Page 1

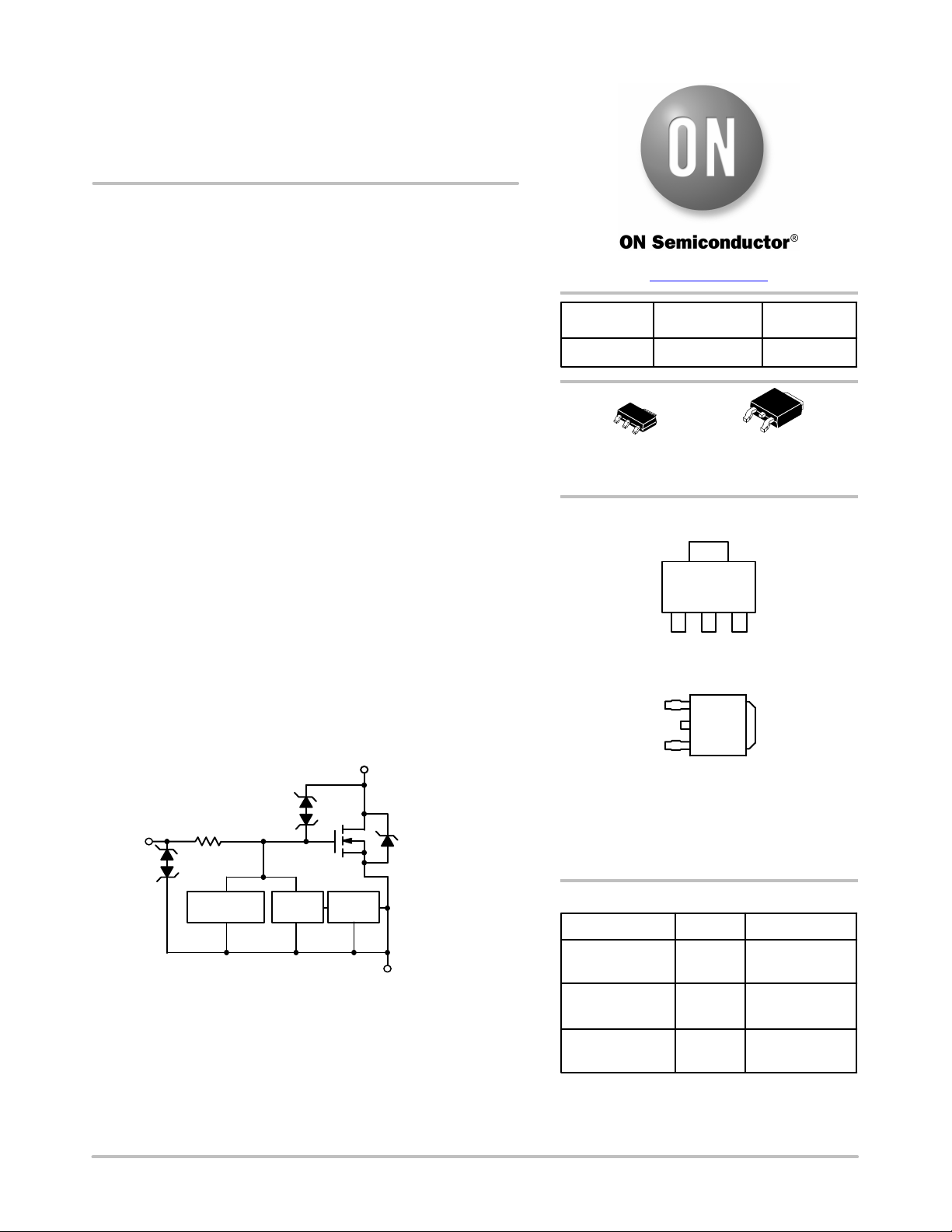

Self-Protected Low Side

Driver with In-Rush Current

Management

NCV8415

The NCV8415 is a three terminal protected Low−Side Smart

Discrete FET. The protection features include Delta Thermal

Shutdown, overcurrent, overtemperature, ESD and integrated

Drain−to−Gate clamping for overvoltage protection. The device also

offers fault indication via the gate pin. This device is suitable for harsh

automotive environments.

Features

• Short−Circuit Protection with In−Rush Current Management

• Delta Thermal Shutdown

• Thermal Shutdown with Automatic Restart

• Overvoltage Protection

• Integrated Clamp for Overvoltage Protection and Inductive

Switching

• ESD Protection

• dV/dt Robustness

• Analog Drive Capability (Logic Level Input)

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q101 Grade 1

Qualified and PPAP Capable

• These Devices are Pb−Free and are RoHS Compliant

Typical Applications

• Switch a Variety of Resistive, Inductive and Capacitive Loads

• Can Replace Electromechanical Relays and Discrete Circuits

• Automotive / Industrial

Drain

Gate

Input

ESD Protection

Overvoltage

Protection

www.onsemi.com

V

DSS

(Clamped)

42 V

SOT−223

CASE 318E

STYLE 3

R

TYP

DS(ON)

80 mW @ 10 V

DPAK

CASE 369C

STYLE 2

MARKING DIAGRAMS

4

AYW

8415G

G

1

23

SOT−223

1

AYWW

2

NCV

8415G

3

DPAK

A = Assembly Location

Y = Year

W, WW = Work Week

G or G = Pb−Free Package

(Note: Microdot may be in either location)

4

MAX

I

D

(Limited)

11 A

Pin Marking

Information

1 = Gate

2 = Drain

3 = Source

4 = Drain

Temperature

Limit

Current

Limit

Figure 1. Block Diagram

© Semiconductor Components Industries, LLC, 2018

January, 2021 − Rev. 0

Current

Sense

Source

ORDERING INFORMATION

Device Package Shipping

NCV8415DTRKG DPAK

NCV8415STT1G SOT−223

NCV8415STT3G SOT−223

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

1 Publication Order Number:

(Pb−Free)

(Pb−Free)

(Pb−Free)

Tape & Reel

Tape & Reel

Tape & Reel

†

2500 /

1000 /

4000 /

NCV8415/D

Page 2

NCV8415

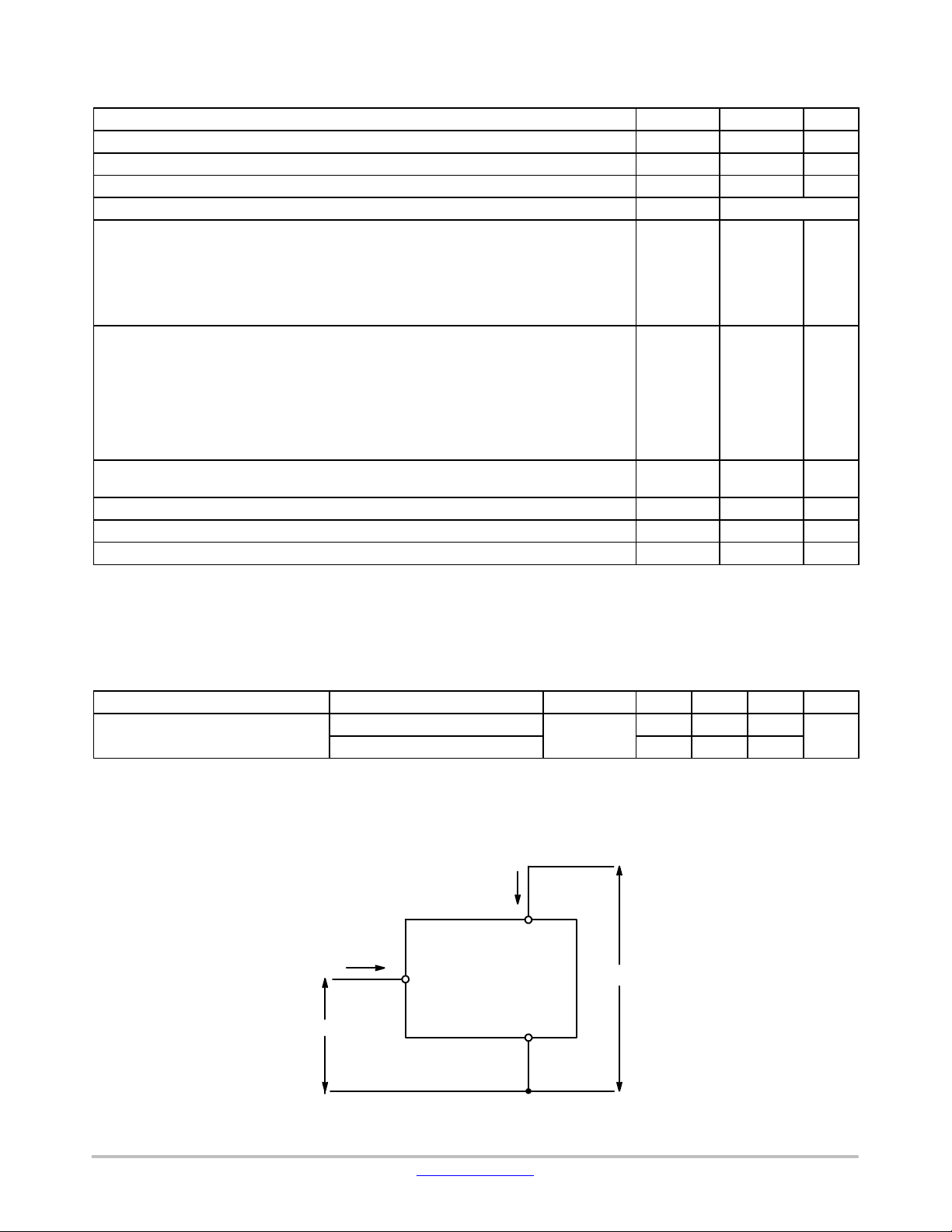

MAXIMUM RATINGS

Rating Symbol Value Unit

Drain−to−Source Voltage Internally Clamped V

Drain−to−Gate Voltage Internally Clamped V

Gate−to−Source Voltage V

Drain Current − Continuous I

Total Power Dissipation (SOT−223)

@ T

= 25°C (Note 1)

A

@ TA = 25°C (Note 2)

DSS

DG

GS

D

P

D

Total Power Dissipation (DPAK)

@ TA = 25°C (Note 1)

@ T

= 25°C (Note 2)

A

Thermal Resistance (SOT−223)

Junction−to−Ambient (Note 1)

Junction−to−Ambient (Note 2)

Junction−to−Case (Soldering Point)

R

q

JA

R

q

JA

R

q

JS

Thermal Resistance (DPAK)

Junction−to−Ambient (Note 1)

Junction−to−Ambient (Note 2)

Junction−to−Case (Soldering Point)

Single Pulse Inductive Load Switching Energy (L = 10 mH, I

T

= 25°C)

Jstart

= 4.2 A, VGS = 5 V, RG = 25 W,

Lpeak

Load Dump Voltage (VGS = 0 and 10 V, RL = 10 W) (Note 3)

Operating Junction Temperature T

Storage Temperature T

R

q

JA

R

q

JA

R

q

JS

E

AS

US* 52 V

J

storage

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Mounted onto a 80 × 80 × 1.6 mm single layer FR4 board (100 sq mm, 1 oz. Cu, steady state).

2. Mounted onto a 80 × 80 × 1.6 mm single layer FR4 board (645 sq mm, 1 oz. Cu, steady state).

3. Load Dump Test B (with centralized load dump suppression) according to ISO16750−2 standard. Guaranteed by design. Not tested in

production. Passed Class C according to ISO16750−1.

42 V

42 V

±14 V

Internally Limited

W

1.29

2.20

1.54

2.99

°C/W

96.4

56.8

10.6

80.8

41.8

3.2

88 mJ

−40 to 150 °C

−55 to 150 °C

ESD ELECTRICAL CHARACTERISTICS (Note 4, 5)

Parameter

Electro−Static Discharge Capability

Human Body Model (HBM)

Charged Device Model (CDM) 1000 − −

4. Not tested in production.

5. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC−Q100−002 (JS−001−2017).

Field Induced Charge Device Model ESD characterization is not performed on plastic molded packages with body sizes smaller than

2 × 2 mm due to the inability of a small package body to acquire and retain enough charge to meet the minimum CDM discharge current

waveform characteristic defined in JEDEC JS−002−2018.

+

V

GS

−

Test Condition Symbol Min Typ Max Unit

ESD

4000 − −

+

I

D

DRAIN

I

G

GATE

V

DS

SOURCE

−

Figure 2. Voltage and Current Convention

V

www.onsemi.com

2

Page 3

NCV8415

ELECTRICAL CHARACTERISTICS (T

Parameter

= 25°C unless otherwise noted)

J

Test Condition Symbol Min Typ Max Unit

OFF CHARACTERISTICS

Drain−to−Source Breakdown Voltage

VGS = 0 V, ID = 10 mA

VGS = 0 V, ID = 10 mA, TJ = 150°C

V

(BR)DSS

42 46 51

42 44 51

V

(Note 6)

Zero Gate Voltage Drain Current

VGS = 0 V, VDS = 32 V

VGS = 0 V, VDS = 32 V, TJ = 150°C

I

DSS

− 0.6 2.0

− 2.4 10

mA

(Note 6)

Gate Input Current VGS = 5 V, VDS = 0 V I

GSS

− 50 70

ON CHARACTERISTICS

Gate Threshold Voltage

Gate Threshold Temperature Coefficient

Static Drain−to−Source On Resistance

VGS = VDS, ID = 150 mA

VGS = VDS, ID = 150 mA (Note 6)

VGS = 10 V, ID = 1.4 A

VGS = 10 V, ID = 1.4 A, TJ = 150°C

V

GS(th)

V

GS(th)/TJ

R

DS(ON)

1.0 1.6 2.0 V

− −4.0 − mV/°C

− 80 100

mW

− 150 190

(Note 6)

VGS = 5.0 V, ID = 1.4 A − 105 120

VGS = 5.0 V, ID = 1.4 A, TJ = 150°C

− 185 210

(Note 6)

VGS = 5.0 V, ID = 0.5 A − 105 120

VGS = 5.0 V, ID = 0.5 A, TJ = 150°C

− 185 210

(Note 6)

Source−Drain Forward On Voltage IS = 7 A, VGS = 0 V V

SD

− 0.88 1.10 V

SWITCHING CHARACTERISTICS (Note 6)

Turn−On Time (10% V

to 90% ID)

GS

Turn−Off Time (90% VGS to 10% ID) t

Turn−On Time (10% VGS to 90% ID)

Turn−Off Time (90% VGS to 10% ID) t

Turn−On Rise Time (10% ID to 90% ID) t

Turn−Off Fall Time (90% ID to 10% ID) t

VGS = 0 V to 5 V, VDD = 12 V,

I

= 1 A

D

VGS = 0 V to 10 V, VDD = 12 V,

ID = 1 A

t

ON

OFF

t

ON

OFF

rise

fall

Slew Rate On (80% VDS to 50% VDS) −dVDS/dt

Slew Rate Off (50% VDS to 80% VDS) dVDS/dt

ON

OFF

− 30 35

− 44 55

− 13 20

− 70 90

− 9 15

− 29 40

0.5 1.63 −

0.4 0.55 −

ms

V/ms

SELF PROTECTION CHARACTERISTICS

Current Limit

VGS = 5 V, VDS = 10 V

VGS = 5 V, VDS = 10 V, TJ = 150°C

I

LIM

7.0 8.8 11

6.4 7.9 9.1

A

(Note 6)

VGS = 10 V, VDS = 10 V (Note 6) 5.2 8.2 11

VGS = 10 V, VDS = 10 V, TJ = 150°C

5.0 7.4 10

(Note 6)

Temperature Limit (Turn−Off)

Thermal Hysteresis

Temperature Limit (Turn−Off)

Thermal Hysteresis

VGS = 5.0 V (Note 6)

VGS = 10 V (Note 6)

T

LIM(OFF)

DT

LIM(ON)

T

LIM(OFF)

DT

LIM(ON)

150 175 185

− 15 −

150 185 200

− 15 −

°C

GATE INPUT CHARACTERISTICS (Note 6)

Device ON Gate Input Current

VGS = 5 V, VDS = 10 V, ID = 1 A

I

GON

35 50 70

mA

VGS = 10 V, VDS = 10 V, ID = 1 A 250 310 450

Current Limit Gate Input Current

VGS = 5 V, VDS = 10 V

I

GCL

45 76 95

VGS = 10 V, VDS = 10 V 320 450 550

Thermal Limit Gate Input Current

VGS = 5 V, VDS = 10 V, ID = 0 A

VGS = 10 V, VDS = 10 V, ID = 0 A

I

GTL

210 240 260

620 700 830

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

6. Not subject to production testing.

www.onsemi.com

3

Page 4

NCV8415

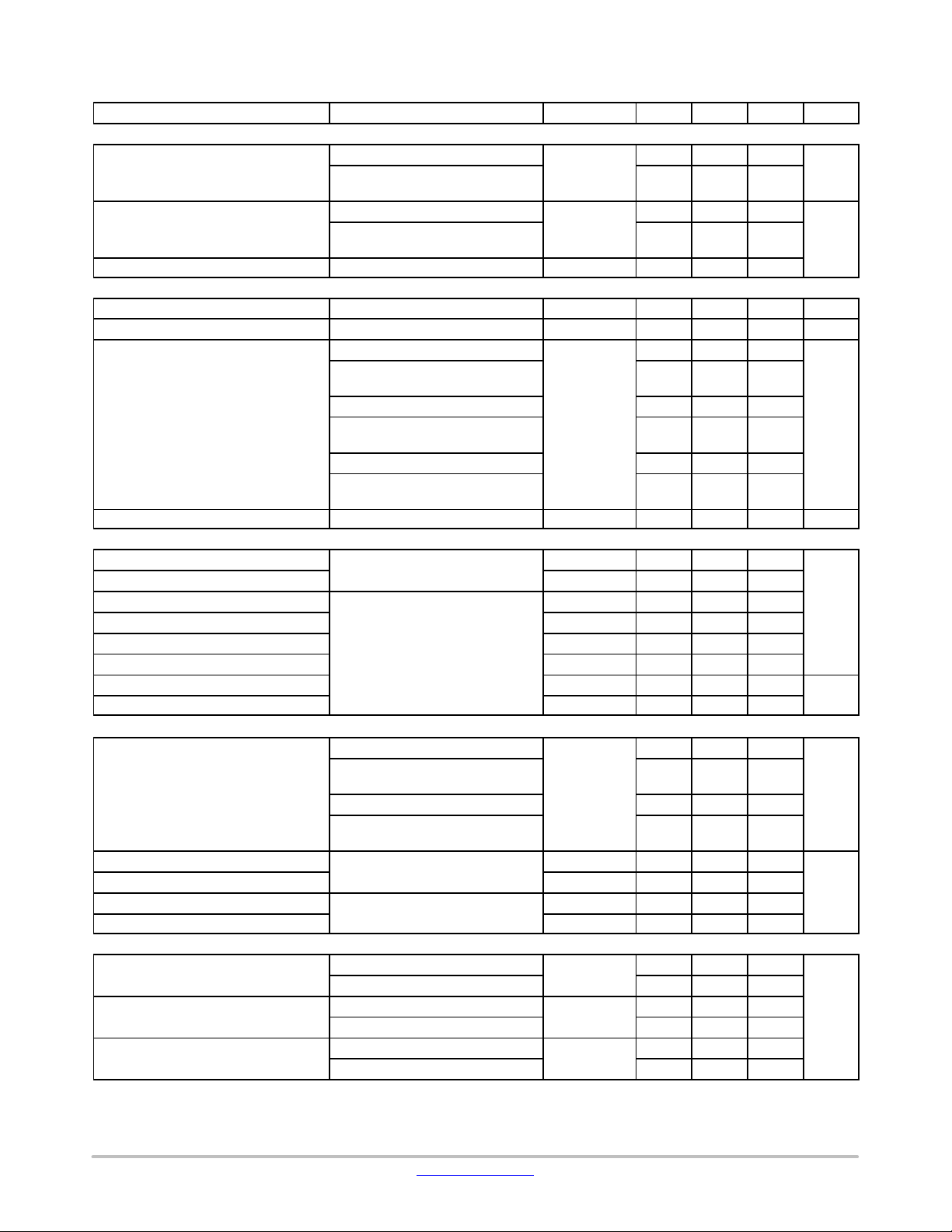

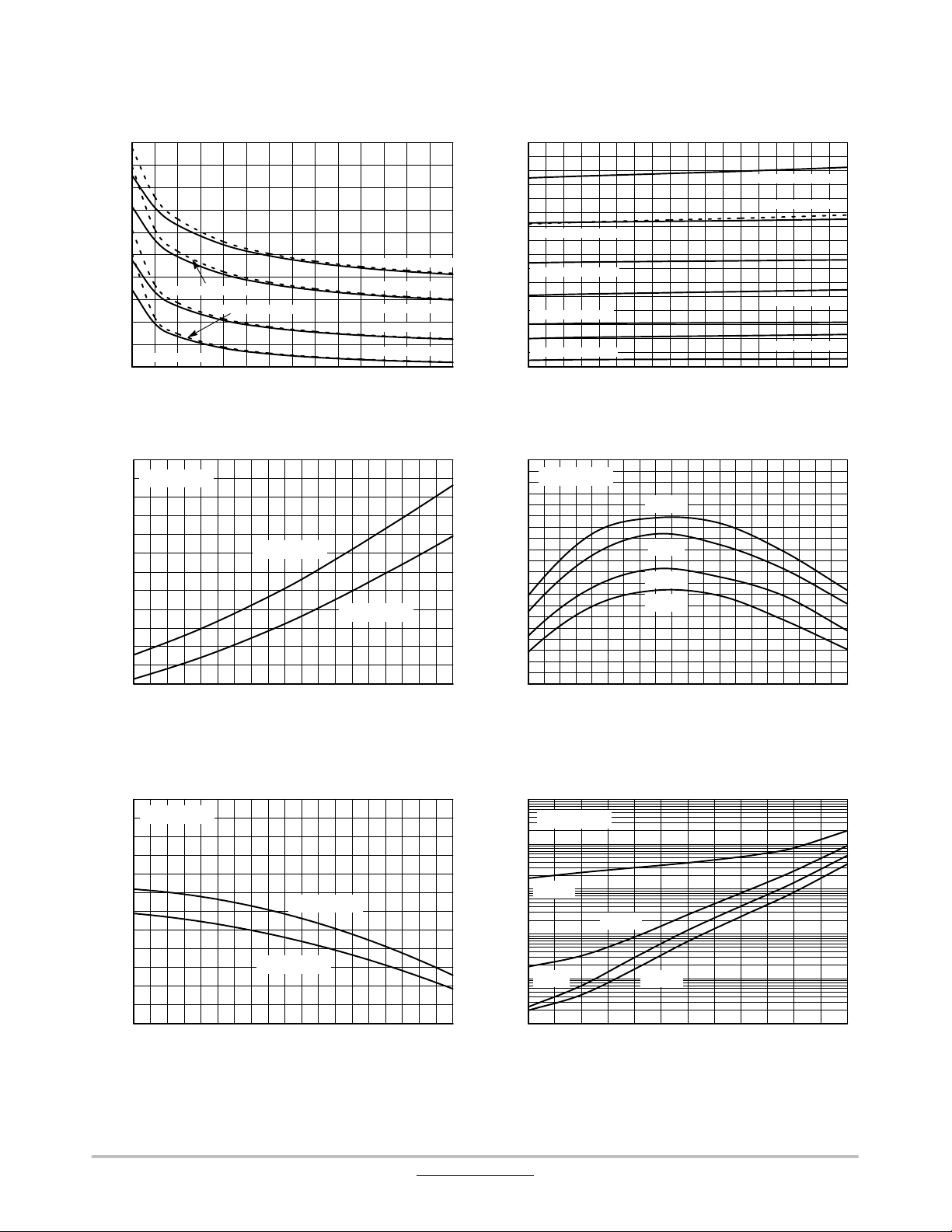

TYPICAL PERFORMANCE CURVES

10

(A)

Lmax

I

T

= 150°C

J(start)

1

10 100

T

J(start)

= 25°C

L (mH)

Figure 3. Single Pulse Maximum Switch−Off

Current vs. Load Inductance

10

(A)

Lmax

I

T

J(start)

= 150°C

T

J(start)

= 25°C

1000

T

= 25°C

J(start)

(mJ)

100

max

E

10

10 100

T

J(start)

= 150°C

L (mH)

Figure 4. Single Pulse Maximum Switching

Energy vs. Load Inductance

1000

T

= 25°C

J(start)

(mJ)

100

max

E

T

J(start)

= 150°C

1

110

tav (ms)

Figure 5. Single Pulse Maximum Inductive

Switch−Off Current vs. Time in Avalanche

12

10

TA = 25°C

6 V

7 V

9 V

10

110

tav (ms)

Figure 6. Single Pulse Maximum Inductive

Switching Energy vs. Time in Avalanche

10

VDS = 10 V

8

8

6

(A)

D

I

6

10 V

8 V

4

2

0

0123 45

VGS = 2.5 V

VDS (V)

Figure 7. On−State Output Characteristics

5 V

4 V

3 V

(A)

D

I

4

2

0

1.5 2.5 3.5 4.5

12345

VGS (V)

Figure 8. Transfer Characteristics

−40°C

25°C

105°C

150°C

www.onsemi.com

4

Page 5

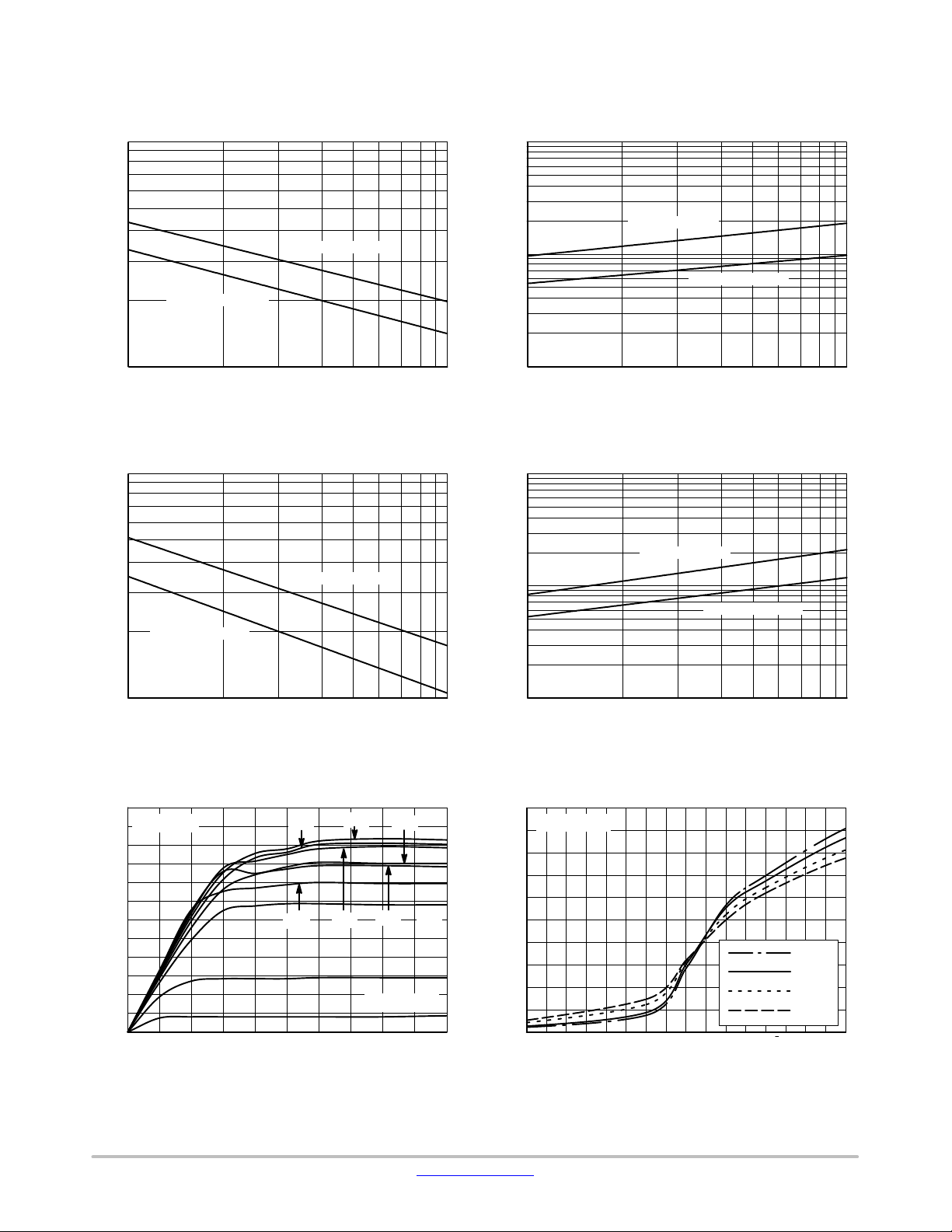

NCV8415

TYPICAL PERFORMANCE CURVES

300

250

200

(mW)

150

DS(ON)

R

100

50

105°C, ID = 1.4 A

−40°C, ID = 1.4 A

−40°C, ID = 0.5 A

345678910

150°C, ID = 1.4 A

150°C, ID = 0.5 A

105°C, ID = 0.5 A

25°C, ID = 1.4 A

25°C, ID = 0.5 A

VGS (V)

Figure 9. R

vs. Gate−Source Voltage

DS(ON)

2.0

ID = 1.4 A

1.75

1.5

DS(ON)

VGS = 5 V

1.25

1.0

VGS = 10 V

Normalized R

0.75

210

190

170

150

150°C, VGS = 10 V

(mW)

130

105°C, VGS = 10 V

DS(ON)

110

R

90

25°C, VGS = 10 V

70

−40°C, VGS = 10 V

50

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

150°C, VGS = 5 V

105°C, VGS = 5 V

25°C, VGS = 5 V

−40°C, VGS = 5 V

ID (A)

Figure 10. R

vs. Drain Current

DS(ON)

12

VDS = 10 V

11.5

11

−40°C

10.5

25°C

105°C

150°C

(A)

LIM

I

10

9.5

9

8.5

8

7.5

0.5

−40 −20 0 20 40 60 80 100 120 140 5 6 7 8 9 10

TJ (5C)

Figure 11. Normalized R

vs. Temperature

DS(ON)

7

5.5 6.5 7.5 8.5 9.5

VGS (V)

Figure 12. Current Limit vs. Gate−Source

Voltage

10

VDS = 10 V

9.5

9

(A)

8.5

LIM

I

VGS = 10 V

8

VGS = 5 V

7.5

7

−40 −20 0 20 40 60 80 100 120 140

TJ (5C)

Figure 13. Current Limit vs. Junction

Temperature

100

10

1

(mA)

DSS

0.1

I

0.01

0.001

www.onsemi.com

5

VGS = 0 V

150°C

105°C

25°C

−40°C

10 15 20 25 30 35 40

VDS (V)

Figure 14. Drain−to−Source Leakage Current

Page 6

NCV8415

TYPICAL PERFORMANCE CURVES

1.2

ID = 150 mA

= V

1.1

(V)

GS(th)

1

V

DS

GS

0.9

0.8

Normalized V

0.7

0.6

−40 −20 0 20 40 60 80 100 120 140

TJ (5C)

Figure 15. Normalized Threshold Voltage vs.

Temperature

140

VDD = 12 V

= 1 A

I

120

R

D

= 0 W

G

100

t

ON

80

60

Time (ms)

t

40

r

t

OFF

20

t

0

345678910

f

VGS (V)

Figure 17. Resistive Load Switching Time vs.

Gate−Source Voltage

1.1

VGS = 0 V

1

−40°C

0.9

0.8

0.7

25°C

105°C

(V)

SD

V

0.6

150°C

0.5

12345678910

IS (A)

Figure 16. Source−Drain Diode Forward

Characteristics

2

VDD = 12 V

= 1 A

I

D

R

= 0 W

1.5

G

−dVDS/dt

ON

1.0

dVDS/dt

OFF

0.5

Drain−Source Voltage Slope (V/ms)

0

345678910

VGS (V)

Figure 18. Resistive Load Switching

Drain−Source Voltage Slope vs. Gate−Source

Voltage

80

VDD = 12 V

70

60

50

I

D

= 1 A

t

, VGS = 10 V

OFF

t

, VGS = 5 V

OFF

40

Time (ms)

30

tON, VGS = 5 V

tr, VGS = 5 V

20

10

tf, VGS = 10 Vtf, VGS = 5 V

tON, VGS = 10 V

tr, VGS = 10 V

0

0 500 1000 1500 2000

RG (W)

Figure 19. Resistive Load Switching Time vs.

Gate Resistance

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

Drain−Source Voltage Slope (V/ms)

0

Drain−Source Voltage Slope vs. Gate Resistance

www.onsemi.com

6

−dVDS/dtON, VGS = 10 V

dVDS/dt

, VGS = 5 V

OFF

dVDS/dt

, VGS = 10 V

OFF

−dVDS/dtON, VGS = 5 V

VDD = 12 V

= 1 A

I

D

0 500 1000 1500 2000

RG (W)

Figure 20. Resistive Load Switching

Page 7

NCV8415

TYPICAL PERFORMANCE CURVES

100

90

80

70

(5C/W)

JA

q

R

60

50

PCB Cu thickness, 2.0 oz

40

0 100 200 300 400 500 600 700

PCB Cu thickness, 1.0 oz

Copper Heat Spreader Area (mm

Figure 21. R

vs. Copper Area (SOT−223)

q

JA

800

2

)

90

80

70

60

(5C/W)

JA

q

R

50

40

PCB Cu thickness, 2.0 oz

30

0 100 200 300 400 500 600 700

PCB Cu thickness, 1.0 oz

Copper Heat Spreader Area (mm

Figure 22. R

vs. Copper Area (DPAK)

q

JA

2

)

100

50% Duty Cycle

20% Duty Cycle

10

10% Duty Cycle

5% Duty Cycle

2% Duty Cycle

1

(t) (5C/W)

R

JA

q

1% Duty Cycle

0.1

Single Pulse

80 × 80 × 1.6 mm Single−Layer PCB, 645 mm2 1 oz. Copper

0.01

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100 1000

Pulse Width (s)

Figure 23. Transient Thermal Resistance (SOT−223)

800

100

50% Duty Cycle

20% Duty Cycle

10

10% Duty Cycle

5% Duty Cycle

2% Duty Cycle

1

(t) (5C/W)

JA

1% Duty Cycle

q

R

0.1

Single Pulse

80 × 80 × 1.6 mm Single−Layer PCB, 645 mm2 1 oz. Copper

0.01

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100 1000

Pulse Width (s)

Figure 24. Transient Thermal Resistance (DPAK)

www.onsemi.com

7

Page 8

NCV8415

APPLICATION INFORMATION

Circuit Protection Features

The NCV8415 has three main protections. Current Limit,

Thermal Shutdown and Delta Thermal Shutdown. These

protections establish robustness of the NCV8415.

Current Limit and Short Circuit Protection

The NCV8415 has current sense element. In the event that

the drain current reaches designed current limit level,

integrated Current Limit protection establishes its constant

level.

Delta Thermal Shutdown

Delta Thermal Shutdown (DTSD) Protection increases

higher reliability of the NCV8415. DTSD consist of two

independent temperature sensors – cold and hot sensors. The

NCV8415 establishes a slow junction temperature rise by

sensing the difference between the hot and cold sensors.

ON/OFF output cycling is designed with hysteresis that

results in a controlled saw tooth temperature profile

(Figure 26). The die temperature slowly rises (DTSD) until

the absolute temperature shutdown (TSD) is reached around

175°C.

Thermal Shutdown with Automatic Restart

Internal Thermal Shutdown (TSD) circuitry is provided to

protect the NCV8415 in the event that the maximum

junction temperature is exceeded. When activated at

typically 175°C, the NCV8415 turns off. This feature is

provided to prevent failures from accidental overheating.

EMC Performance

To improve the EMC performance/robustness, connect

a small ceramic capacitor to the drain pin as close to the

device as possible according to Figure 25.

R

L

Gate

D

DUT

G

S

Figure 25. EMC Capacitor Placement

+

V

DD

−

C

V

Delta TSD

activation

G

I

D

I

NOM

TSD

T

TEST CIRCUITS AND WAVEFORMS

Thermal Transient Limitation Phase Overtemperature

I

LIM

J

Cycling

Nominal

Load

Time

Figure 26. Overload Protection Behavior

www.onsemi.com

8

Page 9

NCV8415

TEST CIRCUITS AND WAVEFORMS

R

L

V

IN

R

G

D

DUT

G

S

I

DS

Figure 27. Resistive Load Switching Test Circuit

+

V

DD

−

90%

V

IN

10%

t

ON

t

r

t

OFF

t

f

90%

I

DS

10%

Time

Figure 28. Resistive Load Switching Waveforms

www.onsemi.com

9

Page 10

NCV8415

TEST CIRCUITS AND WAVEFORMS

L

V

DS

V

IN

R

G

G

DUT

S

t

p

I

DS

D

+

V

DD

−

Figure 29. Inductive Load Switching Test Circuit

5 V

V

IN

t

V

(BR)DSS

av

V

DD

t

p

I

pk

V

DS

0 V

V

I

DS

DS(on)

0

Time

Figure 30. Inductive Load Switching Waveforms

www.onsemi.com

10

Page 11

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

SOT−223 (TO−261)

CASE 318E−04

ISSUE R

DATE 02 OCT 2018

q

q

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

98ASB42680B

SOT−223 (TO−261)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

© Semiconductor Components Industries, LLC, 2018

www.onsemi.com

Page 12

SOT−223 (TO−261)

CASE 318E−04

ISSUE R

DATE 02 OCT 2018

STYLE 1:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 6:

PIN 1. RETURN

2. INPUT

3. OUTPUT

4. INPUT

STYLE 11:

PIN 1. MT 1

2. MT 2

3. GATE

4. MT 2

STYLE 2:

PIN 1. ANODE

2. CATHODE

3. NC

4. CATHODE

STYLE 7:

PIN 1. ANODE 1

2. CATHODE

3. ANODE 2

4. CATHODE

STYLE 12:

PIN 1. INPUT

2. OUTPUT

3. NC

4. OUTPUT

STYLE 3:

PIN 1. GATE

STYLE 8:

STYLE 13:

PIN 1. GATE

2. DRAIN

3. SOURCE

4. DRAIN

CANCELLED

2. COLLECTOR

3. EMITTER

4. COLLECTOR

GENERIC

MARKING DIAGRAM*

AYW

XXXXXG

G

1

A = Assembly Location

Y = Year

W = Work Week

XXXXX = Specific Device Code

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

STYLE 4:

PIN 1. SOURCE

2. DRAIN

3. GATE

4. DRAIN

STYLE 9:

PIN 1. INPUT

2. GROUND

3. LOGIC

4. GROUND

STYLE 5:

PIN 1. DRAIN

2. GATE

3. SOURCE

4. GATE

STYLE 10:

PIN 1. CATHODE

2. ANODE

3. GATE

4. ANODE

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

98ASB42680B

SOT−223 (TO−261)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 13

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

2

1

3

SCALE 1:1

L3

L4

b2

e

GAUGE

L2

PLANE

STYLE 1:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 6:

PIN 1. MT1

2. MT2

3. GATE

4. MT2

4

E

b3

4

12 3

TOP VIEW

L

L1

DETAIL A

ROTATED 90 CW5

STYLE 7:

PIN 1. GATE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

5.80

0.228

A

A

B

D

NOTE 7

b

0.005 (0.13) C

DETAIL A

c

SIDE VIEW

M

H

SEATING

C

PLANE

A1

STYLE 2:

PIN 1. GATE

2. DRAIN

3. SOURCE

4. DRAIN

STYLE 8:

PIN 1. N/C

2. CATHODE

3. ANODE

4. CATHODE

STYLE 3:

PIN 1. ANODE

2. CATHODE

3. ANODE

4. CATHODE

SOLDERING FOOTPRINT*

6.20

0.244

2.58

0.102

3.00

0.118

1.60

0.063

DPAK (SINGLE GAUGE)

CASE 369C

ISSUE F

C

c2

H

BOTTOM VIEW

Z

BOTTOM VIEW

ALTERNATE

CONSTRUCTIONS

STYLE 4:

PIN 1. CATHODE

2. ANODE

3. GATE

4. ANODE

STYLE 9:

PIN 1. ANODE

2. CATHODE

3. RESISTOR ADJUST

4. CATHODE

6.17

0.243

STYLE 10:

STYLE 5:

PIN 1. GATE

2. ANODE

3. CATHODE

4. ANODE

PIN 1. CATHODE

2. ANODE

3. CATHODE

4. ANODE

DATE 21 JUL 2015

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. THERMAL PAD CONTOUR OPTIONAL WITHIN DIMENSIONS b3, L3 and Z.

4. DIMENSIONS D AND E DO NOT INCLUDE MOLD

FLASH, PROTRUSIONS, OR BURRS. MOLD

FLASH, PROTRUSIONS, OR GATE BURRS SHALL

Z

Z

NOT EXCEED 0.006 INCHES PER SIDE.

5. DIMENSIONS D AND E ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. OPTIONAL MOLD FEATURE.

DIM MIN MAX MIN MAX

A 0.086 0.094 2.18 2.38

A1 0.000 0.005 0.00 0.13

b 0.025 0.035 0.63 0.89

b2 0.028 0.045 0.72 1.14

b3 0.180 0.215 4.57 5.46

c 0.018 0.024 0.46 0.61

c2 0.018 0.024 0.46 0.61

D 0.235 0.245 5.97 6.22

E 0.250 0.265 6.35 6.73

e 0.090 BSC 2.29 BSC

H 0.370 0.410 9.40 10.41

L 0.055 0.070 1.40 1.78

L1 0.114 REF 2.90 REF

L2 0.020 BSC 0.51 BSC

L3 0.035 0.050 0.89 1.27

L4 −−− 0.040 −−− 1.01

Z 0.155 −−− 3.93 −−−

MILLIMETERSINCHES

GENERIC

MARKING DIAGRAM*

XXXXXXG

ALYWW

XXXXXX = Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer

to device data sheet for actual part

marking.

AYWW

XXX

XXXXXG

DiscreteIC

mm

ǒ

SCALE 3:1

inches

Ǔ

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

98AON10527D

DPAK (SINGLE GAUGE)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 14

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...