Page 1

NCS29001

LED Backlight Driver

The NCS29001 is an integrated LED driver used in LCD display

backlighting applications. A configurable bill of materials allows the

designer to create a highly efficient solution for a variety of LCD

screen sizes. The NCS29001 uses a boost type converter to deliver

constant current in a string of LEDs. High accuracy PWM dimming is

supported for a frequency up to 500 Hz . The integrated soft start

function provides excellent control during the power up sequence to

avoid current overshoot. The device protects against output

overvoltage, open / short LED, and thermal overload. The NCS29001

is offered in the cost effective SOIC−14 package.

Features

• 8.5 V to 18 V Input Voltage Range

• ±1% Vref Voltage Accuracy to set LED Current

• PWM Controlled Dimming

• Soft Start Limits In−Rush Current

• Open Feedback Protection

• Open LED Protection

• Short LED Protection

• LED String Cathode Short to ground Protection

• Max Duty Cycle Above 90%

• SOIC−14 Package

• This is a Pb−Free Device

Typical Application

• TFT−LCD TV Panels

• LCD Monitor Panels

http://onsemi.com

14

1

SOIC−14 NB

CASE 751A

NCS29001= Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

14

NCS29001G

1

PIN CONNECTIONS

VIN

1

Vref

2

GND

3

PWMin

NCS29001

4

MARKING

DIAGRAM

AWLYWW

GATE

14

13

CS

PGND

12

11

PWMout

© Semiconductor Components Industries, LLC, 2013

October, 2013 − Rev. 1

FBP

STBY

RT

5

6

7

10

FBN

9

COMP

8

OVP

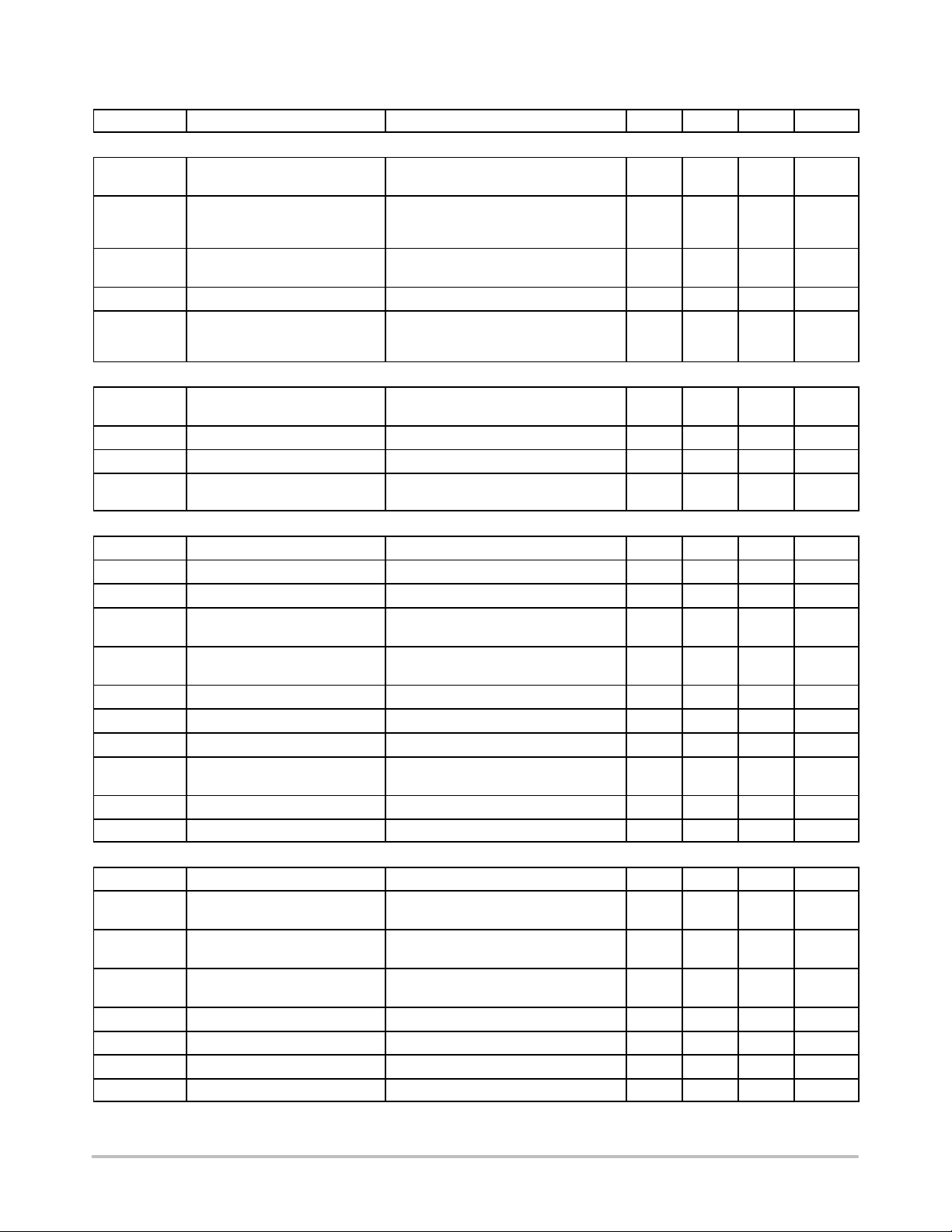

ORDERING INFORMATION

See detailed ordering and shipping information on page 15 of

this data sheet.

1 Publication Order Number:

NCS29001/D

Page 2

NCS29001

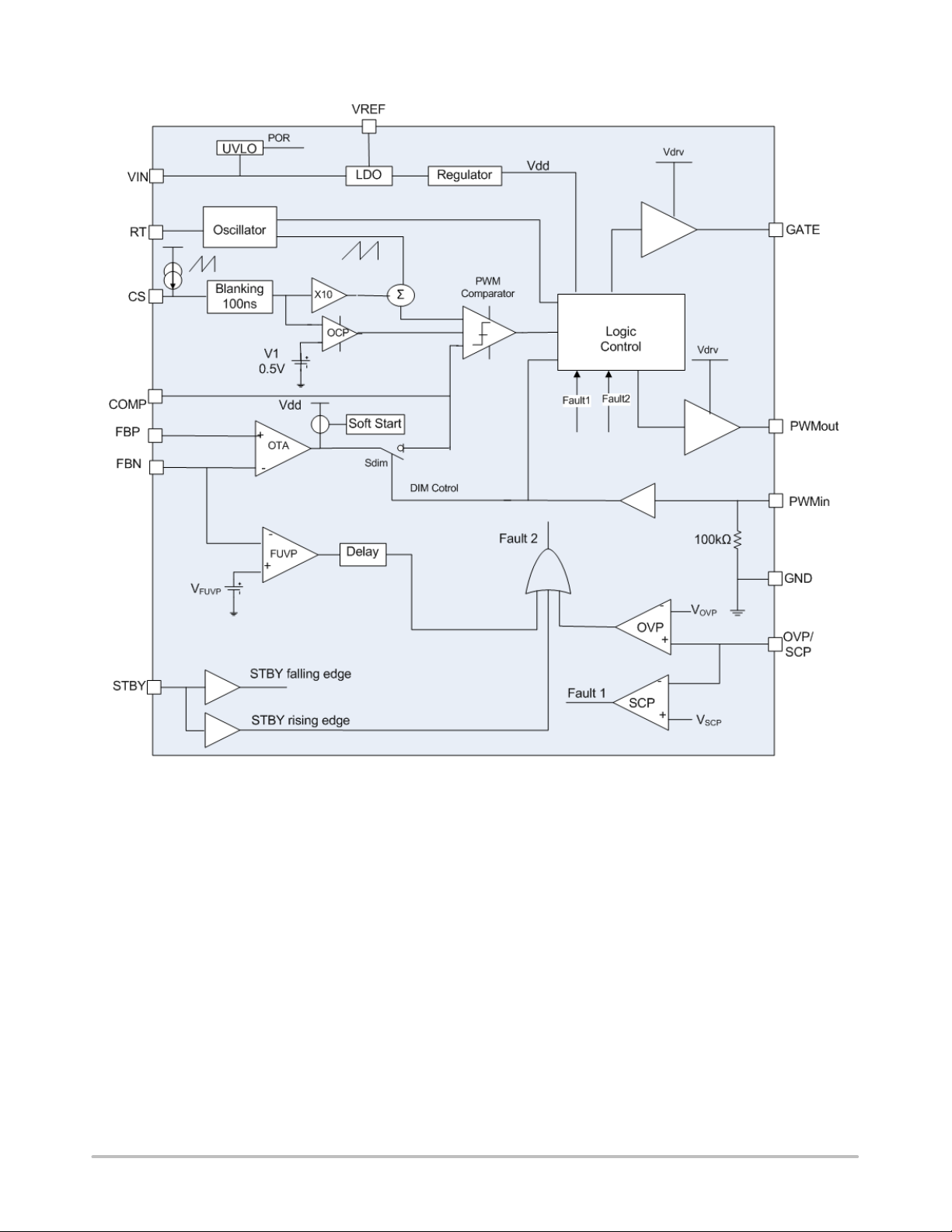

Figure 1. Block Diagram

http://onsemi.com

2

Page 3

NCS29001

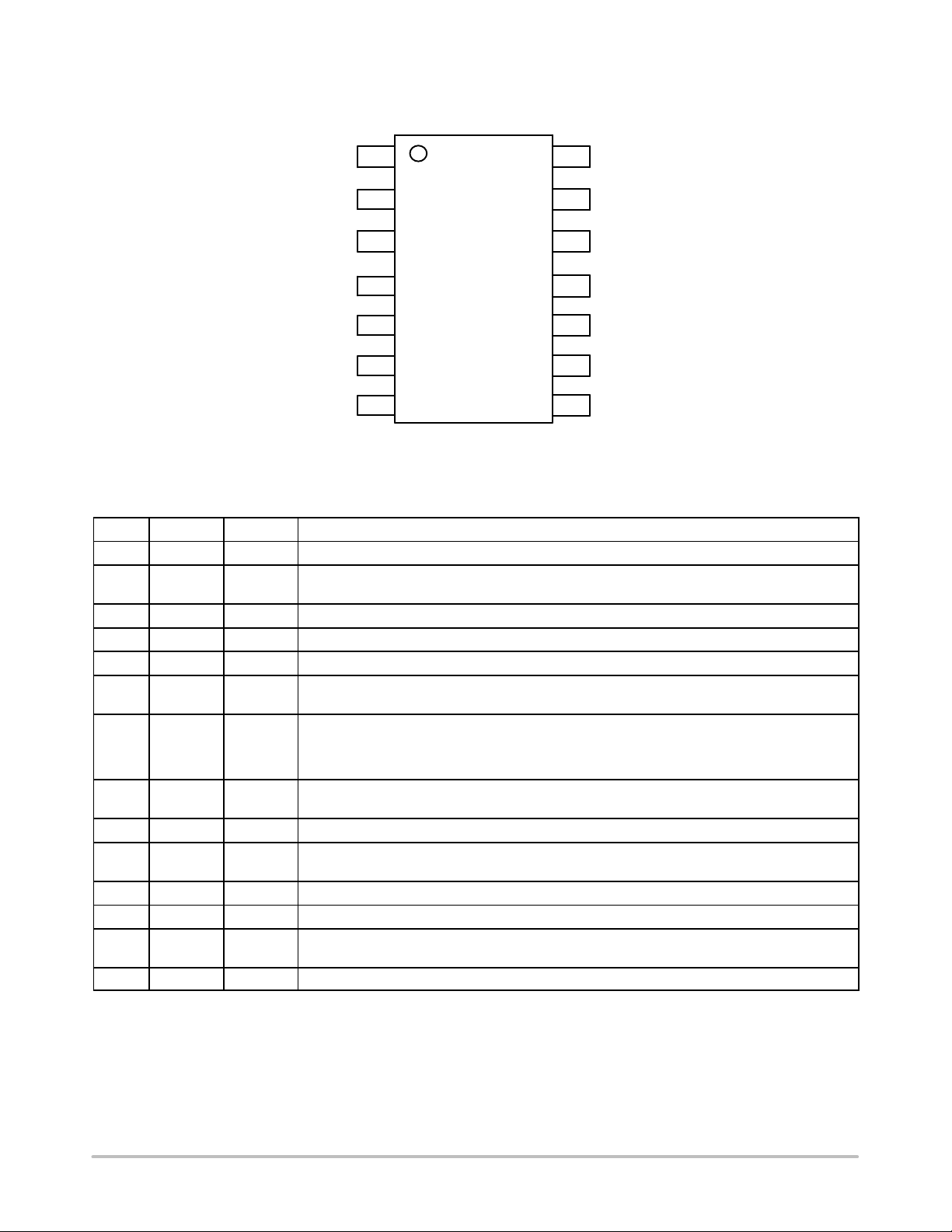

PINOUT ASSIGNMENT

VIN

Vref

GND

PWMin

RT

FBP

STBY

1

2

3

4

5

6 9

7 8

NCS29001

GATE

14

13

CS

12

PGND

11

PMWout

10 FBN

COMP

OVP

Figure 2. NSC29001 Pinout

PIN DESCRIPTION

Pin # Symbol Type Description

1 VIN Input

2 VREF Output

3 GND Ground Analog ground.

4 PWMin Output PWM dimming control input.

5 RT Output The resistor connected between RT and GND sets the switching frequency

6 FBP Input The reference voltage for the feedback (FBN). Reference level can be adjusted from 0.5 V up to

7 STBY Input The converter enters in standby mode when STBY is floating or pulled high. When STBY goes

8 OVP Output This pin provides the overvoltage protection for the converter. When the voltage at this pin

9 COMP Power Loop compensation pin

10 FBN Input Feedback pin and LED cathode connection. External resistor from FBN to GND sets the LED

11 PWMout Output PWM dimming output driver.

12 PGND Ground Power ground.

13 CS Power This pin is used to sense the drain current of the external power MOSFET. It includes a built−in

14 GATE Output This pin is the output GATE driver for an external N−channel power MOSFET

VIN supply input. Small 1.0 mF low ESR bypass capacitor required from VIN to GND.

5 V / 10 mA reference voltage. Small 1.0 mF low ESR bypass capacitor required from VREF to

GND.

3.0 V using an external voltage divider.

from low to high the circuit will discharge the capacitors on the COMP pin and keep PWMout high

to discharge the output capacitor. STBY must remain high for 50 ms before the part enters

standby mode.

exceeds 1.2 V, the boost converter stops immediately and the device enters standby mode.

current.

blanking time.

http://onsemi.com

3

Page 4

NCS29001

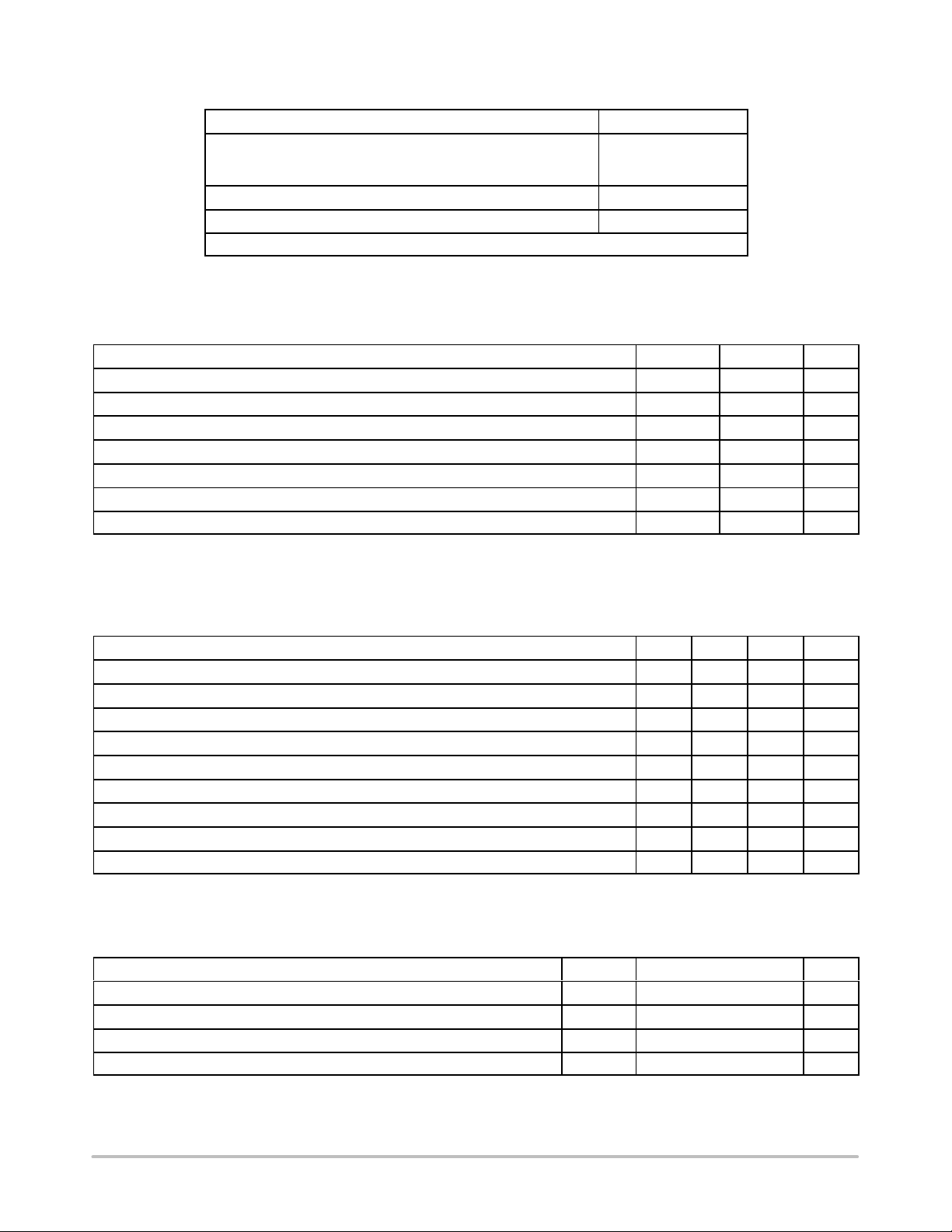

ATTRIBUTES

Characteristics Values

ESD protection (all pins)

Human Body Model (HBM) (Note 1)

Machine Model (MM)

Moisture sensitivity (Note 2) Level 1

Flammability Rating Oxygen Index: 28 to 34 UL 94 V−0 @ 0.125 in

Meets or exceeds JEDEC Spec EIA/JESD78 IC Latch−up Test

1. Human Body Model (HBM), R = 1500 W, C = 100 pF.

2. For additional information, see Application Note AND8003/D.

ABSOLUTE MAXIMUM RATINGS

Rating V

V

IN

PWMin −0.3 5.5 V

STBY −0.3 5.5 V

FBP −0.3 5.5 V

FBN −0.3 5.5 V

OVP −0.3 5.5 V

CS −0.3 5.5 V

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may

affect device reliability.

2 kV

150 V

MIN

V

MAX

−0.3 30 V

Unit

OPERATING CONDITIONS (T

V

IN

= +25°C)

A

Rating

Min Typ Max Unit

8.5 12 18 V

VIL_PWMin: PWMin input low voltage 1 V

VIH_PWMin: PWMin input high voltage 2 V

FBP 0.5 3.0 V

VIL_STBY: STBY input low voltage 1 V

VIH_STBY: STBY input high voltage 2 V

RT clock frequency resistor (Note 3) 20 140

Fdim dimming frequency (5 V amplitude) 100 300 Hz

Ddim dimming duty−cycle 3 95 %

NOTE: With respect to the GND pin.

3. Choose RT to keep clock frequency between 100 kHz and 500 kHz.

THERMAL RATINGS

Parameter Symbol Rating Unit

Junction to ambient thermal impedance (Note 4)

Maximum Junction Temperature (Note 5) T

Operating Ambient Temperature T

Storage temperature T

R

q

JA

J

A

stg

4. Power dissipation must be considered to ensure maximum junction temperature (qJA) is not exceeded.

5. Thermal Pad attached to PCB, 0 lfm airflow, and 76 mm x 76 mm copper area.

150 °C/W

+150 °C

−40 to +85 °C

−65 to +150 °C

kW

http://onsemi.com

4

Page 5

NCS29001

ELECTRICAL SPECIFICATIONS V

Symbol

Parameter Condition Min Typ Max Unit

= 12 V, T

IN

= –40°C to 85°C; typical values are at 25°C

AMB

VIN (VIN Pin)

I

VIN

I

SHUTDOWN

Operating Supply Current VIN = 12 V; PWMin = 5 V; no load,

STBY = 5 V

Shutdown Mode Supply Current PWMin = GND

Ambient temperature 25°C

5 mA

12 uA

STBY = 5 V

UVLO Under Voltage Lockout

VIN Rising 7.5 8 8.5 V

Threshold

DUVLO

T

startup

UVLO Hysteresis 475 mV

Startup time Time from standby falling edge to

steady−state V

dimming pattern − (Note 6)

operation with 30%

boost

100 ms

VREF (VREF Pin)

VREF

Vref voltage

REF bypassed with a 1 mF capacitor to

4.95 5 5.05 V

GND

Line_Reg Line Regulation VIN = 8.5 V to 24 V at I_REF = 10 mA 0.08 0.20 %

Load_Reg Load Regulation 0 mA < I_REF < 10 mA at VIN = 12 V 0.6 mV/mA

ICC (Vref) Iref output current

VREF bypassed with a 1 mF capacitor

10 mA

to GND

GATE (GATE, RT Pins)

V

OH_GATE

I

SOURCE

I

SINK

T

RISE

T

FALL

R

OH

R

OL

D

LSS_MAX

F

OSC

±DF

V

RT

OSC

GATE output high voltage VIN = 12 V 7.5 10 15 V

GATE short circuit current 0.33 0.45 A

GATE sinking current 0.33 0.45 A

GATE output rise time Output voltage rise−time @ CL = 1 nF,

− 40 ns

10−90% of output signal (Note 6)

GATE output fall time Output voltage fall−time @ CL = 1 nF,

− 20 ns

90−10% of output signal (Note 6)

Source resistance 13

Sink resistance 6.0

Maximum Duty Cycle (Note 6) 93 95 %

Boost Switching Frequency

100 500 kHz

range

Frequency Accuracy −10 +10 %

RT pin output voltage 0.85 1 1.15 V

PWM DIMMING (PWMin, PWMout Pins)

V

OH_PWMout

DD_DIM

PWMout output high voltage VIN = 12 V 7.5 10 15 V

PWMout/PWMin Duty cycle

0.98 1 1.02 %

Tolerance

T

RISE

T

FALL

I

SOURCE

I

SINK

R

OH

R

OL

PWMout output rise time Output voltage rise−time @ CL = 1 nF,

− − 2 us

10−90% of output signal

PWMout output fall time Output voltage fall−time @ C

90−10% of output signal

= 1 nF,

L

− − 2 us

PWMout short circuit current 15 20 mA

PWMout sinking current 15 20 mA

Source resistance 270

Sink resistance 230

6. Guaranteed by characterization and design

W

W

W

W

http://onsemi.com

5

Page 6

NCS29001

ELECTRICAL SPECIFICATIONS V

= 12 V, T

IN

Symbol UnitMaxTypMinConditionParameter

CURRENT SENSE (CS Pin)

V

CS

Reference voltage threshold for

current clamp monitoring OCP

comparator

I

RAMP

Slope compensation ramp 130 A/s

PROTECTION (OVP, FBP, FBN Pins)

V

V

V

UVPfb

T

DT

OVP

SCP

SD

SD

Output Overvoltage Protection

on OVP pin

Short Circuit Protection on OVP

pin

Output Undervoltage Protection

on FBN

Thermal Shutdown (Note 6) 140 150 160 °C

TSD hytheresis (Note 6) 15 °C

STANDBY (STBY Pin)

T

STANDBY

Standby mode delay (Note 6) 50 ms

6. Guaranteed by characterization and design

= –40°C to 85°C; typical values are at 25°C

AMB

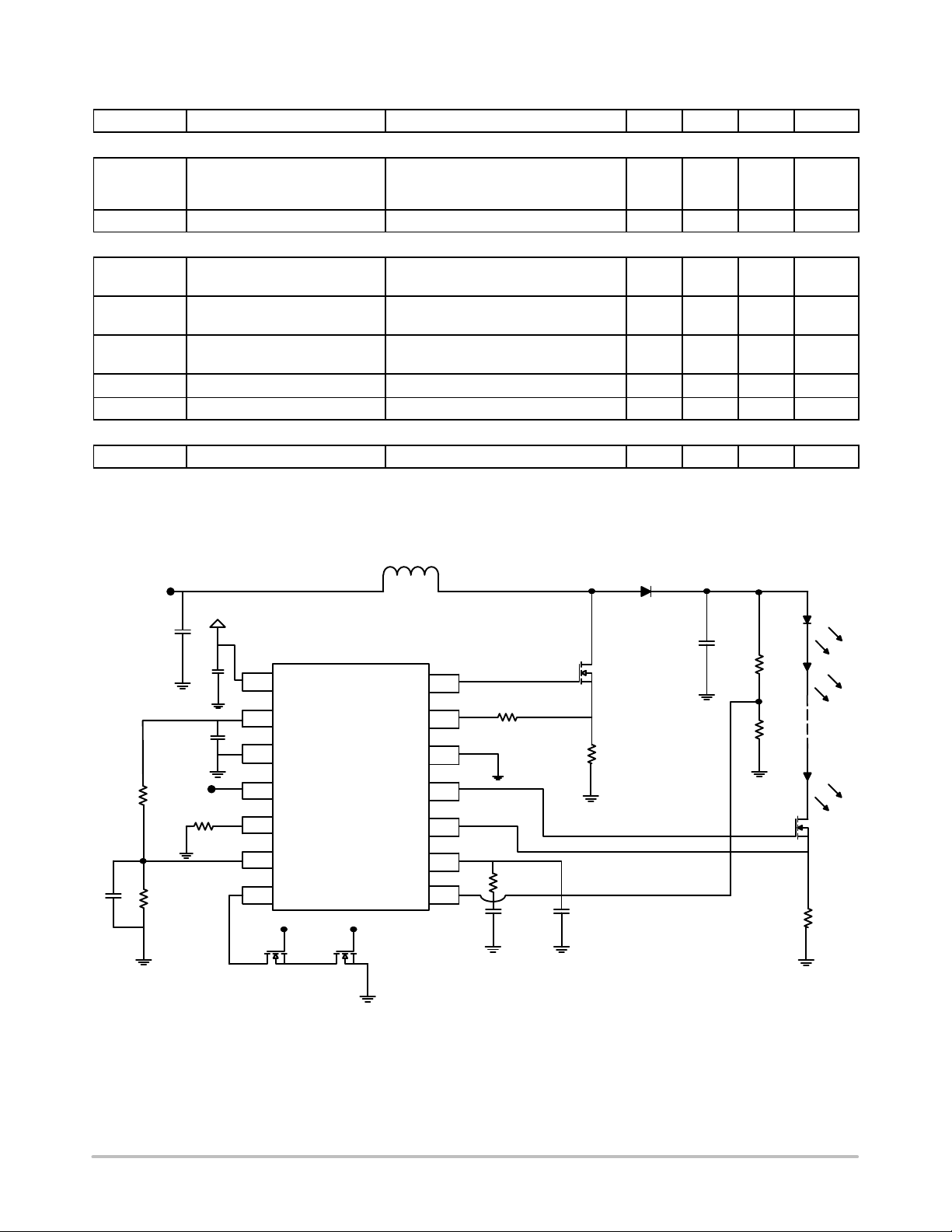

APPLICATION DIAGRAM

0.5 0.6 V

1.2 1.3 V

60 75 mV

60 75 mV

V

Rref1

Rref2

IN

VIN

Inductor

R

Q1

RCS

Q1

D1

C

OUT

R

R

OVP1

OVP2

Q2

L

VIN

IC

NCS29001

1

VIN

2

Vref

3

4

PWMin

5

T

RT

6 FBP COMP

7 8STBY OVP

Backlight O

Standby

PWMout

GATE

PGNDGND

FBN

CS

14

R

sc

13

12

11

10

9

R

comp

C

comp

C

comp2

Figure 3. Application Schematic

http://onsemi.com

6

Page 7

NCS29001

APPLICATION CONDITIONS

Symbol Parameter Condition Min Typ Max Unit

VIN

VIN

Dς

IC

Inductor

V

OUT

h

ΟΥΤ

Standby

VIN pin voltage 8.5 12 18 V

Inductor input voltage 8.5 80

Output voltage range V

VIN

Inductor

VIN

Inductor

VIN

Inductor

Peak efficiency VINIC = 12 V, V

VIN

= 12 V, V

IC

Output Voltage Accuracy including voltage ripple, from −40°C to 85°C,

/VIN

OUT

= 8.5 to 24 V | V

Inductor

= 24 to 50 V | V

= 50 to 80 V | V

= 130 V, I

OUT

= 240 V, I

OUT

VIN

= 8.5 V to 18 V

IC

Max = 5

= 50 to 80 V

OUT

= 80 to 130 V

OUT

= 130 to 240 V

OUT

= 200 mA

OUT

= 200 mA

OUT

50 240 V

95

95

−2 2 %

POWER UP SEQUENCE

VIN

%

UVLO

PWMin

Vcomp

PWMout

GATE

Figure 4. Soft Start Power Up from Standby

For the device to begin the soft start sequence the VIN pin voltage needs to be above the UVLO threshold and the OVP pin

voltage needs to be above the V

threshold. From standby mode soft start will begin when STBY pin goes low and PWMin

SCP

pin goes high and lasts for a fixed number of clock cycles. This ensures that smooth start up if the device is powered on from

standby with a PWM input.

http://onsemi.com

7

Page 8

Vout

Standby

VIN

Vin IC

PWMin

NCS29001

STANDBY ON AND OFF SEQUENCE

Discharging the

output capacitor

UVLO

Vfb & I(LED)

PWMout

GATE

Figure 5. Entering Standby Mode

The STBY pin contains an internal 5 MW pull−up resistor to VREF. This resistor limits current consumption when the device

is in standby mode and also ensures the device will remain in standby if the STBY pin is left floating.

When the STBY goes high the boost converter will stop switching and the PWMout pin will switch, or remain high for 50 ms.

This allows the output capacitor to discharge and the LED current to fall to zero. The device will be in a low power standby

mode and can begin soft start from the next enable sequence.

http://onsemi.com

8

Page 9

VCC > UVLO

POR

POR

NCS29001

STBY falling

edge?

N

STBY,10 uA

PWM Hi

Delay 100uS Max

during Soft start,

and reduced delay

PWMO high

FUVP?

Y

time for normal

operation

Control logic,

Y

Y

N

V1,V2,V4,Vref

Oscilator enabled

SCP&D1 Open?

N

Soft Start,

charging Rc,Cc

throug Iss

VFBN surpass

VFBP?

OTA take

control

PWM Dimming

OVP

N

Y, Fault1

Y

STBY rising

edge?

DRV grouded, PWMO

grounded

N

DRV goes low immediately,

PWMDout goes low

immediately

Y

Figure 6. Power Up State Machine

DRV goes low immediately,

PWMDout keeps high

discharging the output

Cc being discharged,

Delay 50 ms

STBY rising

edge?

0

capacitor,

000

>=1

Fault 2

‘

http://onsemi.com

9

Page 10

NCS29001

SOFT START WITH PWM INPUT

Figure 7 below shows an example of a soft start when the device is powered up from standby with a PWM input. The PWM

signal here is at 100 Hz with a duty cycle of 30%. In this case the LED reaches 100% of its programmed value in 100 ms. This

time can be decreased if the PWM signal runs at a higher duty cycle.

Soft start with PWM dimming active

100ms with 30% dimming duty cycle,

100Hz

PWMin and PWMout

Vfbp

Vfbn & LED

current

LED current reaches 100%

when Vfbn crosses Vfbp

Vcomp is kept during

dimming off

Back light LED brightness gradually

rise to the set value

Figure 7. Soft Start with PWM Input

GATE AND PWMOUT PIN DRIVER CIRCUIT

Since external transistors are required for the boost converter and PWM dimming functions, the device contains an internal

10 V regulator to drive the gate of these transistors. In the case of the PWM transistor this also functions as a level translator

for the PWMin input pin. When selecting external components it is important that the transistor has enough gate drive to ensure

low R

It should be noted that the internal 10 V regulator will start to drop when the VIN voltage is sufficiently low. When the V

for the expected current.

DS(on)

IN

voltage is 8.5 V the gate drivers will be limited to around 7.7 V.

http://onsemi.com

10

Page 11

NCS29001

VREF REFERENCE VOLTAGE

The device contains an accurate 5 V reference that can supply up to 10 mA and can be accessed through the VREF pin. It

can be used to program the LED feedback voltage by using a resistor divider on the FBP pin. This reference is only active when

STBY = low. When the device is in standby mode the VREF pin voltage will drop to 4.2 V typical with a minimum of 3.5 V.

The VREF will return to 5 V immediately when STBY is driven high.

MINIMUM ON & OFF TIME

If the steady state duty cycle and switching frequency combine to generate short Ton times (low VOUT/VIN converter ratio),

the converter will skip some cycles to regulate V

intrinsic loop propagation delay and the switching frequency will be limited by the minimum ON time and OFF time.

THE INDUCTOR SELECTION

For a given application, it is necessary to know the input voltage at the inductor (VIN

set by RFBN and the voltage on the FBP pin, and the switching frequency (F

below:

L

t

max

2 F

The minimal inductor value is determined with the desired peak current flowing through the inductor. Using the chosen

inductor value the steady state duty cycle and peak inductor current can be calculated:

which will increase output voltage ripple. The timing limit is set by the

OUT

), the output current (I

(eq. 1)

sw

1

I

OUT

INDUCTOR

). The inductor can be chosen using the formula

sw

2

V

IN

ǒ

Ǔ

ǒV

V

OUT

OUT

* V

Ǔ

IN

OUT

)

D +

Ǹ

2 L F

sw

I

OUT

V

ǒV

OUT

IN

* V

Ǔ

IN

(eq. 2)

And the inductor peak current is now:

THE CURRENT SENSE RESISTOR

I

peak

+

V

D

IN

L F

sw

+

Ǹ

2 I

OUT

(V

L F

OUT

sw

* VIN)

(eq. 3)

Set a current limit between 2 and 2.5 times the peak inductor current to account for inductor tolerance:

I

+ 2.5 I

limit

peak

(eq. 4)

The current limit reference fixed on the over-current protection comparator is VCS = 0.5 V and the resistance can be calculated

using following the equation:

V

RCS+

SLOPE COMPENSATION

2.5 I

CS

(eq. 5)

peak

After the current sense resistor is calculated additional calculations are needed for the external slope compensation ramp. Using

the R

value the typical slope of the compensation ramp can be calculated:

SENSE

Mramp +

1

2

R

SENSE

V

OUT

* V

L

IN

(eq. 6)

Using the typical value for , the external compensation resistor can be calculated as follows:

RSC+

RAMP

I

RAMP

(eq. 7)

M

The slope compensation ramp has an offset current, , which is used to calculate the peak ramp current and finally the adjusted

current sense resistor.

I

I

RAMP,peak

RCS+

V

CS

I

+ I

* RCS I

limit

OFF

) I

RAMP,peak

) D

RAMP

R

SW

RAMP,peak

(eq. 8)

(eq. 9)

http://onsemi.com

11

Page 12

NCS29001

OUTPUT CAPACITOR and OUTPUT VOLTAGE RIPPLE

Calculating the output voltage ripple will size the output capacitor value. The output voltage ripple equation below takes

into account the parasitic impedance (ESR) of this output capacitor:

I

ǒ1 * D

DV

COUT

+

DV

C

COUT

OUT

I

OUT

F

+

sw

OUT

C

OUT

ǒ1 *

F

Without taking into account the ESR, the output capacitor becomes:

I

C

OUT

u

DV

OUT

OUT

F

sw

If the ESR value of the selected output capacitor is high, the voltage ripple will increase. The error due to the ESR can be

estimated follow the equation below:

SIZING THE COMP PIN CAPACITOR

DV

OUTESR

+ ESR I

The transistor Q1 is turned ON (reset of the duty cycle) when the Vf of the output current amplifier reaches the control output

voltage V

In steady state, at DT

. The control voltage Vc is simply a reduced voltage out of the follower servicing the voltage on the COMP pin.

c

, the voltage at the current amplifier output is represented by the equation below:

sw

VC+ I

peak

Ǔ

2

sw

I

L F

peak

V

OUT

ǒ1 *

RCS G

) ESR I

sw

* V

IN

I

L F

peak

V

* V

OUT

peak

i

OUT

Ǔ

) ESR I

sw

Ǔ

IN

(eq. 13)

(eq. 14)

OUT

(eq. 10)

(eq. 11)

(eq. 12)

V

V

= COMP pin output voltage

comp

V

= Voltage Control of the transconductance amplifier

c

= voltage offset of the transconductance amplifier

V

os

i + C

dv

dt

Vf+

å C

+ VC) V

comp

V

D RCS G

IN

L F

i

EA

+

comp

V

sw

t

comp

OS

rise

i

+

i

EA

Vc) V

t

rise

os

(eq. 15)

(eq. 16)

(eq. 17)

iEA = 4 mA error amplifier output current capability

t

= soft start time

rise

V

= 0.9 V voltage offset due to the follower

os

So

i

t

EA

C

comp

C

comp

+ 0.7

VC) V

i

EA

L F

sw

rise

OS

30 ms

t

VIN D RCS G

L

) V

(eq. 18)

(eq. 19)

OS

During the soft start and with the dimming function activated, the COMP pin voltage is rising during 30 ms within the 100 ms

soft start time so V

holds for another during 70 ms afterwards. Attention needs to be brought to the DC voltage rating. As

comp

the capacitor value decreases and the DC voltage increases, the value chosen needs to be

http://onsemi.com

12

Page 13

NCS29001

SIZING THE R

Combining Equations 2 and 16 gives the following expression for I

RESISTOR for the LOOP STABILITY

comp

I

+

OUT

2 ǒV

OUT

V

f

* V

2

L F

IN

OUT

Ǔ ǒ

:

sw

RCS G

2

Ǔ

i

(eq. 20)

To obtain the small signal equation, partial derivates of the output current are calculated with respect to the control voltage Vc

and the output voltage V

OUT

.

V

C

* V

OUT

2

V

C

* V

L F

2

Ǔ

ǒRCS G

IN

L F

Ǔ ǒ

IN

sw

sw

RCS G

+

2

Ǔ

i

2

Ǔ

i

I

OUT

V

* V

OUT

IN

(eq. 21)

(eq. 22)

I

OUT

∂

+

V

∂

OUT

ǒ

I

OUT

∂

+

V

∂

OUT

2 ǒV

V

OUT

From the AC model below the control to output transfer function can be calculated:

Where

The dynamic resistance r

Z

(s) +

OUT

R1+

AC(LED)

Figure 8. Control to Output Transfer Function

I

OUT

V

ǒ

ǒ

OUT

H(s) +

ESR )

ESR )

1

+

(s)

(s)

H(s) + Z

1

sC

OUT

1

sC

OUT

2

V

ǒ

V

OUT

V

C

Ǔ

R

Ǔ

) R

Req+

OUT

V

(s)

(s)

OUT

eq

eq

* V

2

Fsw L

c

V

OUT

+

I

(s)

+ Req

R

R

ac

Rac R

2

Ǔ

ǒRcs G

IN

(s)

(s)

I

OUT

V

I

OUT

VC(s)

(s)

(s)

C

1 ) s ESR C

1 ) s C

1

1

is evaluated using the LED specification.

RAC+ R

sense

) r

AC(LED)

nb

i

LED

Ǔ

(s)

2

OUT

+

ǒ

ESR ) R

V

OUT

I

OUT

(eq. 23)

(eq. 24)

OUT

* V

(eq. 27)

Ǔ

eq

IN

(eq. 25)

(eq. 26)

http://onsemi.com

13

Page 14

NCS29001

Theory

The control to output transfer function is expressed following the formula below:

s

1 )

w

1 )

Ǔ ǒ

z

s

s

p

sw

RCS G

Ǔ

I

Where

Ho+

I

∂

∂

OUT

V

C

Req+

H(s) + H0

V

L F

C

ǒ

V

* V

OUT

IN

2

(eq. 28)

R

R

AC

RAC) R

1

1

(eq. 29)

Ho+

Ǹ

2 I

fp+

ǒ

OUT

V

OUT

2p

L F

Ǔ

* V

IN

ǒ

ESR ) R

sw

1

G

R

CS

1

Ǔ

C

eq

OUT

i

R

R

AC

RAC) R

1

1

(eq. 30)

(eq. 31)

There is also a right half plane zero:

fz+

2p ESR C

1

OUT

(eq. 32)

As the boost converter also operates in DCM, there is also a right half plane zero regulated to high frequency:

f

rhpz

+

sw

2p D

(eq. 33)

2 f

Type II compensation is used to compensate the two dominant poles fp of the control to output transfer function.

The compensator zero has to be placer at the f

fp+

2p (ESR ) Req) C

frequency of the transfer function.

p

R

1

comp

(ESR ) R

+

OUT

+ fz+

) C

eq

C

comp

2p R

OUT

comp

1

C

comp

(eq. 35)

(eq. 34)

The dominant pole is expressed following the equation:

fp1+

2p REA C

1

comp

(eq. 36)

−

COMP

9

+

gm

Type II

Rcomp

Ccomp

Compensation

Figure 9. Slope Compensation Network

The natural second pole is expressed following the equation:

fp2+

2p R

The zero is expressed following the equation:

fz+

2p R

http://onsemi.com

C

1

comp

1

comp

14

equivalent

C

bw =

pad+Comp2

C

bw

C

comp

Cpad

With

Ccomp2

Cpad=10pF

(eq. 37)

(eq. 38)

Page 15

NCS29001

OSCILLATOR FREQUENCY SETTING

The simplified equation to set the switching frequency using resistor RT:

13750

fsw+

) 5

R

T

(eq. 39)

Where:

is expressed in kW.

R

T

f

us expressed in kHz

sw

FBP OPTIONS

The FBP pin is used to program the feedback voltage that sets the LED current. Typically a resistor divider is used from VREF

to set the voltage between 0.5 V and 3.0 V. Additionally, to save component costs, the feedback voltage can be programmed

with internal 0.8 V (±1.5%) by tying the FBP pin to ground.

FAULT DETECTION:

• Overvoltage Protection: A resistor divider from VOUT can be used to set the overvoltage protection on the OVP pin.

When the OVP pin rises above 1.2 V the converter will shut off immediately and PWMout will be held high for 50 ms

to discharge the output capacitor. After this time the device will enter standby mode requires a high to low transition on

the STBY pin to restart.

• Short Circuit Protection: A resistor divider from VOUT can be used to set the short circuit protection on the OVP pin.

When the OVP pin drops below 75 mV the converter will shut off immediately and enter standby mode. A high to low

transition on the STBY pin is required to restart the device.

• Under Voltage Lockout (UVLO): The converter will immediately shut off and enter standby when the VIN pin voltage

drops below 7.5 V. When the UVLO condition is cleared, a high to low transition on the STBY pin is required to restart

the device.

• Temperature Shutdown: When the internal die temperature reaches 150°C, the device will behave the same as in the

overvoltage condition.

Layout Guidance

In switching converters it is important to use wide, short traces for components in the main switching path. Resistor RCS,

which is in the main switching path through transistor Q1, should be connected to power ground (PGND). Compensation

network components, resistor dividers, and bypass capacitors should be referenced to quiet ground (GND). Bypass capacitors

should be connected as close to the IC as possible.

ORDERING INFORMATION

Device Package Shipping

NCS29001DR2G SOIC−14

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

3000 / Tape & Reel

†

http://onsemi.com

15

Page 16

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

14

1

SCALE 1:1

SOIC−14 NB

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

14

H

M

0.25 B

0.10

14X

0.58

D

M

13X

e

SOLDERING FOOTPRINT*

6.50

1

A

B

8

E

71

b

S

M

0.25 B

A

C

A

A1

SEATING

C

PLANE

1.18

14X

S

1.27

PITCH

DETAIL A

h

X 45

_

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

A3

L

DETAIL A

PROTRUSION. ALLOWABLE PROTRUSION

SHALL BE 0.13 TOTAL IN EXCESS OF AT

MAXIMUM MATERIAL CONDITION.

4. DIMENSIONS D AND E DO NOT INCLUDE

MOLD PROTRUSIONS.

5. MAXIMUM MOLD PROTRUSION 0.15 PER

SIDE.

DIM MIN MAX MIN MAX

A 1.35 1.75 0.054 0.068

A1 0.10 0.25 0.004 0.010

A3 0.19 0.25 0.008 0.010

b 0.35 0.49 0.014 0.019

D 8.55 8.75 0.337 0.344

E 3.80 4.00 0.150 0.157

e 1.27 BSC 0.050 BSC

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.019

L 0.40 1.25 0.016 0.049

M 0 7 0 7

__ __

INCHESMILLIMETERS

GENERIC

MARKING DIAGRAM*

14

XXXXXXXXXG

AWLYWW

1

XXXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 17

SOIC−14

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

STYLE 1:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. NO CONNECTION

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. NO CONNECTION

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 5:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. NO CONNECTION

7. COMMON ANODE

8. COMMON CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 2:

CANCELLED

STYLE 6:

PIN 1. CATHODE

2. CATHODE

3. CATHODE

4. CATHODE

5. CATHODE

6. CATHODE

7. CATHODE

8. ANODE

9. ANODE

10. ANODE

11. ANODE

12. ANODE

13. ANODE

14. ANODE

STYLE 3:

PIN 1. NO CONNECTION

2. ANODE

3. ANODE

4. NO CONNECTION

5. ANODE

6. NO CONNECTION

7. ANODE

8. ANODE

9. ANODE

10. NO CONNECTION

11. ANODE

12. ANODE

13. NO CONNECTION

14. COMMON CATHODE

STYLE 7:

PIN 1. ANODE/CATHODE

2. COMMON ANODE

3. COMMON CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. ANODE/CATHODE

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. COMMON CATHODE

12. COMMON ANODE

13. ANODE/CATHODE

14. ANODE/CATHODE

STYLE 4:

PIN 1. NO CONNECTION

2. CATHODE

3. CATHODE

4. NO CONNECTION

5. CATHODE

6. NO CONNECTION

7. CATHODE

8. CATHODE

9. CATHODE

10. NO CONNECTION

11. CATHODE

12. CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 8:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. ANODE/CATHODE

7. COMMON ANODE

8. COMMON ANODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. NO CONNECTION

12. ANODE/CATHODE

13. ANODE/CATHODE

14. COMMON CATHODE

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 18

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...