Page 1

NCP1835B

Integrated Li−Ion Charger

NCP1835B is an integrated linear charger specifically designed to

charge 1−cell Li−Ion batteries with a constant current, constant

voltage (CCCV) profile.

Its low input voltage capability, adjustable charge current, ability

to maintain regulation without a battery, and its onboard thermal

foldback make it versatile enough to charge from a variety of wall

adapters. The NCP1835B can charge from a standard wall adapter or

from the USB port. It has been optimized to charge low capacity

batteries such as those found in wireless headsets and flash

memory−based MP3 players.

http://onsemi.com

MARKING

DIAGRAM

Features

• Integrated Voltage and Current Regulation

• No External MOSFET, Sense Resistor or Blocking Diode Required

• Charge Current Thermal Foldback

• Integrated Pre−charge Current for Conditioning a Deeply

Discharged Battery

• Integrated End−of−Charge (EOC) Detection

• 1% Voltage Regulation

• 4.2 V Regulated Output Voltage

• Regulation Maintained without a Battery Present

• Programmable Full Charge Current

• Open−Drain Charger Status and Fault Alert Flags

• 2.8 V Output for AC Present Indication and Powering Charging

Subsystems

• Minimum Input Voltage of 2.4 V Allows Use of Current Limited

Adapters

• Automatically Recharging if Battery Voltage Drops after Charging

Cycle is Completed

• Low Profile 3x3 mm DFN Package

• Pb−Free Package is Available

T ypical Applications

• Wireless Headsets

• MP3 Players

• USB Appliances

• Battery Operated Devices

1

1835B

10

9

8

7

6

ALYWG

G

BAT

VSNS

ISEL

V2P8

EN

Shipping

†

1

DFN 3x3

MN SUFFIX

CASE 485C

1835B = Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

PIN CONNECTIONS

V

1

CC

FAULT

CFLG

TIMER

Device

NCP1835BMNR2 DFN−10 3000 Units/Reel

2

DFN 3x3

3

4

GND

5

(Top View)

ORDERING INFORMATION

Package

© Semiconductor Components Industries, LLC, 2006

September, 2006 − Rev . 4

NCP1835BMNR2G DFN−10

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

1 Publication Order Number:

3000 Units/Reel

NCP1835B/D

Page 2

NCP1835B

V

in

CFLG

EN

Microprocessor

V2P8

VSNS

NCP1835B

BAT

GND

15 nF

C

T

0.1 mF

C

2p8

4.7 mF

C

out

V

in

4.7 mF

FAULT

V

CC

C

in

ISEL TIMER

1.6 M

R

ISEL

GND

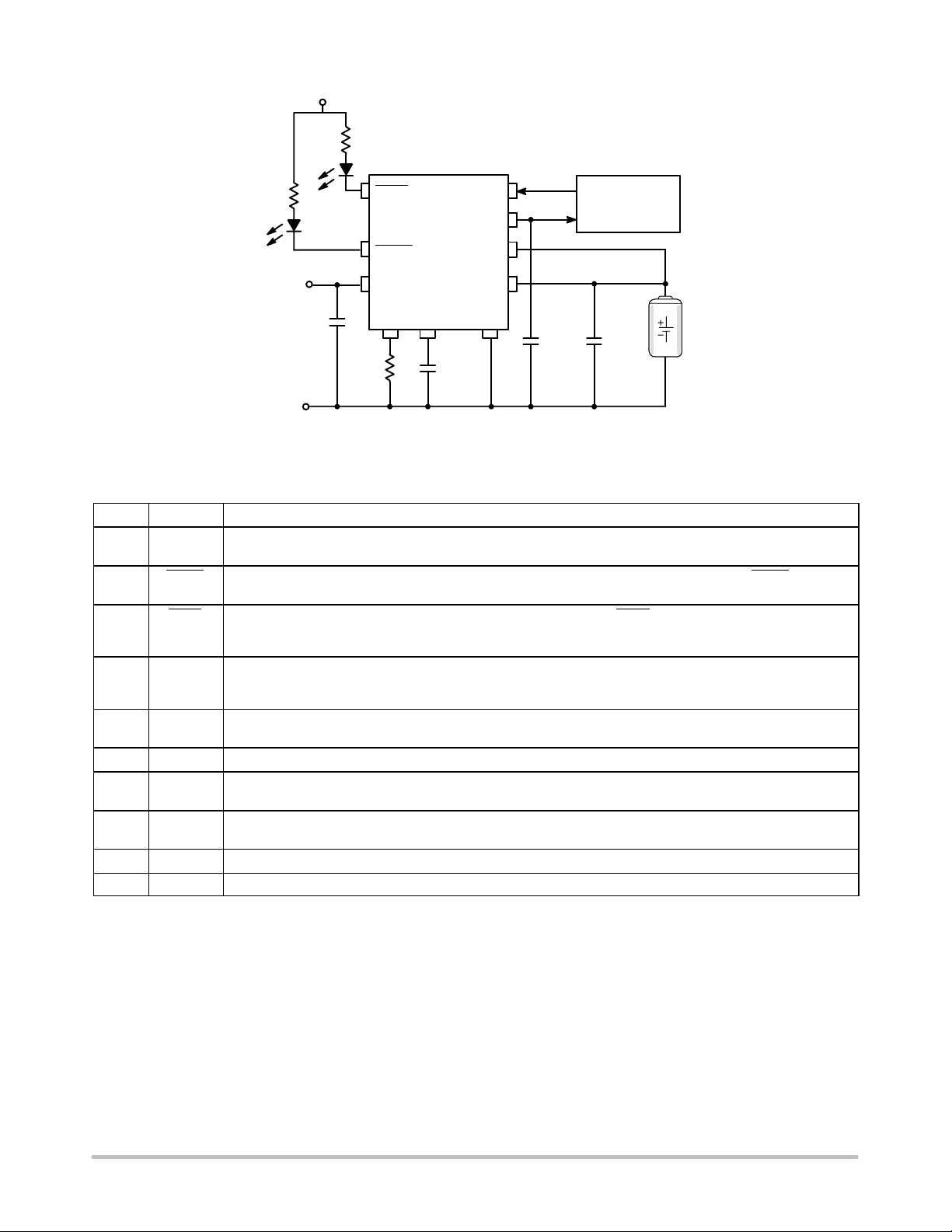

Figure 1. Typical 50 mA Application Circuit

PIN FUNCTION DESCRIPTION

Pin Symbol Description

1 V

CC

2 FAULT An open−drain output indicating fault status. This pin is pulled LOW under any fault conditions. A FAULT condition

3 CFLG An open−drain output indicating charging or end−of−charge states. The CFLG pin is pulled LOW when the charger

4 TIMER Connecting a timing capacitor, C

5 GND Ground pin of the IC. For thermal consideration, it is recommended to solder the exposed metal pad on the back-

6 EN Enable logic input. Connect the EN pin to LOW to disable the charger or leave it floating to enable the charger .

7 V2P8 2.8 V reference voltage output. This pin outputs a 2.8 V voltage source when an adapter is present. The maximum

8 ISEL The full charge current (I

9 VSNS Battery voltage sense pin. Connect this as close as possible to the battery input connection.

10 BAT Charge current output. A minimum 4.7 mF capacitor is needed for stability when the battery is not attached.

Input Supply Voltage. Provides power to the charger. This pin should be bypassed with at least a 4.7 mF ceramic

capacitor to ground.

resets the counter.

is charging a battery. It is forced open when the charge current drops to I

latched until a recharge cycle or a new charge cycle starts.

between this pin and ground to set end−of−charge timeout timer.

TIMEOUT = 14*C

Trickle Charge has a time limit of 1/8 of the TIMEOUT period.

/1.0 nF (minute). The total charge for CC and CV mode is limited to the length of TIMEOUT.

TIME

TIME

. This high impedance mode will be

EOC

side of the package to ground.

loading for this pin is 2.0 mA.

) can be set by connecting a resistor, R

For best accuracy, a resistor with 1% tolerance is recommended.

FCHG

, from the ISEL pin to ground.

ISEL

http://onsemi.com

2

Page 3

NCP1835B

V

CC

V2P8

CFLG

FAULT

Startup,

Control

& Clamp

V2P8

VCC

Resistor

Dividers

Bias Circuits

VREF

Chip

Enable

EN GNDTIMER

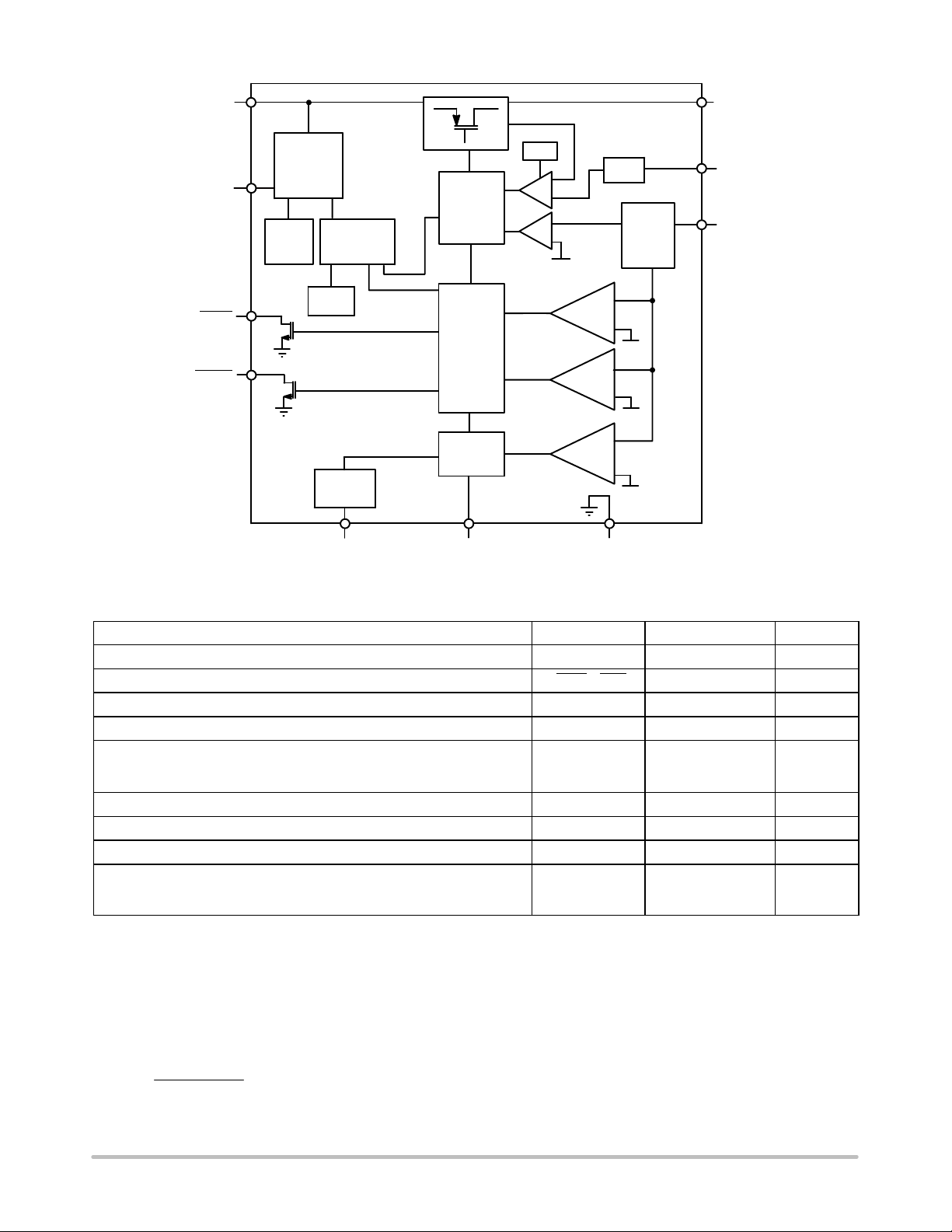

Figure 2. Detailed Block Diagram

Control

LOGIC

TIMER

Temp

CC

CV

VREF

Recharge

Comp

Precharge

Comp

Timer

Comp

IREF

Vbat

Resistor

Dividers

VREF

VREF

VREF

BAT

ISEL

VSNS

MAXIMUM RATINGS

Rating Symbol Value Unit

Supply Voltage V

Status Flag Output Pins V

Voltage Range for Other Pins V

Current Out from BAT Pin I

FAULT

CC

, V

O

CFLG

io

Thermal Characteristics

Thermal Resistance, Junction−to−Air (Note 3)

Power Dissipation, TA = 25°C (Note 3)

R

q

JA

P

D

Moisture Sensitivity (Note 4) MSL Level 1

Operating Ambient Temperature T

Storage Temperature T

A

stg

ESD

Human Body Model

Machine Model

HBM

MM

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. This device series contains ESD protection and is tested per the following standards:

Human Body Model (HBM) per JEDEC standard: JESD22−A114.

Machine Model (MM) per JEDEC standard: JESD22−A115.

2. Latchup Current Maximum Rating: 150 mA per JEDEC standard: JESD78.

3. Measure on 1 inch sq. of 1 oz. copper area. R

sq. of 1 oz. copper area on 4 layer PCB that has 1 single signal layer with the additional 3 solid ground or power planes. The maximum package

is highly dependent on the PCB heatsink area. For example, R

q

JA

power dissipation limit must not be exceeded:

T

P

+

D

with R

q

4. Moisture Sensitivity Level per IPC/JEDEC standard: J−STD−020A.

JA

* T

J(max)

R

qJA

= 68.5°C/W, T

A

= 100°C, PD = 1.09 W.

J(max)

7.0 V

7.0 V

5.5 V

1.2 A

68.5

1.09

°C/W

W

−20 to 70 °C

−55 to 125 °C

2000

200

can be 38°C/W on 1 inch

q

JA

V

V

http://onsemi.com

3

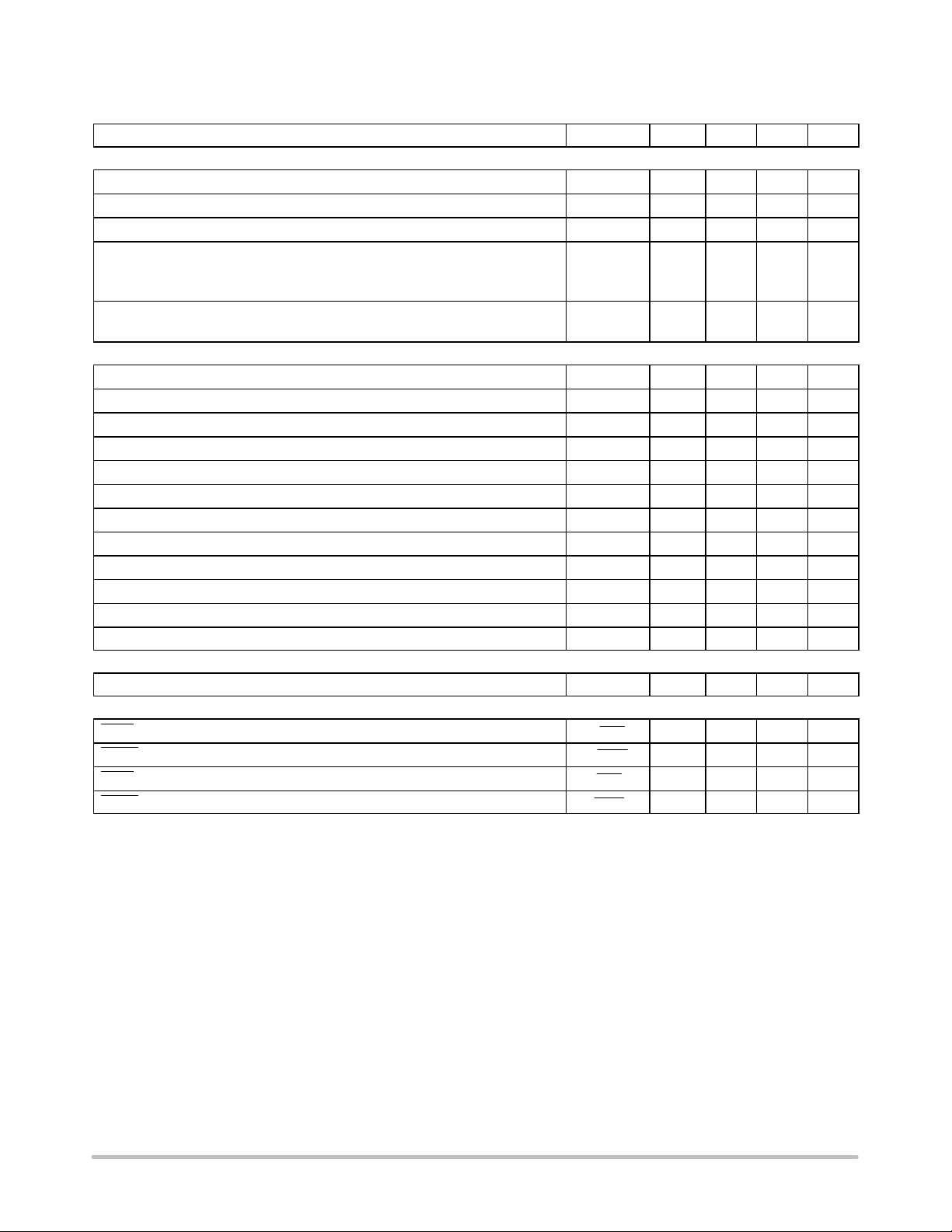

Page 4

NCP1835B

ELECTRICAL CHARACTERISTICS (Typical values are tested at V

= 5.0 V and room temperature, maximum and minimum values

CC

are guaranteed over 0°C to 70°C with a supply voltage in the range of 4.3 V to 6.5 V, unless otherwise noted.)

Characteristic Symbol Min Typ Max Unit

VCC SUPPL Y

Operating Supply Range V

Rising VCC Threshold V

Falling VCC Lockout Threshold V

CC

RISE

FALL

Quiescent VCC Pin Supply Current

Shutdown (EN = Low)

Normal Operation (EN = High)

Battery Drain Current

Manual Shutdown (VCC = 5.0 V , VSNS = 4.0 V, EN = Low)

I

VCC

I

VCC

I

BMS

CHARGING PERFORMANCE

Regulated Output Voltage in Constant Voltage (CV) Mode, I

Dropout Voltage (V

= 3.7 V , I

BAT

= 0.1 A) − − 80 120 mV

CHG

Pre−Charge Threshold Voltage V

Pre−Charge Current (R

Pre−Charge Current (R

= 2.7 MW, V

ISEL

= 270 kW, V

ISEL

= 2.0 V) I

BAT

= 2.0 V) I

BAT

Recommended Full Charge Current I

Full−Charge Current in Constant Current (CC) Mode (R

Full−Charge Current in Constant Current (CC) Mode (R

End−of−Charge Threshold (R

End−of−Charge Threshold (R

= 2.7 MW, V

ISEL

= 270 kW, V

ISEL

BAT

BAT

= V

= V

REG

REG

Recharge Voltage Threshold V

Thermal Foldback Limit (Junction Temperature) (Note 5) T

= 10 mA V

CHG

= 2.7 MW, V

ISEL

= 270 kW, V

ISEL

= 3.7 V) I

BAT

= 3.7 V) I

BAT

) I

) I

REG

PC

PC

PC

FCHG

FCHG

FCHG

EOC

EOC

RECH

LIM

4.158 4.200 4.242 V

OSCILLATOR

Oscillation Period (C

= 15 nF) T

TIME

OSC

STATUS FLAGS

CFLG Pin Recommended Maximum Operating V oltage V

FAULT Pin Recommended Maximum Operating Voltage V

CFLG Pin Sink Current (V

FAULT Pin Sink Current (V

= 0.8 V) I

CFLG

= 0.8 V) I

FAULT

CFLG

FAULT

CFLG

FAULT

5. Guaranteed by design. Not tested in production.

2.8 − 6.5 V

3.0 3.4 3.95 V

2.0 2.4 2.8 V

−

−

30

600

−

−

mA

mA

− − 3.0 mA

2.52 2.8 3.08 V

1.0 20 30 mA

30 50 65 mA

30 − 300 mA

30 45 58 mA

280 310 360 mA

1.0 4.0 11 mA

26 34 42 mA

3.80 4.03 4.155 V

− 100 − °C

2.4 3.0 3.6 ms

− − 6.5 V

− − 6.5 V

5.0 − − mA

5.0 − − mA

http://onsemi.com

4

Page 5

NCP1835B

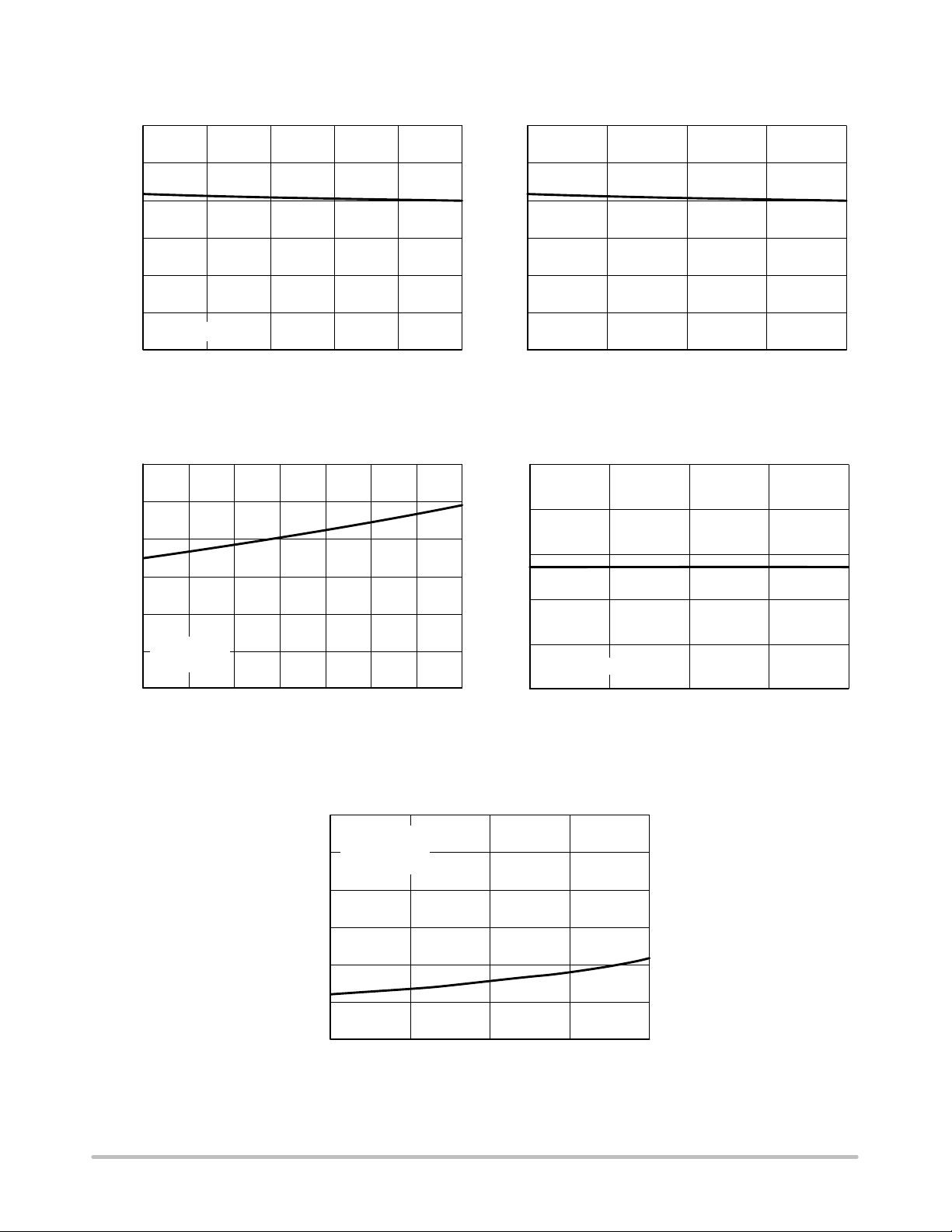

TYPICAL OPERATING CHARACTERISTICS

4.30

4.25

4.20

4.15

4.10

4.05

, REGULATED OUTPUT VOLTAGE (V)

REG

V

VCC = 5 V

4.00

0 0.06 0.12 0.18 0.24 0.3

I

, CHARGE CURRENT (A)

CHG

Figure 3. Regulated Output Voltage vs. Charge

Current

4.30

4.25

4.20

4.15

4.10

VCC = 5 V

4.05

V

floating

, REGULATED OUTPUT VOLTAGE (V)

REG

V

BAT

4.00

−50 −25 0 25 50 75

TA, AMBIENT TEMPERATURE (°C)

100 125

4.30

4.25

4.20

4.15

4.10

4.05

, REGULATED OUTPUT VOLTAGE (V)

4.00

REG

4.5 5 5.5 6 6.5

V

VCC, INPUT VOLTAGE (V)

Figure 4. Regulated Output Voltage (floating) vs.

Input Voltage

0.80

0.78

0.76

0.74

, ISEL VOLTAGE (V)

ISEL

V

0.72

V

= 3.7 V

BAT

0.70

4.5 5.0 5.5 6.0 6.5

VCC, INPUT VOLTAGE (V)

Figure 5. Regulated Output Voltage vs.

Temperature

3.00

V

floating

BAT

R

= 270 k

2.95

ISEL

I

V2P8

= 0

2.90

2.85

2.80

, V2P8 VOLTAGE (V)

2P8

V

2.75

2.70

4.5 5.0 5.5 6.0 6.5

VCC, INPUT VOLTAGE (V)

Figure 7. V2P8 Voltage vs. Input Voltage

http://onsemi.com

Figure 6. ISEL Voltage vs. Input Voltage

5

Page 6

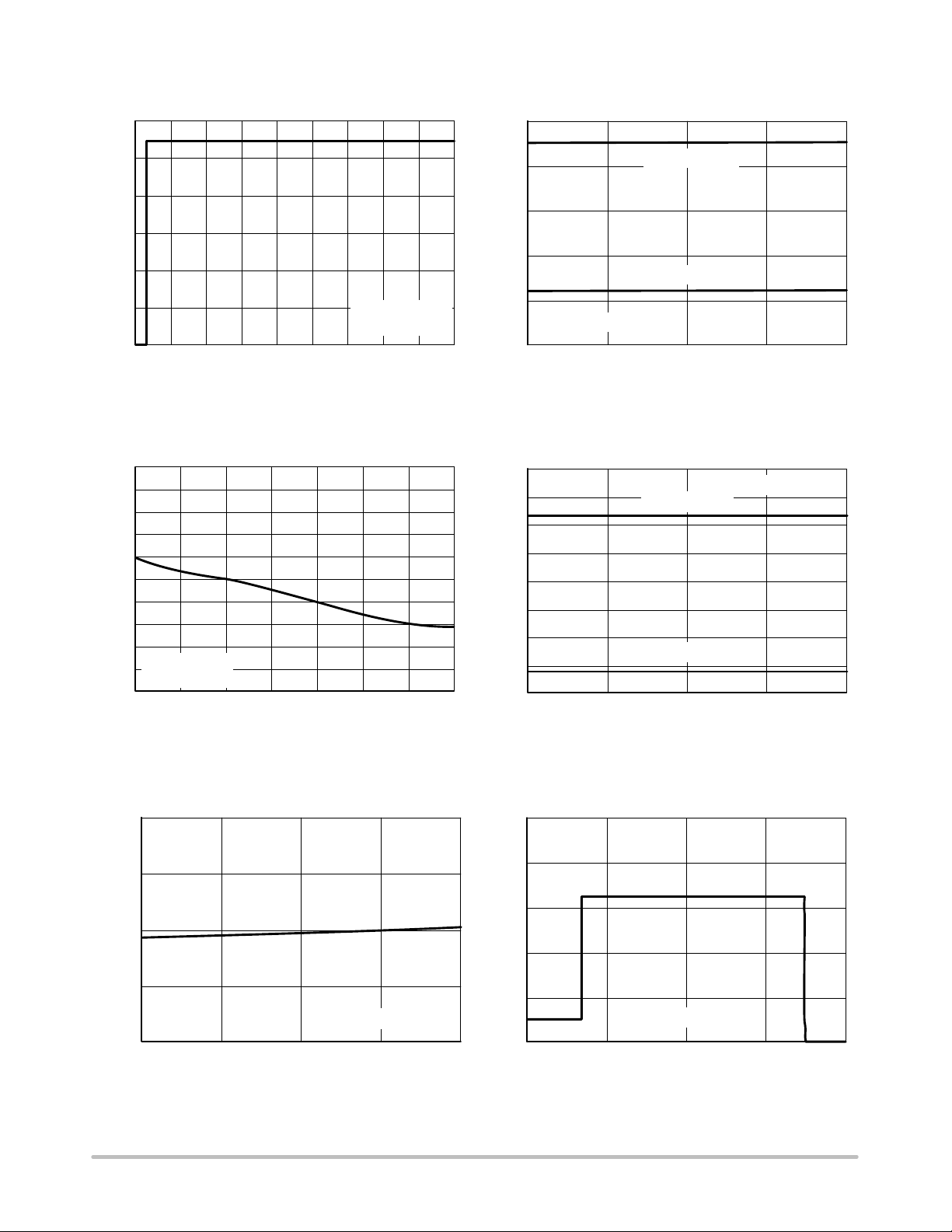

5

V

, V2P8 VOLTAGE (V)

3.0

2.5

5

50

I

, TRICKLE CHARGE CURRENT (mA)

5

V

, RECHARGE VOLTAGE (V)

NCP1835B

TYPICAL OPERATING CHARACTERISTICS

40

R

ISEL

= 270 kW

2.0

1.5

1.0

2P8

0.5

0.0

4.3 4.5 4.7 4.9 5.1

VCC, INPUT VOLTAGE (V)

Figure 8. V2P8 Voltage vs. Input Voltage Figure 9. Trickle Charge Current vs. Input Voltage

100

90

80

70

60

50

40

30

20

V

= 3.7 V

BAT

10

R

=270 kW

PC

ISEL

0

−50 −25 0 25 50 75

TA, AMBIENT TEMPERATURE (°C)

V

R

BAT

ISEL

= 3.7 V

= 270 kW

5.3 5.53.7 3.9 4.1

100 125

30

20

R

= 2.7 MW

ISEL

10

V

= 2.0 V

, TRICKLE CHARGE CURRENT (mA)

PC

I

BAT

0

4.5 5.0 5.5 6.0 6.

VCC, INPUT VOLTAGE (V)

400

350

R

ISEL

= 270 kW

V

300

250

200

150

100

R

, FULL CHARGE CURRENT (mA)

50

FCHG

I

0

ISEL

= 2.7 MW

4.5 5.0 5.5 6.0 6.

VCC, INPUT VOLTAGE (V)

BAT

= 3.7 V

Figure 10. Trickle Charge Current vs. Temperature Figure 11. Full Charge Current vs. Input Voltage

4.10

4.05

4.00

3.95

RECH

3.90

4.5 5.0 5.5 6.0 6.5

Figure 12. Recharge Voltage vs. Input Voltage

R

VCC, INPUT VOLTAGE (V)

= 270 kW

ISEL

http://onsemi.com

500

400

300

200

, CHARGE CURRENT (mA)

100

CHG

I

0

2.5 3.0 3.5 4.0 4.

Figure 13. Charge Current vs. Battery Voltage

6

VCC = 5 V

V

, BATTERY VOLTAGE (V)

BAT

Page 7

NCP1835B

DETAILED OPERATING DESCRIPTION

Overview

Rechargeable Li−Ion/Polymer batteries are normally

charged with a constant current (CC) until the terminal

voltage reaches a fixed voltage threshold, at which point a

constant voltage (CV) is applied and the current drawn by

the battery decays. The charging rate is determined by the

specific rating of the battery. For example, if the battery is

rated at 800 mA−hours, then the recommended maximum

charge rate is 800 mA. For a severely discharged cell, it

takes approximately 2.5−3.5 hours to recharge the battery

at the maximum rate. So, when one charges at less than the

maximum charge rate, the recharge time increases. Also,

the battery should not be continuously charged or the

battery could age faster than necessary. Because of this,

Li−Ion charging systems need to stop charging within a

prescribed time limit regardless of the charge rate.

The NCP1835B is a fully integrated, stand−alone 1−cell

Li−Ion charger which performs the primary battery

charging functions and includes a timer which will

terminate charging if the battery has not completed

charging within a prescribed time period. The charging rate

is user programmable up to 1.0 A and the end−of−charge

timer is also programmable. The NCP1835B has a thermal

foldback loop which reduces the charge rate if the junction

temperature is exceeded. The device also includes several

outputs which can be used to drive LED indicators or

interface to a microprocessor to provide status information.

The adapter providing power to the charger can be a

standard fixed output voltage such as a 5.0 V wall adapter

or it can be a simple current limited adapter.

The NCP1835B comes in two versions with output

voltage regulation thresholds of 4.2 or 4.242 V depending

on the requirements of the specific battery pack being used.

The user determines the charge current by selecting the

resistor R

and determines the length of the

ISEL

end−of−charge timeout timer by selecting the capacitor,

C

.

TIME

Charging Operation

Figure 13 outlines the charging algorithm of the

NCP1835B and Figure 14 graphically illustrates this.

When the charger is powered up and the input voltage rises

above the power−on, rising threshold (nominally 3.4 V),

the charger initiates the charging cycle.

The NCP1835B first determines the cell voltage. If it is

less than the pre−charge threshold (2.8 V), the IC

recognizes the battery as severely discharged. In this state,

the NCP1835B pre−conditions (trickle charges) the battery

by charging it at 10% of the full charge rate (IPC). This slow

charge prevents the battery from being damaged from high

fast charge currents when it is in a deeply discharged state.

The battery voltage should be trickle charged up to 2.8 V

before 1/8 of the preset end−of−charge time is expired. If

it cannot reach this voltage, than the battery is possibly

shorted or damaged. Therefore, the NCP1835B stops

charging and the pre−charge timeout signal asserts the

FAULT flag.

Once the cell voltage crosses the pre−charge threshold,

the device will transition to normal (full−rate) charging at

100% of the programmed full rate charge current (I

FCHG

As the NCP1835B charges the battery, the cell voltage rises

until it reaches the V

threshold, (4.2 or 4.242 V). At the

REG

maximum charge rate, it normally takes about 1 hour to

reach this point from a fully discharged state, and the

battery will be approximately 70−80% recharged. At this

point, the charge transitions to constant voltage mode

where the IC forces the battery to remain at a constant

voltage, V

current required to maintain V

. During this constant voltage state, the

REG

steadily decreases as the

REG

battery approaches full charge. Charge current eventually

falls to a very low value as the battery approaches a fully

charged condition.

The NCP1835B monitors the current into the battery

until it drops to 10% of the full charge rate. This is the

End−of−Charge (EOC) threshold. Normally it takes

1.5−2.5 hours to reach this point. Once the NCP1835B

reaches end−of−charge it opens the CFLG pin and enters

the EOC state. The IC continues to charge the battery until

it reaches TIMEOUT. At that point, the NCP1835B stops

charging. If the system does not reach EOC during the

TIMEOUT period, the NCP1835B views this as a system

fault and asserts the FAULT flag. If the battery voltage

drops below the recharge threshold (which can occur if the

battery is loaded), the IC reinitializes the charging

sequence and begins a new charge cycle. The recharge

voltage threshold, V

, is nominally 4.03 V.

RECH

In the inhibit state, the NCP1835B continues to monitor

the battery voltage, but does not charge the battery. Again,

if the battery voltage drops below the recharge threshold

the IC reinitializes the charging sequence and begins a new

charge cycle.

).

http://onsemi.com

7

Page 8

NCP1835B

Power Up

VCC > V

POR

Y

POR

Initialization

Reset Counter

Trickle

Charge

Charging Flow Chart

?

N

CC

Charge

CV

Charge

N

Trickle

Charge

Set FAULT Low

Latch Up Charger

V

> VPC?

SNS

N

1/8 TIMEOUT?

Y

EN Toggled?

V

≥ V

SNS

REG

?

Y

Ich < I

EOC

?

Y

Y

N

N

N

N

Constant

Current

Charge

TIMEOUT?

Y

Constant

Voltage

Charge

TIMEOUT?

Y

EOC Indication;

Set CFLG High

Keep FAULT High

Charger Inhibited

Reset Counter

Y

V

< V

SNS

N

TIMEOUT?

RECH

N

?

V

V

RECH

SNS

<

?

N

Y

Y

End−of−Charge

or F AULT

Y

N

Start Recharge

Inhibit

Figure 14. Charging Flow Chart

http://onsemi.com

8

Page 9

NCP1835B

V

BAT

I

charge

Trickle

ChargeCCChargeCVCharge

V

in

V

RISE

End of

Charge Recharging

Inhibit

Time

V

V

REG

REG

V

RECH

V

PC

V

REG

Time

I

CHG

I

CHG

I

PC

I

EOC

Time

CFLG

Time

FAULT

Time

V2P8

2.8 V

Time

0

Figure 15. Typical Charging Diagram

T able 1. Charge Status

Condition CFLG FAULT

Trickle, Constant Current and Constant V oltage Charge Low High

End−of−Charge or Shutdown Mode High High

Timeout Fault, V

< 0.35 V or V

ISEL

> 1.4 V High Low

ISEL

http://onsemi.com

9

Page 10

NCP1835B

Charge Status Indicator (CFLG)

CFLG is an open−drain output that indicates battery

charging or End−of−Charge (EOC) status. It is pulled low

when charging in constant current mode and constant

voltage mode. It will be forced to a high impedance state

when the charge current drops to I

. When the charger

EOC

is in shutdown mode, CFLG will also stay in the high

impedance state.

Fault Indicator (FAULT)

FAULT is an open−drain output that indicates that a

charge fault has occurred. It has two states: low or high

impedance. In a normal charge cycle, it stays in a high

impedance state. At fault conditions, it will be pulled low

and terminate the charge cycle. A timeout fault occurs

when the full charge or pre−charge timeouts are violated,

or if the voltage on ISEL is greater than 1.4 V or lower than

0.35 V. There are two ways to get the charger out of a fault

condition and back to a normal charge cycle. One can either

toggle the EN pin from GND to a floating state or reset the

input power supply.

Adapter Present Indicator (V2P8)

V2P8 is an input power supply presence indicator. When

the input voltage, VCC, is above the power on threshold

(V

, nominally 3.4 V) and is also 100 mV above the

RISE

battery voltage, it provides a 2.8 V reference voltage that

can source up to 2.0 mA. This voltage can also be used to

power a microprocessor I/O.

Enable/Disable (EN)

Pulling the EN pin to GND disables the NCP1835B. In

shutdown mode, the internal reference, oscillator, and

control circuits are all turned off. This reduces the battery

drain current to less than 3.0 mA and the input supply

current to 30 mA. Floating the EN pin enables the charger.

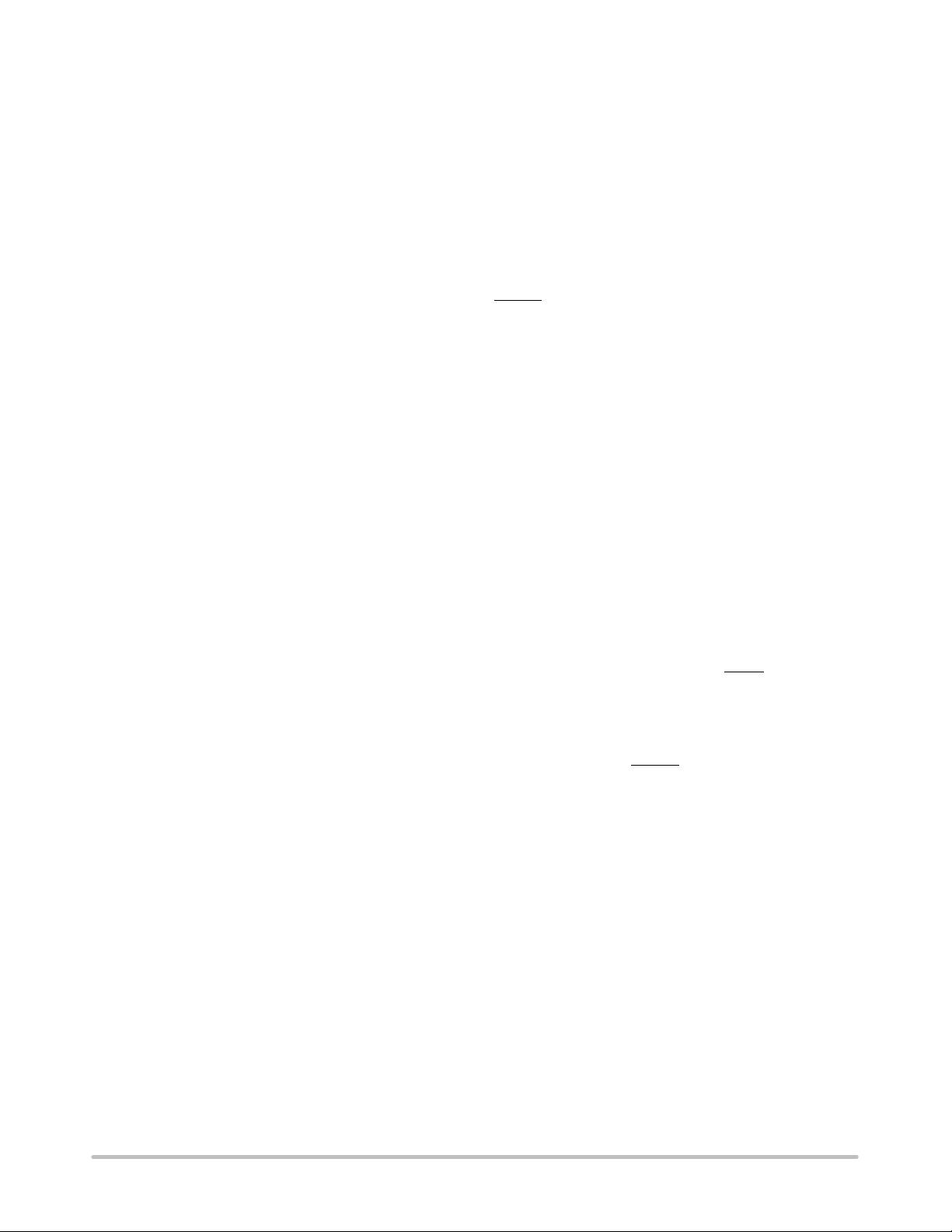

Thermal Foldback

An internal thermal foldback loop reduces the

programmed charge current proportionally if the die

temperature rises above the preset thermal limit (nominally

100°C). This feature provides the charger protection from

over heating or thermal damage. Figure 16 shows the full

charge current reduction due to die temperature increase

across the thermal foldback limit. For a charger with a

1.0 A constant charge current, the charge current starts

decreasing when the die temperature hits 100°C and is

reduced to zero when the die temperature rises to 110°C.

I

FCHG

X−100 mA/C

, CHARGE CURRENT

CHG

I

100°C

TJ, JUNCTION TEMPERATURE

Figure 16. Full Charge Current vs. Junction

Temperature

http://onsemi.com

10

Page 11

NCP1835B

0

70

I

(mA)

0

I

(mA)

600

APPLICATION INFORMATION

Input and Output Capacitor Selection

A 4.7 mF or higher value ceramic capacitor is

recommended for the input bypass capacitor. For the output

capacitor, when there is no battery inserted and the

NCP1835B is used as an LDO with 4.2 V or 4.242 V output

voltage, a 4.7 mF or higher value tantalum capacitor is

recommended for stability. With the battery attached, the

output capacitor can be any type with the value higher than

0.1 mF.

R

Resistor Selection for Programming Charge

ISEL

Current

A single resistor, R

between the ISEL pin and

ISEL,

ground, programs the pre−charge current, full−charge

current, and end−of−charge detection threshold. The

nominal voltage of ISEL is 0.8 V.

60

50

40

PC

30

20

10

C

Selection for Programming Charge Time

TIME

The NCP1835B offers an end−of−charge timeout timer

to prevent the battery from continuously charging which

can cause premature aging or safety issues. The timing

capacitor between TIMER pin and ground, C

TIME

, sets the

end−of−charge time, TIMEOUT, and the pre−charge

timeout. This capacitor is required for proper device

operation.

The internal oscillator charges C

to 1.2 V and then

TIME

discharges it to 0.6 V with 6 mA current in one period.

Therefore, the period of the oscillator is:

T

OSC

+ 2

TIME

c

I

C

+ 0.2 106 C

TIME

(sec)

(eq. 1)

C

dV

A 22−binary counter counts every oscillator period until

it reaches the maximum number corresponding to

end−of−charge time, TIMEOUT.

C

TIMEOUT + 222 T

OSC

+ 14

TIME

1nF

(minute)

(eq. 2)

The NCP1835B will terminate charging and give a

timeout signal if the battery has not completed charging

within the TIMEOUT period. The timeout signal then

forces the FAULT pin low.

The following Table 2 shows the desired TIMEOUT vs.

C

sizes. The C

TIME

is required for proper device

TIME

operation.

0

R

(kW)

ISEL

Figure 17. NCP1835 Pre−charge Current

500

400

300

FC

200

100

0

R

(kW)

ISEL

Figure 18. NCP1835 Full Charge Current

200

180016001400120010008006004002000

Table 2. TIMEOUT vs. C

C

(nF) TIMEOUT (minute)

TIME

0.47 6.6

1 14

5.6 78

8.2 115

10 140

15 210

33 462

56 784

TIME

Size

Thermal Considerations

The NCP1835B is housed in a thermally enhanced

3x3 mm DFN package. In order to deliver the maximum

power dissipation under all conditions, it is very important

that the user solders exposed metal pad under the package

160

1400120010008006004002000

to the ground copper area and then connect this area to a

ground plane through thermal vias. This can greatly reduce

the thermal impedance of the device and further enhance

its power dissipation capability and thus its output current

capability.

http://onsemi.com

11

Page 12

NCP1835B

I

Trickle

CV

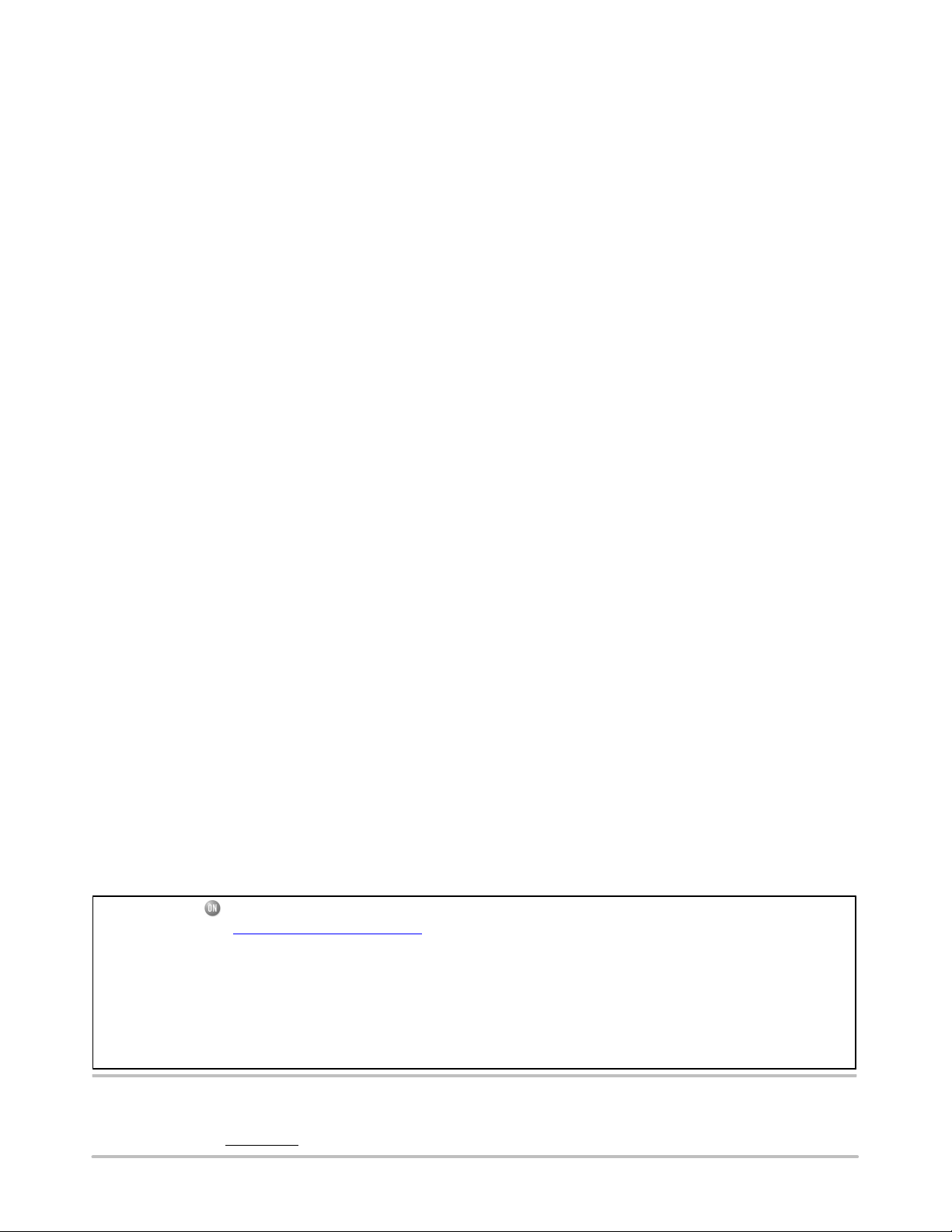

Charging with Constant Voltage Adapters or Current

Limited Adapters

The NCP1835B can be powered from two types of

regulated adapters: a traditional constant voltage type or a

current limited type. Figure 19 illustrates the operation of

the linear charger powered with a standard constant voltage

adapter. The power dissipation in the linear charger is:

P

+ (VCC* V

dis

BAT)

I

CHG

(eq. 3)

The maximum power dissipation P1 happens at the

beginning of a full current charge, since this is the point that

the power supply and the battery voltage have the largest

difference. As the battery voltage rises during charging, the

power dissipation drops. After entering the constant

voltage mode, the power dissipation drops further due to

the decreasing charge current. The maximum power that

the linear charger can dissipate is dependent on the thermal

resistance of the device. In case the device can not handle

the maximum power P1, the thermal foldback loop reduces

Trickle

ChargeCCCharge

V

in

V

BAT

charge

V

PC

I

FCHG

CV

Charge Inhibit

V

REG

Time

Time

the charge current which limits the power dissipation to the

sustained level P2. Figure 19 shows this.

Using the adapter’s current limit can provide better

thermal performance than the above example. A current

limited adapter operates as a constant voltage adapter

before the charge current reaches the current limit. I

must be less than the programmed full charge current

I

. Once the current limit is reached, the adapter will

FCHG

source the current limit I

while its output voltage will

LIM

drop to follow the battery voltage. If the application uses

the adapter to power its systems while the battery is being

charged, this drooping voltage can be an issue.

The worst case power dissipation with a current limited

adapter occurs at the beginning of the constant voltage

mode, which is shown at point P3 in Figure 20. If P3 is

higher than P2, the maximum power dissipation that the

charger can handle, then the thermal foldback function will

be activated.

V

I

charge

V

BAT

in

ChargeCCCharge

V

PC

I

FCHG

I

LIM

Charge

V

REG

Inhibit

Time

Time

LIM

I

I

PC

P

dis

P1

P2

0

Figure 19. Typical Charge Curves with a Constant

Voltage Adapter

PCB Layout Recommendations

The recommended footprint for the 3x3 mm DFN

Time

Time

PC

P

dis

P3

0

Figure 20. Typical Charge Curves with a Current

Limited Adapter

Time

Time

package is included on the Package Dimension page. It is

critical that the exposed metal pad is properly soldered to

the ground copper area and then connected to a ground

plane through thermal vias. The maximum recommended

thermal via diameter is 12 mils (0.305 mm). Limited by the

size of the pad, six thermal vias should allow for proper

thermal regulation without sacrificing too much copper

area within the pad. The copper pad is the primary heatsink

and should be connected to as much top layer metal as

GND

possible to minimize the thermal impedance. Figure 21

illustrates graphically the recommended connection for the

Figure 21. Recommended Footprint

exposed pad with vias.

http://onsemi.com

12

Page 13

NCP1835B

V

The following is a NCP1835B Demo Board Schematic and suggested Bill of Materials.

NCP1835B

V

CC

(T8)

GND

(T9)

C5

FAULT

(T5)

R4

D1

CFLG

(T6)

R5

D2

TIMER

(T10)

C4

VCC

FAULT

CFLG

TIMER V2P8

GND

VCC

BAT

VSNS

ISEL

EN

R3

V2P8

(T4)

D3

C3

2

JP2

1

R8

R2

R9

R1

C1

2

JP1

1

+

−

C2

Figure 22. Demo Board Schematic

Table 3. Bill of Materials

Item Qty. Part Description Designators Suppliers Part Number

1 1 NCP1835B Integrated Li−Ion Charger (DFN−10) U1 ON Semiconductor NCP1835B

2 1 Chip Resistor "1% 0 W (0603) R1 Vishay CRCW06030R00F

3 2 Chip Resistor "1% 2.67 MW (0603) R2 Vishay CRCW06032674

4 1 Chip Resistor "1% 100 kW (0603) R3 Vishay CRCW06031003F

5 2 Chip Resistor "1% 1.0 kW (0603) R4, R5 Vishay CRCW06031001F

6 1 Chip Resistor "1% 432 W (0603) R8 Vishay CRCW06034320F

7 1 Chip Resistor "1% 274 kW (0603) R9 Vishay CRCW06032743F

8 1 Chip Capacitor 1.0 mF/16 V, "20% (0805) C1 Panasonic ECJGVB1C105M

9 1 Chip Capacitor 4.7 mF/10 V, "20% (3528−21) C2 Kemet T491A475K016AS

10 1 Chip Capacitor 0.1 mF/10 V, "10% (0402) C3 Panasonic ECJ0EB1A104K

11 1 Chip Capacitor 15 nF/16 V, "10% (0402) C4 Panasonic ECJ0EB1C153K

12 1 Chip Capacitor 4.7 mF/25 V, "20% (0805) C5 Panasonic ECJ2FB1E475M

13 1 SMT Chip LED Red D1 Agilent HSMH−C150

14 1 SMT Chip LED Green D2 Agilent HSMG−C150

15 1 SMT Chip LED Yellow D4 Agilent HSMY−C150

16 5 Test Pin T1, T2, T7,

T8, T9, T10

17 2 Header Pin Pinch = 2.54 mm JP1, JP2 AMP/Tyco 4−103747−0

AMP/Tyco 4−103747−0

BAT

(T1)

VSNS

(T7)

Li−Ion

Battery

GND

(T2)

http://onsemi.com

13

Page 14

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 2:1

DFN10, 3x3, 0.5P

CASE 485C

ISSUE E

DATE 11 FEB 2016

2X

2X

10X

PIN ONE

REFERENCE

0.15 C

0.15

0.10 C

0.08 C

DETAIL A

K

PACKAGE

OUTLINE

D

A

B

E

C

TOP VIEW

D2

(A3)

A1

10X

DETAIL B

SIDE VIEW

15

E2

10 6

e

10X

b

BOTTOM VIEW

SOLDERING FOOTPRINT*

2.64

L1

ALTERNATE TERMINAL

A1

A

SEATING

C

PLANE

L

0.10 C

A B

0.05

C

NOTE 3

10X

0.55

L

ALTERNATE A−2ALTERNATE A−1

DETAIL A

CONSTRUCTIONS

CONSTRUCTIONS

A1

WETTABLE FLANK OPTION

CONSTRUCTION

A3

DETAIL B

ALTERNATE

DETAIL B

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

L

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL AND IS

MEASURED BETWEEN 0.25 AND 0.30 MM FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED PAD AS WELL AS

THE TERMINALS.

5. TERMINAL b MAY HAVE MOLD COMPOUND MATERIAL ALONG

SIDE EDGE. MOLD FLASHING MAY NOT EXCEED 30 MICRONS

ONTO BOTTOM SURFACE OF TERMINAL b.

6. FOR DEVICE OPN CONTAINING W OPTION, DETAIL A AND B

ALTERNATE CONSTRUCTION ARE NOT APPLICABLE. WETTABLE FLANK CONSTRUCTION IS DETAIL B AS SHOWN ON

SIDE VIEW OF PACKAGE.

MOLD CMPDEXPOSED Cu

ALTERNATE B−2ALTERNATE B−1

A3

MILLIMETERS

DIM MIN MAX

A 0.80 1.00

A1 0.00 0.05

A3 0.20 REF

b 0.18 0.30

D 3.00 BSC

D2 2.40 2.60

E 3.00 BSC

E2 1.70 1.90

e 0.50 BSC

K 0.19 TYP

L 0.35 0.45

L1 0.00 0.03

GENERIC

MARKING DIAGRAM*

XXXXX

XXXXX

ALYWG

G

XXXXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

1.90

0.50

PITCH

DIMENSIONS: MILLIMETERS

10X

0.30

3.30

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON03161D

DFN10, 3X3 MM, 0.5 MM PITCH

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 15

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor ’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...