查询NUP4201DR2 供应商

NUP4201DR2

Advance Information

Low Capacitance Surface

Mount TVS for High-Speed

Data Interfaces

The NUP4201DR2 transient voltage suppressor is designed to

protect equipment attached to high speed communication lines from

ESD, EFT, and lighting.

Features:

• SO–8 Package

• Peak Power – 500 Watts 8 x 20 S

• ESD Rating:

IEC 61000–4–2 (ESD) 15 kV (air) 8 kV (contact)

IEC 61000–4–4 (EFT) 40 A (5/50 ns)

IEC 61000–4–5 (lighting) 23 (8/20 s)

• UL Flammability Rating of 94V–0

T ypical Applications:

• High Speed Communication Line Protection

• USB Power and Data Line Protection

• Video Line Protection

• Base Stations

• HDSL, IDSL Secondary IC Side Protection

• Microcontroller Input Protection

http://onsemi.com

SO–8 LOW CAPACITANCE

VOLTAGE SUPPRESSOR

500 WATTS PEAK POWER

6 VOLTS

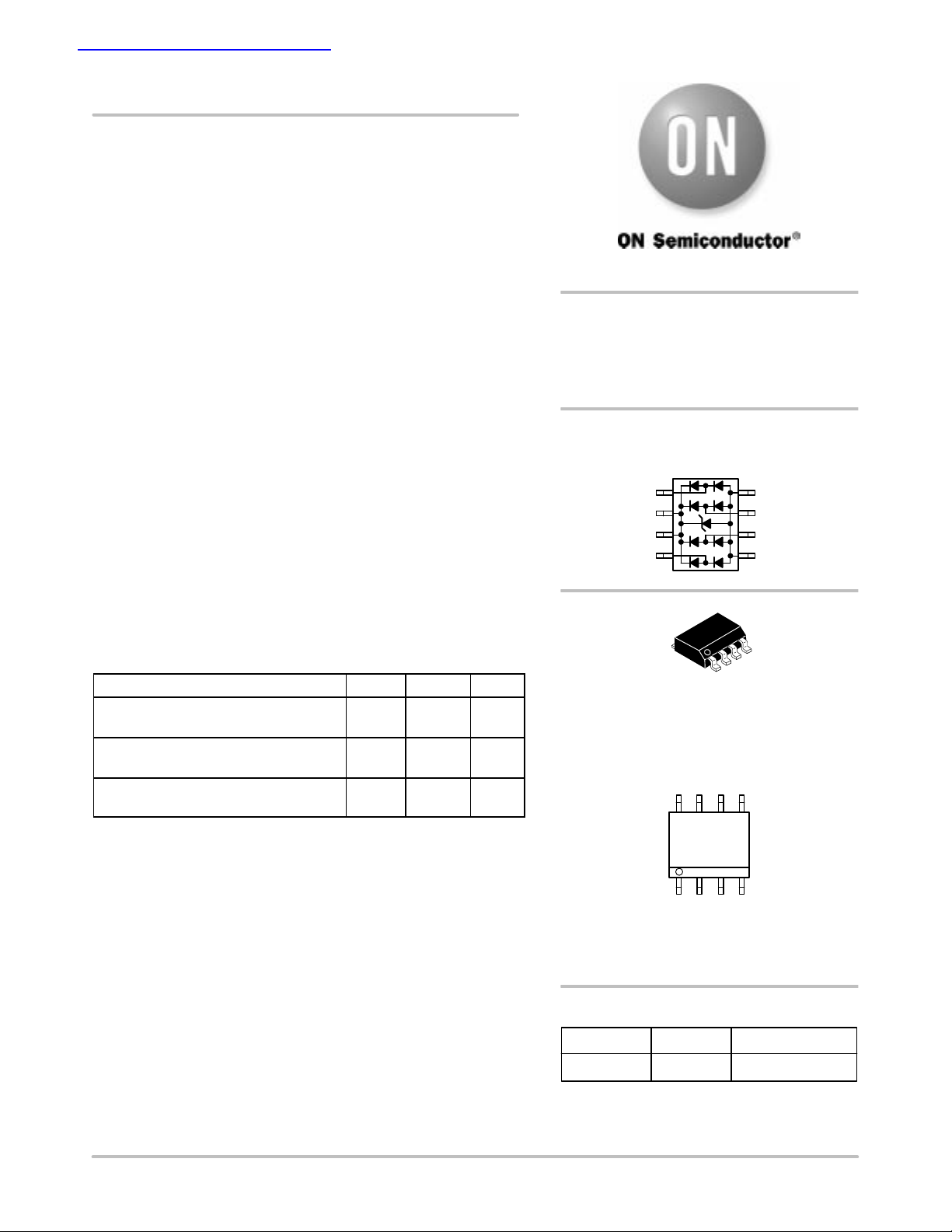

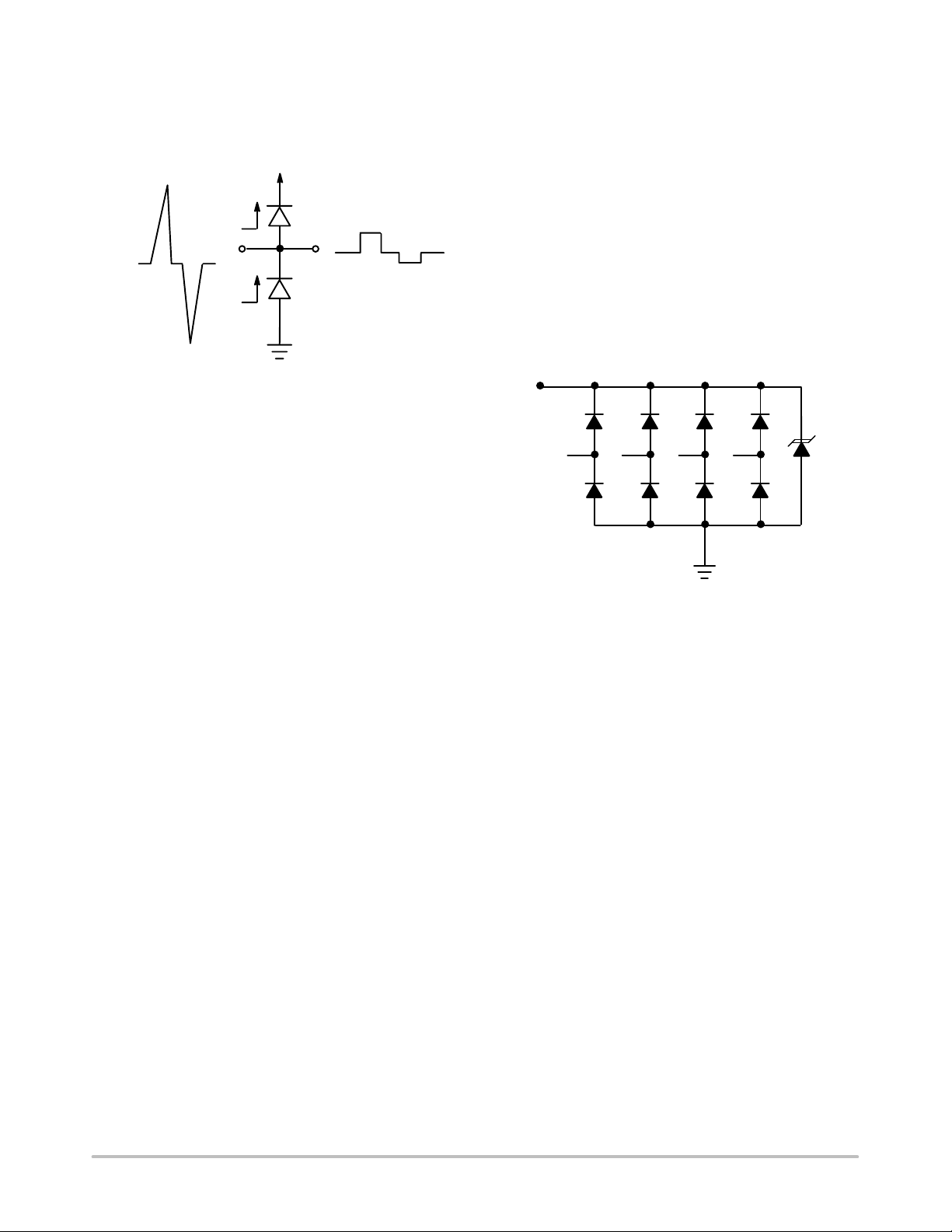

PIN CONFIGURATION

AND SCHEMATIC

I/O 1 1

REF 1 2

REF 1 3

I/O 2 4

8 REF 2

7 I/O 4

6 I/O 3

5 REF 2

MAXIMUM RATINGS

Rating Symbol Value Unit

Peak Power Dissipation

8 x 20 S @ T

Junction and Storage

Temperature Range

Lead Solder Temperature –

Maximum 10 Seconds Duration

1. Non–repetitive current pulse 8 x 20 S exponential decay waveform

This document contains information on a new product. Specifications and information

herein are subject to change without notice.

= 25°C (Note 1)

A

P

TJ, T

T

stg

500 W

–55 to

+150

260 °C

pk

L

°C

8

1

SO–8

CASE 751

PLASTIC

MARKING DIAGRAM

P4201

LYW

P4201 = Device Code

L = Location Code

Y = Year

W = Work Week

ORDERING INFORMATION

Device Package Shipping

NUP4201DR2 SO–8 2500/Tape & Reel

Semiconductor Components Industries, LLC, 2002

April, 2002 – Rev. 0

1 Publication Order Number:

NUP4201DR2/D

NUP4201DR2

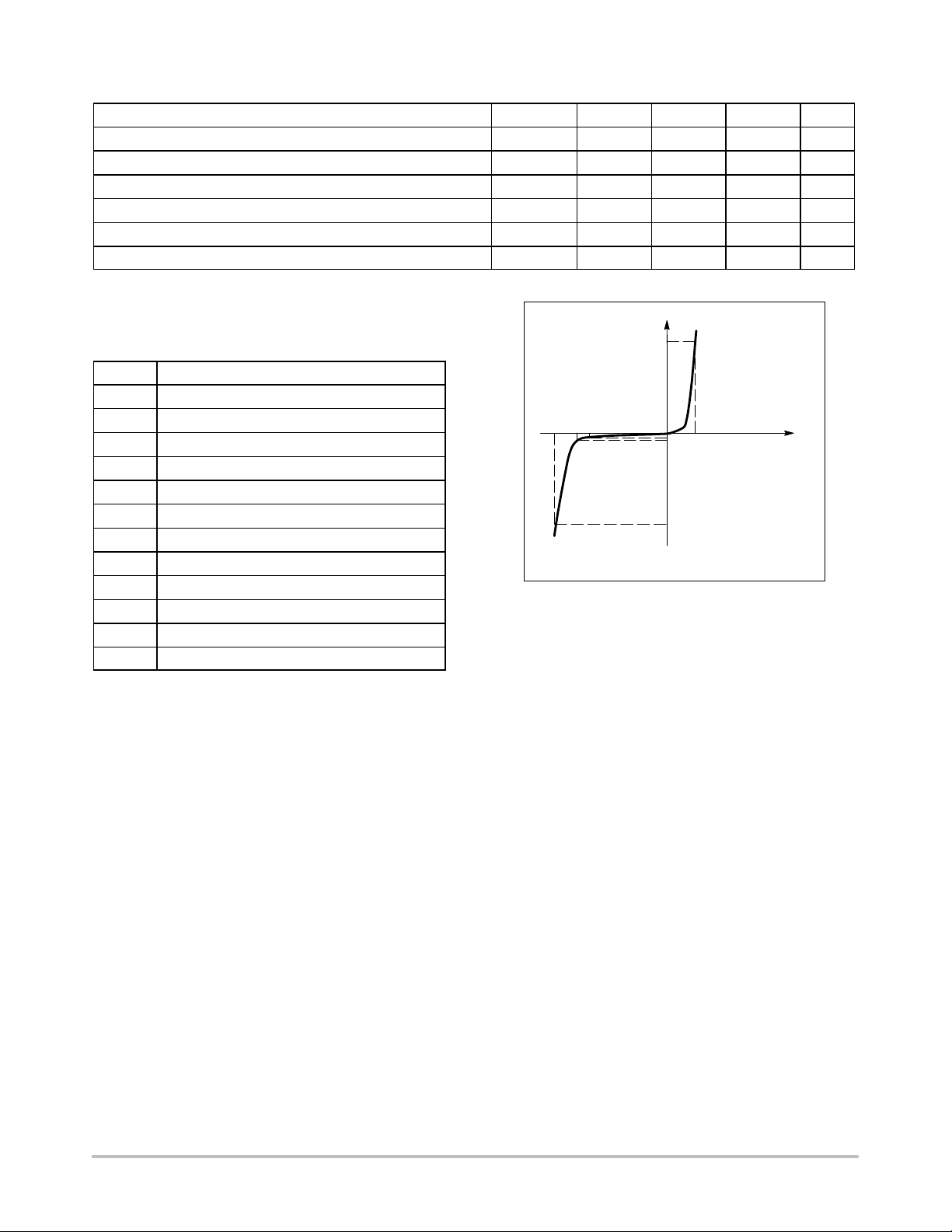

ELECTRICAL CHARACTERISTICS

Characteristic Symbol Min Typ Max Unit

Reverse Breakdown Voltage @ It = 1.0 mA V

Reverse Leakage Current @ V

= 5.0 Volts I

RWM

Maximum Clamping Voltage @ IPP = 1.0 A, 8 x 20 S V

Maximum Clamping Voltage @ IPP = 10 A, 8 x 20 S V

BR

R

C

C

Between I/O Pins and Ground @ DC Bias = 0 V, 1.0 MHz Capacitance – 5.0 10 pF

Between I/O Pins and I/O @ DC Bias = 0 V, 1.0 MHz Capacitance – 2.5 5.0 pF

6.0 – – V

N/A – 10 A

N/A – 9.8 V

N/A – 12 V

ELECTRICAL CHARACTERISTICS

(TA = 25°C unless otherwise noted)

UNIDIRECTIONAL (Circuit tied to Pins 1 and 3 or 2 and 3)

Symbol

I

PP

V

C

V

RWM

I

R

V

BR

I

T

V

BR

I

F

V

F

Z

ZT

I

ZK

Z

ZK

Maximum Reverse Peak Pulse Current

Clamping Voltage @ I

Working Peak Reverse Voltage

Maximum Reverse Leakage Current @ V

Breakdown Voltage @ I

Test Current

Maximum Temperature Coefficient of V

Forward Current

Forward Voltage @ I

Maximum Zener Impedance @ I

Reverse Current

Maximum Zener Impedance @ I

Parameter

PP

RWM

T

BR

F

ZT

ZK

VCV

V

RWM

BR

Uni–Directional TVS

I

I

F

I

V

R

F

I

T

I

PP

V

http://onsemi.com

2

NUP4201DR2

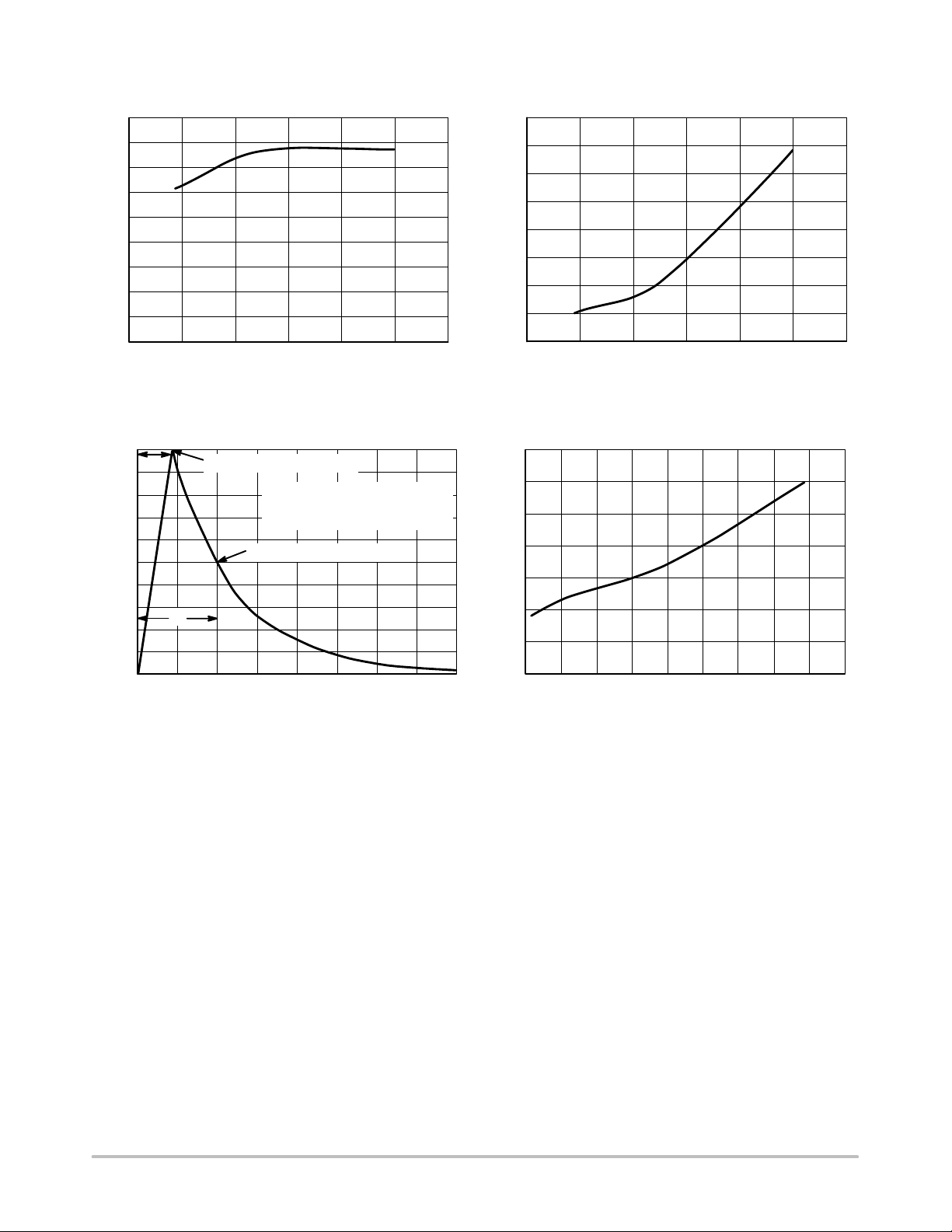

TYPICAL CHARACTERISTICS

9

8

7

6

5

4

3

2

, REVERSE BREAKDOWN (V)

Z

V

1

0

–100 0

–50

50 150

T, TEMPERATURE (°C)

100 200

Figure 1. Reverse Breakdown versus

Temperature

100

t

r

90

80

70

60

50

40

30

20

% OF PEAK PULSE CURRENT

10

0

0204060

PEAK VALUE I

t

P

@ 8 s

RSM

PULSE WIDTH (tP) IS DEFINED

AS THAT POINT WHERE THE

PEAK CURRENT DECAY = 8 s

HALF VALUE I

t, TIME (s)

/2 @ 20 s

RSM

Figure 3. 8 × 20 s Pulse Waveform

80

8

7

6

5

4

3

2

, REVERSE LEAKAGE (A)

R

I

1

0

–100 –50 50 100

0 150

T, TEMPERATURE (°C)

Figure 2. Reverse Leakage versus

Temperature

35

30

25

20

15

10

, CLAMPING VOLTAGE (V)

C

V

5

0

0204060

10 30 50 70 90

I

, PEAK PULSE CURRENT (A)

PP

Figure 4. Clamping Voltage versus Peak Pulse

Current

200

80

http://onsemi.com

3

NUP4201DR2

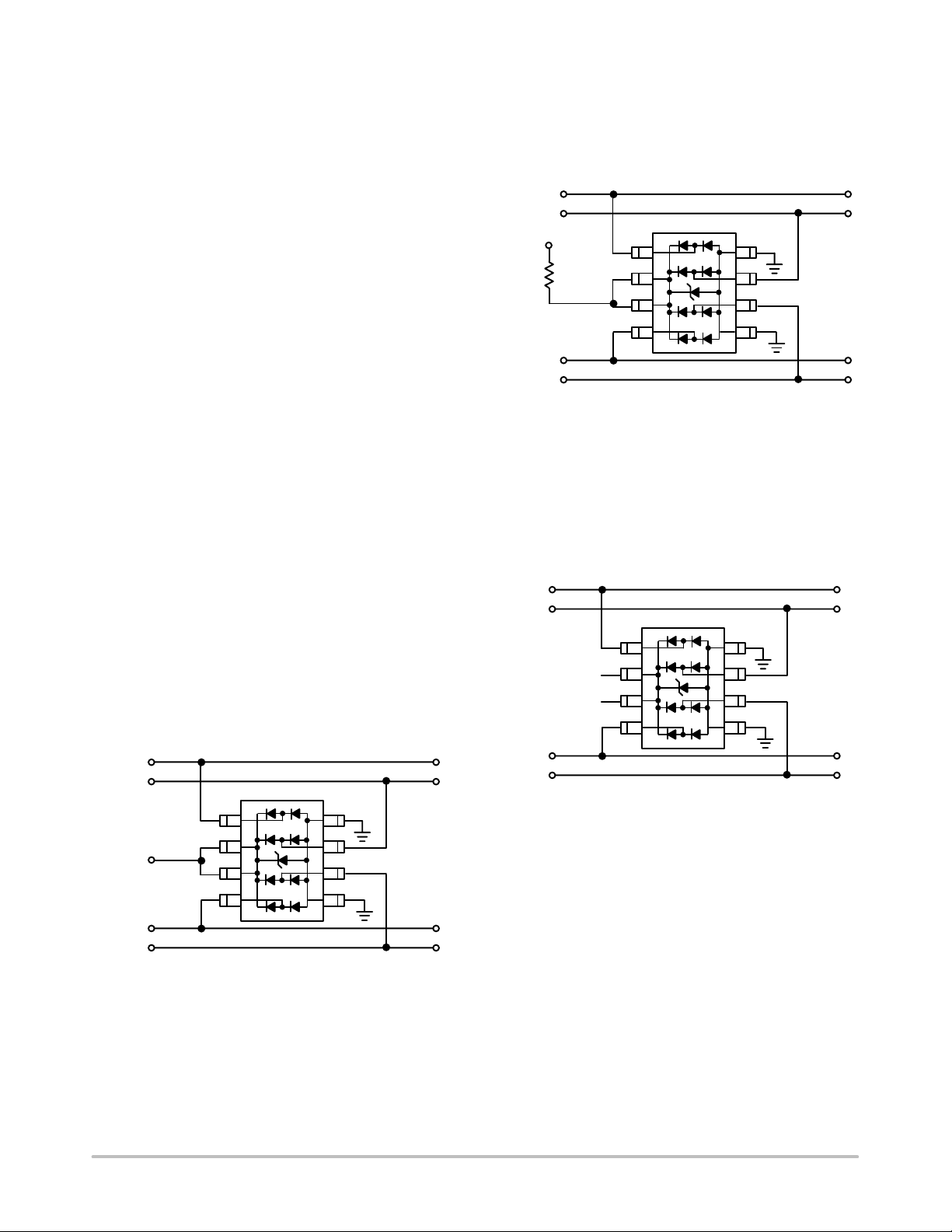

Applications information

The new NUP4201DR2 device is a low capacitance TVS

Diode array designed to protect sensitive electronics such as

communications systems, computers, and computer

peripherals against damage due to ESD conditions or

transient voltage conditions. Because of its low capacitance

array configuration, it can be used in high speed I/O data

lines.

The integrated design of the NUP4201DR2 device offers

surge rated, low capacitance steering diodes and a TVS

diode integrated in a single package (SO–8). If a transient

condition occurs, the steering diodes will drive the transient

condition to the positive polarity of the power supply or to

ground. The TVS device protects the power line against

over–voltage conditions to avoid damage in any

downstream components.

NUP4201DR2 Device’s Configurations Options

The NUP4201DR2 is able to protect up to four data lines

against transient over–voltage conditions by driving them to

a fixed reference point for clamping purposes. The steering

diodes will be forward biased whenever the voltage on the

protected line exceeds the reference voltage (Vcc+Vf). The

diodes will drive the transient current away from the

sensitive circuit.

Data lines are connected at pins 1,4,6 and 7. The negative

reference is connected at pins 5 and 8. These pins must be

connected directly to ground by using a ground plane to

minimize the PCB’s ground inductance. It is very important

to reduce as much as possible the PCB trace lengths to

minimize parasitic inductances.

Option 1

Four Data lines protection and power supply protection

using Vcc as reference.

Option 2

Four Data lines protection with Bias and power supply

isolation resistor.

I/O 1

I/O 2

V

CC

10 K

1

2

3

4

I/O 3

I/O 4

8

7

6

5

The NUP4201DR2 device can be isolated from the power

supply by connecting a series resistor between pins 2 & 3 and

Vcc. A resistor of 10Kohms is recommended for isolation

purposes. The internal TVS and steering diodes remain

biased, which provides the advantage of lower capacitance.

Option 3

Four Data lines protection using internal TVS diode as

reference.

I/O 1

I/O 2

NC

NC

1

2

3

4

8

7

6

5

I/O 1

I/O 2

V

CC

I/O 3

I/O 4

1

2

3

4

8

7

6

5

For this configuration, connect pins 2 & 3 directly to the

positive supply rail (Vcc), the data lines are referenced to the

supply voltage. The internal TVS diode prevents

over–voltage on the supply rail.

http://onsemi.com

I/O 3

I/O 4

In the case of applications in which a positive supply

reference is not available or full isolation is required, the

internal TVS could be used as the reference, so for this

purpose, the pins 2 and 3 are not connected. In this case, the

steering diodes will conduct whenever the voltage on the

protected line exceeds the working voltage of the TVS plus

one diode drop (Vc=Vf + V

4

TVS).

NUP4201DR2

“Rail to Rail” Protection Topology

The following figure shows a case when discrete diodes

are configured for rail to rail protection on an I/O line:

V

CC

ESD

Positive

ESD

Negative

11

12

D1

D2

VF + V

CC

–VF

Upon the above figure, it is possible to observe that if a

positive ESD condition occurs, the D1 diode will be forward

biased while the D2 diode will be biased when a negative

ESD condition occurs. A valid first approximation of the

resulting clamping voltage due to the protection diodes can

be made as follows:

For positive pulse conditions:

Vc = Vcc + Vf

For negative pulse conditions:

Vc = –Vf

It is important to mention that effects of parasitic

inductances must be considered for fast rise time transient

conditions because the clamping voltage on the protected

circuit will be different than in the previous case. A valid

approximation of the resulting clamping voltage can be

made as show below:

For positive pulse conditions:

Vc = Vcc + Vf + (L di

ESD/dt)

For negative pulse conditions:

Vc = –Vf – (L diESD/dt)

As shown in the formulas, the clamping voltage (Vc) not

only depends on the Vf of the steering diodes but also in the

L di

ESD/dt factor, so this is why it is very important to have

a good board layout to minimize the effects of the parasitic

inductances.

Nevertheless, some disadvantages are still present when

discrete diodes are used to suppress ESD conditions in “rail

to rail” configuration. If the ESD current is too high, it can

potentially result in the damage of any components

connected to that rail and it is also possible to experience

damage in the discrete diodes if their power dissipation

capability is exceeded.

The NUP4201DR2 On Semiconductor’s device provides

a concept named “RailClamp” which is designed to

eliminate the disadvantages of the usage of discrete diodes

for ESD protection. The RailClamp concept is achieved

with the integration of the TVS device in together with the

steering diodes.

D1

D2

Rail to Rail Protection with integrated TBS to achieve the

RailClamp concept

D3

D4

D5

D6

D7

D8

0

During an ESD condition, the ESD current will be driven

to ground through the TVS device, so the resulting clamping

voltage on the protected IC will be:

Vc = VF(RailClamp) + VTVS.

The clamping voltage of the TVS device is shown as part

of the specifications of the NUP4201DR2 datasheet. The

clamping voltage will depend on the magnitude of the ESD

current. The steering diodes are fast switching devices with

unique forward voltage and low capacitance characteristics.

http://onsemi.com

5

UPSTREAM

USB PORT

V

BUS

D+

D–

GND

V

BUS

NUP2201DT1

V

BUS

NUP4201DR2

Typical Applications

USB

Controller

C

C

V

BUS

V

R

T

R

T

V

BUS

C

T

T

R

T

R

T

NUP4201DR2

BUS

D+

DOWNSTREAM

D–

USB PORT

GND

V

BUS

V

BUS

DOWNSTREAM

D+

D–

USB PORT

GND

C

T

T

RTIP

RRING

T1/E1

TRANCEIVER

TTIP

TRING

ESD Protection for USB Port

V

CC

TI/E1 Interface Protection

R1

R3

R2

NUP4201DR2

R4

R5

T1

T2

http://onsemi.com

6

NUP4201DR2

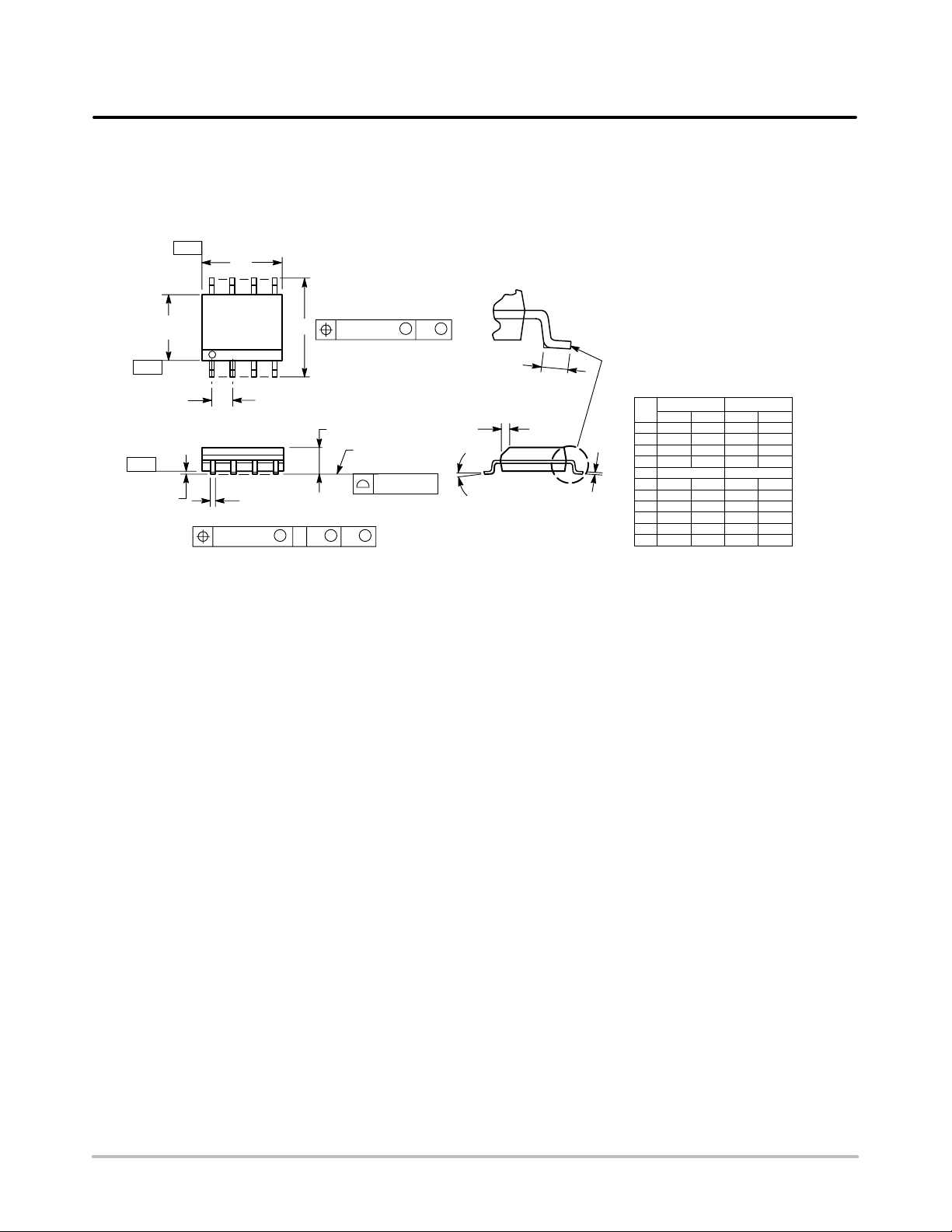

Transient Voltage Suppressor – Surface Mount

500 Watts Peak Power

SO–8

CASE 751–07

ISSUE W

–Y–

–Z–

–X–

A

58

B

1

S

0.25 (0.010)

4

M

M

Y

K

G

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

Y

SXS

N

X 45

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

http://onsemi.com

7

NUP4201DR2

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make

changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

NUP4201DR2/D

8

Loading...

Loading...