Page 1

EVBUM2528/D

NCP51705 Mini Evaluation

Board User'sManual

NCP51705 SiC Driver Evaluation Board

for Existing or New PCB Designs

www.onsemi.com

INTRODUCTION

Purpose

This document describes the use and applications for the

NCP51705 SiC driver mini EVB. The EVB is designed on

a four layer PCB and includes the NCP51705 driver and all

the necessary drive circuitry. The EVB also includes an

on−board digital isolator and the ability to solder any

MOSFET or SiC MOSFET in a T0247 high voltage

package. The EVB does not include a power stage and is

generic from the point of view that it is not dedicated to any

particular topology. It can be used in any low−side or

high−side power switching application. For bridge

configurations two or more of these EVBs can be configured

in a totem pole type drive configuration. The EVB can be

considered as an isolator+driver+T0247 discrete module.

NCP51705 Description

The NCP51705 driver is designed to primarily drive SiC

MOSFET transistors. To achieve the lowest possible

EVAL BOARD USER’S MANUAL

conduction losses, the driver is capable of delivering the

maximum allowable gate voltage to the SiC MOSFET

device. By providing high peak current during turn−on and

turn−off, switching losses are also minimized. For improved

reliability, dV/dt immunity and even faster turn−off, the

NCP51705 can utilize its on−board charge pump to generate

a user selectable negative voltage rail.

For full compatibility and to minimize the complexity of

the bias solution in isolated gate drive applications the

NCP51705 also provides an externally accessible 5V rail to

power the secondary side of digital or high speed opto

isolators.

The NCP51705 offers important protection functions

such as under−voltage lockout monitoring for the bias power

and thermal shutdown based on the junction temperature of

the driver circuit.

© Semiconductor Components Industries, LLC, 2017

December, 2017 − Rev. 0

1 Publication Order Number:

EVBUM2528/D

Page 2

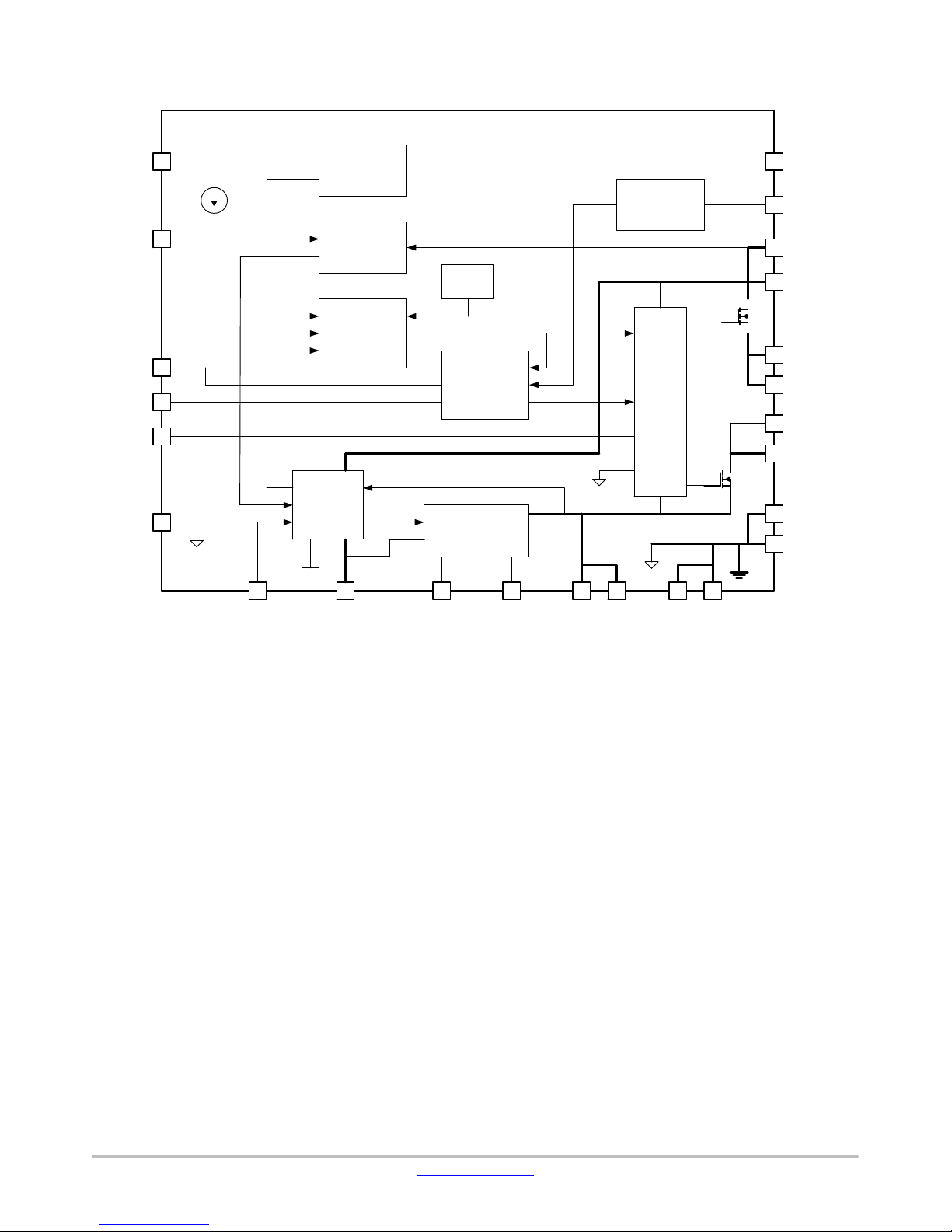

NCP51705 Block Diagram

EVBUM2528/D

NCP51705

V5V

UVSET

IN+

IN-

XEN

SGND

23

25

mA

5V REG

DESAT /

CURRENT

SENSE

24

UVLO

TSD

21

22

20

19

SVDD

DESAT

/CS

VDD

VDD

5V_OK

VDD_OK

VEE_OK

1

PROTECTION

LOGIC

INPUT LOGIC

2

3

RUN

DRIVER

LOGIC

&

LEVEL

SHIFT

18

17

14

13

OUTSRC

OUTSRC

OUTSNK

OUTSNK

CHARGE

4

PUMP REG

CPCLK

CHARGE PUMP

POWER STAGE

5

VEESET

6

VCH

7

C+

8

C-

11 12 9 10

VEE

VEE

PGND

PGND

PGND

16

PGND

15

Figure 1. NCP51705 Functional Block Diagram

www.onsemi.com

2

Page 3

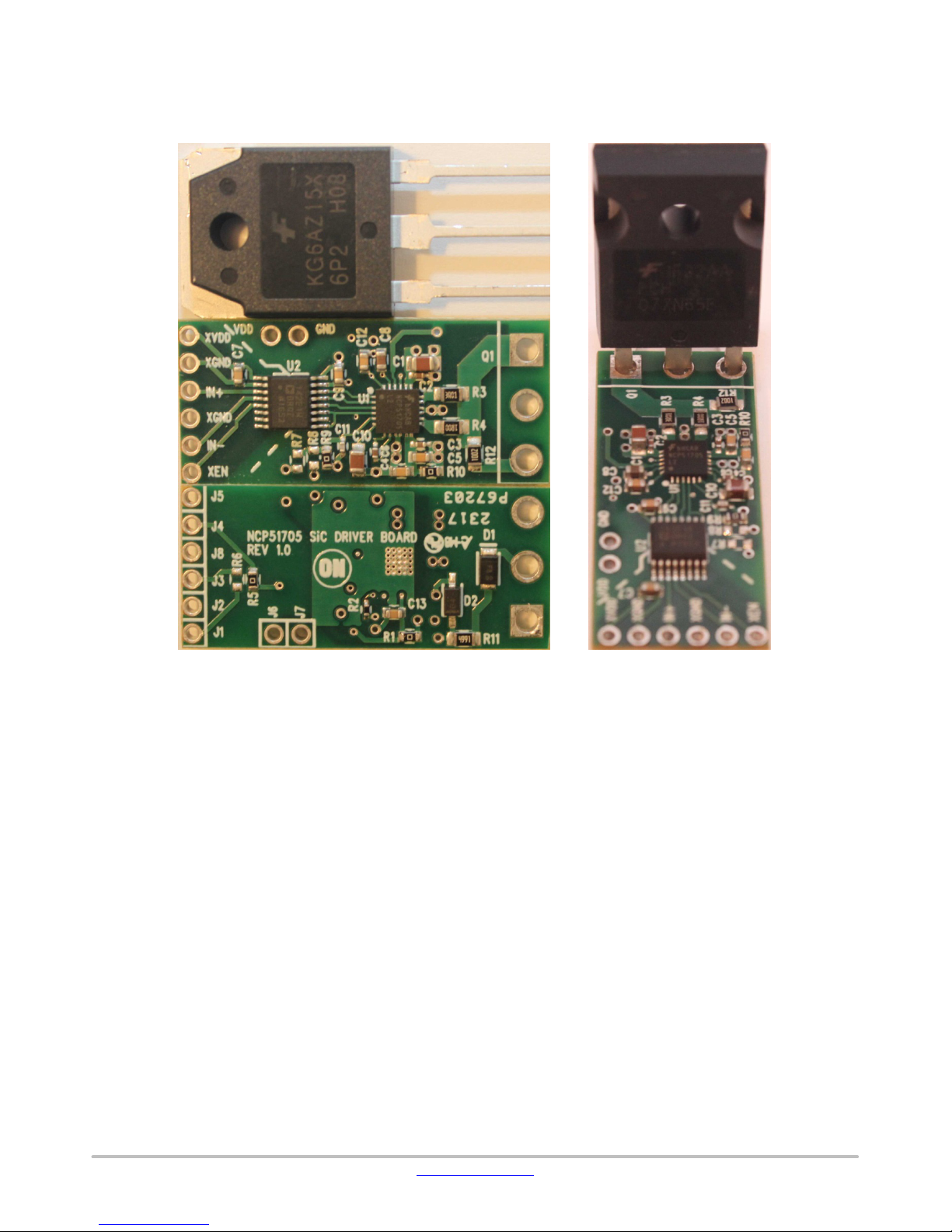

SUMMARY OF EVB

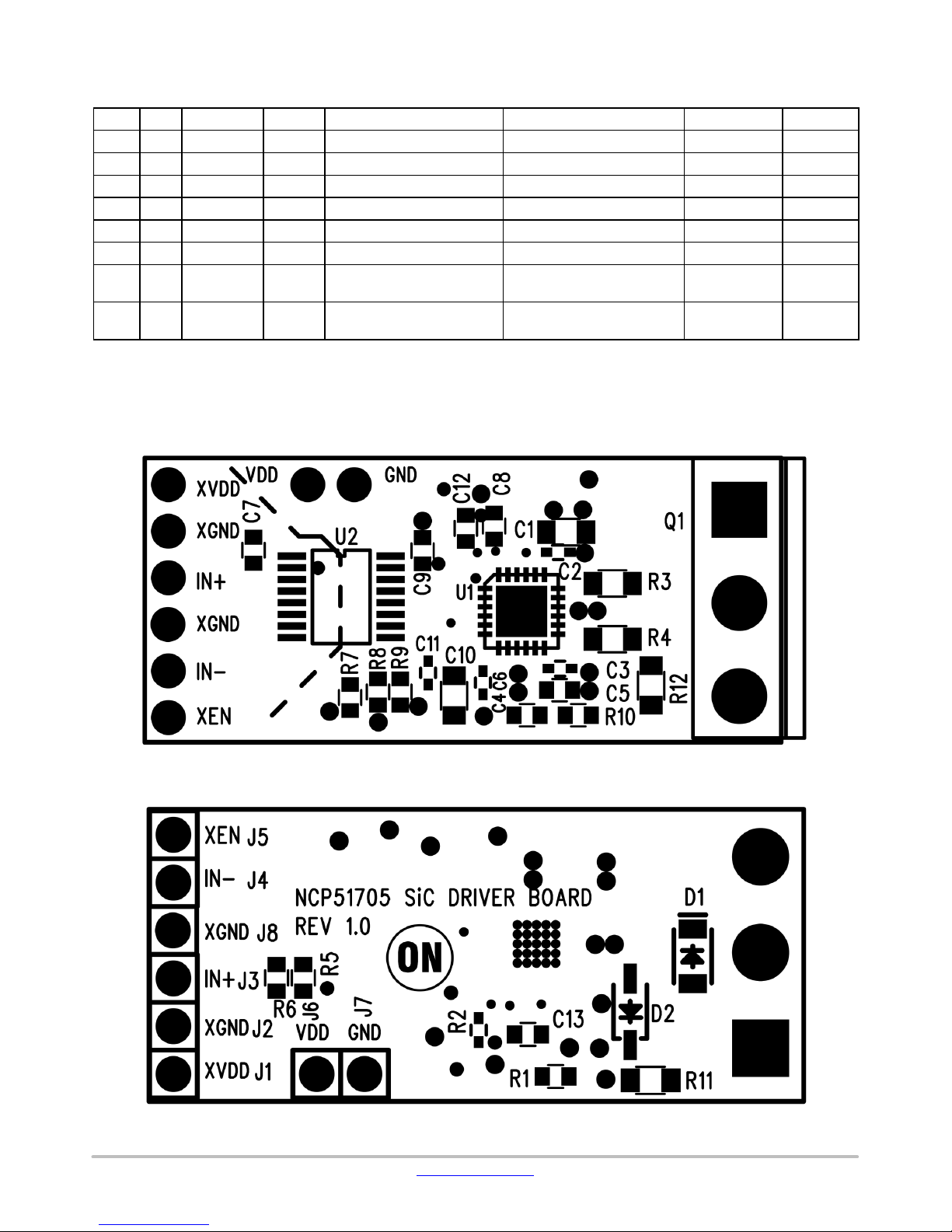

EVB Photos

EVBUM2528/D

Figure 2. NCP51705 EVB (35 mm x 15 mm x 5 mm) − Top and Bottom View (T0−247 Shown for Scale)

www.onsemi.com

3

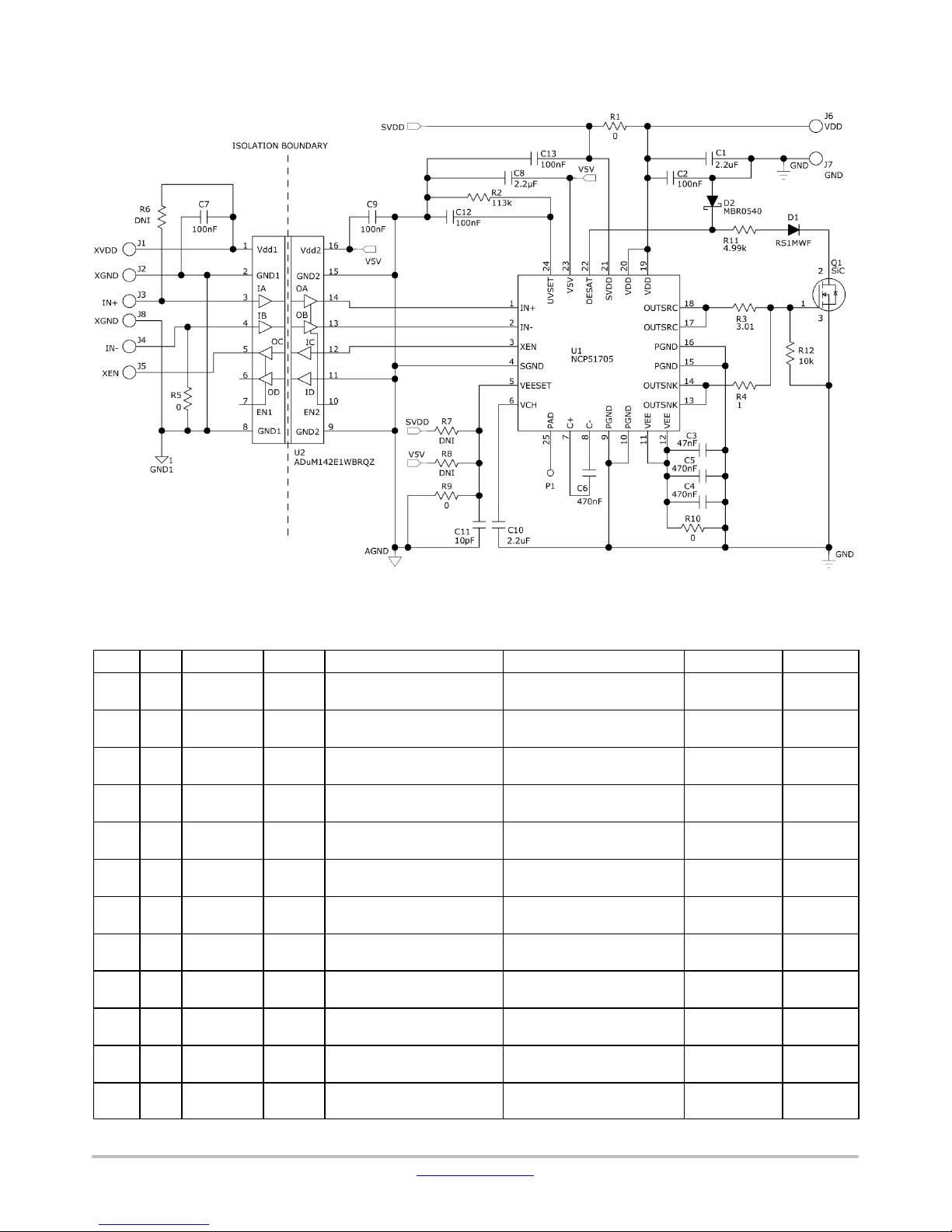

Page 4

EVB Schematic

EVBUM2528/D

Figure 3. NCP51705 EVB Schematic

Table 1. BILL OF MATERIALS

Item Qty Reference Value Part Number Description Manufacturer Pkg Type

1 2 C1 C10

2 2 C2 C13 100 nF C1005X7R1H104M050BE CAP, SMD, CERAMIC, 50 V,

3 1 C3 47 nF GRM155R71E473KA88D CAP, SMD, CERAMIC, 25 V,

4 2 C4−5 470 nF GRM188R71E474KA12D CAP, SMD, CERAMIC, 25 V,

5 1 C6 470 nF C1005X5R1E474K050BB CAP, SMD, CERAMIC, 25 V,

6 3 C7 C9

C12

7 1 C8

8 1 C11 10 pF GRM1555C1H100JA01D CAP, SMD, CERAMIC, 50 V,

9 1 D1 RS1MWF Diode, Fast, 1 A, 1000 V,

10 1 D2 MBR0540 Diode, Shottky, 40 V,

11 1 Q1 DNI MOSFET, N−CH, 600 V,

12 4 R1 R5

R9−10

2.2 mF

100 nF C0603C104K8RACTU CAP, SMD, CERAMIC, 10 V,

2.2 mF

CGA4J3X7R1H225M125AE CAP, SMD, CERAMIC, 50 V,

X7R

X7R

X7R

X7R

X5R

X7R

LMK107B7225KA−T CAP, SMD, CERAMIC, 10 V,

X7R

NPO

Std. Rec.

500 mA, 510 mV

20 A, 190 mW

0 RC0603JR−070RL RES, SMD, 1/10 W STD 603

STD 805

STD 402

STD 402

STD 603

STD 402

STD 603

STD 603

STD 402

Vishay SOD123F

ON

Semiconductor

ON

Semiconductor

SOD−123

TO−247

www.onsemi.com

4

Page 5

EVBUM2528/D

Table 1. BILL OF MATERIALS

Item Pkg TypeManufacturerDescriptionPart NumberValueReferenceQty

13 1 R2 113k RC0402FR−07200KL RES, SMD, 1/16 W STD 402

14 1 R3 3.01 RMCF0805FT3R01

15 1 R4 1 RMCF0805FT1R00

16 3 R6−8 DNI RES, SMD, 1/10 W STD 603

17 1 R11 4.99k RC0805FR−074K99L

18 1 R12 10k RC0805FR−0710KL RES, SMD, 1/8 W STD 805

19 1 U1 NCP51705 SiC Driver, Single, 6 A,

20 1 U2 ADuM142E1WBRQZ Digital Isolator, RF, 4−Chan-

RES, SMD, 1/8 W

RES, SMD, 1/8 W

RES, SMD, 1/8 W

Single

nel

PCB Assembly and Layers

Figure 4 through Figure 9 shows the top and bottom

assembly and the four−layers of the PCB. The PCB is 35 mm

x 15 mm x 5 mm (length x width x height) where the width

of the PCB is approximately the width of a T0−247 body.

STD 805

STD 805

STD 805

ON

Semiconductor

Analog

Devices

WQFN−24

QSOP−16

Figure 4. Top Assembly

Figure 5. Bottom Assembly

www.onsemi.com

5

Page 6

EVBUM2528/D

Figure 6. Top Layer

Figure 7. Layer 2

Figure 8. Layer 3

www.onsemi.com

6

Page 7

EVBUM2528/D

Figure 9. Bottom Layer

I/O Connectors

There are 7 I/O connectors described in Table 2 below.

The mC (or, PWM control IC) output (J3, J4), the XVDD and

XGND (J1, J2) and the XEN (J5) signals are noted as

“primary” ground referenced. There is no true “primary”

and “secondary” ground but there is 1.5 kV galvanic

isolation across the isolation boundary. It is especially

important to maintain isolation in high−side, high−voltage,

switching applications where the “secondary” VDD (J6, J7)

floats VDD volts above the power supply input voltage:

Table 2. I/O CONNECTOR DESCRIPTIONS

Ref Des Name I/O GND Ref Type Description Value (V)

J1 XGND Input Primary Plated Hole External primary ground from PWM side 0

J2 XVDD Input Primary Plated Hole External VDD from PWM side (isolator bias) 5

(Note 1)

J3 IN+ Input Primary Plated Hole Non−inverting, PWM input 3.3<V

J4 IN− Input Primary Plated Hole Inverting PWM input

J5 XEN Output Primary Plated Hole XEN fault flag or sync signal from NCP51705 5

J6 VDD Input Secondary Plated Hole NCP51705 VDD <20

J7 GND Input Secondary Plated Hole NCP51705 secondary ground 0

J8 XGND Input Primary Plated Hole External primary ground from PWM side 0

1. The digital isolator, U2, requires that the amplitude of the PWM input (IN+ or IN−) be equal to VDD (XVDD) and less than or equal to 5 V.

3.3<V

IN+

(Note 1)

IN

(Note 1)

<5

<5

-

www.onsemi.com

7

Page 8

EVBUM2528/D

EVB INSTALL CONFIGURATIONS

Mounting into Existing PCB − Option 1

The NCP51705, SiC Driver Mini EVB can be mounted

into an existing power board, shown as “Main PCB” in

Figure 10. If there are no components or low profile surface

mount components only, the mini EVB can be mounted

parallel to the main PCB as shown in Figure 10. The T0−247,

SiC MOSFET leads would pass through the mini EVB

plated thru−holes and into the main PCB. Or, if necessary,

the gate lead of the T0−247, SiC MOSFET can be soldered

to the plated thru−hole on the mini EVB and cut so that it

does not contact the main PCB, as shown in the dotted box

in Figure 10. For mechanical strength, it is preferred that the

T0−247 gate lead pass through both PCB’s.

T0−247

SiC

PWM Input

(flying lead)

Kapton tape

Mini EVB

Main PCB

S

Side View

Figure 10. Mini EVB Installation − Option 1

Recommended Procedure for Option 1 Mounting into an

Existing PCB

1. On the main PCB, isolate the gate drive to the

T0−247 SiC MOSFET. If the existing design

includes a gate drive resistor, removing it should

serve the purpose of isolating the gate drive to the

T0−247. If there is no series component between

the PWM signal source and the T0−247 gate lead,

the gate drive PCB track will need to be cut.

2. Measure the resistance between the PWM source

and the T0−247 gate lead (or PWM source to gate

drive transformer/isolator if applicable). Verify

reading is high impedance (open).

3. If a T0−247 discrete is installed in the main PCB,

remove it now.

4. Place Kapton or non−conductive tape over the

main PCB area directly beneath the mini EVB.

This is to avoid the possibility of having any

components on the bottom of the mini EVB touch

components or conductive surfaces on the main

PCB.

5. Solder a flying lead of bus wire to the main PCB,

PWM signal. Make sure there is enough length of

the PWM input (flying lead) to reach through the

mini EVB plated thru−hole (J3 or J4)

6. For non−inverting PWM input logic, verify that

R5 (0 W) is installed and R6 is removed. This is

the correct configuration of the mini EVB for

non−inverting PWM input logic.

Option – Cut T0−247 gate lead

T0−247

SiC

Mini EVB

Kapton tape

GDS

Back View

T0−247

SiC

Mini EVB

Main PCB

GDS

7. For inverting PWM input logic, verify that R6

(0 W) is installed and R5 is removed. This is the

correct configuration of the mini EVB for

inverting PWM input logic.

8. Solder the T0−247 through just the mini EVB first

9. With the T0−247 installed into the mini EVB,

install and solder the T0−247 leads into the main

PCB

10. Solder the other end of the PWM input (flying

lead) to IN+ (J3) for non−inverting PWM

applications or IN− (J4) for inverting PWM

applications.

11. Using the same size bus wire, solder the remaining

connections between J1, J2, J5 and J8 of the mini

EVB to the appropriate locations on the main

PCB.

12. Solder flying leads from J6−7 for bias voltage to

the NCP51705. Note that J6−7 are across the

isolation boundary from J1−5 and J8.

Mounting into Existing PCB − Option 2

If components mounted on the main PCB interfere with

mounting the mini EVB as described by Option 1

(Figure 10), the T0−247 leads can be formed (lead length

may need to be added) with the mini EVB mounted

perpendicular to the main PCB as shown in Figure 11, option

2. If required, both mounting options allow the application

of a heat sink to the T0−247 package. If high dV/dt is present

on the drain of the T0−247, the EVB should be angled, away

from being parallel to the T0−247, as much as possible.

www.onsemi.com

8

Page 9

EVBUM2528/D

Mini EVB

PWM Input

(flying lead)

Side View

T0−247

SiC

Main PCB

S

Figure 11. Mini EVB Installation − Option 2

Recommended Procedure for Option 2 Mounting into an

Existing PCB

1. On the main PCB, isolate the gate drive to the

T0−247 SiC MOSFET. If the existing design

includes a gate drive resistor, removing it should

serve the purpose of isolating the gate drive to the

T0−247. If there is no series component between

the PWM signal source and the T0−247 gate lead,

the gate drive PCB track will need to be cut.

2. Measure the resistance between the PWM source

and the T0−247 gate lead (or PWM source to gate

drive transformer/isolator if applicable). Verify

reading is high impedance (open).

3. If a T0−247 discrete is installed in the main PCB,

remove it now.

4. Solder a flying lead of bus wire to the main PCB,

PWM signal. Make sure there is enough length of

the PWM input (flying lead) to reach through the

mini EVB plated thru−hole (J3 or J4)

5. For non−inverting PWM input logic, verify that

R5 (0 W) is installed and R6 is removed. This is

the correct configuration of the mini EVB for

non−inverting PWM input logic.

6. For inverting PWM input logic, verify that R6

(0 W) is installed and R5 is removed. This is the

correct configuration of the mini EVB for

inverting PWM input logic.

7. Make appropriate modifications to lead form the

T0−247 leads as shown in Figure 11. If the T0−247

leads are not long enough to provide sufficient

clearance between the mini EVB and T0−247 case

and allow the leads to pass through the mini EVB

and down through the main PCB, then extending

the lead length may be necessary.

8. After the T0−247 leads have been formed, check

for fit through the mini EVB and down into the

main PCB

Option – Cut T0−247 gate lead

T0−247

T0−247

SiC

Mini EVB

G

DS

Back View

T0−247

SiC

Mini EVB

Main PCB

SiC

DS

G

9. Solder the T0−247 through just the mini EVB first

10. With the T0−247 installed into the mini EVB,

install and solder the T0−247 leads into the main

PCB

11. Solder the other end of the PWM input (flying

lead) to IN+ (J3) for non−inverting PWM

applications or IN− (J4) for inverting PWM

applications.

12. Using the same size bus wire, solder the remaining

connections between J1, J2, J5 and J8 of the mini

EVB to the appropriate locations on the main

PCB.

13. Solder flying leads from J6−7 for bias voltage to

the NCP51705. Note that J6−7 are across the

isolation boundary from J1−5 and J8.

Mounting into New PCB Design

The NCP51705, SiC Driver Mini EVB can also be used as

an isolator+driver+T0−247 “driver module” that can be

integrated into a new PCB design. The gate lead of the

T0−247 between the mini EVB and the main PCB is for

mechanical strength only. For main PCB layout, the gate

lead extends down through the main PCB and can be

soldered to an isolated plated thru−hole. As shown in

Figure 12, shoulder pins with appropriate flange are one

option that can be used as mounting pins between J1−8 of the

mini EVB and the main PCB. Another option, shown in

Figure 13, is to use a 100 mil center on center header which

is a row of pins through a plastic header. The plastic header

is used as a standoff for setting the mounting height between

the mini EVB and the main PCB. The hole pattern for

building a schematic library decal of the driver module is

shown in Figure 14.

www.onsemi.com

9

Page 10

EVBUM2528/D

80.0 (min)

T0−247

SiC

Mini EVB

Main PCB

S

Side View

T0−247

SiC

Mini EVB

GDS

Back View

Figure 12. New PCB Design using Shoulder Pins (80 mil minimum mounting height)

80.0 (min)

T0−247

SiC

Mini EVB

Main PCB

S

Side View

T0−247

SiC

Mini EVB

GDS

Back View

Figure 13. New PCB Design using 100 mil Interconnect Header Pins (80 mil minimum mounting height)

Figure 14. NCP51705 SiC Driver Mini EVB PCB Hole Pattern (All Dimensions in mils)

www.onsemi.com

10

Page 11

TESTING WITHOUT INSTALLING INTO A PCB

EVBUM2528/D

The NCP51705, SiC Driver Mini EVB can also be tested

without installing into a main PCB. However, since this

EVB was designed for small form factor there are no test

points included for connecting voltage probes. The EVB

should be hand probed carefully since the components are

very fine pitch or flying leads connected to desired probe

points can be attached. Note that the IN+/IN− PWM

amplitude must be equal to the XVDD (5 V). The 20 V DC

bias (VDD and GND) is on the secondary side of the digital

isolator and therefore has a separate/isolated return ground

20V DC

5V DC

AFG 5VPK,

150kHz, 50%

from the 5 V DC bias (XVDD and XGND). The

recommended series load of 470 pF and 4.99 W is close to

what might be representative of a SiC gate drive input

impedance. Leaded passive components can be soldered

into the T0−247 holes as shown in Figure 15. Alternatively,

a T0−247 SiC MOSFET can also be soldered in place for Q1

and used as a load for the NCP51705. Note that testing

without installing into a power stage, leaves the DESAT pin

open since there is no active drain signal. The effect of

operating DESAT this way is explained in section ‘DESAT’.

470pF

4.99W

Figure 15. Test Configuration of EVB without Installing into Main PCB

Turn−on Procedure

1. Apply XVDD = 5 V (Voltage for primary side of

the digital isolator, U2)

2. Apply VDD = 20 V (VDD bias voltage for the

NCP5170, SiC driver, Note: UVLO

3. Apply IN+=5V

, 150 kHz, 50% (Reducing the

PK

ON

= 17 V)

frequency to less than ~90 kHz will show DESAT

active as described in section ‘DESAT’)

configuration are easily set by removing/installing resistors

according to Table 3. Note that R10 must be removed for any

VEE configuration other than 0 V. VDD

programmable by the UVSET resistor as described in

section ‘UVSET’ but VEE

is fixed at 80% of the VEE

UVLO

regulate value. If desired, the NCP5170 internal VEE charge

pump can be disabled and an external negative voltage can

be applied to VEE. When providing VEE from an external

negative voltage supply, it is recommended to apply VEE

VEE

The EVB is preconfigured for VEE=0V. Operating the

EVB this way will result in switching between

0V < OUT < VDD. Several other options for negative VEE

Table 3. VEESET CONFIGURATION OPTIONS

VEESET COMMENT VEE VEE

VDD

V5V

OPEN Remove R7, R8, R9, R10 −3 V −2.4 V

GND

GND Remove R7, R8, R9, R10. Apply negative external voltage within the range of −8V < V

Install R7 = 0 W, Remove R8, R9, R10 9V < VEESET < VDD

Install R7 = 0 W, Remove R7, R9, R10

Install R9 = R10 = 0 W, Remove R7, R8

prior to VDD. Any time the internal VEE charge pump is

disabled (VEESET = 0 V), VEE

is disabled and is

UVLO

therefore shown as “NA” in Table 3.

−8 V −6.4 V

−5 V −4 V

0 V NA

< 0V −V

EXT

EXT

UVLO

UVLO

NA

is

www.onsemi.com

11

Page 12

EVBUM2528/D

UVSET

The UVSET function is set by R2 and determines the

UVLO turn−on threshold. The EVB is preconfigured with

R2 = 113 kW which equates to UVLO turn−on (V

ON

) of

~17 V. The UVLO turn−on threshold can be changed by

selecting R2 according to a desired UVLO turn−on

threshold, VON:

V

R2+

DESAT

ON

6 25mA

(eq. 1)

DESAT is a type of over−current protection dedicated to

monitoring the I

of the SiC MOSFET. The EVB is

DxRDS

preconfigured with R11 = 4.99 kW (DESAT resistor). The

internal DESAT threshold is fixed at V

DESAT(TH)

=7.5V and

the DESAT signal amplitude is adjustable by R11.

R11 = 4.99 kW may not be the correct resistor value for

some applications. If V

> 7.5 V during normal

DESAT

operation, decrease R11 to lower the signal amplitude. If

DESAT is active, the trailing edge of the OUT pulse is

terminated or reduced with respect to the input pulse (IN+).

The waveforms shown in Figure 16, show VDESAT < 7.5 V

during normal, 80 kHz, operation. Since DESAT is

operating with no load, the amplitude is varied by varying

the IN+ frequency. Figure 17 shows IN+ increased to

150 kHz and VDESAT = 7.5 V. The trailing edge of OUT is

clearly terminated compared to IN+ indicating that DESAT

is active.

www.onsemi.com

12

Page 13

WAVEFORMS

EVBUM2528/D

Figure 16. IN+ = 150 kHz, 50%, VDESAT = 5 V, DESAT Inactive

Figure 17. IN+ = 80 kHz, 50%, VDESAT = 7.5 V, DESAT Active

www.onsemi.com

13

Page 14

EVBUM2528/D

Figure 18. IN+ Falling to XEN Rising Delay, tD1 = 83 ns

Figure 19. IN+ Rising to XEN Falling Delay, tD2 = 34 ns

www.onsemi.com

14

Page 15

EVBUM2528/D

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

www.onsemi.com

15

EVBUM2528/D

Loading...

Loading...