查询CS8129YDW16G供应商

CS8129

5.0 V, 750 mA Low Dropout

Linear Regulator with

Lower RESET Threshold

The CS8129 is a precision 5.0 V linear regulator capable of sourcing

750 mA. The RESET threshold voltage has been lowered to 4.2 V so

that the regulator can be used with 4.0 V microprocessors. The lower

RESET threshold also permits operation under low battery conditions

(5.5 V plus a diode). The RESET’s delay time is externally

programmed using a discrete RC network. During powerup, or when

the output goes out of regulation, RESET remains in the low state for

the duration of the delay. This function is independent of the input

voltage and will function correctly as long as the output voltage

remains at or above 1.0 V. Hysteresis is included in the Delay and the

RESET comparators to improve noise immunity. A latching discharge

circuit is used to discharge the delay capacitor when it is triggered by a

brief fault condition.

The regulator is protected against a variety of fault conditions: i.e.

reverse battery, overvoltage, short circuit and thermal runaway

conditions. The regulator is p rotected a gainst v olt age t ransient s r a nging

from −5 0 V to +40 V. Short c ircuit current is limite d to 1.2 A ( typ).

The CS8129 is packaged in a 5 lead TO−220 and a 16 lead surface

mount package.

Features

• 5.0 V ±3.0% Regulated Output

• Low Dropout Voltage (0.6 V @ 0.5 A)

• 750 mA Output Current Capability

• Reduced RESET Threshold for Use with 4.0 V Microprocessors

• Externally Programmed RESET Delay

• Fault Protection

− Reverse Battery

− 60 V, −50 V Peak Transient Voltage

− Short Circuit

− Thermal Shutdown

• Pb−Free Packages are Available*

http://onsemi.com

TO−220

FIVE LEAD

T SUFFIX

CASE 314D

1

5

TO−220

FIVE LEAD

1

1

5

16

1

See detailed ordering and shipping information in the package

dimensions section on page 8 of this data sheet.

See general marking information in the device marking

section on page 8 of this data sheet.

ORDERING INFORMATION

DEVICE MARKING INFORMATION

TVA SUFFIX

CASE 314K

TO−220

FIVE LEAD

THA SUFFIX

CASE 314A

SO−16WB

DW SUFFIX

CASE 751G

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

© Semiconductor Components Industries, LLC, 2006

June, 2006 − Rev. 8

1 Publication Order Number:

CS8129/D

CS8129

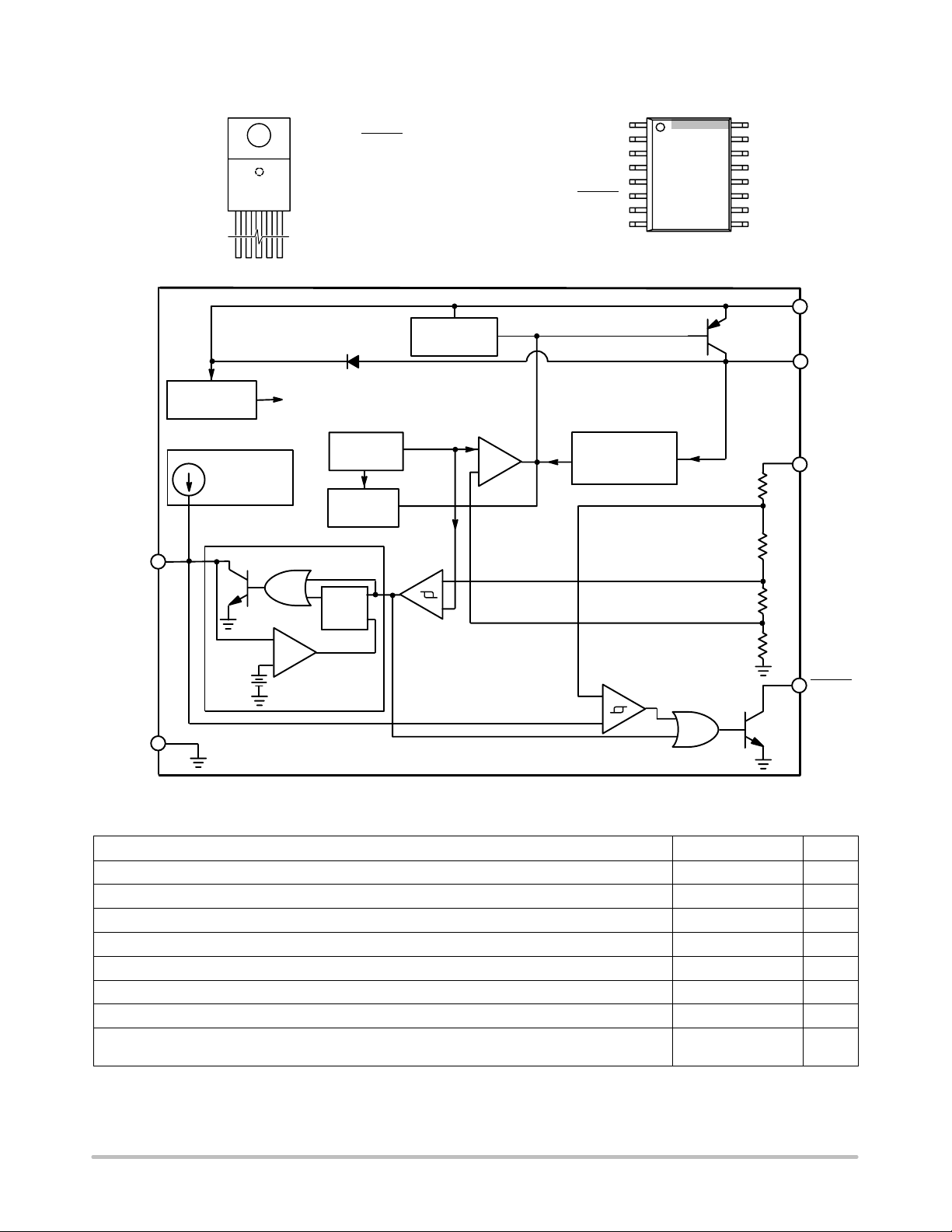

PIN CONNECTIONS

TO−220 5−LEAD

1

Pre−Regulator

Charge

Current

Generator

Pin 1. V

IN

2. RESET

3. GND

4. Delay

5. V

OUT

Regulated Supply

for Circuit Bias

Bandgap

Reference

Thermal

Shutdown

Over Voltage

Shutdown

Error

Amplifier

−

+

1

V

IN

NC

NC

GND

GND

RESET

Delay

Anti−Saturation

and

Current Limit

SO−16 WB

16

V

OUT

NC

V

OUT(SENSE)

GND

GND

GND

NCNC

NC

V

IN

V

OUT

V

OUT

(SENSE)

Delay

Latching Discharge

−

S

Q

+

R

−

+

V

DISCHARGE

+

Delay

Comparator

RESET

−

GND

Figure 1. Block Diagram

ABSOLUTE MAXIMUM RATINGS

Rating Value Unit

Input Operating Range −0.5 to 26 V

Power Dissipation Internally Limited −

Peak Transient Voltage (46 V Load Dump @ 14 V VIN) −50, 60 V

Output Current Internally Limited −

Electrostatic Discharge (Human Body Model) 4.0 kV

Junction Temperature −55 to +150 °C

Storage Temperature Range −55 to +150 °C

Lead Temperature Soldering: Wave Solder (through hole styles only) (Note 1)

Reflow (SMD styles only) (Note 2)

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. 10 second maximum.

2. 60 seconds max above 183°C.

260 peak

230 peak

°C

http://onsemi.com

2

CS8129

ELECTRICAL CHARACTERISTICS (−40°C ≤ T

R

RESET

= 4.7 kW to V

unless otherwise noted.) (Note 3)

OUT

≤ 125°C, −40 ≤ TJ ≤ 150°C, 6.0 ≤ VIN ≤ 26 V, 5.0 mA ≤ I

A

≤ 500 mA,

OUT

Characteristic Test Conditions Min Typ Max Unit

OUTPUT STAGE (V

OUT)

Output Voltage − 4.85 5.0 5.15 V

Dropout Voltage I

Supply Current I

Line Regulation 6.0 V ≤ VIN ≤ 26 V, I

Load Regulation 50 mA ≤ I

Ripple Rejection f = 120 Hz, VIN = 7.0 to 17 V, I

= 500 mA − 0.35 0.60 V

OUT

OUT

I

OUT

I

OUT

= 10 mA

= 100 mA

= 500 mA

OUT

= 50 mA − 5.0 50 mV

OUT

≤ 500 mA, VIN = 14 V − 10 50 mV

= 250 mA 54 75 − dB

OUT

−

−

−

2.0

6.0

55

7.0

12

100

Current Limit − 0.75 1.20 − A

Overvoltage Shutdown − 32 − 40 V

Reverse Polarity Input Voltage DC

V

≥ −0.6 V, 10 W Load

OUT

−15 −30 − V

Thermal Shutdown Guaranteed by Design 150 180 210 °C

RESET AND DELAY FUNCTIONS

Delay Charge Current V

RESET Threshold V

RESET Hysteresis VRH = V

Delay Threshold Charge, V

Delay Hysteresis

RESET Output Voltage Low

RESET Output Leakage V

Delay Capacitor Discharge Voltage Discharge Latched “ON”, V

Delay Time

= 2.0 V 5.0 10 15

DELAY

Increasing, V

OUT

V

Decreasing, V

OUT

RT(ON)

Discharge, V

1.0 V < V

OUT

C

DELAY

DC(HI)

OUT

> V

RT(H)

= 0.1 mF, (Note 4)

RT(ON)

RT(OFF)

− V

RT(OFF)

DC(LO)

−

< V

, 3.0 kW to V

RT(L)

Current − 0 10

OUT

> V

OUT

RT

4.05

4.00

50 150 250 mV

3.25

2.85

200 400 800 mV

− 0.1 0.4 V

− 0.2 0.5 V

16 32 48 ms

4.35

4.20

3.50

3.10

4.50

4.45

3.75

3.35

3. To observe safe operating junction temperatures, low duty cycle pulse testing is used in tests where applicable.

4. Assuming ideal capacitor.

C

V

Delay Time +

Delay

Delay Threshold Charge

I

Charge

+ C

3.5 105(typ)

Delay

mA

mA

mA

mA

V

V

V

V

mA

PACKAGE LEAD DESCRIPTION

PACKAGE LEAD #

TO−220

SO−16WB

1 1 V

16 5 V

5 LEAD

LEAD SYMBOL FUNCTION

IN

OUT

Unregulated supply voltage to IC.

Regulated 5.0 V output.

4, 5, 11, 12, 13 3 GND Ground Connection.

8 4 Delay Timing capacitor for RESET function.

6 2 RESET CMOS/TTL compatible output lead. RESET goes low whenever V

below 6.0% of it’s regulated value.

14 N/A V

OUT(SENSE)

Remote sensing of output voltage.

http://onsemi.com

3

OUT

drops

CS8129

120

55

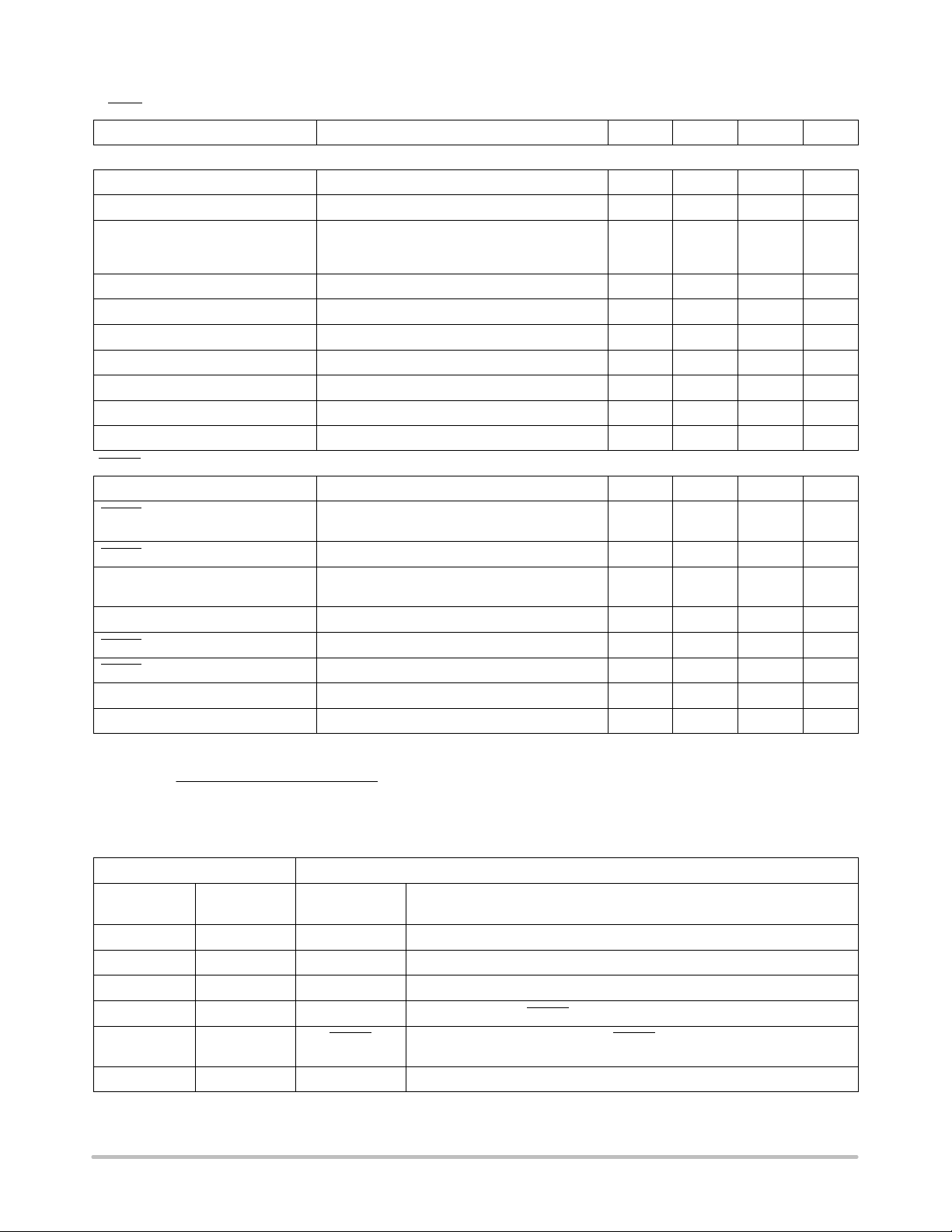

TYPICAL PERFORMANCE CHARACTERISTICS

R

= 25 W

LOAD

50

45

40

35

30

(mA)

25

CQ

I

125°C

20

15

25°C

10

5

0

01234 6 8 105

Figure 2. Quiescent Current vs. Input Voltage

5.5

R

= 25 W

5.0

LOAD

4.5

4.0

3.5

3.0

(V)

OUT

V

2.5

2.0

125°C

1.5

1.0

0.5

0

01234 6 8 105

25°C

Figure 4. Output Voltage vs. Input Voltage

−40°C

VIN (V)

Over Temperature

−40°C

VIN (V)

Over Temperature

Room Temp

R

= 6.67 W

100

LOAD

80

. (mA)

CQ

I

60

R

LOAD

= 10 W

40

20

7

9

0

012 34 5

R

= 25 W

LOAD

R

= NO LOAD

LOAD

678910

VIN (V)

Figure 3. Quiescent Current vs. Input

Voltage Over Load Resistance

5.5

Room Temp

5.0

4.5

4.0

3.5

3.0

(V)

R

=

LOAD

2.5

OUT

NO LOAD

V

2.0

1.5

1.0

R

= 10 W

LOAD

0.5

7

9

0

01234 6 8 105

Figure 5. V

R

= 6.67 W

LOAD

VIN (V)

vs. VIN Over R

OUT

7

9

LOAD

100

VIN = 6−26 V

80

60

40

TEMP = 25°C

20

0

−20

Line Reg. (mV)

−40

−60

TEMP = 125°C

−80

−100

0 800100 200 700300 400

Output Current (mA)

Figure 6. Line Regulation vs. Output Current

TEMP = −40°C

600500

http://onsemi.com

100

80

60

40

20

0

−20

−40

Load Regulation (mV)

−60

−80

−100

0 800100 200 700300 400

Figure 7. Load Regulation vs. Output Current

4

TEMP = −40°C

TEMP = 25°C

VIN = 14 V

TEMP = 125°C

600500

Output Current (mA)

CS8129

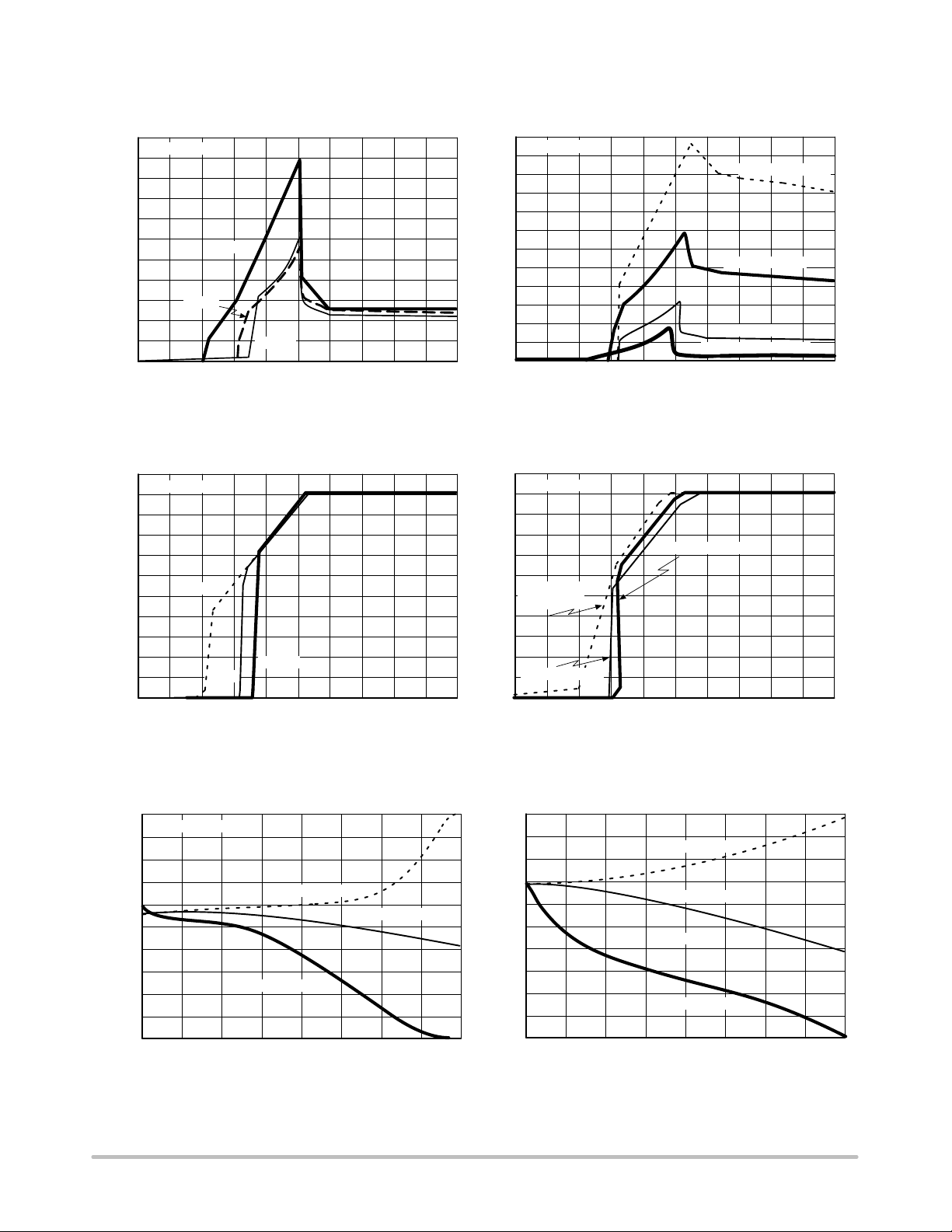

)

900

800

700

600

500

400

125°C

300

Dropout Voltage (mV)

200

100

0

0

100 200 300 400 500

Output Current (mA)

Figure 8. Dropout Voltage vs. Output Current Figure 9. Quiescent Current vs. Output Current

I

90

80

OUT

C

OUT

& 0.1 mF, ESR = 0

70

60

50

40

C

= 10 mF, ESR = 1.0 W

Rejection (dB)

30

OUT

20

C

10

0

10010110210310410

OUT

Frequency (Hz)

Figure 10. Ripple Rejection Figure 11. Output Capacitor ESR

−40°C

600 700

= 250 mA

= 10 mF, ESR = 1.0

= 10 mF, ESR = 1.0 W

5

10610710

25°C

800

100

90

80

70

60

50

40

30

Quiescent Current (mA)

20

10

0

0 100 200 500 600 800

3

10

2

10

1

10

0

10

−1

10

ESR (ohms)

−2

10

−3

10

−4

10

8

10

0

VIN = 14 V

10

125°C

−40°C

300 400 700

Output Current (mA)

CO = 47/68 mF

Stable Region

CO = 47 mF

CO = 68 mF

1

10

2

Output Current (mA)

25°C

10

3

(3)

V

OUT

RESET

DELAY

V

RT(ON)

V

RT(OFF)

V

DC(HI)

V

DC(LO)

V

RH

(1)

V

RL

t

DELAY

V

DH

(2)

(2)

(1) = No Delay Capacitor

(2) = With Delay Capacitor

(3) = Max: RESET

Voltage (1.0 V

V

DIS

Figure 12. RESET Circuit Waveform

http://onsemi.com

5

CS8129

*

to

F

CIRCUIT DESCRIPTION

The CS8129 RESET function has hysteresis on both the

reset and delay comparators, a latching Delay capacitor

discharge circuit, and operates down to 1.0 V.

The RESET circuit output is an open collector type with

ON and OFF parameters as specified. The RESET output

NPN transistor is controlled by the two circuits described

(see Block Diagram on page 2).

Low Voltage Inhibit Circuit

This circuit monitors output voltage, and when output

voltage is below the specified minimum causes the RESET

output transistor to b e i n t he O N ( saturation) s tate. When the

output volta ge i s a bove t he specified l evel, t hi s c ircui t permits

the RESET output transistor to go into the OFF state if

allowed by the RESET Delay circuit.

Reset Delay Circuit

This circuit provides a programmable (by external

capacitor) delay on the RESET output lead. The Delay lead

provides source current to the external delay capacitor only

when the “Low Voltage Inhibit” circuit indicates that output

voltage is above V

. Otherwise, the Delay lead sinks

RT(ON)

current to ground (used to discharge the delay capacitor).

The discharge current is latched ON when the output voltage

is below V

. The Delay capacitor is fully discharged

RT(OFF)

anytime the output voltage falls out of regulation, even for

a short period of time. This feature ensures that a controlled

RESET pulse is generated following detection of an error

condition. The circuit allows the RESET output transistor to

go to the OFF (open) state only when the voltage on the

Delay lead is higher than V

V

IN

CIN*

00 nF

Delay

0.1 mF

*C

is required if regulator is far from the power source filter.

IN

**C

is required for stability.

OUT

Figure 13. Test & Application Circuit

Delay

CS8129

RESET

GND

DC(HI)

V

OUT

.

R

RST

4.7 kW

C

OUT

10 mF

100 m

*

The Delay time for the RESET function is calculated from

the formula:

If C

Delay

Delay time +

C

Delay time + C

= 0.1 mF, Delay time (ms) = 32 ms ±50%: i.e.

Delay

Delay(mF)

V

Delay Threshold

I

Charge

3.2 10

5

16 ms to 48 ms. The tolerance of the capacitor must be taken

into account to calculate the total variation in the delay time.

APPLICATION NOTES

STABILITY CONSIDERATIONS

The output or compensation capacitor helps determine

three main characteristics of a linear regulator: start−up

delay, load transient response and loop stability.

The capacitor value and type should be based on cost,

availability, size and temperature constraints. A tantalum or

aluminum electrolytic capacitor is best, since a film or

ceramic capacitor with almost zero ESR can cause

instability. The aluminum electrolytic capacitor is the least

expensive solution, but, if the circuit operates at low

temperatures (−25°C to −40 °C), both the value and ESR of

the capacitor will vary considerably. The capacitor

manufacturers data sheet usually provides this information.

The value for the output capacitor C

shown in Figure

OUT

13 should work for most applications, however it is not

necessarily the optimized solution.

To determine an acceptable value for C

for a particular

OUT

application, start with a tantalum capacitor of the

recommended value and work towards a less expensive

alternative part.

Step 1: Place the completed circuit with a tantalum

capacitor of the recommended value in an environmental

chamber at the lowest specified operating temperature and

monitor the outputs with an oscilloscope. A decade box

connected in series with the capacitor will simulate the

higher ESR of an aluminum capacitor. Leave the decade box

outside the chamber, the small resistance added by the

longer leads is negligible.

Step 2: With the input voltage at its maximum value,

increase the load current slowly from zero to full load while

observing the output for any oscillations. If no oscillations

are observed, the capacitor is large enough to ensure a stable

design under steady state conditions.

Step 3: Increase the ESR of the capacitor from zero using

the decade box and vary the load current until oscillations

appear. Record the values of load current and ESR that cause

the greatest oscillation. This represents the worst case load

conditions for the regulator at low temperature.

Step 4: Maintain the worst case load conditions set in

step 3 and vary the input voltage until the oscillations

increase. This point represents the worst case input voltage

conditions.

Step 5: If the capacitor is adequate, repeat steps 3 and 4

with the next smaller valued capacitor. A smaller capacitor

will usually cost less and occupy less board space. If the

output oscillates within the range of expected operating

conditions, repeat steps 3 and 4 with the next larger standard

capacitor value.

http://onsemi.com

6

CS8129

P

)

Step 6: Test the load transient response by switching in

various loads at several frequencies to simulate its real

working environment. Vary the ESR to reduce ringing.

Step 7: Raise the temperature to the highest specified

operating temperature. Vary the load current as instructed in

step 5 to test for any oscillations.

Once the minimum capacitor value with the maximum

ESR is found, a safety factor should be added to allow for the

tolerance of the capacitor and any variations in regulator

performance. Most good quality aluminum electrolytic

capacitors have a tolerance of ± 20% so the minimum value

found should be increased by at least 50% to allow for this

tolerance plus the variation which will occur at low

temperatures. The ESR of the capacitor should be less than

50% of the maximum allowable ESR found in step 3 above.

CALCULATING POWER DISSIPATION IN A SINGLE

OUTPUT LINEAR REGULATOR

The maximum power dissipation for a single output

regulator (Figure 14) is:

D(max)

+

NJ

V

IN(max)

* V

OUT(min)

Nj

I

OUT(max)

) V

IN(max)IQ

(1

where:

V

V

I

OUT(max)

is the maximum input voltage,

IN(max)

OUT(min)

is the minimum output voltage,

is the maximum output current for the

application, and

IQ is the quiescent current the regulator consumes at

I

OUT(max)

Once the value of P

permissible value of R

The value of R

.

is known, the maximum

D(max)

can be calculated:

qJA

R

qJA

150°C * T

+

qJA

can then be compared with those in the

A

P

D

(2)

package section of the data sheet. Those packages with

R

’s less than the calculated value in equation 2 will keep

qJA

the die temperature below 150°C.

In some cases, none of the packages will be sufficient to

dissipate the heat generated by the IC, and an external

heatsink will be required.

I

IN

V

IN

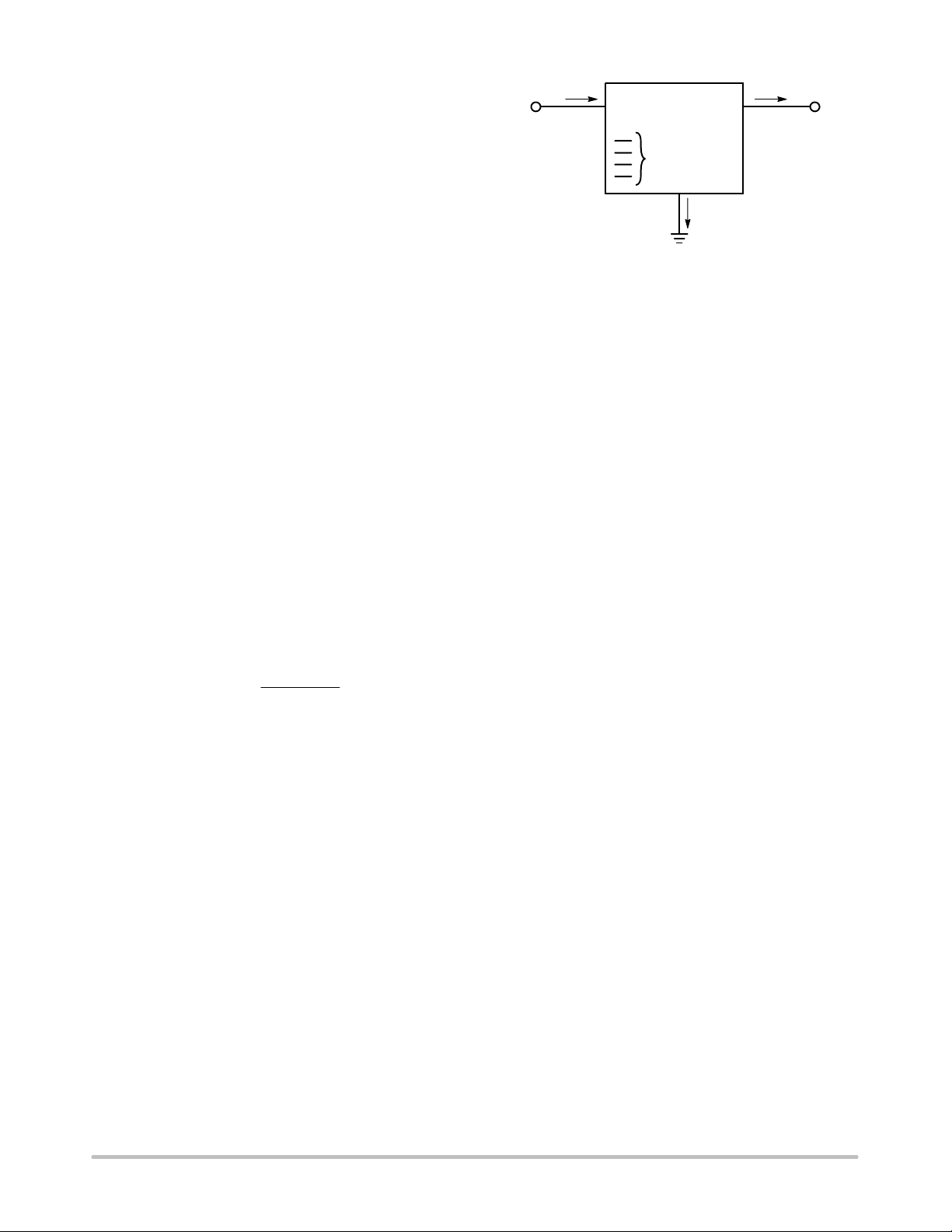

SMART

REGULATOR

Control

Features

I

Q

I

OUT

V

®

OUT

Figure 14. Single Output Regulator With Key

Performance Parameters Labeled

HEAT SINKS

A heat sink effectively increases the surface area of the

package to improve the flow of heat away from the IC and

into the surrounding air.

Each material in the heat flow path between the IC and the

outside environment will have a thermal resistance. Like

series electrical resistances, these resistances are summed to

determine the value of R

R

+ R

qJA

qJC

qJA

.

) R

qCS

) R

qSA

(3)

where:

R

= the junction−to−case thermal resistance,

qJC

R

= the case−to−heatsink thermal resistance, and

qCS

R

= the heatsink−to−ambient thermal resistance.

qSA

R

appears in the package section of the data sheet. Like

qJC

R

, it too is a function of package type. R

qJA

qCS

and R

qSA

are

functions of the package type, heatsink and the interface

between them. These values appear in heat sink data sheets

of heat sink manufacturers.

http://onsemi.com

7

CS8129

MARKING DIAGRAMS

SO−16 WB

16

CS8129

AWLYYWWG

1

A = Assembly Location

WL = Wafer Lot

YY, Y = Year

WW = Work Week

G = Pb−Free Package

AWLYWWG

1

CS

8129

TO−220 5−LEAD

CS8129

AWLYWWG

1

CS

8129

AWLYWWG

1

ORDERING INFORMATION

Device Package Shipping

CS8129YT5 TO−220*

CS8129YT5G TO−220*

CS8129YTHA5 TO−220*

CS8129YTHA5G TO−220*

CS8129YTVA5 TO−220*

CS8129YTVA5G TO−220*

CS8129YDW16 SO−16WB

CS8129YDW16G SO−16WB

CS8129YDWR16 SO−16WB

CS8129YDWR16G SO−16WB

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

STRAIGHT

STRAIGHT

(Pb−Free)

HORIZONTAL

50 Units / Rail

HORIZONTAL

(Pb−Free)

VERTICAL

VERTICAL

(Pb−Free)

47 Units / Rail

(Pb−Free)

1000 / Tape & Reel

(Pb−Free)

†

http://onsemi.com

8

−Q−

U

K

D

5 PL

B

B1

12345

0.356 (0.014) T

M

G

DETAIL A−A

A

M

Q

CS8129

PACKAGE DIMENSIONS

TO−220

CASE 314D−04

ISSUE F

SEATING

−T−

PLANE

C

E

L

J

H

B

B1

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION D DOES NOT INCLUDE

INTERCONNECT BAR (DAMBAR) PROTRUSION.

DIMENSION D INCLUDING PROTRUSION SHALL

NOT EXCEED 10.92 (0.043) MAXIMUM.

DIM MIN MAX MIN MAX

A 0.572 0.613 14.529 15.570

B 0.390 0.415 9.906 10.541

B1 0.375 0.415 9.525 10.541

C 0.170 0.180 4.318 4.572

D 0.025 0.038 0.635 0.965

E 0.048 0.055 1.219 1.397

G 0.067 BSC 1.702 BSC

H 0.087 0.112 2.210 2.845

J 0.015 0.025 0.381 0.635

K 0.977 1.045 24.810 26.543

L 0.320 0.365 8.128 9.271

Q 0.140 0.153 3.556 3.886

U 0.105 0.117 2.667 2.972

MILLIMETERSINCHES

DETAIL A−A

http://onsemi.com

9

TO−220

−Q−

0.356 (0.014)

CS8129

PACKAGE DIMENSIONS

TVA SUFFIX

CASE 314K−01

ISSUE O

NOTES:

SEATING

−T−

PLANE

C

B

E

W

U

12345

A

L

F

K

M

D

5 PL

M

M

T

Q

G

J

S

R

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION D DOES NOT INCLUDE

INTERCONNECT BAR (DAMBAR) PROTRUSION.

DIMENSION D INCLUDING PROTRUSION SHALL

NOT EXCEED 10.92 (0.043) MAXIMUM.

DIM MIN MAX MIN MAX

A 0.560 0.590 14.22 14.99

B 0.385 0.415 9.78 10.54

C 0.160 0.190 4.06 4.83

D 0.027 0.037 0.69 0.94

E 0.045 0.055 1.14 1.40

F 0.530 0.545 13.46 13.84

G 0.067 BSC 1.70 BSC

J 0.014 0.022 0.36 0.56

K 0.785 0.800 19.94 20.32

L 0.321 0.337 8.15 8.56

M 0.063 0.078 1.60 1.98

Q 0.146 0.156 3.71 3.96

R 0.271 0.321 6.88 8.15

S 0.146 0.196 3.71 4.98

U 0.460 0.475 11.68 12.07

W 55°°

MILLIMETERSINCHES

Q

U

D5X

0.014 (0.356) T

B

−P−

TO−220

THA SUFFIX

CASE 314A−03

ISSUE E

NOTES:

SEATING

−T−

PLANE

C

OPTIONAL

CHAMFER

A

G

E

L

F

K

J

5X

S

M

M

P

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION D DOES NOT INCLUDE

INTERCONNECT BAR (DAMBAR) PROTRUSION.

DIMENSION D INCLUDING PROTRUSION SHALL

NOT EXCEED 0.043 (1.092) MAXIMUM.

INCHES

DIMAMIN MAX MIN MAX

0.572 0.613 14.529 15.570

B 0.390 0.415 9.906 10.541

C 0.170 0.180 4.318 4.572

D 0.025 0.038 0.635 0.965

E 0.048 0.055 1.219 1.397

F 0.570 0.585 14.478 14.859

G 0.067 BSC 1.702 BSC

J 0.015 0.025 0.381 0.635

K 0.730 0.745 18.542 18.923

L 0.320 0.365 8.128 9.271

Q 0.140 0.153 3.556 3.886

S 0.210 0.260 5.334 6.604

U 0.468 0.505 11.888 12.827

MILLIMETERS

http://onsemi.com

10

SO−16 WB

16 9

M

B

H8X

M

0.25

0.25 B

14X

CS8129

PACKAGE DIMENSIONS

CASE 751G−03

ISSUE C

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

D

A

q

E

_

h X 45

81

B16X

M

S

A

T

B

S

A

SEATING

T

PLANE

C

e

A1

L

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

3. DIMENSIONS D AND E DO NOT INLCUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN

EXCESS OF THE B DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS

DIM MIN MAX

A 2.35 2.65

A1 0.10 0.25

B 0.35 0.49

C 0.23 0.32

D 10.15 10.45

E 7.40 7.60

e 1.27 BSC

H 10.05 10.55

h 0.25 0.75

L 0.50 0.90

q 0 7

__

PACKAGE THERMAL DATA

TO−220

Parameter

R

q

JC

R

q

JA

Typical 2.1 23 °C/W

Typical 50 105 °C/W

FIVE LEAD

SO−16WB Unit

SMART REGULATOR is a registered trademark of Semiconductor Components Industries, LLC (SCILLC).

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

http://onsemi.com

11

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

CS8129/D

Loading...

Loading...