Page 1

High-Voltage Switcher for

Low Power Offline SMPS

NCP1060, NCP1063

The NCP106X products integrate a fixed frequency current mode

controller with a 700 V MOSFET. Available in a PDIP−7, SOIC−10 or

SOIC−16 package, the NCP106X offer a high level of integration,

including soft−start, frequency−jittering, short−circuit protection,

skip−cycle, adjustable peak current set point, ramp compensation, and a

Dynamic Self−Supply (eliminating the need for an auxiliary winding).

Unlike other monolithic solutions, the NCP106X is quiet by nature:

during nominal load operation, the part switches at one of the available

frequencies (60 kHz or 100 kHz). When the output power demand

diminishes, the IC automatically enters frequency foldback mode and

provides excellent efficiency at light loads. When the power demand

reduces further, it enters into a skip mode to reduce the standby

consumption down to a no load condition.

Protection features include: a timer to detect an overload or a

short−circuit event, Overvoltage Protection with auto−recovery and

AC input line voltage detection (A version).

The ON proprietary integrated Over Power Protection (OPP) lets

you harness the maximum delivered power without affecting your

standby performance simply via external resistors.

For improved standby performance, the connection of an auxiliary

winding stops the DSS operation and helps to reduce input power

consumption below 50 mW at high line.

NCP106x can be seamlessly used both in non−isolated and in

isolated topologies.

16

www.onsemi.com

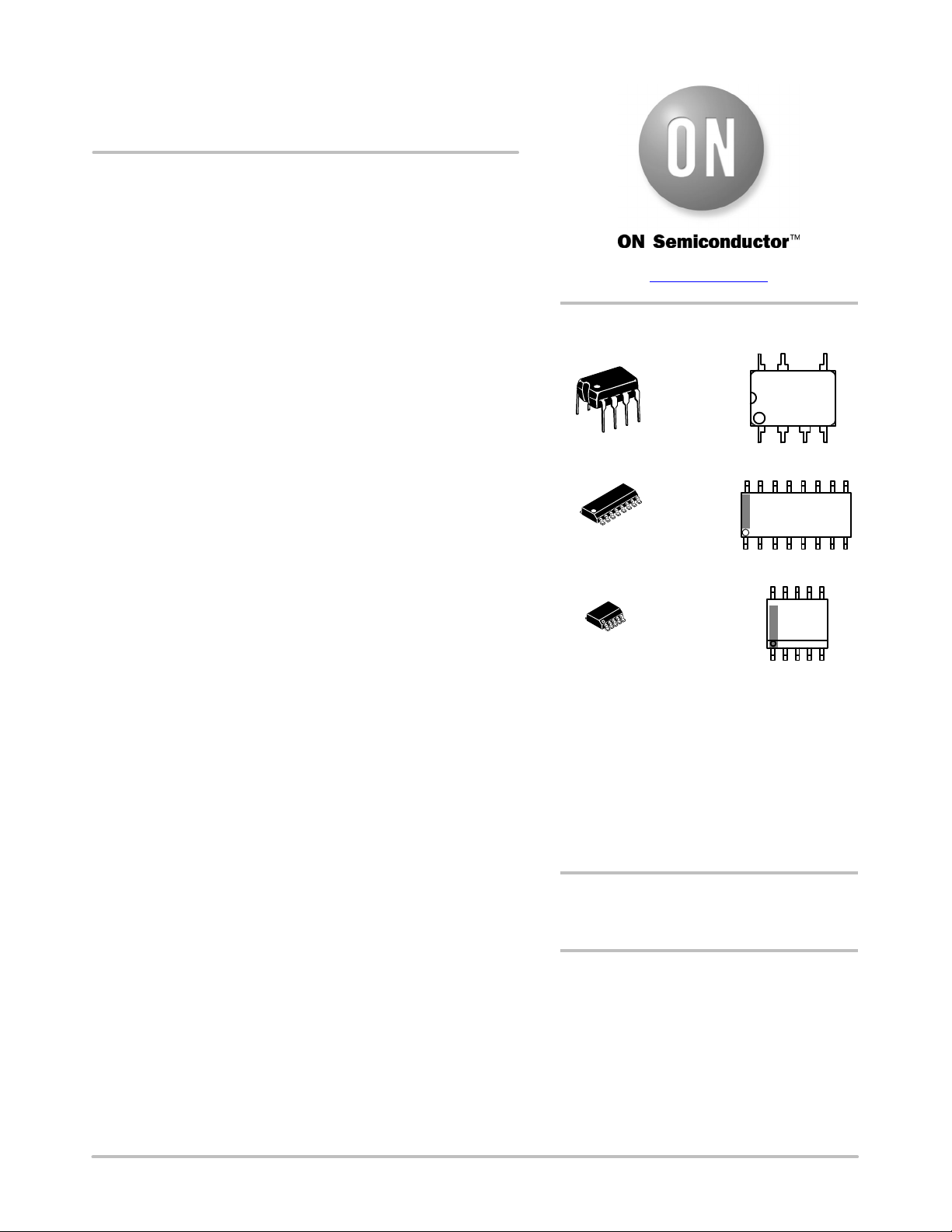

MARKING DIAGRAMS

7

PDIP−7

8

1

1

10

1

CASE 626A

AP SUFFIX

SOIC−16

CASE 751B−05

D SUFFIX

SOIC−10

CASE 751BQ

AD or BD SUFFIX

1

16

NCP1063fyyyG

1

10

1

P106xfyyy

AWL

YYWWG

AWLYWW

1060fyyy

ALYWX

G

Features

• Built−in 700 V MOSFET with R

of 34 W (NCP1060) and

DS(on)

11.4 W (NCP1063)

• Large Creepage Distance Between High−voltage Pins

• Current−Mode Fixed Frequency Operation – 60 kHz or 100 kHz

(130 kHz on demand)

• Adjustable Peak Current: see below table

• Fixed Ramp Compensation

• Direct Feedback Connection for Non−isolated Converter

• Internal and Adjustable Over Power Protection (OPP) Circuit

• Skip−Cycle Operation at Low Peak Currents Only

• Dynamic Self−Supply: No Need for an Auxiliary Winding

• Internal 4 ms Soft−Start

• Auto−Recovery Output Short Circuit Protection with Timer−Based

Detection

• Auto−Recovery Overvoltage Protection with Auxiliary Winding

Operation

• Frequency Jittering for Better EMI Signature

• No Load Input Consumption < 50 mW

• Frequency Foldback to Improve Efficiency at Light Load

• These Devices are Pb−Free and are RoHS Compliant

x = Power Switch Circuit

On−state Resistance

(0 = 34 W, 3 = 11.4 W)

f = Brown In (A = Yes, B = No)

yyy = Oscillator Frequency

(060 = 60 kHz, 100 = 100 kHz)

A = Assembly Location

L, WL = Wafer Lot

Y, YY = Year

W, WW = Work Week

G or G = Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information on page 28 of

this data sheet.

Typical Applications

• Auxiliary / Standby Isolated and

Non−isolated Power Supplies

• Power Meter SMPS

• Wide Vin Low Power Industrial SMPS

© Semiconductor Components Industries, LLC, 2014

March, 2021 − Rev. 10

1 Publication Order Number:

NCP1060/D

Page 2

NCP1060, NCP1063

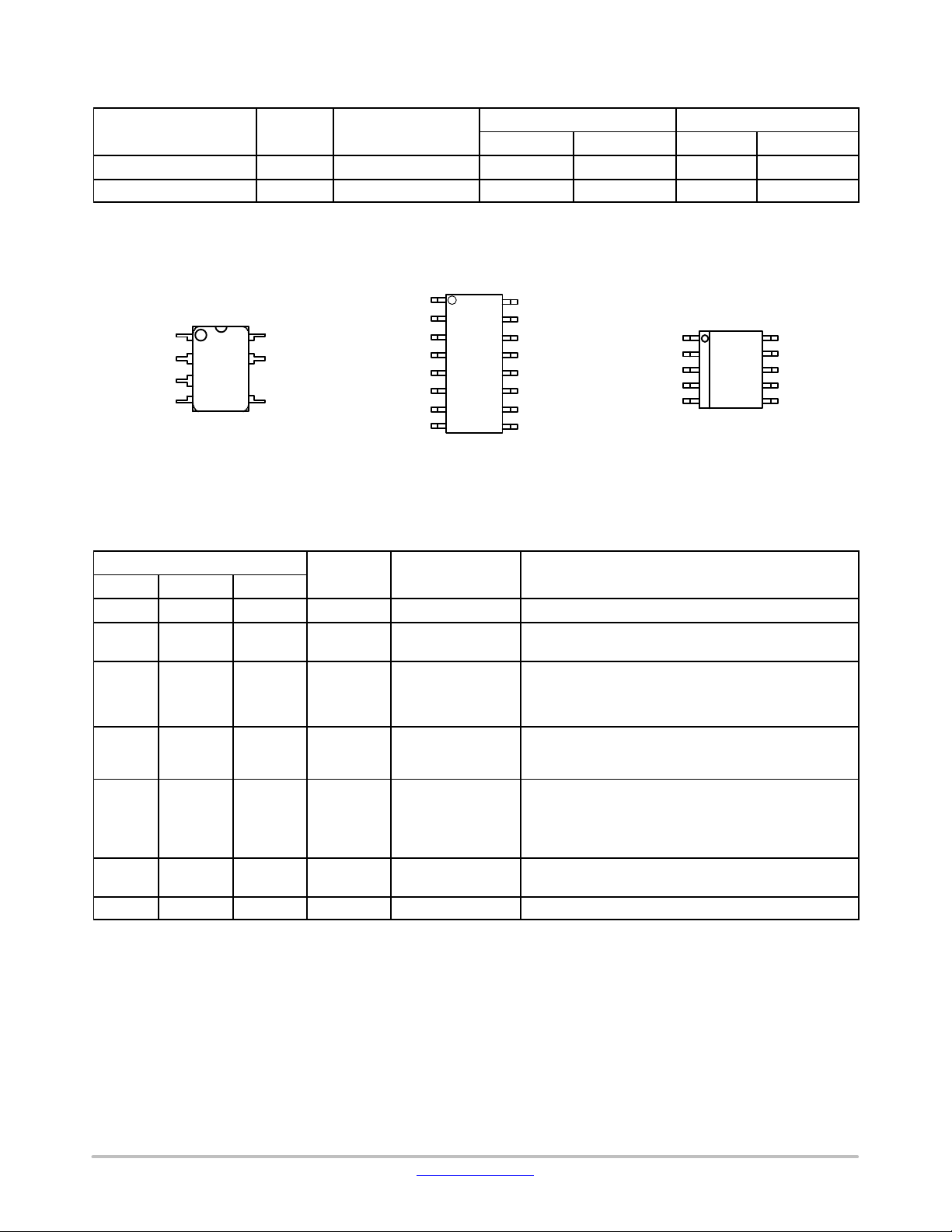

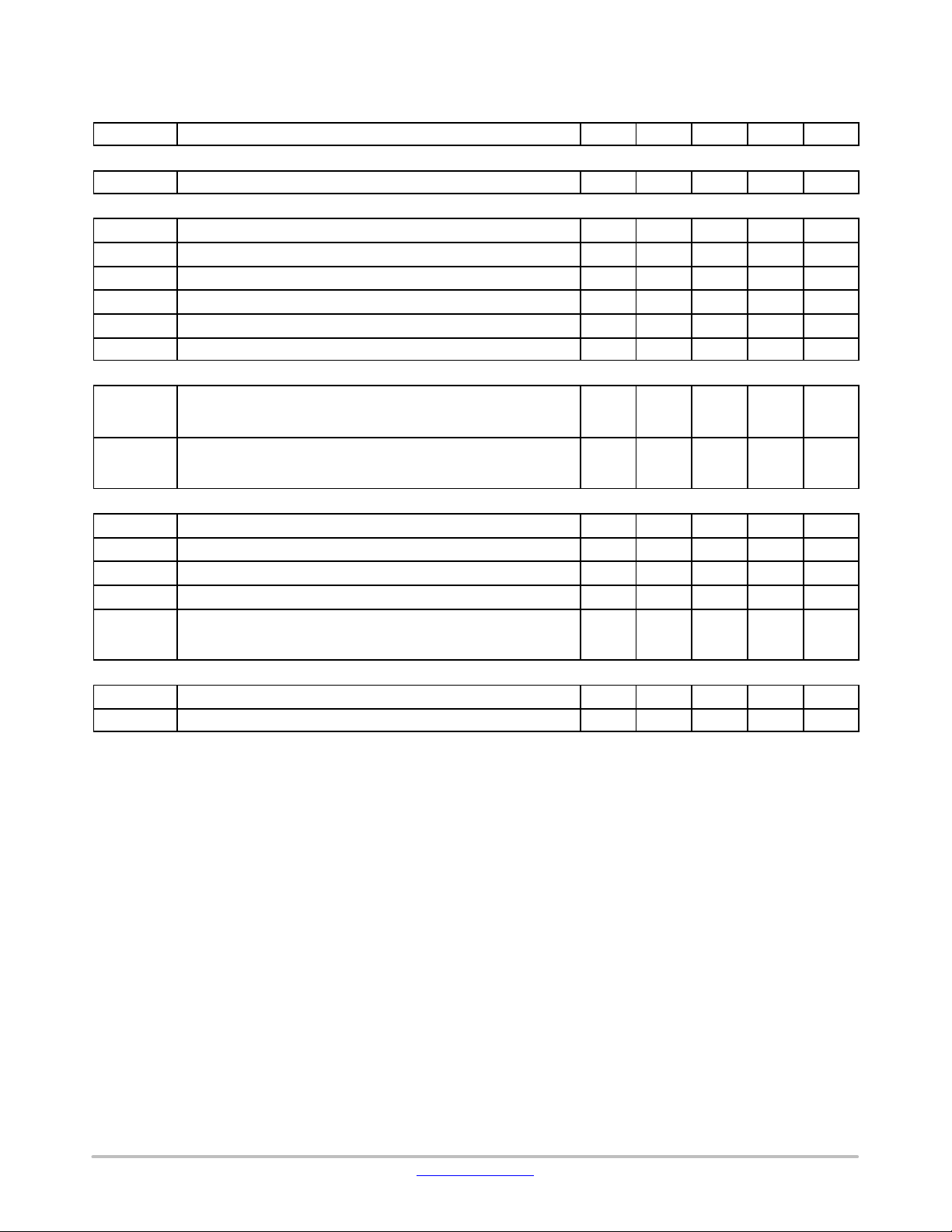

Table 1. PRODUCT INFORMATION & INDICATIVE MAXIMUM OUTPUT POWER

230 Vac + 15% 85 − 265 Vac

Product R

NCP1060 60 kHz

NCP1063 100 kHz

DS(on)

34 W

11.4 W

NOTE: Informative values only, with T

on minimum copper area as recommended.

= 25°C, T

amb

I

IPK(0)

300 mA 3.3 W 8.3 W 1.9 W 4.7 W

780 mA 6.2 W 15.5 W 3.3 W 7.8 W

= 100°C, PDIP−7 package, Self supply via Auxiliary winding and circuit mounted

case

Adapter Open Frame Adapter Open Frame

GND

VCC

LIM/OPP

FB

PDIP−7

DRAIN

DRAIN

COMP

GND

GND

GND

GND

VCC

LIM/OPP

FB

COMP

SOIC−16

DRAIN

DRAIN

DRAIN

DRAIN

N.C.

N.C.

N.C.

N.C.

GND

VCC

LIM/OPP

FB

COMP

SOIC−10

Figure 1. Pin Connections

Table 2. PIN FUNCTION DESCRIPTION

Pin No

PDIP 7 SOIC 10 SOIC 16

1 1 1−4 GND The IC Ground

2 2 5 V

3 3 6 LIM/OPP Ipeak set / Over

4 4 7 FB Feedback signal

5 5 8 Comp Compensation The error amplifier output is available on this pin. The

6 9−12 This un−connected pin ensures adequate creepage dis-

7,8 6−10 13−16 Drain Drain connection The internal drain MOSFET connection

Pin Name Function Pin Description

CC

Powers the internal

circuitry

This pin is connected to an external capacitor. The V

includes an auto−recovery over voltage protection.

The current drown from the pin decreases Ipeak of the

power limitation

primary winding. If resistive divider from the auxiliary

winding is connected to this pin it sets the OPP compensation level (it diminishes the peak current.)

This is the inverting input of the trans conductance error

input

amplifier. It is normally connected to the switching power

supply output through a resistor divider.

network connected between this pin and ground adjusts

the regulation loop bandwidth. Also, by connecting an

opto−coupler to this pin, the peak current set point is

adjusted accordingly to the output power demand.

tance

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DD

www.onsemi.com

2

Page 3

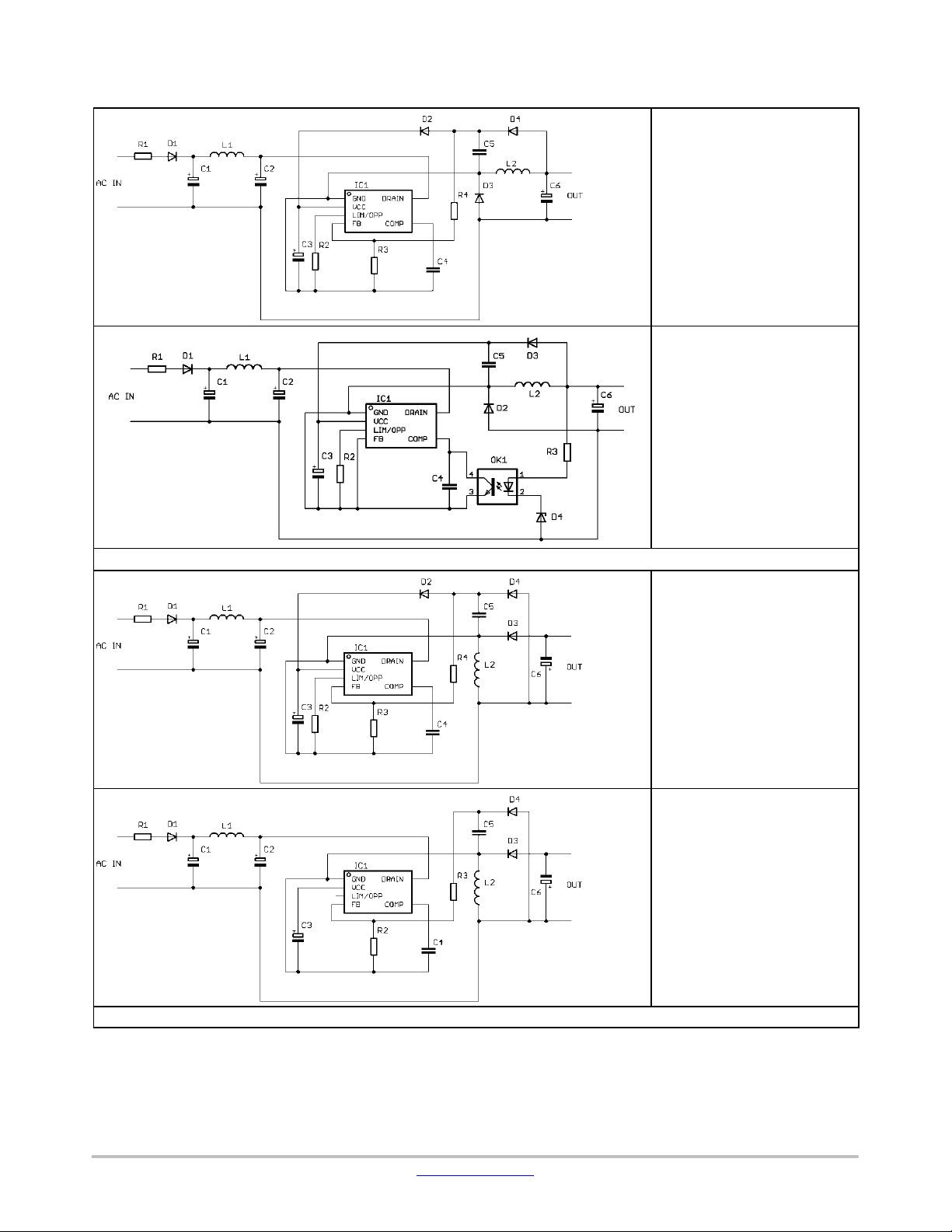

Table 3. TYPICAL APPLICATIONS

NCP1060, NCP1063

• If the output voltage is above

9.0 V typ. (between Vcc(on)

level and Vovp level) Vcc is

supplied from output via D2

• If the output voltage is

below 9.0 V, D2 is redundant,

the IC is supplied from DSS

• R2 limits maximum output

power (can be omitted if not

required)

• Direct feedback, resistive

divider formed by R3, R4 sets

output voltage

• If the output voltage is above

9.0 V typ. (between Vcc(on)

level and Vovp level) Vcc is

supplied from output via D3

• If the output voltage is below

9.0 V, D3 and C5 are

redundant, the IC is supplied

from DSS

• R2 limits maximum output

power (can be omitted if not

required)

• Optocoupler feedback

Typical Non−isolated Application – Buck Converter

• If the output voltage is above

9.0 V typ. between V

level and V

supplied from output via D2

• R2 limits maximal output

power

• Direct feedback, resistive

divider formed by R3, R4 sets

output voltage

• VCC supplied from DSS

• Output voltage is below 9.0 V

typ.

• LIM/OPP pin floating − no limit

output power

• Direct feedback, resistive

divider formed by R2, R3 sets

output voltage

OVP

CC(ON)

level − VCC

Typical Non−isolated Application – Buck−Boost Converter

www.onsemi.com

3

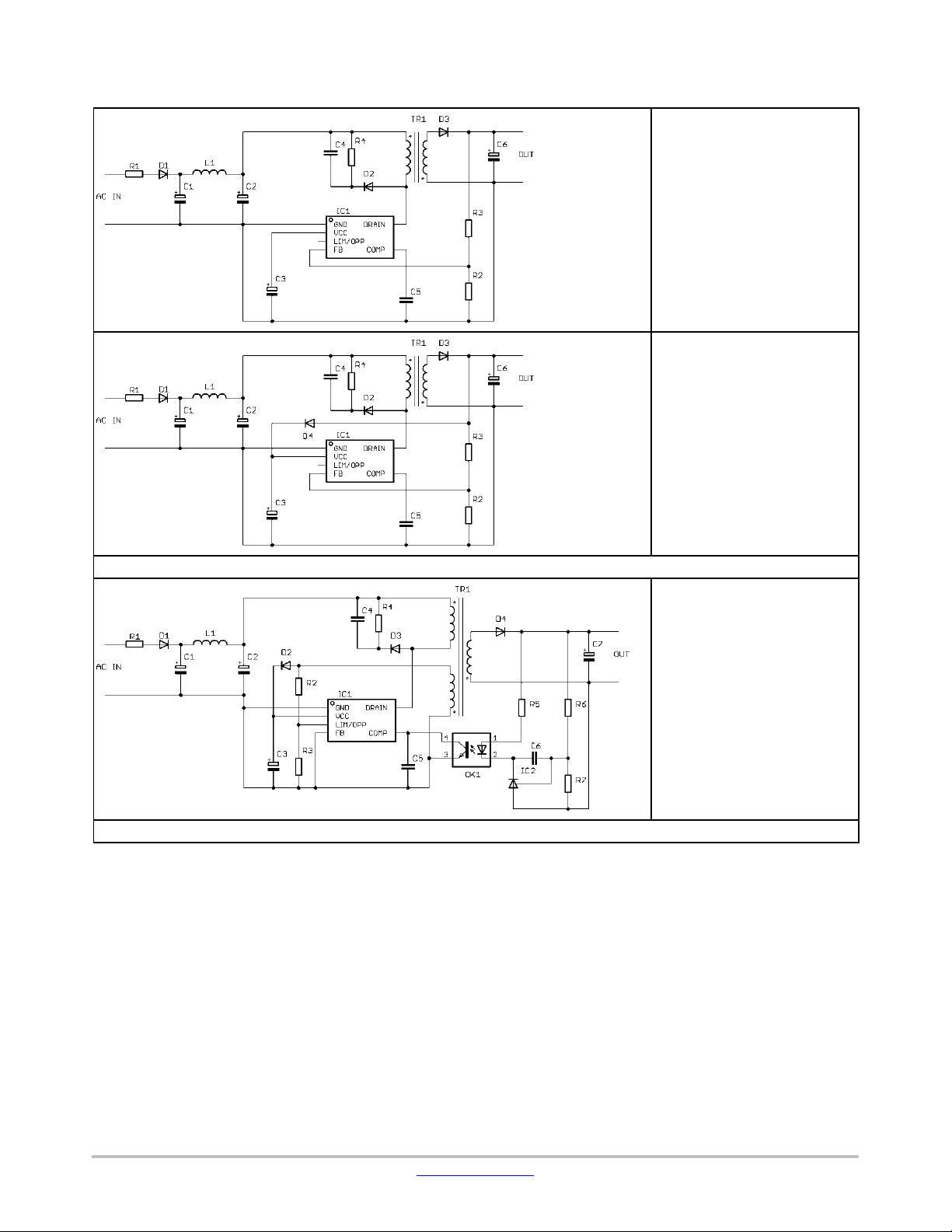

Page 4

Table 3. TYPICAL APPLICATIONS (continued)

NCP1060, NCP1063

• VCC supplied from DSS

• Output voltage is below 9.0 V

typ.

• LIM/OPP pin floating − no limit

output power

• Resistive divider formed by R2,

R3 sets output voltage

• If the output voltage is above

9.0 V typ. between V

level and V

supplied from output via D4

• LIM/OPP pin floating − no limit

output power

• Resistive divider formed by R2,

R3 sets output voltage

OVP

CC(ON)

level − VCC

Typical Non−isolated Application – Flyback Converter

Typical Isolated Application – Flyback Converter

• VCC supplied from auxiliary

winding

• Resistive divider formed by R2,

R3 sets output power limit and

over power protection

• Optocoupler feedback,

resistive divider formed by R6,

R7 sets output voltage

www.onsemi.com

4

Page 5

NCP1060, NCP1063

VCC

R

COMP(up)

V

COMP(REF )

DRAIN

ms Filter

80−

V

OVP

I

pflag

VCC OVP

SCP

t

SCP

S

Q

R

t

recovery

Jittering

OSC

LineOK

Sawtooth

OFF

TSD

S

Foldback

Q

VCC

Management

LineOK

UVLO

Sawtooth

R

I

COMPskip

SKIP

Ramp

SKIP = ”1”èShut down some

blocks to reduce consumption

compensation

UVLO

Reset

V

dd

OFF UVLO

Line

Detection

V

CC

LEB

GND

COMP

FB

I

FB

FB/COMP

Processing

I

I

COMPfault

I

to CS setpoint

COMP

I

LMOP (min)ILMOP (max )

0

I

LMDEC

I

LMDEC

pflag

I

FreezeIpk(0)

I

LMOP

I

PKL

I

LMOP

V

LMOP

LIM/OPP

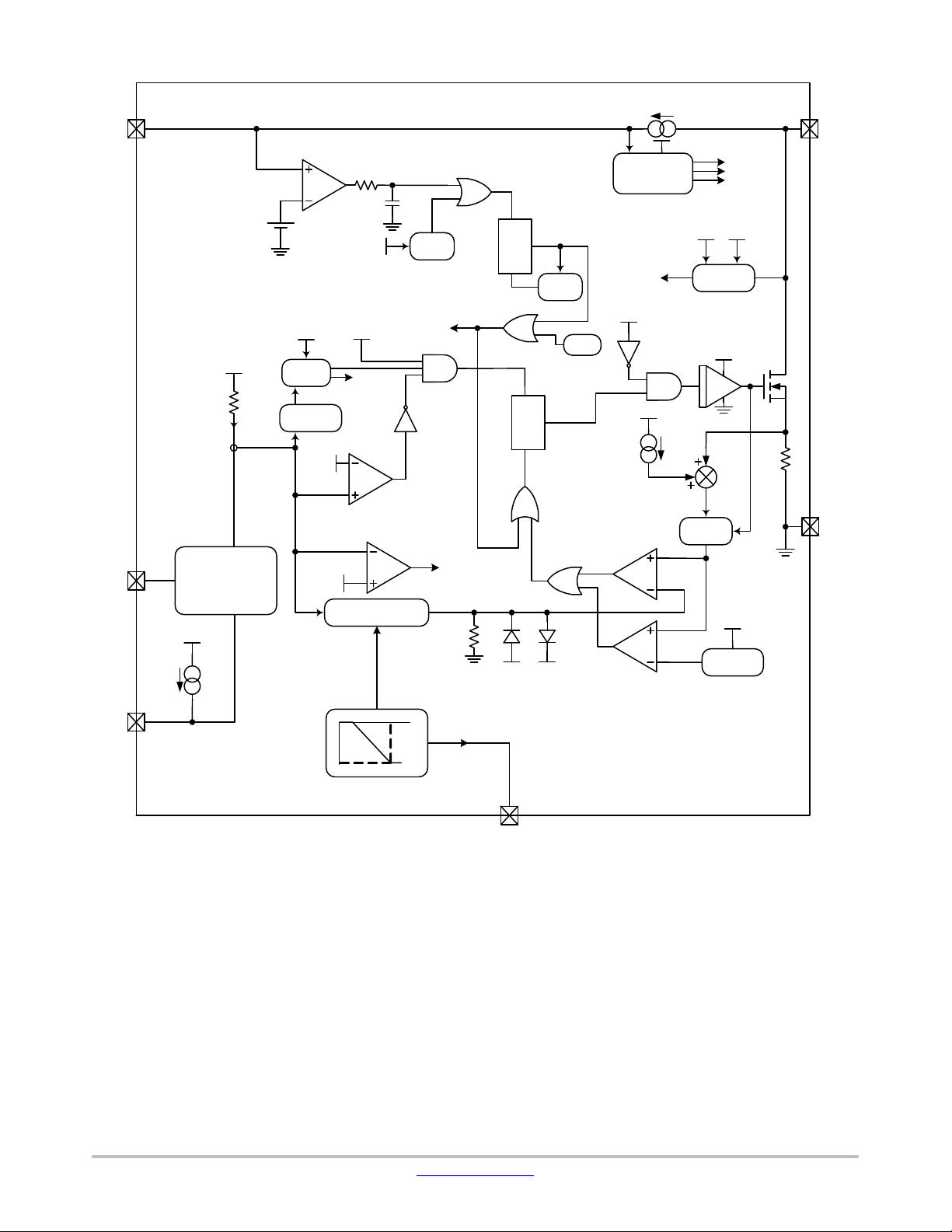

Figure 2. Simplified Internal Circuit Architecture

Reset

Soft−Start

Reset SS as recoving from

SCP, TSD, VCC OVP or UVLO

www.onsemi.com

5

Page 6

NCP1060, NCP1063

Table 4. MAXIMUM RATING TABLE (All voltages related to GND terminal)

Rating

Power supply voltage, V

pin, continuous voltage V

CC

Voltage on all pins, except Drain and VCC pin Vinmax −0.3 to 10 V

Drain voltage BVdss −0.3 to 700 V

Maximum Current into VCC pin I

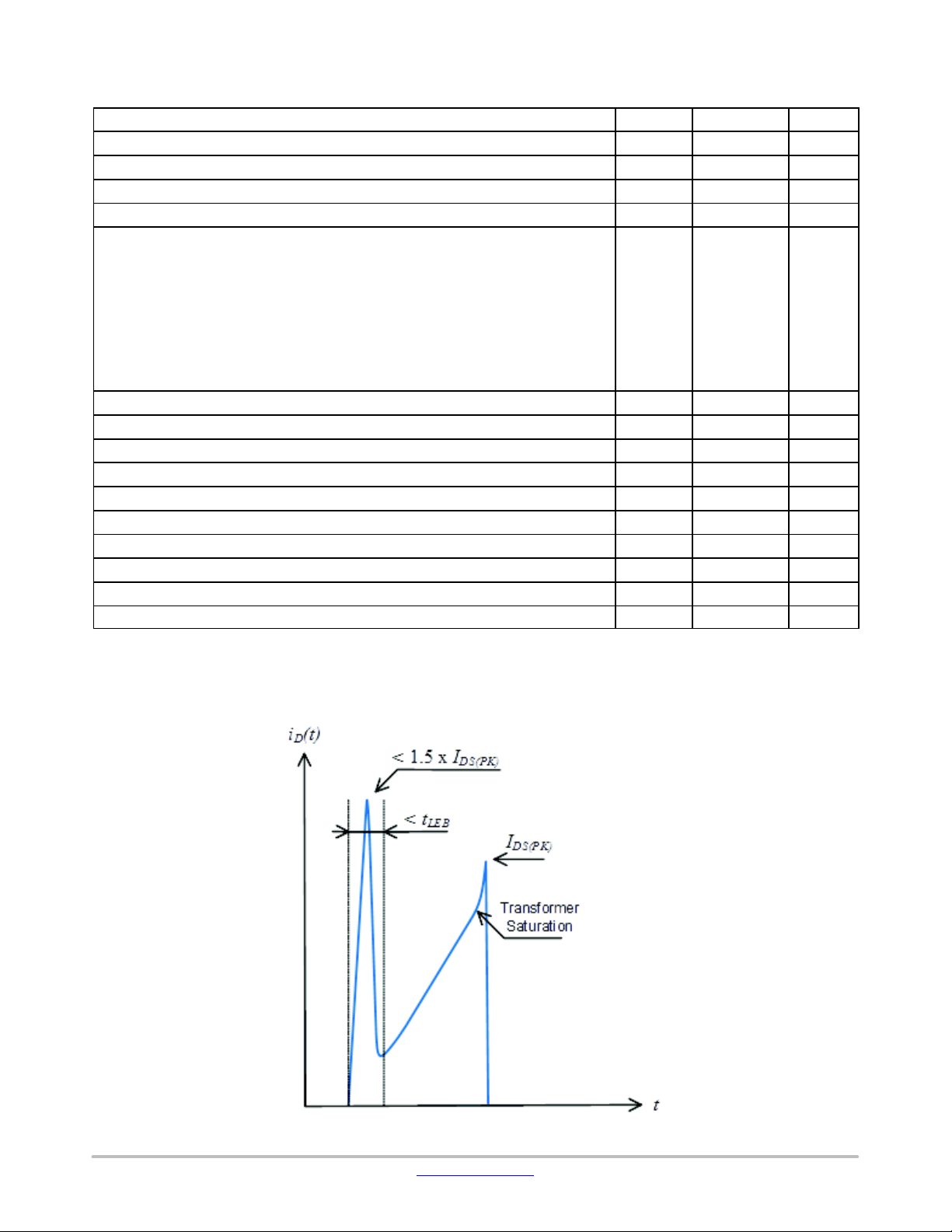

Drain Current Peak during Transformer Saturation (TJ = 150°C, Note 2):

NCP1060

NCP1063

Drain Current Peak during Transformer Saturation (T

= 125°C, Note 2):

J

NCP1060

NCP1063

Drain Current Peak during Transformer Saturation (T

= 25°C, Note 2):

J

NCP1060

NCP1063

Thermal Resistance, Junction−to−Air – PDIP7 with 200 mm@ of 35−m copper area

Thermal Resistance, Junction−to−Air – SOIC10 with 200 mm@ of 35−m copper area

Thermal Resistance, Junction−to−Air – SOIC16 with 200 mm@ of 35−m copper area

Junction−to−Top Thermal Characterization Parameter – PDIP7

Junction−to−Top Thermal Characterization Parameter – SOIC10

Junction−to−Top Thermal Characterization Parameter – SOIC16

Junction Temperature Range T

Storage Temperature Range T

Human Body Model ESD Capability (All pins except HV pin) per JEDEC JESD22−A114F HBM 2 kV

Charged−Device Model ESD Capability per JEDEC JESD22−C101E CDM 1 kV

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. This device contains latch−up protection and exceeds 100 mA per JEDEC Standard JESD78.

2. Maximum drain current I

on. Figure 3 below provides spike limits the device can tolerate.

is obtained when the transformer saturates. It should not be mixed with short pulses that can be seen at turn

DS(PK)

Symbol Value Unit

CC

CC

I

DS(PK)

−0.3 to 20 V

10 mA

mA

300

850

335

950

520

1500

R

θ

JA

R

θ

JA

R

θ

JA

Y

JT

Y

JT

Y

JT

J

stg

115 °C/W

132 °C/W

104 °C/W

7.3 °C/W

2.3 °C/W

2.5 °C/W

−40 to +150 °C

−60 to +150 °C

Figure 3. Spike Limits

www.onsemi.com

6

Page 7

NCP1060, NCP1063

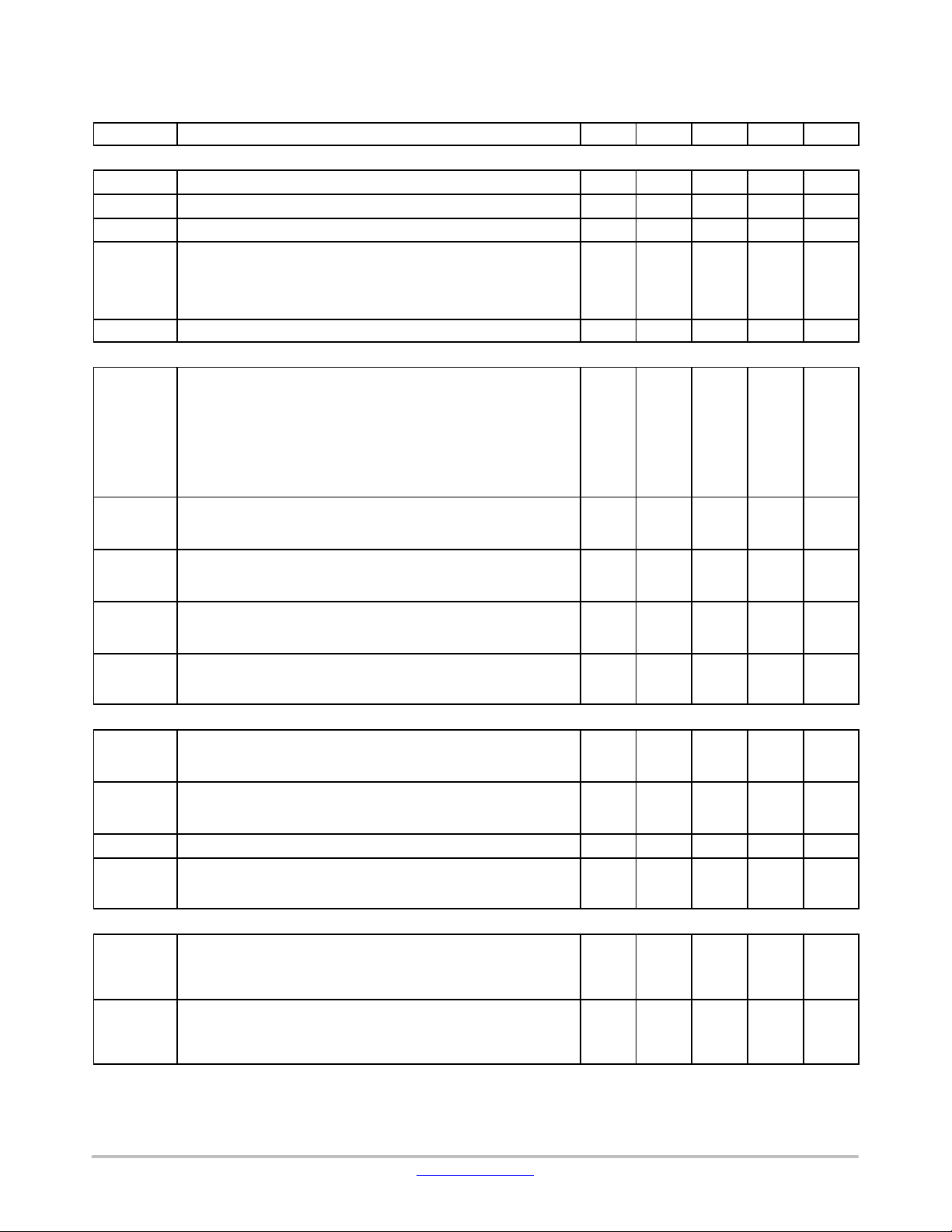

Table 5. ELECTRICAL CHARACTERISTICS

(For typical values T

Symbol

SUPPLY SECTION AND VCC MANAGEMENT

V

CC(on)

V

CC(min)

V

CC(off)

I

CC1

I

CCskip

POWER SWITCH CIRCUIT

R

DS(on)

BV

DSS

I

DSS(off)

t

r

t

f

t

on(min)

INTERNAL START−UP CURRENT SOURCE

I

start1

I

start2

V

CCTH

V

start(min)

CURRENT COMPARATOR

I

IPK

I

IPK(0)

3. The final switch current is: I

the primary inductor in a flyback, and t

L

P

4. Oscillator frequency is measured with disabled jittering.

= 25°C, for min/max values TJ = −40°C to +125°C, VCC = 14 V unless otherwise noted)

J

Rating Pin Min Typ Max Unit

VCC increasing level at which the switcher starts operation 2 (5) 8.4 9.0 9.5 V

VCC decreasing level at which the HV current source restarts 2 (5) 7.0 7.5 7.8 V

VCC decreasing level at which the switcher stops operation (UVLO) 2 (5) 6.7 7.0 7.2 V

Internal IC consumption, NCP1060 switching at 60 kHz, LIM/OPP = 0 A

Internal IC consumption, NCP1060 switching at 100 kHz, LIM/OPP = 0 A

Internal IC consumption, NCP1063 switching at 60 kHz, LIM/OPP = 0 A

Internal IC consumption, NCP1063 switching at 100 kHz, LIM/OPP = 0 A

Internal IC consumption, COMP is 0 V (No switching on MOSFET) 2 (5) − 340 −

Power Switch Circuit on−state resistance

NCP1060 (Id = 50 mA)

Tj = 25°C

Tj = 125°C

NCP1063 (Id = 50 mA)

Tj = 25°C

Tj = 125°C

Power Switch Circuit & Startup breakdown voltage

= 120 mA, Tj = 25°C)

(ID

(off)

Power Switch & Startup breakdown voltage off−state leakage current

Tj = 125°C (Vds = 700 V)

Switching characteristics (RL = 50 W, VDS set for I

Turn−on time (90% − 10%)

Turn−off time (10% − 90%)

Minimum on time

NCP1060

NCP1063

High−voltage current source, VCC = V

CC(on)

High−voltage current source, VCC = 0 V 7, 8

VCC Transient level for I

start1

to I

toggling point 2 (5) − 1.4 − V

start2

Minimum startup voltage, VCC = 0 V 7, 8

Maximum internal current setpoint at 50% duty cycle

FB = 2 V, LIM/OPP = 0 mA, Tj = 25°C

NCP1060

NCP1063

Maximum internal current setpoint at beginning of switching cycle

FB = 2 V, LIM/OPP pin open Tj = 25°C

NCP1060

NCP1063

/ (Vin/LP + Sa) x Vin/LP + Vin/L

IPK(0)

the propagation delay.

prop

2 (5) −

7, 8

(6−10)

(13−16)

7, 8

(6−10)

(13−16)

7, 8

(6−10)

(13−16)

= 0.7 x Ilim)

drain

7, 8

(6−10)

(13−16)

7, 8

(6−10)

(13−16)

– 200 mV 7, 8

(6−10)

(13−16)

(6−10)

(13−16)

(6−10)

(13−16)

−

−

−

−

x t

, with Sa the built−in slope compensation, Vin the input voltage,

P

prop

0.92

−

−

−

−

−

−

−

0.97

0.99

1.07

34

65

11.4

22

−

−

−

−

41

72

14.0

24

mA

700 − − V

− 84 −

−

−

−

−

20

10

200

230

−

−

−

−

5 8 12 mA

− 0.5 − mA

21 V

mA

−

−

250

650

−

−

mA

268

702

300

780

332

858

mA

W

mA

ns

ns

www.onsemi.com

7

Page 8

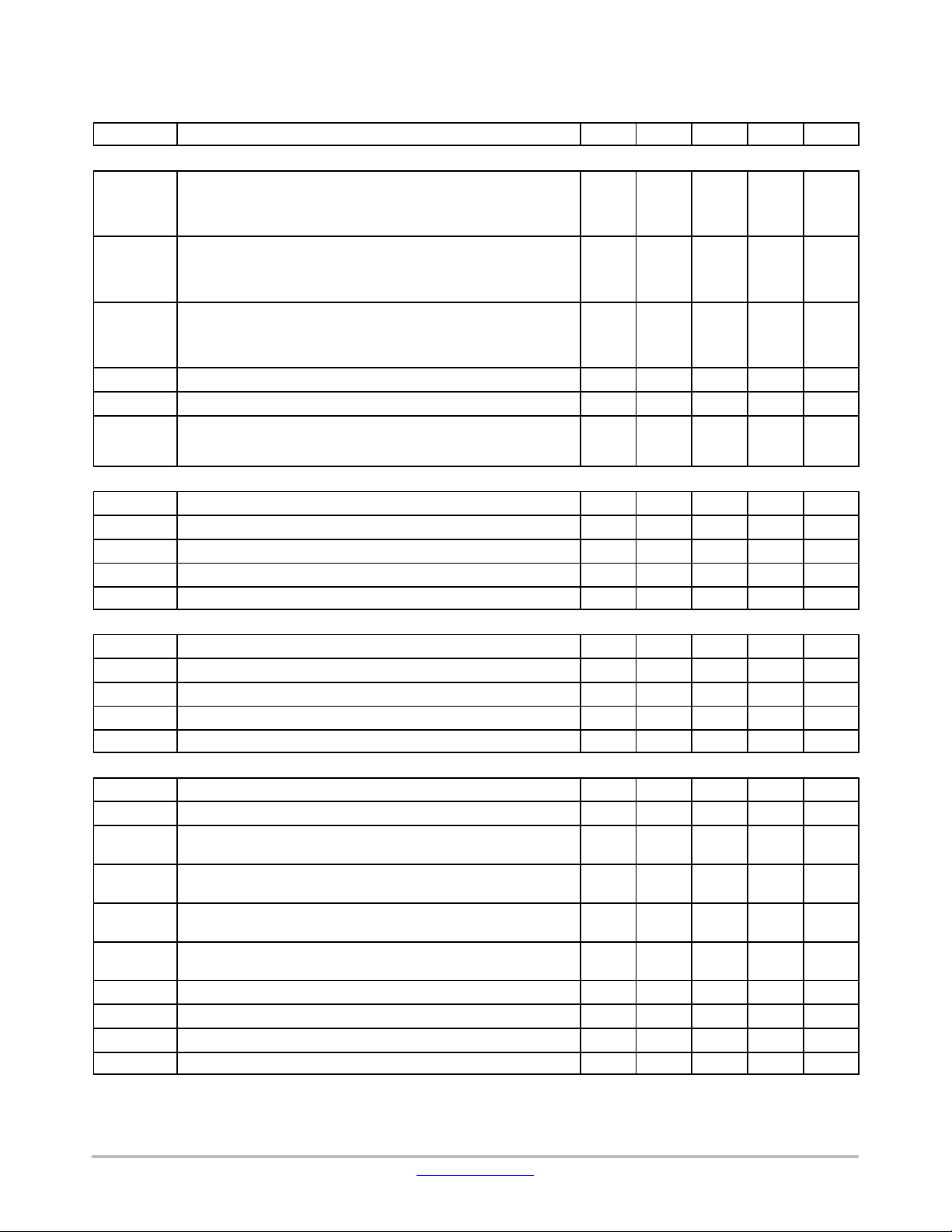

NCP1060, NCP1063

Table 5. ELECTRICAL CHARACTERISTICS (continued)

(For typical values T

Symbol UnitMaxTypMinPinRating

CURRENT COMPARATOR

I

IPKSW

I

IPKSW

I

LMDEC

t

SS

t

prop

t

LEB

INTERNAL OSCILLATOR

f

OSC

f

OSC

f

jitter

f

swing

D

max

ERROR AMPLIFIER SECTION

V

REF

I

FB

G

M

I

OTAlim

V

OTAen

COMPENSATION SECTION

I

COMPfault

I

COMP100%

I

COMPfreeze

V

COMP(REF)

R

COMP(up)

V

LMOP

I

LMOP

I

LMOP(min)

I

LMOP(max)

I

LMOP(neg)

3. The final switch current is: I

LP the primary inductor in a flyback, and t

4. Oscillator frequency is measured with disabled jittering.

= 25°C, for min/max values TJ = −40°C to +125°C, VCC = 14 V unless otherwise noted)

J

Final switch current with a primary slope of 200 mA/ms,

F

= 60 kHz (Note 3), LIM/OPP pin open

SW

NCP1060

NCP1063

Final switch current with a primary slope of 200 mA/ms,

F

= 100 kHz (Note 3), LIM/OPP pin open

SW

NCP1060

NCP1063

Maximum internal current setpoint at beginning of switching cycle

FB = 2 V, LIM/OPP = −285 mA, Tj = 25°C

NCP1060

NCP1063

Soft−start duration (guaranteed by design) − − 4 − ms

Propagation delay from current detection to drain OFF state − − 70 − ns

Leading Edge Blanking Duration

NCP1060

NCP1063

Oscillation frequency, 60 kHz version, Tj = 25°C (Note 4) − 54 60 66 kHz

Oscillation frequency, 100 kHz version, Tj = 25°C (Note 4) − 90 100 110 kHz

Frequency jittering in percentage of f

OSC

Jittering swing frequency − − 300 − Hz

Maximum duty−cycle − 62 66 72 %

Voltage Feedback Input (V

= 2.5 V) 4 (7) 3.2 3.3 3.4 V

COMP

Input Bias Current (VFB = 3.3 V) 4 (7) − 1 −

Transconductance 5 (8) 2 mS

OTA maximum current capability (VFB > V

OTAen

FB voltage to disable OTA 4 (7) 0.7 1.3 1.7 V

COMP current for which Fault is detected 5 (8) − −40 −

COMP current for which internal current set−point is 100% (I

COMP current for which internal current setpoint is:

I

Freeze1 or 2

(NCP1060/3)

Equivalent pull−up voltage in linear regulation range

(Guaranteed by design)

Equivalent feedback resistor in linear regulation range

(Guaranteed by design)

Voltage on LIM/OPP pin @ I

Voltage on LIM/OPP pin @ I

= −35 mA

LMOP

= −250 mA, Tj = 25°C

LMOP

Maximum current from LIM/OPP pin 3 (6) −330 −420

Current at which LIM/OPP starts to decrease I

Current at which LIM/OPP stops to decrease I

Negative Active Clamp Voltage (I

/ (Vin/LP + Sa) x Vin/LP + Vin/L

IPK(0)

LMOP

the propagation delay.

prop

PEAK

= −2.5 mA) 3 (6) −0.7 V

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

− − ±6 − %

) 5 (8) ±150

) 5 (8) − −44 −

IPK(0)

5 (8) − −80 −

5 (8) − 2.7 − V

5 (8) − 17.7 −

3 (6) 1.40

1.28

PEAK

3 (6) −20 −26 −32

3 (6) −285

x t

, with Sa the built−in slope compensation, Vin the input voltage,

P

prop

330

740

320

710

128

312

130

160

1.50

1.35

−

−

−

−

−

−

−

−

1.60

1.42

mA

mA

mA

ns

mA

mA

mA

mA

mA

kΩ

V

mA

mA

mA

www.onsemi.com

8

Page 9

NCP1060, NCP1063

Table 5. ELECTRICAL CHARACTERISTICS (continued)

(For typical values T

Symbol UnitMaxTypMinPinRating

COMPENSATION SECTION

I

LMOP(pos)

FREQUENCY FOLDBACK & SKIP

I

COMPfold

I

COMPfold(end)

f

min

I

COMPskip

I

Freeze1

I

Freeze2

RAMP COMPENSATION

S

a(60)

S

a(100)

PROTECTIONS

t

SCP

t

recovery

V

OVP

t

OVP

V

HV(EN)

TEMPERATURE MANAGEMENT

TSD

TSD

hyst

3. The final switch current is: I

the primary inductor in a flyback, and t

L

P

4. Oscillator frequency is measured with disabled jittering.

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

= 25°C, for min/max values TJ = −40°C to +125°C, VCC = 14 V unless otherwise noted)

J

Positive Active Clamp (Guaranteed by design) 3 (6) 2.5 mA

Start of frequency foldback COMP pin current level 5 (8) − −68 −

End of frequency foldback COMP pin current level, fsw = f

min

5 (8) − −100 −

mA

mA

The frequency below which skip−cycle occurs − 21 25 29 kHz

The COMP pin current level to enter skip mode 5 (8) − −120 −

Internal minimum current setpoint (I

Internal minimum current setpoint (I

COMP

COMP

= I

COMPFreeze

= I

COMPFreeze

) in NCP1060 − 110 − mA

) in NCP1063 − 270 − mA

The internal ramp compensation @ 60 kHz:

NCP1060

NCP1063

−

−

−

−

8.4

15.6

The internal ramp compensation @ 100 kHz:

NCP1060

NCP1063

−

−

−

−

14

26

−

−

−

−

mA

mA/ms

mA/ms

Fault validation further to error flag assertion − 35 48 − ms

OFF phase in fault mode − − 400 − ms

VCC voltage at which the switcher stops pulsing 2 (5) 17.0 18.0 18.8 V

The filter of VCC OVP comparator − − 80 −

The drain pin voltage above which allows MOSFET operate, which is

detected after TSD, UVLO, SCP, or V

OVP mode. (A version only)

CC

7,8

(6−10)

(13−16)

67 87 110 V

ms

Temperature shutdown (Guaranteed by design) − 150 163 − °C

Hysteresis in shutdown (Guaranteed by design) − − 20 − °C

/ (Vin/LP + Sa) x Vin/LP + Vin/L

IPK(0)

the propagation delay.

prop

x t

, with Sa the built−in slope compensation, Vin the input voltage,

P

prop

www.onsemi.com

9

Page 10

NCP1060, NCP1063

TYPICAL CHARACTERISTICS

9.15

9.10

9.05

9.00

VOLTAGE (V)

8.95

8.90

8.85

7.00

6.98

6.96

6.94

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 4. V

7.52

7.50

7.48

7.46

7.44

7.42

7.40

VOLTAGE (V)

7.38

7.36

7.34

120 120

100806040200−20−40

vs. Temperature Figure 5. V

CC(on)

7.32

800

700

600

500

400

vs. Temperature

CC(min)

100806040200−20−40

VOLTAGE (V)

6.92

6.90

6.88

0.95

0.94

0.93

0.92

0.91

CURRENT (mA)

0.90

0.89

0.88

Figure 8. I

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 6. V

TEMPERATURE (°C) TEMPERATURE (°C)

CC1 60 kHz

300

CURRENT (mA)

200

100

120

100806040200−20−40

vs. Temperature Figure 7. I

CC(off)

100806040200−20−40

120 120

0

0.99

0.98

0.97

0.96

0.95

CURRENT (mA)

0.94

0.93

0.92

vs. Temperature Figure 9. I

DSS(off)

CC1 100 kHz

vs. Temperature

vs. Temperature

100806040200−20−40

120

100806040200−20−40

www.onsemi.com

10

Page 11

NCP1060, NCP1063

TYPICAL CHARACTERISTICS

310

308

306

304

302

300

298

296

CURRENT (mA)

294

292

290

288

Figure 10. I

12

10

8

6

770

765

760

755

750

745

740

CURRENT (mA)

735

730

725

120

100806040200−20−40

TEMPERATURE (°C) TEMPERATURE (°C)

IPK(0)1060

vs. Temperature Figure 11. I

720

0.6

0.5

0.4

0.3

IPK(0)1063

vs. Temperature

100806040200−20−40

120

4

CURRENT (mA)

2

0

70

60

50

40

30

RESISTIVITY (W)

20

10

0

Figure 14. R

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 12. I

TEMPERATURE (°C) TEMPERATURE (°C)

DS(on)1060

0.2

CURRENT (mA)

0.1

100806040200−20−40

120

vs. Temperature Figure 13. I

start1

100806040200−20−40

0

25

20

15

10

RESISTIVITY (W)

5

0

vs. Temperature Figure 15. R

vs. Temperature

start2

DS(on)1063

100806040200−20−40

100806040200−20−40

vs. Temperature

120

120120

www.onsemi.com

11

Page 12

NCP1060, NCP1063

TYPICAL CHARACTERISTICS

60.0

59.5

59.0

58.5

58.0

57.5

57.0

FREQUENCY (kHz)

56.5

56.0

55.5

Figure 16. f

109

108

107

106

105

104

103

CURRENT (mA)

102

101

100

Figure 18. I

100

99

98

97

96

95

FREQUENCY (kHz)

94

93

120

100806040200−20−40

TEMPERATURE (°C) TEMPERATURE (°C)

vs. Temperature Figure 17. f

OSC60

120

100806040200−20−40

TEMPERATURE (°C) TEMPERATURE (°C)

freeze1060

vs. Temperature Figure 19. I

92

274

272

270

268

266

264

262

CURRENT (mA)

260

258

256

OSC100

freeze1063

vs. Temperature

vs. Temperature

120

100806040200−20−40

120

100806040200−20−40

66.2

66.1

66.0

65.9

65.8

DUTY CYCLE (%)

65.7

65.6

Figure 20. D

25.8

25.6

25.4

25.2

25.0

24.8

FREQUENCY (kHz)

24.6

120 120

100806040200−20−40

TEMPERATURE (°C) TEMPERATURE (°C)

vs. Temperature Figure 21. f

(max)

24.4

vs. Temperature

min

www.onsemi.com

12

100806040200−20−40

Page 13

NCP1060, NCP1063

TYPICAL CHARACTERISTICS

430

425

420

415

410

405

TIME (ms)

400

395

390

385

18.2

18.1

18.0

17.9

17.8

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 22. t

recovery

53

52

51

50

49

TIME (ms)

48

47

120

100806040200−20−40

46

vs. Temperature Figure 23. t

92

91

90

89

88

vs. Temperature

SCP

120

100806040200−20−40

17.7

VOLTAGE (V)

17.6

17.5

17.4

3.34

3.33

3.32

3.31

3.30

3.29

3.28

VOLTAGE (V)

3.27

3.26

3.25

3.24

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 24. V

TEMPERATURE (°C) TEMPERATURE (°C)

Figure 26. V

87

VOLTAGE (V)

86

85

100806040200−20−40

120

vs. Temperature Figure 25. V

OVP

100806040200−20−40

120

vs. Temperature Figure 27. V

REF

84

1.6

1.4

1.2

1.0

0.8

0.6

VOLTAGE (V)

0.4

0.2

0

vs. Temperature

HV(EN)

vs. Temperature

OTAen

100806040200−20−40

120

100806040200−20−40

120

www.onsemi.com

13

Page 14

NCP1060, NCP1063

TYPICAL CHARACTERISTICS

2.5

NCP1063

2.0

1.5

(A)

DS(PK)

1.0

I

0.5

0

NCP1060

TJ, JUNCTION TEMPERATURE (°C)

Figure 28. Drain Current Peak during Transformer

Saturation vs. Junction Temperature

1.100

1.075

1.050

1.025

(25°C)(−)

DSS

1.000

/BV

DSS

0.975

BV

0.950

150

1251007550250−25−50

0.925

TEMPERATURE (°C)

80

125

1006040200−20−40

Figure 29. Breakdown Voltage vs. Temperature

www.onsemi.com

14

Page 15

NCP1060, NCP1063

APPLICATION INFORMATION

Introduction

The NCP106X offers a complete current−mode control

solution. The component integrates everything needed to

build a rugged and cost effective Switch−Mode Power

Supply (SMPS) featuring low standby power. The Quick

Selection Table, Table 6, details the differences between

references, mainly peak current setpoints, R

DS(on)

value and

operating frequency.

• Current−mode Operation: the controller uses

current−mode control architecture.

• 700 V –_ Power MOSFET: Due to ON Semiconductor

Very High Voltage Integrated Circuit technology, the

circuit hosts a high−voltage power MOSFET featuring

a 34 W or 11.4 W R

– Tj = 25°C. This value lets

DS(on)

the designer build a power supply up to 7.8 W or

15.5 W operated on universal mains. An internal

current source delivers the startup current, necessary to

crank the power supply.

• Dynamic Self−supply: Due to the internal high voltage

current source, this device could be used in the

application without the auxiliary winding to provide

supply voltage.

• Short Circuit Protection: by permanently monitoring

the COMP line activity, the IC is able to detect the

presence of a short−circuit, immediately reducing the

output power for a total system protection. A t

SCP

timer

is started as soon as the COMP current is below

threshold, I

COMPfault

, which indicates the maximum

peak current. If at the end of this timer the fault is still

present, then the device enters a safe, auto−recovery

burst mode, affected by a fixed timer recurrence,

t

. Once the short has disappeared, the controller

recovery

resumes and goes back to normal operation.

• Built−in VCC Over Voltage Protection: when the

auxiliary winding is used to bias the V

an internal comparator is connected to V

the voltage on the pin exceeds a level of V

typically), the controller immediately stops switching

and waits a full timer period (t

recovery

attempting to restart. If the fault is gone, the controller

resumes operation. If the fault is still there, e.g. a

broken opto−coupler, the controller protects the load

through a safe burst mode.

pin (no DSS),

CC

pin. In case

CC

OVP

) before

(18 V

• Line Detection: An internal comparator monitors the

drain voltage as recovering from one of the following

situations:

♦ Short Circuit Protection,

♦ V

OVP is confirmed,

CC

♦ UVLO,

♦ TSD

• If the drain voltage is lower than the internal threshold

(V

avoids operating at too low ac input. This is also called

brown−in function in some fields. For applications not

using standard AC mains (24 Vdc industrial bus for

instance), the B version doesn’t incorporate this line

detection and let the device start as soon as voltage

supply reaches V

), the internal power switch is inhibited. This

HV(EN)

start(min).

• Frequency Jittering: an internal low−frequency

modulation signal varies the pace at which the

oscillator frequency is modulated. This helps spreading

out energy in conducted noise analysis. To improve the

EMI signature at low power levels, the jittering remains

active in frequency foldback mode.

• Soft−start: a 4 ms soft−start ensures a smooth startup

sequence, reducing output overshoots.

• Frequency Foldback Capability: a continuous flow of

pulses is not compatible with no−load/light−load

standby power requirements. To excel in this domain,

the controller observes the COMP pin current

information and when it reaches a level of I

COMPfold

,

the oscillator then starts to reduce its switching

frequency as the feedback current continues to increase

(the power demand continues to reduce). It can go

down to 25 kHz (typical) reached for a feedback level

of I

COMPfold(end)

(100 mA roughly). At this point, if the

power continues to drop, the controller enters classical

skip−cycle mode.

• Skip: if SMPS naturally exhibits a good efficiency at

nominal load, it begins to be less efficient when the

output power demand diminishes. By skipping

un−needed switching cycles, the NCP106X drastically

reduces the power wasted during light load conditions.

• Ipeak Set: If current in range 26 mA and 285 mA is

drawn from the pin, the peak current is proportionally

reduced down to 40% of its original value. This feature

enables to designer to set up the peak current to the

value which is ideal for the application.

By routing a portion of the negative voltage present during

the on−time on the auxiliary winding to the LIM/OPP pin,

the user has a simple and non−dissipative means to alter the

maximum peak current setpoint as the bulk voltage

increases.

www.onsemi.com

15

Page 16

NCP1060, NCP1063

Startup Sequence

When the power supply is first powered from the mains

outlet, the internal current source (typically 8.0 mA) is

biased and charges up the V

Once the voltage on this V

level (typically 9.0 V), the current source turns off and

pulses are delivered by the output stage: the circuit is awake

and activates the power MOSFET if the bulk voltage is

capacitor from the drain pin.

CC

capacitor reaches the V

CC

Vbulk

I1

R

limit

CC(on)

above V

bulk voltage is above V

level (87 V typically) for A version and if

HV(EN)

start(min)

(21 V dc) for B version.

There is no disable level for drain pin voltage, the device will

stop switching when the input voltage is removed and

sub−sequentially the V

t

timer elapses. Figure 30 details the simplified internal

SCP

reaches the V

CC

CC(OFF)

level, or

circuitry.

I

1

I2

C

VCC

CC1

+ −

V

OVP

Figure 30. The Internal Arrangement of the Start−up Circuitry

Being loaded by the circuit consumption, the voltage on

the V

capacitor goes down. When VCC is below V

CC

CC(min)

level (7.5 V typically), it activates the internal current source

to bring V

takes place whose low frequency depends on the V

toward V

CC

level and stops again: a cycle

CC(on)

CC

I

start1

V

CC(on)

V

CC(min)

VCC > 18 V ?

à

OVP fault

Drain

+−

5

8

capacitor and the IC consumption. A 1.5 V ripple takes place

on the V

V

CC(min)

pin whose average value equals (V

CC

)/2. Figure 31 portrays a typical operation of the

DSS.

CC(on)

+

www.onsemi.com

16

Page 17

10

NCP1060, NCP1063

9

9.0 V

8

7

V

6

CC

7.5 V

5

V (V)

4

Device

Internal

3

2

V

CCTH

1

0

012345678910

Pulses

TIME (ms)

Startup Duration

Figure 31. The Charge/Discharge Cycle over a 1 mF VCC Capacitor

As one can see, even if there is auxiliary winding to provide

energy for V

, it happens that the device is still biased by

CC

DSS during start−up time or some fault mode when the

voltage on auxiliary winding is not ready yet. The V

capacitor shall be dimensioned to avoid VCC crosses V

level, which stops operation. The ΔV between V

V

is 0.5 V. There is no current source to charge V

CC(off)

CC(min)

CC

CC(off)

and

CC

capacitor when driver is on, i.e. drain voltage is close to zero.

Hence the V

C

Take the 60 kHz device as an example. C

capacitor can be calculated using

CC

I

@ D

VCC

w

CC1

f

OSC

max

@ DV

VCC

(eq. 1)

should be

above

0.8 m @ 72%

54 kHz @ 0.5

+ 21 nF.

A margin that covers the temperature drift and the voltage

drop due to switching inside FET should be considered, and

thus a capacitor above 0.1 mF is appropriate.

The VCC capacitor has only a supply role and its value

does not impact other parameters such as fault duration or

the frequency sweep period for instance. As one can see on

Figure 30, an internal OVP comparator, protects the

switcher against lethal V

runaways. This situation can

CC

occur if the feedback loop optocoupler fails, for instance,

and you would like to protect the converter against an over

voltage event. In that case, the over voltage protection

(OVP) circuit and immediately stops the output pulses for

t

duration (400 ms typically). Then a new start−up

recovery

attempt takes place to check whether the fault has

disappeared or not. The OVP paragraph gives more design

details on this particular section.

Fault Condition – Short−circuit on V

CC

In some fault situations, a short−circuit can purposely

occur between V

and GND. In high line conditions (V

CC

HV

= 370 VDC) the current delivered by the startup device will

seriously increase the junction temperature. For instance,

since I

T

), the device would dissipate 370 x 5 m = 1.85 W. To avoid

j

equals 5 mA (the min corresponds to the highest

start1

this situation, the controller includes a novel circuitry made

of two startup levels, I

as V

is below a 1.4 V level, the source delivers I

CC

start1

and I

. At power−up, as long

start2

start2

(around 500 mA typical), then, when VCC reaches 1.4 V, the

source smoothly transitions to I

value. As a result, in case of short−circuit between V

and delivers its nominal

start1

CC

and

GND, the power dissipation will drop to 370 x 500 m =

185 mW. Figure 31 portrays this particular behavior.

The first startup period is calculated by the formula C x V

= I x t, which implies a 1 m x 1.4 / 500 m = 2.8 ms startup time

for the first sequence. The second sequence is obtained by

toggling the source to 8 mA with a delta V of V

= 9.0 – 1.4 = 7.6 V, which finally leads to a second

V

CCTH

CC(on)

–

startup time of 1 m x 7.6 / 8 m = 0.95 ms. The total startup

time becomes 2.8 m + 0.95 m = 3.75 ms. Please note that this

calculation is approximated by the presence of the knee in

the vicinity of the transition.

www.onsemi.com

17

Page 18

NCP1060, NCP1063

Fault Condition – Output Short−circuit

As soon as VCC reaches V

, drive pulses are

CC(on)

internally enabled. If everything is correct, the auxiliary

winding increases the voltage on the V

pin as the output

CC

voltage rises. During the start−sequence, the controller

smoothly ramps up the peak drain current to maximum

setting, i.e. I

, which is reached after a typical period of

IPK

4 ms. When the output voltage is not regulated, the current

coming through COMP pin is below I

COMPfault

level (40 mA

typically), which is not only during the startup period but

also anytime an overload occurs, an internal error flag is

V

CC

CC(on)

V

CC(min)

IpFlag

V

COMP

Timer

DRV

internal

Open loop FB

Fault

48 ms typ.

400 ms typ.

V

asserted, Ipflag, indicating that the system has reached its

maximum current limit set point. The assertion of this flag

triggers a fault counter t

completion, I

remains asserted, all driving pulses are

pflag

stopped and the part stays off in t

(48 ms typically). If at counter

SCP

duration (about

recovery

400 ms). A new attempt to re−start occurs and will last

48 ms providing the fault is still present. If the fault still

affects the output, a safe burst mode is entered, affected by

a low duty−cycle operation (11%). When the fault

disappears, the power supply quickly resumes operation.

Figure 32 depicts this particular mode:

Figure 32. In Case of Short−circuit or Overload, the NCP106X Protects Itself and the Power Supply via a Low

Frequency Burst Mode. The V

Auto−recovery Over Voltage Protection

The particular NCP106X arrangement offers a simple

way to prevent output voltage runaway when the

optocoupler fails. As Figure 33 shows, a comparator

monitors the V

voltage into the C

pin. If the auxiliary pushes too much

CC

capacitor, then the controller

VCC

considers an OVP situation and stops the internal drivers.

When an OVP occurs, all switching pulses are permanently

disabled. After t

delay, it resumes the internal drivers.

recovery

If the failure symptom still exists, e.g. feedback

opto−coupler fails, the device keeps the auto−recovery OVP

mode. It is recommended insertion of a resistor (

between the auxiliary dc level and the V

is Maintained by the Current Source and Self−supplies the Controller

CC

IC against high voltage spikes, which can damage the IC,

and to filter out the Vcc line to avoid undesired OVP

activation. R

should be carefully selected to avoid

limit

triggering the OVP as we discussed, but also to avoid

disturbing the V

in low / light load conditions.

CC

Self−supplying controllers in extremely low standby

applications often puzzles the designer. Actually, if a SMPS

operated at nominal load can deliver an auxiliary voltage of

an arbitrary 16 V (V

(V

) when entering standby. This is because the

stby

), this voltage can drop below 10 V

nom

recurrence of the switching pulses expands so much that the

R

)

pin to protect the

CC

limit

low frequency re−fueling rate of the V

enough to keep a proper auxiliary voltage.

capacitor is not

CC

www.onsemi.com

18

Page 19

NCP1060, NCP1063

Drain

V

CC (on )

V

CC (min )

=9.0V

=7.5V

I

start 1

V

CC

R

limit

D1

Shut down

Internal DRV

80

filter

ms

V

OVP

GND

C

VCC C

AUX N

Figure 33. A More Detailed View of the NCP106X Offers Better Insight on how to Properly Wire

an Auxiliary Winding

V

OVP

V

CC(on)

V

CC(min)

V

CC

AUX

I

COMP

TIMER

DRV

internal

Fault level

48 ms typ.

Figure 34. Describes the Main Signal Variations when the Part Operates in Auto−recovery OVP

Soft−start

The NCP106X features a 4 ms soft−start which reduces

the power−on stress but also contributes to lower the output

overshoot. Figure 35 shows a typical operating waveform.

400 ms typ.

The NCP106X features a novel patented structure which

offers a better soft−start ramp, almost ignoring the start−up

pedestal inherent to traditional current−mode supplies.

www.onsemi.com

19

Page 20

V

CC

0V (fresh PON)

NCP1060, NCP1063

V

CCON

Drain current

Figure 35. The 4 ms Soft−start Sequence

Jittering

Frequency jittering is a method used to soften the EMI

signature by spreading the energy in the vicinity of the main

switching component. The NCP106X offers a ±6%

deviation of the nominal switching frequency. The sweep

Jitter ramp

Max Ip

4ms

sawtooth is internally generated and modulates the clock up

and down with a fixed frequency of 300 Hz. Figure 36 shows

the relationship between the jitter ramp and the frequency

deviation. It is not possible to externally disable the jitter.

63.6 kHz

60 kHz

56.4 kHz

adjustable

Figure 36. Modulation Effects on the Clock Signal by the Jittering Sawtooth

Line Detection (for A version only)

An internal comparator monitors the drain voltage as

recovering from one of the following situations:

• Short Circuit Protection,

• V

OVP is confirmed,

CC

www.onsemi.com

Internal

sawtooth

• UVLO

• TSD

If the drain voltage is lower than the internal threshold

V

inhibited. This avoids operating at too low ac input.

20

(87 Vdc typically), the internal power switch is

HV(EN)

Page 21

NCP1060, NCP1063

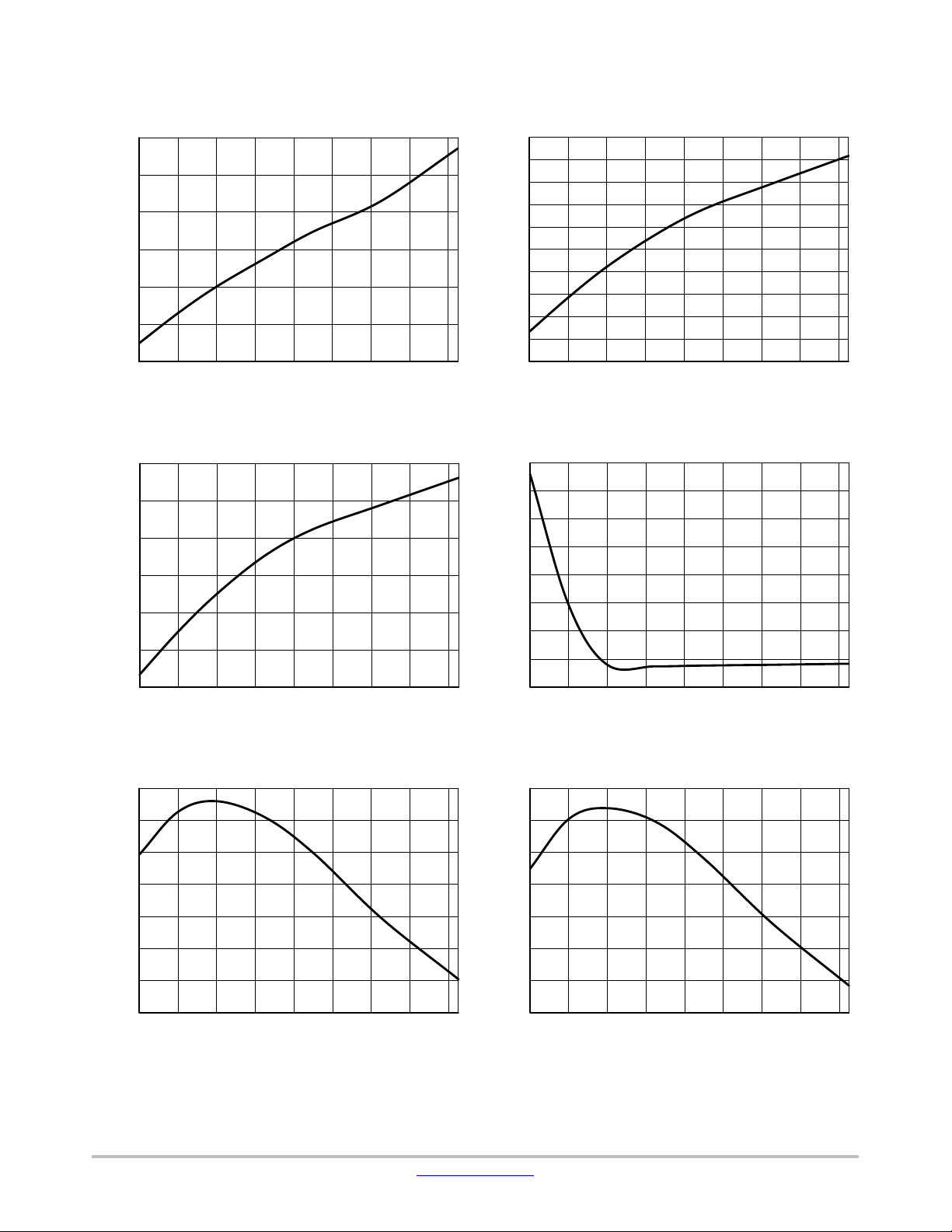

Frequency Foldback

The reduction of no−load standby power associated with

the need for improving the efficiency, requires to change the

traditional fixed−frequency type of operation. This device

implements a switching frequency foldback when the

COMP current passes above a certain level, I

COMPfold

around 68 mA. At this point, the oscillator enters frequency

foldback and reduces its switching frequency.

The internal peak current set−point is following the

COMP current information until its level reaches I

110

100

90

80

70

60

50

40

Frequency [kHz]

30

20

10

, set

Freeze

Below this value, the peak current setpoint is frozen to 30%

of the I

. The only way to further reduce the transmitted

PK(0)

power is to diminish the operating frequency down to F

(25 kHz typically). This value is reached at a COMP current

level of I

COMPfold(end)

(100 mA typically). Below this point,

if the output power continues to decrease, the part enters skip

cycle for the best noise−free performance in no−load

conditions. Figure 37 and Figure 38 depict the adopted

scheme for the part.

.

NCP106x 60 kHz

NCP106x 100 kHz

min

50 60 70 80 90 100

I

[mA]

COMP

Figure 37. By Observing the Current on the COMP Pin, the Controller Reduces

its Switching Frequency for an Improved Performance at Light Load

900

800

NCP1060

NCP1063

700

600

500

400

300

200

Current set point [mA]

100

0

40 50 60 70 80 90 100 110

I

[mA]

COMP

Figure 38. Ipk Set−point is Frozen at Lower Power Demand

www.onsemi.com

21

Page 22

NCP1060, NCP1063

350

300

250

200

150

100

Current set point [mA]

50

0

40 50 60 70 80 90 100 110

I

[mA]

COMP

NCP1060

NCP1063

Figure 39. Ipk Set−point is Frozen at Lower Power Demand (I

Feedback and Skip

Figure 40 depicts the relationship between COMP pin

voltage and current. The COMP pin operates linearly as the

absolute value of COMP current (I

) is above 40 mA. In

COMP

3.5

3.0

2.5

2.0

[V]

COMP

1.5

V

1.0

0.5

0.0

-180 -160 -140 -120 -100 -80 -60 -40 -20 0

≥ 285 mA)

LMOP

this linear operating range, the dynamic resistance is

17.7 kW typically (R

COMP(up)

voltage is 2.7 V typically (V

) and the effective pull up

COMP(REF)

). When I

decreases, the COMP voltage will increase to 3.2 V.

I

[μA]

COMP

COMP

is

Figure 40. COMP Pin Voltage vs. Current

Figure 41 depicts the skip mode block diagram. When the

COMP current information reaches I

COMPskip

, the internal

clock setting the flip−flop is blanked and the internal

consumption of the controller is decreased. The hysteresis of

www.onsemi.com

internal skip comparator is minimized to lower the ripple of

the auxiliary voltage for VCC pin and V

during skip mode. It easies the design of V

of power supply

OUT

over load

CC

range.

22

Page 23

Jittering

NCP1060, NCP1063

OSC

R

COMP(UP)

COMP

Ilimit and OPP Function

V

COMP(REF)

Foldback

I

COMPskip

Figure 41. Skip Cycle Schematic

SKIP

S

Q

Q

R

CS comparator

DRV stage

The function makes the integrated circuit more flexible. The current drawn out of LIM/OPP pin defines the current set point.

900

NCP1060

800

700

NCP1063

600

500

400

300

200

Current set point [mA]

100

0

0 50 100 150 200 250 300 350

Figure 42. Ipk Set−point Dependence on I

There are several known ways to implement Over Power

Protection (OPP), all suffering from particular problems.

These problems range from the added consumption burden

on the converter or the skip−cycle disturbance brought by

the current−sense offset. A way to reduce the power

capability at high line is to capitalize on the negative voltage

swing present on the auxiliary diode anode. During the

power switch on−time, this point dips to –NV

, N being the

in

turns ratio between the primary winding and the auxiliary

winding. The negative plateau on auxiliary winding will

have an amplitude dependant on the input voltage. Resistors

I

[mA]

LMOP

Current

LMOP

R

OPPU

and R

(Figure 43) define current drawn from

OPPL

LIM/OPP and the negative voltage on auxiliary winding.

The negative voltage is tied up with bulk voltage, so the

higher the bulk voltage is, the deeper is the negative voltage

on auxiliary winding, the higher current is drawn from

LIM/OPP pin and the lower the peak current is. During the

internal MOSFET off period, voltage on auxiliary winding

is positive, but the IC ignores the LIM/OPP current. The

positive LIM/OPP current has no influence on proper IC

function.

www.onsemi.com

23

Page 24

NCP1060, NCP1063

VCC

D4

I

COMP

I

LMOP

Aux

winding

I

0

I

COMP

LMDEC

C2

R

OPPU

LIM/OPP

R

OPPL

Figure 43. The OPP Circuitry Affects the Maximum Peak Current Set Point

Ramp Compensation and Ipk Set−point

In order to allow the NCP106X to operate in CCM with a

duty cycle above 50%, a fixed slope compensation is

internally applied to the current−mode control.

Here we got a table of the ramp compensation, the initial

current set point, and the final current set−point of different

versions of switcher.

to CS setpoint

mA

25

250

OSC

S

MOSFET

Q

I

LMDEC

R

I

mA

I

LMOP

IPKL

FreezeIpk(0)

Vramp + Vsense

NCP1060 NCP1063

f

sw

S

I

pk(Duty

=50%)

I

pk(0)

a

60 kHz 100 kHz 60 kHz 100 kHz

8.4 mA/ms 14 mA/ms 15.6 mA/ms 26 mA/ms

250 mA 650 mA

300 mA 780 mA

Figure 44 depicts the variation of IPK set−point vs. the

power switcher duty ratio, which is caused by the internal

ramp compensation.

900

800

700

NCP1060

NCP1063

600

500

400

300

Ipk set-point [mA]

200

100

0

0% 10% 20% 30% 40% 50% 60% 70%

Dutty Ratio [%]

Figure 44. IPK Set−point Varies with Power Switch on Time, which is Caused by the Ramp Compensation

FB Pin Function

The FB pin is used in non isolated SMPS application only.

Portion of the output voltage is connected into the pin. The

voltage is compared with internal V

(3.3 V) using

REF

Operation Transconductance Amplifier (Figure 45). The

OTAs output is connected to COMP pin. The OTA output is

accessible through the COMP pin and is used for the loop

compensation, usually an RC network. The current

capability of OTA is limited to −150 mA typically. The

positive current is defined by internal R

and V

COMP(ref)

voltage. If FB path loop is broken (i.e. the FB

pin is disconnected), an internal current I

pull up the FB pin and the IC stops switching to avoid

uncontrolled output voltage increasing.

In isolated topology, the FB pin should be connected to

GND pin. In this configuration no current flows from OTA

to COMP pin (OTA is disabled) so the OTA has no influence

on regulation at all.

COMP(up)

(1 mA typ.) will

FB

resistor

www.onsemi.com

24

Page 25

NCP1060, NCP1063

V

COMP (REF )

R

COMP (up)

I

COMP

COMP

I

FB

OTA out = 0 A

if FB = 0 V

FB

OTA

V

REF

Figure 45. FB Pin Connection

Design Procedure

The design of an SMPS around a monolithic device does

not differ from that of a standard circuit using a controller

and a MOSFET. However, one needs to be aware of certain

characteristics specific of monolithic devices. Let us follow

the steps:

V

min = 90 Vac or 127 Vdc once rectified, assuming a low

in

bulk ripple

I

OTAlim

V

max = 265 Vac or 375 Vdc

in

V

= 12 V

out

= 5 W

P

out

Operating mode is CCM

η = 0.8

1. The lateral MOSFET body−diode shall never be

forward biased, either during start−up (because of

a large leakage inductance) or in normal operation

as shown in Figure 46. This condition sets the

maximum voltage that can be reflected during toff.

As a result, the Flyback voltage which is reflected

on the drain at the switch opening cannot be larger

than the input voltage. When selecting

components, you thus must adopt a turn ratio

which adheres to the following equation:

N @ǒV

out

) V

Ǔ

f

t V

in,min

2. In our case, since we operate from a 127 V DC rail

while delivering 12 V, we can select a reflected

voltage of 120 V dc maximum. Therefore, the turn

ratio Np:Ns must be smaller than

V

reflect

V

) V

out

+

f

120

12 ) 0.5

+ 9.6orNp:Nst 9.6.

Here we choose N = 8 in this case. We will see later

on how it affects the calculation.

(eq. 2)

350

250

150

50.0

−50.0

1.004M 1.011M 1.018M 1.025M 1.032M

> 0 !!

Figure 46. The Drain−source Wave Shall always be Positive

www.onsemi.com

25

Page 26

Figure 47. Primary Inductance Current

Evolution in CCM

3. Lateral MOSFETs have a poorly doped

body−diode which naturally limits their ability to

sustain the avalanche. A traditional RCD clamping

network shall thus be installed to protect the

MOSFET. In some low power applications, a

simple capacitor can also be used since

V

drain,max

+ Vin) N @ǒV

where L

is the leakage inductance, C

f

out

) V

Ǔ

) I

f

peak

@

Ǹ

capacitance at the drain node (which is increased by

the capacitor you will wire between drain and

source), N the N

voltage, V

finally, I

the secondary diode forward drop and

f

the maximum peak current. Worse case

peak

turn ratio, V

P:NS

out

occurs when the SMPS is very close to regulation,

e.g. the V

target is almost reached and I

out

pushed to the maximum. For this design, we have

selected our maximum voltage around 650 V (at V

= 375 Vdc). This voltage is given by the RCD clamp

installed from the drain to the bulk voltage. We will

see how to calculate it later on.

4. Calculate the maximum operating duty−cycle for

this flyback converter operated in CCM:

d

max

+

+

N @ǒV

1 )

N @ǒV

out

1

V

in,min

N@(V

@ V

out

out

@ V

Ǔ

f

@Vf)

) V

Ǔ

f

in,min

+ 0.44

5. To obtain the primary inductance, we have the

choice between two equations:

Vin@ d

2

Ǔ

in

L +

ǒ

fsw@ K @ P

NCP1060, NCP1063

and defines the amount of ripple we want in CCM (see

Figure 47).

• Small K: deep CCM, implying a large primary

inductance, a low bandwidth and a large leakage

inductance.

• Large K: approaching DCM where the RMS losses are

worse, but smaller inductance, leading to a better

leakage inductance.

From Equation 6, a K factor of 1 (50% ripple), gives an

inductance of:

L +

DI

+

L

The peak current can be evaluated to be:

I

peak

On IL, I

I

Lavg

L

f

(eq. 3)

C

tot

the total

tot

the output

is still

peak

(eq. 4)

(eq. 5)

in

6. Based on the above numbers, we can now evaluate

I

d,rms

7. Off−time and on−time switching losses can be

Where, assume the V

voltage.

DI

where K +

(

127 @ 0.44

60k @ 1 @ 5

Vin@ d

L @ f

sw

I

avg

+

d

can also be calculated:

Lavg

+ I

peak

L

I

Lavg

2

)

+ 10.04 mH

127 @ 0.44

+

10.04m @ 60k

DI

L

)

+

2

DI

L

*

+ 158m *

2

49.2 m

0.44

+ 92.8 mA peak to peak

92.8 m

)

92.8m

+ 158 mA

2

+ 111.6 mA

2

the conduction losses:

2

DI

+ d @ǒI

Ǹ

+ 0.44 @ǒ0.1582* 0.158 @ 0.0928 )

Ǹ

+ 57 mA

peak

2

* I

peak

@ DIL)

If we take the maximum R

L

3

for a 125°C

DS(on)

Ǔ

0.0928

3

2

junction temperature, i.e. 34 W, then conduction

losses worse case are:

P

cond

+ I

d,rms

2

@ R

DS(on)

+ 110 mW

estimated based on the following calculations:

I

@ǒV

P

peak

+

off

0.158 @(127 ) 100 @ 2)@ 10n

+

+ 15.5 mW

) V

bulk

2T

2 @ 16.7 m

is equal to 2 times of reflected

clamp

SW

clamp

Ǔ

@ t

off

(eq. 6)

Ǔ

www.onsemi.com

26

Page 27

NCP1060, NCP1063

I

@ǒV

Pon+

valley

0.0464 @ (127 ) 100) @ 10 n

+

+ 2.1 mW

) N @ (V

bulk

6 @ T

6 @ 16.7 m

SW

) Vf)Ǔ@ t

out

on

(eq. 7)

It is noted that the overlap of voltage and current seen on

MOSFET during turning on and off duration is dependent on

the snubber and parasitic capacitance seen from drain pin.

Therefore the t

and ton in Equation 7 and Equation 8 have

off

to be modified after measuring on the bench.

8. The theoretical total power is then

117 + 15.5 + 2.1 = 127.6 mW

9. If the NCP106X operates at DSS mode, then the

losses caused by DSS mode should be counted as

losses of this device on the following calculation:

P

+ I

DSS

MOSFET Protection

CC1

@ V

+ 0.8m @ 375 + 300 mW

in.max

(eq. 8)

As in any Flyback design, it is important to limit the drain

excursion to a safe value, e.g. below the MOSFET BVdss

which is 700 V. Figure 48 a−b−c present possible

implementations:

Figure 48. a, b, c : Different Options to Clamp the Leakage Spike

Figure 48a: the simple capacitor limits the voltage

according to the lateral MOSFET body−diode shall never be

forward biased, either during start−up (because of a large

leakage inductance) or in normal operation as shown by

Figure 46. This condition sets the maximum voltage that can

be reflected during t

. As a result, the flyback voltage

off

which is reflected on the drain at the switch opening cannot

be larger than the input voltage. When selecting

components, you must adopt a turn ratio which adheres to

the following Equation 3. This option is only valid for low

power applications, e.g. below 5 W, otherwise chances exist

to destroy the MOSFET. After evaluating the leakage

inductance, you can compute C with (Equation 4). Typical

values are between 100 pF and up to 470 pF. Large

capacitors increase capacitive losses...

Figure 48b: the most standard circuitry is called the RCD

network. You calculate R

clamp

and C

clamp

using the

following formulae:

R

+

clamp

C

+

clamp

V

is usually selected 50−80 V above the reflected

clamp

value N x (V

2 @ V

V

ripple

+ Vf). The diode needs to be a fast one and

out

@ǒV

clamp

L

V

clamp

@ fsw@ R

leak

clamp

@ I

clamp

) N @ (V

2

@ f

leak

out

sw

) Vf)

Ǔ

(eq. 9)

a MUR160 represents a good choice. One major drawback

of the RCD network lies in its dependency upon the peak

current. Worse case occurs when I

and V

is close to reach the steady−state value.

out

and Vin are maximum

peak

Figure 48c: this option is probably the most expensive of

all three but it offers the best protection degree. If you need

a very precise clamping level, you must implement a zener

diode or a TVS. There are little technology differences

behind a standard zener diode and a TVS. However, the die

area is far bigger for a transient suppressor than that of zener.

A 5 W zener diode like the 1N5388B will accept 180 W peak

power if it lasts less than 8.3 ms. If the peak current in the

worse case (e.g. when the PWM circuit maximum current

limit works) multiplied by the nominal zener voltage

exceeds these 180 W, then the diode will be destroyed when

the supply experiences overloads. A transient suppressor

like the P6KE200 still dissipates 5 W of continuous power

but is able to accept surges up to 600 W @ 1 ms. Select the

zener or TVS clamping level between 40 to 80 volts above the

reflected output voltage when the supply is heavily loaded.

As a good design practice, it is recommended to

implement one of this protection to make sure Drain pin

voltage doesn’t go above 650 V (to have some margin

between Drain pin voltage and BVdss) during most stringent

operating conditions (high Vin and peak power).

www.onsemi.com

27

Page 28

NCP1060, NCP1063

Power Dissipation and Heatsinking

The NCP106X welcomes two dissipating terms, the DSS

current−source (when active) and the MOSFET. Thus, P

= P

DSS

+ P

MOSFET

. It is mandatory to properly manage the

heat generated by losses. If no precaution is taken, risks exist

to trigger the internal thermal shutdown (TSD). To help

dissipating the heat, the PCB designer must foresee large

copper areas around the package. Take the PDIP−7 package

as an example, when surrounded by a surface approximately

200 mm2 of 35 mm copper, the maximum power the device

can thus evacuate is:

tot

T

* T

+

Jmax

P

max

R

qJA

ambmax

(eq. 10)

which gives around 870 mW for an ambient of 50°C and a

maximum junction of 150°C. If the surface is not large

enough, the R

is growing and the maximum power the

JA

θ

device can evacuate decreases. Figure 49 gives a possible

layout to help drop the thermal resistance.

Figure 49. A Possible PCB Arrangement to Reduce the Thermal Resistance Junction−to−Ambient

Bill of material:

C1 Bulk capacitor, input DC voltage is connected to the capacitor

C2, R1, D1 Clamping elements

C3 Vcc capacitor

OK1 Optocoupler

R2 Resistor to setting I

Table 6. ORDERING INFORMATION

Device Frequency R

NCP1060AP060G 60 kHz 34 Yes

NCP1060AP100G 100 kHz 34 Yes 50 Units / Rail

NCP1060AD060R2G 60 kHz 34 Ye s

NCP1060AD100R2G 100 kHz 34 Yes 2500 / Tape & Reel

NCP1060BD060R2G 60 kHz 34 No 2500 / Tape & Reel

NCP1060BD100R2G 100 kHz 34 No 2500 / Tape & Reel

NCP1063AP060G 60 kHz 11.4 Ye s

NCP1063AP100G 100 kHz 11.4 Yes 50 Units / Rail

NCP1063AD060R2G 60 kHz 11.4 Ye s

NCP1063AD100R2G 100 kHz 11.4 Ye s 2500 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

PEAK

current

DS(on)

Brown In Package Type Shipping

PDIP−7

(Pb−Free)

SOIC−10

(Pb−Free)

PDIP−7

(Pb−Free)

SOIC−16

(Pb−Free)

50 Units / Rail

2500 / Tape & Reel

50 Units / Rail

2500 / Tape & Reel

†

www.onsemi.com

28

Page 29

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

PDIP−7 (PDIP−8 LESS PIN 6)

SCALE 1:1

D

14

NOTE 8

TOP VIEW

e/2

A1

D1

e

SIDE VIEW

A

58

H

E1

b2

B

A2

A

NOTE 3

L

SEATING

PLANE

C

8X

b

M

0.010 CA

MBM

CASE 626A

ISSUE C

E

END VIEW

WITH LEADS CONSTRAINED

NOTE 5

M

eB

END VIEW

NOTE 6

DATE 22 APR 2015

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. DIMENSIONS A, A1 AND L ARE MEASURED WITH THE PACKAGE SEATED IN JEDEC SEATING PLANE GAUGE GS−3.

4. DIMENSIONS D, D1 AND E1 DO NOT INCLUDE MOLD FLASH

OR PROTRUSIONS. MOLD FLASH OR PROTRUSIONS ARE

NOT TO EXCEED 0.10 INCH.

5. DIMENSION E IS MEASURED AT A POINT 0.015 BELOW DATUM

PLANE H WITH THE LEADS CONSTRAINED PERPENDICULAR

TO DATUM C.

6. DIMENSION eB IS MEASURED AT THE LEAD TIPS WITH THE

LEADS UNCONSTRAINED.

c

7. DATUM PLANE H IS COINCIDENT WITH THE BOTTOM OF THE

LEADS, WHERE THE LEADS EXIT THE BODY.

8. PACKAGE CONTOUR IS OPTIONAL (ROUNDED OR SQUARE

CORNERS).

INCHES

DIM MIN MAX

A −−−− 0.210

A1 0.015 −−−−

A2 0.115 0.195 2.92 4.95

b 0.014 0.022

b2

0.060 TYP 1.52 TYP

C 0.008 0.014

D 0.355 0.400

D1 0.005 −−−−

E 0.300 0.325

E1 0.240 0.280 6.10 7.11

e 0.100 BSC

eB −−−− 0.430 −−− 10.92

L 0.115 0.150 2.92 3.81

M −−−− 10

MILLIMETERS

MIN MAX

−−− 5.33

0.38 −−−

0.35 0.56

0.20 0.36

9.02 10.16

0.13 −−−

7.62 8.26

2.54 BSC

−−− 10

°°

GENERIC

MARKING DIAGRAM*

XXXXXXXXX

AWL

YYWWG

XXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

98AON11774D

PDIP−7 (PDIP−8 LESS PIN 6)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

Page 30

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

−A−

16 9

−B−

18

G

K

C

−T−

SEATING

PLANE

D

16 PL

0.25 (0.010) A

M

S

B

T

S

CASE 751B−05

8 PLP

0.25 (0.010) B

SOIC−16

ISSUE K

M

DATE 29 DEC 2006

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

M

S

X 45

R

_

F

J

PROTRUSION. ALLOWABLE DAMBAR PROTRUSION

SHALL BE 0.127 (0.005) TOTAL IN EXCESS OF THE D

DIMENSION AT MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

____

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

STYLE 1:

PIN 1. COLLECTOR

2. BASE

3. EMITTER

4. NO CONNECTION

5. EMITTER

6. BASE

7. COLLECTOR

8. COLLECTOR

9. BASE

10. EMITTER

11. NO CONNECTION

12. EMITTER

13. BASE

14. COLLECTOR

15. EMITTER

16. COLLECTOR

STYLE 5:

PIN 1. DRAIN, DYE #1

2. DRAIN, #1

3. DRAIN, #2

4. DRAIN, #2

5. DRAIN, #3

6. DRAIN, #3

7. DRAIN, #4

8. DRAIN, #4

9. GATE, #4

10. SOURCE, #4

11. GATE, #3

12. SOURCE, #3

13. GATE, #2

14. SOURCE, #2

15. GATE, #1

16. SOURCE, #1

STYLE 2:

PIN 1. CATHODE

2. ANODE

3. NO CONNECTION

4. CATHODE

5. CATHODE

6. NO CONNECTION

7. ANODE

8. CATHODE

9. CATHODE

10. ANODE

11. NO CONNECTION

12. CATHODE

13. CATHODE

14. NO CONNECTION

15. ANODE

16. CATHODE

STYLE 6:

PIN 1. CATHODE

2. CATHODE

3. CATHODE

4. CATHODE

5. CATHODE

6. CATHODE

7. CATHODE

8. CATHODE

9. ANODE

10. ANODE

11. ANODE

12. ANODE

13. ANODE

14. ANODE

15. ANODE

16. ANODE

STYLE 3:

PIN 1. COLLECTOR, DYE #1

2. BASE, #1

3. EMITTER, #1

4. COLLECTOR, #1

5. COLLECTOR, #2

6. BASE, #2

7. EMITTER, #2

8. COLLECTOR, #2

9. COLLECTOR, #3

10. BASE, #3

11. EMITTER, #3

12. COLLECTOR, #3

13. COLLECTOR, #4

14. BASE, #4

15. EMITTER, #4

16. COLLECTOR, #4

STYLE 7:

PIN 1. SOURCE N‐CH

2. COMMON DRAIN (OUTPUT)

3. COMMON DRAIN (OUTPUT)

4. GATE P‐CH

5. COMMON DRAIN (OUTPUT)

6. COMMON DRAIN (OUTPUT)

7. COMMON DRAIN (OUTPUT)

8. SOURCE P‐CH

9. SOURCE P‐CH

10. COMMON DRAIN (OUTPUT)

11. COMMON DRAIN (OUTPUT)

12. COMMON DRAIN (OUTPUT)

13. GATE N‐CH

14. COMMON DRAIN (OUTPUT)

15. COMMON DRAIN (OUTPUT)

16. SOURCE N‐CH

STYLE 4:

PIN 1. COLLECTOR, DYE #1

2. COLLECTOR, #1

3. COLLECTOR, #2

4. COLLECTOR, #2

5. COLLECTOR, #3

6. COLLECTOR, #3

7. COLLECTOR, #4

8. COLLECTOR, #4

9. BASE, #4

10. EMITTER, #4

11. BASE, #3

12. EMITTER, #3

13. BASE, #2

14. EMITTER, #2

15. BASE, #1

16. EMITTER, #1

SOLDERING FOOTPRINT

1

16X

0.58

89

8X

6.40

16X

1.12

16

DIMENSIONS: MILLIMETERS

1.27

PITCH

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42566B

SOIC−16

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 31

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

10

1

SCALE 1:1

2X 5 TIPS

D

D

H

1

C0.20

B

TOP VIEW

C0.10

A

A1

SIDE VIEW

RECOMMENDED

SOLDERING FOOTPRINT*

10X

0.58

2X

C0.10 A-B

A

2X

C0.10 A-B

610

E

5

b10X

M

0.25

10X

C

C0.10

e

C

1.00

PITCH

SEATING

PLANE

L2

A-B D

DETAIL A

SOIC−10 NB

CASE 751BQ

ISSUE B

F

h

X 45

A3

L

DETAIL A

_

END VIEW

C

SEATING

PLANE

M

DATE 26 NOV 2013

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE PROTRUSION

SHALL BE 0.10mm TOTAL IN EXCESS OF ’b’

AT MAXIMUM MATERIAL CONDITION.

4. DIMENSIONS D AND E DO NOT INCLUDE

MOLD FLASH, PROTRUSIONS, OR GATE

BURRS. MOLD FLASH, PROTRUSIONS, OR

GATE BURRS SHALL NOT EXCEED 0.15mm

PER SIDE. DIMENSIONS D AND E ARE DETERMINED AT DATUM F.

5. DIMENSIONS A AND B ARE TO BE DETERMINED AT DATUM F.

6. A1 IS DEFINED AS THE VERTICAL DISTANCE

FROM THE SEATING PLANE TO THE LOWEST

POINT ON THE PACKAGE BODY.

MILLIMETERS

DIMDMIN MAX

A 1.25 1.75

A1 0.10 0.25

A3 0.17 0.25

b 0.31 0.51

4.80 5.00

E 3.80 4.00

e 1.00 BSC

H 5.80 6.20

h 0.37 REF

L 0.40 0.80

L2 0.25 BSC