Page 1

USB Power Delivery

4-Switch Buck Boost

Controller

NCV81599, NCP81599

The NCV81599 USB Power Delivery (PD) Controller is a

synchronous buck boost that is optimized for converting battery

voltage or adaptor voltage into power supply rails required in

notebook, tablet, and desktop systems, as well as many other

consumer devices using USB PD standard and C−Type cables. The

NCV81599 is fully compliant to the USB Power Delivery

Specification when used in conjunction with a USB PD or C−Type

Interface Controller. NCV81599 is designed for applications requiring

dynamically controlled slew rate limited output voltage that require

either voltage higher or lower than the input voltage. The NCV81599

drives 4 NMOSFET switches, allowing it to buck or boost and support

the functions specified in the USB Power Delivery Specification

which is suitable for all USB PD applications. The USB PD Buck

Boost Controller operates with a supply and load range of 4.5 V to

32 V.

Features

• Wide Input Voltage Range:

from 4.5 V to 32 V for NCV81599

from 4.5 V to 28 V for NCP81599

• Dynamically Programmed Frequency from 150 kHz to 1.2 MHz

2

• I

C Interface

• Real Time Power Good Indication

• Controlled Slew Rate Voltage Transitioning

• Feedback Pin with Internally Programmed Reference

• Support USBPD/QC2.0/QC3.0 Profile

• 2 Independent Current Sensing Inputs

• Over Temperature Protection

• Adaptive Non−Overlap Gate Drivers

• Over−Voltage and Over−Current Protection

• AEC−Q100 Qualified (NCV81599)

• 5 x 5 mm QFN32 Package

www.onsemi.com

32

1

QFN32 5x5, 0.5P

CASE 485CE

(NCP81599)

MARKING DIAGRAM

1

NCx81599

AWLYYWWG

G

NCx81599 = Specific Device Code

x = V or P

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

Typical Application

1

QFNW32 5x5, 0.5P

CASE 484AB

(NCV81599)

• Automotive USB Charging Ports

• Wireless Charging

• Consumer Electronics

32

ORDERING INFORMATION

Device Package Shipping

NCV81599MWTXG QFN32

(Pb−Free)

NCP81599MNTXG QFN32

(Pb−Free)

†For information on tape and reel specifications, including part orientation

and tape sizes, please refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

© Semiconductor Components Industries, LLC, 2017

March, 2021 − Rev. 3

5000 / Tape & Reel

2500 / Tape & Reel

†

1 Publication Order Number:

NCV81599/D

Page 2

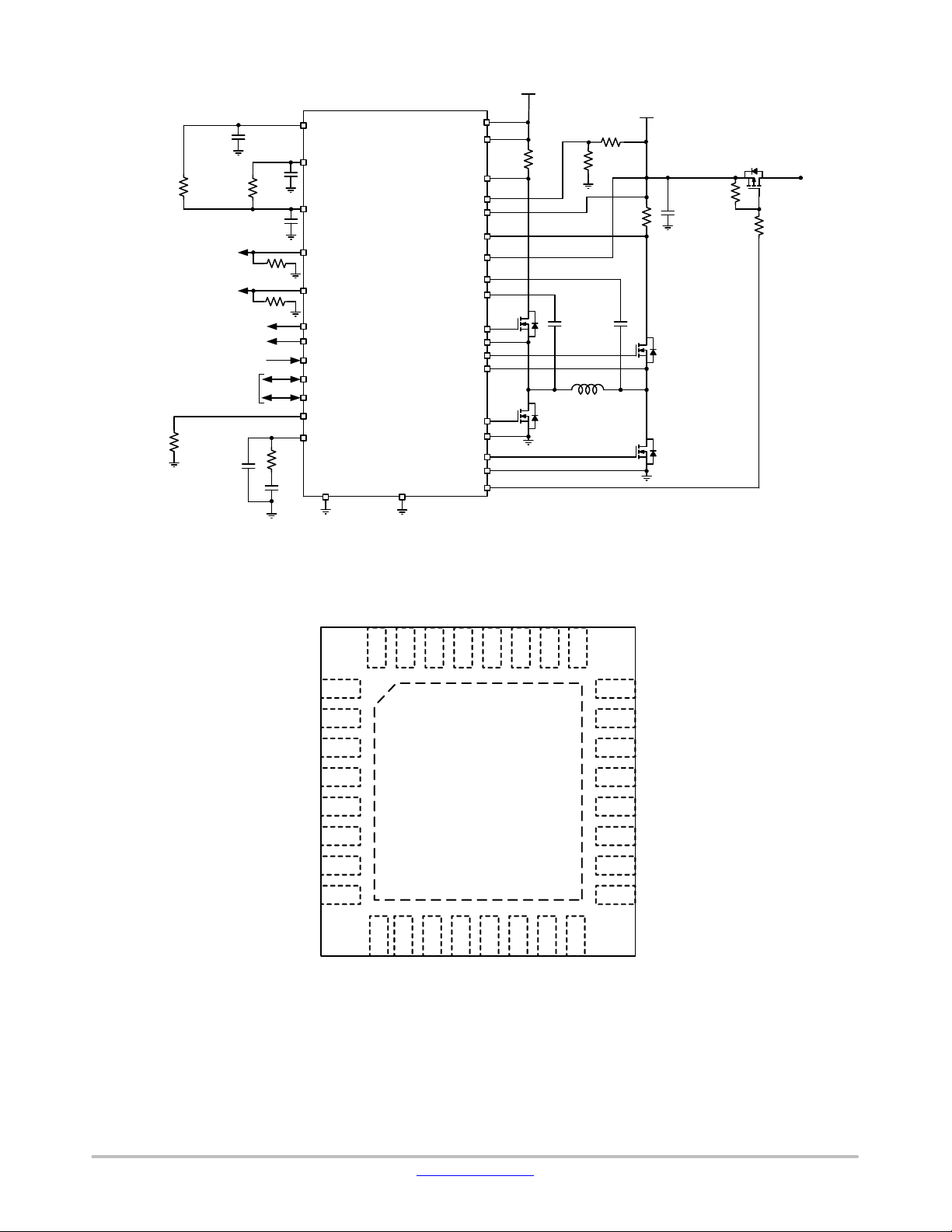

R

VCCD

Current Sense 1

Current Sense 2

Curret Limit Indicator

R

ADDR

C

VCCD

R

DRV

Interrupt

Enable

I2C

CP

NCV81599, NCP81599

V1

RS2

CB2

V2

Q6

VBUS

RPU

CO1

RPD

S4

S3

VCCD

C

VDRV

VDRV

VCC

C

VCC

CS1

R

CS1

CS2

R

CS2

CLIND

INT

EN

SDA

SCL

ADDR

COMP

RC

AGND

CC

THPAD

CSP1

CSN1

CSN2

CSP2

BST2

BST1

HSG1

VSW1

HSG2

VSW2

LSG1

PGND1

LSG2

PGND2

PDRV

V1

RS1

FB

V2

S1

S2

CB1

L1

HSG1

LSG1

PGND1

CSN1

CSP1

V1

CS1

CLIND

Figure 1. Typical Application Circuit

VSW1

BST1

VCC

VDRV

31 30 29 28 27 26 2532

1

2

3

4

Exposed Thermal Pad

5

(THPAD)

6

7

8

INT

SCL

SDA

ADDR

VCCD

AGND

V2

AGND

VSW2

1514131211109 16

COMP

BST2

EN

24

23

22

21

20

19

18

17

HSG2

LSG2

PGND2

CSP2

CSN2

FB

CS2

PDRV

Figure 2. Pinout

www.onsemi.com

2

Page 3

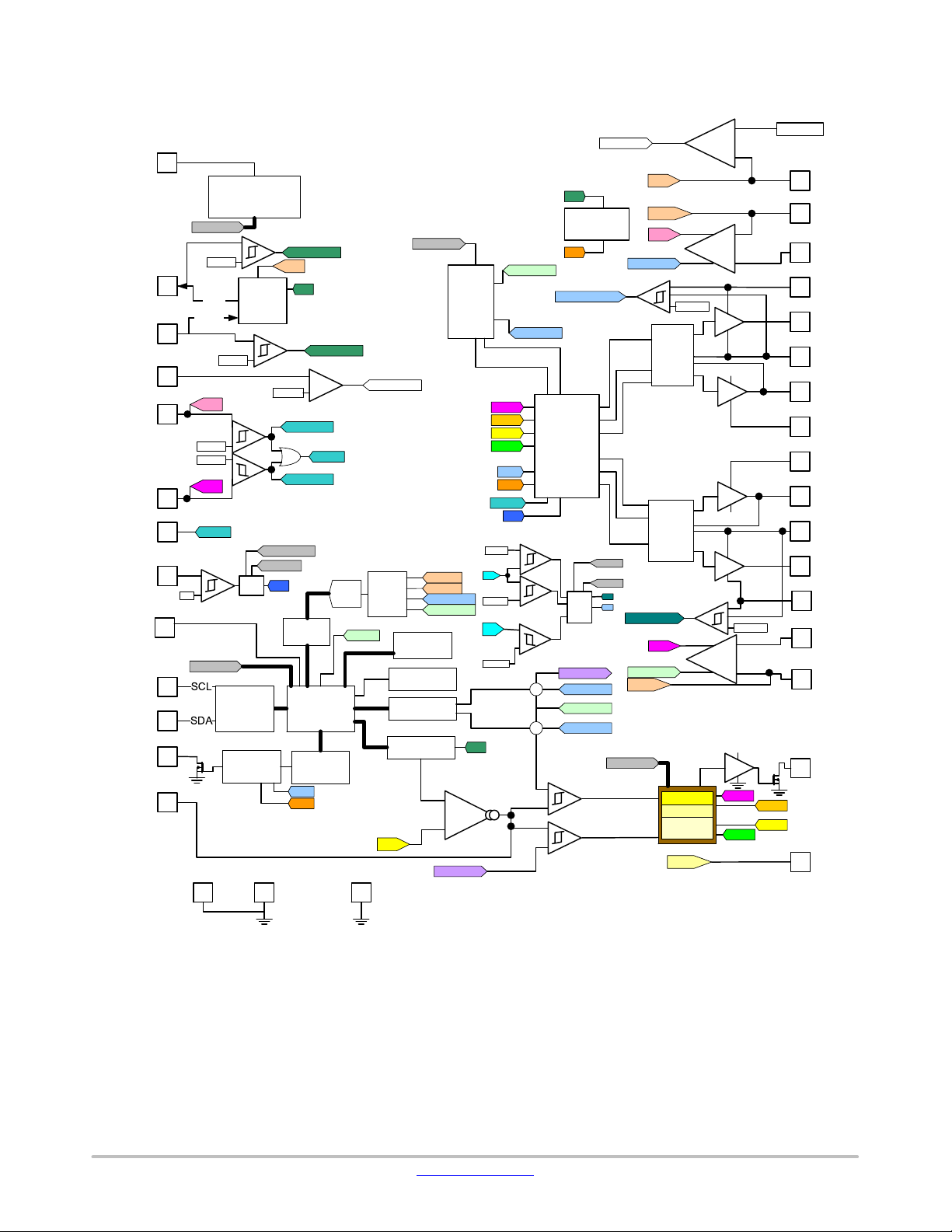

NCV81599, NCP81599

ADDR

VCC

VDRV

V2

CS1

CS2

CLIND

EN

VCCD

SDA

SCL

INT

COMP

CONFIG

VDRV

CS1

CLIMP1

CLIMP2

CS2

CLIND

0.8V

CONFIG

4.0V

VCC

−

+

I2C ADDR

SETTING

4.0V

+

−

−

+

I2C

Interface

Interface

AGND

+

−

Startup

INPUT

UVLO

+

−

EN_MASK

EN_INT

EN

LOGIC

INT

Vcc_rdy

V1

BG

OV2_th

CLINDP1

CLINDP2

EN

Value

Register

Configuration

Registers

PG

TS

VDRV_rdy

+

−

CLIND

ADC

Digital

Status

THPAD

PDRV

V2_OVLO

Analog

Mux

Registers

Master OSC

Oscillator

Reference

VFB

CONFIG

FB

V1

CS1

CS2

Limit

0_Ramp

OCP

logic

VFB

PG_High

VFB

Ramp_0

Ramp_180

BG

Error OTA

500μS/100μS

+

_

SW1

SW2

SW3

SW4

PG

TS

CLIND

PG_Low

OV_REF

CS2_INT

CS1_INT

EN

−

+

−

+

+

−

∑

∑

BG

Shutdown

TS

Boot1 _UVLO

Control

Logic

LOGIC

0_Ramp

CS1_INT

CS2_INT

CS1_INT

180_Ramp

−

+

−

+

v1_OVLO

Thermal

OV_MSK

PG_MSK

OV

PG/

OV/

PG

CONFIG

V1

CSP1

CS1

CS1_INT

Logic_1

Drive

Logic_2

Boot2 _UVLO

CS2

CS2_INT

CSN2

+

Boot1V

NOL

Drive

NOL

Buck Logic

Boost Logic

Buck Boost

Logic

VFB

+

VDRV

VDRV

+

VDRV

SW1

SW4

_

OV1_th

V1

CSP1

+

_

CSN1

BST1

HSG1

VSW1

LSG1

PGND1

PGND2

LSG2

VSW2

HSG2

BST2

Boot2 V

+

_

CSP2

CSN2

PDRV

SW2

SW3

FB

Figure 3. Block Diagram

www.onsemi.com

3

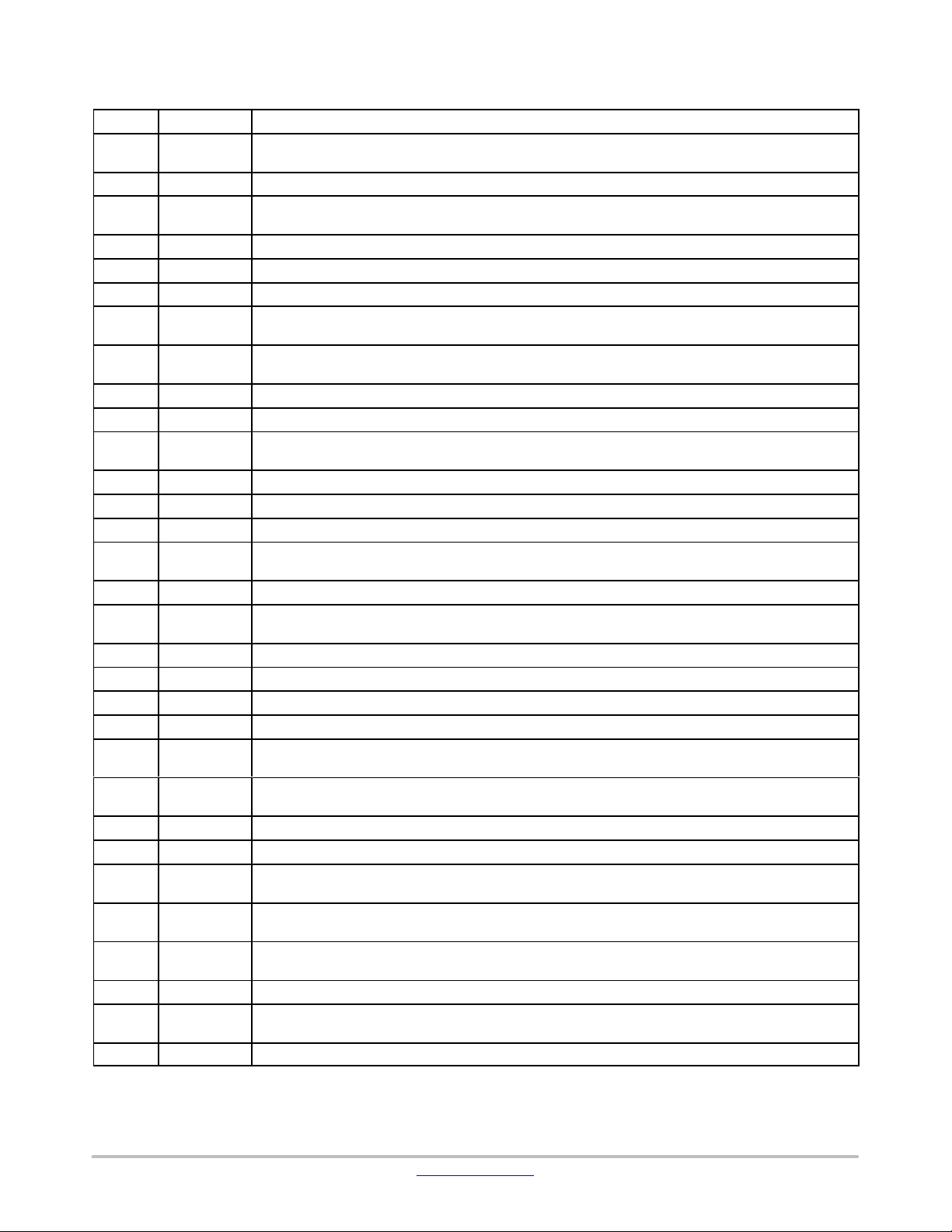

Page 4

NCV81599, NCP81599

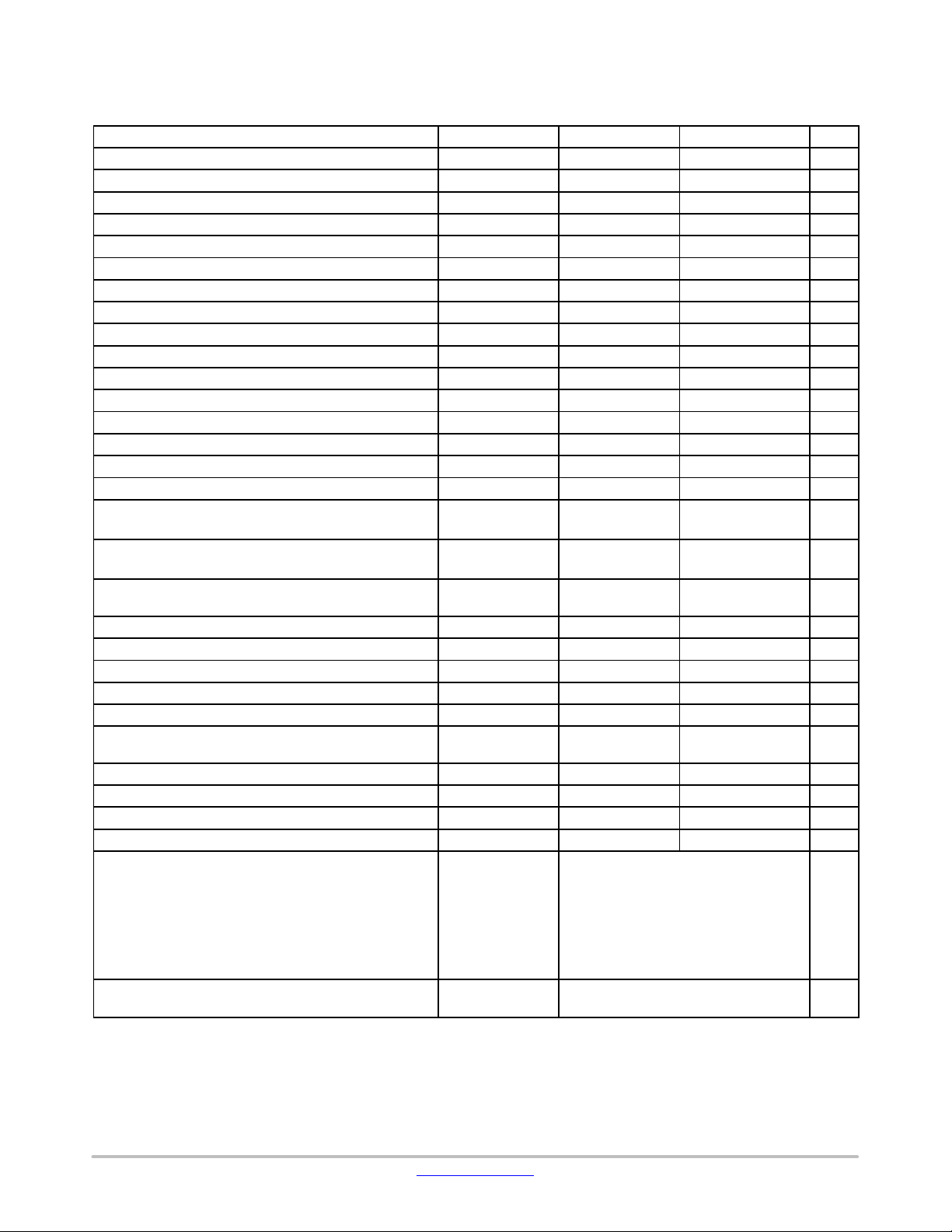

Table 1. PIN FUNCTION DESCRIPTION

Pin Pin Name Description

1 HSG1 S1 gate drive. Drives the S1 N−channel MOSFET with a voltage equal to VDRV superimposed on the switch

2 LSG1 Drives the gate of the S2 N−channel MOSFET between ground and VDRV.

3, 22 PGND Power ground for the low side MOSFET drivers. Connect these pins closely to the source of the bottom

4 CSN1 Negative terminal of the current sense amplifier.

5 CSP1 Positive terminal of the current sense amplifier.

6 V1 Input voltage of the converter

7 CS1 Current sense amplifier output. CS1 will source a current that is proportional to the voltage across RS1 to an

8 CLIND Open drain output, high voltage on CLIND pin indicates that the CS1 or CS2 voltage has exceeded the I2C

9 SDA I2C interface data line.

10 SCL I2C interface clock line.

11 INT Interrupt is an open drain output that indicates the state of the output power, the internal thermal trip, and oth-

12 ADDR

13−14 AGND The ground pin for the analog circuitry.

15 COMP Output of the transconductance amplifier used for stability in closed loop operation.

16 EN Logic high enables the switching and logic low shuts down and reset the device. Middle level makes the de-

17 PDRV The open drain output used to control a PMOSFET.

18 CS2 Current sense amplifier output. CS2 will source a current that is proportional to the voltage across RS2 to an

19 FB Feedback voltage of the output, negative terminal of the gm amplifier.

20 CSN2 Negative terminal of the current sense amplifier.

21 CSP2 Positive terminal of the current sense amplifier.

23 LSG2 Drives the gate of the S3 N−channel MOSFET between ground and VDRV.

24 HSG2 S4 gate drive. Drives the S4 N−channel MOSFET with a voltage equal to VDRV superimposed on the switch

25 BST2 Bootstrapped Driver Supply. The BST2 pin swings from a forward voltage drop below VDRV up to a forward

26 VSW2 Switch Node. VSW2 pin swings from a diode voltage drop below ground up to output voltage.

27 V2 Output voltage of the converter. Connect to the output externally for OVLO sense.

28 VCCD

29 VDRV

30 VCC The VCC pin supplies power to the internal circuitry. The VCC is the output of a linear regulator which is pow-

31 VSW1 Switch Node. VSW1 pin swings from a diode voltage drop below ground up to V1.

32 BST1 Bootstrapped Driver Supply. The BST1 pin swings from a forward voltage drop below VDRV up to a forward

33 THPAD Center Thermal Pad. Connect to AGND externally.

node voltage VSW1.

N−channel MOSFETs.

external resistor. CS1 voltage can be monitored with a high impedance input. Ground this pin if not used.

programmed limit.

2

er I

C programmable functions.

I2C address pin, placing a less than 200 kW resistor to the ground to set the I2C address.

vice to stop switching and keep the VCC alive.

external resistor. CS2 voltage can be monitored with a high impedance input. Ground this pin if not used.

node voltage VSW2.

voltage drop below VOUT + VDRV. Place a 0.1 mF capacitor from this pin to VSW2.

Internal digital power supply input. Always connect VCCD to VCC. A 1 mF capacitor should be placed close to

the part to decouple this line.

Internal voltage supply to the driver circuits. A 1 mF capacitor should be placed close to the part to decouple

this line.

ered from V1. Pin should be decoupled with a 1 mF capacitor for stable operation.

voltage drop below V1 + VDRV. Place a 0.1 mF capacitor from this pin to VSW1.

www.onsemi.com

4

Page 5

NCV81599, NCP81599

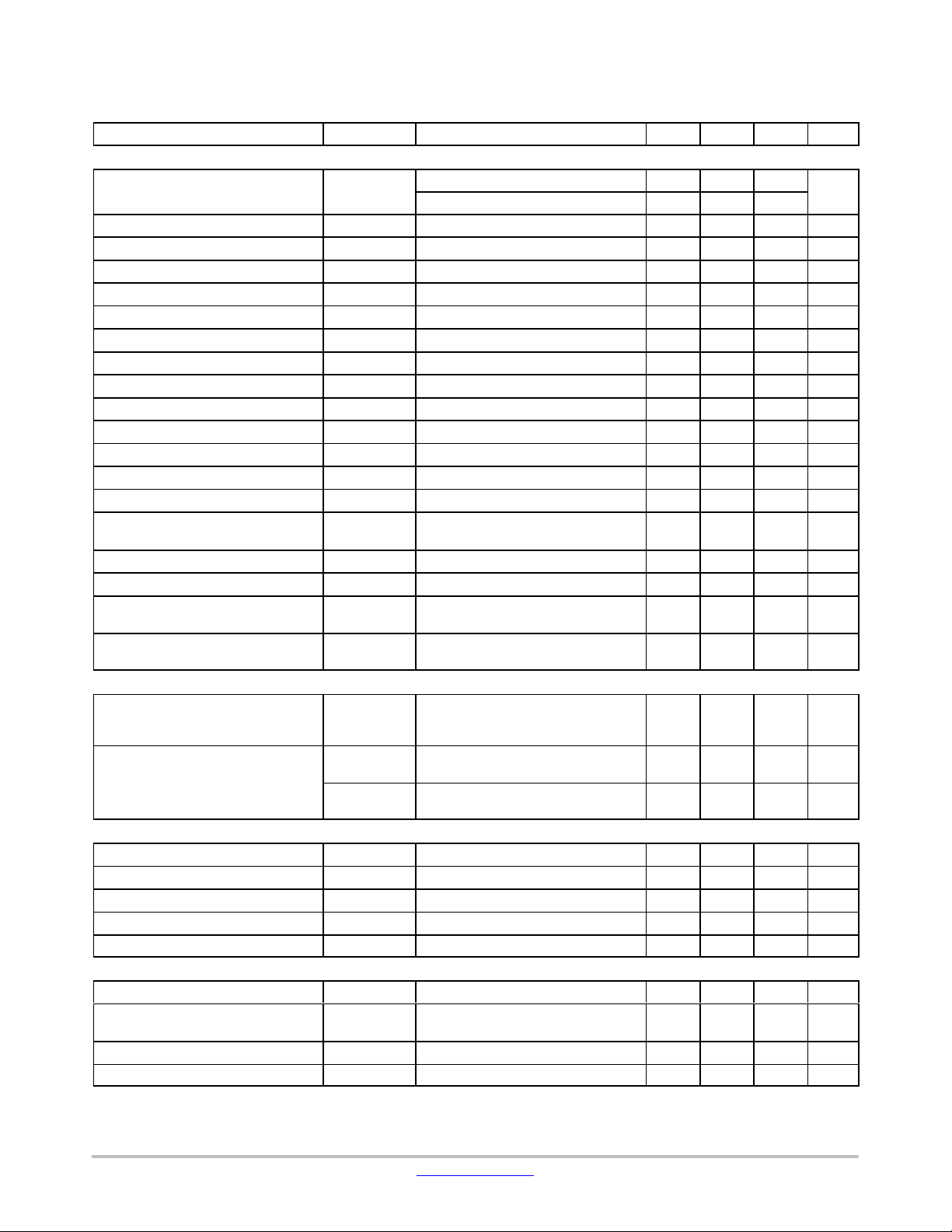

Table 2. MAXIMUM RATINGS

Over operating free−air temperature range unless otherwise noted

Rating

VCCD Input Voltage VCCD −0.3 5.5 V

Address Pin Output Voltage ADDR −0.3 5.5 V

Driver Input Voltage VDRV −0.3 5.5 V

Internal Regulator Output VCC −0.3 5.5 V

Output of Current Sense Amplifiers CS1, CS2 −0.3 5.5 V

Current Limit Indicator CLIND −0.3 VCC + 0.3 V

Interrupt Indicator INT −0.3 VCC + 0.3 V

Enable Input EN −0.3 5.5 V

I2C Communication Lines SDA, SCL −0.3 VCC + 0.3 V

Compensation Output COMP −0.3 VCC + 0.3 V

V1 Power Stage Input Voltage V1 −0.3 35 V, 40 V (20 ns) V

Positive Current Sense CSP1 −0.3 35 V, 40 V (20 ns) V

Negative Current Sense CSN1 −0.3 35 V, 40 V (20 ns) V

Positive Current Sense CSP2 −0.3 35 V, 40 V (20 ns) V

Negative Current Sense CSN2 −0.3 35 V, 40 V (20 ns) V

Feedback Voltage FB −0.3 5.5 V

Driver 1 and Driver 2 Positive Rails BST1,

High Side Driver 1 and Driver 2 HSG1,

Switching Nodes and Return Path of Driver 1 and Driver 2 VSW1, VSW2 −2.0 V,

Low Side Driver 1 and Driver 2 LSG1, LSG2 −0.3 V 5.5 V

PMOSFET Driver PDRV −0.3 35 V, 40 V (20 ns) V

Voltage Differential AGND to PGND −0.3 0.3 V

CSP1−CSN1, CSP2−CSN2 Differential Voltage CS1DIF, CS2DIF −0.5 0.5 V

PDRV Maximum Current PDRVI 0 10 mA

PDRV Maximum Pulse Current

(100 ms on time, with > 1 s interval)

Maximum VCC Current VCCI 0 mA

Operating Junction Temperature Range (Note 1) TJ −40 150 °C

Operating Ambient Temperature Range TA −40 125 °C

Storage Temperature Range TSTG −55 150 °C

Thermal Characteristics (Note 2)

QFN 32 5mm x 5mm

Maximum Power Dissipation @ TA = 25°C

Maximum Power Dissipation @ TA = 85°C

Thermal Resistance Junction−to−Air with Solder

Thermal Resistance Junction−to−Case Top with Solder

Thermal Resistance Junction−to−Case Bottom with Solder

Lead Temperature Soldering (10 sec):

Reflow (SMD styles only) Pb−Free (Note 3)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. The maximum package power dissipation limit must not be exceeded.

2. The value of QJA is measured with the device mounted on a 3in x 3in, 4 layer, 0.062 inch FR−4 board with 1.5 oz. copper on the top and

bottom layers and 0.5 ounce copper on the inner layers, in a still air environment with T

3. 60−180 seconds minimum above 237°C.

Symbol Min Max Unit

−0.3 V wrt/PGND

BST2

HSG2

PDRVIPUL 0 200 mA

PD

PD

RQJA

RQJCT

RQJCB

RF 260 Peak °C

−0.3 V wrt/VSW

−0.3 V wrt/PGND

−0.3 V wrt/VSW

−5 V (100 ns)

4.1

2.1

30

1.7

2.0

A = 25°C.

40 V

5.5 V wrt/VSW

40 V

5.5 V wrt/VSW

35 V, 40 V (20 ns) V

°C/W

°C/W

°C/W

V

V

W

W

www.onsemi.com

5

Page 6

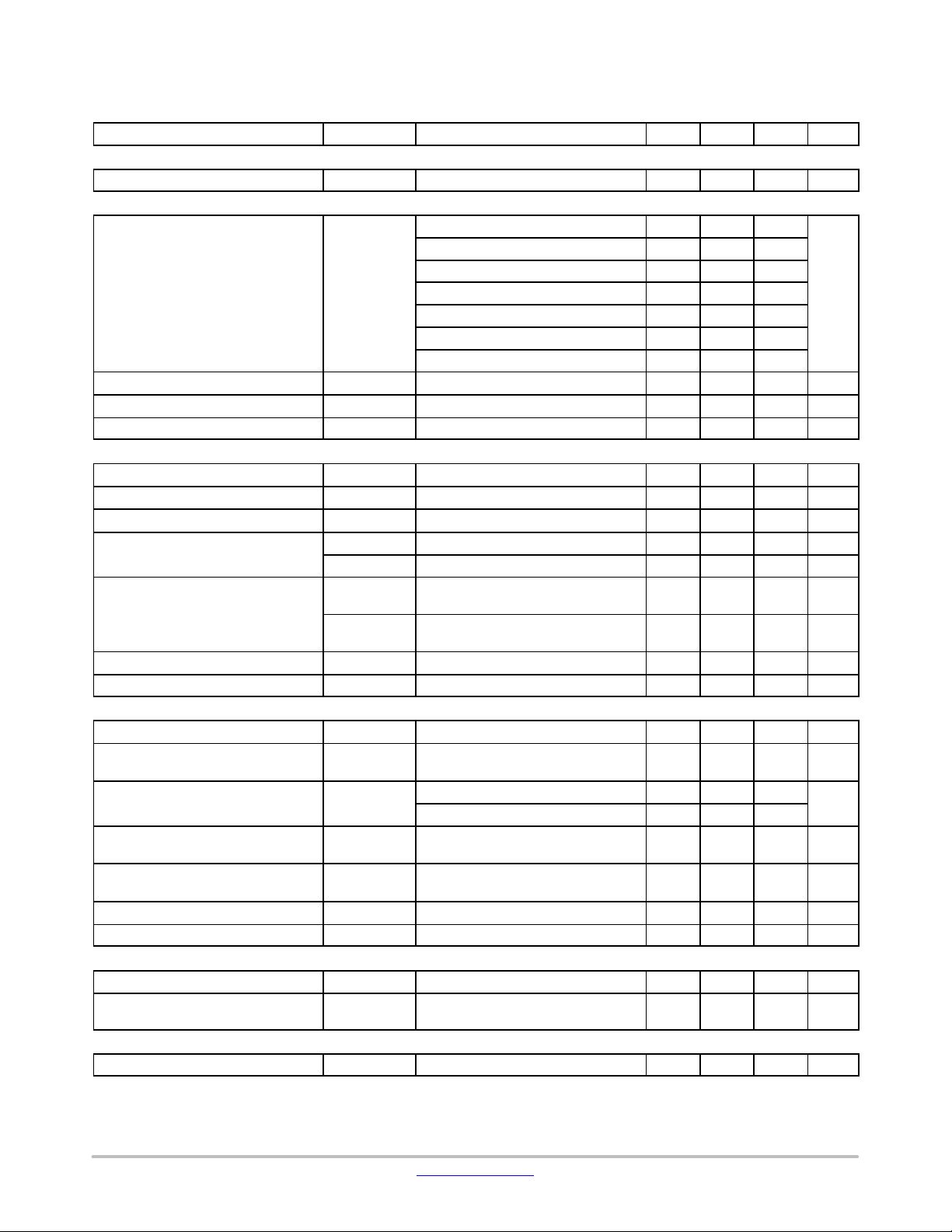

NCV81599, NCP81599

Table 3. ELECTRICAL CHARACTERISTICS

= 12 V, V

(V1

= 5 V , T

out

Parameter

POWER SUPPLY

V1 Operating Input Voltage V1

VDRV Operating Input Voltage VDRV 4.5 5 5.5 V

VCCD Operating Input Voltage VCCD 4.5 5.5 V

VCC UVLO Rising Threshold VCC

VCC UVLO Falling Threshold VCC

UVLO Hysteresis for VCC VCCV

VDRV UVLO Rising Threshold VDRV

VDRV UVLO Falling Threshold VDRV

VDRV UVLO Hysteresis VDRV

VCC Output Voltage VCC With no external load 4.5 5 V

VCC Drop Out Voltage VCCDROOP 30 mA load 100 mV

VCC Output Current Limit IOUT

VCC Short Current Limit IVCC_SHORT VCC short 14.6 mA

V1 Shutdown Supply Current IVCC_SD EN < 0.4 V, V1 = 12 V 8.0 15

V1 Normal Current IV1 0.8 V < EN < 1.88 V, 4.5 V ≤ V1 ≤

VCCD Standby Current IVCCD 0.8 V < EN < 1.88 V 4 mA

VCCD Switching Current IVCCD_SW EN > 2.2 V 4.1 mA

VDRIVE Switching Current Buck IV1_SW EN = 5 V, Cgate = 2.2 nF,

VDRIVE Switching Current Boost IV1_SW EN = 5 V, Cgate = 2.2 nF,

VOLTAGE OUTPUT

Voltage Output Accuracy

Voltage Accuracy Over Temperature

TRANSCONDUCTANCE AMPLIFIER

Gain Bandwidth Product

Transconductance GM1 Default 500

Max Output Source Current limit GMSOC 60 80

Max Output Sink Current limit GMSIC 60 80

Voltage Ramp Vramp 1.2 V

INTERNAL BST SWITCH

Pass FET Rds(on)

Reverse Leakage Current from BST

pin to VDRV pin

BST−VSW UVLO BST

BST−VSW UVLO BST

4. Ensured by design. Not production tested.

5. Typical value only. Not production tested.

= +25°C for typical value; −40°C < T

A

Symbol Test Conditions Min Typ Max Units

RISE

FALL

HYS

RISE

FALL

HYS

VCC

FB DAC_TARGET = 00110010

VOUTERT VFB ≥ 0.5 V

VOUTER T

GBW (Note 4) 5.2 MHz

RBST IF = 1 mA 60

DIL BST = 32 V, T

_UVLO

_UVLO

= TJ < 125°C for min/max values unless noted otherwise)

A

NCV81599 4.5 32

NCP81599 4.5 28

4.21 4.27 4.35 V

3.90 3.96 4.06 V

Falling Hysteresis 300 mV

4.21 4.31 4.35 V

3.90 4.01 4.06 V

300 mV

VCC Loaded to 4.3 V, EN > 0.8 V 80 97 mA

mA

7.3 mA

32 V, (No Switching)

16 mA

VSW = 0 V, FSW = 600 kHz

15 mA

VSW = 0 V, FSW = 600 kHz

DAC_TARGET = 01111000

DAC_TARGET = 11001000

1.188

1.98

−1.0

0.495

VFB < 0.5 V

= 25°C

A

VFB ≥ 0.5 V −0.45 0.45

−5

0.5

1.2

2.0

0.505

1.212

2.02

1.0

5

mV

mS

mA

mA

= 25°C 0.05 1

A

mA

Falling 3.2 3.5 3.8 V

Rising 3.4 3.7 4.1 V

V

V

%

%

W

www.onsemi.com

6

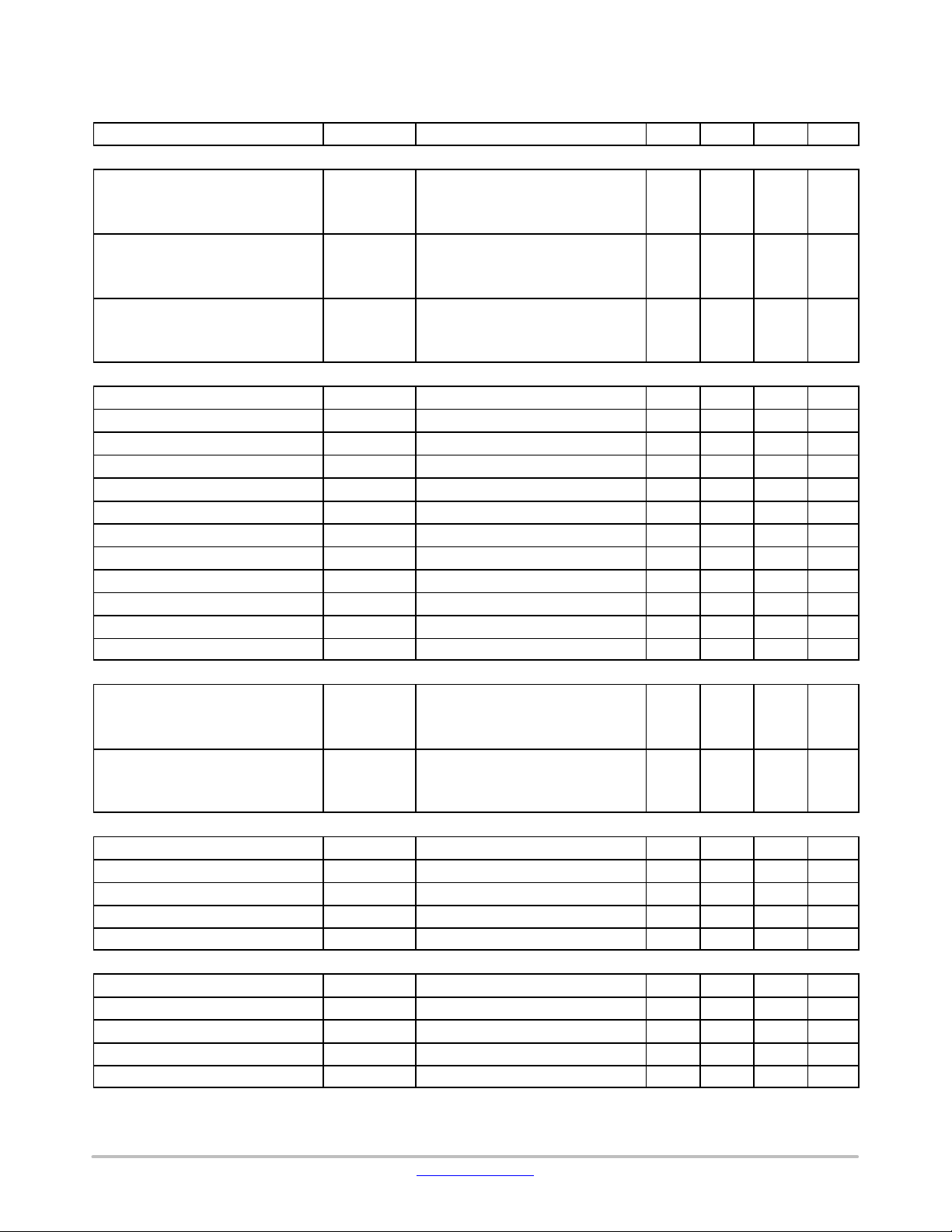

Page 7

NCV81599, NCP81599

Table 3. ELECTRICAL CHARACTERISTICS (continued)

= 12 V, V

(V1

= 5 V , T

out

Parameter UnitsMaxTypMinTest ConditionsSymbol

INTERNAL BST SWITCH

BST−VSW Hysteresis

OSCILLATOR

Oscillator Frequency

Oscillator Frequency Accuracy FSWE −12 12 %

Minimum On Time MOT Measured at 10% to 90% of VCC (Note 4) 100 ns

Minimum Off Time MOFT Measured at 90% to 10% of VCC (Note 4) 100 ns

INT THRESHOLDS

Interrupt Low Voltage

Interrupt High Leakage Current INII 5 V 3 100 nA

Interrupt Startup Delay INTPG Soft Start end to PG positive edge 2.1 ms

Interrupt Propagation Delay

Power Good Threshold

FB Overvoltage Threshold FB_OV 115 %

Overvoltage Propagation Delay VFB_OVDL 1 Cycle

EXTERNAL CURRENT SENSE (CS1,CS2)

Positive Current Measurement High

Transconductance Gain Factor CSGT Current Sense Transconductance

Transconductance Deviation CSGE

Input Current Sense Common Mode

Range

Output Current Sense Common Mode

Range

Input Sense Voltage Full Scale ISVFS (Note 4) 100 mV

CS Output Voltage Range CSOR VSENSE = 100 mV Rset = 6k (Note 4) 0 3 V

EXTERNAL CURRENT LIMIT (CLIND)

Current Limit Indicator Output Low

Current Limit Indicator Output High

Leakage Current

INTERNAL CURRENT SENSE

Internal Current Sense Gain for PWM

4. Ensured by design. Not production tested.

5. Typical value only. Not production tested.

= +25°C for typical value; −40°C < T

A

BST

_HYS

FSW_0

VINTI IINT(sink) = 2 mA 0.2 V

PGI Delay for power good in 3.3 ms

PGO Delay for power good out 100 ns

PGTH Power Good in from falling

PGTH Power Good out from rising

CS10 CSP1−CSN1 or CSP2−CSN2 = 25 mV 125

CSCMMR_I CSP1 is tied to V1 4.5 32 V

CSCMMR_O 4 25.5 V

CLINDL

ICLINDH Pull up to 5 V 65 100 nA

ICG CSPx−CSNx = 25 mV 9.4 10 10.5 V/V

= TJ < 125°C for min/max values unless noted otherwise)

A

(Note 4) 200 mV

FSW = 001 (Note 5) 150

FSW = 000, default 552 600 648

FSW = 010 300

FSW = 011 450

FSW = 100 740

FSW = 101 880

FSW = 110 1145

104

Power Good out from falling

93

106

Power Good in from rising

95

5 mS

Vsense = 10 mV to 100 mV

CSPx−CSNx = 10 mV −30 30

CSPx−CSNx = 25 mV to 100 mV −20 20

Input current = 500 mA

7.0 100 mV

kHz

%

%

mA

%

www.onsemi.com

7

Page 8

NCV81599, NCP81599

Table 3. ELECTRICAL CHARACTERISTICS (continued)

= 12 V, V

(V1

= 5 V , T

out

Parameter UnitsMaxTypMinTest ConditionsSymbol

INTERNAL CURRENT SENSE

Positive Peak Current Limit Trip

Positive Peak Current Limit Latch−off OCP_L CLIP = 00 (default)

Negative Valley Current Limit Trip NVCLT CLIN = 00 (default)

SWITCHING MOSFET DRIVERS

HSG1 Pullup Resistance

HSG1 Pulldown Resistance HSG1_PD BST−VSW = 5 V 0.8

LSG1 Pullup Resistance LSG1_PU LSG −PGND = 5 V 2.4

LSG1 Pulldown Resistance LSG1_PD LSG −PGND = 5 V 0.7

HSG2 Pullup Resistance HSG2_PU BST−VSW = 5 V 2.7

HSG2 Pulldown Resistance HSG2_PD BST−VSW = 5 V 0.9

LSG2 Pullup Resistance LSG2_PU LSG −PGND = 5 V 2.0

LSG2 Pulldown Resistance LSG2_PD LSG −PGND = 5 V 0.7

HSG1 Falling to LSG1 Rising Delay HSLSD1 16 ns

LSG1 Falling to HSG1 Rising Delay LSHSD1 36 ns

HSG2 Falling to LSG2 Rising Delay HSLSD2 35 ns

LSG2 Falling to HSG2 Rising Delay LSHSD2 56 ns

SLEW RATE/SOFT START

Charge Slew Rate

(VOUT measured at V2 pin)

Discharge Slew Rate

(VOUT measured at V2 pin)

ENABLE

EN LDO High Threshold Voltage

EN LDO Low Threshold Voltage ENLDOLT 530 570 mV

EN Switching High Threshold Voltage ENHT 2.15 V

EN Switching Low Threshold Voltage ENLT 1.65 1.87 V

EN Pull Up Current (Default on) IEN_UP EN = 0.8 V 3.0

ADDR

Internal Current Source

ADDR0 ADDR = 74 H 110 mV

ADDR1 ADDR = 75 H 220 260 300 mV

ADDR2 ADDR = 76 H 380 440 500 mV

ADDR3 ADDR = 77 H 600 715 830 mV

4. Ensured by design. Not production tested.

5. Typical value only. Not production tested.

= +25°C for typical value; −40°C < T

A

PPCLT CLIP = 00 (default)

HSG1_PU BST−VSW = 5 V 2

SLEWP Slew = 00, FB = 0.1 VOUT

SLEWN Slew = 00, FB = 0.1 VOUT

ENLDOHT 770 810 mV

IADDR 9 10 11

= TJ < 125°C for min/max values unless noted otherwise)

A

34 39

CLIP = 01

CLIP = 10

CLIP = 11

CLIP = 01

CLIP = 10

CLIP = 11

34 40

CLIN = 01

CLIN = 10

CLIN = 11

Slew = 01, FB = 0.1 VOUT

Slew = 10, FB = 0.1 VOUT

Slew = 11, FB = 0.1 VOUT

Slew = 01, FB = 0.1 VOUT

Slew = 10, FB = 0.1 VOUT

Slew = 11, FB = 0.1 VOUT

23

44 mV

11

70

70

39

23

106

45 mV

25

15

0

0.6

1.2

2.4

4.8

−0.6

−1.2

−2.4

−4.8

mV

W

W

W

W

W

W

W

W

mV/ms

mV/ms

mA

mA

www.onsemi.com

8

Page 9

NCV81599, NCP81599

Table 3. ELECTRICAL CHARACTERISTICS (continued)

= 12 V, V

(V1

= 5 V , T

out

Parameter UnitsMaxTypMinTest ConditionsSymbol

I2C INTERFACE

Voltage Threshold Rising

Voltage Threshold Falling I2CVTH_F 0.9 V

Communication Speed I2CSP 1 MHz

THERMAL SHUTDOWN

Thermal Shutdown Threshold

Thermal Shutdown Hysteresis TSDHYS (Note 4) 28 °C

PDRV

PDRV Operating Range

PDRV Leakage Current PDRV_IDS FET OFF, VPDRV = 32 V 180 nA

PDRV Drain−Source Voltage PDRV_VDS ISNK = 10 mA 0.20 V

INTERNAL ADC

Range

LSB Value ADCLSB (Note 4) 20 mV

Error ADCFE (Note 4) 1 LSB

INPUT OVLO

Input OVLO Rising Threshold

Input OVLO Falling Threshold V

Input OVLO Debounce Time (Note 4) 2

Input OVLO Recover Debounce Time (Note 4) 1 ms

OUTPUT OVLO

Output OVLO Threshold

(Register 06h, bit [5:4])

Output OVLO Debounce Time (Note 4) 1

4. Ensured by design. Not production tested.

5. Typical value only. Not production tested.

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

= +25°C for typical value; −40°C < T

A

I2CVTH_R 1.2 V

TSD (Note 4) 151 °C

ADCRN (Note 4) 0 2.55 V

V

OVLOIN_R

OVLOIN_F

V

OVLO_O

= TJ < 125°C for min/max values unless noted otherwise)

A

0 32 V

sel_v2th = 00

sel_v2th = 01

sel_v2th = 10 (Default)

sel_v2th = 11

34 V

28.5 V

15

22.5

30

36

ms

V

ms

www.onsemi.com

9

Page 10

NCV81599, NCP81599

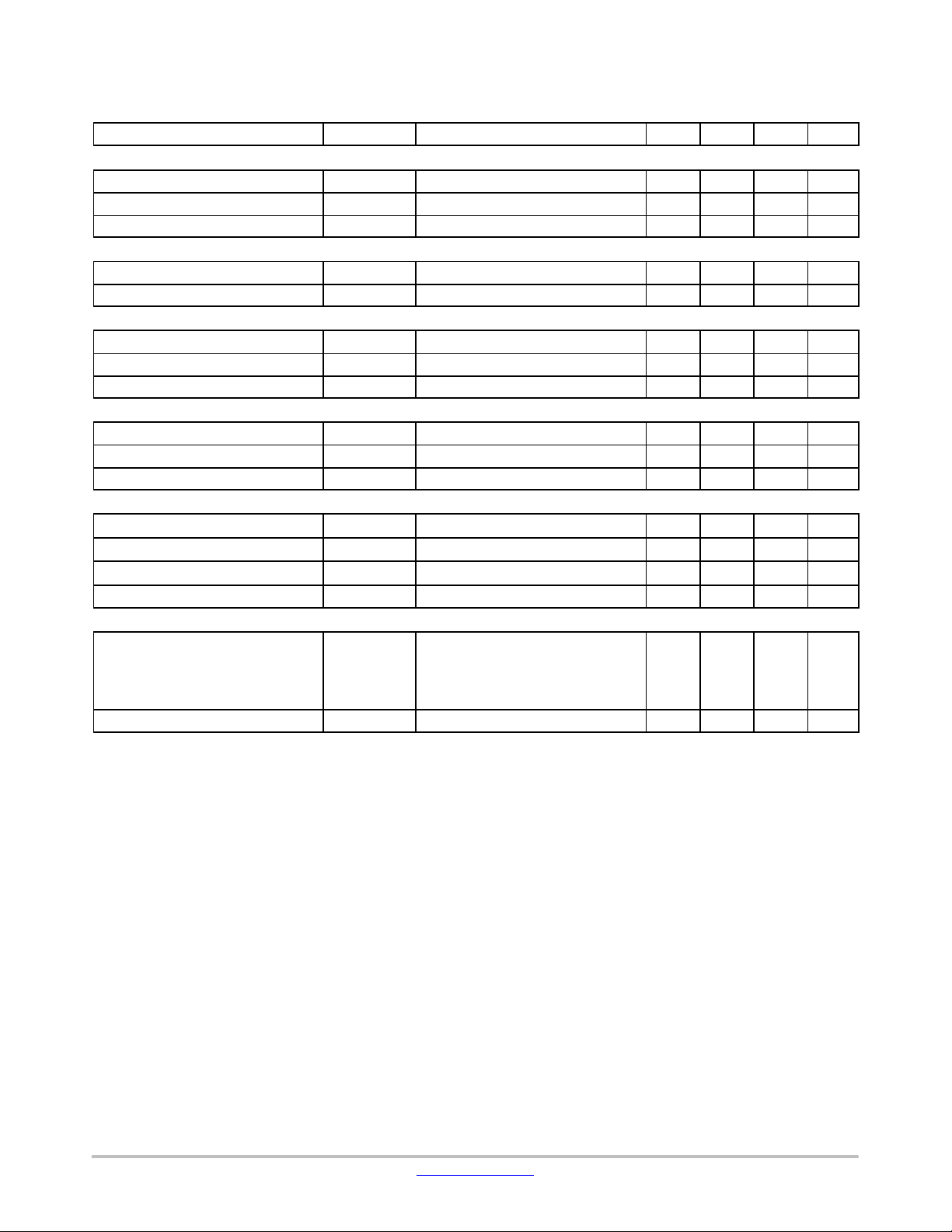

TYPICAL CHARACTERISTICS

Figure 1. Switching Frequency vs.

Temperature

Figure 3. VCC Load Regulation Figure 4. VCC Line Regulation (20 mA Load)

Figure 2. VCC vs. Temperature

Figure 5. Shutdown Supply Current vs.

Temperature

Figure 6. V1 Normal Current vs. Temperature

www.onsemi.com

10

Page 11

NCV81599, NCP81599

TYPICAL CHARACTERISTICS

6

5.5

5

4.5

4

3.5

VCCD Current (mA)

3

2.5

2

−50 0 50 100 150

Ambient Temperature (

C)°

Figure 7. VCCD Current vs. Temperature,

VCCD = 5.0 V

Figure 9. VDRIVE Switching Current Buck vs.

Temperature

Figure 8. ENABLE Rising Threshold vs.

Temperature

Figure 10. VDRIVE Switching Current Boost

vs. Temperature

Figure 11. Voltage Accuracy vs. Temperature

(FB Setting > 500 mV)

www.onsemi.com

Figure 12. Voltage Accuracy vs. Temperature

11

Page 12

NCV81599, NCP81599

TYPICAL CHARACTERISTICS

Figure 13. Voltage Ramp Up

(slew rate = 0.6 V/ms)

Figure 15. Voltage Ramp Up

(slew rate = 4.8 V/ms)

Figure 14. Voltage Ramp Down

(slew rate = 0.6 V/ms)

Figure 16. Voltage Ramp Down

(slew rate = 4.8 V/ms)

www.onsemi.com

12

Page 13

Vout

NCV81599, NCP81599

TYPICAL CHARACTERISTICS

Vout

Load current (2A/div)

Vin=24V, Vout=5V, Load=0.3A to 3A

Vin=24V, Vout=5V, Load=0.5A to 5A

Load current (2A/div)

Figure 17. 5 V Load Step Figure 18. 20 V Load Step

Figure 19. OCP Cycle−by−Cycle Waveform Figure 20. OCP Hiccup Waveform

Figure 21. OVP Waveform Figure 22. V2 Secondary OVP Waveform

www.onsemi.com

13

Page 14

NCV81599, NCP81599

TYPICAL CHARACTERISTICS

EN

Vsw2

Vsw1

Vout

Vin=12V, Vout=20V Vin=12V, Vout=20V

Figure 23. Shutdown by EN

Vout gradually walks down, after EN pin goes

Vout is discharged by load current, after EN pin

down from high (5V) to middle (1V)

Vsw1

Figure 24. Shutdown by EN

does down from high (5V) to low (0V)

EN

Vsw2

Vout

Figure 25. Efficiency vs. Load (MOSFET part number is NTMFS4C10N)

www.onsemi.com

14

Page 15

NCV81599, NCP81599

APPLICATION INFORMATION

Dual Edge Current Mode Control

When dual edge current mode control is used, two voltage

ramps are generated that are 180 degrees out of phase. The

inductor current signal is added to the ramps to incorporate

current mode control. In Figure 26, the COMP signal from

the compensation output interacts with two triangle ramps

to generate gate signals to the switches from S1 to S4. Two

ramp signals cross twice at midpoint within a cycle. When

COMP is above the midpoint, the system will operate at

Ramp1+i_sense

comp

Ramp2+i_sense

S1

S2

S3

boost mode with S1 always on and S2 always off, but S3 and

S4 turning on alternatively in an active switching mode.

When COMP is below the midpoint, the system will

operation at buck mode, with S4 always on and S3 always

off, but S1 and S2 turning on alternatively in an active

switching mode. The controller can switch between buck

and boost mode smoothly based on the COMP signal from

peak current regulation.

S4

L1S1

V1 V2

S2

Figure 26. Transitions for Dual Edge 4 Switch Buck Boost

S4

S3

www.onsemi.com

15

Page 16

NCV81599, NCP81599

Feedback and Output Voltage Profile

The feedback of the converter output voltage is connected

to the FB pin of the device through a resistor divider.

Internally FB is connected to the inverting input of the

internal transconductance error amplifier. The

non−inverting input of the gm amplifier is connected to the

internal reference. The internal reference voltage is by

default 0.5 V. Therefore a 10:1 resistor divider from the

in default. The reference voltage can be adjusted with

10 mV (default) or 5 mV steps from 0.1 V to 2.55 V through

the voltage profile register (01H), which makes the

continuous output voltage profile possible through an

external resistor divider. For example, by default, if the

external resistor divider has a 10:1 ratio, the output voltage

profile will be able to vary from 1 V to 25.5 V with 100 mV

steps.

converter output to the FB will set the output voltage to 5 V

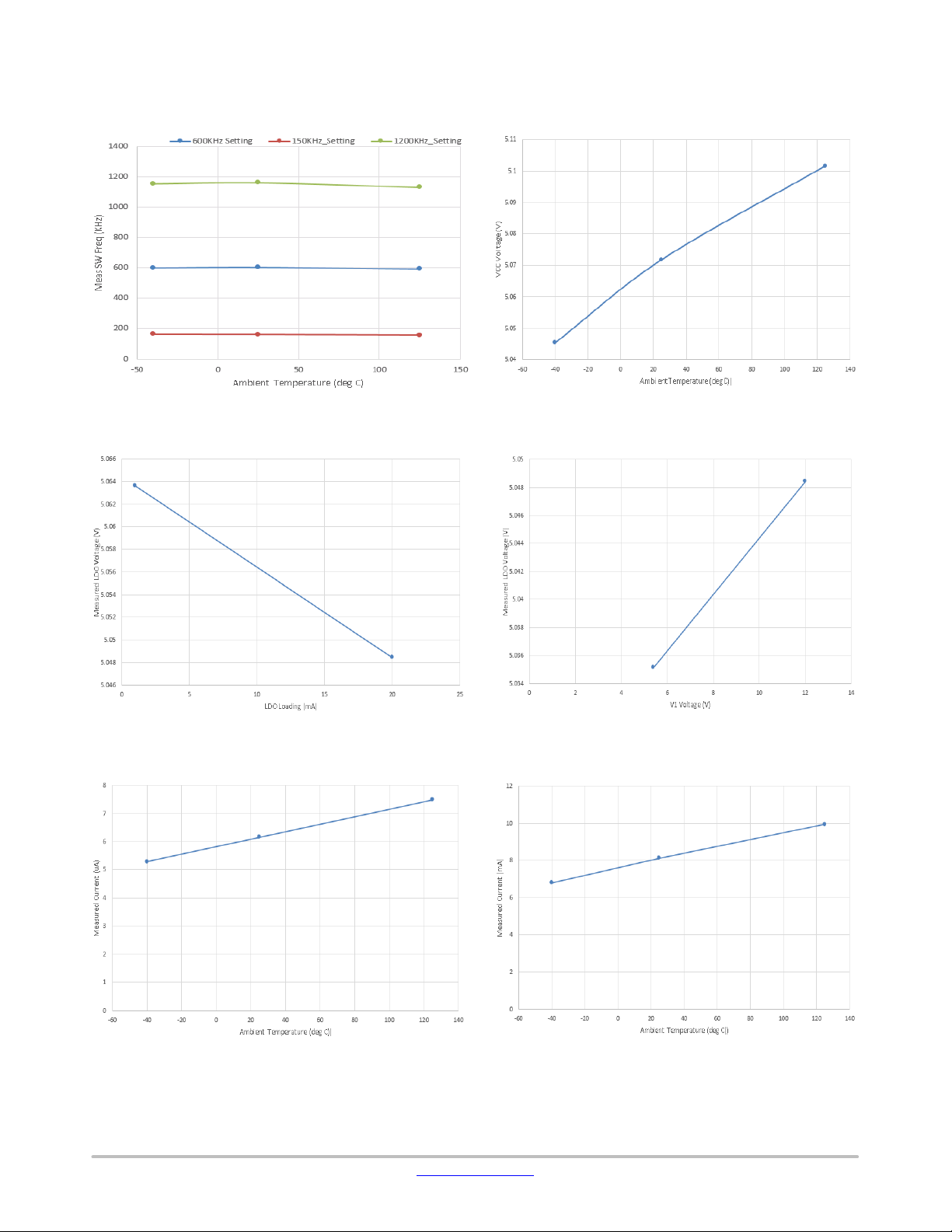

Table 4. VOLTAGE PROFILE REGISTER SETTINGS

dac_target Isb

dac_target (01h)

bit_8 bit_7 bit_6 bit_5 bit_4 bit_3 bit_2 bit_1 bit_0

0 0 0 0 0 0 0 0 00 1 5

… … … … … … … … … … …

0 0 1 0 0 0 0 1 21 0 330

0 0 1 0 0 0 0 1 21 1 335

… … … … … … … … … … …

0 0 1 1 0 0 1 0 32 0 500 (Default)

… … … … … … … … … … …

1 1 0 0 1 0 0 0 C8 0 2000

… … … … … … … … … … …

1 1 1 1 1 1 1 1 FF 0 2550

1 1 1 1 1 1 1 1 FF 1 2555

dac_target (01h)

Hex Value

(03h, bit 4)

Reference DAC

Voltage (mV)

Transconductance Voltage Error Amplifier

To maintain loop stability under a large change in

capacitance, the NCV81599 can change the gm of the

internal transconductance error amplifier from 87 mS to

Table 5. AVAILABLE TRANSCONDUCTANCE SETTING

Address AMP_2 AMP_1 AMP_0

0 0 0 87

0 0 1 100

0 1 0 117

07h, bit [2:0]

Programmable Slew Rate

0 1 1 333

1 0 0 400

1 0 1 500 (default)

1 1 0 667

1 1 1 1000

The slew rate of the NCV81599 is controlled via the I2C

registers with the default slew rate set to 0.6 mV/ms

(FB = 0.1 V2, assume the resistor divider ratio is 10:1)

which is the slowest allowable rate change. The slew rate is

used when the output voltage starts from 0 V to a user

selected profile level, changing from one profile to another,

or when the output voltage is dynamically changed. The

1000 mS allowing the DC gain of the system to be increased

more than a decade triggered by the adding and removal of

the bulk capacitance or in response to another user input.

The default transconductance is 500 mS.

Amplifier GM Value (mS)

output voltage is divided by a factor of the external resistor

divider and connected to FB pin. The 9 Bit DAC is used to

increase the reference voltage in 10 or 5 mV increments. The

slew rate is decreased by using a slower clock that results in

a longer time between voltage steps, and conversely

increases by using a faster clock. The step monotonicity

depends on the bandwidth of the converter where a low

www.onsemi.com

16

Page 17

NCV81599, NCP81599

bandwidth will result in a slower slew rate than the selected

value. The available slew rates are shown in Table 6. The

selected slew rate is maintained unless the current limit is

DAC_TARGET

DAC_TARGET_LSB

V2

FB = 0.1*V2

Figure 27. Slew Rate Limiting Block Diagram and Waveforms

Table 6. SLEW RATE SELECTION

Soft Start or

Voltage Transition

Address Slew Bits

Slew_0

02h, bit [1:0]

Slew_1

Slew_2

Slew_3

(FB = 0.1*V2)

0.6 mV/ms

1.2 mV/ms

2.4 mV/ms

4.8 mV/ms

The discharge slew rate is accomplished in much the same

way as the charging except the reference voltage is

decreased rather than increased. The slew rate is maintained

unless the negative current limit is reached. If the negative

current limit is reached, the output voltage is decreased at the

maximum rate allowed by the current limit (see the negative

current limit section).

Soft−Start and EN Pin

During a 0 V soft−start, standard converters can start in

synchronous mode and have a monotonic rising of output

voltage. If a prebias exists on the output and the converter

starts in synchronous mode, the prebias voltage could be

discharged. The NCV81599 controller ensures that if a

prebias is detected, the soft−start is completed in a

non−synchronous mode to prevent the output from

discharging. During soft−start, the output rising slew rate

will follow the slew rate register with default value set to

0.6 mV/ms (FB = 0.1*V2).

tripped; in which case the increased voltage will be governed

by the positive current limit until the output voltage falls or

the fault is cleared.

V

2.56

9 bit DAC

VREF

+

−

CC

RC

CI

The EN Pin has 2 levels of threshold: the internal LDO and

2

I

C function are powered up when EN pin reaches ~0.8 V;

while the buck−boost conversion starts when EN pin reaches

~2.0 V. The EN pin can NOT work with very slow dv/dt

signals. Please always keep the EN pin input signal faster

than 0.5 V/ms. The EN pin has a pull−up current of ~3 mA,

so that an open EN pin powers up the NCV81599. To keep

the EN pin signal faster enough, please keep total

capacitance on the EN pin below 4.7 nF.

When the EN pin goes from high (above ENHT) down to

middle (below ENLT, but still above ENLDOHT), the

NCV81599 walks down the Vout gradually to zero, in the

discharge slew rate selected by “voltage transition slew rate”

register value, as shown in waveforms in Figure 23. All the

2

I

C register value stays.

When the EN pin goes from high (above ENHT) down to

low (below ENLDOLT), the NCV81599 stops all switching

immediately, and Vout is discharged by load current, as

shown in waveforms in Figure 24. Internal LDO shuts down,

and all I

Frequency Programming

2

C register value resets.

The switching frequency of the NCV81599 can be

programmed from 150 kHz to 1.2 MHz via the I

2

C interface.

The default switching frequency is set to 600 kHz. The

switching frequency can be changed on the fly. However, it

is a good practice to disable the part and then program to a

different frequency to avoid transition glitches at large load

current.

www.onsemi.com

17

Page 18

NCV81599, NCP81599

VCC

Internal Path

CS1 or CS2

Table 7. FREQUENCY PROGRAMMING TABLE

Name Bit Definition Description

Freq1 03H [2:0] Frequency Setting 3 Bits that Control the Switching Frequency from 150 kHz to 1.2 MHz.

000: 600 kHz (default)

001: 150 kHz

010: 300 kHz

011: 450 kHz

100: 750 kHz

101: 900 kHz

110: 1.2 MHz

111: Reserved

Current Sense Amplifiers

Internal precision differential amplifiers measure the

potential between the terminal CSP1 and CSN1 or CSP2 and

CSN2. Current flows from the input V1 to the output in a

buck boost design. Current flowing from V1 through the

switches to the inductor passes through R

external sense resistor, R

, has a significant effect on

SENSE

SENSE

. The

the function of current sensing and limiting systems and

must be chosen with care. First, the power dissipation in the

resistor should be considered. The system load current will

cause both heat and voltage loss in R

. The power loss

SENSE

and voltage drop drive the designer to make the sense

resistor as small as possible while still providing the input

dynamic range required by the measurement. Note that input

dynamic range is the difference between the maximum input

signal and the minimum accurately measured signal, and is

limited primarily by input DC offset of the internal

ILOAD

Rsense

5 mW

CSP1/CSP2

CSN1/CSN2

+

+

−

−

amplifier. In addition, R

V

does not exceed the maximum input voltage

SENSE

must be small enough that

SENSE

100 mV, even under peak load conditions.

The potential difference between CSPx and CSNx is level

shifted from the high voltage domain to the low voltage

VCC domain where the signal is split into two paths.

The first path, or external path, allows the end user to

observe the analog or digital output of the high side current

sense. The external path gain is set by the end user allowing

the designer to control the observable voltage level. The

voltage at CS1 or CS2 can be converted to 7 bits by the ADC

and stored in the internal registers which are accessed

through the I

2

C interface.

The second path, or internal path, has internally set gain

of 10 and allows cycle by cycle precise limiting of positive

and negative peak input current limits.

VCM

CLIND

10x(CSP1-CSN1)

+

−

10X

+

−

CLIP

10x(CSP2-CSN2)

CLIN

+

−

+

−

−

+

CS2 MUX

2

CS1 MUX

2

CS1

Positive Current

+

Limit

−

Negative Current

+

Limit

−

RAMP 1

RAMP 2

ADC

CS2

CS1

C

CS2

C

CS1

R

Figure 28. Block Diagram and Typical Connection for Current Sense

www.onsemi.com

18

R

CS2

Page 19

NCV81599, NCP81599

Positive Current Limit Internal Path

The NCV81599 has a pulse by pulse current limiting

function activated when a positive current limit triggers.

CSP1/CSN1 will be the positive current limit sense channel.

When a positive current limit is triggered, the current

pulse is truncated. In both buck mode and in boost mode the

S1 switch is turned off to limit the energy during an over

current event. The current limit is reset every switching

cycle and waits for the next positive current limit trigger. In

this way, current is limited on a pulse by pulse basis. Pulse

by pulse current limiting is advantageous for limiting energy

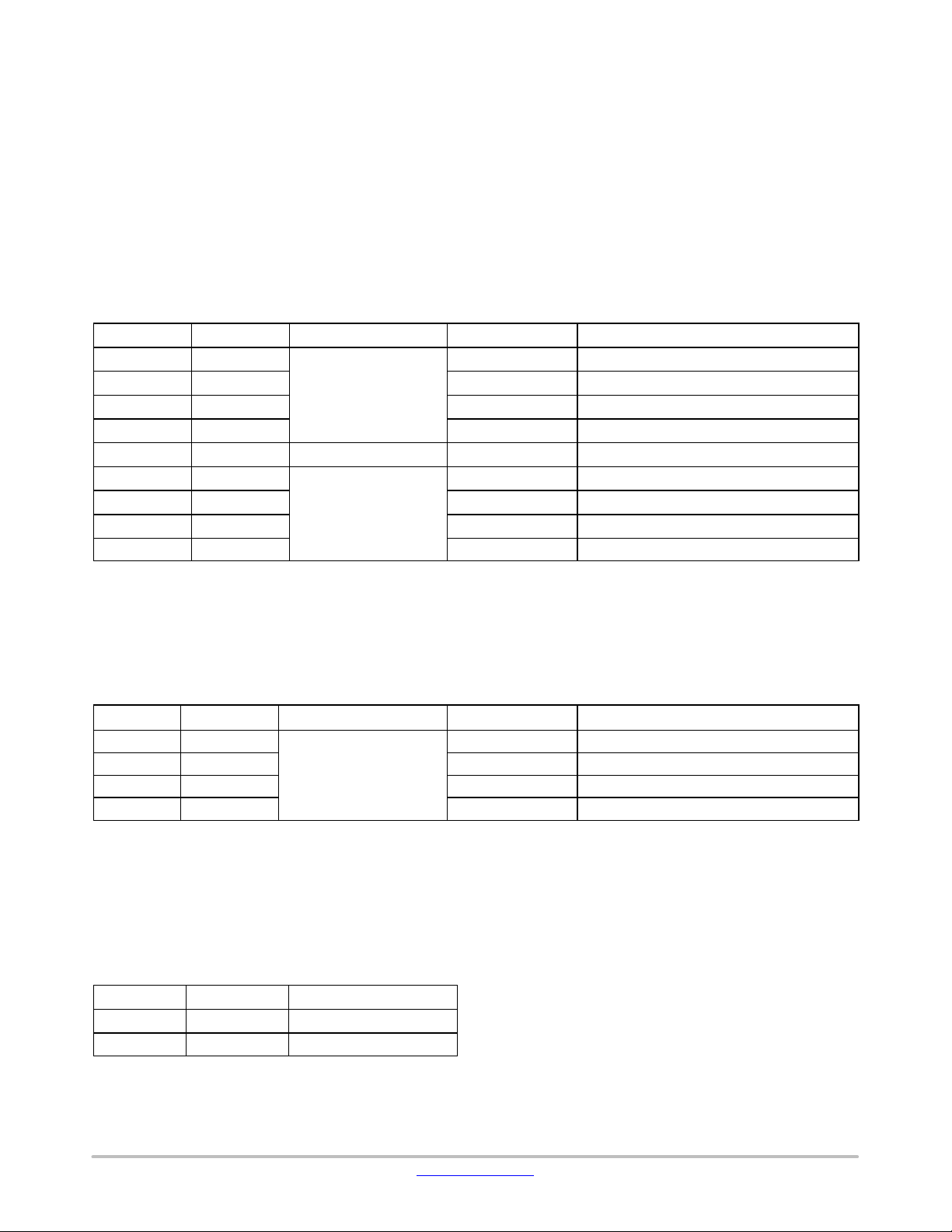

Table 8. INTERNAL PEAK CURRENT LIMIT

CLIN_1 CLIN_0 Address CSP2−CSN2 (mV)

0 0

0 1 −25 −5

1 0 −15 −3

1 1 0 0

CLIP_1 CLIP_0 Address CSP1−CSN1 (mV)

0 0

0 1 23 4.6

1 0 11 2.2

1 1 70 14

05h, bit[5:4]

05h, bit[1:0]

into a load in over current situations but are not up to the task

of limiting energy into a low impedance short. To address the

low impedance short, the NCV81599 does pulse by pulse

current limiting for 500 ms known as Ilim timeout, the

controller will enter into hiccup mode. The NCV81599

remains in fast stop state with all switches driven off for 10

ms. Once the 10 ms has expired, the part is allowed to soft

start to the previously programmed voltage and current level

if the short circuit condition is cleared.

The internal current limits can be controlled via the I

interface as shown in Table 8.

−40 (Default) −8

38 (Default) 7.6

Current at RSENSE = 5 mW (A)

Current at RSENSE = 5 mW (A)

2

C

Positive Current Limit Internal Latch−off

In addition to the positive current limit, there is a latch−off

over current protection, to provide quick protection against

output short and inductor saturation. The latch−off over

current protection, OCP_L, sensed across CSP2−CSN2

Table 9. THE LATCH−OFF CURRENT LIMIT OCP_L

CLIP_1 CLIP_0 Address

0 0

0 1 38 7.6

1 0 23 4.6

1 1 106 21.2

05h, bit[1:0]

Once the latch−off current limit protection is triggered, an

input OCP_L fault is set. All four switches are driven off

immediately. The OCP_L interrupt register bit set to 1. Only

toggling the EN or input power recycle can reset the part.

The latch−off current limit OCP_L can be disabled via I

2

C

register as shown in the following table.

Table 10. OCP_L LATCH−OFF CURRENT LIMIT

ENABLING AND DISABLING

Address Dis_OCP_L Description

04h, bit[1] 0 OCP_L Action Enabled

04h, bit[1] 1 OCP_L Action Disabled

Negative Current Limit Internal Path

Negative current limit can be activated in a few instances,

including light load synchronous operation, heavy load to

pins, has its threshold around twice that of the positive

current limit. As listed in the following table, OCP_L

threshold is set by the same I

CLIP_0, which set the internal positive peak current limit at

the same time.

CSP2−CSN2 (mV)

70 (Default) 14

Current at RSENSE = 5 mW (A)

light load transition, output overvoltage, and high output

voltage to lower output voltage transitions. CSP2/CSN2 will

be the negative current limit sense channel.

During light load synchronous operation, or heavy load to

light load transitions the negative current limit can be

triggered during normal operation. When the sensed current

exceeds the negative current limit, the S4 switch is shut off

preventing the discharge of the output voltage both in buck

mode and in boost mode if the output is in the power good

range. Both in boost mode and in buck mode when a

negative current is sensed, the S4 switch is turned off for the

remainder of either the S4 or S2 switching cycle and is

turned on again at the appropriate time. In buck mode, S4 is

turned off at the negative current limit transition and turned

on again as soon as the S2 on switch cycle ends. In boost

mode, the S4 switch is the rectifying switch and upon

2

C register bits, CLIP_1 and

www.onsemi.com

19

Page 20

NCV81599, NCP81599

negative current limit the switch will shut off for the

remainder of its switching cycle. The internal negative

current limits can be controlled via the I

2

C interface as

shown in Table 8.

External Path (CS1, CS2, CLIND)

The voltage drop across the sense resistors as a result of

the load can be observed on the CS1 and CS2 pins. Both

CS1, CS2 can be monitored with a high impedance input.

The voltage drop is converted into a current by a

transconductance amplifier with a typical GM of 5 mS. The

final gain of the output is determined by the end users

selection of the R

resistors. The output voltage of the CS

CS

pin can be calculated from Equation 1. The user must be

careful to keep the dynamic range below 2.56 V when

considering the maximum short circuit current.

VCS+ (I

RCS+

Table 11. REGISTER SETTING FOR THE CLIM COMPARATORS

AVERAGE*RSENSE

I

AVERAGE*RSENSE

Address CLIMx_1 CLIMx_0 CSx_LIM (V)

06h, bit [3:0]

* Trans) * RCSt 2.56 V å

V

CS

* Trans

0 0 0.25 .5 1

0 1 0.75 1.5 3

1 0 1.5 3 6

1 1

t

I

MAX

*R

2.56 V

SENSE

* Trans

(eq. 1)

2.5

The speed and accuracy of the dual amplifier stage allows

the reconstruction of the input and output current signal,

creating the ability to limit the peak current. If the user would

like to limit the mean DC current of the switch, a capacitor

can be placed in parallel with the R

resistors. CS1, CS2

CS

can be monitored with a high impedance input.

CS1, CS2 voltages are connected internally to 2 high

speed low offset comparators. When the external CLIND

flag is triggered, i.e, CLIND pin voltage is pulled high, it

indicates that one of the internal comparators has exceeded

the preset limit (CSx_LIM). The default comparator setting

is 250 mV which is a limit of 500 mA with a current sense

resistor of 5 mW and an R

resistor of 20 kW. The external

CS

current limit settings are shown in Table 11.

Current at RSENSE = 5 mW

RSET = 20 kW (A)

5 10

Current at RSENSE = 5 mW

RSET = 10 kW (A)

Overvoltage Protection (OVP)

When the divided output voltage is 15% (typical) above

the internal reference voltage for greater than one switching

cycle, an OV fault is set. During an overvoltage fault, S1 is

driven off, S2 is driven on, and S3 and S4 are modulated to

discharge the output while preventing the inductor current

from going beyond the I

2

C programmed negative current

limit.

L1S1

V1 V2

S2

Figure 29. Diagram for OV Protection

S4

S3

During overvoltage fault detection the switching

frequency changes from its I

2

C set value to 50 kHz to reduce

the power dissipation in the switches and prevent the

inductor from saturating. OVP is disabled during voltage

changes to ensure voltage changes and glitches during

slewing are not falsely reported as faults. The OVP faults are

reengaged 2 ms after completion of the soft start.

OV_REF

VFB

OV_MSK

Figure 30. OV Block Diagram

Input Overvoltage Lockout (OVLO) Protection

−

+

OV

The goal of the input OVLO fault detection is to protect

our IC from overvoltage damage and obtain regulation again

once the OVLO fault is cleared. OVLO can be a latched

shutdown or hiccup mode by a user register.

In a latched shutdown mode, when the input voltage is

higher than V

OVLOIN_R

for greater than the debounce time,

an input OVLO fault is set. All switches are driven off

immediately. The PG and input OVLO interrupt registers

are set to 1. Only toggling the EN or input power recycle can

reset the part.

In a hiccup mode, when the input voltage is higher than

V

OVLOIN_R

for greater than the debounce time, an input

OVLO fault is set. The OVLO debounce time is to filter any

overvoltage spike that is shorter than the time. During an

input OV fault, all switches are driven off immediately. The

www.onsemi.com

20

Page 21

NCV81599, NCP81599

DAC voltage is reset to 0. The PG and input OVLO interrupt

registers are set to 1. Once the input voltage falls under the

threshold, the debounce time starts counting. If input OVLO

keeps not detected during the OVLO recover debounce time,

a soft start will be reengaged.

Input OVLO detection starts from the beginning of

soft−start and ends in shutdown.

Output OVLO Protection and V2 Pin

The goal of the output OVLO fault detection is to protect

the MOSFET from overvoltage damage. The overvoltage

can be created by accidently write a wrong number in the

DAC_target register or installation problem on the external

feedback voltage divider. The default output OVLO

threshold is 30V. Customer can write to the 2−bit output

OVLO register 06h bit[5:4], sel_ov2th to configure the

threshold.

The output OVLO threshold can be set as 15V, 22.5V, 30V

and 36V, therefore it can be used for customer user cases that

requires a max output voltage of 10V, 15V, 20V and 25.5V,

respectively. Since most of the time, OVP should be able to

protect the output over voltage, the output OVLO threshold

are set >40% higher than the max output in that range. When

the output has run away due to either external voltage divider

or DAC configure error, output OVLO will kick into action.

Output OVLO has a latched shutdown mode. When the

output voltage is higher than the output OVLO threshold for

greater than the debounce time, an OVLO fault is set. The

output OVLO interrupt register will be set to 1. All switches

are driven off immediately. The PG and output OVLO

interrupt registers are set to 1. Toggling the EN or input

power recycle can reset the part.

Output OVLO detection starts from the beginning of

soft−start and ends in shutdown.

The output OVLO is sensed on the V2 pin. In some

extreme conditions, the V2 pin voltage, i.e. the output

voltage, may be pulled to negative, such as when the output

is short by a long cable. When V2 pin voltage goes negative,

the NCV81599 may enter a VCC UVLO, which resets all

registers to default and initial a soft−start. To prevent

negative voltage on V2 pin, a resistor, such as 1 kW, can be

placed between V2 pin and output voltage.

VTOP= 2.56 V

Gate

Signals

9R

R

VREF/SS

+

−

To

Driver

COMP

FB

V2

Code Gen

Profile Margin

Output

OVLO

Threshold

2

0.1*Vsw 2

M

U

X

9 bit DAC

1.5V, 2.2 5V,

3.0V, 3. 6V

−

+

Figure 31. Output OVLO

Power Good Monitor (PG)

NCV81599 provides two window comparators to monitor

the internal feedback voltage. The target voltage window is

±5% of the reference voltage (typical). Once the feedback

voltage is within the power good window, a power good

indication is asserted once a 3.3 ms timer has expired. If the

feedback voltage falls outside a ±7.5% window for greater

than 1 switching cycle, the power good register is reset.

Power good is indicated on the INT pin if the I

2

C register is

set to display the PG state. When DAC is set to below

400 mV, the PG high threshold is kept at a constant voltage,

and the PG low threshold is kept at 0 to avoid false

triggering.

PG_MSK

PG_Low

VFB

PG_High

−

+

−

+

PG

V2

www.onsemi.com

21

Figure 32. PG Block Diagram

Page 22

107.5%

105%

100%Vref

95%

92.5%

Power Not Good

V

FB

Power Not Good

NCV81599, NCP81599

Power Good

S4

L

S3

NCV81599

PDRV

VBUS

10μF

USB port

PG

Figure 33. Power Good Diagram

Thermal Shutdown

The NCV81599 protects itself from overheating with an

internal thermal shutdown circuit. If the junction

temperature exceeds the thermal shutdown threshold

(typically 150°C), all MOSFETs will be driven to the off

state, and the part will wait until the temperature decreases

to an acceptable level. The fault will be reported to the fault

register and the INT flag will be set unless it is masked.

When the junction temperature drops below 125°C

(typical), the part will discharge the output voltage to Vsafe

0V.

PFET Drive

The PMOS drive is an open drain output used to control

the turn on and turn off of PMOSFET switches at a floating

potential. The external PMOS can be used as a cutoff switch,

enable for an auxiliary power supply, or a bypass switch for

a power supply. The RDSon of the pulldown NMOSFET is

typically 20 W allowing the user to quickly turn on large

PMOSFET power channels.

Table 12. PFET ACTIVATION TABLE

Address PFET_DRV Description

04h, bit [0]

0 NFET OFF (Default)

1 NFET ON

PFET_DRV

Figure 34. PFET Drive

Analog to Digital Converter

The analog to digital converter is a 7−bit A/D which can

be used as an event recorder, an input voltage sampler,

output voltage sampler, input current sampler, or output

current sampler. The converter digitizes real time data

during the sample period. The internal precision reference is

used to provide the full range voltage; in the case of V1(input

voltage), or FB (with 10:1 external resistor divider) the full

range is 0 V to 25.5 V. The V1 is internally divided down by

10 before it is digitized by the ADC, thus the range of the

measurement is 0 V−2.55 V, same as FB. The resolution of

the V1 and FB voltage is 20 mV at the analog mux, but since

the voltage is divided by 10 output voltage resolution will be

200 mV. Therefore, the highest input voltage report is

200 mV x 127 = 25.4 V. When CS1 and CS2 are sampled, the

range is 0 V−2.55 V. The resolution will be 20 mV in the CS

monitoring case. The actual current can be calculated by

dividing the CS1 or CS2 values with the factor of Rsense ×

5mS × RCSx, the total gain from the current input to the

external current monitoring outputs.

www.onsemi.com

22

Page 23

0.1*V1

NCV81599, NCP81599

Figure 35. Analog to Digital Converter

Table 13. ADC RESULT BYTE

Address MSB 5 4 3 2 1 LSB

10h, 11h, 12h, 13h D6 D5 D4 D3 D2 D1 D0

Table 14. REGISTER SETTING FOR ENABLING DESIRED ADC BEHAVIOUR

Address ADC_2 ADC_1 ADC_0 Description

08h, bit [4:2]

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

Set Amux to VFB

Sets Amux to V1

Set Amux to CS2

Set Amux to CS1

Select all in rotating sequence (VFB, V1, CS2, CS1, VFB, …)

Table 15. REGISTER SETTING FOR ADC TRIGGER MANNER

Address ADC Trigger Description

08h, bit [1:0]

00

01

10

Trigger a 1x read by a fault condition (Default)

Trigger a 1x read

Trigger a continuous read

Interrupt Control

The interrupt controller continuously monitors internal

interrupt sources, generating an interrupt signal when a

system status change is detected. Individual bits generating

2

interrupts will be set to 1 in the INTACK register (I

C read

only registers), indicating the interrupt source. INTACK

register is automatically reset by an I

2

C read. All interrupt

sources can be masked by writing 1 in register INTMSK of

09h and 0Ah. Masked sources will never generate an

interrupt request on the INT pin. The INT pin is an open

drain output. A non−masked interrupt request will result in

the INT pin being driven high. When the host reads the

INTACK registers, the INT pin will be driven low and the

interrupt register INTACK is cleared. Figure 36 illustrates

the interrupt process.

www.onsemi.com

23

Page 24

OCP_L

OCP_L_MASK

V2OVP

V2OVP_MASK

V1OVP

V1OVP_MASK

TSD

TSD_MASK

OCP_P

OCP_P_MASK

OV

OV_MASK

CLIND

CLIND_MASK

PG_BAR

NCV81599, NCP81599

INT

PG_BAR_MASK

VCHN

VCHN_MASK

Figure 36. Interrupt Logic

Table 16. INTERPRETATION TABLE

Interrupt Name Register name Address Description

OCP_L ocp_l 14h, bit [6] Internal positive over current latch−off

V2OVP v2ovp 14h, bit [5] Output secondary over voltage

V1OVP v1ovp 14h, bit [4] Input over voltage

TSD tsd 14h, bit [3] Thermal shut down

OCP_P ocp_p 14h, bit [2] Internal positive over current

OV ov 14h, bit [1] Output over voltage

CLIND ext_clind_ocp 14h, bit [0] External over current trip from CLIND

VCHN vchn 15h, bit [1] Output negative voltage change

PG_BAR pg_int 15h, bit [0] Power good bar thresholds exceeded

I2C Address and Registers

NCV81599 can set up to 4 different I2C addresses by

sensing the shunt resistor voltage at ADDR pin. The chip

will source a 10 mA current to the ADDR resistor and sense

the voltage corresponding to different I2C addresses

everytime when it is powered on. Suggest to put resistors of

0 W, 26.1 kW, 44.2 kW, 71.5 kW from ADDR pin to GND to

set I2C address 74H, 75H, 76H, 77H respectively.

Unused bits in the register map below are marked with

“−”. Writing either “1” or “0” into these unused bits in

user−programmable registers does NOT change any

function/performance of the NCV81599.

www.onsemi.com

24

Page 25

Table 17. I2C REGISTER MAP BIT DETAIL

ADDR

(Hex)

00h − − 0 0 en_int en_mask − − 00h

01h dac_target 32h

02h − − − − − − slew_rate 00h

03h − − v1ovp_lat dac_target_isb − pwm_frequency 00h

04h − − cs2_dchrg cs1_dchrg − − dis_ocp_l pfet 00h

05h − − ocp_clim_neg − − ocp_clim_pos 00h

06h − − sel_ov2th cs2_clim_pos cs1_clim_pos 20h

07h − − − − − gm_amp_setting 05h

08h − − dis_adc amux_sel amux_trigger 00h

User−programmable Registers

09h − int_mask

0Ah − − − − − − int_mask_vchn int_mask_pg 00h

− 0B .. 0Fh

10h − vfb

11h − vin

12h − cs2

13h − cs1

Registers

14h − ocp_l v2ovp v1ovp tsd ocp_p ov ext_clind_ocp

User Read−only

15h − − − − − − vchn pg_int

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

_ocp_l

int_mask_v2ovp int_mask_v1ovp int_mask_tsd int_mask_ocp_p int_mask_ov int_mask_clind 00h

NCV81599, NCP81599

www.onsemi.com

25

Page 26

NCV81599, NCP81599

I2C Interface

The I2C interface can support 5 V TTL, LVTTL, 2.5 V and

1.8 V interfaces with two precision SCL and SDA

comparators with 1 V thresholds shown in Figure 37. The

part cannot support 5 V CMOS levels as there can be some

ambiguity in voltage levels.

I2C Compatible Interface

The NCV81599 can support a subset of I2C protocol as

detailed below. The NCV81599 communicates with the

5V CMOS

Vcc =4.5V−5.5V

V

OH

V

IH

V

TH

V

IL

VOL=0.5V

=4.44V

= 0.7*vcc

= 0.5*vcc

= 0.3*vcc

TTL

Vcc =4.5V−5.5V

V

OH

V

IH

VTH = 1.5V

V

IL

VOL=0.4V

Vcc =2.7V−3.6V

EIS/JEDEC 8−5

=2.4V

=2.0V

=0.8V

LVTTL

V

V

V

OH

V

IH

IL

OL

=2.4V

=2.0V

=0.8V

=0.4V

external processor by means of a serial link using a 400 kHz

up to 1.2 MHz I

2

C two−wire interface protocol. The I2C

interface provided is fully compatible with the Standard,

2

Fast, and High−Speed I

C modes. The NCV81599 is not

intended to operate as a master controller; it is under the

control of the main controller (master device), which

controls the clock (pin SCL) and the read or write operations

through SDA. The I

2

C bus is an addressable interface (7−bit

addressing only) featuring two Read/Write addresses.

2. 5

Vcc =2.3V−2.7V

EIS/JEDEC 8−5

V

OH

V

IH

V

IL

V

OL

=2.0V

=1.7V

=0.7V

=0.4V

1.8V

Vcc =1.65V−1.95V

EIS/JEDEC 8−7

= VCC−0.45V

V

OH

= 0.65*Vcc

V

IH

= 0.35*Vcc

V

IL

=0.45V

V

OL

1.0V Threshold

Figure 37. I2C Thresholds and Comparator Thresholds

I2C Communication Description

The first byte transmitted is the chip address (with the LSB

bit set to 1 for a Read operation, or set to 0 for a Write

operation). Following the 1 or 0, the data will be:

• In case of a Write operation, the register address

(@REG) pointing to the register for which it will be

written is followed by the data that will written in that

location. The writing process is auto−incremental, so

From MCU to NCV81599

From NCV81599 to MCU

Start IC ADDRESS 1 ACK DATA 1 ACK Data n /ACK STOP

1 Read

Start IC ADDRESS 0 ACK DATA 1 ACK Data n STOP Write Inside Part

the first data will be written in @REG, the contents of

@REG are incremented, and the next data byte is

placed in the location pointed to @REG + 1..., etc.

• In case of a Read operation, the NCV81599 will output

the data from the last register that has been accessed by

the last write operation. Like the writing process, the

reading process is auto−incremental.

/ACK

ACK

READ OUT

FROM PART

0 Write

If part does not Acknowledge, the /NACK will be followed by a STOP or Sr. If part

Acknowledges, the ACK can be followed by another data or STOP or Sr.

Figure 38. General Protocol Description

www.onsemi.com

26

Page 27

NCV81599, NCP81599

Read Out from Part

The master will first make a “Pseudo Write” transaction

with no data to set the internal address register. Then, a stop

From MCU to NCV81599

From NCV81599 to MCU

Start IC ADDRESS 0 ACK

0 Write

Start IC ADDRESS 1 ACK DATA 1 ACK Data n STOP Write Inside Part

1 Read

From MCU to NCV81599

Sets Internal

Register Pointer

Register Address ACK STOP

Register Address

Value

Figure 39. Read Out From Part

then start or a repeated start will initiate the Read transaction

from the register address the initial Write transaction was

pointed to:

/ACK

Register Address + (n+1)

Value

N Register Read

From NCV81599 to MCU

Start IC ADDRESS 0 ACK Register REG Address ACK

0 Write

Start IC ADDRESS 1 ACK DATA 1 ACK Data n STOP

1 Read

Sets Internal

Register Pointer

Register Address + (n−1)

Value

k Register Read

Figure 40. Write Followed by Read Transaction

Write In Part

Write operation will be achieved by only one transaction.

After the chip address, the MCU first data will be the internal

From MCU to NCV81599

From NCV81599 to MCU

Start IC ADDRESS 0 ACK Register REG Address ACK

Sets Internal

Register pointer

Write Value in

Register REG

REG Value

Register Address + (n+1) +

(k−1) Value

ACK

N Register Read

/ACK

Write Value in

Register REG + (n−1)

REG + (n−1) Value

ACK

register desired to access, the following data will be the data

written in REG, REG + 1, REG + 2, ..., REG + (n−1).

Write Value in

Register REG

REG Value

ACK

Write Value in

Register REG + (n−1)

REG + (n−1) Value

STOP

ACK

STOP

0 Write

N Register Read

Figure 41. Write in n Registers

www.onsemi.com

27

Page 28

NCV81599, NCP81599

I2C Communication Considerations

• It takes at least 3.3 ms for the digital core to reset all the

registers, so it is recommended not to change the

register value until at least 3.3 ms after the output

voltage finish ramping to a steady state.

• It is recommended to avoid setting reference voltage

profile below 0.1 V. When 0 V output is needed, it is

recommended to ramp down the output by pulling EN

pin low with external circuit or by I2C communication

in the firmware. Setting output voltage profile to 0 via

I2C is not recommended.

www.onsemi.com

28

Page 29

NCV81599, NCP81599

DESIGN CONSIDERATIONS

dv/dt Induced False Turn On

In synchronous buck converters, there is a well−known

phenomenon called “low side false turn−on,” or “dv/dt

induced turn on”, which can be potentially dangerous for the

switch itself and the reliability of the entire converter. The

Vgs’

+

−

Vsw1

C

gd

C

gs

Vin

S1

Drain

S2

Source

L

dV/dt

Buck phase dv/dt induced false

turn on equivalent circuit

4−Switch

Buck−boost

Controller

R

pu_ds(on)

R

LSG1

pd_ds(on)

GND

R

g_ext

Figure 42. dv/dt Induced False Turn−on Equivalent Circuit of a 4−switch Buck−boost Converter

Gate

R

g_int

Figure 42 shows false turn on equivalent circuit of the

buck phase and the boost phase at the moment a positive

dv/dt transition appears across the drain−to−source junction.

The detailed analysis of this phenomenon can be found in

Gate Driver Design Considerations for 4−Switch

Buck−Boost Converters.

Select the Switching Power MOSFET

The MOSFETs used in the power stage of the converter

should have a maximum drain−to−source voltage rating that

exceeds the sum of steady state maximum drain−to−source

voltage and the turn−off voltage spike with a considerable

margin (20%~50%).

When selecting the switching power MOSFET, the

MOSFET gate capacitance should be considered carefully

to avoid overloading the 5 V LDO. For one MOSFET, the

allowed maximum total gate charge Q

can be estimated by

g

Equation 2:

I

driver

where I

Qg+

f

sw

is the gate drive current and fsw is the switching

driver

(eq. 2)

frequency.

It is recommended to select the MOSFETs with smaller

than 3 nF input capacitance (C

). The gate threshold

iss

voltage should be higher than 1.0 V due to the internal

adaptive non−overlap gate driver circuit.

In order to prevent dv/dt induced turn−on, the criteria for

selecting a rectifying switch is based on the Q

Q

is the gate−to−source charge before the gate voltage

gs(th)

reaches the threshold voltage. Lowering C

gd/Qgs(th)

gd

ratio.

will reduce

dv/dt induced voltage magnitude. Moreover, it also depends

4−switch buck−boost converter is not exempt from this

issue. To make things worse, errors are made when designers

simply copy the circuit parameters of a buck converter

directly to the boost phase of the 4−switch buck−boost

converter.

Vgs’

Vout

Drain

C

gd

S4

+

C

gs

−

Source

Vsw2

S3

dV/dt

L

4−Switch

Buck−boost

Controller

R

pu_ds(on)

R

g_ext

HSG2

R

pd_ds(on)

Vsw2

Boost phase dv/dt induced

false turn on equivalent circuit

on dt/C

, Vds and threshold voltage Vth. One way of

gs

Gate

R

g_int

interpreting the dv/dt induced turn−on problem is when V

reaches the input voltage, the Miller charge should be

smaller than the total charge on C

at the Vth level, so that

gs

the rectifying switches will not be turned on. Then we will

have the following relation:

C

Vgs+

gd

Cgd) C

Qgdt Q

Vdst V

gs

GS(th)

gs(th)

(eq. 3)

(eq. 4)

We can simply use Equation 4 to evaluate the rectifying

device’s immunity to dv/dt induced turn on. Ideally, the

charge Q

should not be greater than 1.5*Q

gd

gs(th)

in order to

leave enough margin.

Select Gate Drive Resistors

To increase the converter’s dv/dt immunity, the dv/dt

control is one approach which is usually related to the gate

driver circuit. A first intuitive method is to use higher pull

up resistance and gate resistance for the active switch. This

would slow down the turn on of the active switch, effectively

decreasing the dv/dt. Table 18 shows the recommended

value for MOSFETs’ gate resistors.

Table 18. RECOMMENDED VALUE for Gate Resistors

Buck Phase Boost Phase

HSG1

LSG1

(3.3~5.1)W

0W

HSG2

LSG2

0W

(3.3~5.1)W

An alternative approach is to add an RC snubber circuit to

the switching nodes V

sw1

and V

. This is the most direct

sw2

ds

www.onsemi.com

29

Page 30

NCV81599, NCP81599

way to reduce the dv/dt. The side effect of the above two

methods are that losses would be increased because of slow

switching speed.

LAYOUT GUIDELINES

Electrical Layout Considerations

Good electrical layout is a key to make sure proper

operation, high efficiency, and noise reduction.

• Current Sensing: Run two dedicated trace with decent

width in parallel (close to each other to minimize the

loop area) from the two terminals of the input side or

output side current sensing resistor to the IC. Place the

common−mode RC filter components in general

proximity of the controller.

Route the traces into the pads from the inside of the current

sensing resistor. The drawing below shows how to rout the

traces.

Current Path

PCB Trace

Current Sense

Resistor

CSP/CSN

• Gate Driver: Run the high side gate, low side gate and

switching node traces in a parallel fashion with decent

width. Avoid any sensitive analog signal trace from

crossing over or getting close. Recommend routing

Vsw1/2 trace to high−side MOSFET source pin instead

of copper pour area. The controller should be placed

close to the switching MOSFETs gate terminals and

keep the gate drive signal traces short for a clean

MOSFET drive. It’s OK to place the controller on the

opposite side of the MOSFETs.

• I2C Communication: SDA and SCL pins are digital

pins. Run SDA and SCL traces in parallel and reduce

the loop area. Avoid any sensitive analog signal trace or

noise source from crossing over or getting close.

• V1 Pin: Input for the internal LDO. Place a decoupling

capacitor in general proximity of the controller. Run a

dedicated trace from system input bus to the pin and do

not route near the switching traces.

• VCC Decoupling: Place decoupling caps as close as

possible to the controller VCC pin. Place the RC filter

connecting with VDRV pin in general proximity of the

controller. The filter resistor should be not higher than

10 W to prevent large voltage drop.

• VDRV Decoupling: Place decoupling caps as close as

possible to the controller VDRV pin.

• Input Decoupling: The device should be well

decoupled by input capacitors and input loop area

should be as small as possible to reduce parasitic

inductance, input voltage spike, and noise emission.

Usually, a small low−ESL MLCC is placed very close

to the input port. Place these capacitors on the same

PCB layer with the MOSFETs instead of on different

layers and using vias to make the connection.

• Output Decoupling: The output capacitors should be

as close as possible to the load.

• Switching Node: The converter’s switching node

should be a copper pour to carry the current, but

compact because it is also a noise source of electrical

and magnetic field radiation. Place the inductor and the

switching MOSFETs on the same layer of the PCB.

• Bootstrap: The bootstrap cap and an option resistor

need to be in general close to the controller and directly

connected between pin BST1/2 and pin SW1/2

respectively.

• Ground: It would be good to have separated ground

planes for PGND and AGND and connect the AGND

planes to PGND through a dedicated net tie or 0 W

resistor.

• Voltage Sense: Route a “quiet” path for the input and

output voltage sense. AGND could be used as a remote

ground sense when differential sense is preferred.

• Compensation Network: The compensation network

should be close to the controller. Keep FB trace short to

minimize it capacitance to ground.

Thermal Layout Considerations

Good thermal layout helps power dissipation and junction

temperature reduction.

• The exposed pads must be well soldered on the board.

• A four or more layers PCB board with solid ground

planes is preferred for better heat dissipation.

• More free vias are welcome to be around IC and

underneath the exposed pads to connect the inner

ground layers to reduce thermal impedance.

• Use large area copper pour to help thermal conduction

and radiation.

• Do not put the inductor too close to the IC, thus the heat

sources are distributed.

www.onsemi.com

30

Page 31

QFNW32 5x5, 0.5P

8

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

32

1

SCALE 2:1

PIN ONE

REFERENCE

0.10 C

0.08 C

NOTE 4

DETAIL A

32X

L

K

D

TOP VIEW

DETAIL B

C

C

SIDE VIEW

D2

9

8

1

32

e

e/2

BOTTOM VIEW

RECOMMENDED

SOLDERING FOOTPRINT*

1

25

5.30

3.35

A

B

L

E

A

(A3)

SEATING

C

PLANE

17

E2

32X

b

M

0.10 BC

M

0.05 C

A1

32X

0.63

A4

A

NOTE 3

CASE 484AB

ISSUE D

L3

L4

L

ALTERNATE

EXPOSED

COPPER

PLATING

DETAIL B

PLATED

SURFACES

CONSTRUCTION

A4

SECTION C−C

DETAIL A

ALTERNATE

CONSTRUCTION

L3

DATE 07 SEP 201

L3

L4

NOTES:

1. DIMENSIONS AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.10 AND 0.20MM FROM THE TERMINAL TIP.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN NOM

A4

A1

A3

A 0.80 0.90

A1 −−− −−−

A3 0.20 REF

A4

0.10 −−− −−−

b 0.20 0.25

D

4.90 5.00

D2 3.00 3.10

E

4.90 5.00

E2 3.00 3.10

e 0.50 BSC

K

0.35 −−− −−−

L 0.30 0.40

L3

−−− −−− 0.10

L4 0.08 REF

MAX

1.00

0.05

0.30

5.10

3.20

5.10

3.20

0.50

GENERIC

MARKING DIAGRAM*

1

XXXXXXXX

XXXXXXXX

AWLYYWWG

G

XXXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

3.35

PACKAGE

OUTLINE

0.50

PITCH

DIMENSION: MILLIMETERS

32X

0.30

5.30

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

98AON14940G

QFNW32 5x5, 0.5P

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 32

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

32

1

SCALE 2:1

PIN ONE

REFERENCE

0.15 C

0.10 C

0.08 C

NOTE 4

DETAIL A

D

0.15

C

TOP VIEW

DETAIL B

(A3)

SIDE VIEW

D2

8

E2

1

32

e

e/2

BOTTOM VIEW

RECOMMENDED

SOLDERING FOOTPRINT*

5.30

3.70

A

B

E

A

A1

C

K

17

32X

32X

L

b

M

0.10 BC

M

0.05 C

32X

0.62

24

25

QFN32 5x5, 0.5P

CASE 485CE

ISSUE O

L1

CONSTRUCTIONS

SEATING

PLANE

A-B

NOTE 3

L

DETAIL A

ALTERNATE

DETAIL B

ALTERNATE

CONSTRUCTION

L

MOLD CMPDEXPOSED Cu

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.30 MM FROM THE TERMINAL TIP.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN MAX

A 0.80 1.00

A1 −−− 0.05

A3 0.20 REF

b 0.20 0.30

D 5.00 BSC

D2 3.40 3.60

E 5.00 BSC

E2

3.40 3.60

e 0.50 BSC

K 0.20 −−−

L 0.30 0.50

L1 −−− 0.15

GENERIC

MARKING DIAGRAM*

1

XXXXXXXX

XXXXXXXX

AWLYYWWG

XXXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package