Page 1

3 MHz, 125 mA Low Power

Operational Amplifier

NCS20061/2/4,

NCV20061/2/4

The NCS20061/2/4 is a family of single, dual and quad Operational

Amplifiers (Op Amps) with 3 MHz of Gain−Bandwidth Product

(GBWP) while consuming only 125 mA of Quiescent current per

opamp. The NCS2006x has Input Offset Voltage of 4 mV and operates

from 1.8 V to 5.5 V supply voltage over a wide temperature range

(−40°C to 125°C). The Rail−to−Rail In/Out operation allows the use of

the entire supply voltage range while taking advantage of the 3 MHz

GBWP. Thus, this family offers superior performance over many

industry standard parts. These devices are AEC−Q100 qualified which

is denoted by the NCV prefix.

NCS2006x’s low current consumption and low supply voltage

performance in space saving packages, makes them ideal for sensor

signal conditioning and low voltage current sensing applications in

Automotive, Consumer and Industrial markets.

Features

• Gain−Bandwidth Product: 3 MHz

• Low Supply Current/ Channel: 125 mA typ (V

• Low Input Offset Voltage: 4 mV max

• Wide Supply Range: 1.8 V to 5.5 V

• Wide Temperature Range: −40°C to +125°C

• Rail−to−Rail Input and Output

• Unity Gain Stable

• Available in Single, Dual and Quad Packages

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100

Qualified and PPAP Capable

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

= 1.8 V)

S

www.onsemi.com

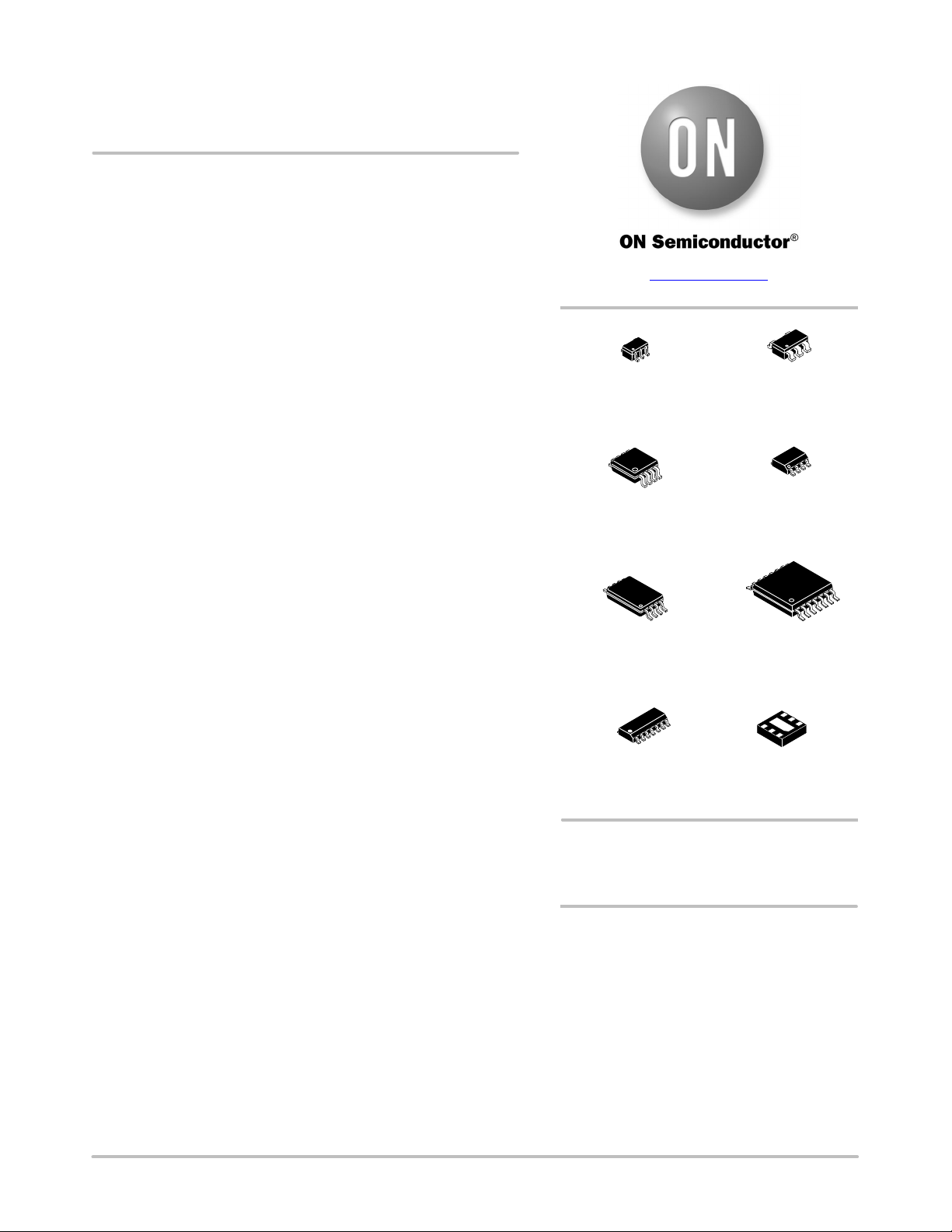

SC70−5

CASE 419A

Micro8]/MSOP8

CASE 846A

TSSOP−8

CASE 948S

14

1

SOIC−14

CASE 751A

5

1

TSOP−5/SOT23−5

CASE 483

8

1

SOIC−8

CASE 751

14

1

TSSOP−14

CASE 948G

6

1

UDFN6

CASE 517AP

Applications

• Automotive

• Battery Powered/ Portable

• Sensor Signal Conditioning

• Low Voltage Current Sensing

• Filter Circuits

• Unity Gain Buffer

© Semiconductor Components Industries, LLC, 2017

January, 2021 − Rev. 15

DEVICE MARKING INFORMATION

See general marking information in the device marking

section on page 2 of this data sheet.

ORDERING INFORMATION

See detailed ordering and shipping information on page 3 of

this data sheet.

1 Publication Order Number:

NCS2006/D

Page 2

NCS20061/2/4, NCV20061/2/4

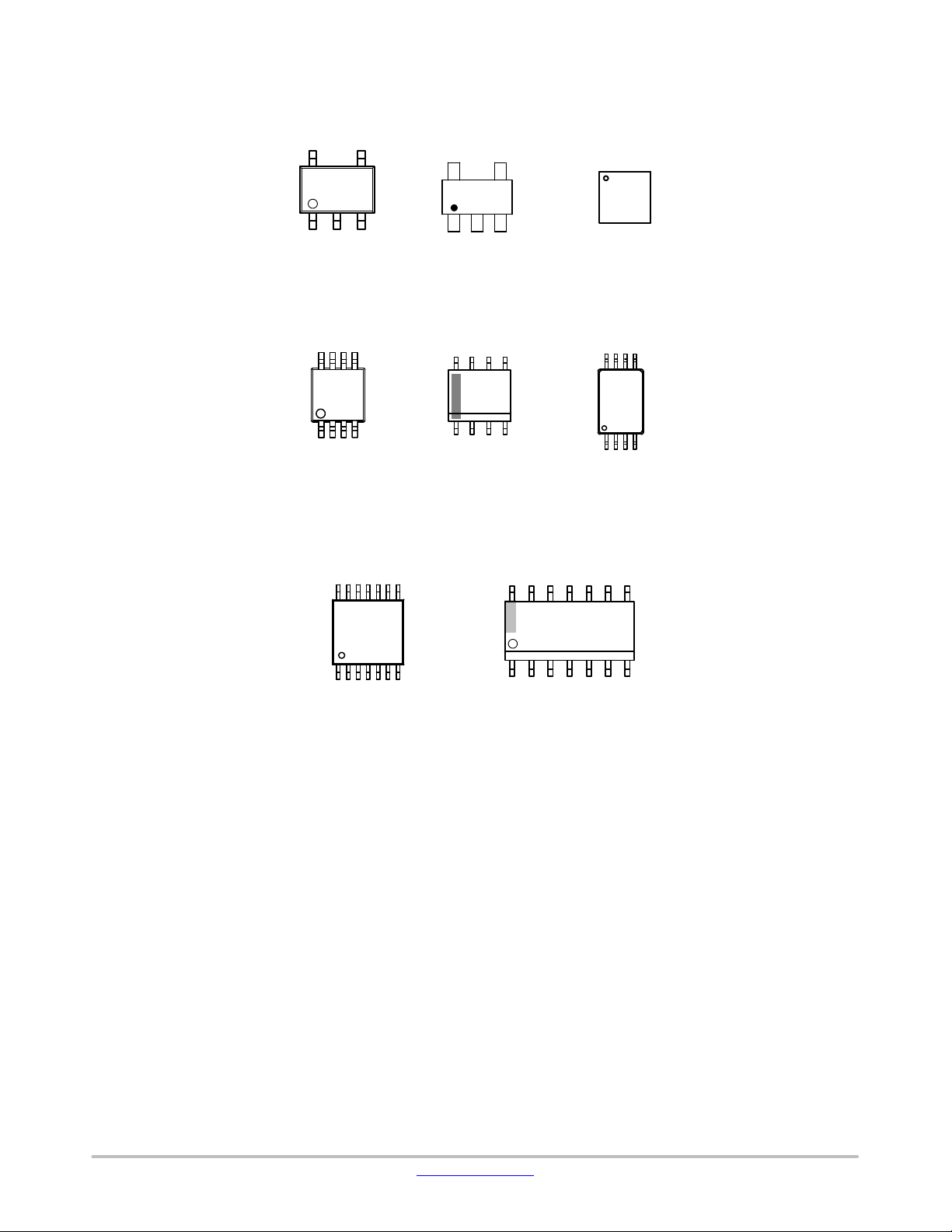

MARKING DIAGRAMS

Single Channel Configuration

NCS20061, NCV20061

XXMG

G

SC70−5

CASE 419A

8

XXXX

AYW G

G

1

Micro8]/MSOP8

CASE 846A

14

XXXX

XXXX

ALYWG

G

1

TSSOP−14

CASE 948G

5

XXXAYWG

G

1

TSOP−5/SOT23−5

CASE 483

Dual Channel Configuration

NCS20062, NCV20062

8

XXXXXX

ALYW

G

1

SOIC−8

CASE 751

Quad Channel Configuration

NCS20064, NCV20064

14

XXXXXXXXG

AWLYWW

1

SOIC−14

CASE 751A

1

XX MG

G

UDFN6

CASE 517AP

XXX

YWW

AG

TSSOP−8

CASE 948S

XXXXX = Specific Device Code

A = Assembly Location

WL, L = Wafer Lot

Y = Year

WW, W = Work Week

G or G = Pb−Free Package

(Note: Microdot may be in either location)

www.onsemi.com

2

Page 3

NCS20061/2/4, NCV20061/2/4

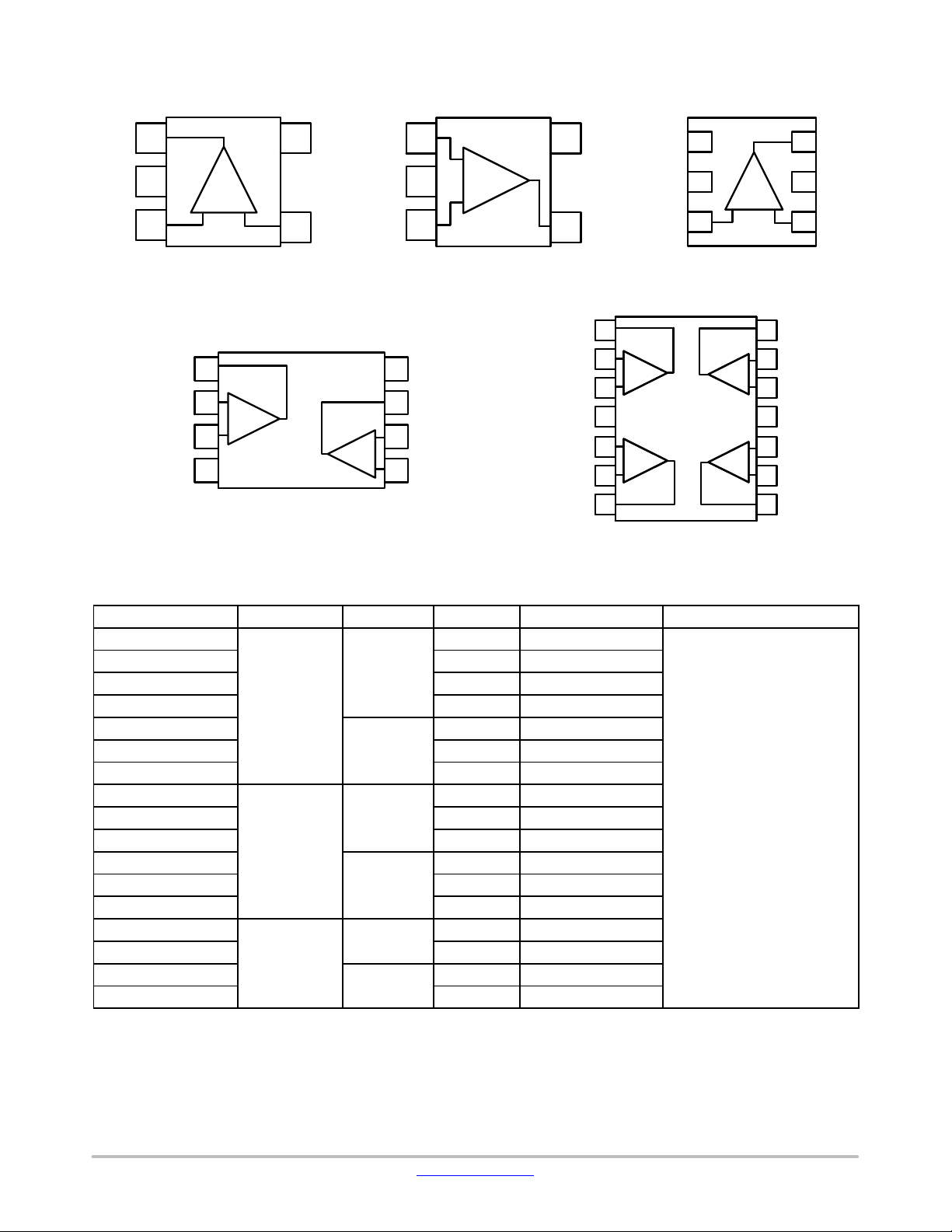

Single Channel Configuration

NCS20061, NCV20061

1

OUT

2

VSS

+

3

IN+

SC70−5, SOT23−5 (TSOP−5)

SQ2, SN2 Pinout

OUT 1

IN− 1

IN+ 1

1

2

3

VSS

4

Micro8/MSOP8, SOIC−8, TSSOP−8

5

VDD

−

4

IN−

Dual Channel Configuration

NCS20062, NCV20062

−

+

−

+

1

IN+

+

VSS

2

−

3

IN−

SC70−5, SOT23−5 (TSOP−5)

SQ3, SN3 Pinout

8

VDD

7

OUT 2

6

IN− 2

IN+ 2

5

Figure 1. Pin Connections

5

VDD

4

OUT

Quadruple Channel Configuration

NCS20064, NCV20064

IN− 1

IN+ 1

VDD

IN+ 2

IN− 2

1

2

−

+

3

4

5

+

−

6

7

TSSOP−14, SOIC−14

OUT 1

OUT 2

VSS

NC

IN−

1

2

3

+

−

UDFN6 1.6 x 1.6

14

OUT 4

IN− 4

13

−

+

IN+ 4

12

VSS

11

IN+ 3

10

+

−

IN− 3

9

OUT 3

8

6

OUT

5

VDD

4

IN+

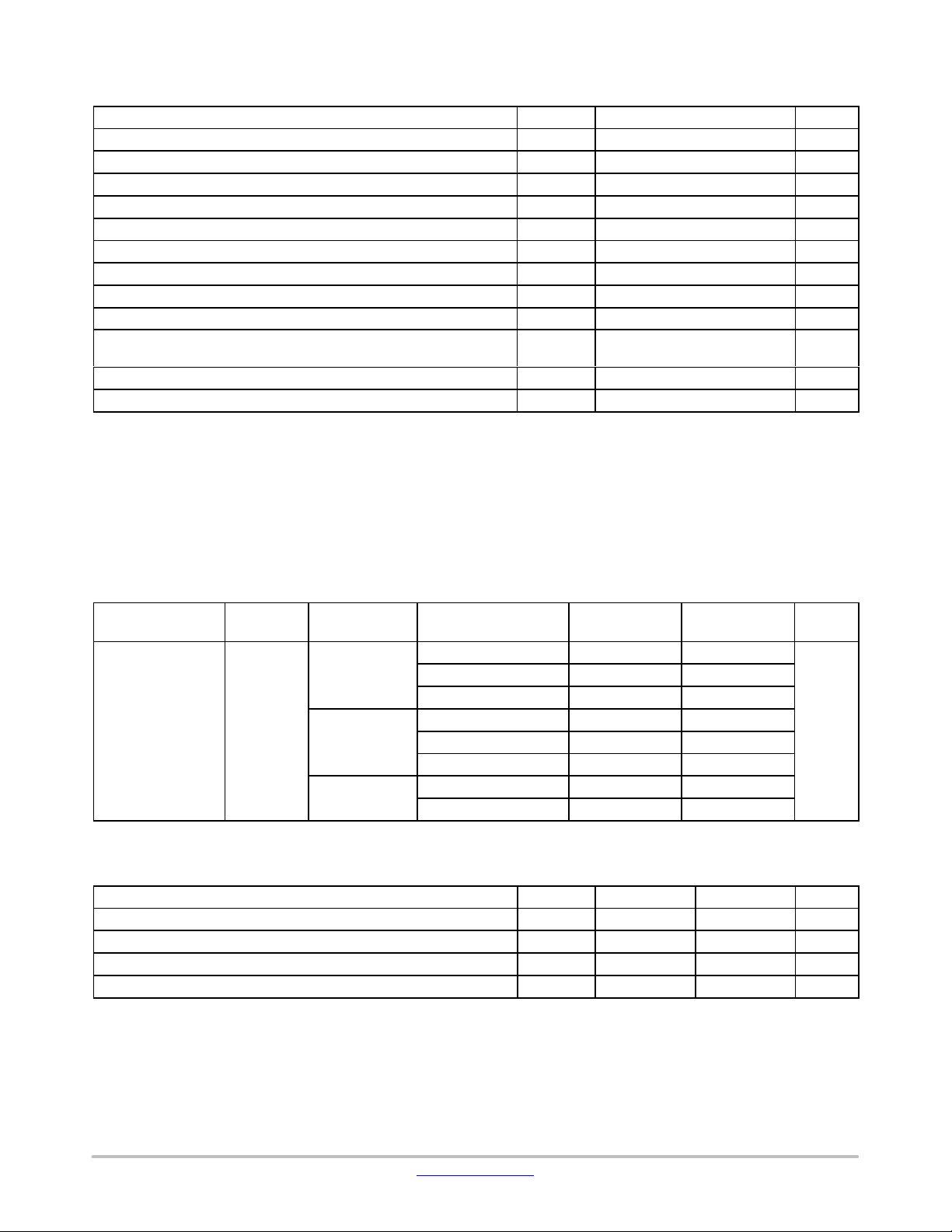

ORDERING INFORMATION

Device Configuration Automotive Marking Package Shipping

NCS20061SQ3T2G

NCS20061SN2T1G AEP SOT23−5/TSOP−5

NCS20061SN3T1G AEQ SOT23−5/TSOP−5

NCS20061MUTAG AG UDFN6

NCV20061SQ3T2G*

NCV20061SN2T1G* AEP SOT23−5/TSOP−5

NCV20061SN3T1G* AEQ SOT23−5/TSOP−5

NCS20062DMR2G

NCS20062DR2G NCS20062 SOIC−8

NCS20062DTBR2G K62 TSSOP−8

NCV20062DMR2G*

NCV20062DR2G* NCS20062 SOIC−8

NCV20062DTBR2G* K62 TSSOP−8

NCS20064DR2G

NCS20064DTBR2G 264 TSSOP−14

NCV20064DR2G*

NCV20064DTBR2G* 264 TSSOP−14

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D

*NCV Prefix for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q100 Qualified and PPAP

Capable.

Single

Dual

Quad

No

Yes

No

Yes

No

Yes

AAM SC70

AAM SC70

2K62 Micro8/MSOP8

Contact local sales office for

more information

2K62 Micro8/MSOP8

20064 SOIC−14

20064 SOIC−14

†

www.onsemi.com

3

Page 4

NCS20061/2/4, NCV20061/2/4

ABSOLUTE MAXIMUM RATINGS (Note 1)

Rating

Supply Voltage (VDD – VSS) (Note 2) V

Input Voltage V

Differential Input Voltage V

Maximum Input Current I

Maximum Output Current I

Continuous Total Power Dissipation (Note 2) P

Maximum Junction Temperature T

Storage Temperature Range T

Mounting Temperature (Infrared or Convection – 20 sec) T

ESD Capability (Note 3) Human Body Model

Charge Device Model

Latch−Up Current (Note 4) I

Moisture Sensitivity Level (Note 5) MSL Level 1

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS for Safe Operating Area.

2. Continuous short circuit operation to ground at elevated ambient temperature can result in exceeding the maximum allowed junction

temperature of 150°C. Output currents in excess of the maximum output current rating over the long term may adversely affect reliability.

Shorting output to either VDD or VSS will adversely affect reliability.

3. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per JEDEC standard Js−001−2017 (AEC−Q100−002)

ESD Charged Device Model tested per JEDEC standard JS−002−2014 (AEC−Q100−011)

4. Latch−up Current tested per JEDEC standard JESD78E (AEC−Q100−004)

5. Moisture Sensitivity Level tested per IPC/JEDEC standard: J-STD-020A

Symbol Limit Unit

6 V

+ 0.5 V

DD

±V

s

±10 mA

±100 mA

200 mW

150 °C

−65 to 150 °C

260 °C

2000

2000

100 mA

V

V

ESD

ESD

S

I

ID

I

O

D

J

STG

mount

HBM

CDM

LU

VSS − 0.5 to V

THERMAL INFORMATION

Single Layer

Parameter Symbol Channels Package

Board (Note 6)

SC−70 490 444

Single

SOT23−5/TSOP−5 310 247

UDFN6 276 239

Junction to Ambient

Thermal Resistance

q

JA

Dual

Micro8/MSOP8 236 167

SOIC−8 190 131

TSSOP−8 253 194

SOIC−14 130 99

Quad

6. Value based on 1S standard PCB according to JEDEC51−3 with 1.0 oz copper and a 300 mm2 copper area

7. Value based on 1S2P standard PCB according to JEDEC51−7 with 1.0 oz copper and a 100 mm

TSSOP−14 178 140

2

copper area

Multi−Layer

Board (Note 7)

Unit

°C/W

OPERATING RANGES

Parameter Symbol Min Max Unit

Operating Supply Voltage V

Differential Input Voltage V

Input Common Mode Range V

Ambient Temperature T

S

ID

ICM

A

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

1.8 5.5 V

V

S

VSS – 0.2 VDD + 0.2 V

−40 125 °C

V

www.onsemi.com

4

Page 5

NCS20061/2/4, NCV20061/2/4

ELECTRICAL CHARACTERISTICS AT VS = 1.8 V

TA = 25°C; RL ≥ 10 kW; VCM = V

Boldface limits apply over the specified temperature range, T

Parameter

INPUT CHARACTERISTICS

Input Offset Voltage

Offset Voltage Drift

Input Bias Current (Note 8) I

Input Offset Current (Note 8) I

Channel Separation XTLK f = 1 kHz 125 dB

Differential Input Resistance R

Common Mode Input Resistance R

Differential Input Capacitance C

Common Mode Input Capacitance C

Common Mode Rejection Ratio CMRR

OUTPUT CHARACTERISTICS

Open Loop Voltage Gain

Short Circuit Current I

Output Voltage High V

Output Voltage Low V

AC CHARACTERISTICS

Unity Gain Bandwidth UGBW 3 MHz

Slew Rate at Unity Gain SR VIN = 1.2 Vpp, Gain = 1 1.2

Phase Margin

Gain Margin A

Settling Time t

Open Loop Output Impedance Z

NOISE CHARACTERISTICS

Total Harmonic Distortion plus Noise THD+N VIN = 1.2 Vpp, f = 1 kHz, Av = 1 0.005 %

Input Referred Voltage Noise e

Input Referred Current Noise i

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio

Power Supply Quiescent Current I

8. Performance guaranteed over the indicated operating temperature range by design and/or characterization.

= mid−supply unless otherwise noted.

OUT

= −40°C to 125°C. (Note 8)

A

Symbol Conditions Min Typ Max Unit

V

OS

DVOS/DT

IB

OS

ID

IN

ID

CM

VCM = VSS – 0.2 to VDD + 0.2 48 73

VCM = VSS + 0.2 to VDD − 0.2 45

A

VOL

SC

Output to positive rail, sinking current 19

Output to negative rail, sourcing current 15

OH

OL

y

m

m

S

Voltage output swing from positive rail

Voltage output swing from negative rail

VIN = 1.2 Vpp,

Gain = 1

OL

n

n

PSRR No Load

DD

Per channel, no load 125 170

0.5 3.5 mV

4 mV

1

1 pA

1500 pA

1 pA

1100 pA

10

10

1 pF

5 pF

86 120

80

3 19

V

= VDD − V

OH

OUT

20

3 19

V

= V

OUT

− V

SS

20

OL

60 °

10 dB

Settling time to 0.1% 2.3 ms

Settling time to 0.01% 6

See

Figure

25

f = 1 kHz 20

f = 10 kHz 15

f = 1 kHz 300 fA/√Hz

67 90

64

mV/°C

V/ms

nV/√Hz

GW

GW

dB

dB

mA

mV

mV

W

dB

mA

www.onsemi.com

5

Page 6

NCS20061/2/4, NCV20061/2/4

ELECTRICAL CHARACTERISTICS AT VS = 3.3 V

TA = 25°C; RL ≥ 10 kW; VCM = V

Boldface limits apply over the specified temperature range, T

Parameter

INPUT CHARACTERISTICS

Input Offset Voltage

Offset Voltage Drift

Input Bias Current (Note 9) I

Input Offset Current (Note 9) I

Channel Separation XTLK f = 1 kHz 125 dB

Differential Input Resistance R

Common Mode Input Resistance R

Differential Input Capacitance C

Common Mode Input Capacitance C

Common Mode Rejection Ratio CMRR

OUTPUT CHARACTERISTICS

Open Loop Voltage Gain

Short Circuit Current I

Output Voltage High V

Output Voltage Low V

AC CHARACTERISTICS

Unity Gain Bandwidth UGBW 3 MHz

Slew Rate at Unity Gain SR VIN = 2.5 Vpp, Gain = 1 1.2

Phase Margin

Gain Margin A

Settling Time t

Open Loop Output Impedance Z

NOISE CHARACTERISTICS

Total Harmonic Distortion plus Noise THD+N VIN = 2.5 Vpp, f = 1 kHz, Av = 1 0.005 %

Input Referred Voltage Noise e

Input Referred Current Noise i

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio

Power Supply Quiescent Current I

9. Performance guaranteed over the indicated operating temperature range by design and/or characterization.

= mid−supply unless otherwise noted.

OUT

= −40°C to 125°C. (Note 9)

A

Symbol Conditions Min Typ Max Unit

V

OS

DVOS/DT

IB

OS

ID

IN

ID

CM

VCM = VSS – 0.2 to VDD + 0.2 53 76

VCM = VSS + 0.2 to VDD − 0.2 48

A

VOL

SC

Output to positive rail, sinking current 19

Output to negative rail, sourcing current 15

OH

OL

y

m

m

S

Voltage output swing from positive rail

Voltage output swing from negative rail

VIN = 2.5 Vpp,

Gain = 1

OL

n

n

PSRR No Load

DD

Per channel, no load 135 180

0.5 3.5 mV

4 mV

1

1 pA

1500 pA

1 pA

1100 pA

10

10

1 pF

5 pF

90 120

86

3 24

V

= VDD − V

OH

OUT

25

3 24

V

= V

OUT

− V

SS

25

OL

60 °

10 dB

Settling time to 0.1% 2.3 ms

Settling time to 0.01% 3.1

See

Figure

25

f = 1 kHz 20

f = 10 kHz 15

f = 1 kHz 300 fA/√Hz

67 90

64

mV/°C

V/ms

nV/√Hz

GW

GW

dB

dB

mA

mV

mV

W

dB

mA

www.onsemi.com

6

Page 7

NCS20061/2/4, NCV20061/2/4

ELECTRICAL CHARACTERISTICS AT VS = 5.5 V

TA = 25°C; RL ≥ 10 kW; VCM = V

Boldface limits apply over the specified temperature range, T

Parameter

INPUT CHARACTERISTICS

Input Offset Voltage

Offset Voltage Drift

Input Bias Current (Note 10) I

Input Offset Current (Note 10) I

Channel Separation XTLK f = 1 kHz 125 dB

Differential Input Resistance R

Common Mode Input Resistance R

Differential Input Capacitance C

Common Mode Input Capacitance C

Common Mode Rejection Ratio CMRR

OUTPUT CHARACTERISTICS

Open Loop Voltage Gain A

Short Circuit Current I

Output Voltage High V

Output Voltage Low V

AC CHARACTERISTICS

Unity Gain Bandwidth

Slew Rate at Unity Gain SR VIN = 5 Vpp, Gain = 1 1.2

Phase Margin

Gain Margin A

Settling Time t

Open Loop Output Impedance Z

NOISE CHARACTERISTICS

Total Harmonic Distortion plus Noise THD+N VIN = 5 Vpp, f = 1 kHz, Av = 1 0.005 %

Input Referred Voltage Noise e

Input Referred Current Noise i

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio

Power Supply Quiescent Current I

10.Performance guaranteed over the indicated operating temperature range by design and/or characterization.

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

= mid−supply unless otherwise noted.

OUT

= −40°C to 125°C. (Note 10)

A

Symbol Conditions Min Typ Max Unit

V

OS

DVOS/DT

IB

OS

ID

IN

ID

CM

VCM = VSS – 0.2 to VDD + 0.2 55 79

VCM = VSS + 0.2 to VDD − 0.2 51

VOL

SC

Output to positive rail, sinking current 19

Output to negative rail, sourcing current 15

OH

OL

Voltage output swing from positive rail

Voltage output swing from negative rail

UGBW 3 MHz

y

m

m

S

VIN = 5 Vpp,

Gain = 1

OL

n

n

PSRR No Load

DD

Per channel, no load 140 200

0.5 3.5 mV

4 mV

1

1 pA

1500 pA

1 pA

1100 pA

10

10

1 pF

5 pF

90 120

86

3 24

V

= VDD − V

OH

OUT

25

3 24

V

= V

OUT

− V

SS

25

OL

60 °

10 dB

Settling time to 0.1% 2.3

Settling time to 0.01% 3.1

See

Figure

25

f = 1 kHz 20

f = 10 kHz 15

f = 1 kHz 300 fA/√Hz

67 90

64

mV/°C

GW

GW

dB

dB

mA

mV

mV

V/ms

ms

W

nV/√Hz

dB

mA

www.onsemi.com

7

Page 8

NCS20061/2/4, NCV20061/2/4

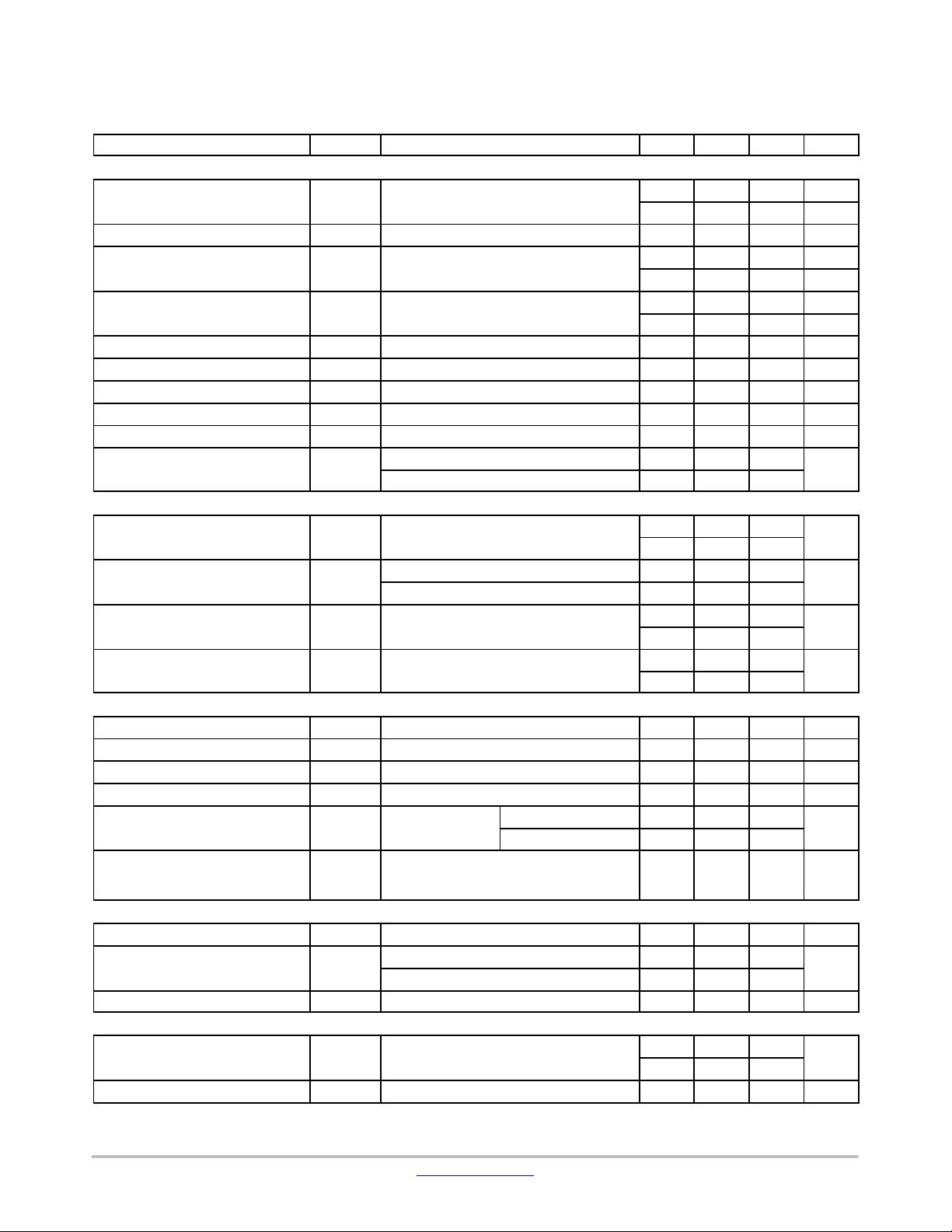

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, RL ≥ 10 kW, VCM = V

= mid−supply unless otherwise specified

OUT

SUPPLY CURRENT (mA)

1000

OFFSET VOLTAGE (mV)

180

160

140

T = 25°C

120

T = 125°C

100

T = −40°C

80

SUPPLY VOLTAGE (V) TEMPERATURE (°C)

Figure 2. Quiescent Current per Channel vs.

5.5

5.04.54.03.53.02.52.01.5

180

160

VS = 5.5 V

140

VS = 3.3 V

120

SUPPLY CURRENT (mA)

100

VS = 1.8 V

80

60 140

Figure 3. Quiescent Current vs. Temperature

Supply Voltage

1000

OFFSET VOLTAGE (mV)

900

800

700

600

500

400

300

200

100

VS = 5.5 V

VS = 3.3 V

VS = 1.8 V

0

40 140

900

800

700

600

500

400

300

200

100

T = −40°C

T = 0°C

T = 25°C

T = 85°C

T = 125°C

0

SUPPLY VOLTAGE (V) TEMPERATURE (°C)

5.04.54.03.53.02.52.01.5

5.5

Figure 4. Offset Voltage vs. Supply Voltage Figure 5. Offset Voltage vs. Temperature

1201008040200−20−40

1201008060200−20−40

2000

1600

1200

800

400

−400

−800

OFFSET VOLTAGE (mV)

−1200

−1600

−2000

VS = 5.5 V

12 units

0

COMMON MODE VOLTAGE (V) FREQUENCY (Hz)

Figure 6. Offset Voltage vs. Common Mode

Voltage

140

120

100

80

60

GAIN (dB)

40

AV−10

V

20

R

C

0

−22 dBm Input

2.11.40.70−0.7−1.4−2.1−2.8

−20

2.8

www.onsemi.com

8

Gain

Phase Margin

= 5.5 V

S

= 10 kW

L

= 15 pF

L

Figure 7. Open−loop Gain and Phase Margin

vs. Frequency

180

135

90

PHASE MARGIN (°)

45

0

10M1M100k10k1k10010

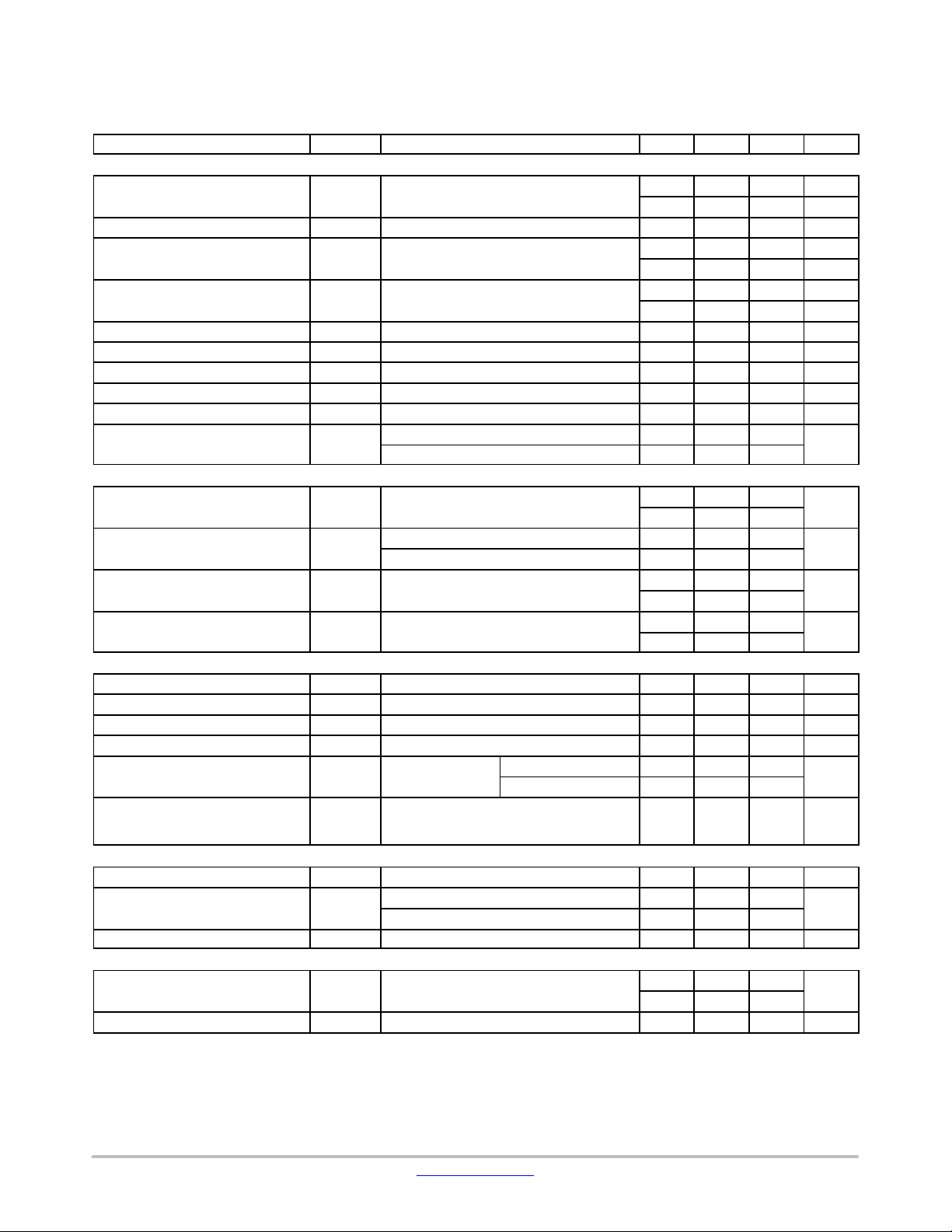

Page 9

NCS20061/2/4, NCV20061/2/4

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, RL ≥ 10 kW, VCM = V

= mid−supply unless otherwise specified

OUT

70

VS = 5.5 V

R

60

= 10 kW

L

T = 25°C

50

40

30

20

PHASE MARGIN (°)

10

0

5004003002001000

100

10

1

0.1

THD+N (%)

0.01

0.001

VS = 5.5 V

= 1 kHz

f

IN

A

= 1

V

10.10.01

CAPACITIVE LOAD (pF) OUTPUT VOLTAGE (Vrms)

Figure 8. Phase Margin vs. Capacitive Load Figure 9. THD + N vs. Output Voltage

1

0.1

AV = 1 V/V

R

= 10 kW

L

T

= 25°C

A

1 V

RMS

VS = 1.8 V

600

VS = 5.5 V

500

400

300

THD+N (%)

0.01

VS = 3.3 V

VOLTAGE NOISE (nV/√Hz)

200

100

VS = 5.5 V

0.001

0

10k1k10010

FREQUENCY (Hz) FREQUENCY (Hz)

Figure 10. THD + N vs. Frequency Figure 11. Input Voltage Noise vs. Frequency

100

90

80

VS = 1.8 V, PSRR+

70

VS = 1.8 V, PSRR−

60

50

40

PSRR (dB)

30

20

10

0

VS = 5.5 V, PSRR+

VS = 5.5 V, PSRR−

CURRENT NOISE (fA/√Hz)

900

800

700

600

500

400

300

200

100

VS = 5.5 V

0

100k10k1k100101

FREQUENCY (Hz) FREQUENCY (Hz)

Figure 12. Input Current Noise vs. Frequency Figure 13. PSRR vs. Frequency

100k10k1k100101

1M100k10k1k10010

www.onsemi.com

9

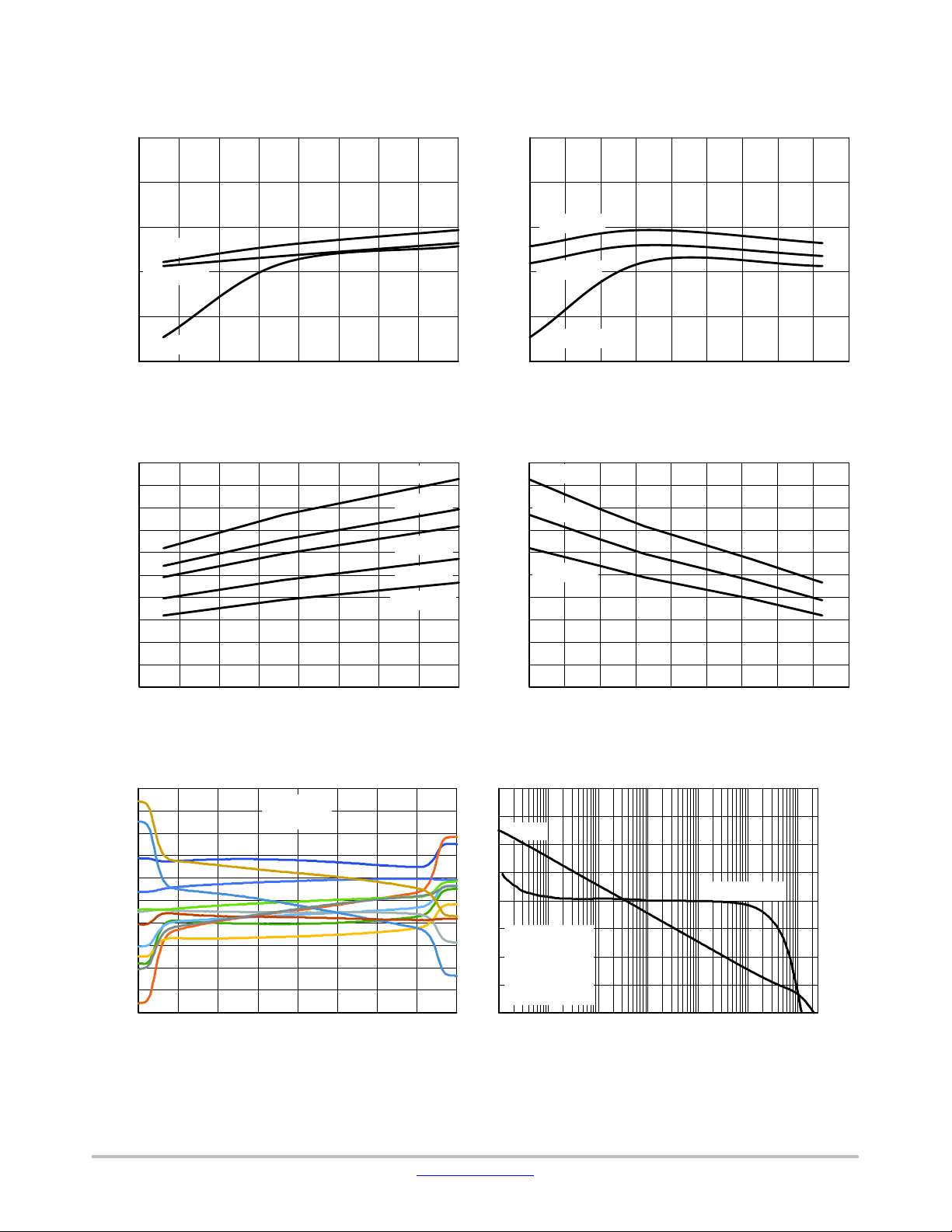

Page 10

NCS20061/2/4, NCV20061/2/4

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, RL ≥ 10 kW, VCM = V

= mid−supply unless otherwise specified

OUT

120

VS = 5.5 V

100

VS = 3.3 V

80

VS = 1.8 V

60

CMRR (dB)

40

20

0

500

400

300

200

100

0

OUTPUT VOLTAGE TO NEGATIVE RAIL (mV)

Figure 16. Output Voltage Low to Rail Figure 17. Non−Inverting Small Signal

300

AV = 1

250

200

150

RAIL (mV)

100

50

OUTPUT VOLTAGE TO POSITIVE

0

1M100k10k1k10010

FREQUENCY (Hz) OUTPUT CURRENT (mA)

VS = 1.8 V

VS = 3.3 V

VS = 5.5 V

Figure 14. CMRR vs. Frequency Figure 15. Output Voltage High to Rail

0.100

0.075

20151050

0.050

0.025

−0.025

VOLTAGE (V)

−0.050

−0.075

−0.100

0

3210−1

TIME (ms)

VS = 1.8 V

VS = 3.3 V

VS = 5.5 V

OUTPUT CURRENT (mA)

Transient Response

15.012.510.07.55.02.50

4

0.100

0.075

0.050

0.025

−0.025

VOLTAGE (V)

−0.050

−0.075

−0.100

0

56

TIME (ms) TIME (ms)

Figure 18. Inverting Small Signal Transient

Response

1.5

1.0

0.5

0

VOLTAGE (V)

−0.5

−1.0

−1.5

8

743210−1−2

www.onsemi.com

10

543210−1

Figure 19. Non−Inverting Large Signal

Transient Response

6

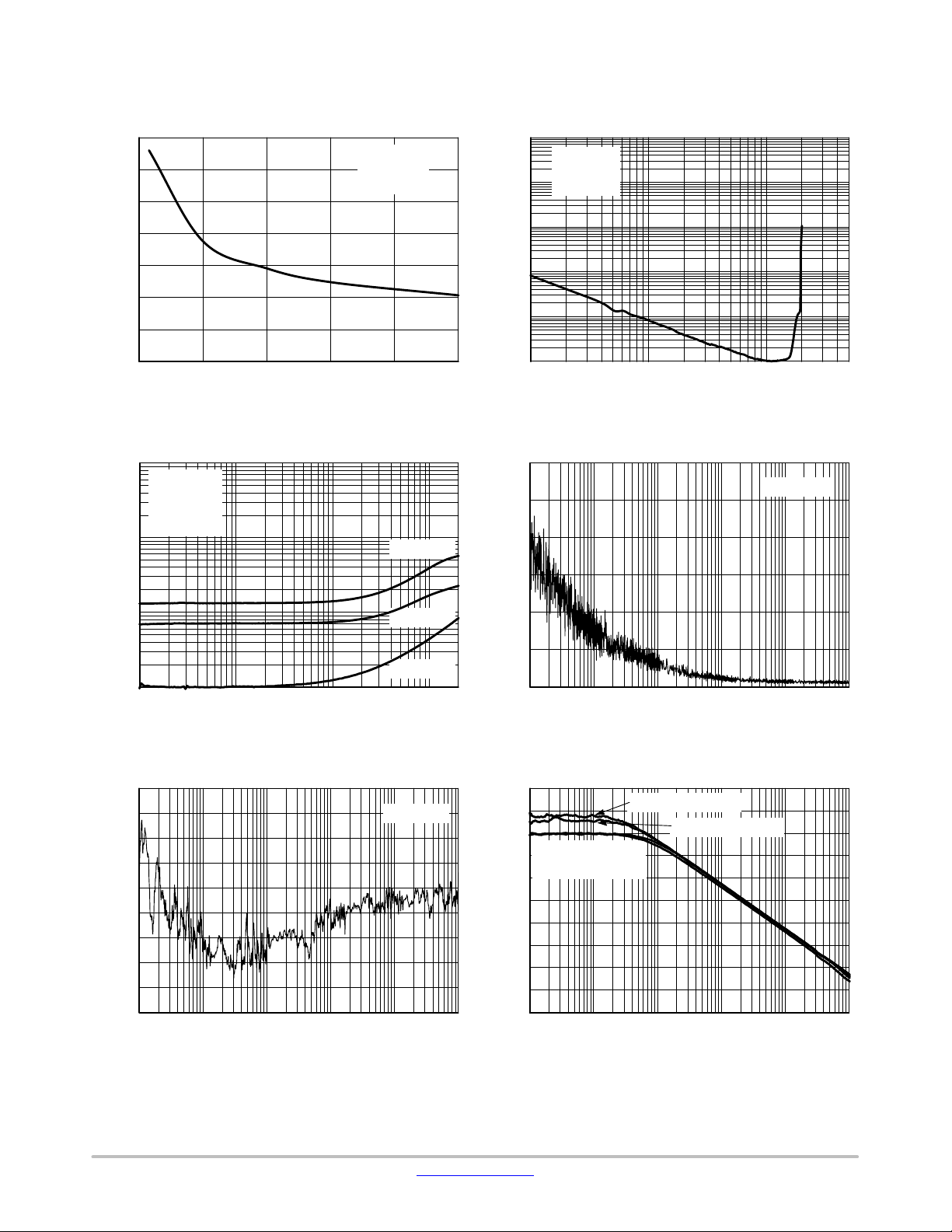

Page 11

NCS20061/2/4, NCV20061/2/4

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, RL ≥ 10 kW, VCM = V

= mid−supply unless otherwise specified

OUT

1.5

1.0

0.5

0

VOLTAGE (V)

−0.5

−1.0

−1.5

543210−1−2

TIME (ms)

Figure 20. Inverting Large Signal Transient

Response

18

16

14

12

10

8

6

4

I

2

CURRENT (pA)

OS

0

I

IB+

−2

−4

I

IB−

−6

−0.5 5.5

0.5 1.5 2.5 4.5 6.0

COMMON MODE VOLTAGE (V) TIME (s)

Figure 22. Input Bias Current vs. Common

Mode Voltage

67

5.04.03.53.02.01.00

8

600

500

400

300

200

CURRENT (pA)

100

0

−100

Figure 21. Input Bias and Offset Current vs.

6

4

2

0

−2

VOLTAGE (mV)

−4

−6

I

IB+

I

IB−

I

OS

80 140

1201006040200−20−40

TEMPERATURE (°C)

Temperature

3710

98654210

Figure 23. 0.1 Hz to 10 Hz Noise

−60

100k

−80

10k

−100

V

S

= 3.3 V

1k

−120

OUTPUT IMPEDANCE (W)

CHANNEL SEPARATION (dB)

−140

10M1M100k10k1k100

FREQUENCY (Hz)

100

10 100 1k 10k 100k 1M 10M

FREQUENCY (Hz)

Figure 24. Channel Separation vs. Frequency Figure 25. Open Loop Output Impedance

vs. Frequency

www.onsemi.com

11

V

S

V

S

= 1.8 V

= 5.5 V

Page 12

NCS20061/2/4, NCV20061/2/4

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, RL ≥ 10 kW, VCM = V

1.5

SR+

1.4

1.3

1.2

SR−

SLEW RATE (V/ms)

1.1

= mid−supply unless otherwise specified

OUT

1.0

40 140

TEMPERATURE (°C)

Figure 26. Slew Rate vs. Temperature

1201008060200−20−40

www.onsemi.com

12

Page 13

NCS20061/2/4, NCV20061/2/4

Application Information

The NCS/NCV20061/2/4 family of operational

amplifiers is manufactured using ON Semiconductor’s

CMOS process. Products in this class are general purpose,

unity−gain stable amplifiers and include single, dual and

quad configurations.

Rail−to−Rail Input with No Phase Reversal

The NCS operational amplifiers are designed to prevent

phase reversal or any similar issues when the input pins

potential exceed the supply voltages by up to 100 mV.

Figure 6 shows the input voltage exceeding the supply

limits.

The input stage of the NCS/NCV 20061/2/4 family

consists of two differential CMOS input stages connected in

parallel: the first is constructed using paired PMOS devices

and it operates at low common mode input voltages (VCM);

the second stage is build using paired NMOS devices to

operate at high VCM. The transition between the two input

stages occurs at a common mode input voltage of

approximately VDD–1.3V and it is visible in Figure 6

(Offset vs. VCM).

Limiting input voltages

In order to prevent damage and/or improper operation of

these amplifiers, the application circuit must never expose

the input pins to voltages or currents higher than the

Absolute Maximum Ratings.

The internal ESD structure includes special diodes to

protect the input stages while maintaining a low Input Bias

(IIB) current. The input protection circuitry clamp the inputs

when the signals applied exceed more than one diode drop

below VSS or one diode drop above VDD. Very fast ESD

events (within the limits specified) trigger the protection

structure so the operational amplifier is not damaged.

However, in some applications, it can be necessary to

prevent excessive voltages from reaching the operational

amplifier inputs by adding external clamp diodes. A possible

solution is presented in Figure 27, where the four low−drop

fast diodes (Shottky preferred) are used in parallel with the

internal structure to divert the excessive energy to the supply

rails where it can be easily dissipated or absorbed by the

supply capacitors. The application designer should also take

into account that these external diodes add leakage currents

and parasitic capacitance that must be considered when

evaluating the end−to−end performance of the amplifier

stage.

Limiting input currents

In order to prevent damage/ improper operation of these

amplifiers, the application circuit must limit the currents

flowing in and out of the input pins. A possible solution is

presented in Figure 27 by means of the two added series

resistors. The minimum value for R_IN− and R_IN+ should

be calculated using Ohm’s Law so they limit the input pin

currents to less than the absolute maximum values specified.

The application designer should take into account that these

resistors also add parasitic inductance that must be

considered when evaluating performance.

Combining the current limiting resistors with the voltage

limiting diodes creates a solid input protection structure, that

can be used to insure reliable operation of the amplifier even

in the hardest conditions.

Figure 27. Typical Protection of the Operational Amplifier Inputs

Rail−to−Rail Output

The maximum output voltage swing is dependent of the

particular output load. According to the specification, the

output can reach within 25 mV of either supply rail when

load resistance is 10 kΩ. Figure 15 and Figure 16 shows the

load drive capabilities of the part under different conditions.

Output current is internally limited to 15 mA typ.

Capacitive Loads

Driving capacitive loads can create stability problems for

voltage feedback opamps, as it is a known possible cause for:

www.onsemi.com

• degraded phase margin

• lowered bandwidth

• gain peaking of the frequency response

• overshoot and ringing of the step response.

While the NCS/NCV20061/2/4 family of opamps are

capable of driving capacitive loads up to 100pF, adding a

small resistor in series to the output (R_ISO in Figure 28)

will increase the feedback loop’s phase margin. This leads

to higher stability by making the equivalent load more

resistive at high frequencies.

13

Page 14

NCS20061/2/4, NCV20061/2/4

Figure 28. Driving Capacitive Loads

Simulating the application with ON Semiconductor’s

P−SPICE models is a good starting point for selecting the

isolation resistor’s value, and then bench testing the

frequency and step response can be used to fine−tune the

value according to the desired characteristic.

Unity Gain Bandwidth

Interfacing a high impedance sensor’s output to a

relatively low−impedance ADC input usually requires an

intermediate stage to avoid unwanted interference of the two

devices, and this stage needs to have a high input impedance,

a low output impedance and high output current.

The unity gain buffer is recommended here (Figure 29).

The ADC’s internal sampling capacitor requires a buffer

front−end to recharge it faster than the sampling time, and

this problem is even worse if more channels are sampled by

the same ADC using an internal multiplexer. In order to

achieve a settling time shorter than the multiplexed

sampling rate, an RC stage is recommended between the

buffer and the ADC input. The R resistor’s value should be

low enough to charge the capacitor quickly, but at the same

time large enough to isolate the capacitive load from the

opamp’s output to preserve phase margin. When transients

are generated by the sensor’s output, first the two opamp’s

inputs see a high differential voltage between them, then the

output settles and brings the inverting input back to the

correct voltage.

To successfully accommodate for example a 0.1 V to 4 V

sensor signal, the opamp’s differential input range of the

NCS(V) 20061/2/4 series is close to the supply range

VDD−VSS, and the output will match the input. The

differential input voltage is limited only by the ESD

protection structure and not by back−to−back diodes

between inputs.

Figure 29. Unity Gain Buffer Stage for Sampling with ADC

Power Supply Bypassing

For AC, the power supply pins (VDD and VSS for split

supply, VDD for single supply) should be bypassed locally

with a quality capacitor in the range of 100 nF (ceramics are

recommended for their low ESR and good high frequency

response) as close as possible to the opamp’s supply pins.

For DC, a bulk capacitor in the range of 1 mF within inches

distance from the opamp can provide the increased currents

required to drive higher loads.

Unused Operational Amplifiers

Occasionally not all the opamps offered in the quad

packages are needed for a specific application. They can be

connected as “buffering ground” as shown in Figure 30, a

solution that does not need any extra parts. Connecting them

differently (inputs split to rails, left floating, etc.) can

sometimes cause unwanted oscillation, crosstalk, increased

current consumption, or add noise to the supply rails.

Figure 30. Unused Operational Amplifiers

PCB Surface Leakage

The Printed Circuit Board’s surface leakage effects should

be estimated if the lowest possible input bias current is

critical. Dry environment surface current increases further

when the board is exposed to humidity, dust or chemical

contamination. For harsh environment conditions,

protecting the entire board surface (with all the exposed

metal pins and soldered areas) is advised. Conformal coating

or potting the board in resin proves effective in most cases.

www.onsemi.com

14

Page 15

NCS20061/2/4, NCV20061/2/4

An alternate solution for reduced leakage is the use of

guard rings around sensitive pins and pads. A proper guard

ring should have low impedance and be biased to the same

voltage as the sensitive pin so no current flows in between.

For an inverting amplifier, the non−inverting input is

usually connected to supply’s ground (or virtual ground at

half the rail voltage in single supply applications) so it can

represent a good ring solution. When routing the PCB traces,

create a closed perimeter around the inverting input pad (which

carries the signal) and connect it to the non−inverting input.

For a non−inverting amplifier, use a similarly shaped

(rectangle or circle) copper trace around the non−inverting

input pad (which carries the signal) and connect it to the

inverting input pin, which presents a much lower impedance

thanks to the feedback network.

PCB Routing Recommendations

Even when some operational amplifier is expected to

amplify only the useful DC signal, it can also pick some high

frequency noise altogether and amplify it accordingly, if the

design allows it. In order to reach the specified operational

amplifier parameters and to avoid high frequency

Applications Example

interference issues, it is recommended that the PCB layout

respects some basic guidelines:

• A dedicated layer for the ground plane should be used

whenever possible and all supply decoupling capacitors

should connect to it by vias.

• Copper traces should be as short as possible.

• High current paths should not be shared by small signal

or low current traces.

• If present, switching power supply blocks should be

kept away from the analog sensitive areas to avoid

potential conducted and radiated noise issues.

• When different circuit taxonomies share the same

board, it is recommended to keep separated the power

areas, the digital areas and the small signal analog

areas. Small−signal parts in the signal path should be

placed as close as possible to the opamp’s input pins.

• Metal shielding the sensitive areas and the “offender”

blocks may be required in some cases.

In a sensitive application, a good PCB design can take longer

but it will save troubleshooting time.

Second Order Active Low Pass Filter

Using an opamp with a low input bias current allows the

use of higher value resistors and smaller capacitors for the

same filter application. As a trade−off for the increased

impedance and lower consumption obtained, the higher

value resistors may also bring higher noise and sensibility to

board contamination, and possibly frequency response

changes (the increased R*C time constant due to parasitic

capacitances can change the gain vs. frequency plot).

An example of an active low−pass filter using the

NCS2006x operational amplifier can be found in Figure 31.

The filter’s 3 dB Bandwidth is approximately 25 KHz,

followed by a −40 dB/dec roll−off as in Figure 32. Such

filters with flat response in the sampled signal band are

recommended as a front−end for ADC’s to avoid aliasing.

Figure 32. Filter’s Frequency Response

Using the P−SPICE models provided by

ON Semiconductor is recommended as a starting point for

component selection, and then values can be further

fine−tuned during bench testing the application.

Figure 31. Second Order Active Low Pass Filter

Micro8 is a trademark of International Rectifier

www.onsemi.com

15

Page 16

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SC−88A (SC−70−5/SOT−353)

SCALE 2:1

CASE 419A−02

ISSUE L

DATE 17 JAN 2013

S

0.40

0.0157

A

G

45

−B−

12 3

D

5 PL

C

H

SOLDER FOOTPRINT

0.50

0.0197

MM

B0.2 (0.008)

N

K

0.65

0.025

0.65

0.025

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. 419A−01 OBSOLETE. NEW STANDARD

419A−02.

4. DIMENSIONS A AND B DO NOT INCLUDE

MOLD FLASH, PROTRUSIONS, OR GATE

BURRS.

INCHES

DIMAMIN MAX MIN MAX

B 1.15 1.350.045 0.053

C 0.80 1.100.031 0.043

D 0.10 0.300.004 0.012

G 0.65 BSC0.026 BSC

H --- 0.10---0.004

J 0.10 0.250.004 0.010

K 0.10 0.300.004 0.012

N 0.20 REF0.008 REF

S 2.00 2.200.079 0.087

MILLIMETERS

1.80 2.200.071 0.087

J

GENERIC MARKING

DIAGRAM*

XXXMG

G

XXX = Specific Device Code

M = Date Code

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

1.9

0.0748

STYLE 1:

PIN 1. BASE

2. EMITTER

3. BASE

4. COLLECTOR

5. COLLECTOR

STYLE 6:

PIN 1. EMITTER 2

2. BASE 2

3. EMITTER 1

4. COLLECTOR

5. COLLECTOR 2/BASE 1

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

STYLE 2:

PIN 1. ANODE

2. EMITTER

3. BASE

4. COLLECTOR

5. CATHODE

STYLE 7:

PIN 1. BASE

2. EMITTER

3. BASE

4. COLLECTOR

5. COLLECTOR

98ASB42984B

SC−88A (SC−70−5/SOT−353)

SCALE 20:1

STYLE 3:

PIN 1. ANODE 1

2. N/C

3. ANODE 2

4. CATHODE 2

5. CATHODE 1

STYLE 8:

PIN 1. CATHODE

2. COLLECTOR

3. N/C

4. BASE

5. EMITTER

mm

ǒ

Ǔ

inches

STYLE 4:

PIN 1. SOURCE 1

2. DRAIN 1/2

3. SOURCE 1

4. GATE 1

5. GATE 2

STYLE 9:

PIN 1. ANODE

2. CATHODE

3. ANODE

4. ANODE

5. ANODE

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

STYLE 5:

PIN 1. CATHODE

2. COMMON ANODE

3. CATHODE 2

4. CATHODE 3

5. CATHODE 4

Note: Please refer to datasheet for

style callout. If style type is not called

out in the datasheet refer to the device

datasheet pinout or pin assignment.

PAGE 1 OF 1

www.onsemi.com

Page 17

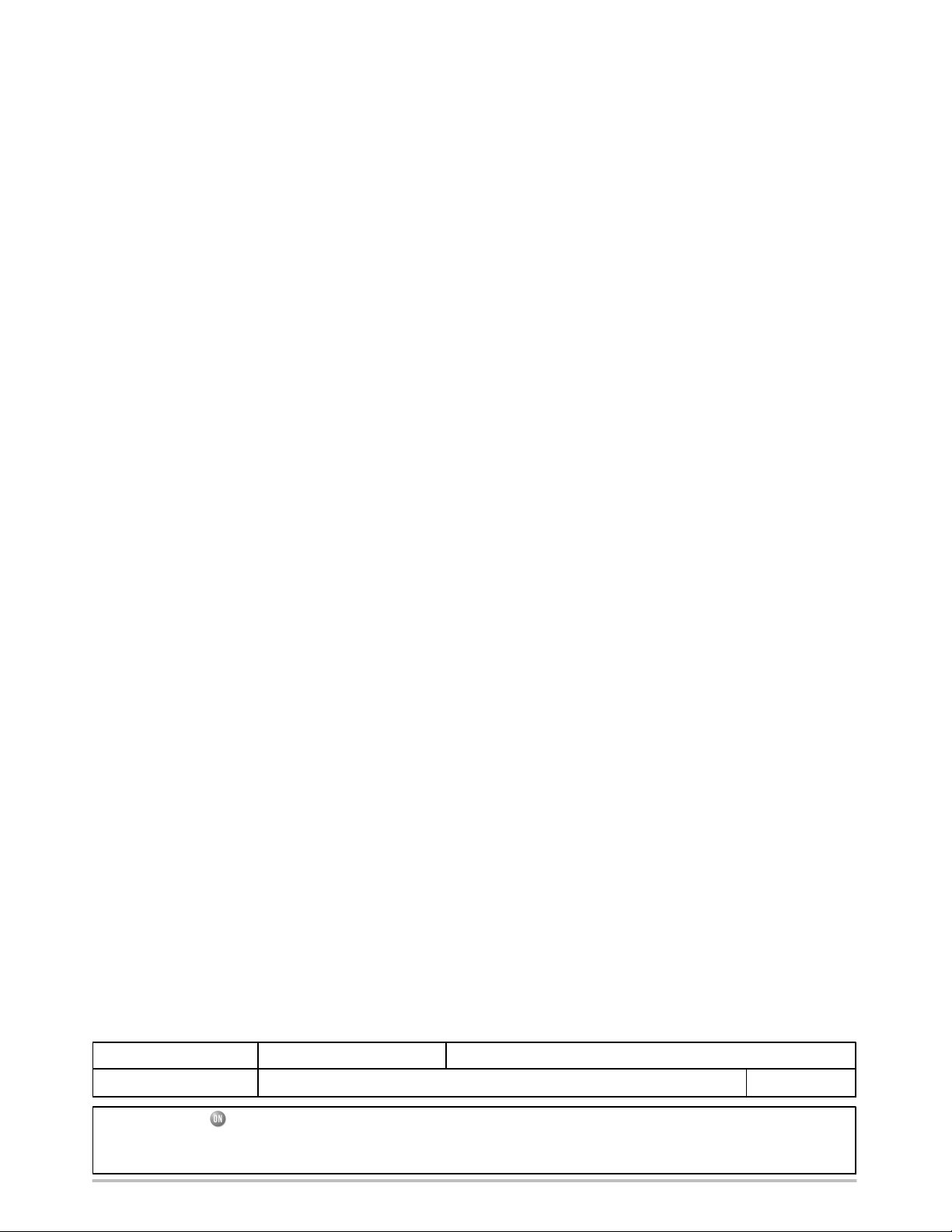

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

5

1

SCALE 2:1

NOTE 5

2X

2X

T0.10

B

A

54

B

123

G

A

T0.20

TOP VIEW

0.05

H

SIDE VIEW

D

0.205XC AB

S

C

SEATING

C

PLANE

TSOP−5

CASE 483

ISSUE N

K

J

END VIEW

DETAIL Z

M

DETAIL Z

DATE 12 AUG 2020

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. MAXIMUM LEAD THICKNESS INCLUDES LEAD FINISH

THICKNESS. MINIMUM LEAD THICKNESS IS THE

MINIMUM THICKNESS OF BASE MATERIAL.

4. DIMENSIONS A AND B DO NOT INCLUDE MOLD

FLASH, PROTRUSIONS, OR GATE BURRS. MOLD

FLASH, PROTRUSIONS, OR GATE BURRS SHALL NOT

EXCEED 0.15 PER SIDE. DIMENSION A.

5. OPTIONAL CONSTRUCTION: AN ADDITIONAL

TRIMMED LEAD IS ALLOWED IN THIS LOCATION.

TRIMMED LEAD NOT TO EXTEND MORE THAN 0.2

FROM BODY.

MILLIMETERS

DIM MIN MAX

A

2.85 3.15

B

1.35 1.65

C 0.90 1.10

D 0.25 0.50

G 0.95 BSC

H 0.01 0.10

J 0.10 0.26

K 0.20 0.60

M 0 10

__

S 2.50 3.00

SOLDERING FOOTPRINT*

1.9

0.95

0.037

1.0

0.039

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

0.074

0.028

0.7

2.4

0.094

SCALE 10:1

mm

ǒ

inches

GENERIC

MARKING DIAGRAM*

5

XXXAYWG

G

1

Analog

XXX = Specific Device Code

A = Assembly Location

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

Ǔ

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

5

XXX MG

G

1

Discrete/Logic

XXX = Specific Device Code

M = Date Code

G = Pb−Free Package

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

98ARB18753C

TSOP−5

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 18

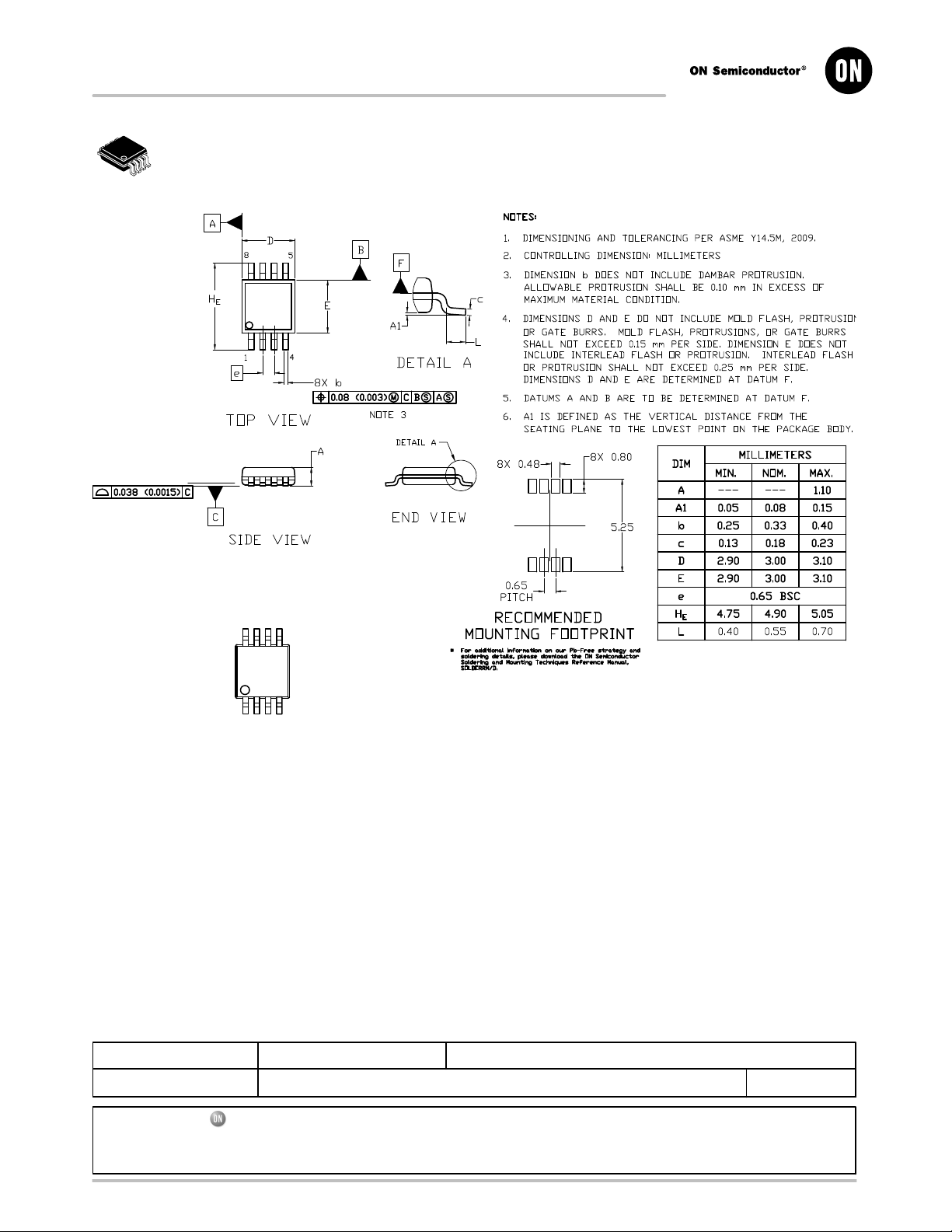

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

6

1

SCALE 4:1

A

B

E

A

(A3)

SEATING

C

A1

3

PLANE

2X

PIN ONE

REFERENCE

6X

DETAIL A

0.10 C

2X

0.05 C

0.05 C

6X

L

D

0.10 C

TOP VIEW

DETAIL B

SIDE VIEW

D2

1

UDFN6 1.6x1.6, 0.5P

CASE 517AP

ISSUE O

L1

CONSTRUCTION

EXPOSED Cu

A1

DETAIL A

OPTIONAL

DETAIL B

CONSTRUCTION

L

OPTIONAL

MOLD CMPD

A3

DATE 26 OCT 2007

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30 mm FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN MAX

A 0.45 0.55

A1 0.00 0.05

A3 0.13 REF

b 0.20 0.30

D 1.60 BSC

E 1.60 BSC

e 0.50 BSC

D2 1.10 1.30

E2 0.45 0.65

K 0.20 −−−

L 0.20 0.40

L1 0.00 0.15

GENERIC

MARKING DIAGRAM*

1

XX MG

G

E2

K6X

e

BOTTOM VIEW

46

b

6X

0.10 B

NOTE 3

0.05ACC

SOLDERMASK DEFINED

MOUNTING FOOTPRINT*

1.26

6X

0.52

1

0.50 PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

0.61

6X

0.32

1.90

XX = Specific Device Code

M = Date Code

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer

to device data sheet for actual part

marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON25711D

6 PIN UDFN, 1.6X1.6, 0.5P

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 19

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

8

1

SCALE 1:1

−Y−

−Z−

−X−

A

58

B

1

4

G

H

D

0.25 (0.010) Z

M

SOLDERING FOOTPRINT*

7.0

0.275

S

Y

SXS

0.25 (0.010)

C

SEATING

PLANE

1.52

0.060

0.155

0.10 (0.004)

4.0

M

M

Y

N

SOIC−8 NB

CASE 751−07

ISSUE AK

K

X 45

_

M

J

MARKING DIAGRAM*

8

XXXXX

ALYWX

1

XXXXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

8

XXXXX

ALYWX

G

1

IC

IC

(Pb−Free)

DATE 16 FEB 2011

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

GENERIC

8

XXXXXX

AYWW

1

Discrete

XXXXXX = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

8

XXXXXX

AYWW

1

Discrete

(Pb−Free)

G

0.6

0.024

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 20

STYLE 1:

PIN 1. EMITTER

2. COLLECTOR

3. COLLECTOR

4. EMITTER

5. EMITTER

6. BASE

7. BASE

8. EMITTER

STYLE 5:

PIN 1. DRAIN

2. DRAIN

3. DRAIN

4. DRAIN

5. GATE

6. GATE

7. SOURCE

8. SOURCE

STYLE 9:

PIN 1. EMITTER, COMMON

2. COLLECTOR, DIE #1

3. COLLECTOR, DIE #2

4. EMITTER, COMMON

5. EMITTER, COMMON

6. BASE, DIE #2

7. BASE, DIE #1

8. EMITTER, COMMON

STYLE 13:

PIN 1. N.C.

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 17:

PIN 1. VCC

2. V2OUT

3. V1OUT

4. TXE

5. RXE

6. VEE

7. GND

8. ACC

STYLE 21:

PIN 1. CATHODE 1

2. CATHODE 2

3. CATHODE 3

4. CATHODE 4

5. CATHODE 5

6. COMMON ANODE

7. COMMON ANODE

8. CATHODE 6

STYLE 25:

PIN 1. VIN

2. N/C

3. REXT

4. GND

5. IOUT

6. IOUT

7. IOUT

8. IOUT

STYLE 29:

PIN 1. BASE, DIE #1

2. EMITTER, #1

3. BASE, #2

4. EMITTER, #2

5. COLLECTOR, #2

6. COLLECTOR, #2

7. COLLECTOR, #1

8. COLLECTOR, #1

STYLE 2:

PIN 1. COLLECTOR, DIE, #1

2. COLLECTOR, #1

3. COLLECTOR, #2

4. COLLECTOR, #2

5. BASE, #2

6. EMITTER, #2

7. BASE, #1

8. EMITTER, #1

STYLE 6:

PIN 1. SOURCE

2. DRAIN

3. DRAIN

4. SOURCE

5. SOURCE

6. GATE

7. GATE

8. SOURCE

STYLE 10:

PIN 1. GROUND

2. BIAS 1

3. OUTPUT

4. GROUND

5. GROUND

6. BIAS 2

7. INPUT

8. GROUND

STYLE 14:

PIN 1. N−SOURCE

2. N−GATE

3. P−SOURCE

4. P−GATE

5. P−DRAIN

6. P−DRAIN

7. N−DRAIN

8. N−DRAIN

STYLE 18:

PIN 1. ANODE

2. ANODE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. CATHODE

8. CATHODE

STYLE 22:

PIN 1. I/O LINE 1

2. COMMON CATHODE/VCC

3. COMMON CATHODE/VCC

4. I/O LINE 3

5. COMMON ANODE/GND

6. I/O LINE 4

7. I/O LINE 5

8. COMMON ANODE/GND

STYLE 26:

PIN 1. GND

2. dv/dt

3. ENABLE

4. ILIMIT

5. SOURCE

6. SOURCE

7. SOURCE

8. VCC

STYLE 30:

PIN 1. DRAIN 1

2. DRAIN 1

3. GATE 2

4. SOURCE 2

5. SOURCE 1/DRAIN 2

6. SOURCE 1/DRAIN 2

7. SOURCE 1/DRAIN 2

8. GATE 1

SOIC−8 NB

CASE 751−07

ISSUE AK

STYLE 3:

STYLE 7:

STYLE 11:

STYLE 15:

STYLE 19:

STYLE 23:

PIN 1. DRAIN, DIE #1

2. DRAIN, #1

3. DRAIN, #2

4. DRAIN, #2

5. GATE, #2

6. SOURCE, #2

7. GATE, #1

8. SOURCE, #1

PIN 1. INPUT

2. EXTERNAL BYPASS

3. THIRD STAGE SOURCE

4. GROUND

5. DRAIN

6. GATE 3

7. SECOND STAGE Vd

8. FIRST STAGE Vd

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. DRAIN 2

7. DRAIN 1

8. DRAIN 1

PIN 1. ANODE 1

2. ANODE 1

3. ANODE 1

4. ANODE 1

5. CATHODE, COMMON

6. CATHODE, COMMON

7. CATHODE, COMMON

8. CATHODE, COMMON

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. MIRROR 2

7. DRAIN 1

8. MIRROR 1

PIN 1. LINE 1 IN

2. COMMON ANODE/GND

3. COMMON ANODE/GND

4. LINE 2 IN

5. LINE 2 OUT

6. COMMON ANODE/GND

7. COMMON ANODE/GND

8. LINE 1 OUT

STYLE 27:

PIN 1. ILIMIT

2. OVLO

3. UVLO

4. INPUT+

5. SOURCE

6. SOURCE

7. SOURCE

8. DRAIN

DATE 16 FEB 2011

STYLE 4:

PIN 1. ANODE

2. ANODE

3. ANODE

4. ANODE

5. ANODE

6. ANODE

7. ANODE

8. COMMON CATHODE

STYLE 8:

PIN 1. COLLECTOR, DIE #1

2. BASE, #1

3. BASE, #2

4. COLLECTOR, #2

5. COLLECTOR, #2

6. EMITTER, #2

7. EMITTER, #1

8. COLLECTOR, #1

STYLE 12:

PIN 1. SOURCE

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 16:

PIN 1. EMITTER, DIE #1

2. BASE, DIE #1

3. EMITTER, DIE #2

4. BASE, DIE #2

5. COLLECTOR, DIE #2

6. COLLECTOR, DIE #2

7. COLLECTOR, DIE #1

8. COLLECTOR, DIE #1

STYLE 20:

PIN 1. SOURCE (N)

2. GATE (N)

3. SOURCE (P)

4. GATE (P)

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 24:

PIN 1. BASE

2. EMITTER

3. COLLECTOR/ANODE

4. COLLECTOR/ANODE

5. CATHODE

6. CATHODE

7. COLLECTOR/ANODE

8. COLLECTOR/ANODE

STYLE 28:

PIN 1. SW_TO_GND

2. DASIC_OFF

3. DASIC_SW_DET

4. GND

5. V_MON

6. VBULK

7. VBULK

8. VIN

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 21

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

14

1

SCALE 1:1

SOIC−14 NB

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

14

H

M

0.25 B

0.10

14X

0.58

D

M

13X

e

SOLDERING FOOTPRINT*

6.50

1

A

B

8

E

71

b

M

0.25 B

S

A

C

A

A1

SEATING

C

PLANE

1.18

14X

S

1.27

PITCH

DETAIL A

h

X 45

_

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

A3

L

DETAIL A

PROTRUSION. ALLOWABLE PROTRUSION

SHALL BE 0.13 TOTAL IN EXCESS OF AT

MAXIMUM MATERIAL CONDITION.

4. DIMENSIONS D AND E DO NOT INCLUDE

MOLD PROTRUSIONS.

5. MAXIMUM MOLD PROTRUSION 0.15 PER

SIDE.

DIM MIN MAX MIN MAX

A 1.35 1.75 0.054 0.068

A1 0.10 0.25 0.004 0.010

A3 0.19 0.25 0.008 0.010

b 0.35 0.49 0.014 0.019

D 8.55 8.75 0.337 0.344

E 3.80 4.00 0.150 0.157

e 1.27 BSC 0.050 BSC

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.019

L 0.40 1.25 0.016 0.049

M 0 7 0 7

__ __

INCHESMILLIMETERS

GENERIC

MARKING DIAGRAM*

14

XXXXXXXXXG

AWLYWW

1

XXXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 22

SOIC−14

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

STYLE 1:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. NO CONNECTION

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. NO CONNECTION

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 5:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. NO CONNECTION

7. COMMON ANODE

8. COMMON CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 2:

CANCELLED

STYLE 6:

PIN 1. CATHODE

2. CATHODE

3. CATHODE

4. CATHODE

5. CATHODE

6. CATHODE

7. CATHODE

8. ANODE

9. ANODE

10. ANODE

11. ANODE

12. ANODE

13. ANODE

14. ANODE

STYLE 3:

PIN 1. NO CONNECTION

2. ANODE

3. ANODE

4. NO CONNECTION

5. ANODE

6. NO CONNECTION

7. ANODE

8. ANODE

9. ANODE

10. NO CONNECTION

11. ANODE

12. ANODE

13. NO CONNECTION

14. COMMON CATHODE

STYLE 7:

PIN 1. ANODE/CATHODE

2. COMMON ANODE

3. COMMON CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. ANODE/CATHODE

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. COMMON CATHODE

12. COMMON ANODE

13. ANODE/CATHODE

14. ANODE/CATHODE

STYLE 4:

PIN 1. NO CONNECTION

2. CATHODE

3. CATHODE

4. NO CONNECTION

5. CATHODE

6. NO CONNECTION

7. CATHODE

8. CATHODE

9. CATHODE

10. NO CONNECTION

11. CATHODE

12. CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 8:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. ANODE/CATHODE

7. COMMON ANODE

8. COMMON ANODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. NO CONNECTION

12. ANODE/CATHODE

13. ANODE/CATHODE

14. COMMON CATHODE

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 23

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 2:1

Micro8

CASE 846A−02

ISSUE K

DATE 16 JUL 2020

GENERIC

MARKING DIAGRAM*

8

XXXX

AYW G

G

1

XXXX = Specific Device Code

A = Assembly Location

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

STYLE 1:

PIN 1. SOURCE

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 2:

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. DRAIN 2

7. DRAIN 1

8. DRAIN 1

STYLE 3:

PIN 1. N-SOURCE

2. N-GATE

3. P-SOURCE

4. P-GATE

5. P-DRAIN

6. P-DRAIN

7. N-DRAIN

8. N-DRAIN

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB14087C

MICRO8

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 24

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

14

1

SCALE 2:1

0.10 (0.004)

SEATING

−T−

PLANE

S

U0.15 (0.006) T

2X L/2

L

PIN 1

IDENT.

S

U0.15 (0.006) T

C

D

SOLDERING FOOTPRINT

1

14X REFK

0.10 (0.004) V

14

1

M

8

7

A

−V−

G

7.06

TSSOP−14 WB

U

T

B

N

−U−

J

H

CASE 948G

ISSUE C

S

S

N

F

DETAIL E

J1

SECTION N−N

DETAIL E

0.25 (0.010)

M

K

K1

DATE 17 FEB 2016

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION SHALL

NOT EXCEED 0.25 (0.010) PER SIDE.

5. DIMENSION K DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL

IN EXCESS OF THE K DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

7. DIMENSION A AND B ARE TO BE

DETERMINED AT DATUM PLANE −W−.

INCHESMILLIMETERS

−W−

DIM MIN MAX MIN MAX

A 4.90 5.10 0.193 0.200

B 4.30 4.50 0.169 0.177

C −−− 1.20 −−− 0.047

D 0.05 0.15 0.002 0.006

F 0.50 0.75 0.020 0.030

G 0.65 BSC 0.026 BSC

H 0.50 0.60 0.020 0.024

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

GENERIC

MARKING DIAGRAM*

14

XXXX

XXXX

ALYWG

G

1

A = Assembly Location

L = Wafer Lot

Y = Year

0.65

PITCH

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

14X

0.36

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

14X

1.26

98ASH70246A

TSSOP−14 WB

DIMENSIONS: MILLIMETERS

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

PAGE 1 OF 1

www.onsemi.com

Page 25

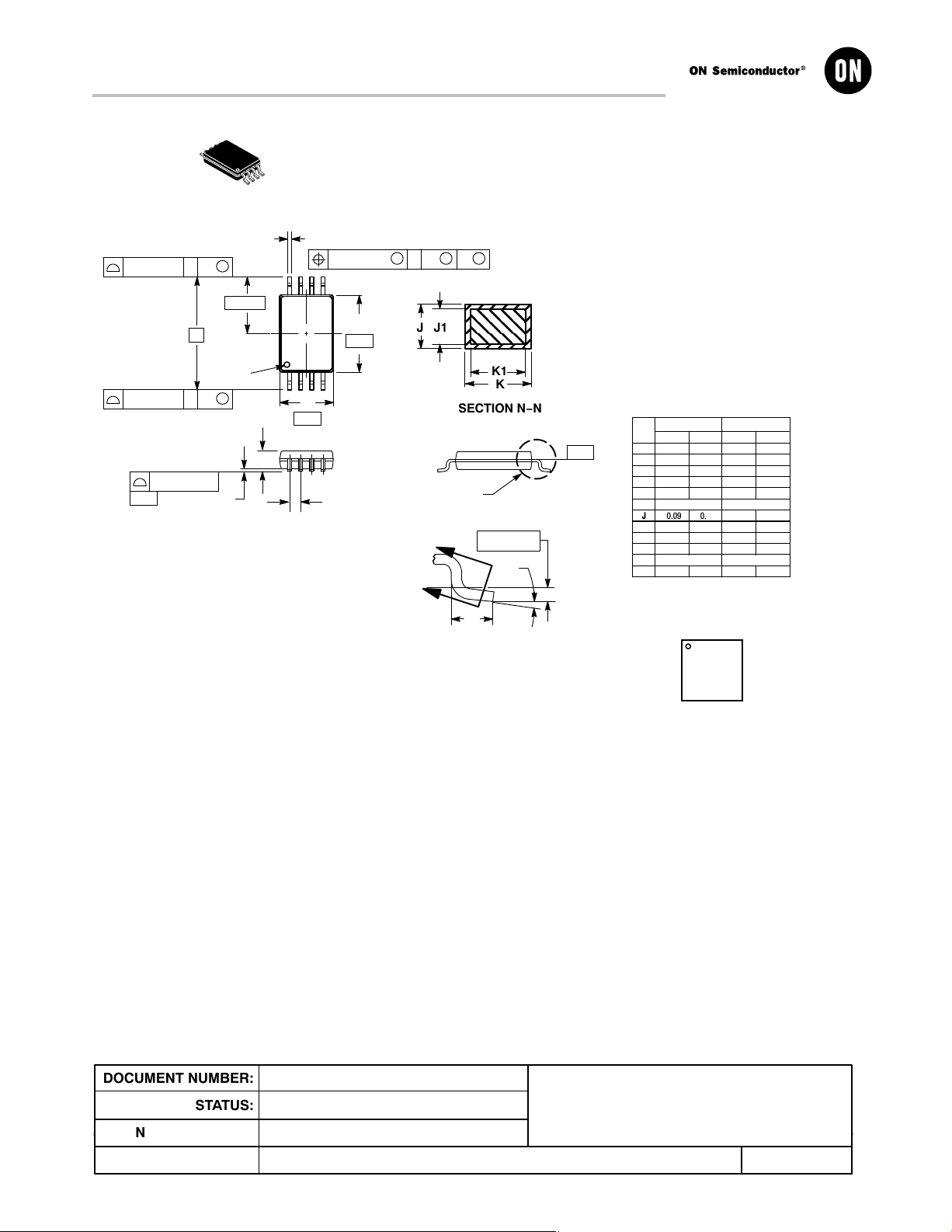

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 2:1

TSSOP−8

CASE 948S−01

ISSUE C

DATE 20 JUN 2008

0.076 (0.003)

−T−

SEATING

PLANE

8x REFK

U

T

JJ1

S

S

K1

K

SECTION N−N

S

U0.20 (0.008) T

2X L/2

85

L

PIN 1

IDENT

S

U0.20 (0.008) T

0.10 (0.004) V

−U−

1

4

A

M

B

−V−

C

D

G

DETAIL E

N

0.25 (0.010)

M

−W−

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH.

PROTRUSIONS OR GATE BURRS. MOLD FLASH

OR GATE BURRS SHALL NOT EXCEED 0.15

(0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED 0.25 (0.010)

PER SIDE.

5. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

6. DIMENSION A AND B ARE TO BE DETERMINED

AT DATUM PLANE -W-.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 4.30 4.50 0.169 0.177

C --- 1.10 --- 0.043

D 0.05 0.15 0.002 0.006

F 0.50 0.70 0.020 0.028

G 0.65 BSC 0.026 BSC

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

INCHESMILLIMETERS

N

GENERIC

F

DETAIL E

MARKING DIAGRAM*

XXX

YWW

A G

G

XXX = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

DOCUMENT NUMBER:

STATUS:

NEW STANDARD:

© Semiconductor Components Industries, LLC, 2002

October, 2002 − Rev. 0

DESCRIPTION:

98AON00697D

ON SEMICONDUCTOR STANDARD

TSSOP−8

http://onsemi.com

1

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

Electronic versions are uncontrolled except when

accessed directly from the Document Repository. Printed

versions are uncontrolled except when stamped

“CONTROLLED COPY” in red.

Case Outline Number:

PAGE 1 OF 2

XXX

Page 26

DOCUMENT NUMBER:

98AON00697D

PAGE 2 OF 2

ISSUE REVISION DATE

O RELEASED FOR PRODUCTION. 18 APR 2000

A ADDED MARKING DIAGRAM INFORMATION. REQ. BY V. BASS. 13 JAN 2006

B CORRECTED MARKING DIAGRAM PIN 1 LOCATION AND MARKING. REQ. BY C.

13 MAR 2006

REBELLO.

C REMOVED EXPOSED PAD VIEW AND DIMENSIONS P AND P1. CORRECTED

20 JUN 2008

MARKING INFORMATION. REQ. BY C. REBELLO.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

© Semiconductor Components Industries, LLC, 2008

Case Outline Number:

June, 2008 − Rev. 01C

948S

Page 27

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910