Page 1

System Basis Chip with

CAN FD, LDO Regulator and

Wake-up Comparator

NCV7451

The system basis chip (SBC) NCV7451 integrates +5 V / 250 mA

LDO regulator with a high−speed CAN FD transceiver and local

wake−up comparator, directly controlled by dedicated pins.

Features

• 5 V ±2% / 250 mA LDO

♦ Current Limitation with Fold−back

♦ Output Voltage Monitoring

• One High−Speed CAN FD Transceiver

♦ Compliant to ISO11898−2:2016

♦ CAN FD Timing Specified up to 5 Mbps

♦ Current Limitation, Reverse Current Protected

♦ TxDC Timeout

• Local Wake−up Comparator

♦ Integrated Pull−up / Pull−down Current Source

• Very Low Current Quiescent Consumption

• Window Watchdog

• Direct Control

• Thermal Shutdown Protection

• AEC−Q100 Qualified and PPAP Capable

• Wettable Flank Package for Enhanced Optical Inspection

• This is a Pb−Free Device

www.onsemi.com

1

DFNW14 4.5x3, 0.65P

CASE 507AC

MARKING DIAGRAM

NCV

7451

ALYW

G

NCV7451 = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

Typical Applications

• Automotive

• Industrial Networks

PIN CONNECTIONS

TxDC

GND

VR1

RxDC

RSTN

WD_EN

WDI

1

2

3

4

5

6

7

NCV7451

14

CAN_EN

13

CANH

12

CANL

11

GND

10

VS

9

WAKE

8

WAKE_OUT

ORDERING INFORMATION

Device Package Shipping

NCV7451MW0R2G DFNW14

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

5000 / Tape &

Reel

†

© Semiconductor Components Industries, LLC, 2020

February, 2021 − Rev. 0

1 Publication Order Number:

NCV7451/D

Page 2

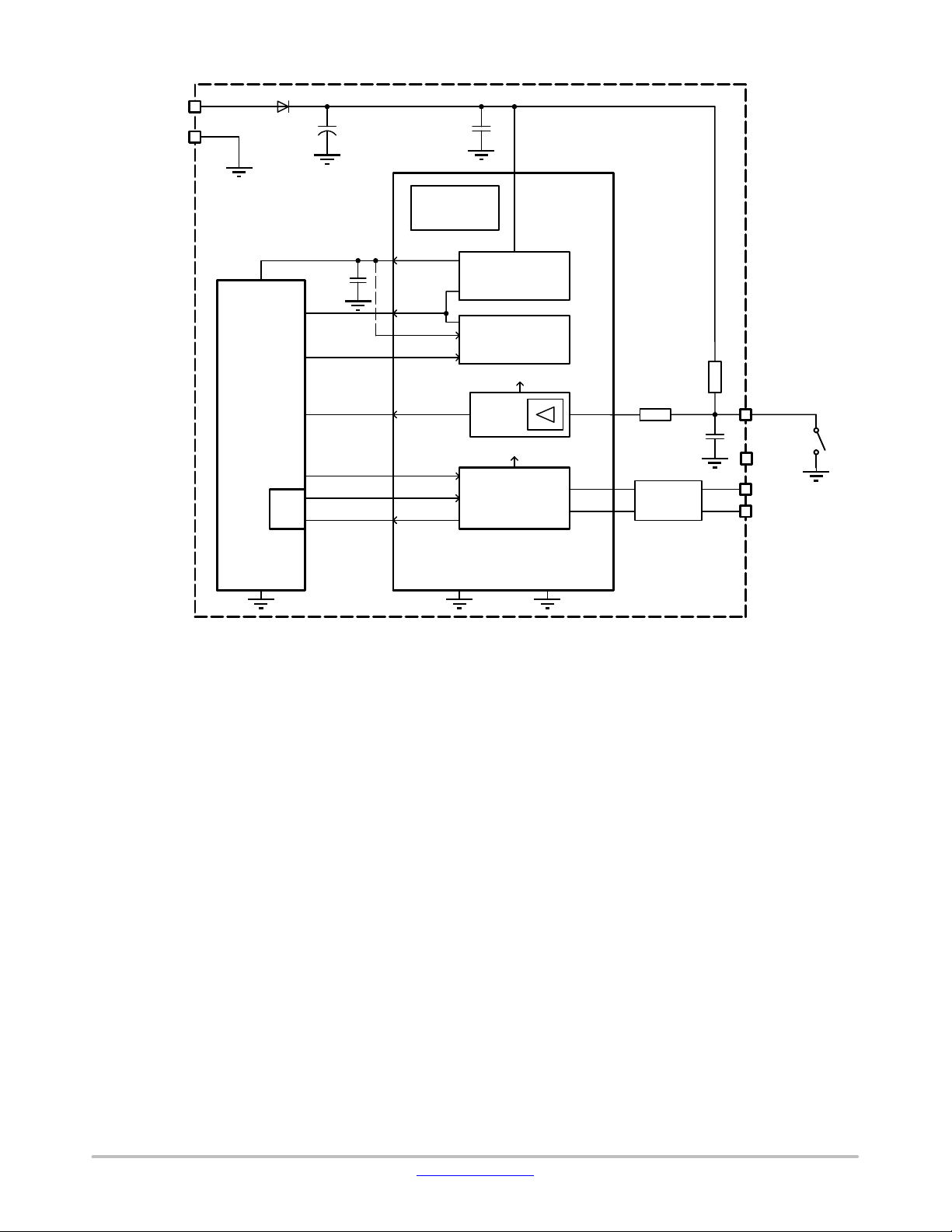

NCV7451

Battery

connection

VDD

RESET

MCU

CAN

Cbuf

4u7

100n

References,

oscillator

VR1

RSTN

WD_EN

WDI

WAKE_OUT

CAN_EN

TxDC

RxDC

VS

VR1

5 V / 250 mA

Watchdog

VS

Local

wakeup

VR1

CAN

NCV7451

WAKE

CANH

CANL

3k3

10n

Termination,

Protection

CAN bus

GND

GNDGND

Figure 1. Simplified Application Diagram

www.onsemi.com

2

Page 3

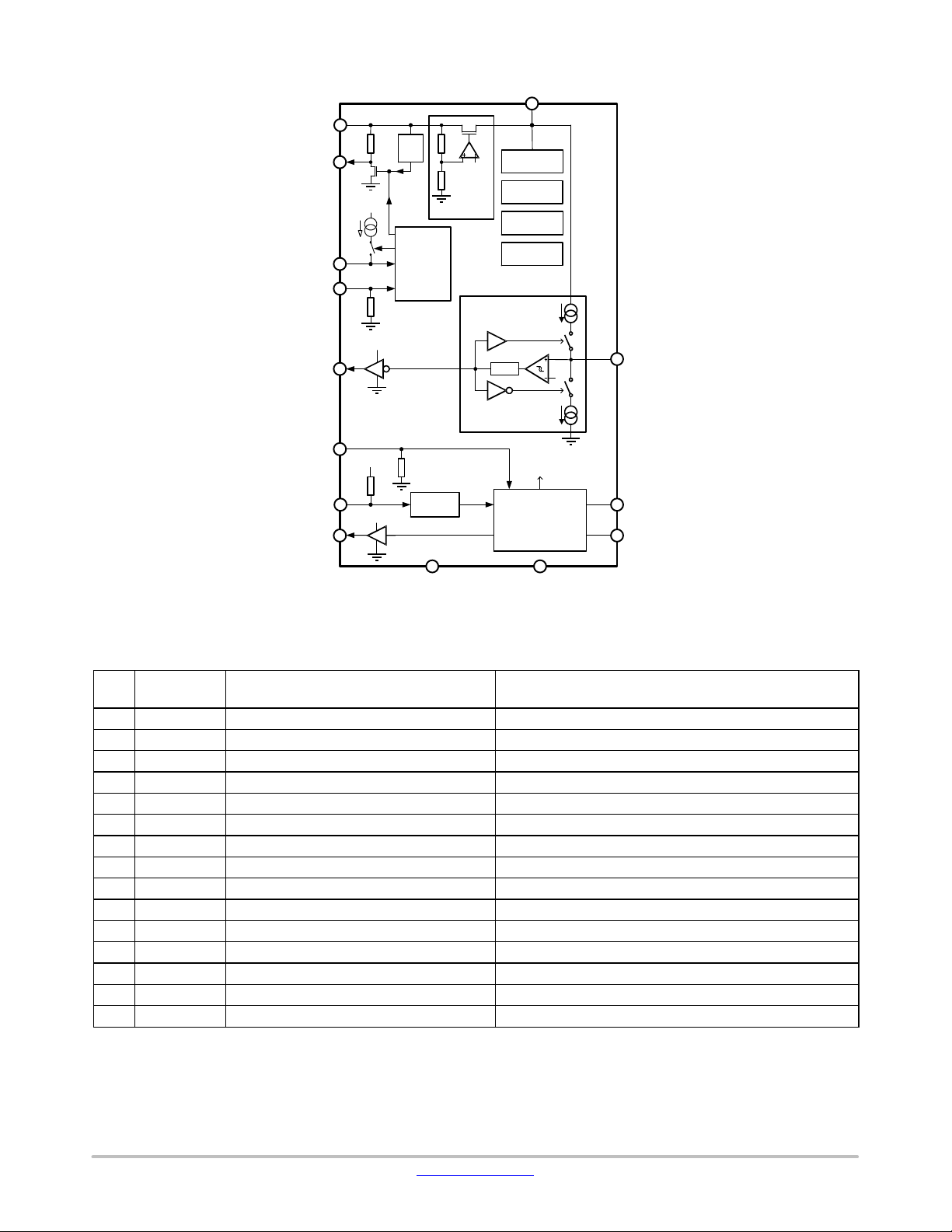

VR1

RSTN

NCV7451

VS1

3

UV

VR1

OV

ref

LDO

Regulator

5

10

Internal

supply

References

Thermal

Monitoring

WD_EN

WDI

WAKE_OUT

CAN_EN

TxDC

RxDC

6

7

8

14

1

4

VR1

VR1

VR1

Watchdog

Tx

Timeout

2

GND

Oscillator

Filt.

Local

Wakeup

VR1

CAN

11

GND

9

13

12

WAKE

CANH

CANL

ref

Figure 2. Block Diagram

PIN FUNCTION DESCRIPTION

Pin

No.

Pin Name

(LV = Low Voltage; HV = High Voltage)

1 TxDC LV digital input; internal pull−up CAN transmitter data input

2 GND Ground connection Ground supply (all GND pins have to be connected externally)

3 VR1 LV supply output Output of the 5 V / 250 mA low−drop regulator

4 RxDC LV digital output; push−pull CAN receiver data output

5 RSTN LV digital output; open drain; internal pull−up Reset signal to the MCU

6 WD_EN LV digital input; internal pull−up current Watchdog enable input

7 WDI LV digital input; internal pull−down Watchdog trigger input

8 WAKE_OUT LV digital output WAKE pin output (inverted WAKE level)

9 WAKE HV input; pull−up/−down current WAKE pin

10 VS HV supply input Main supply input

11 GND Ground connection Ground supply (all GND pins have to be connected externally)

12 CANL CAN bus interface CANL line of the CAN bus

13 CANH CAN bus interface CANH line of the CAN bus

14 CAN_EN LV digital input; internal pull−down CAN transceiver enable input

EP Exposed pad Substrate (has to be connected to all GND pins externally)

Pin Type

Description

www.onsemi.com

3

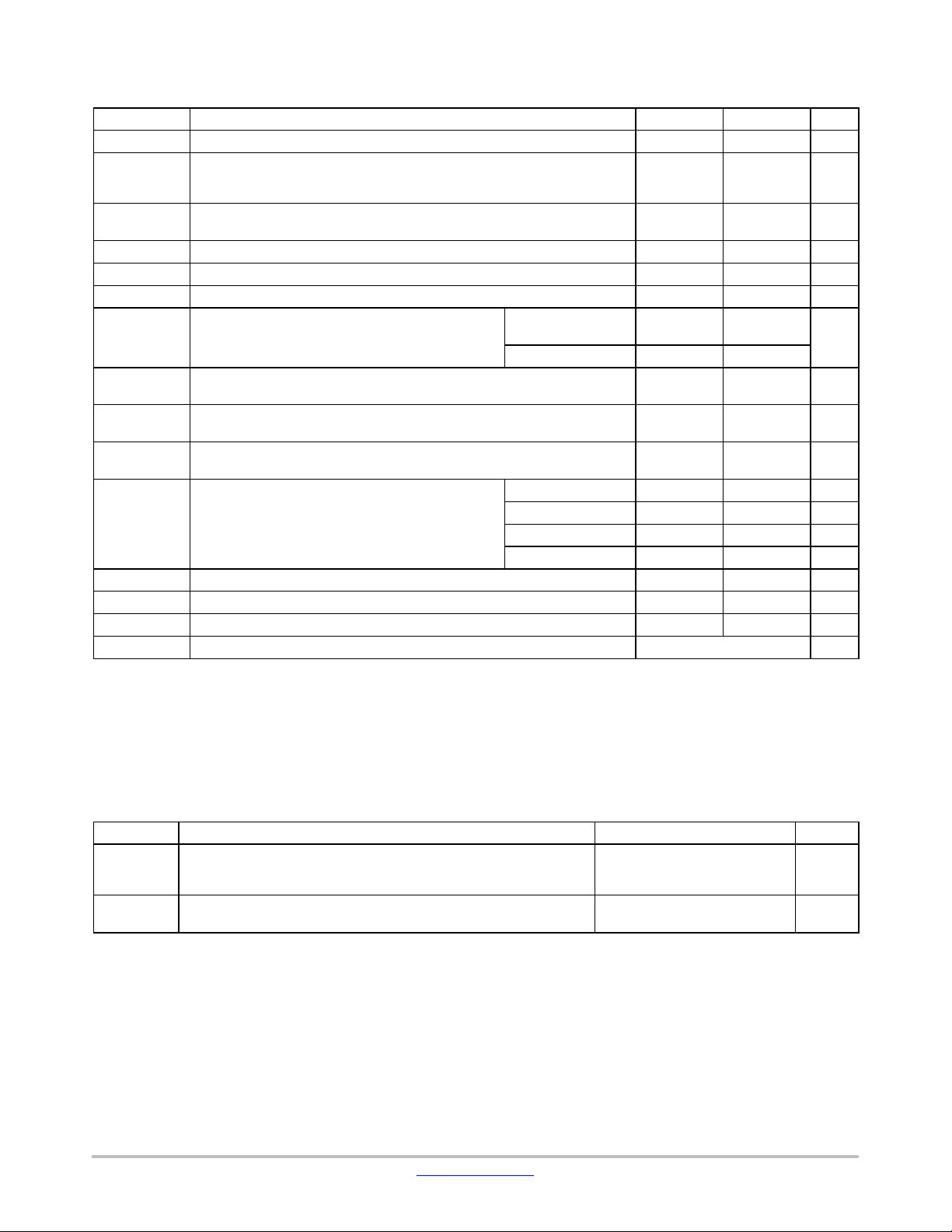

Page 4

NCV7451

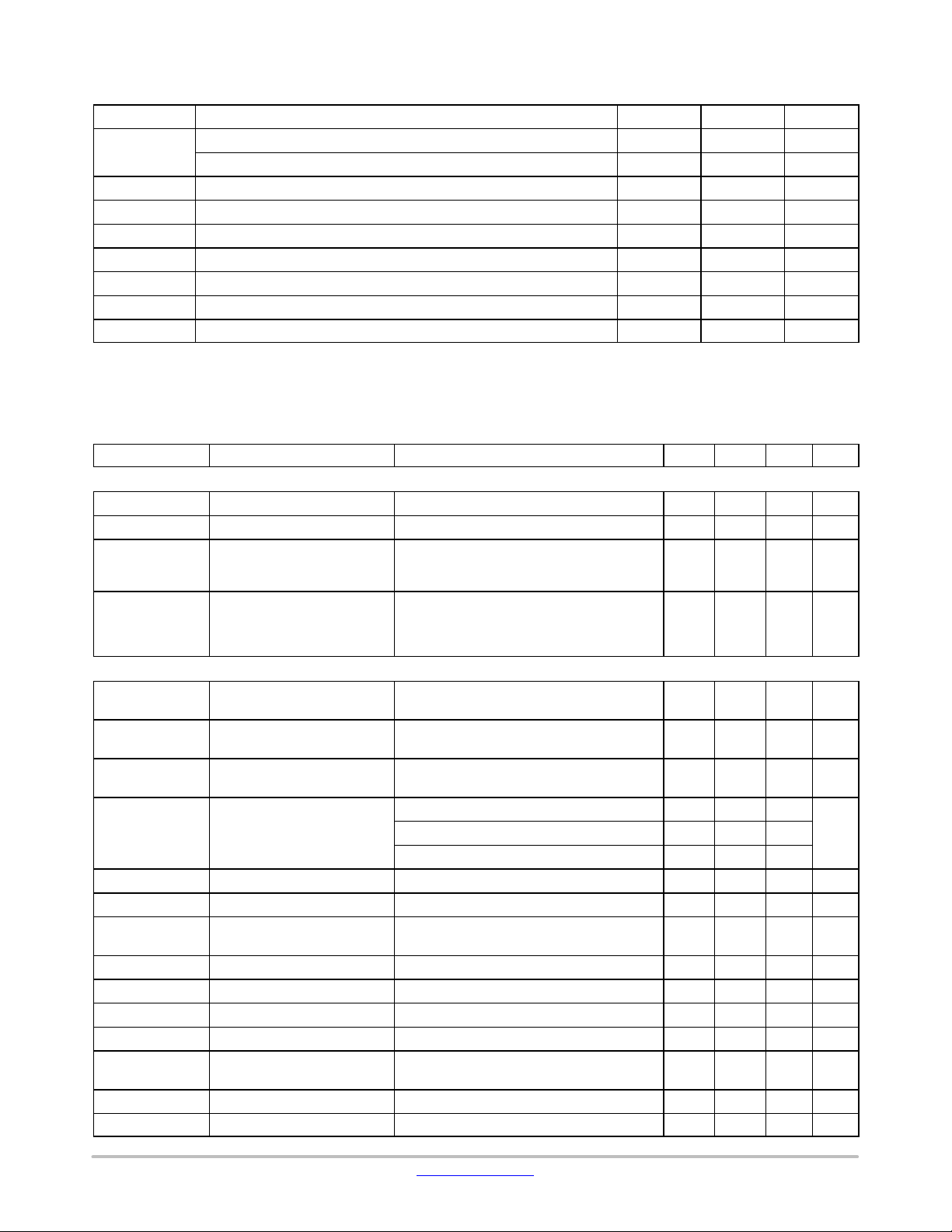

MAXIMUM RATINGS

Symbol Rating Min Max Unit

VS DC Power Supply Voltage (Note 1) *0.3 +40 V

VR1 LDO Supply pin output voltage *0.3 6 or VS+0.3

(whichever

is lower)

VdigIO DC voltage on digital pins (CAN_EN, WD_EN, WDI, RSTN, RxDC, TxDC,

*0.3 VR1+0.3 V

WAKE_OUT)

WAKE DC WAKE pin Input Voltage *40 +40 V

CANH, CANL DC voltage on pin CANH and CANL *40 +40 V

Vdiff Differential DC voltage between any two pins (incl. CANH and CANL) *40 +40 V

V_ESD

HBM

ESD capability, Device HBM, according to

AEC−Q100−002 (EIA/JESD22−A114); (Note 2)

Pins VS, CANH,

CANL, WAKE

*8 +8

Other pins *4 +4

V_ESD

MM

V_ESD

CDM

V_ESD

IEC

V_SCHAF Voltage transients, Test pulses According to

ESD capability; MM, according to AEC−Q100−003 (EIA/JESD22−A115);

all pins

ESD capability; CDM, according to AEC−Q100−011 (EIA/JESD22−C101);

all pins

ESD capability; System HBM, according to IEC61000−4−2;

pins VS, CANH, CANL, WAKE; (Note 3)

Test pulse 1 *100 − V

ISO7637*2, Class D;

pins VS, CANH, CANL, WAKE

Test pulse 2a − +75 V

−200 +200 V

*750 +750 V

−6 +6 kV

Test pulse 3a *150 − V

Test pulse 3b − +100 V

Tj Junction Temperature Range *40 +150 °C

Tstg Storage Temperature Range *55 +150 °C

Tsld Peak Soldering Temperature (Note 4) − 260 °C

MSL Moisture Sensitivity Level 1 −

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS, RECOMMENDED OPERATING RANGES and/or APPLICATION INFORMATION for Safe

Operating parameters.

2. Equivalent to discharging a 100 pF capacitor through a 1.5 kW resistor

3. Equivalent to discharging a 150 pF capacitor through a 330 W resistor; WAKE pin stressed through an external series resistor of 3.3 kW and

with 10 nF capacitor on the module input, VS pin decoupled with 100 nF.

4. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D

V

kV

THERMAL CHARACTERISTICS

Symbol Rating Value Unit

R

θJA

R

ψJC

Thermal Characteristics,

Thermal Resistance, Junction−to−Air (Note 5)

Thermal Reference, Junction−to−Air (Note 6)

Thermal Characteristics,

Thermal Resistance, Junction−to−Case

77

52

7

°C/W

°C/W

5. Value based on test board according to JESD51−3 standard, signal layer with 10% trace coverage.

6. Value based on test board according to JESD51−7 standard, signal layers with 20% trace coverage, inner planes with 90% coverage.

www.onsemi.com

4

Page 5

NCV7451

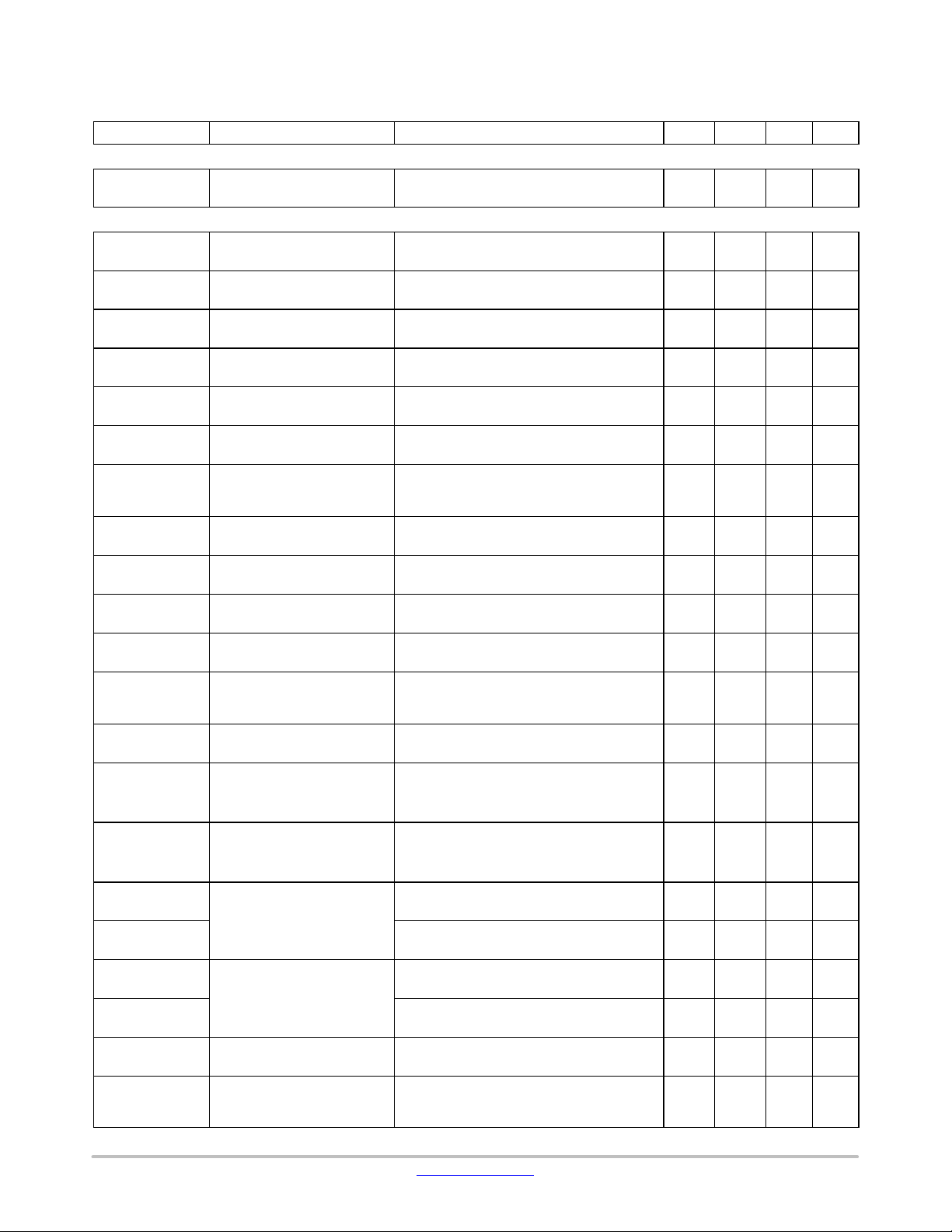

RECOMMENDED OPERATING RANGES

Symbol Rating Min Max Unit

VS

VR1 VR1 regulator output voltage 4.9 5.1 V

I(VR1) VR1 regulator output current (including CAN transceiver consumption) 0 250 mA

VdigIO Digital inputs/outputs voltage 0 VR1 V

WAKE WAKE input voltage 0 VS V

CANH, CANL CAN bus pins voltage −40 40 V

T

J

T

A

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

ELECTRICAL CHARACTERISTICS

6 V v VS v 18 V; −40°C v Tj v 150°C; 4.75 V v VR1 v 5.25 V; R

Symbol Parameter Conditions Min Typ Max Unit

VS SUPPLY

VS_PORH

VS_PORL VS POR threshold VS falling 2.0 − 3.5 V

Is_off VS consumption, low−power VS = 14 V, VR1 on (not loaded), WAKE float-

Is_act VS consumption, active VS = 14 V, VR1 on (loaded by 100 mA, not

VR1 VOLTAGE REGULATOR

V_VR1

Ilim_VR1 Regulator current limitation Maximum VR1 overload current,

Ishort_VR1 Regulator short current Maximum VR1 short current, VR1 < RES_VR1 125

Vdrop_VR1 Dropout Voltage

Loadreg_VR1 Load Regulation 1 mA v I(VR1) v 100 mA −50 − 50 mV

Linereg_VR1 Line Regulation I(VR1) v 100 mA −40 − 40 mV

Cload_VR1 VR1 load capacity

RES_VR1 VR1 Reset threshold VR1 voltage decreasing 4.3 4.5 4.7 V

RES_hyst_VR1 VR1 Reset threshold hysteresis 0.05 0.1 0.2 V

tfilt_RES_VR1 VR1 undervoltage filter time − 15 −

OV_VR1 VR1 overvoltage threshold VR1 voltage increasing / decreasing 5.5 − 6.0 V

OV_hyst_VR1 VR1 overvoltage threshold

tfilt_OV_VR1 VR1 overvoltage filter time − 15 −

toff_VR1 VR1 off time after TSD − 1.0 − s

Functional supply voltage 5.0 28 V

Supply voltage for valid parameter specification 6.0 18 V

Junction Temperature −40 150 °C

Ambient Temperature −40 125 °C

= 60 W, CLT = 100 pF, CST not used, unless otherwise specified.

LT

VS POR threshold VS rising 3.4 − 4.1 V

ing, CAN bus recessive,

CAN_EN = Low, WD_EN = Low, Tj v 85°C

included in Is_act), WAKE floating, CAN bus

recessive,

CAN_EN = High, WD_EN = High, TxDC = High

Regulator output voltage 0 mA v I(VR1) v 250 mA (including internal

CAN consumption), 6 V v VS v 28 V

VR1 > RES_VR1

I(VR1) = 100 mA, VS = 5 V − 0.2 0.4

I(VR1) = 100 mA, VS = 4.5 V − 0.2 0.5

I(VR1) = 50 mA, VS = 4.5 V − 0.1 0.4

ESR < 200 mW, ceramic capacitor recommended

hysteresis

− 28 35

− 3.7 5.0 mA

4.9 5.0 5.1 V

250 − 650 mA

1/2 x

Ilim_VR1

1.0 4.7 −

− 0.06 − V

325 mA

mA

V

mF

ms

ms

www.onsemi.com

5

Page 6

NCV7451

ELECTRICAL CHARACTERISTICS (continued)

6 V v VS v 18 V; −40°C v Tj v 150°C; 4.75 V v VR1 v 5.25 V; R

Symbol UnitMaxTypMinConditionsParameter

VR1 VOLTAGE REGULATOR

Is_add_VR1

CAN BUS LINES (Pins CANH and CANL)

I

o(rec)

I

LI

V

o(rec)(CANH)

V

o(rec)(CANL)

V

o(off)(CANH)

V

o(off)(CANL)

V

o(off)(diff)

V

o(dom)(CANH)

V

o(dom)(CANL)

V

o(sym)

V

o(dom)(diff)

V

o(dom)(diff)_arb

V

o(rec)(diff)

I

o(sc)(CANH)

I

o(sc)(CANL)

V

i(rec)(diff)_NM

V

i(rec)(diff)_LP

V

i(dom)(diff)_NM

V

i(dom)(diff)_ LP

V

i(diff)(th)_NM

V

i(diff)(th)_LP

VS consumption adder of VR1 (Note 7) − 0.01 x

Recessive output current at

pins CANH and CANL

Input leakage current

Recessive output voltage at

CAN enabled;

−27 V < V

CANH

0 W v R(VR1 to GND) < 1 MW;

V

= V

CANH

CANH

CAN enabled; TxDC = High; no load 2.0 2.5 3.0 V

pin CANH

Recessive output voltage at

CAN enabled; TxDC = High; no load 2.0 2.5 3.0 V

pin CANL

Recessive output voltage at

CAN disabled; no load −0.1 0 0.1 V

pin CANH

Recessive output voltage at

CAN disabled; no load −0.1 0 0.1 V

pin CANL

Differential bus output volt-

CAN disabled; no load −0.2 0 0.2 V

age in off mode

(V

− V

CANH

Dominant output voltage at

pin CANH

Dominant output voltage at

pin CANL

Driver output voltage

symmetry (V

Differential bus output

voltage (V

Differential bus output

voltage during arbitration

(V

− V

CANH

Differential bus output

voltage (V

Short circuit output current at

pin CANH

Short circuit output current at

pin CANL

Differential input voltage

range

recessive state

CANL

CANH

CANH

CANL

CANH

)

− V

)

− V

+ V

CANL

CANL

CANL

CAN enabled; 50 Ω v RLT v 65 Ω;

TxDC = Low; t < t

CAN enabled; 50 Ω v RLT v 65 Ω;

TxDC = Low; t < t

CAN enabled; CST = 4.7 nF; TxDC driven by

)

square wave up to 1 MHz

CAN enabled; 45 Ω v RLT v 65 Ω;

)

TxDC = Low; dominant

CAN enabled; RLT = 2240 Ω;

TxDC = Low; dominant; (Note 7)

CAN enabled; no load;

)

V

= High; recessive

TxDC

CAN enabled; TxDC = Low;

= −3 V

V

CANH

−3 V v V

CANH

CAN enabled; TxDC = Low;

= 36 V

V

CANL

−3 V v V

CANL

CAN enabled; no load;

−12 V v V

CAN disabled; no load;

−12 V v V

Differential input voltage

range

dominant state

CAN enabled; no load;

−12 V v V

CAN disabled; no load;

−12 V v V

Differential receiver threshold

voltage in normal mode

Differential receiver threshold

voltage in wake−up−detection mode

CAN enabled;

−12 V v V

CAN disabled;

−12 V v V

= 60 W, CLT = 100 pF, CST not used, unless otherwise specified.

LT

I(VR1)

−5.0 − 5.0 mA

, V

< 32 V

CANL

−5.0 0 5.0

= 5 V

2.75 3.5 4.5 V

dom(TxDC)

0.5 1.5 2.25 V

dom(TxDC)

0.9 − 1.1 VR1

1.5 2.25 3.0 V

1.5 − 5.0 V

−50 0 50 mV

v 18 V

v 18 V

−100

−100

40

−1.5

−70 −40

2.0

70 100

100

3.0 − 0.5 V

, V

CANL

v 12 V

CANH

−3.0 − 0.4 V

, V

CANL

v 12 V

CANH

0.9 − 8.0 V

, V

CANL

v 12 V

CANH

1.05 − 8.0 V

, V

CANL

v 12 V

CANH

0.5 − 0.9 V

, V

CANL

v 12 V

CANH

0.4 − 1.05 V

, V

CANL

v 12 V

CANH

− A

mA

mA

mA

www.onsemi.com

6

Page 7

NCV7451

ELECTRICAL CHARACTERISTICS (continued)

6 V v VS v 18 V; −40°C v Tj v 150°C; 4.75 V v VR1 v 5.25 V; R

Symbol UnitMaxTypMinConditionsParameter

CAN BUS LINES (Pins CANH and CANL)

R

i(cm)(CANH)

R

i(cm)(CANL)

R

i(cm)(m)

R

i(diff)

C

i(CANH)

C

i(CANL)

C

i(diff)

TIMING CHARACTERISTICS (see Figure 3, Figure 4 and Figure 5)

t

d(TxDC−BUSon)

t

d(TxDC−BUSoff)

t

d(BUSon−RxDC)

t

d(BUSoff−RxDC)

t

pd_dr

t

pd_rd

t

wake_filt

t

dwakerd

t

dwakedr

t

wake_to

t

dom(TxDC)

t

Bit(RxDC)

t

Bit(Vi(diff))

Common−mode input resistance at pin CANH

Common−mode input resistance at pin CANL

Matching between pin CANH

and pin CANL common

−2 V v V

−2 V v V

V

CANH

= V

CANH

CANH

CANL

mode input resistance

Differential input resistance 25 50 75 kΩ

Input capacitance at pin

TxDC = High; (Note 7) − 7.5 20 pF

CANH

Input capacitance at pin

TxDC = High; (Note 7) − 7.5 20 pF

CANL

Differential input capacitance TxDC = High; (Note 7) − 3.75 10 pF

Propagation delay TxDC to

CAN enabled − 65 − ns

bus active

Propagation delay TxDC to

CAN enabled − 90 − ns

bus inactive

Propagation delay bus active

CAN enabled − 60 − ns

to RxDC

Propagation delay bus inac-

CAN enabled − 65 − ns

tive to RxDC

Propagation delay TxDC to

CAN enabled 50 100 170 ns

RxDC dominant to recessive

transition

Propagation delay TxDC to

CAN enabled 50 120 170 ns

RxDC recessive to dominant

transition

Dominant time for wake−up

CAN_EN = Low 0.15 − 1.8

via bus

Delay to flag wake event (re-

CAN_EN = Low; Valid bus wake−up event 0.5 − 6.0

cessive to dominant transitions)

Delay to flag wake event

CAN_EN = Low; Valid bus wake−up event 0.5 − 6.0

(dominant to recessive transitions)

Bus time for wake−up time-

CAN_EN = Low 1.0 − 10 ms

out

TxDC dominant time for time-

CAN_EN = High; TxDC = Low 1.0 − 10 ms

out

Bit time on RxDC pin

Bit time on bus pins

(CANH − CANL)

t

t

t

t

Bit(TxDC)

Bit(TxDC)

Bit(TxDC)

Bit(TxDC)

= 500 ns 400 − 550 ns

= 200 ns 120 − 220 ns

= 500 ns 435

= 200 ns 155

= 60 W, CLT = 100 pF, CST not used, unless otherwise specified.

LT

, V

v 7 V 15 25 37 kΩ

CANL

, V

v 7 V 15 25 37 kΩ

CANL

= 5 V −1.0 0 1.0 %

−

530 ns

−

210 ns

ms

ms

ms

Dt

Rec

Receiver timing symmetry

Bit(RxDC)

t

Bit(Vi(diff))

−

= t

Dt

Rec

t

t

Bit(TxDC)

Bit(TxDC)

= 500 ns −65 − 40 ns

= 200 ns −45 − 15 ns

www.onsemi.com

7

Page 8

NCV7451

ELECTRICAL CHARACTERISTICS (continued)

6 V v VS v 18 V; −40°C v Tj v 150°C; 4.75 V v VR1 v 5.25 V; R

Symbol UnitMaxTypMinConditionsParameter

TIMING CHARACTERISTICS (see Figure 3, Figure 4 and Figure 5)

t

d(LP−NM)

WATCHDOG TIMING

twd_acc

t_wd_TO Timeout watchdog period After WD_EN low → high transition or RSTN

t_wd_CW Window watchdog closed win-

t_wd_OW Window watchdog open window 85 100 115 ms

t_WDI Minimum WDI pulse width ac-

WAKE INPUT

Vth_WAKE

Vhys_WAKE WAKE pin threshold hysteresis 0.1 − 0.7 V

tfilt_WAKE WAKE wake−up filter time 10 − 50

Ipu_WAKE Pull−up current on WAKE pin V(WAKE) = 4 V −11 − −3.0

Ipd_WAKE Pull−down current on WAKE pin V(WAKE) = 2 V 3.0 − 11

DIGITAL OUTPUTS, RxDC, WAKE_OUT

IoutL_pinx

IoutH_pinx High−level output driving cur-

DIGITAL OUTPUT RSTN

IoutL_RSTN

VoutL_RSTN Low−level output voltage,

Rpu_RSTN Internal pull−up resistor to VR1 5.0 10.0 19

t_RSTN Reset pulse length after VR1

DIGITAL INPUTS TxDC, CAN_EN, WD_EN, WDI

VinL_pinx

VinH_pinx High−level input voltage (logical

Vin_hys_pinx Input voltage hysteresis − 200 − mV

Rpu_pinx Internal pull−up resistor to VR1;

Rpd_pinx Internal pull−down resistor to

Ipu_WD_EN Internal pull−up current to VR1,

tper_pu_WDEN WD_EN pull−up current source

Mode change delay from

wake−up detection to normal

mode

Watchdog timing accuracy −15 − 15 %

dow

cepted as a watchdog service

WAKE pin threshold 2.0 − 4.0 V

Low−level output driving current pinx is logical Low, forced V(pinx) = 0.4 V 1.0 6.0 12 mA

rent

Low−level output driving current RSTN is active (logical Low),

low VR1/VS

undervoltage or watchdog

failure

Low−level input voltage (logical

“Low”)

“High”)

pin TxDC

ground; pins CAN_EN, WDI

pin WD_EN

activation period

CAN_EN = Low → High − 25 47

pulse

pinx is logical High,

forced V(pinx) = VR1 − 0.4 V

forced V(RSTN) = 0.4 V

VR1 > 4.7 V, I(RSTN) = 0.6 mA − 0.2 0.4

VR1 > 2 V, VS < VR1, I(RSTN) = 0.1 mA − 0.2 0.4

VR1 = 0 V, VS > 2 V, I(RSTN) = 0.2 mA − 0.2 0.4

6.8 8.0 9.2

− − 0.8 V

2.0 − − V

55 100 185 kΩ

55 100 185 kΩ

V(WD_EN) = 0 V, pull−up current source active 50 100 200

WD_EN = CAN_EN = Low − 610 −

= 60 W, CLT = 100 pF, CST not used, unless otherwise specified.

LT

56 65 74 ms

5.1 6.0 6.9 ms

6.0 − −

−8.0 −3.0 −1.0 mA

2.0 5.0 12 mA

ms

ms

ms

mA

mA

V

kW

kW

mA

ms

www.onsemi.com

8

Page 9

NCV7451

ELECTRICAL CHARACTERISTICS (continued)

6 V v VS v 18 V; −40°C v Tj v 150°C; 4.75 V v VR1 v 5.25 V; R

Symbol UnitMaxTypMinConditionsParameter

DIGITAL INPUTS TxDC, CAN_EN, WD_EN, WDI

ton_pu_WDEN

WD_EN pull−up current source

WD_EN = CAN_EN = Low − 5.0 −

activation on−time

THERMAL PROTECTION

Ts d

Tsd_hys Thermal shutdown level hys-

Thermal shutdown level Temperature increasing 155 165 175 °C

Temperature decreasing − 10 − °C

teresis

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

7. Not tested in production, guaranteed by design.

6-18 V

100 nF

VR1

= 60 W, CLT = 100 pF, CST not used, unless otherwise specified.

LT

VS

CANH

ms

15 pF

4.7 uF

CAN_EN

TxDC

RxDC

NCV7451

GND

CANL

R

/2

LT

C

C

/2

R

LT

R

LT

100 pF

= 60 W

Figure 3. Test Circuit for CAN Timing Characteristics

recessive

1

TxDC

CANH

CANL

V

=

i(diff)

− V

V

CANH

dominant

0.3 × VR1

900 mV

CANL

recessive

0.7 × VR1

500 mV

LT

RxDC

t

d(TxDC−BUSon)

1

TxDC Edge length below 10 ns

0.3 × VR1

t

d(BUSon−RxDC)

t

d(TxDC−BUSoff)

0.7 × VR1

t

d(BUSoff−RxDC)

Figure 4. CAN Transceiver Timing Diagram − Propagation Delays

www.onsemi.com

9

Page 10

NCV7451

Reset or previous

WD service

Timeout WD

period

WD service

bit(TxDC)

0.7 × VR1

t

bit(TxDC)

500 mV

0.7 × VR1

t

pd_drtbit(RxDC)

t

bit(Vi(diff))

0.3 × VR1

t

pd_rd

900 mV

0.3 × VR1

1

TxDC

V

i(diff)

V

CANH

=

− V

0.3 × VR1

CANL

RxDC

1

TxDC Edge length below 10 ns

5 × t

Figure 5. CAN Transceiver Timing Diagram − Loop Delay and Recessive Bit Time

nominal t _wd_TO

Safe trigger of timeout WD

Previous

t_wd_trig

nominal t _wd_CW

t_ wd_TO

tolerance

nominal t _wd_ OW

WD expired

Window WD

period

Closed window

(WD trigger would be too early )

Figure 6. Watchdog Modes Timing

t _wd_ CW

tolerance

Safe trigger of window WD

recommended

WD trigger

t _wd _OW

tolerance

www.onsemi.com

10

Page 11

NCV7451

FUNCTIONAL DESCRIPTION

Supply Concept

The device has one battery supply pin VS, supplying the

VR1 regulator and logic control. The supply line has to be

properly decoupled by filtering capacitors close to the

device pin.

VR1 Low−drop Regulator

VR1 is a low−drop output regulator providing 5 V voltage

derived from the VS main supply. It is able to deliver up to

250 mA and is primarily intended to supply the on−chip

CAN transceiver, the application microcontroller unit

(MCU) and related 5 V loads (e.g. its own MCU−related

digital inputs/outputs). An external capacitor needs to be

connected on VR1 pin in order to ensure the regulator’s

stability and to filter the disturbances caused by the

connected loads.

VR1 voltage supplies all the digital low−voltage

input/output pins.

The protection and monitoring of the VR1 regulator

consist of the following features:

♦ VR1 Current Limitation – the two−level current

limitation controlled by VR1 reset comparator to

reduce the power dissipation in case of shorts to

ground by the current fold−back (see Figure 7)

♦ VR1 Reset Comparator – the VR1 regulator output

is compared with a reset level RES_VR1. If the VR1

level drops below this level for longer than

tfilt_RES_VR1, a reset towards the MCU is

generated through the RSTN pin and the CAN

transceiver is disabled.

♦ VR1 Overvoltage Reset Comparator – the VR1

regulator output is compared with an overvoltage

level OV_VR1. If the VR1 level crosses this

threshold for longer than tfilt_OV_VR1, a reset

towards the MCU is generated through the RSTN

pin and the CAN transceiver is disabled.

♦ Temperature (see Figure 14)

V(VR1)

V_VR1

Ilim_VR1Ishort _VR1

RES_hys_VR1

I(VR1)

RES_VR1

Figure 7. VR1 Current Fold−back

V(VS)

OV_VR1

RES_VR1

VS_PORH

VS_PORL

V(VR1)

V_VR1

<tfilt_OV_VR1

<tfilt_RES_VR1

tfilt_RES_VR1

RSTN

t_RSTN

Mode

CAN Transceiver

Off

Reset Normal functionality Normal Rst Off

Figure 8. VS1 and VR1 Monitoring

The SBC contains one high−speed CAN transceiver

compliant with ISO11898−2:2016. The transceiver consists

of the following sub−blocks: transmitter, receiver, and

wake−up detector.

If enabled (CAN_EN = High), the CAN transceiver is

ready to provide the full−speed interface between the bus

and a CAN controller connected on pins RxDC (received

data) and TxDC (data to transmit).

Vdrop_VR1

tfilt_RES_VR1

tfilt_RES_VR1

tfilt_RES_VR1

t_RSTN

Reset

In order to prevent a faulty node from blocking the bus

traffic, the maximum length of the transmitted dominant

symbol is limited by a time−out counter to t

case the TxDC Low signal exceeds the timeout value, the

transmitter returns automatically to the recessive state. The

transmission is again de−blocked when TxDC pin returns to

high (recessive) state.

If the CAN block is disabled (CAN_EN = Low) or RSTN

pin active (Low) due to failed watchdog service or VR1

dom(TxDC)

. In

www.onsemi.com

11

Page 12

NCV7451

undervoltage / overvoltage, the CAN transceiver is in its

wake−up detection state. Logical level on TxDC is ignored

and pin RxDC is kept high until a CAN bus wake−up is

detected. The CAN bus wake−up corresponds to a pattern

consisting of dominant – recessive – dominant symbols of

at least t

bus afterwards. The pattern must be received within t

each. The RxDC starts following the CAN

wake_filt

wake_to

to be recognized as a valid wake−up event, otherwise

internal wake−up logic is reset.

EN_CAN

CANH

CANL

RxDC

t

wake_filttwake_filt

< t

wake_to

t

wake_filt

t

dwakerd

Figure 9. CAN Wake−up Pattern

WAKE Comparator

WAKE pin is a high−voltage input typically used to

monitor an external contact or switch. The inverted logical

level on pin WAKE can be polled via WAKE_OUT output

push−pull pin.

A stable logical level of the WAKE signal is ensured even

without an external connection:

• if the WAKE level is High for longer than tfilt_WAKE,

an internal pull−up current source is connected to

WAKE pin

• if the WAKE level stays Low for longer than

tfilt_WAKE, an internal pull−down current source is

connected to WAKE pin

Vth_WAKE

WAKE

Voltage

tfilt_WAKE

WAKE

_OUT

Current

souce

Pull-down Pull-up

Figure 10. WAKE Pin Functionality

Watchdog

The on−chip watchdog requires that the MCU software

“triggers” or “services” the watchdog in a specified time

frame. A correct watchdog service consists of high−to−low

transition on the WDI input. The watchdog timer re−starts

immediately after a successful trigger is received.

After any Reset event (power−up, watchdog failure, VR1

under−/overvoltage, thermal shutdown) or watchdog enable

(WD_EN = Low → High), the watchdog always starts in a

timeout mode. The MCU software must serve the watchdog

any time before the time−out expiration. After the watchdog

is triggered for the first time, it starts working in a window

mode operation: the watchdog time is split to two distinct

parts – a closed window, where the watchdog may not be

triggered, is followed by an open window where the MCU

must send a valid watchdog trigger (see Figure 12).

Vhys_WAKE

tfilt_WAKE

Pull-down

Vs < Vs_PORL

Any mode

WD_EN = low

Unpowered

Disabled

Vs > Vs_PORH

WD_EN = high

WD_EN = high

Reset

No trigger

within

t_wd_TO

Timeout

Trigger

Figure 11. Watchdog Operating Modes

www.onsemi.com

12

Trigger

Closed

Window

Trigger

t_wd_CW

elapsed

No trigger

within t_wd_OW

Open

Window

Page 13

NCV7451

ÇÇ

WD Enable

WD_EN

Service Service Service

WDI

RSTN

Closed

Open

Closed

WD status

off

Timeout

window

t_wd_CW <t_wd_OW t_wd_trig<t_wd_TO

window

window

Open

window

Figure 12. Correct Watchdog Services

In case the watchdog is not triggered before the timeout or

open window elapses (Figure 13, Figure 14), or trigger is

sent within the closed window (Figure 15), RSTN signal is

generated and then watchdog restarted in the timeout mode

again.

WD Enable

WD_EN

WDI

RSTN

WD status

off Timeout

Figure 13. Missed Watchdog in Timeout Mode

WD_EN

Timeout elapsed

Reset

t_RSTNt_wd_TO

Open Window elapsed

Timeout

Closed

window

t_wd_CW

Open

win.

WD_EN

Trigger in

Closed Window

WDI

RSTN

WD status

Closed

win.

Reset

t_RSTN

Timeout

Closed

window

t_wd_CW t_wd_CW<t_wd_CW

Open

win.

Closed

window

Open

win.

Figure 15. Watchdog Service during Closed Window

The WD_EN pin has an integrated pull−up source to

enable the watchdog in case the pin is disconnected from the

application. To reduce the power consumption in the

low−power mode (watchdog and CAN disabled), the

WD_EN pull−up current source is switched on for

ton_pu_WDEN time with period of tper_pu_WDEN. The

pin state is sampled in the end of the current source

activation. Once High level is detected on the WD_EN pin,

the current source is activated permanently.

To ensure the High level is correctly detected if the pin

becomes floating, external WD_EN capacitance should stay

below 50 pF.

After the rising edge on WD_EN pin, the MCU should

wait tper_pu_WDEN before the first watchdog service.

WD_EN

Ipu_WD_EN

Pull-up current

WD status

Enabled

WD_EN

sampled

tper_pu_WDEN

Disabled

WD_EN

sampled

ton_pu_WDEN

WD_EN

sampled

Enabled

(timeout )

WDI

RSTN

WD status

Closed

window

Open

Reset

window

t_wd_OWt_wd_CW t_RSTN

Timeout

Closed

window

t_wd_CW

Figure 14. Missed Watchdog in Window Mode

Open

window

www.onsemi.com

13

Figure 16. WD_EN Pull−up Current Source Activation

Thermal Protection

A thermal protection circuit protects the IC from damage

by complete device de−activation if the junction

temperature exceeds a value of Tsd.

The device recovers automatically after the junction

temperature drops below Tsd level lowered by hysteresis

Tsd_hys and toff_VR1 (typ. 1 second) expires.

Page 14

Operating Modes

The device operating modes are directly controlled by

CAN_EN input pin and failure events (see Figure 17).

NCV7451

POWER OFF

VR1: off

CAN: off

WAKE: off

Watchdog: off

RSTN: HiZ / Low (if VS>2 V)

VS <VS_PORL

Any

mode

VS >

VS_PORH

Correct

Correct

WD service

POWER−UP

VR1: starting

CAN: off

WAKE: on

Watchdog: off

RSTN: Low

RES_VR1 < VR1 < OV_VR1

RESET

VR1: on

CAN: wakeup detection

WAKE: on

Watchdog: off

RSTN: Low

t_RSTN elapsed

NORMAL

VR1: on

CAN: on

WAKE: on

Watchdog: per WD_EN

RSTN: High

CAN_EN = 0

CAN_EN = 1

Low−Power

VR1: on

CAN: wakeup detection

WAKE: on

Watchdog: per WD_EN

RSTN: High

OK20201015.01

toff_VR1

elapsed

VR1 < RES_VR1

or

VR1 > OV_VR1

or

Watchdog failure

Cool−down

VR1: off

CAN: off

WAKE: off

Watchdog: off

RSTN: Low

Tj < (Tsd –

Tsd_hys)

Thermal Shutdown

VR1: off

CAN: off

WAKE: off

Watchdog: off

RSTN: Low

Tj > Tsd

Any

mode

Figure 17. Operating Modes Diagram

www.onsemi.com

14

Page 15

NCV7451

ISO11898−2:2016 PARAMETER CROSS−REFERENCE TABLE

ISO 11898−2:2016 Specification NCV7451 Datasheet

Parameter Notation Symbol

DOMINANT OUTPUT CHARACTERISTICS

Single ended voltage on CAN_H

Single ended voltage on CAN_L V

Differential voltage on normal bus load V

Differential voltage on effective resistance during arbitration V

Differential voltage on extended bus load range (optional) V

DRIVER SYMMETRY

Driver symmetry

DRIVER OUTPUT CURRENT

Absolute current on CAN_H

Absolute current on CAN_L I

RECEIVER OUTPUT CHARACTERISTICS, BUS BIASING ACTIVE

Single ended output voltage on CAN_H

Single ended output voltage on CAN_L V

Differential output voltage V

RECEIVER OUTPUT CHARACTERISTICS, BUS BIASING INACTIVE

Single ended output voltage on CAN_H

Single ended output voltage on CAN_L V

Differential output voltage V

TRANSMIT DOMINANT TIMEOUT

Transmit dominant timeout, long

Transmit dominant timeout, short t

STATIC RECEIVER INPUT CHARACTERISTICS, BUS BIASING ACTIVE

Recessive state differential input voltage range

Dominant state differential input voltage range V

STATIC RECEIVER INPUT CHARACTERISTICS, BUS BIASING INACTIVE

Recessive state differential input voltage range

Dominant state differential input voltage range V

RECEIVER INPUT RESISTANCE

Differential internal resistance

Single ended internal resistance R

RECEIVER INPUT RESISTANCE MATCHING

Matching a of internal resistance

IMPLEMENTATION LOOP DELAY REQUIREMENT

Loop delay

DATA SIGNAL TIMING REQUIREMENTS for use with bit rates above 1 Mbit/s and up to 2 Mbit/s

Transmitted recessive bit width @ 2 Mbit/s

Received recessive bit width @ 2 Mbit/s t

Receiver timing symmetry @ 2 Mbit/s

V

I

V

V

R

t

Bit(RXD)

CAN_H

CAN_L

Diff

Diff

Diff

V

SYM

CAN_H

CAN_L

CAN_H

CAN_L

Diff

CAN_H

CAN_L

Diff

t

dom

dom

V

Diff

Diff

V

Diff

Diff

R

Diff

CAN_H

CAN_L

m

R

t

Loop

Bit(Bus)

Dt

Rec

V

o(dom)(CANH)

V

o(dom)(CANL)

V

o(dom)(diff)

V

o(dom)(diff)_arb

NA

V

o(sym)

I

o(SC)(CANH)

I

o(SC)(CANL)

V

o(rec)(CANH)

V

o(rec)(CANL)

V

o(rec)(diff)

V

o(off)(CANH)

V

o(off)(CANL)

V

o(off)(dif)

t

dom(TxDC)

NA

V

i(rec)(diff)_NM

V

i(dom)(diff)_NM

V

i(rec)(diff)_LP

V

i(dom)(diff)_LP

R

i(diff)

R

i(cm)(CANH)

R

i(cm)(CANL)

R

i(cm)(m)

t

pd_rd

t

pd_dr

t

Bit(Vi(diff))

t

Bit(RxDC)

Dt

Rec

www.onsemi.com

15

Page 16

NCV7451

ISO11898−2:2016 PARAMETER CROSS−REFERENCE TABLE (continued)

ISO 11898−2:2016 Specification NCV7451 Datasheet

Parameter SymbolNotation

DATA SIGNAL TIMING REQUIREMENTS for use with bit rates above 2 Mbit/s and up to 5 Mbit/s

Transmitted recessive bit width @ 5 Mbit/s

Transmitted recessive bit width @ 5 Mbit/s t

Received recessive bit width @ 5 Mbit/s

MAXIMUM RATINGS OF V

Maximum rating V

Diff

General maximum rating V

CAN_H

CAN_H

, V

and V

Optional: Extended maximum rating V

CAN_L

CAN_L

CAN_H

AND V

and V

DIFF

CAN_L

MAXIMUM LEAKAGE CURRENTS ON CAN_H AND CAN_L, UNPOWERED

Leakage current on CAN_H, CAN_L

BUS BIASING CONTROL TIMINGS

CAN activity filter time, long

CAN activity filter time, short t

Optional: Wake−up timeout, short t

Optional: Wake−up timeout, long t

Timeout for bus inactivity (Required for selective wake−up implementation only) t

Bus Bias reaction time (Required for selective wake−up implementation only) t

t

Bit(RXD)

V

V

V

V

I

CAN_H

I

Bit(Bus)

Dt

Rec

V

Diff

CAN_H

CAN_L

CAN_H

CAN_L

CAN_L

t

Filter

Filter

Wake

Wake

Silence

Bias

t

Bit(Vi(diff))

t

Bit(RxDC)

Dt

Rec

Vdiff

CANH

CANL

NA

,

I

LI

NA

t

wake_filt

NA

t

wake_to

NA

NA

www.onsemi.com

16

Page 17

PIN ONE

REFERENCE

0.08

NOTE 4

C0.10

C

C

C

DETAIL A

1

D

TOP VIEW

DETAIL B

SIDE VIEW

D2

NCV7451

PACKAGE DIMENSIONS

DFNW14 4.5x3, 0.65P

CASE 507AC

ISSUE D

NOTES:

A B

LL

ALTERNATE

E

DETAIL A

CONSTRUCTION

EXPOSED

COPPER

A

A1

PLATING

A4

DETAIL B

C

SEATING

PLANE

14X

L

PLATED

SURFACES

A4

L3

A3

7

SECTION C−C

L3L3

1. DIMENSIONS AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMESNION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.30 MM FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

5. THIS DEVICE CONTAINS WETTABLE FLANK

DESIGN FEATURES TO AID IN FILLET FORMATION ON THE LEADS DURING MOUNTING.

MILLIMETERS

DIM MIN NOM

A 0.80 0.85

A1 −−− −−−

A3

A4

0.10 −−− −−−

b 0.25 0.30

D

4.40 4.50

D2 4.13 4.20

E

2.90 3.00

E2 1.53 1.60

e 0.65 BSC

K

L 0.35 0.40

L3

0.00 0.05 0.10

0.20 REF

0.30 REF

MAX

0.90

0.05

0.35

4.60

4.27

3.10

1.67

0.45

E2

14

K

e

BOTTOM VIEW

8

b

14X

M

C AB

0.10

M

NOTE 3

C

0.05

3.60

RECOMMENDED

SOLDERING FOOTPRINT*

4.35

4.23

1.75

14

1

0.65

PITCH

14X

0.33

DIMENSIONS: MILLIMETERS

8

7

14X

0.75

PACKAGE

OUTLINE

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

www.onsemi.com

17

Page 18

NCV7451

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor ’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

18

Loading...

Loading...