Connect voltage/current probes to signals of interest, for

example PWM signal, phase current, IGBT collector

voltage etc.

• Connect DVM to monitor the IGBT virtual junction

temperature to the test points as shown in Figure 6

• Power on the DSP/MCU Board

• Connect USB from DSP/MCU Board to Host computer

for commanding the PWM signals duty ratio and Inverter

fundamental output frequency to the Inverter

• Set the control power supply as the following

♦ Voltage: 12 V

♦ Current Limit = 3 A

• Turn on the control power supply and all the fault LEDs

will be lit. Press the reset switch (see Figure 11) to clear

all the faults.

• Set the HVDC Power Supply to 400 V

• Turn on the HVDC Power supply

• Set the cooler system flow rate to desired value. eg

10 LPM to the power module.

• Turn on the cooling system to the Power module

• Turn on the cooling system to the Load

• Enable the Inverter by turning on the PWM Logic via host

computer

• Adjust the Duty ratio and Inverter fundamental frequency

to get desired output current

• Monitor the IGBT Junction Temperature

• Record the Cooler System Inlet and Outlet Temperature

• Record the output phase current

www.onsemi.com

10

Page 11

EVBUM2704

Figure 11. Location of Reset Switch

TEST RESULT SUMMARY

Following the steps listed above, inverter testing has been

done to verify the function of the evaluation kit as well as the

performance of the VE−Trac Dual power module. Driving

capability of the power module with reference cooling

140

120

100

80

TJ [°C]

60

40

20

0

0 100 200 300 400 500 600

heatsink was verified by monitoring On−chip temperature

sensor vs Phase current.

Test Results under the Condition of: Tcoolant = 25C

DC BUS = 400 V Fsw = 8 kHz / 10 kHz.

Flow rate = 10 LPM

TJ_8 kHZ [°C]

TJ_10 kHZ [°C]

I∅ [ARMS]

Figure 12. IGBT Junction Temperature vs Phase Current; Tcoolant = 25C Flow Rate = 10 LPM,

Bus Voltage = 400 V, Switching Freq = 8 & 10 kHz

www.onsemi.com

11

Page 12

EVBUM2704

Figure 13. Switching Waveforms, C1: U Phase Current; C2: W Phase Voltage (Low Side Switch);

C3: W Phase Current; C4: Input PWM Signal (W Phase Low Side)

Test Results under the Condition of: Tcoolant = 65 C

DC BUS = 400 V Fsw = 8 kHz / 10 kHz.

Flow rate = 10 LPM

180

160

140

120

TJ [°C]

100

TJ_8 kHZ [°C]

80

60

0 100 200 300 400 500 600

I∅ [ARMS]

TJ_10 kHZ [°C]

Figure 14. IGBT Junction Temperature vs Phase Current; Tcoolant = 65C Flow Rate = 10 LPM,

Bus Voltage = 400 V, Switching Freq = 8 kHz / 10 kHz

www.onsemi.com

12

Page 13

EVBUM2704

Figure 15. Switching Waveforms, C1: U Phase Current; C3: W Phase Current

VE−Trac is trademark of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

www.onsemi.com

13

Page 14

ON Semiconductor and the ON Semiconductor logo are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or

other countries. ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

subject to all applicable copyright laws and is not for resale in any manner.

The evaluation board/kit (research and development board/kit) (hereinafter the “board”) is not a finished product and is as such not available for sale to consumers. The board is only intended

for research, development, demonstration and evaluation purposes and should as such only be used in laboratory/development areas by persons with an engineering/technical training

and familiar with the risks associated with handling electrical/mechanical components, systems and subsystems. This person assumes full responsibility/liability for proper and safe handling.

Any other use, resale or redistribution for any other purpose is strictly prohibited.

The board is delivered “AS IS” and without warranty of any kind including, but not limited to, that the board is production−worthy, that the functions contained in the board will meet your

requirements, or that the operation of the board will be uninterrupted or error free. ON Semiconductor expressly disclaims all warranties, express, implied or otherwise, including without

limitation, warranties of fitness for a particular purpose and non−infringement of intellectual property rights.

ON Semiconductor reserves the right to make changes without further notice to any board.

You are responsible for determining whether the board will be suitable for your intended use or application or will achieve your intended results. Prior to using or distributing any systems

that have been evaluated, designed or tested using the board, you agree to test and validate your design to confirm the functionality for your application. Any technical, applications or design

information or advice, quality characterization, reliability data or other services provided by ON Semiconductor shall not constitute any representation or warranty by ON Semiconductor,

and no additional obligations or liabilities shall arise from ON Semiconductor having provided such information or services.

The boards are not designed, intended, or authorized for use in life support systems, or any FDA Class 3 medical devices or medical devices with a similar or equivalent classification in

a foreign jurisdiction, or any devices intended for implantation in the human body. Should you purchase or use the board for any such unintended or unauthorized application, you shall

indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that ON Semiconductor

was negligent regarding the design or manufacture of the board.

This evaluation board/kit does not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC,

CE or UL, and may not meet the technical requirements of these or other related directives.

FCC WARNING – This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by ON Semiconductor to

be a finished end product fit for general consumer use. It may generate, use, or radiate radio frequency energy and has not been tested for compliance with the limits of computing devices

pursuant to part 15 of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment may cause interference with radio

communications, in which case the user shall be responsible, at its expense, to take whatever measures may be required to correct this interference.

ON Semiconductor does not convey any license under its patent rights nor the rights of others.

LIMITATIONS OF LIABILITY: ON Semiconductor shall not be liable for any special, consequential, incidental, indirect or punitive damages, including, but not limited to the costs of

requalification, delay, loss of profits or goodwill, arising out of or in connection with the board, even if ON Semiconductor is advised of the possibility of such damages. In no event shall

ON Semiconductor’s aggregate liability from any obligation arising out of or in connection with the board, under any theory of liability, exceed the purchase price paid for the board, if any.

For more information and documentation, please visit www.onsemi.com

.

. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This literature is

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...