Page 1

NCP51561 EVBUM

L

B

B

E

B

A

A

A

Isolated Dual Channel Gate

Driver Evaluation Board

User's Manual

Introduction

This user manual supports the evaluation board for the NCP51561.

It should be used in conjunction with the NCP51561 datasheets as well

as ON’s application notes and technical support team. Please visit

ON’s website at www.onsemi.com

This document describes the proposed solution for 5 kV

.

RMS

EVAL BOARD USER’S MANUA

isolated dual channel gate driver using the NCP51561. This user’s

guide also includes information regarding operating procedures,

input/output connections, an electrical schematic, printed circuit board

(PCB) layout, and a bill of material (BOM) for the evaluation board.

Description

The NCP51561 are isolated dual−channel gate driver with

4.5 A / 9 A source and sink peak current respectively. They are

designed for fast switching to drive power MOSFETs, and SiC

Figure 1. Evaluation Board Photo

MOSFET power switches. The NCP51561 offers short and matched

propagation delays.

Two independent and 5 kV

galvanically isolated gate driver

RMS

channels can be used in any possible configuration of two low−side,

two high−side switches or a half−bridge driver with programmable

dead time. A Enable pin shutdown both outputs simultaneously when

is set low.

The NCP51561 offers other important protection functions such as

independent under−voltage lockout for both gate drivers and enable

function.

Key Features

• Flexible: Dual Low−Side, Dual High−Side or Half−Bridge Gate

Driver

• Independent UVLO Protections for Both Output Drivers

• Output Supply Voltage from 9.5 V to 30 V with 8 V for MOSFET,

17 V UVLO for SiC, Thresholds

• 4.5 A Peak Source, 9 A Peak Sink Output Current Capability

• Common Mode Transient Immunity CMTI > 200 V/ns

• Propagation Delay Typical 36 ns with

♦ 8 ns Max Delay Matching per channel

♦ 8 ns Max Pulse−Width Distortion

• User Programmable Input Logic

♦ Single or Dual−input modes via ANB

♦ ENABLE or DISABLE Mode

• User Programmable Dead−Time

FUNCTIONAL BLOCK DIAGRAM

V

DD

INA

INB

ANB

NA/DIS

DT

GND

• Isolation & Safety

♦ 5 kV

Galvanic Isolation from Input to each Output and

RMS

1500 V Peak Differential Voltage between Output Channels

(per UL1577 Requirements)

♦ 1200 V Working Voltage (per VDE0884−11 Requirements)

www.onsemi.com

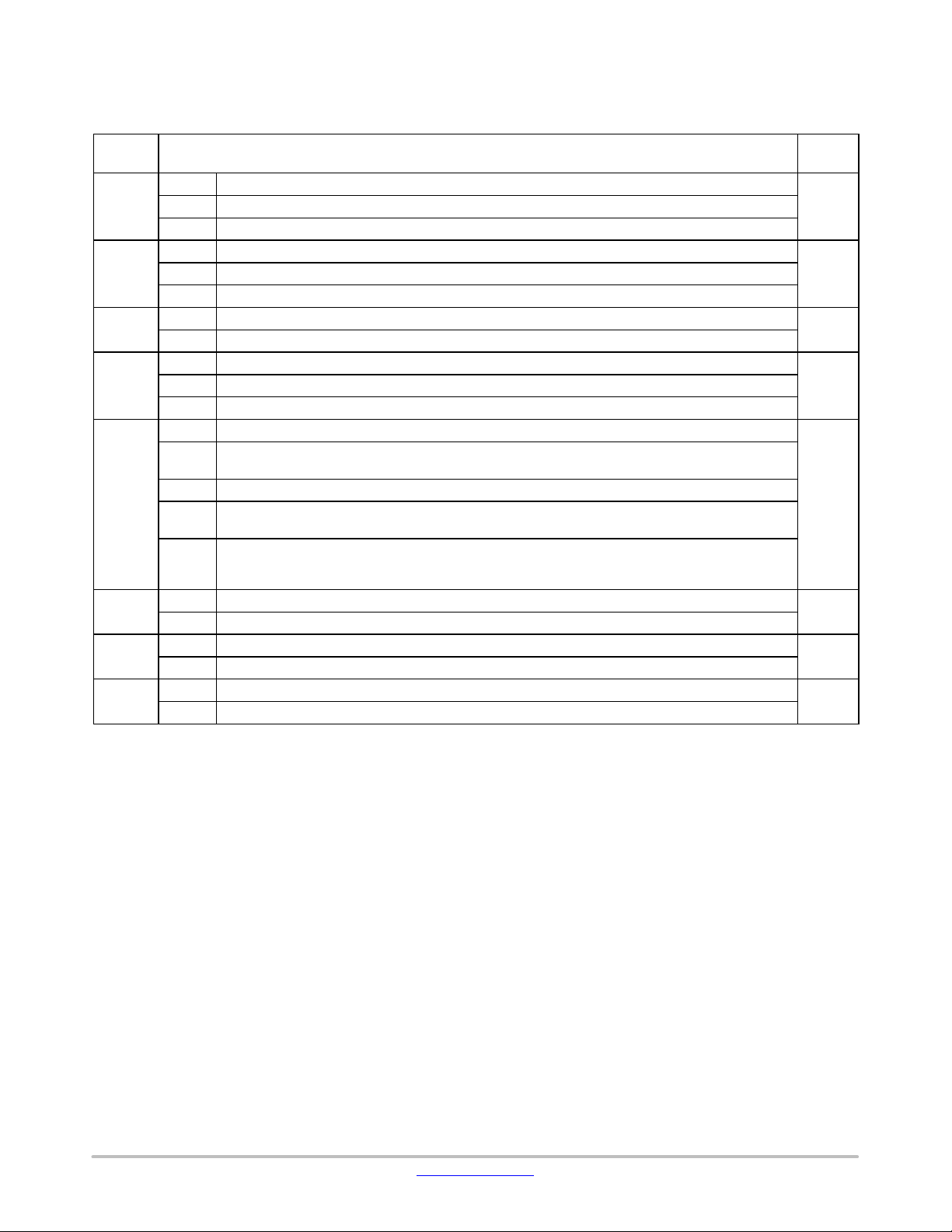

PIN CONNECTIONS

1

INA

2

INB

3

V

DD

4

GND

5

ENA/DIS

DT

6

ANB

7

8

V

DD

VDD UVLO

INA

INB

LOGIC

DEAD

TIME

CONTROL

INA

INB

Tx Rx

Tx

VCCA

OUTA

VSSA

VCCB

OUTB

VSSB

Isolation

Input to Output

Rx

UVLO

[5V, 8V, 17V]

UVLO

[5V, 8V, 17V]

NC

NC

16

15

14

13

12

11

10

9

Functional

Isolation

VCC

LOGIC

LOGIC

OUT

VSS

NC

NC

VCC

OUT

VSS

© Semiconductor Components Industries, LLC, 2020

March, 2021 − Rev. 1

1 Publication Order Number:

EVBUM2771/D

Page 2

NCP51561 EVBUM

EVALUATION BOARD OPERATION

This section describes how to operate the NCP51561

evaluation board (EVB). Make external connections to the

NCP51561 EVB using either the installed test−points or by

installing wires into the connectors. The main connections

that must be made to the EVB are the analog supply voltage,

input signal, and output load and monitoring equipment.

Features

• Evaluation board for the NCP5156x product family in a

wide body SOIC−16 package

• 3 V to 5.0 V VDD power supply range, and up to 30 V

VCCA/VCCB power supply range

• 4.5 A and 9 A source/sink current driving capability

• 5 kV

Isolation for 1 minute per UL 1577

RMS

• TTL −compatible inputs

• Allowable input voltage up to 18 V with for INA, INB,

and ANB pins

• Onboard trimmer potentiometer for dead−time

programming

• 3−position header with for INA, INB, ENA/DIS and

DT

• 2−position header with for ANB

• Support for half−bridge test with MOSFETs, IGBTs

and SiC MOSFETs with connection to external power

stage

Power and Ground

NOTE: Connecting the all power supplies in reverse

polarity (backwards) will instantly device when

power is turned on and device damage can

result.

The primary side of the EVM (V

3 V to 5.0 V power supply and connected via J2. T est point

DD) operates from a single

(TP6 and TP7) is available for monitoring the primary

power supply.

The EVM provides connections for evaluating the output

side (V

CCA, VSSA, VCCB, and VSSB) power supplies for the

channel A and B, from a minimum 9.5 V to maximum 30 V

for 8 V UVLO version as shown in Figure 4. V

CCA and VCCB

can be monitored via TP9 and TP13, respectively.

The V

CCA and VCCB pin should be bypassed with a

capacitor with a value of at least ten times the gate

capacitance, and over 100 nF and located as close to the

device as possible for the purpose of decoupling. A low

ESR, ceramic surface mount capacitor is necessary. We had

recommends using 2 capacitors; a over 100 nF ceramic

surface−mount capacitor, and another a tantalium or

electrolytic capacitor of few microfarads added in parallel.

Input and Output

1. Connection of primary−side power supply to the

V

connector [J2].

DD

2. Connection of secondary−side power supply to the

V

CCA

and V

connector [J9, and J13].

CCB

3. Connection of INA signal to the SIGNAL

connector [J1−1, and J4].

4. Connection of INB signal to the SIGNAL

connector [J1−2, and J5].

5. Connection of ENABLE signal to the ENA/DIS

connector [J1−3, and J15].

6. Connection of ANB signal to the ANB jumper

[J11].

7. Connection of DC link power supply to the V

DC

connector [J6].

8. Connection of bridge output to the V

connector

SSA

[J7 and J12].

www.onsemi.com

2

Page 3

Evaluation Board Jumper Setting

Table 1. EVB JUMPER SETTING

Jumper

Jumper Setting Options

Default

Option1

Jumper not installed, INA/PWM signal provided by external signal and this pin is default low if left open

Option2

Jumper on J4−INA−2 and J4−INA−3 set INA low

Option3

Jumper on J4−INA−2 and J4−INA−1 set INA high

Option1

Jumper not installed, INB signal provided by external signal and this pin is default low if left open

Option2

Jumper on J5−INB−2 and J5−INB−3 set INB low

Option3

Jumper on J5−INB−2 and J5−INB−1 set INB high

Option1

Jumper on J11−ANB−2 and J11−ANB−4 set ANB low for dual input mode

1

Option2

Jumper on J11−ANB−1 and J11−ANB−3 set ANB high for single input (PWM) mode

Option1

Jumper not installed, DISABLE signal provided by external signal and this pin is default low if left open

Option2

Jumper on J15−ENA/DIS−2 and J15−ENA/DIS−3 set DISABLE low (Or ENABLE low)

Option3

Jumper on J15−ENA/DIS−2 and J15−ENA/DIS−1 set DISABLE high (Or ENABLE high)

Option1

Jumper not installed and R13 is open or below 1 kW, shoot−through prevention with 10−ns dead time

4

Option2

Jumper on J14−DT−1 and J14−DT−2 set DT VDD for allows driver both output overlap or driver output

Option3

Jumper on J14−DT−3 and J14−DT−4 set DT for fixed resistance for 20 kW.

Option4

Jumper not installed and R13 = 100 kW. It is recommended close to the DT pin to achieve better noise

Option5

Jumper on J14−DT−5 and J14−DT−6 set the dead time by DT (in ns) = R

(in kW) × 10. For better

Option1

Jumper on T.P1−1 and T.P1−2 for half−bridge application

Option2

Jumper off T.P1−1 and T.P1−2 for bench test.

Option1

Jumper on T.P2−1 and T.P2−2 and jumper on J16−2 and J16−4 for single power supply (VCCA=VCCB)

Option2

Jumper on T.P2−1 and T.P2−2 and and jumper on J16−1 and J16−3 for VCCA bootstrap supply

Option1

Jumper on T.P3−1 and T.P3−2 for single power supply (e.g. VSSA=VSSB)

Option2

Jumper off T.P3−1 and T.P3−2 for dual power supply

J4−INA

NCP51561 EVBUM

Setting

Option1

J5−INB

J11−ANB

J15−EN

A/DIS

J14_DT

T.P1

T.P2

T.P3

Option1

Option

Option2

Option

follow input signals (INA & INB)

immunity.

DT

noise immunity and dead−time matching, We recommends to parallel a 2.2−nF or above bypassing

capacitor from DT pin to GND.

Option2

Option1

Option1

Evaluation Board Setting before Power Up

1. If the ENABLE function is used, ENA/DIS pin

(PIN5) should be connected to VDD (PIN3 or

PIN8) through a wire−bridge between pin 1 and

In addition, Cross−conduction between both driver

outputs (OUTA, and OUTB) is not allowed with

minimum dead time (t

the DT pin is floating (Open).

pin 2 of J15 or this pin is default HIGH if left

open.

On the other hand, if using the Disable mode ,

should be connect ENA/DIS pin to GND pin

through a wire−bridge between pin 2 and pin 3 of

J15.

2. If using the dual input mode, should be ANB pin

(PIN7) connected to GND (PIN4) through a

wire−bridge between pin 2 and pin 4 of J11 or this

pin is default low if left open.

On the other hand, if using the single input mode,

should be connect ANB pin to VDD pin through a

wire−bridge between pin 1 and pin 3 of J11.

3. Should be connect to the resistance between DT

pin (pin6) and GND (pin4) for dead−time control

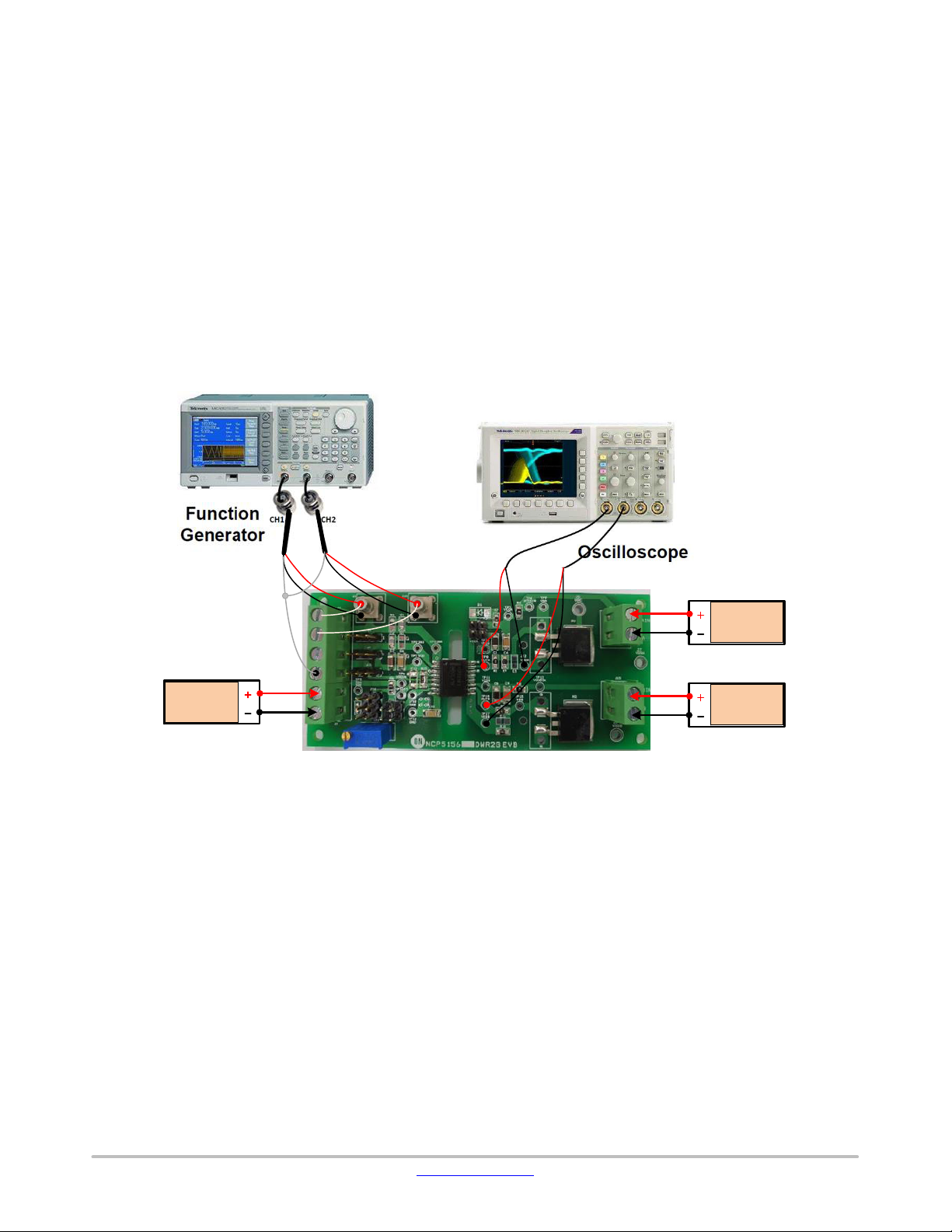

Bench Setup

The bench setup diagram includes the function generator,

power supplies and oscilloscope connections.

Follow the connection procedure below and use Figure 2

as a reference

• Make sure all the output of the function generator,

power supplies are disabled before connection

• Function generator channel−A channel applied on INA

(J3 or J1 pin−1) ↔ TP1 as seen in Figure 2.

• Function generator channel−B channel applied on INB

(J10 or J1 pin−2) ↔ TP2 as seen in Figure 2.

• If the ENABLE function is not used, ENA/DIS pin

(PIN5) should be connected to VDD (PIN3 or PIN8)

mode.

www.onsemi.com

3

DTMIN) typically 10 ns when

Page 4

NCP51561 EVBUM

through a wire−bridge between pin 1 and pin 2 of J15

or this pin is default HIGH if left open.

• If using the dual input signals (INA and INB) with

same polarity, should be DT pin (PIN6) connected to

VDD (PIN3 or 8) through a wire−bridge between pin 1

and pin 2 of J14.

On the other hand, if using the dual input signals with

opposite polarity, should be connect to the resistance

(R13) between DT pin (pin6) and GND (pin4) or DT

pin is floating (Open).

• If using the dual input mode, should be ANB pin

(PIN7) connected to GND (PIN4) through a

wire−bridge between pin 2 and pin 4 of J11 or this pin

is default low if left open.

On the other hand, if using the single input mode,

should be connect ANB pin to VDD pin through a

wire−bridge between pin 1 and pin 3 of J11.

• Power supply #1: positive node applied on J2 pin−1 (or

TP6), and negative node applied on J2 pin−2.

• Power supply #2: positive node applied on J9 pin−1(or

TP14), negative node connected directly to J9 pin−2 (or

TP10) and should be connected to VAIN and VCCA

through a wire−bridge between pin 2 and pin 4 of J16.

• Power supply #3: positive node applied on J13 pin−1

(or TP13), negative node connected directly to J13

pin−2 (or TP17)

• Oscilloscope channel−A probes TP8 ↔ TP10, smaller

measurement loop is preferred

• Oscilloscope channel−B probes TP14 ↔ TP17, smaller

measurement loop is preferred

POWER

SUPPLY #1

(5V/0.05A)

Figure 2. Bench Setup Diagram and Configuration

POWER

SUPPLY #2

(12V/0.1A)

POWER

SUPPLY #3

(12V/0.1A)

www.onsemi.com

4

Page 5

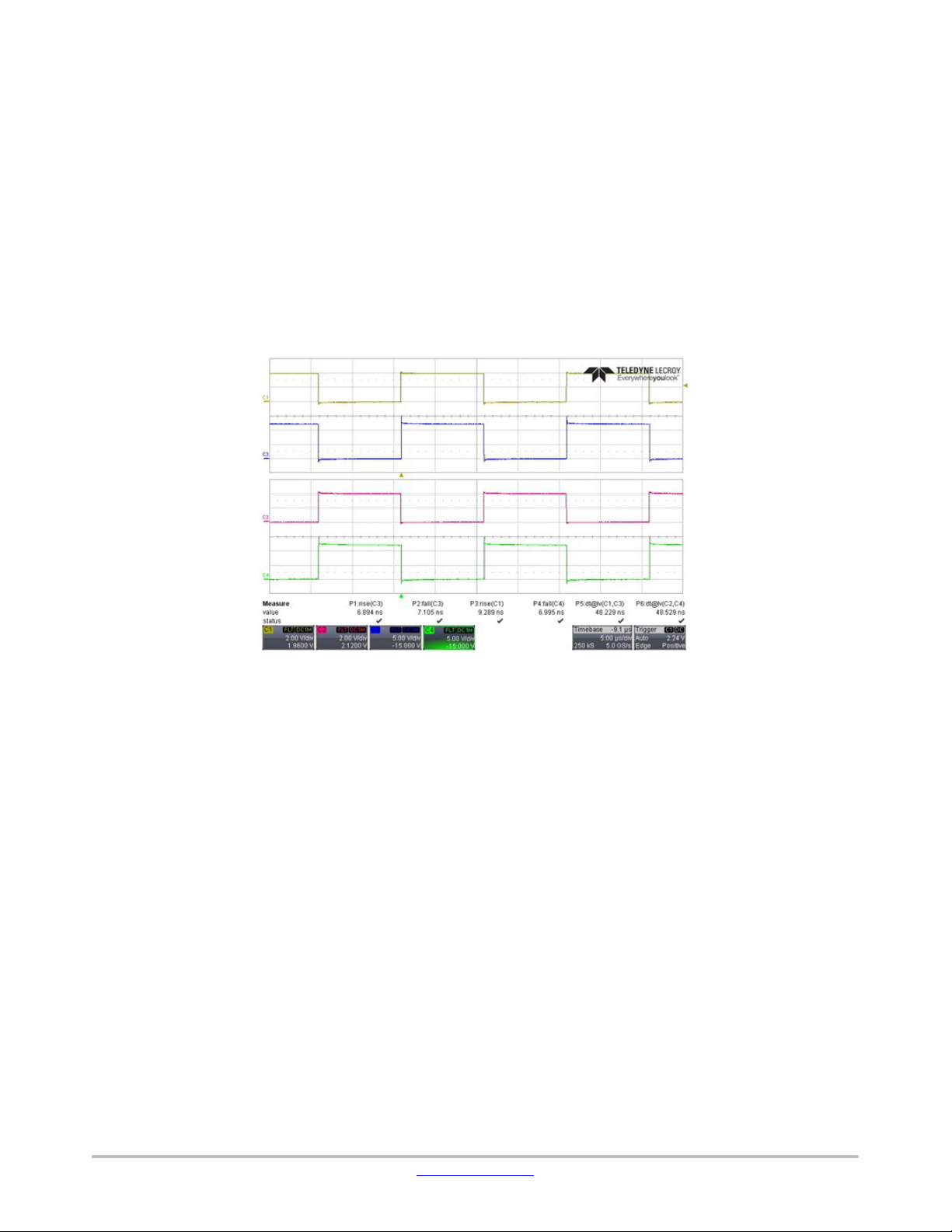

Power Up and Power Down Procedure

Power Up

1. Could be connect VSSA pin to VSSB pin through

a wire−bridge between pin 1 and pin 2 of T.P3, if

the Half−Bridge application is not used.

2. Enable power supply through pin1 of J2 VDD

connector in primary−side

3. Enable power supply through pin1 of J9 VCCA

connector and through pin1 of J13 VCCB

connector in secondary−side

Measure the quiescent current of VCCA, and

VCCB on DMM1 and DMM2 ranges from 0.5 mA

to approximately 1.0 mA if everything is set

correctly;

NCP51561 EVBUM

4. Enable the function generator, two−channel

outputs: channel−A and channel−B;

5. There will be:

A. Stable pulse output on the channel−A and

channel−B in the oscilloscope

B. Scope frequency measurement is the same with

function generator output;

C. DMM #1 and #2 read measurement results

should be around 2.5 mA ± 1 mA under no load

conditions. For more information about operating

current, refer to the NCP51561 data sheet.

CH1: INA, CH2: INB, CH3: OUTA, and CH4: OUTB

Figure 3. Experimental Waveforms of Input to Output

Power Down

1. Disable function generator

2. Disable power supply of VCCA, and VCCB in

secondary−side

3. Disable power supply of VDD in primary−side

4. Disconnect cables and probes

www.onsemi.com

5

Page 6

NCP51561 EVBUM

Table 2. LIST OF TEST POINT

TP

Reference

Description

TP1

INA

Logic Input for Channel A with internal pull−down resistor to GND.

TP2

INB

Logic Input for Channel B with internal pull−down resistor to GND.

TP3

VCCA

TP4

VCCAIN

TP5

ENA/DIS

Logic Input High enables both output channels. Internal pull−up resistor

TP6

VDDIN

TP7

VDD

TP8

OUTA

TP9

VGA

TP10

VSSA

Ground for Channel A

TP11

VCCB

Supply Voltage for Output Channel B.

TP12

GND

Ground Input−side. (all signals on input−side are referenced to this pin)

TP13

VCCBIN

Supply Voltage for Output Channel B.

TP14

OUTB

TP15

VGB

TP16

DT

Input for programmable Dead−Time

TP17

VSSB

Ground for Channel B

TP18

ANB

Logic Input for changing the input signal configuration with internal pull−down resistor to GND. The OUTA

l

Figure 4 shows an application schematic of NCP51561 for

an evaluation board.

TP7

J4

1

J10

PWMA

PWMB

ENA

GND

VDD

GND

J3

2

J1

J2

3

1

J5

2

1

3

2

4

3

J15

1

2

3

TP6

R6

0

1

2

R12

20k

J11

1

2

J14

1

3

5

R11

500k

2.2nF

C12

TP1

C1

R1

DNP

10pF

51

C2

R3

DNP

10pF

51

C7

C6

0.22uF

10uF

TP5

3

4

2

4

6

DNP

TP16

TP18

R13

100k

C10

0.22uF

U1

TP2

1

INA

2

INB

3

V

DD

4

GND

5

ENA/DIS

6

DT

ANB

7

8

V

DD

NCP51561

VCCA

OUTA

VSSA

NC

NC

VCCB

OUTB

VSSB

VAIN

J6

VDC

TP4

M1

R7

10k

J9

1

VCCA

VSSA

TP3

J16

D1

3

4

VCCA

16

15

0.22uF

C3

R5

4.7

R2

1

DNP

2

US1MFA

10

TP9

R4

VAIN

0

C4

10uF

C5

DNP

1 nF

14

T.P1

J7

VSSA

J12

VSSA

J13

1

VCCB

2

VSSB

J8

VSSB

0.22uF

TP10

T.P2

VCCBVAIN

12

T.P3

VSSBVSSA

12

TP13

DNP

TP15

C11

1 nF

R8

0

C9

C8

10uF

R9

4.7

12

M2

R10

10k

TP8

13

12

TP11

VCCB

11

10

9

TP17

TP14

Figure 4. Typical Application Schematic of NCP51561 EVB

List of Test Point

Table 2 show the test point list of NCP51561 for an

evaluation board.

Supply Voltage for Output Channel A.

It is recommended to place a bypass capacitor from VCCA to VSSA.

Input−side Supply Voltage.

It is recommended to place a bypass capacitor from VDD to GND.

Output for Channel A

It is recommended to place a bypass capacitor from VCCB to VSSB.

Output for Channel B

and OUTB as complementary outputs from one PWM input signal on the INA pin regardless the INB signa

when the ANB pin is high. The INB pin should be pulled down to GND (recommended) or floating (not recommended) when the ANB pin is high. The ANB pin should be kept low when INA and INB pins control the

OUTA and OUTB individually.

www.onsemi.com

6

Page 7

NCP51561 EVBUM

Table 3. ELECTRICAL SPECIFICATIONS

Rating

Symbol

Min

Max

Unit

Power Supply Voltage – Input side

VDD3.0

5.0

V

V

V

Logic Input Voltage at pins INA, INB, and ANB

VIN018V

Logic Input Voltage at pin ENA/DIS

V

0

5.0

V

Table 4. BILL OF MATERIAL

Reference

Qty

Description

Value

Footprint

Manufacturer

U11Gate driver

NCP51561

16 SOIC−WB

ON Semiconductor

D10Diode

US1MFA

SOD−123FL

ON Semiconductor

R1, R3

0

Resistors

5.1

SMD 2012

R21Resistors

2.2

SMD 2012

R4,R6, R83Resistors

0

SMD 2012

R5 ,R92Resistor

4.7

SMD 2012

R7, R102Resistor

10 k

SMD 2012

R11

1

Variable Resistor

500 k

R121Resistor

20 k

SMD 2012

R131Resistor

100 k

SMD 3216

C1, C2

2

Capacitor, Ceramic

10 pF, 50 V

SMD 2012

C3 , C6, C8, C10

4

Capacitor, Ceramic

0.22 uF, 50 V

SMD 3216

C7

3

Capacitor, Ceramic

10 uF, 16 V

SMD 3216

C4, C9

2

Capacitor, Ceramic

10 uF, 50 V

SMD 3216

C5, C11

2

Capacitor, Ceramic

1 nF, 50 V

SMD 2012

C12

1

Capacitor, Ceramic

2.2 nF, 50 V

SMD 3216

M1, M22TBD

J11Connector

EB21A−04−D

Adam Tech

J2,J9, J13

3

Connector

EB21A−02−D

Adam Tech

J3, J10

2

BNC Connector

SMB

J4, J5, J15

3

Header 3

J11, J16

2

Header 2 × 2

J141Header 3 × 2

J6,J7,J8, J12

2

Connector

Electrical Specifications

Table 3 shows the recommended operating conditions of

NCP51561 for the evaluation board.

Power Supply Voltage – Driver side

Operating Junction Temperature Tj −40

8−V UVLO Version

17−V UVLO Version 18 30

V

CCA

, V

ENA/DIS

CCB

Bill of Material (BOM)

Table 4 shows the bill of material (BOM) of NCP51561

for the evaluation board.

W

W

W

W

W

W

W

W

9.5 30

+150

°C

www.onsemi.com

7

Page 8

NCP51561 EVBUM

Input Stage

The input pins of NCP51561 is based on a TTL

compatible input−threshold logic that is independent of the

V

supply voltage for INA, INB, ANB, and ENA/DIS

DD

pins.

The logic level compatible input provides a typically high

threshold of 1.6 V and a typically low threshold of 1.1 V. The

input impedance of the NCP51561 is 200 kW typically, as

shown in Figure 5.

V

DD

TP1

INA

TP2

INB

TP5

ENA/DIS

J4

J5

J15

And we recommends an RC network is to be added on the

PWM input pins, INA and INB, for reducing the impact of

system noise and ground bounce, for example, 51 W (R1,

and R3) with 10 pF (C1, and C2) is an acceptable choice as

shown in Figure 5.

INA, INB, ENA/DIS and ANB

signal can be monitored

via TP1, TP2, TP5 and TP18, respectively.

INA

1

R1

R3

C7

C8

C2

C1

2

3

4

5

INB

V

GND

ENA/DIS

200 k

200 k

DD

200 k

Figure 5. Recommended Input Circuit

Output Stage

The output stage is able to sink/source typically around

4.5 A/9 A at 25°C for the NCP51561.

The EVB comes populated with a 1−nF load (C5, and

C11) on the output side. The OUTA and OUTB can be

monitored directly via TP8 and TP14, respectively.

The EVB also allows for evaluation of the device with an

MOSFET load in either of the standard TO−220, TO−3P,

TP18

J11

ANB

7

200 k

TO−247, and TO−252 (D−PAK), and TO−263 (D2PAK )

footprints. During evaluation with an MOSFET load, the

pre−installed capacitive load (C5 and C11) can be

disconnected from the each output.

The EVB provides an additional connection (J6) for

applying an external power supply to the MOSFET Drain.

The EVB is not intended for high voltage testing and the

voltage applied to J6 should be limited to 50 V DC.

www.onsemi.com

8

Page 9

NCP51561 EVBUM

PERFORMANCE OF EVALUATION BOARD

This section describes application guidance and operation

of the NCP51561 for an evaluation board (EVB) include key

functions.

Input Signal Configuration

The NCP51561 allows changing the input signal pin

configuration by the ANB pin for user convenience. (e.g.

single input – dual output, or dual input – dual output).

(a) INB = OPEN (LOW) with DT = Open

CH1: INA, CH2: ANB, CH3: OUTA, and CH4: OUTB

Figure 6. Experimental Waveforms of ANB Function with Dead−time

ANB Function

The NCP51561 allows changing the input signal pin

configuration by the ANB pin for user convenience. There

are two operating modes that allow changing the

configuration of the input to output channels (e.g. single

input – dual output, or dual input – dual output).

Figure 6 and Figure 7 shows the experimental result of

ANB function with and without dead−time control.

(b) INB = OPEN (LOW) with R

= 100 kW

DT

(a) INB = HIGH with DT = Open (b) INB = HIGH with DT = VDD

CH1: INA, CH2: ANB, CH3: OUTA, and CH4: OUTB

Figure 7. Experimental Waveforms of ANB Function

www.onsemi.com

9

Page 10

NCP51561 EVBUM

Protection Function

NCP51561 provide the protection features include Enable

function, and Under−Voltage Lockout (UVLO) of power

supplies in primary−side (V

channels (V

(INB)

OUTA

(OUTB)

Protection

Status

ENABLE

INA

CCA

, and V

CCB

), and secondary−side both

DD

).

Figure 8. Timing Chart of Enable Function

t1

Figure 9 shows an experimental result of enable function

that the ENA/DIS pin voltage goes to LOW state in normal

Enable Function

Figure 8 shows the timing chart of enable function. If the

ENA/DIS pin voltage goes to LOW state in normal

operation, the gate driver enters the shutdown (disable)

mode.

External Shutdown

t2

operation, the both driver output is turned−off immediately

even though input signals, INA and INB, are HIGH state.

CH1: INA and INB, CH2: ENA/DIS, CH3: OUTA, and CH4: OUTB

Figure 9. Experimental Waveforms of Enable Function

www.onsemi.com

10

Page 11

NCP51561 EVBUM

Under−Voltage Lockout Protection VDD

The NCP51561 provides the Under−Voltage Lockout

(UVLO) protection function for VDD in primary−side as

shown in Figure 10. The OUTA and OUTB as

CH1: INA, CH2: VDD, CH3: OUTA, and CH4: OUTB

complementary outputs from one PWM input signal on the

INA pin regardless the INB signal when the ANB pin is high.

As test result, the VDD UVLO turn−on and off threshold

voltages are around 2.8 V and 2.7 V respectively.

Figure 10. Experimental Waveforms of VDD Under−Voltage Lockout Protection

Under−Voltage Lockout Protection VCCx (VCCA and

VCCB)

The NCP51561 provides the Under−Voltage Lockout

(UVLO) protection function for both gate drive output for

VCCA and VCCB for 8 V version in secondary−side as

shown in Figure 11. The OUTA and OUTB as

complementary outputs from one PWM input signal on the

INA pin regardless the INB signal when the ANB pin is high.

As test result, the VCC UVLO turn−on and off threshold

voltages are around 8.7 V and 8.2 V respectively.

CH1: INA, CH2: VCCA, and VCCB, CH3: OUTA, and CH4: OUTB

Figure 11. Experimental Waveforms of VCC Under−Voltage Lockout Protection

www.onsemi.com

11

Page 12

NCP51561 EVBUM

Experimental Waveforms with Different DT

Configurations

This section shows experimental test results of dead−time

control with different DT configuration.

DT Pin Floating or Left Open

(J14−DT Option 1 in Table 1)

The dead−time(DT) between the outputs (OUTA and

OUTB) of the two channels is typically around 10 ns, which

is preset for shoot−through prevention as shown in

Figure 12.

CH1: INA, CH2: INB, CH3: OUTA, and CH4: OUTB

Figure 12. Experimental Waveforms if DT is left Open

DT Pin Connected to VDD (J14−DT Option 2 in Table 1)

Overlap is allowed both switches from conducting even

though at the same time when the DT pin pulled to VDD as

shown in Figure 13.

CH1: INA, CH2: INB, CH3: OUTA, and CH4: OUTB

Figure 13. Overlap is Allowed when DT Connected to VDD

www.onsemi.com

12

Page 13

NCP51561 EVBUM

DT Pin Connected to RDT (J14−DT Option 3 in Table 1)

Overlab is not allowed both switches at the same time

when the dead time (DT) control mode. The dead−time (DT)

between both outputs is set according to:

DT (in ns) = 10 × R

(in kW).

DT

CH1: INA, CH2: INB, CH3: OUTA, and CH4: OUTB

Figure 14. Experimental Waveforms if DT Connected to R

Figure shown the experimental results when the

dead−time control resistance for 100 kW.

DT

Dead Time Characteristics

Figure 15 shows the dead time characteristics and

operating modes according to the dead−time resistance

values of the NCP51561.

tDT [ns]

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0

Minimum Dead−time

MODE A – DT pin Open

t

=

10 ns

DT

Cross−conduction prevention active

1 50 100 150

Figure 15. Dead Time (DT vd. RDT)

Dead−time Control Range

MODE B – 1 k <R

t

[ns]=10⋅ RDT[k ]

DT

Cross−conduction prevention active

200

Output Overlap ENABLED

MODE C – DT pin pull to V

tDT=

0 ns

Cross−conduction prevention disabled

<500 k

W

W

R

DT

W

DT

250 300 500350 400 450

[k ]

W

DD

www.onsemi.com

13

Page 14

NCP51561 EVBUM

Output Driving Current Capability

Figure 16 shows the experimental result of source and

sink peak currents driving capability around 4.5 A and 10 A

(a) Source Current Capability (b) Sink Current Capability

CH1: INPUT, and CH2: OUTPUT Current

Figure 16. Experimental Waveforms of Current Driving Capability

ESD Structure

Figure 17 shows the multiple diodes related to an ESD

protection components of NCP51561. This illustrates the

absolute maximum rating for the device.

respectively at 25°C when the supply voltage (VCCA and

VCCB) is applied 12 V.

INA

INB

ENA/DIS

ANB

DT

VCCAVDD

3,8

1

2

5

7

6

20 V

5.5 V

33 V

33 V

4 9

16

15

OUTA

14

VSSA

11

VCCB

10

OUTB

GND

Figure 17. ESD Structure

www.onsemi.com

14

Page 15

NCP51561 EVBUM

VSSA

VSSB

Printed Circuit Board

Figure 18 shows the photograph of NCP51561 evaluation board.

.

INA

INB

EN

GND

V

DD

NCP51561

GND

Figure 18. Evaluation Board Picture (Top View)

Figure 19 shows the printed circuit board layout of

NCP51561 evaluation board.

V

CCA

V

CCB

(a) Top & Bottom View

(b) Top View

(c) Bottom View

Figure 19. Printed Circuit Board

www.onsemi.com

15

Page 16

ON Semiconductor and the ON Semiconductor logo are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or

other countries. ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

subject to all applicable copyright laws and is not for resale in any manner.

The evaluation board/kit (research and development board/kit) (hereinafter the “board”) is not a finished product and is as such not available for sale to consumers. The board is only intended

for research, development, demonstration and evaluation purposes and should as such only be used in laboratory/development areas by persons with an engineering/technical training

and familiar with the risks associated with handling electrical/mechanical components, systems and subsystems. This person assumes full responsibility/liability for proper and safe handling.

Any other use, resale or redistribution for any other purpose is strictly prohibited.

The board is delivered “AS IS” and without warranty of any kind including, but not limited to, that the board is production−worthy, that the functions contained in the board will meet your

requirements, or that the operation of the board will be uninterrupted or error free. ON Semiconductor expressly disclaims all warranties, express, implied or otherwise, including without

limitation, warranties of fitness for a particular purpose and non−infringement of intellectual property rights.

ON Semiconductor reserves the right to make changes without further notice to any board.

You are responsible for determining whether the board will be suitable for your intended use or application or will achieve your intended results. Prior to using or distributing any systems

that have been evaluated, designed or tested using the board, you agree to test and validate your design to confirm the functionality for your application. Any technical, applications or design

information or advice, quality characterization, reliability data or other services provided by ON Semiconductor shall not constitute any representation or warranty by ON Semiconductor,

and no additional obligations or liabilities shall arise from ON Semiconductor having provided such information or services.

The boards are not designed, intended, or authorized for use in life support systems, or any FDA Class 3 medical devices or medical devices with a similar or equivalent classification in

a foreign jurisdiction, or any devices intended for implantation in the human body. Should you purchase or use the board for any such unintended or unauthorized application, you shall

indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that ON Semiconductor

was negligent regarding the design or manufacture of the board.

This evaluation board/kit does not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC,

CE or UL, and may not meet the technical requirements of these or other related directives.

FCC WARNING – This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by ON Semiconductor to

be a finished end product fit for general consumer use. It may generate, use, or radiate radio frequency energy and has not been tested for compliance with the limits of computing devices

pursuant to part 15 of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment may cause interference with radio

communications, in which case the user shall be responsible, at its expense, to take whatever measures may be required to correct this interference.

ON Semiconductor does not convey any license under its patent rights nor the rights of others.

LIMITATIONS OF LIABILITY: ON Semiconductor shall not be liable for any special, consequential, incidental, indirect or punitive damages, including, but not limited to the costs of

requalification, delay, loss of profits or goodwill, arising out of or in connection with the board, even if ON Semiconductor is advised of the possibility of such damages. In no event shall

ON Semiconductor’s aggregate liability from any obligation arising out of or in connection with the board, under any theory of liability, exceed the purchase price paid for the board, if any.

For more information and documentation, please visit www.onsemi.com

.

. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This literature is

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...