Page 1

© Semiconductor Components Industries, LLC, 2011

December, 2011 − Rev. P0

1 Publication Order Number:

NCN49597/D

NCN49597

Product Preview

Power Line Carrier Modem

ON Semiconductor’s NCN49597 is an IEC 61334−5−1 compliant

power line carrier modem using spread−FSK (S−FSK) modulation for

robust low data rate communication over power lines. NCN49597 is

built around an ARM processor core, and includes the MAC layer.

With this robust modulation technique, signals on the power lines can

pass long distances. The half−duplex operation is automatically

synchronized to the mains, and can be up to 4800 bits/sec.

The product configuration is done via its serial interface, which

allows the user to concentrate on the development of the application.

The NCN49597 is implemented in ON Semiconductor mixed signal

technology, combining both analog circuitry and digital functionality

on the same IC.

Features

• Power Line Carrier Modem for 50 and 60 Hz Mains

• Fully compliant to IEC 61334−5−1 and CENELEC EN 50065−1

• Complete Handling of Protocol Layers Physical to MAC

• Programmable Carrier Frequencies in CENELEC A-Band from 9 to

95 kHz; B−Band from 95 to 125 kHz, in 10 Hz Steps

• Half Duplex

• Data Rate Selectable:

300 – 600 – 1200 − 2400 – 4800 baud (@ 50 Hz)

360 – 720 – 1440 − 2880 – 5760 baud (@ 60 Hz)

• Synchronization on Mains

• Repetition Algorithm Boost the Robustness of Communication

• SCI Port to Application Microcontroller

• SCI Baudrate Selectable: 9.6 – 19.2 – 38.4 − 115.2 kb

• Power Supply 3.3 V

• Ambient Temperature Range: −40°C to +80°C

• These Devices are Pb−Free and are RoHS Compliant*

Typical Applications

• ARM: Automated Remote Meter Reading

• Remote Security Control

• Streetlight Control

• Transmission of Alerts (Fire, Gas Leak, Water Leak)

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

This document contains information on a product under development. ON Semiconductor

reserves the right to change or discontinue this product without notice.

ON

e3

ARM

See detailed ordering and shipping information in the package

dimensions section on page 27 of this data sheet.

ORDERING INFORMATION

XXXX = Date Code

Y = Plant Identifier

ZZ = Traceability Code

http://onsemi.com

MARKING DIAGRAMS

152

QFN52 8x8, 0.5P

CASE 485M

XXXXYZZ

NCN 49597

C597−901

1

52

Page 2

NCN49597

http://onsemi.com

2

APPLICATION

Application Example

PC20111120 .1

TX_OUT

NCN49597

TX_ENB

ZC_IN

REF_OUT

RX_IN

RX_OUT

XTAL _IN

XTAL_OUT

Appli

&

Metering

mC

TXD

RXD

BR0

BR1

RESB

VSSA

VSS

T_REQ

VDD

VDDA

3V3_A 3V3_D

1:2

C

1

R

1

C

2

R

2

C

DREF

C

16

C

17

3V3_A

D

5

D

1

D

2

D

3

D

4

R

12

C

11

C

12

R

14

C

15

C

14

Y

1

NCS5650

Enable

C

3

C

4

C

6

C

7

R

6

R

5R4

R

7

R

9

R

10

2

Vcom

+B

−B

+A

−A

OutA

OutB

8

9

13

12 5

4

3

1

6

7

VCC

10 11

VEE

Vuc

19

151420

GNDuC

Rlim

Vwarn

3V3_D12V

R

11

C

5

C

10

C

9

12V

R

3

MAINS

Tr

C

8

C

13

U

1

U

2

3V3_D

VDD1V8

R

8

SEN

EXT_CLK_E

Figure 1. Typical Application for the NCN49597S−FSK Modem

Figure 1 shows an S−FSK PLC modem build around

NCN49597. For synchronization the line frequency is

coupled in via a 1 MW resistor. The Schottky diode pair D

5

clamps the voltage within the input range of the zero cross

detector. In the receive path a 2

nd

order high pass filter

blocks the mains frequency. The corner point defined by C

1

,

C

2

, R1 and R2 is designed at 10 kHz. In the transmit path a

3

th

order low pass filter build around the NCS5650 power

operational amplifier suppresses the 2

nd

and 3rd harmonics

to be in line with the CENELEC EN 50065−1 specification.

The filter components are tuned for a space and mark

frequency of 63.3 and 74 kHz respectively. The output of the

amplifier is coupled via a DC blocking capacitor C

10

to a 2:1

pulse transformer Tr. The secondary of this transformer is

coupled to the mains via a high voltage capacitor C

11

. High

energetic transients from the mains are clamped by the

protection diode combination D

3

, D4 together with D1, D2.

Because the mains is not galvanic isolated care needs to be

taken when interfacing to a microcontroller or a PC!

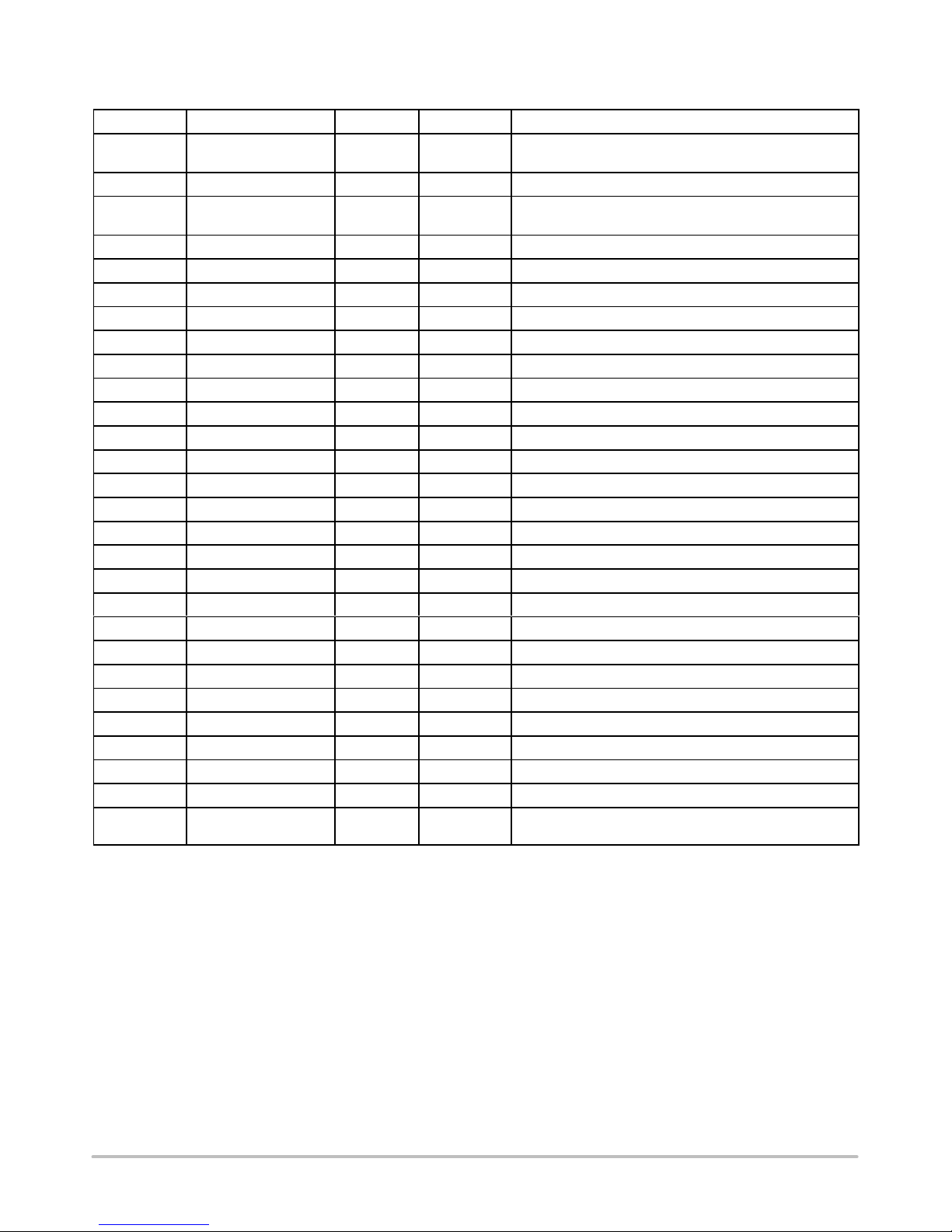

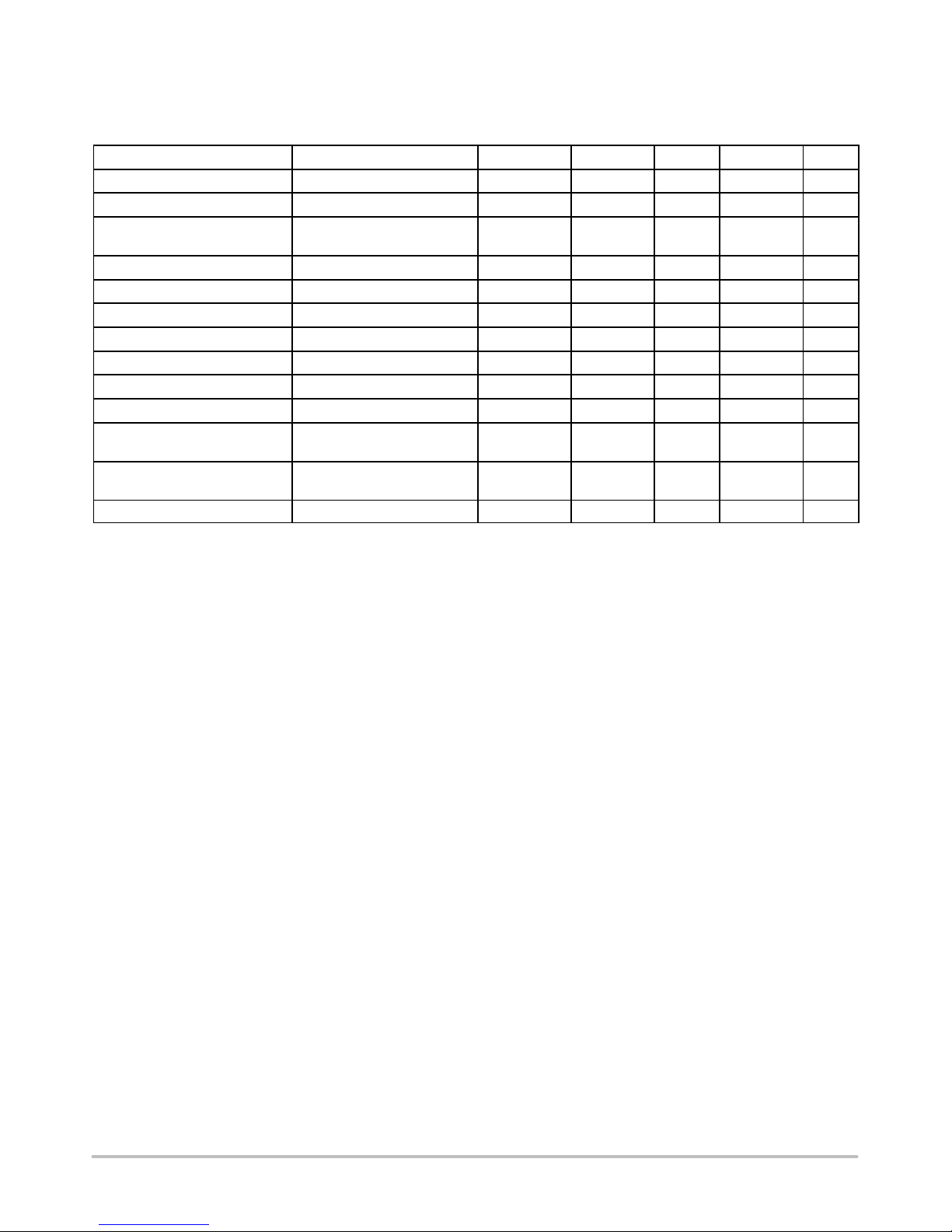

Table 1. EXTERNAL COMPONENTS LIST AND DESCRIPTION

Component Function − Remark Typ Value Tolerance Unit

C1, C

2

High pass receive filter 1.5 ±10% nF

C5, C

DREF

V

REF_OUT

; V

REF_OUT

decoupling cap − ceramic 1 −20 +80%

mF

C7, C9, C16, C

17

Decoupling block capacitor 100 −20 +80% nF

C

3

TX_OUT coupling capacitor 470 ±20% nF

C

4

Low pass transmit filter 470 ±10% pF

C

6

Low pass transmit filter 68 ±10% pF

C

8

Low pass transmit filter 3 ±10% pF

C

10

TX coupling cap; 1 A rms ripple @ 70 kHz 10 ±20%

mF

Page 3

NCN49597

http://onsemi.com

3

Table 1. EXTERNAL COMPONENTS LIST AND DESCRIPTION

Component UnitToleranceTyp ValueFunction − Remark

C

11

High Voltage coupling capacitor; 630 V 220 ±20% nF

C

12

Zero Cross noise suppression 100 ±20% pF

C13, C

14

X−tal load capacitor 22 ±20% pF

C

15

Decoupling block capacitor 1.8 V internal supply 1 −20 +80%

mF

R

1

High pass receive filter 22 ±1%

kW

R

2

High pass receive filter 11 ±1%

kW

R3, R9, R

12,

R

13

High pass receive filter; Alarm current ; Pull up 10 ±1%

kW

R

4

Low pass transmit filter 3,3 ±1%

kW

R

5

Low pass transmit filter 10 ±1%

kW

R

6

Low pass transmit filter 8,2 ±1%

kW

R

7

Low pass transmit filter 500 ±1%

W

R

8

Low pass transmit filter 3 ±1%

kW

R

10

TX Coupling resistor ; 0.5 W 0,47 ±1%

W

R

11

Zero Cross coupling HiV 1 ±5%

MW

D1, D

2

High current Schottky Clamp diodes MBRA430

D3, D

4

TVS diodes P6SMB6.8AT3G

D

5

Double low current Schottky clamp diode BAS70−04

Y1 X−tal 48 MHz

Tr 2:1 Pulse transformer

U1 PLC modem NCN49597

U2 Power Operational Amplifier NCS5650

Table 2. ABSOLUTE MAXIMUM RATINGS

Rating Symbol Min Max Unit

ABSOLUTE MAXIMUM RATINGS SUPPLY

Power Supply Pins VDD, VDDA, VSS, VSSA

Absolute max. digital power supply

V

DD_ABSM

V

SS

− 0.3 3.9 V

Absolute max. analog power supply V

DDA_ABSM

V

SSA

−

0.3

3.9 V

Absolute max. difference between digital and analog power supply V

DD

− V

DDA_ABSM

−0.3 0.3 V

Absolute max. difference between digital and analog ground V

SS

− V

SSA_ABSM

−0.3 0.3 V

ABSOLUTE MAXIMUM RATINGS NON 5V SAFE PINS

Non 5V Safe Pins: TX_OUT, ALC_IN, RX_IN, RX_OUT, REF_OUT, ZC_IN, XIN, XOUT, TDO, TDI, TCK, TMS, TRSTB, TEST

Absolute maximum input for normal digital inputs and analog inputs V

IN_ABSM

V

SS

− 0.3 V

DD

+ 0.3 V

Absolute maximum voltage at any output pin V

OUT_ABSM

V

SS

− 0.3 V

DD

+ 0.3 V

ABSOLUTE MAXIMUM RATINGS 5V SAFE PINS

5V Safe Pins: TX_ENB, TXD, RXD, BR0, BR1, IO3 .. IO11, RESB

Absolute maximum input for digital 5V safe inputs

V

5VS_ABSM

V

SS

− 0.3 6.0 V

Absolute maximum voltage at 5V safe output pin V

OUT5V_ABSM

V

SS

− 0.3 3.9 V

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

Page 4

NCN49597

http://onsemi.com

4

Normal Operating Conditions

Operating ranges define the limits for functional operation and parametric characteristics of the device as described in the

Normal Operating Conditions section and for the reliability specifications as listed in Detailed Hardware Description section.

Functionality outside these limits is not implied.

Total cumulative dwell time outside the normal power supply voltage range or the ambient temperature under bias, must be

less than 0.1% of the useful life as defined in Detailed Hardware Description section.

Table 3. OPERATING RANGES

Rating Symbol Min Max Unit

Power supply voltage range V

DD

3.0 3.6 V

Ambient Temperature T

A

−25 80 °C

Extended Ambient Temperature on special request T

A

−40 80 °C

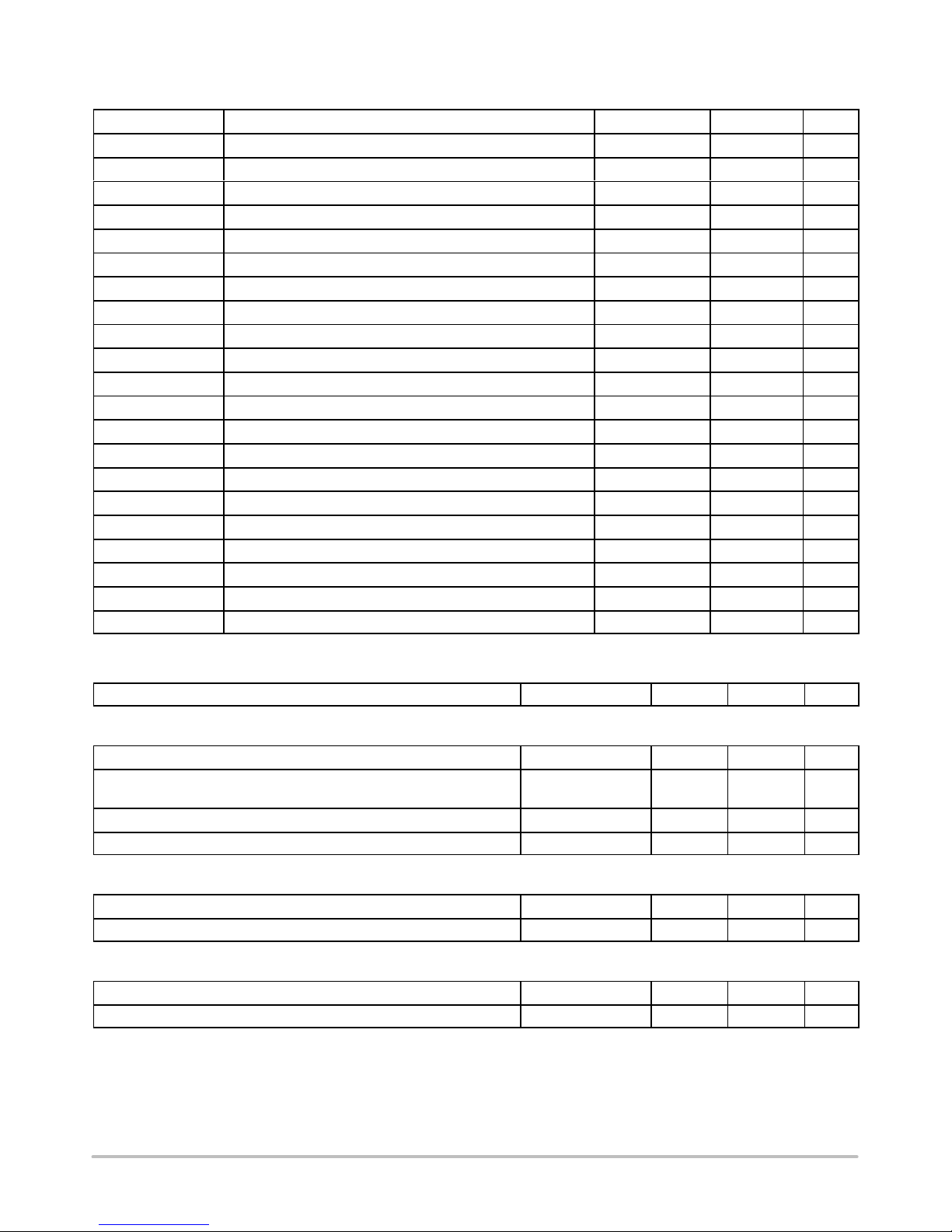

PIN DESCRIPTION

QFN Packaging

AMIS49597

1

2

3

4

5

6

7

8

9

10

11

12

13

26

25

24

23

22

21

20

19

18

17

16

15

14

39

38

37

36

35

34

33

32

31

30

29

28

27

40

41

42

43

44

45

46

47

48

49

50

51

52

NC

REF_O UT

NC

RX_IN

RX_OUT

VSSA

VDDA

NC

NC

ALC_IN

TX_OUT

NC

NC

IO8

IO9

TXD /PRES

XIN

XOUT

VDD 1V8

VSS

VDD

TXD

IO10

RXD

SCK

SDI

IO7

IO6

TMS

TCK

TDI

TDO

IO0/RX_DATA

IO5

IO4

IO3

NC

M50Hz _IN

SDO

CSB

T_REQ

SEN

BR1

BR0

CRC

IO11

TEST

NC

NC

TRST

RES

TX_EN

Figure 2. QFN Pin−out of NCN49597 (Top view)

Table 4. NCN49597QFN PIN FUNCTION DESCRIPTION

Pin No. Pin Name I/O Type Description

1 ZC_IN In A 50/60 Hz input for mains zero cross detection

3..5, 12..15,

23, 34

IO3 .. IO11 In/Out D, 5V Safe General Purpose I/O

6 RX_DATA Out D, 5V Safe Data reception indication (open drain output)

7 TDO Out D, 5V Safe Test data output

8 TDI In D, 5V Safe Test data input (internal pull down)

9 TCK In D, 5V Safe Test clock (internal pull down)

10 TMS In D, 5V Safe Test mode select (internal pull down)

11 TRSTB In D, 5V Safe Test reset bar (internal pull down, active low)

Page 5

NCN49597

http://onsemi.com

5

Table 4. NCN49597QFN PIN FUNCTION DESCRIPTION

Pin No. DescriptionTypeI/OPin Name

16 TXD/PRES Out D, 5V Safe Output of transmitted data (TXD) or PRE_SLOT signal

(PRES)

17 XIN In A Xtal input (can be driven by an internal clock)

18 XOUT Out A Xtal output (output floating when XIN driven by external

clock)

19 VDD1V8 P 1V8 regulator output. Foresee a decoupling capacitor

20 VSS P Digital ground

21 VDD P 3.3V digital supply

22 TXD Out D, 5V Safe SCI transmit output (open drain)

24 RXD In D, 5V Safe SCI receive input (Schmitt trigger output)

25 SCK Out D SPI interface external Flash

26 SDI In D SPI interface external Flash

27 SDO Out D SPI interface external Flash

28 CSB In D SPI interface external Flash

29 T_REQ In D, 5V Safe Transmit Request input

30 SEN In D Boot option

31 BR1 In D, 5V Safe SCI baud rate selection

32 BR0 In D, 5V Safe SCI baud rate selection

33 CRC Out D, 5V Safe Correct frame CRC indication (open drain output)

35 RESB In D, 5V Safe Master reset bar (Schmitt trigger input, active low)

36 TEST In D Hardware Test enable (internal pull down)

37 TX_ENB Out D, 5V Safe TX enable bar (open drain)

42 TX_OUT Out A Transmitter output

43 ALC_IN In A Automatic level control input

46 VDDA P 3.3V analog supply

47 VSSA P Analog ground

48 RX_OUT Out A Output of receiver low noise operational amplifier

49 RX_IN In A Positive input of receiver low noise operational amplifier

51 REF_OUT Out A Reference output for stabilization

2, 38..41, 44,

45,50, 52

NC Pins 2, 38..41, 44, 45, 50, 52 are not connected. These

pins need to be left open or connected to the GND plane.

P: Power pin 5V Safe: IO that support the presence of 5V on bus line

A: Analog pin Out: Output signal

D: Digital pin In: Input signal

Detailed Pin Description

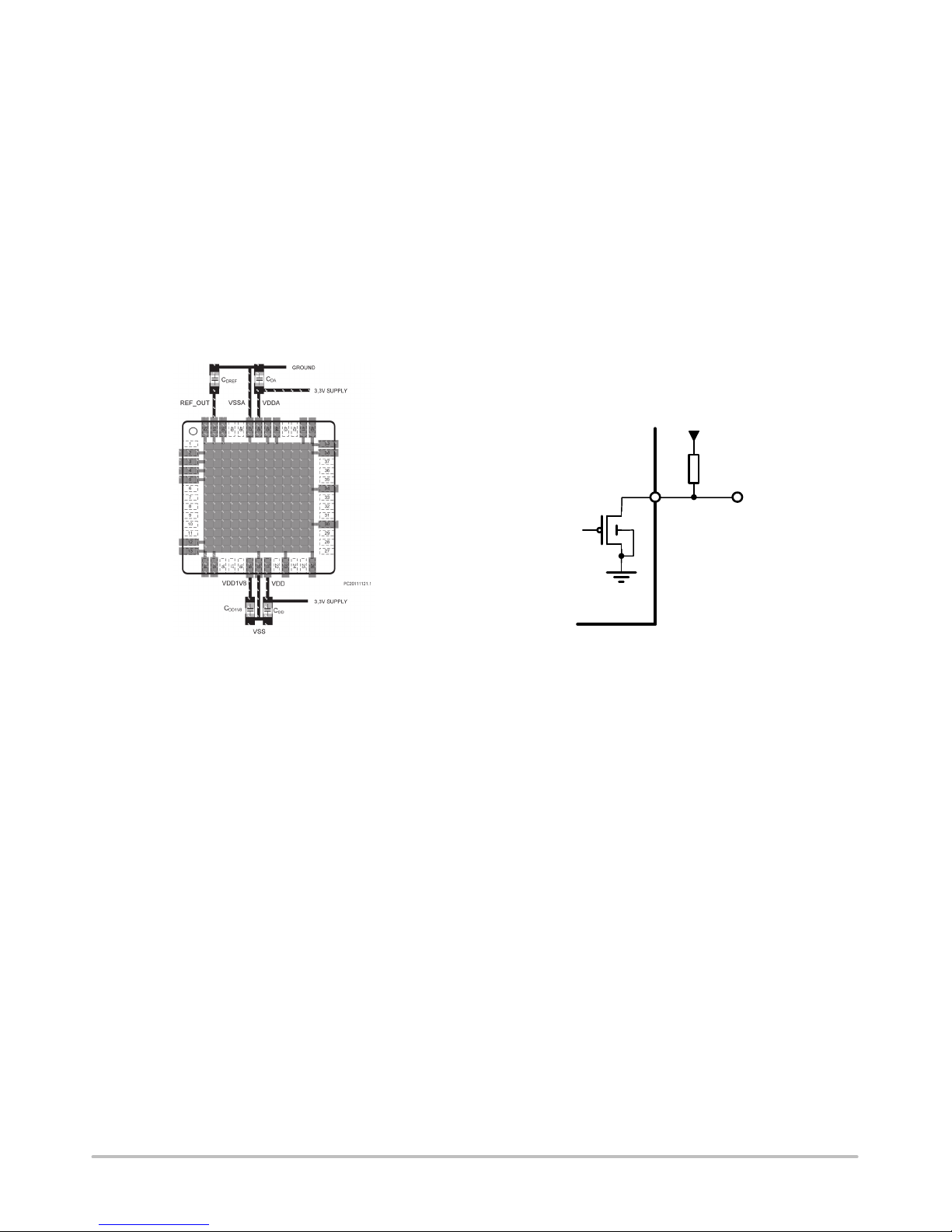

VDDA

VDDA is the positive analog supply pin. Nominal voltage

is 3.3 V. A ceramic decoupling capacitor C

DA

= 100 nF must

be placed between this pin and the VSSA. Connection path

of this capacitance to the VSSA on the PCB should be kept

as short as possible in order to minimize the serial resistance.

REF_OUT

REF_OUT is the analog output pin which provides the

voltage reference used by the A/D converter. This pin must

be decoupled to the analog ground by a 1 mF ceramic

capacitance C

DREF

. The connection path of this capacitor to

Page 6

NCN49597

http://onsemi.com

6

the VSSA on the PCB should be kept as short as possible in

order to minimize the serial resistance.

VSSA

VSSA is the analog ground supply pin.

VDD

VDD is the 3.3 V digital supply pin. A ceramic decoupling

capacitor C

DD

= 100 nF must be placed between this pin and

the VSS. Connection path of this capacitance to the VSS on

the PCB should be kept as short as possible in order to

minimize the serial resistance.

VSS

VSS is the digital ground supply pin.

Figure 3: Recommended Layout of the Placement of

Decoupling Capacitors

VDD1V8

This is an additional power supply pin to decouple an

internal LDO regulator. The decoupling capacitor should be

placed as close as possible to this output pin as illustrated in

Figure 4.

RX_OUT

RX_OUT is the output analog pin of the receiver low

noise input op−amp. This op−amp is in a negative feedback

configuration.

RX_IN

RX_IN is the positive analog input pin of the receiver low

noise input op−amp. Together with RX_OUT and

REF_OUT, an active high pass filter is realized. This filter

removes the main frequency (50 or 60 Hz) from the received

signal. The filter characteristics are determined by external

capacitors and resistors. A typical application schematic can

be found in paragraph 50/60 Hz Suppression Filter.

ZC_IN

ZC_IN is the mains frequency analog input pin. The signal

is used to detect the zero cross of the 50 or 60 Hz sine wave.

This information is used, after filtering with the internal

PLL, to synchronize frames with the mains frequency. In

case of direct connection to the mains it is advised to use a

series resistor of 1 MW in combination with two external

clamp diodes in order to limit the current flowing through

the internal protection diodes.

RX_DATA

RX_DATA is a 5 V compliant open drain output. An

external pull−up resistor defines the logic high level as

illustrated in Figure 4. A typical value for the pull−up

resistance “R” is 10 kW. The signal on this output depends

on the status of the data reception. If NCN49597waits for

configuration RX_DATA outputs a pulse train with a 10 Hz

frequency. After Synchronization Confirm Time out

RX_DATA = 0. If NCN49597is searching for

synchronization RX_DATA = 1.

PC20090722. 2

V

SSD

+5V

Output

R

Figure 4. Representation of 5V Safe Output

TDO, TDI, TCK, TMS, and TRSTB

All these pins are part of the JTAG bus interface. The

JTAG interface is used during production test of the IC and

will not be described here. Input pins (TDI, TCK, TMS, and

TRSTB) contain internal pull−down resistance. TDO is an

output. When not used, the JTAG interface pins may be left

floating.

TXD/PRES

TXD/PRES is the output for either the transmitting data

(TX_DATA) or a synchronization signal with the time−slots

(PRE_SLOT). TXD/PRES. More information can be found

in paragraph Local Port.

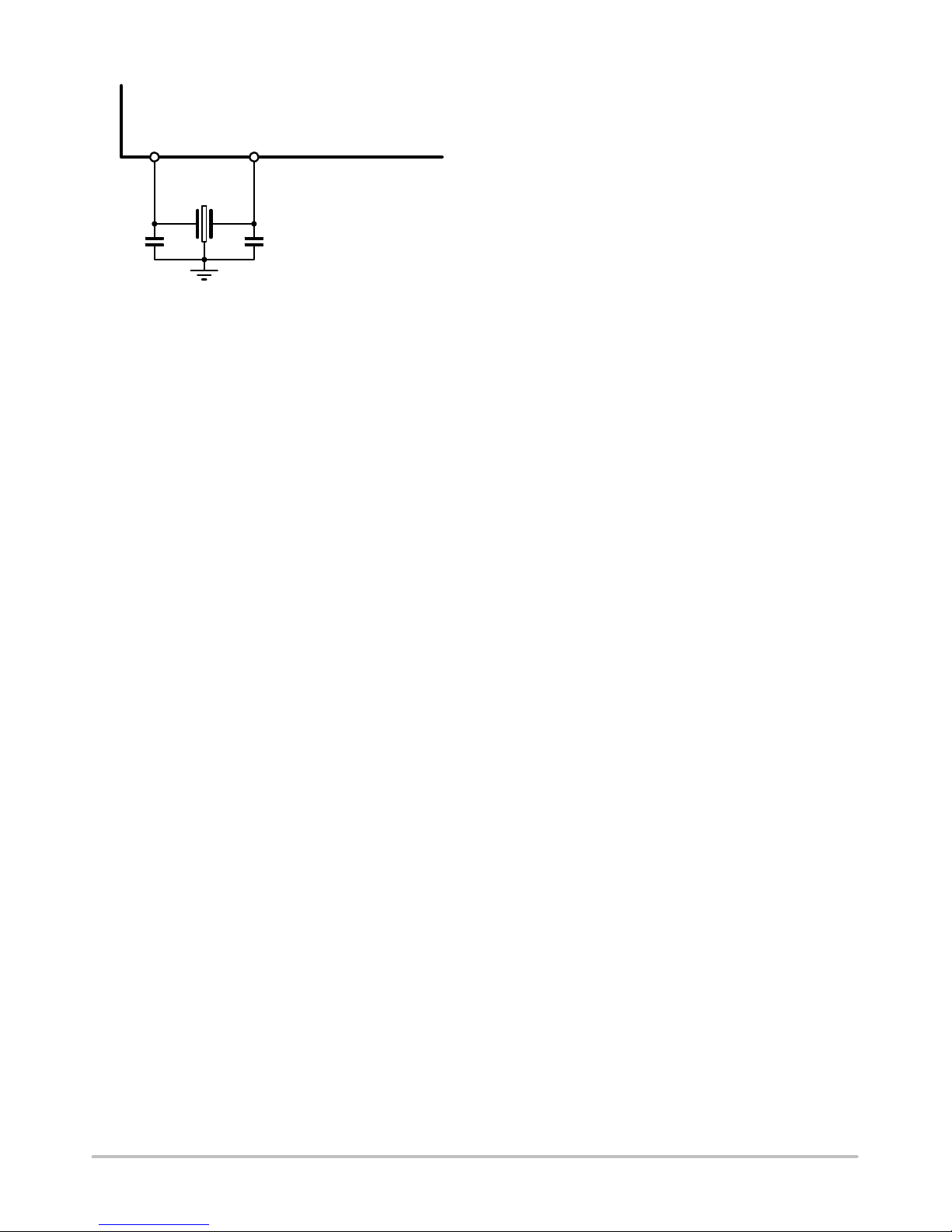

XIN

XIN is the analog input pin of the oscillator. It is connected

to the interval oscillator inverter gain stage. The clock signal

can be created either internally with the external crystal and

two capacitors or by connecting an external clock signal to

XIN. For the internal generation case, the two external

capacitors and crystal are placed as shown in Figure 5. For

the external clock connection, the signal is connected to XIN

and XOUT is left unused.

Page 7

NCN49597

http://onsemi.com

7

XTAL_IN

PC20111118.1

XTAL_OUT

C

X

V

SSA

C

X

48 MHz

Figure 5. Placement of the Capacitors and Crystal

with Clock Signal Generated Internally

The crystal is a classical parallel resonance crystal of

48 MHz. The values of the capacitors C

X

are given by the

manufacturer of the crystal. A typical value is 36 pF. The

crystal has to fulfill impedance characteristics specified in

the NCN49597data sheet. As an oscillator is sensitive and

precise, it is advised to put the crystal as close as possible on

the board and to ground the case.

XOUT

XOUT is the analog output pin of the oscillator. When the

clock signal is provided from an external generator, this

output must be floating. When working with a crystal, this

pin cannot be used directly as clock output because no

additional loading is allowed on the pin (limited voltage

swing).

TXD

TXD is the digital output of the asynchronous serial

communication (SCI) unit. Only half−duplex transmission

is supported. It is used to realize the communication between

the NCN49597and the application microcontroller. The

TXD is an open drain IO (5 V safe). External pull−up

resistances (typically 10 kW) are necessary to generate the

5 V level. See Figure 4 for the circuit schematic.

RXD

This is the digital input of the asynchronous SCI unit.

Only half−duplex transmission is supported. This pin

supports a 5 V level. It is used to realize the communication

between the NCN49597and the application microcontroller.

RXD is a 5 V safe input.

T_REQ

T_REQ is the transmission request input of the Serial

Communication Interface. When pulled low its initiate a

local communication from the application micro controller

to NCN49597. T_REQ is a 5 V safe input. See also

paragraph Error! Reference source not found..

BR1, BR0

BR0 and BR1 are digital input pins. They are used to select

the baud rate (bits/second) of the Serial Communication

Interface unit. The rate is defined according to Error!

Reference source not found.. The values are taken into

account after a reset, hardware or software. Modification of

the baud rate during function is not possible. BR0 and BR1

are 5 V safe.

CRC

CRC is a 5 V compliant open drain output. An external

pull−up resistor defines the logic high level as illustrated in

Figure 4. A typical value for this pull−up resistance “R” is

10 kW. The signal on this output depends on the cyclic

redundancy code result of the received frame. If the cyclic

redundancy code is correct CRC = H during the pause

between two time slots.

RESB

RESB is a digital input pin. It is used to perform a

hardware reset of the NCN49597. This pin supports a 5 V

voltage level. The reset is active when the signal is low

(0 V).

TEST

TEST is a digital input pin with internal pull down resistor

used to enable the Hardware Test Mode of the chip. When

TEST is left open or forced to ground Normal Mode is

enabled. When TEST is forced to VDD the Hardware Test

Mode is enabled. This mode is used during production test

of the IC and will not be described here. TEST pin is not 5 V

safe.

TX_ENB

TX_ENB is a digital output pin. It is low when the

transmitter is activated. The signal is available to turn on the

line driver. TX_ENB is a 5 V safe with open drain output,

hence a pull−up resistance is necessary achieve the

requested voltage level associated with a logical one. See

also Figure 4 for reference.

TX_OUT

TX_OUT is the analog output pin of the transmitter. The

provided signal is the S−FSK modulated frames. A filtering

operation must be performed to reduce the second and third

order harmonic distortion. For this purpose an active filter

is suggested. See also paragraph Transmitter Output

TX_OUT.

ALC_IN

ALC_IN is the automatic level control analog input pin.

The signal is used to adjust the level of the transmitted

signal. The signal level adaptation is based on the AC

component. The DC level on the ALC_IN pin is fixed

internally to 1.65 V. Comparing the peak voltage of the AC

signal with two internal thresholds does the adaptation of the

gain. Low threshold is fixed to 0.4 V. A value under this

threshold will result in an increase of the gain. The high

threshold is fixed to 0.6 V. A value over this threshold will

result in a decrease of the gain. A serial capacitance is used

to block the DC components. The level adaptation is

performed during the transmission of the first two bits of a

new frame. Eight successive adaptations are performed. See

Page 8

NCN49597

http://onsemi.com

8

also paragraph Amplifier with Automatic Level Control

(ALC).

SCK, SDI, SDO, CSB

These signals from the SPI interface to an optional

external Flash. See Reference 1.

ELECTRICAL CHARACTERISTICS

DC and AC Characteristics

Oscillator: Pin XIN, XOUT

In production the actual oscillation of the oscillator and duty cycle will not be tested. The production test will be based on

the static parameters and the inversion from XIN to XOUT in order to guarantee the functionality of the oscillator.

Table 5. OSCILLATOR

Parameter Test Conditions Symbol Min Typ Max Unit

Crystal frequency (Note 1) f

CLK

−100 ppm 48 +100 ppm MHz

Duty cycle with quartz connected (Note 1) 40 60 %

Start−up time (Note 1) T

startup

50 ms

Load capacitance external crystal (Note 1) C

L

18 pF

Series resistance external crystal (Note 1) R

S

20 40 80

W

Maximum Capacitive load on

XOUT

XIN used as clock input CL

XOUT

50 pF

Low input threshold voltage XIN used as clock input VIL

XOUT

0.3 V

DD

V

High input threshold voltage XIN used as clock input VIH

XOUT

0.7 V

DD

V

Low output voltage XIN used as clock input,

XOUT = 2 mA

VOL

XOUT

0.3 V

High input voltage XIN used as clock input VOH

XOUT

V

DD

− 0.3 V

1. Guaranteed by design. Maximum allowed series loss resistance is 80 W

Page 9

NCN49597

http://onsemi.com

9

Zero Cross Detector and 50/60 Hz PLL: Pin ZC_IN

Table 6. ZERO CROSS DETECTOR AND 50/60 HZ PLL

Parameter Test Conditions Symbol Min Typ Max Unit

Maximum peak input current Imp

ZC_IN

−20 20 mA

Maximum average input current During 1 ms Imavg

ZC_IN

−2 2 mA

Mains voltage (ms) range With protection resistor at

ZC_IN

V

MAINS

90 550 V

Rising threshold level (Note 2) VIR

ZC_IN

1.9 V

Falling threshold level (Note 2) VIF

ZC_IN

0.9 V

Hysteresis (Note 2) VHY

ZC_IN

0.4 V

Lock range for 50 Hz (Note 3) MAINS_FREQ = 0 (50 Hz) Flock

50Hz

45 55 Hz

Lock range for 60 Hz (Note 3) MAINS_FREQ = 0 (60 Hz) Flock

60Hz

54 66 Hz

Lock time (Note 3) MAINS_FREQ = 0 (50 Hz) Tlock

50Hz

15 s

Lock time (Note 3) MAINS_FREQ = 0 (60 Hz) Tlock

60Hz

20 s

Frequency variation without going

out of lock (Note 3)

MAINS_FREQ = 0 (50 Hz) DF

60Hz

0.1 Hz/s

Frequency variation without going

out of lock (Note 3)

MAINS_FREQ = 0 (60 Hz) DF

50Hz

0.1 Hz/s

Jitter of CHIP_CLK (Note 3) Jitter

CHIP_CLK

−25 25

ms

2. Measured relative to VSS

3. These parameters will not be measured in production since the performance is totally dependent of a digital circuit which will be guaranteed

by the digital test patterns.

Page 10

NCN49597

http://onsemi.com

10

Transmitter External Parameters: Pin TX_OUT, ALC_IN, TX_ENB

To guarantee the transmitter external specifications the TX_CLK frequency must be 12 MHz ± 100 ppm.

Table 7. TRANSMITTER EXTERNAL PARAMETERS

Parameter Test Conditions Symbol Min Ty p Max Unit

Maximum peak output level f

TX_OUT

= 23 – 75 kHz

f

TX_OUT

= 95 kHz

Level control at max. output

V

TX_OUT

0.85

0.76

1.15

1.22

Vp

Second order harmonic distortion f

TX_OUT

= 95 kHz

Level control at max. output

HD2 −54 dB

Third order harmonic distortion f

TX_OUT

= 95 kHz

Level control at max. output

HD3 −53 dB

Frequency accuracy of the generated sine wave

(Notes 4 and 6) Df

TX_OUT

30 Hz

Capacitive output load at pin

TX_OUT

(Note 4) CL

TX_OUT

20 pF

Resistive output load at pin

TX_OUT

RL

TX_OUT

5

kW

Turn off delay of TX_ENB output (Note 5) Td

TX_ENB

0.25 0.5 ms

Automatic level control attenuation

step

ALC

step

2.9 3.1 dB

Maximum attenuation ALC

range

20.3 21.7 dB

Low threshold level on ALC_IN VTL

ALC_IN

−0.46 −0.36 V

High threshold level on ALC_IN VTH

ALC_IN

−0.68 −0.54 V

Input impedance of ALC_IN pin R

ALC_IN

111 189

kW

Power supply rejection ration of the

transmitter section

PSRR

TX_OUT

10

(Note 7)

35

(Note 8)

dB

4. This parameter will not be tested in production.

5. This delay corresponds to the internal transmit path delay and will be defined during design.

6. Taking into account the resolution of the DDS and an accuracy of 100ppm of the crystal.

7. A sinusoidal signal of 10 kHz and 100 mVpp is injected between VDDA and VSSA. The digital AD converter generates an idle pattern. The

signal level at TX_OUT is measured to determine the parameter.

8. A sinusoidal signal of 50 Hz and 100 mVpp is injected between VDDA and VSSA. The digital AD converter generates an idle pattern. The

signal level at TX_OUT is measured to determine the parameter.

The LPF filter + amplifier must have a frequency characteristic between the limits listed below. The absolute output level

depends on the operating condition. In production the measurement will be done for relative output levels where the 0 dB

reference value is measured at 50 kHz with a signal amplitude of 100 mV.

Table 8. TRANSMITTER FREQUENCY CHARACTERISTICS

Frequency (kHz)

Attenuation

Unit

Min Max

10 −0.5 0.5 dB

95 −1.3 0.5 dB

130 −4.5 −2.0 dB

165 −3.0 dB

330 −18.0 dB

660 −36.0 dB

1000 −50 dB

2000 −50 dB

Page 11

NCN49597

http://onsemi.com

11

Receiver External Parameters: Pin RX_IN, RX_OUT, REF_OUT

Table 9. RECEIVER EXTERNAL PARAMETERS

Parameter Test Conditions Symbol Min Ty p Max Unit

Input offset voltage 42 dB AGC gain = 42 dB V

OFFS_RX_IN

5 mV

Input offset voltage 0 dB AGC gain = 0 dB V

OFFS_RX_IN

50 mV

Max. peak input voltage (corresponding to 62.5% of the SD full

scale)

AGC gain = 0 dB (Note 9) V

MAX_RX_IN

0.85 1.15 Vp

Input referred noise of the analog

receiver path

AGC gain = 42 dB

(Notes 9 and 10)

NF

RX_IN

150 nV/ǠHz

Input leakage current of receiver

input

I

LE_RX_IN

−1 1

mA

Max. current delivered by

REF_OUT

I

Max_REF_OUT

−300 300 mA

Power supply rejection ratio of the

receiver input section

AGC gain = 42 dB (Note 11)

PSRR

LPF_OUT

10 dB

AGC gain = 42 dB (Note 12) 35

AGC gain step AGC

step

5.7 6.3 dB

AGC range AGC

range

39.9 44.1 dB

Analog ground reference output

voltage

V

REF_OUT

1.52 1.78 V

Signal to noise ratio at 62.5 % of

the SD full scale

(Notes 9 and 13) SN

AD_OUT

54 dB

Clipping level at the output of the

gain stage (RX_OUT)

V

CLIP_AGC_IN

1.15 1.65 Vp

9. Input at RX_IN, no other external components.

10.Characterization data only. Not tested in production.

11.A sinusoidal signal of 10 kHz and 100 mVpp is injected between VDDA and VSSA. The signal level at the differential LPF_OUT and

REF_OUT output is measured to determine the parameter.

12.A sinusoidal signal of 50 Hz and 100 mVpp is injected between VDDA and VSSA. The signal level at the differential LPF_OUT output is

measured to determine the parameter.

13.These parameters will be tested in production with an input signal of 95 kHz and 1 Vp by reading out the digital samples at the point AD_OUT

with the default settings of T_RX_MOD[7], SDMOD_TYP, DEC_TYP, and COR_F_ENA. The AGC gain is switched to 0 dB.

The receive LPF filter + AGC + low noise amplifier must have a frequency characteristic between the limits listed below.

The absolute output level depends on the operating condition.

Table 10. RECEIVER FREQUENCY CHARACTERISTICS

Frequency (kHz)

Attenuation

Unit

Min Max

10 −0.5 0.5 dB

95 −1.3 0.5 dB

130 −4.5 −2.0 dB

165 −3.0 dB

330 −18.0 dB

660 −36.0 dB

1000 −50 dB

2000 −55 dB

Page 12

NCN49597

http://onsemi.com

12

Power−on−Reset (POR)

Table 11. POWER−ON−RESET

Parameter Test Conditions Symbol Min Ty p Max Unit

POR threshold V

POR

1.7 2.7 V

Power supply rise time 0 to 3V T

RPOR

1 ms

Digital Outputs: TDO, CLK_OUT

Table 12. DIGITAL OUTPUTS: TDO, CLK_OUT

Parameter Test Conditions Symbol Min Ty p Max Unit

Low output voltage I

XOUT

= 4 mA V

OL

0.4 V

High output voltage I

XOUT

= −4 mA V

OH

0.85 V

DD

V

Digital Outputs with Open Drain: TX_ENB, TXD

Table 13. DIGITAL OUTPUTS WITH OPEN DRAIN: TX_ENB, TXD, RX_DATA, CRC, T_REQ

Parameter Test Conditions Symbol Min Ty p Max Unit

Low output voltage I

XOUT

= 4 mA V

OL

0.4 V

Digital Inputs: BR0, BR1

Table 14. DIGITAL INPUTS: BR0, BR1

Parameter Test Conditions Symbol Min Ty p Max Unit

Low input level V

IL

0.2 V

DD

V

High input level 0 to 3 V V

IH

0.8 V

DD

V

Input leakage current I

LEAK

−10 10

mA

Digital Inputs with Pull Down: TDI, TMS, TCK, TRSTB, TEST

Table 15. DIGITAL INPUTS WITH PULL DOWN: TDI, TMS, TCK, TRSTB, TEST

Parameter Test Conditions Symbol Min Ty p Max Unit

Low input level V

IL

0.2 V

DD

V

High input level V

IH

0.8 V

DD

V

Pull down resistor (Note 14) R

PU

7 50

kW

14.Measured around a bias point of VDD/2.

Digital Schmitt Trigger Inputs: RXD, RESB

Table 16. DIGITAL SCHMITT TRIGGER INPUTS: RXD, RESB

Parameter Test Conditions Symbol Min Ty p Max Unit

Rising threshold level V

T+

0.80 V

DD

V

Falling threshold level V

T−

0.2 V

DD

V

Input leakage current I

LEAK

−10 10

mA

Page 13

NCN49597

http://onsemi.com

13

Current Consumption

Table 17. CURRENT CONSUMPTION

Parameter Test Conditions Symbol Min Ty p Max Unit

Current consumption in receive

mode

Current through V

DD

and V

DDA

(Note 15)

I

RX

60 80 mA

Current consumption in transmit

mode

Current through V

DD

and V

DDA

(Note 15)

I

TX

60 80 mA

Current consumption when RESB

= 0

Current through V

DD

and V

DDA

(Note 15)

I

RESET

4 mA

15.f

CLK

= 48 MHz.

INTRODUCTION

General Description

The NCN49597 is a single chip half duplex S−FSK

modem dedicated to power line carrier (PLC) data

transmission on low− or medium−voltage power lines. The

device offers complete handling of the protocol layers from

the physical up to the MAC. NCN49597 complies with the

CENELEC EMC standard EN 50065−1 and the

IEC 61334−5−1 standards. It operates from a single 3.3 V

power supply and is interfaced to the power line by an

external power driver and transformer. An internal PLL is

locked to the mains frequency and is used to synchronize the

data transmission at data rates of 300, 600, 1200, 2400 and

4800 baud for a 50 Hz mains frequency, or 360, 720, 1440,

2880 and 5760 baud for a 60 Hz mains frequency. In both

cases this corresponds to 3, 6, 12 or 24 data bits per half cycle

of the mains period.

S−FSK is a modulation and demodulation technique that

combines some of the advantages of a classical spread

spectrum system (e.g. immunity against narrow band

interferers) with the advantages of the classical FSK system

(low complexity). The transmitter assigns the space

frequency f

S to “data 0” and the mark frequency fM to

“data 1”. The difference between S−FSK and the classical

FSK lies in the fact that f

S and fM are now placed far from

each other, making their transmission quality independent

from each other (the strengths of the small interferences and

the signal attenuation are both independent at the two

frequencies). The frequency pairs supported by the

NCN49597 are in the range of 9 − 150 kHz with a typical

separation of 10 kHz.

The conditioning and conversion of the signal is

performed at the analog front−end of the circuit. The further

processing of the signal and the handling of the protocol is

digital. At the back−end side, the interface to the application

is done through a serial interface. The digital processing of

the signal is partitioned between hardwired blocks and a

microprocessor block. The microprocessor is controlled by

firmware. Where timing is most critical, the functions are

implemented with dedicated hardware. For the functions

where the timing is less critical, typically the higher level

functions, the circuit makes use of the ARM microprocessor

core.

The processor runs DSP algorithms and, at the same time,

handles the communication protocol. The communication

protocol, in this application, contains the MAC = Medium

Access Control Layer. The program running on the

microprocessor is stored into ROM. The working data

necessary for the processing is stored in an internal RAM. At

the back−end side the link to the application hardware is

provided by a Serial Communication Interface (SCI). The

SCI is an easy to use serial interface, which allows

communication between an external processor used for the

application software and the NCN49597 modem. The SCI

works on two wires: TXD and RXD. Baud rate is

programmed by setting 2 bits (BR0, BR1).

Because the low protocol layers are handled in the circuit,

the NCN49597 provides an innovative architectural split.

Thanks to this, the user has the benefit of a higher level

interface of the link to the PLC medium. Compared to an

interface at the physical level, the NCN49597 allows faster

development of applications. The user just needs to send the

raw data to the NCN49597 and no longer has to take care of

the protocol detail of the transmission over the specific

medium. This last part represents usually 50% of the

software development costs.

Page 14

NCN49597

http://onsemi.com

14

Minor User TypeMajor User Type

PC 201111 12 .2

SPY

Application

NCN49597in

MONITOR mode

TEST

Application

NCN49597in

TEST mode

CLIENT

Application

NCN49597in

MASTER mode

SERVER

Application

NCN49597in

SLAVE mode

SERVER

Application

NCN49597in

SLAVE mode

Figure 6. Application Examples

NCN49597 is intended to connect equipment using

Distribution Line Carrier (DLC) communication. It serves

two major and two minor types of applications:

• Major types:

♦ Master or Client:

A Master is a client to the data served by one or

many slaves on the power line. It collects data from

and controls the slave devices. A typical application

is a concentrator system

♦ Slave or Server:

A Slave is a server of the data to the Master. A

typical application is an electricity meter equipped

with a PLC modem.

• Minor type:

♦ Spy or Monitor:

Spy or Monitor mode is used to only listen to the

data that comes across the power line. Only the

physical layer frame correctness is checked. When

the frame is correct, it is passed to the external

processor.

♦ Test Mode:

The Software Test Mode is used to test the

compliance of a PLC modem conforms to

CENELEC. EN 50065−1 by a continuous broadcast

of f

S

or fM.

Page 15

NCN49597

http://onsemi.com

15

Functional Description

The block diagram below represents the main functional units of the NCN49597:

Communication Controller

ARM

Risc

Core

Serial

Comm.

Interface

Local Port

Test

Control

POR

Watchdog

Timer 1 & 2

SPI

Interrupt

Control

Data

RAM

Program

ROM

AAF AGC A/D

REF

S−FSK

Demodulator

Receiver (S−FSK Demodulator)

Clock and Control

Zero

crossing

PLL OSC

Clock Generator

& Timer

Transmit Data

& Sine Synthesizer

D/A

LP

Filter

Transmitter (S−FSK Modulator)

RX_DATA

RESB

JTAG I/F

TEST

TX_ENB

TX_OUT

ALC_IN

RX_OUT

RX_IN

REF_OUT

M50Hz_IN

XIN XOUTVDDA VSSA VDDD VSSD

NCN49597

PC20111019.2

TO Power Amplifier

FROM Line Coupler

TO Application

Micro Controller

TxD

RxD

T_REQ

BR0

BR1

CRC

TX_DATA / PRE _SLOT

5

VDD1V8

IO[9:3]

5

SPI I/F

5

Figure 7. S−FSK Modem NCN49597 Block Diagram

Transmitter

The NCN49597 Transmitter function block prepares the

communication signal which will be sent on the

transmission channel during the transmitting phase. This

block is connected to a power amplifier which injects the

output signal on the mains through a line−coupler.

Receiver

The analog signal coming from the line−coupler is low

pass filtered in order to avoid aliasing during the conversion.

Then the level of the signal is automatically adapted by an

automatic gain control (AGC) block. This operation

maximizes the dynamic range of the incoming signal. The

signal is then converted to its digital representation using

sigma delta modulation. From then on, the processing of the

data is done in a digital way. By using dedicated hardware,

a direct quadrature demodulation is performed. The signal

demodulated in the base band is then low pass filtered to

reduce the noise and reject the image spectrum.

Clock and Control

According to the IEC 61334−5−1 standard, the frame data

is transmitted at the zero cross of the mains voltage. In order

to recover the information at the zero cross, a zero cross

detection of the mains is performed. A phase−locked loop

(PLL) structure is used in order to allow a more reliable

reconstruction of the synchronization. This PLL permits as

well a safer implementation of the ”repetition with credit”

function (also known as chorus transmission). The clock

generator makes use of a precise quartz oscillator master.

The clock signals are then obtained by the use of a

programmed division scheme. The support circuits are also

contained in this block. The support circuits include the

necessary blocks to supply the references voltages for the

AD and DA converters, the biasing currents and power

supply sense cells to generate the right power off and startup

conditions.

Page 16

NCN49597

http://onsemi.com

16

48 bit @ 2400 baud

20 ms

t

PC20100609.1

Figure 8. Data Stream is in Sync with Zero Cross of the Mains (example for 50 Hz)

Communication Controller

The Communication Controller block includes the

micro−processor, its peripherals: RAM, ROM, UART,

TIMER, and the Power on reset. The processor uses the

ARM Reduced Instruction Set Computer (RISC)

architecture optimized for IO handling. For most of the

instructions, the machine is able to perform one instruction

per clock cycle. The microcontroller contains the necessary

hardware to implement interrupt mechanisms, timers and is

able to perform byte multiplication over one instruction

cycle. The microcontroller is programmed to handle the

physical layer (chip synchronization), and the MAC layer

conform to IEC 61334−5−1. The program is stored in a

masked ROM. The RAM contains the necessary space to

store the working data. The back−end interface is done

through the Serial Communication Interface block. This

back−end is used for data transmission with the application

micro controller (containing the application layer for

concentrator, power meter, or other functions) and for the

definition of the modem configuration.

Local Port

The controller uses 3 output ports to inform about the

actual status of the PLC communication. RX_DATA

indicates if Receiving is in progress, or if NCN49597 is

waiting for synchronization, or of it configures. CRC

indicates if the received frames are valid (CRC = OK).

TXD/PRES is the output for either the transmitting data

(TX_DATA) or a synchronization signal with the time−slots

(PRE_SLOT).

Serial Communication Interface

The local communication is a half duplex asynchronous

serial link using a receiving input (RxD) and a transmitting

output (TxD). The input port T_REQ is used to manage the

local communication with the application micro controller

and the baud rate can be selected depending on the status of

two inputs BR0, BR1. These two inputs are taken in account

after an NCN49597 reset. Thus when the application micro

controller wants to change the baud rate, it has to set the two

inputs and then provoke a reset.

DETAILED HARDWARE DESCRIPTION

Clock and Control

According to the IEC 61334−5−1 standard, the frame data

is transmitted at the zero cross of the mains voltage. In order

to recover the information at the zero cross, a zero cross

detection of the mains is performed. A phase−locked loop

(PLL) structure is used in order to allow a more reliable

reconstruction of the synchronization. The output of this

block is the clock signal CHIP_CLK, 8 times over sampled

with the bit rate. The oscillator makes use of precise 48 MHz

quartz. This clock signal together with CHIP_CLK is fed

into the Clock Generator and time block. Here several

internal clock signals and timings are obtained by the use of

a programmed division scheme.

Page 17

NCN49597

http://onsemi.com

17

Clock and Control

Zero

crossing

PLL OSC

Clock Generator

& Timer

ZC_IN

XIN XOUT

PC20090619.4

BIT_CLK

BYTE_CLK

FRAME_CLK

PRE_BYTE_CLK

PRE_FRAME_CLK

PRE_SLOT

CHIP_CLK

Figure 9. Clock and Control Block

Zero Cross Detector

ZC_IN is the mains frequency analog input pin. The signal

is used to detect the zero cross of the 50 or 60 Hz sine wave.

This information is used, after filtering with the internal

PLL, to synchronize frames with the mains frequency. In

case of direct connection to the mains it is advised to use a

series resistor of 1 MW in combination with two external

Schottky clamp diodes in order to limit the current flowing

through the internal protection diodes.

FROM

MAINS

Clock & Control

ZC_IN

ZeroCross

PLL

CHIP_CLK

Debounce

Filter

3V3_A

1MW

PC20100608.1

100 pF

BAS70−04

Figure 10. Zero Cross Detector with Falling Edge De−bounce Filter

The zero cross detector output is logic zero when the input

is lower than the falling threshold level and a logic one when

the input is higher than the rising threshold level. The falling

edges of the output of the zero cross detector are de−bounced

by a period between 0.5 ms and 1 ms. The Rising edges are

not de−bounced.

Page 18

NCN49597

http://onsemi.com

18

t

10 ms

V

MAINS

ZeroCross

t

ZCD

VIR

ZC_ IN

PC20090620 .1

VIF

ZC_ IN

t

DEBOUNCE

= 0,5 .. 1 ms

Figure 11. Zero Cross Detector Signals and Timing (example for 50 Hz)

50/60 Hz PLL

The output of the zero cross detector is used as an input for

a PLL. The PLL generates the clock CHIP_CLK which is 8

times the bit rate and which is in phase with the rising edge

crossings. The PLL locks on the zero cross from negative to

positive phase. The bit rate is always an even multiple of the

mains frequency, so following combinations are possible:

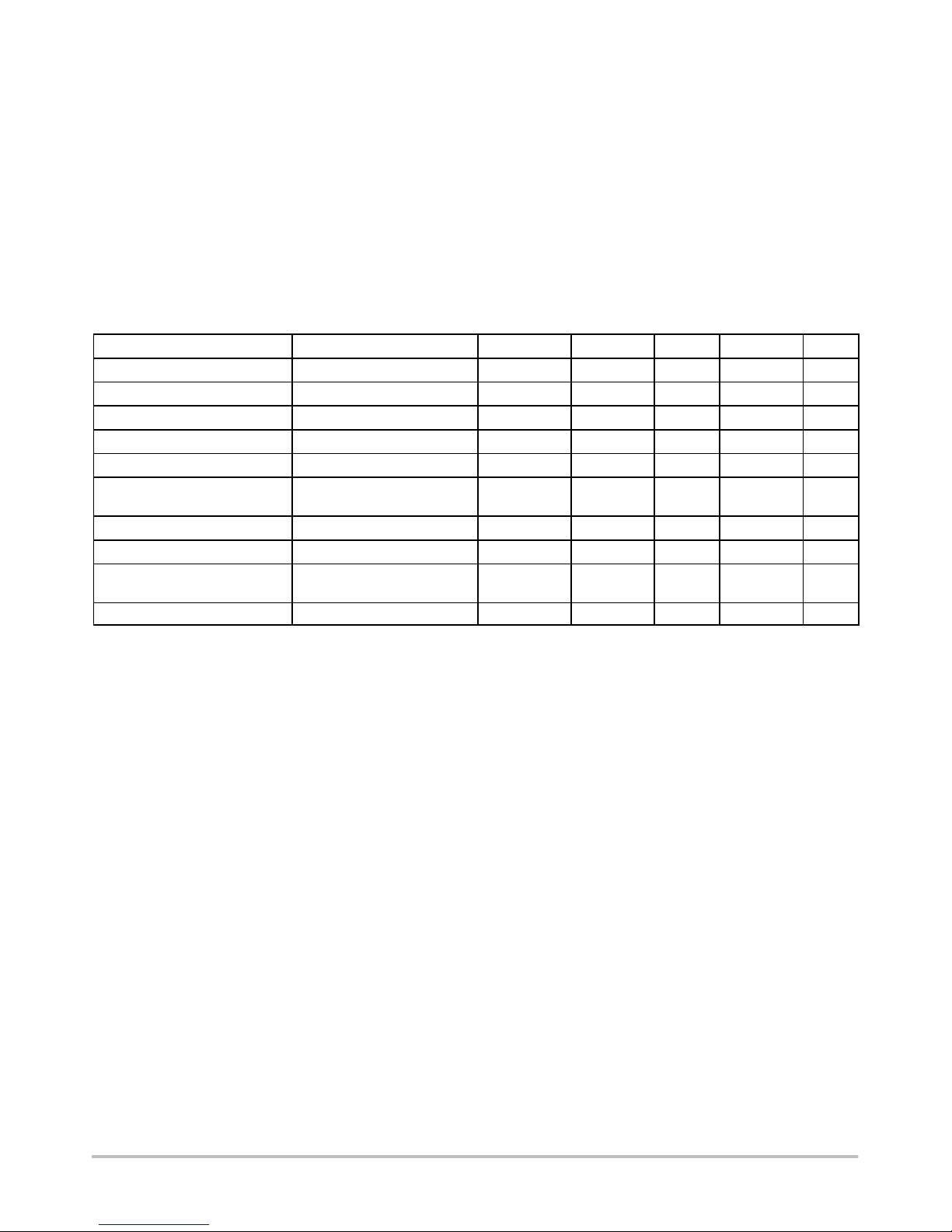

Table 18. CHIP_CLK IN FUNCTION OF SELECTED BAUD RATE AND MAINS FREQUENCY

BAUD[1:0] MAINS_FREQ Baudrate CHIP_CLK

00

50 Hz

300 2400 Hz

01 600 4800 Hz

10 1200 9600 Hz

11 2400 19200 Hz

00

60 Hz

360 2880 Hz

01 720 5760 Hz

10 1440 11520 Hz

11 2880 23040 Hz

In case no zero crossings are detected the PLL freezes its internal timers in order to maintain the CHIP_CLK timing.

Page 19

NCN49597

http://onsemi.com

19

6 bit @ 300 baud

t

10 ms

V

MAINS

ZeroCross

t

ZCD

VIR

ZC _IN

CHIP _CLK

PC 20090 619 .3

PLL in lock

Start of Physical PreFrame (*)

*The start of the Physical Subframe is shifted back with R_ZC_ADJUST[7:0] x 26 mS = t

ZCD

to compensate for the zero cross delay.

Figure 12. Zero Cross Adjustment to Compensate for Zero Cross Delay (example for 50 Hz)

The phase difference between the zero cross of the mains

and CHIP_CLK can be tuned. This opens the possibility to

compensate for external delay t

ZCD

(e.g. opto coupler) and

for the 1.9 V positive threshold VIR

ZC_IN

of the zero cross

detector. This is done by pre−loading the PLL counter with

a number value stored in register R_ZC_ADJUST[7:0]. The

adjustment period or granularity is 26 ms. The maximum

adjustment is 255 x 26 ms = 6.6 ms which corresponds with

1/3rd of the 50 Hz mains sine period.

Table 19. ZERO CROSS DELAY COMPENSATION

R_ZC_ADJUST[7:0] Compensation

0000 0000

0 ms

0000 0001

26 ms

0000 0010

52 ms

0000 0011

78 ms

… …

1111 11 0 1

6589 ms

1111 111 0

6615 ms

1111 1111

6641 ms

Oscillator

The oscillator works with a standard parallel resonance

crystal of 48 MHz. XIN is the input to the oscillator inverter

gain stage and XOUT is the output.

Page 20

NCN49597

http://onsemi.com

20

XTAL_IN

PC20111118.1

XTAL_OUT

C

X

V

SSA

C

X

48 MHz

Figure 13. Placement of the Capacitors and Crystal

with Clock Signal Generated Internally

For correct functionality the external circuit illustrated in

Figure 13 must be connected to the oscillator pins. For a

crystal requiring a parallel capacitance of 18 pF C

X

must be

around 36 pF. (Values of capacitors are indicative only and

are given by the crystal manufacturer). To guarantee startup

the series loss resistance of the crystal must be smaller than

60 W.

The oscillator output f

CLK

= 48 MHz is the base frequency

for the complete IC. The clock frequency for the ARM f

ARM

= f

CLK.

The clock for the transmitter, f

TX_CLK

is equal to

f

CLK

/ 4 or 12 MHz. All the transmitter internal clock signals

will be derived from f

TX_CLK

. The clock for the receiver,

f

RX_CLK

is equal to f

CLK

/ 8 or 6 MHz. All the receiver

internal clock signals will be derived from f

RX_CLK.

Clock Generator and Timer

The CHIP_CLK and f

CLK

are used to generate a number

of timing signals used for the synchronization and interrupt

generation. The timing generation has a fixed repetition rate

which corresponds to the length of a physical subframe. (see

paragraph Error! Reference source not found.)

The timing generator is the same for transmit and receive

mode. When NCN49597 switches from receive to transmit

and back from transmit to receive, the R_CHIP_CNT

counter value is maintained. As a result all timing signals for

receive and transmit have the same relative timing. The

following timing signals are defined as:

BIT_CLK

63 64 652871 2872 102879 2 3 4 5 6 7 8 9

CHIP_CLK

BYTE_CLK

FRAME_CLK

PRE_FRAME_CLK

PRE_BYTE_CLK

R_CHIP_CNT

PRE_SLOT

PC20090619.1

Start of the physical subframe

Figure 14. Timing Signals

CHIP_CLK: is the output of the PLL and 8 times the bit rate

on the physical interface. See also paragraph 50/60 Hz PLL.

BIT_CLK: is active at counter values 0, 8, 16, .. 2872 and

inactive at all other counter values. This signal is used to

indicate the transmission of a new bit.

BYTE_CLK: is active at counter values 0, 64, 128, .. 2816

and inactive at all other counter values. This signal is used

to indicate the transmission of a new byte.

Page 21

NCN49597

http://onsemi.com

21

FRAME_CLK: is active at counter values 0 and inactive at

all other counter values. This signal is used to indicate the

transmission or reception of a new frame.

PRE_BYTE_CLK is a signal which is 8 CHIP_CLK

sooner than BYTE_CLK. This signal is used as an interrupt

for the internal microcontroller and indicates that a new byte

for transmission must be generated.

PRE_FRAME_CLK is a signal which is 8 CHIP_CLK

sooner than FRAME_CLK. This signal is used as an

interrupt for the internal microcontroller and indicates that

a new frame will start at the next FRAME_CLK.

PRE_SLOT is logic 1 between the rising edge of

PRE_FRAME_CLK and the rising edge of FRAME_CLK.

This signal can be provided at the digital output pin

TXD/PRES when R_CONF[7] = 0 (See paragraph Local

Port and Error! Reference source not found., field

R_CONF_TXD_PRES_SEL) and can be used by the external

host controller to synchronize its software with the

FRAME_CLK of NCN49597.

Transmitter Path Description (S−FSK Modulator)

For the generation of the space and mark frequencies, the

direct digital synthesis (DDS) of the sine wave signals is

performed under the control of the microprocessor. After a

signal conditioning step, a digital to analog conversion is

performed. As for the receive path, a sigma delta modulation

technique is used. In the analog domain, the signal is low

pass filtered, in order to remove the high frequency

quantization noise, and passed to the automatic level

controller (ALC) block, where the level of the transmitted

signal can be adjusted. The determination of the signal level

is done through the sense circuitry.

Transmitter(S−FSK Modulator)

PC20091019.1

ARM

Interface

&

Control

TX_OUT

Transmit Data

& Sine Synthesizer

D/A

LP

Filter

ALC

control

ALC_IN

TO RECEIVER

f

MIfMQfSIfSQ

TX_EN

Figure 15. Transmitter Block Diagram

ARM Interface and Control

The interface with the ARM consists in a 8−bit data

registers R_TX_DATA, 2 control registers R_TX_CTRL

and R_ALC_CTRL, a flag TX_RXB defining transmit and

receive and 2 16−bit wide frequency step registers R_FM

and R_FS defining f

M

(mark frequency = data 1) and f

S

(space frequency = data 0). All these registers are memory

mapped. Some of them are for internal use only and cannot

be accessed by the user.

Processing of the physical frame (preamble, MAC

address, CRC) is done by the ARM.

Sine Wave Generator

A sine wave is generated with a direct digital synthesizer

DDS. The synthesizer generates in transmission mode a sine

wave either for the space frequency (f

S

, data 0) or for the

mark frequency (f

M

, data1). In reception the synthesizer

generates the sine and cosine waves for the mixing process,

f

SI

, fSQ, fMI, fMQ (space and mark signals in phase and

quadrature). The space and mark frequencies are defined in

an individual step 16 bit wide register.

Table 20. FS AND FM STEP REGISTERS

ARM Register Hard Reset Soft Reset Description

R_FS[15:0] 0000h 0000h Step register for the space frequency f

S

R_FM[15:0] 0000h 0000h Step register for the mark frequency f

M

Page 22

NCN49597

http://onsemi.com

22

The space and mark frequency can be calculated as:

• f

S

= R_FS[15:0]_dec x f

DDS

/2

18

• f

M

= R_FM[15:0]_dec x f

DDS

/2

18

Or the content of both R_FS[15:0] and R_FM[15:0] are

defined as:

• R_FS[15:0]_dec = Round(2

18

x fS/f

DDS

)

• R_FM[15:0]_dec = Round(2

18

x fM/f

DDS

)

♦ Where f

DDS

= 3 MHz is the direct digital

synthesizer clock frequency.

After a hard or soft reset or at the start of the transmission

(when TX_RXB goes from 0 to 1) the phase accumulator

must start at it’s 0 phase position, corresponding with a 0 V

output level. When switching between f

M

and fS the phase

accumulator must give a continuous phase and not restart

from phase 0

When NCN49597 goes into receive mode (when

TX_RXB goes from 1 to 0) the sine wave generator must

make sure to complete the active sine period.

The control logic for the transmitter generates a signal

TX_ENB to enable the external power amplifier. TX_ENB

is 1 when the NCN49597 is in receive mode. TX_ENB is 0

when NCN49597is in transmit mode. When going from

transmit to receive mode (TX_RXB goes from 1 to 0) the

TX_ENB signal is kept active for a short period of t

dTX_ENB

.

The control logic for the transmitter generates a signal

TX_DATA which corresponds to the transmitted S−FSK

signal. When transmitting f

M

TX_DATA is logic 1. When

transmitting f

S

TX_DATA is logic 0. When the transmitter

is not enabled (TX_RXB = 0) TX_DATA goes to logic 1 at

the next BIT_CLK.

PC20090610.1

TX_DATA

TX_RXB

t

dTX_ENB

BIT_CLK

TX_ENB

TX_OUT

Figure 16. TX_ENB Timing

DA Converter

A digital to analog SD converter converts the sine wave

digital word to a pulse density modulated (PDM) signal. The

PDM signal is converted to an analog signal with a first order

switched capacitor filter.

Low Pass Filter

A 3rd order continuous time low pass filter in the transmit

path filters the quantization noise and noise generated by the

ΣΔ DA converter. The typical corner frequency f

−3dB

= 138

kHz and is internally trimmed to compensate for process

variation. This filter can be tuned to f

−3dB

= 1508 kHz as

described in reference [1].

Amplifier with Automatic Level Control (ALC)

The pin ALC_IN is used for level control of the

transmitter output level. First peak detection is done. The

peak value is compared to two thresholds levels:

VTL

ALC_IN

and VTH

ALC_IN

. The result of the peak

detection is used to control the setting of the level of

TX_OUT. The level of TX_OUT can be attenuated in 8 steps

of 3 dB typical.

After hard or soft reset the level is set at minimum level

(maximum attenuation) When going to reception mode

(when TX_RXB goes from 1 to 0) the level is kept in

memory so that the next transmit frame starts with the old

level. The evaluation of the level is done during 1

CHIP_CLK period.

Depending on the value of peak level on ALC_IN the

attenuation is updated:

• Vp

ALC_IN

< VTL

ALC

: increase the level with one 6 dB

step

• VTL

ALC

≤ Vp

ALC_IN

≤ VTH

ALC

: don’t change the

level

• Vp

ALC_IN

> VTH

ALC

: decrease the level with one 6 dB

step

Page 23

NCN49597

http://onsemi.com

23

The gain changes in the next CHIP_CLK period.

An evaluation phase and a level adjustment take 2

CHIP_CLK periods. ALC operation is enabled only during

the first 16 CHIP_CLK cycles after a hard or soft reset or

after going into transmit mode.

The automatic level control can be disabled by setting

register R_ALC_CTRL[3] = 1. In this case the transmitter

output level is fixed to the programmed level in the register

R_ALC_CTRL[2:0]. See Reference 1.

Table 21. FIXED TRANSMITTER OUTPUT ATTENUATION

ALC_CTRL[2:0] Attenuation

000 0 dB

001 −3 dB

010 −6 dB

011 −9 dB

100 −12 dB

101 −15 dB

110 −18 dB

111 −21 dB

Remark:

Transmitter Output TX_OUT

The transmitter output is DC coupled to the TX_OUT pin.

Because the complete analog part of NCN49597 is

referenced to the analogue ground REF_OUT, a decoupling

capacitor C

1

is needed when connecting NCN49597 to

external circuitry working with another ground. To suppress

the second and third order harmonic of the generated S−FSK

signal it is recommended to use a 2

nd

or 4th order low pass

filter. In Figure 17 a MFB topology of a 2

nd

order filter is

illustrated.

ALC

control

ALC _IN

Transmitter (S−FSK Modulator )

PC 20091216.1

ARM

Interface

&

Control

TX_OUT

LP

Filter

TX_EN

TO TX POWER

OUTPUT STAGE

FROM LINE

DRIVER

C

1

R

1

V

SSA

C

2

R

2

R

3

C

3

C

4

R

4

Figure 17. TX_OUT Filter

Receiver Path Description

Receiver Block Diagram

The receiver takes in the analog signal from the line

coupler, conditions it and demodulates it in a data−stream to

the communication controller. The operation mode and the

baud rate are made according to the setting in R_CONF,

R_FS and R_FM. The receive signal is applied first to a high

pass filter. Therefore NCN49597 has a low noise operational

amplifier at the input stage which can be used to make a high

pass active filter to attenuate the mains frequency. This high

pass filter output is followed by a gain stage which is used

in an automatic gain control loop. This block also performs

a single ended input to differential output conversion. This

gain stage is followed by a continuous time low pass filter

to limit the bandwidth. A 4

th

order sigma delta converter

converts the analog signal to digital samples. A quadrature

demodulation for f

S

and fM is than performed by an internal

DSP, as well the handling of the bits and the frames.

Page 24

NCN49597

http://onsemi.com

24

RX_OUT

RX_IN

REF_OUT

PC20090610.2

LOW NOISE

OPAMP

REF

1,65 V

TO

DIGITAL

Receiver (Analog Path)

Gain LPF

4th

order

SD AD

FROM

DIGITAL

Figure 18. Analog Path of the Receiver

PC20110610.3

Abs

value

accu

Receiver (Digital Path)

1

st

Decimator

Noise

Shaper

Compen−

sator

AGC

Control

FROM

ANALOG

TO

GAIN

f

SI

f

MQ

f

SQ

Sliding

Filter

Sliding

Filter

Sliding

Filter

Sliding

Filter

Quadrature Demodulator

f

S

f

M

2

nd

Decimator

2

nd

Decimator

2

nd

Decimator

2

nd

Decimator

I

M

Q

M

I

S

Q

S

f

MI

FROM TRANSMITTER

f

MQfSIfSQ

Figure 19. Digital Path of the Receiver ADC and Quadrature Demodulation

50/60 Hz Suppression Filter

NCN49597 receiver input provides a low noise input

operational amplifier in a follower configuration which can

be used to make a 50/60 Hz suppression filter with a

minimum number of external components. Pin RX_IN is the

positive input and RX_OUT is the output of the input low

noise operational amplifier. REF_OUT is the analog output

pin which provides the voltage reference (1.65 V) used by

the A/D converter. This pin must be decoupled from the

analog ground by a 1 mF ceramic capacitance (C

DREF

). It is

not allowed to load this pin.

PC20090722.1

C

1

R

1

C

2

R

2

C

DREF

RX_OUT

RX_IN

REF_OUT

Received

Signal

V

SSA

LOW NOISE

OPAMP

REF

1,65 V

TO AGC

Receiver (S−FSK Demodulator)

2

3

4

V

IN

Figure 20. External Component Connection for 50/60 Hz Suppression Filter

RX_IN is the positive analog input pin of the receiver low

noise input op−amp. Together with the output RX_OUT an

active high pass filter is realized. This filter removes the

main frequency (50 or 60 Hz) from the received signal. The

filter characteristics are determined by external capacitors

and resistors. Typical values are given in Table 27. For these

values and after this filter, a typical attenuation of 85 dB at

50 Hz is obtained. Figure 21 represents external

components connection. In a typical application the

coupling transformer in combination with a parallel

capacitance forms a high pass filter with a typical

attenuation of 60 dB. The combined effect of the two filters

Page 25

NCN49597

http://onsemi.com

25

decreases the voltage level of 230 Vrms at the mains

frequency well below the sensitivity of the NCN49597.

T

Frequency (Hz)

10

100 1k 10k 100k

Vin/Vrx_out (dB)

−140

−100

−60

−20

20

Figure 21. Transfer Function of 50 Hz Suppression Circuit

Table 22. VALUE OF THE RESISTORS AND CAPACITORS

Component Value Unit

C

1

1.5 nF

C

2

1.5 nF

C

DREF

1

mF

R

1

22

kW

R

2

11

kW

Remark: The analog part of NCN49597 is referenced to the

internal analog ground REF_OUT = 1.65 V (typical value).

If the external circuitry works with a different analogue

reference level one must be sure to place a decoupling

capacitor.

Auto Gain Control (AGC)

The receiver path has a gain stage which is used for

automatic gain control. The gain can be changed in 8 steps

of 6 dB. The control of the AGC is done by a digital circuit

which measures the signal level after the AD converter, and

regulates the average signal in a window around a

percentage of the full scale. The AGC works in 2 cycles: a

measurement cycle at the rising edge of the CHIP_CLK and

an update cycle starting at the next CHIP_CLK.

Low Noise Anti Aliasing Filter

The receiver has a 3rd order continuous time low pass filter

in the signal path. This filter is in fact the same block as in

the transmit path which can be shared because

NCN49597works in half duplex mode. The typical corner

frequency f

−3dB

= 138 kHz and is internally trimmed to

compensate for process variation.

A/D Converter

The output of the low pass filter is input for an analog 4

th

order sigma−delta converter. The DAC reference levels are

supplied from the reference block. The digital output of the

converter is fed into a noise shaping circuit blocking the

quantization noise from the band of interest, followed by a

decimation and a compensation step.

Quadrature Demodulator

The quadrature demodulation block takes the AD signal

and mixes it with the in−phase and quadrature phase of the

f

S

and fM carrier frequencies. After a low pass filter and

rectification the mixer output signals are further processed

in software. There the accumulation over a period of

CHIP_CLK is done which results in the discrimination of

data 0 and data 1.

Page 26

NCN49597

http://onsemi.com

26

Bit Sync

At the transmit side the data−stream is in sync and in phase

with the zero crossing of the mains. The complex impedance

of the power line together with propagation delay in the zero

cross detector and loop delay in the Rx−filter circuitry will

cause a shift between the physical transmitted bit and the

received S−FSK signal as illustrated in Figure 23.

Mains

Transmitted

bit stream

Bit delay

Transmission over the Power Line

Modulation

Bit 0 Bit1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8

t

PC20101119 .1

Figure 22. Bit Delay Cause by Transmission Over a Power Line

To compensate for this delay between physical and

demodulated bit a synchro bit value is introduced. It shifts

forward the Hardware Demodulating process up to 7 chip

clocks. See Figure 24.

Bit 0 Bit1 Bit 2

CHIP_CLK

SBV[2:0] = 0 SBV[2:0] = 3

PC20101119 .2

Figure 23. Compensation for Bit Delay by Shifting

Forward the Start of the Demodulating Process

The synchro bit value can be set using register SBV [2:0].

Table 23. SYNCHRO BIT VALUE

SBV[2:0] Bit Delay

000 0 CHIP_CLK

001 1 CHIP_CLK

010 2 CHIP_CLK

011 3 CHIP_CLK

100 4 CHIP_CLK

101 5 CHIP_CLK

110 6 CHIP_CLK

111 7 CHIP_CLK

Communication Controller

The Communication Controller block includes the ARM

CORTEX M0 32 bit RISC processor, its peripherals: Data

RAM, Program ROM, TIMERS 1 and 2, Interrupt Control,

TEST−Control, Watchdog and Power On Reset (POR), I/O

ports and the Serial Communication Interface (SCI). The

micro−processor is programmed to handle the physical layer

(chip synchronization), and the MAC layer conform to

IEC 61334−5−1. The program is stored in a masked ROM.

The RAM contains the necessary space to store the working

data. The back−end interface is done through the Local Port

and Serial Communication Interface block. This back−end

is used for data transmission with the application micro

controller (containing the application layer for concentrator,

power meter, or other functions) and for the definition of the

modem configuration.

More details can be found in Reference 1.

Page 27

NCN49597

http://onsemi.com

27

Communication Controller

ARM

Risc

Core

POR

Watchdog

Timer 1 & 2

Interrupt

Control

Data

RAM

RESB

TEST

PC20091111.1

TX _ENB

TDI

TDO

TMS

TRSTB

TCK

Test

Control

FROM

RECEIVER

TO

TRANSMIT

Serial

Comm.

Interface

Local Port

RX _ DATA

TxD

RxD

T_ REQ

BR 0

BR 1

CRC

TXD /PRES

Program

ROM

Figure 24. Communication Controller

REFERENCE

In this document references are made to:

1. Design Manual NCN49597

http://www.onsemi.com

2. EN 50065−1: Signaling on low−voltage electrical

installations in the frequency range 3 kHz to

148.5 kHz

http://connect.nen.nl/~/Preview.aspx?artfile=4257

28&RNR=66840

3. [3] ERDF−CPT−Linky−SPEC−FONC−CPL

version V1.0 Linky PLC profile functional

specification

http://www.erdfdistribution.fr/medias/Linky/ERD

F−CPT−Linky−SPEC−FONC−CPL.pdf

4. DLMS UA 1000−2 Ed. 7.0 DLMS/COSEM

Architecture and Protocols

http://www.dlms.com/documentation/dlmsuacolou

redbookspasswordprotectedarea/index.html

5. IEC 61334−5−1 Lower layer S−FSK Profile.

http://webstore.iec.ch/preview/info_iec61334−5−1

%7Bed2.0%7Db.pdf

6. IEC 61334−5−1 Lower layer S−FSK Profile.

http://webstore.iec.ch/preview/info_iec61334−5−1

%7Bed2.0%7Db.pdf

Table 24. ORDERING INFORMATION

Device Temperature Range Package Shipping

†

NCN49597C5972G −25°C – 80°C QFN−52

(Pb−Free)

Tube

NCN49597C5972RG −25°C – 80°C QFN−52

(Pb−Free)

Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specification Brochure, BRD8011/D.

Page 28

NCN49597

http://onsemi.com

28

PACKAGE DIMENSIONS

QFN52 8x8, 0.5P

CASE 485M−01

ISSUE C

C0.15

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.25 AND 0.30

MM FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

A

D

E

B

C0.08

A1

A3

A

D2

L

NOTE 3

C0.15

2X

2X

SEATING PLANE

C0.10

A2

C

E2

52 X

e

1

13

14 26

27

39

4052

b

52 X

A0.10 BC

0.05

C

DIM MIN MAX

MILLIMETERS

A 0.80 1.00

A1 0.00 0.05

A2 0.60 0.80

A3 0.20 REF

b 0.18 0.30

D 8.00 BSC

D2 6.50 6.80

E 8.00 BSC

E2 6.50 6.80

e 0.50 BSC

K 0.20 ---

REF

K

52 X

L 0.30 0.50

PIN ONE

REFERENCE

SOLDERING FOOTPRINT

DIMENSIONS: MILLIMETERS

8.30

6.75

6.75

0.50

0.62

0.30

52X

52X

PITCH

8.30

PKG

OUTLINE

RECOMMENDED

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

NCN49597/D

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local