Page 1

Controller for Automotive

LED Lamps

NCV7693

The NCV7693 is a device which drives multiple external switching

components for 3 independent functions. The average current in each

LED string can be regulated with a proper choice of duty−cycle and

battery voltage. The target application for this device is automotive

rear combination lamps. Each individual driver has its own diagnostic

to detect open load, short circuit to ground or to battery.

LED average brightness levels are easily programmed using

appropriate duty cycle control and external resistors in series with the

switching transistors.

Multiple strings of LEDs can be operated with a single NCV7693

device. The device is available in a TSSOP−14 package.

Features

• 3x Pulse Width Modulation (PWM) Control

• Independent Diagnostic Feedback per Function

• External Switching Device for Wide Current Range Flexibility

• External Resistors Define Maximum Current

• Open LED String Diagnostic

• Short−Circuit LED String Diagnostic

• Thermal Shut−down Diagnostic and Protection

• Protection against Short−Circuit on the PWM Input Pins

• Multiple LED String Control

• TSSOP−14 Package

• AEC−Q100 Qualified and PPAP Capable

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Applications

• Rear Combination Lamps (RCL)

• Daytime Running Lights (DRL)

• Fog Lights

• Center High Mounted Stop Lamps (CHMSL) Arrays

• Turn Signal and Other Externally Modulated Applications

• General Automotive LED Driver

www.onsemi.com

14

1

TSSOP−14 WB

CASE 948G

MARKING DIAGRAM

14

NCV

7693

ALYWG

G

1

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

Device Package Shipping

NCV7693DB0R2G TSSOP−14

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

2500 /

Tape & Reel

†

© Semiconductor Components Industries, LLC, 2017

December, 2019 − Rev. 1

1 Publication Order Number:

NCV7693/D

Page 2

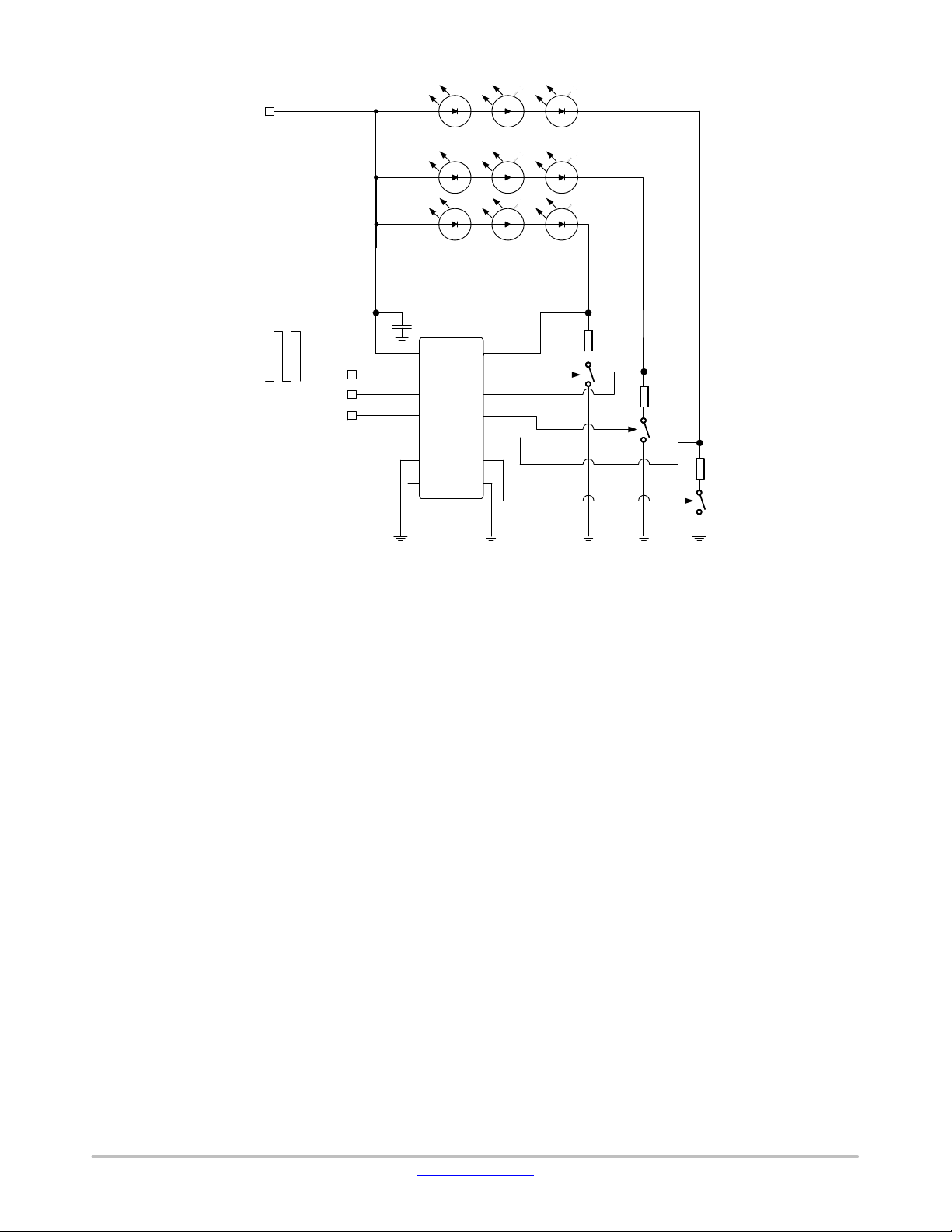

VSupply

NCV7693

PWM 1

PWM 2

PWM 3

VS

FB1

SW1

IO1

IO2

FB2

SW2

IO3

n.c.

FB3

SW3

TSTEN

n.c.

GND

Figure 1. Application Diagram

R1

R2

R3

www.onsemi.com

2

Page 3

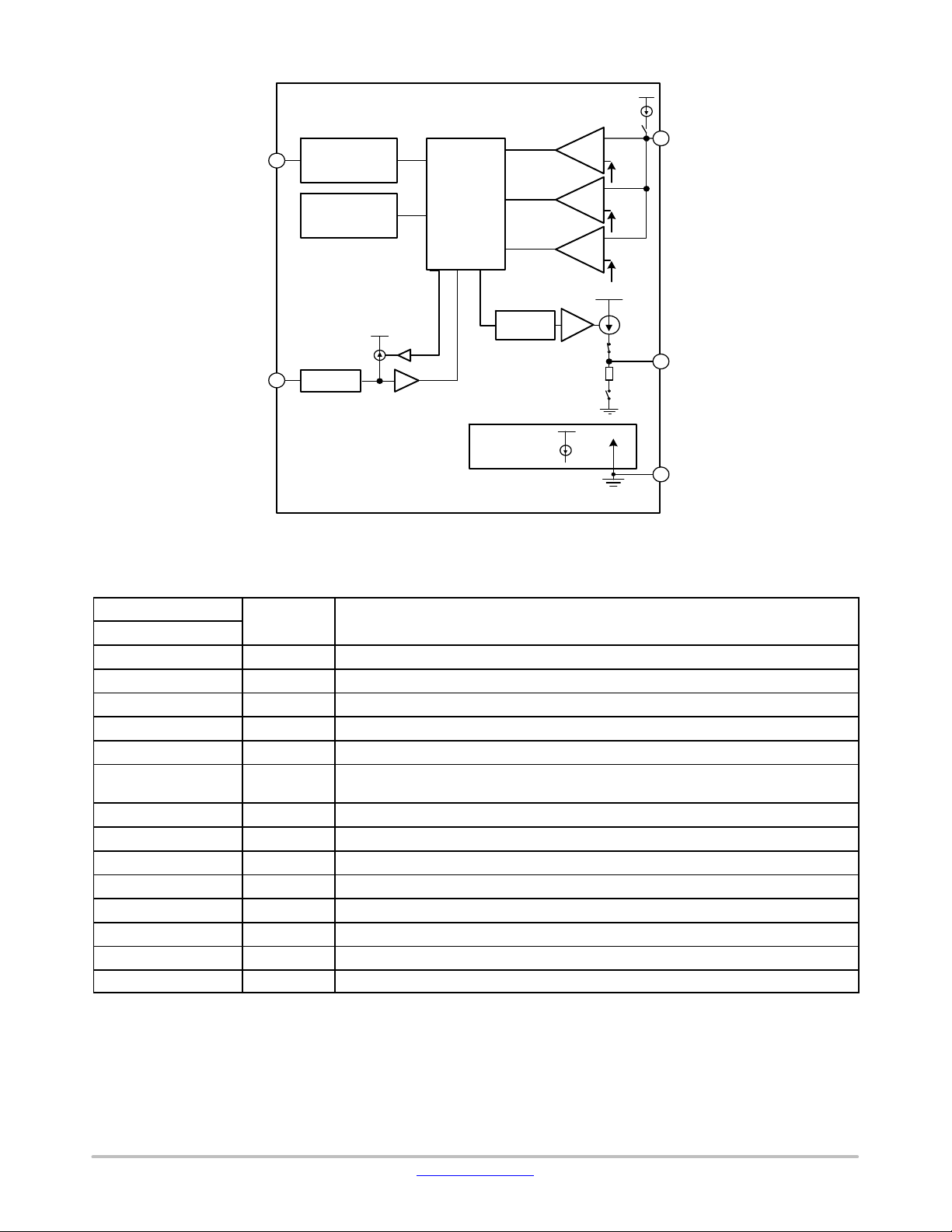

NCV7693

VS

VS

IOx

PIN FUNCTION DESCRIPTION

TSSOP−14 Package

Pin #

1 VS Automotive Battery input voltage

2 IO1 Logic input1 for output SW1 on / off control and diagnostic feedback. Pull high for output on.

3 IO2 Logic input2 for output SW2 on / off control and diagnostic feedback. Pull high for output on.

4 IO3 Logic input3 for output SW3 on / off control and diagnostic feedback. Pull high for output on.

5 NC Not connected

6 TSTEN Pin used for test purpose only, has to be connected to GND pin during the normal

7 NC Not connected

8 GND Ground

9 SW3 Switch Driver 3 for external transistor

10 FB3 Feedback pin for error detection on SW3

11 SW2 Switch Driver 2 for external transistor

12 FB2 Feedback pin for error detection on SW2

13 SW1 Switch Driver 1 for external transistor

14 FB1 Feedback pin for error detection on SW1

Label Description

Supply

Monitoring

Thermal

Monitoring

Protection

3.15V

7mA

operation.

OL

Error

Monitoring

Filtering

& decoding

SC _GND

SC _VS

Slew Rate

Control

Reference

Voltages

and Currents

Figure 2. Block Diagram

+

+

+

Refx

−

−

−

5.5V

FBx

Ref 1

Ref 2

Ref 3

SWx

GND

www.onsemi.com

3

Page 4

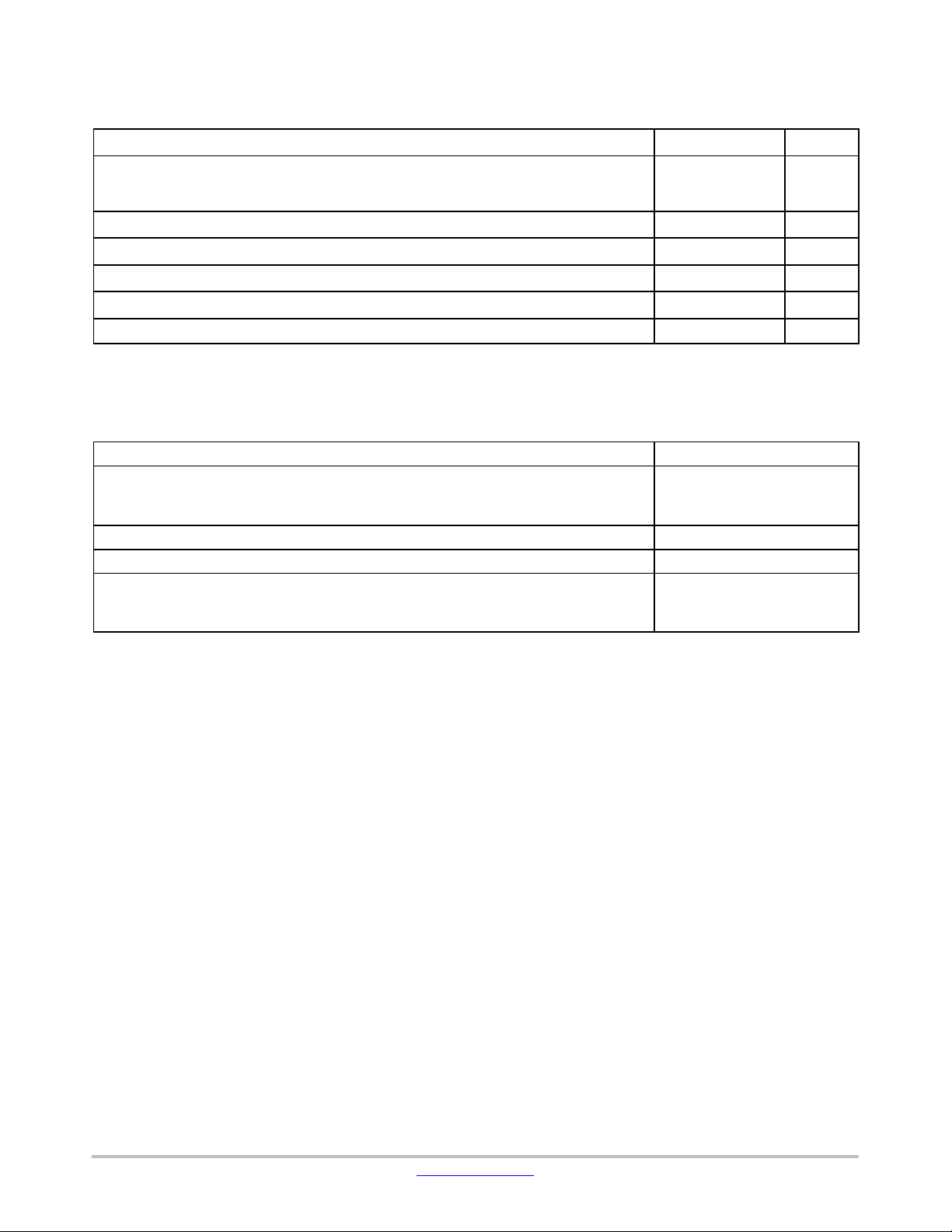

MAXIMUM RATINGS

(Voltages are with respect to GND, unless otherwise specified)

NCV7693

Rating

Value Unit

Supply Voltage (VS)

DC

Peak Transient

−0.3 to 50

50

V

V

High Voltage Input−Output Pins (IO1, IO2, IO3) −40 to 50 V

High Voltage Input Pins (FB1, FB2, FB3) −0.3 to 50 V

Low Voltage Pins (SW1, SW2, SW3) −0.3 to 6.5 V

Junction Temperature, T

J

−40 to 150 °C

Peak Reflow Soldering Temperature: Pb−Free, 60 to 150 seconds at 217°C (Note 1) 260 peak °C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. For additional information, please see or download the ON Semiconductor Soldering and Mounting Techniques Reference Manual,

SOLDERRM/D and Application Note AND8003/D.

ATTRIBUTES

Characteristic Value

ESD Capability

Human Body Model without any filter all Iox versus GND and VS versus GND

Charge Device Model

Moisture Sensitivity MSL2

Storage Temperature Range −55 to 150°C

Package Thermal Resistance − TSSOP−14 (Note 3)

Junction–to–Ambient, R

Junction–to–Case, R

q

JA

Y

JC

2. Minimum ±2 kV HBM for all pin combinations.

3. Values represent typical still air steady−state thermal performance on 1 oz. copper FR4 PCB with 650 mm

±6.0 kV (Note 2)

≥ ±750 V

135°C/W

45°C/W

2

copper area.

www.onsemi.com

4

Page 5

NCV7693

ELECTRICAL CHARACTERISTICS

(6.17 V < VS < 16 V, Transistor NPN = BCP56 or NMOS = NVR5198, −40°C ≤ TJ ≤ 150°C, unless otherwise specified) (Note 4)

Characteristic Conditions Min Typ Max Unit

General Parameters

Supply Current

VS = 14 V, all IOx > 2.2 V, SWx current subtracted

VS = 14 V, all IOx = 0 V

Under Voltage Lockout VS rising (Note 5) 2.24 3.35 4.43 V

Under Voltage Lockout Hysteresis (Note 5) − 500 − mV

Thermal Shutdown (TSD) (Note 5) 155 170 190 °C

Thermal Hysteresis (Note 5) − 15 − °C

Switch Driver

Output Source Current

SWx = 0.7 V (Note 6), −40°C ≤ TJ ≤ +25°C 25 50 − mA

Output Source Current SWx = 0.7 V (Note 6), +25°C ≤ TJ ≤ +125°C 15 30 − mA

Output Source Current SWx = 0.7 V (Note 6), +125°C ≤ TJ ≤ +150°C 7.0 15 − mA

Swx ON Voltage

ISWx = −100 mA, 7 V < VS < 19 V

ISWx = −100 mA

Open Load Timing

Open Load Detection Threshold

IOx High 0.7 0.85 1.0 V

Open Load Blanking Time 10 22 35

Short Circuit to VS

Short Circuit Detection Threshold

IOx High VS−1.0 VS−1.2 VS−1.4 V

Input pull−up current on FBx pins Tested at V(FBx) = VS − 1.0 V −35 −20 −2.0

Short Circuit Blanking Time Tested at 15 V 5.0 10 15

Short Circuit to Ground

Short Circuit Detection Threshold

IOx Low 0.7 0.85 1.0 V

Short Circuit Blanking Time Tested at 15 V 10 22 35

IOx

Input High Threshold

Input Low Threshold 1.1 − − V

Hysteresis − 0.52 − V

Input Pull−down Resistor Tested at V(IOx) = 15 V 75 150 300

IOx Clamp Voltage in error mode PWMx > 5 V, 2 mA < I(IOx) < 9.5 mA 2.80 3.15 3.46 V

AC Characteristics

Propagation Delay

IOx rising to Iout

Propagation Delay

IOx falling to Iout

Propagation Delay

IOx rising to Vout

Propagation Delay

IOx falling to Vout

BJT

BJT

NMOS

NMOS

50% criterion (Note 7) − 5 15

50% criterion (Note 7) − 5 15

From IOx input high threshold to 90% rising of

SWx_ON Voltage, C

= 470 pF

load

From IOx input low threshold to 10% falling of

SWx_ON Voltage, C

= 470 pF

load

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

4. Designed to meet these characteristics over the stated voltage and temperature recommended operating ranges, though may not be 100%

parametrically tested in production.

5. Guaranteed by design.

6. This current is designed to decrease over temperature in case the switching element is an external bipolar to compensate internal heating

and Beta.

7. Evaluated at VS = 14V.

2.2

30

4.5

4.5

5.2

185

5.5

−

10

380

6.5

−

− − 2.2 V

− − 5

− − 5

mA

mA

V

V

ms

mA

ms

ms

kW

ms

ms

ms

ms

www.onsemi.com

5

Page 6

NCV7693

TYPICAL PERFORMANCE CHARACTERISTICS

Equivalent schematics

The following figure gives the equivalent schematics of the user relevant inputs and outputs. The diagrams are simplified

representations of the circuits used.

VS

VS

μA

VS

IOx

VS

Type 1: VS supply pin

3.15V

I

=7mA

fault

Pull−down

150kW

Fault

PWMx_ON / OFF

Low Power mode

OL, SC_ GND

SC_VS

Type 2: FBx input pins

Slope Control / current derating

SWx_ON / OFF / Low power mode

V

V

REF 1

REF 2

5.5V

VS

1kW

Pull−down

= 10+10= 20

FBx

I

=7−50mA

SWx

I

FBx

SWx

Type 3: IOx output pins

Type 4: SWx output pins

Figure 3. Input and Output Equivalent Diagrams

www.onsemi.com

6

Page 7

NCV7693

Detailed Operating Description

The NCV7693 device provides low−side current drive via

an external switching transistor in series with the LEDs and

a resistor. The drop across the resistor plus either the V

the V

of the transistor is supposed to be above 1V in

DS

CE

or

normal operation. Dimming is performed using the

dedicated PWM at the IOx pins of the IC.

Output Drive

Figure 4 shows an example of the typical output drive

configuration. The average current through the external

LED is equal to:

Vsupply

I

LED

+

ǒ

VS * VF* V

R

10kΩ

10kΩ

Ǔ

DROP

DC

optional

1.5kW+/−5%

Where;

VS is the Automotive Battery input voltage,

V

is the sum of the forward voltage of the LEDs,

F

V

DROP

BJT) or V

is either V

(in case NMOSFET is chosen),

DS

(saturation voltage of the chosen

CEsat

DC is the Duty Cycle present at the input of the IOx pins

and

R the series resistance with the LEDs (typical value range

is in between 50 and 100 W).

optional

100nF

VS

FBx

from

NCV7693

4.7k

+/−5%

IOx

W

TSTEN

SWx

GND

μC

30kΩ

μC

to

10kΩ

PWM / DIAG

C1

2.2nF

2.2nF

Figure 4. Output Drive configuration

www.onsemi.com

7

Page 8

NCV7693

Open Load Detection

Faulted output strings due to open load conditions

sometimes require detection in an automotive rear lighting

system. The NCV7693 provides that feature.

When LED driver is ON (PWM is active high) and when

the voltage on the FBx pin is detected below 0.85 V for more

Vsupply

10kΩ

optional

1.5kW+/−5%

10kΩ

from

μC

30kΩ

μC

to

10kΩ

PWM / DIAG

C1

2.2nF

2.2nF

Figure 5. Open Load Detection

than 22 ms typical then an open load error is activated. The

IOx pin is pulled down to 3.15 V typical allowing the

mcontroller to detect the error when the PWM input signal

is activated High. During open load condition the driver

stays active. If the open load disappears the device is

working properly again and the diagnostic flag disappears.

optional

100nF

4.7k

+/−5%

VS

NCV7693

IOx

W

TSTEN

FBx

SWx

GND

*recommended if MOSFET is used

10kΩ

*

or

www.onsemi.com

8

Page 9

NCV7693

Short Circuit to Ground Detection

The FeedBack (FBx) pins of the device are used as inputs

to detect a fault when the resistor on top of either the

collector or the drain of the external transistor is shorted to

Ground. When LED driver is OFF (PWM is low) and when

the voltage on the FBx pin is detected below 0.85 V for more

than 22 ms typical then a SC to Ground is latched. The IOx

pin is then pulled down to 3.15 V typical allowing the

Vsupply

10kΩ

optional

1.5kW+/−5%

10kΩ

from

μC

30kΩ

μC

to

10kΩ

PWM / DIAG

C1

2.2nF

2.2nF

Figure 6. Short Circuit to Ground Detection

mcontroller to detect the error when the PWM input signal

is activated High. During SC to Ground condition the driver

stays active. If the short circuit disappears the device is

working properly on next falling edge of the PWM input pin.

If at least one IOx pin remains High, then short to Ground

detection is guaranteed. Note that in case all IOx pins are

Low, the device is in low power mode and a short to Ground

cannot be detected.

optional

100nF

4.7k

+/−5%

VS

NCV7693

IOx

W

TSTEN

FBx

SWx

GND

*recommended if MOSFET is used

10kΩ

or

*

www.onsemi.com

9

Page 10

NCV7693

Short Circuit to VS Detection

The FeedBack (FBx) pins of the device are used as inputs

to detect a fault when the resistor on top of either the

collector or the drain of the external transistor is shorted to

the battery voltage. This error is detected when the driver is

ON (PWM active High). The threshold voltage detection is

referenced 1.2 V typical down from the VS pin. A voltage

of less than 1.2 V between VS and FBx for more than 10 ms

then a SC to VS is detected. The IOx pin is then pulled down

Vsupply

10kΩ

optional

1.5kW+/−5%

10kΩ

from

μC

30kΩ

μC

to

10kΩ

PWM / DIAG

C1

2.2nF

2.2nF

Figure 7. Short Circuit to VS Detection

to 3.15 V typical allowing the mcontroller to detect the error

when the PWM input signal is activated High. Because of

the large power dissipation possible during this error, the

driver is switched OFF. If the SC disappears the device is

working properly on next rising edge of the PWM input pin.

In case multiple strings are connected to the same driver (see

Figure 9), this error is only detected at the condition each

string is shorted to VS (a single string detection is not

detected because of the blocking diodes).

optional

100nF

4.7k

+/−5%

VS

NCV7693

IOx

W

TSTEN

FBx

SWx

GND

*recommended if MOSFET is used

10kΩ

or

*

Thermal shut down

The thermal shut down circuit checks the internal junction

temperature of the device. When the internal temperature

rises above the Thermal shutdown threshold, then after a

short filter time the output channels are switched off. The

filter is implemented to avoid parasitic TSD, switching off

the driver in case of TSD, will also make the IOx pin is then

pulled down to 3.15 V typical allowing the mcontroller to

detect the error when the PWM input signal is activated

High. It is the responsibility of the mcontroller to

switch−OFF all IOx when the error is detected to avoid large

power dissipation in the device due to the large current

flowing in the IOx pins.

www.onsemi.com

10

Page 11

NCV7693

Vsupply

Vsupply

from

6.5V

10kΩ

DC/DC

Automotive Grade

(example: NCV8853

buck controller)

100nF

optional

W

1.5k

+/−5%

VS

FBx

10kΩ

NCV7693

4.7k

+/−5%

IOx

SWx

or

W

TSTEN

GND

10kΩ

*

μC

PWM / DIAG

30kΩ

μC

to

10kΩ

C1

2.2nF

2.2nF

*recommended if MOSFET is used

Figure 8. Application diagram with a DC/DC

optional

10kΩ

from

100nF

optional

1.5kW+/−5%

VS

FBx

10kΩ

NCV7693

4.7k

+/−5%

IOx

SWx

W

TSTEN

GND

μC

PWM / DIAG

30kΩ

μC

to

10kΩ

C1

2.2nF

2.2nF

or or

*

10kΩ

*recommended if MOSFET is used

Figure 9. Application diagram with multiple strings

www.onsemi.com

11

Page 12

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

14

1

SCALE 2:1

0.10 (0.004)

SEATING

−T−

PLANE

S

U0.15 (0.006) T

2X L/2

L

PIN 1

IDENT.

S

U0.15 (0.006) T

C

D

SOLDERING FOOTPRINT

1

14X REFK

0.10 (0.004) V

14

1

M

8

7

A

−V−

G

7.06

TSSOP−14 WB

U

T

B

N

−U−

J

H

CASE 948G

ISSUE C

S

S

N

F

DETAIL E

J1

SECTION N−N

DETAIL E

0.25 (0.010)

M

K

K1

DATE 17 FEB 2016

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION SHALL

NOT EXCEED 0.25 (0.010) PER SIDE.

5. DIMENSION K DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL

IN EXCESS OF THE K DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

7. DIMENSION A AND B ARE TO BE

DETERMINED AT DATUM PLANE −W−.

INCHESMILLIMETERS

−W−

DIM MIN MAX MIN MAX

A 4.90 5.10 0.193 0.200

B 4.30 4.50 0.169 0.177

C −−− 1.20 −−− 0.047

D 0.05 0.15 0.002 0.006

F 0.50 0.75 0.020 0.030

G 0.65 BSC 0.026 BSC

H 0.50 0.60 0.020 0.024

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

GENERIC

MARKING DIAGRAM*

14

XXXX

XXXX

ALYWG

G

1

A = Assembly Location

L = Wafer Lot

Y = Year

0.65

PITCH

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

14X

0.36

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

14X

1.26

98ASH70246A

TSSOP−14 WB

DIMENSIONS: MILLIMETERS

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

PAGE 1 OF 1

www.onsemi.com

Page 13

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...