Page 1

查询CS1112供应商

CS1112

Quad Power Output Driver

The CS1112 is a Power Output Driver. The IC incorporates four

protected DMOS low–side drivers designed to drive inductive and

resistive loads in an automotive environment. The outputs are

controlled by an 8–bit serial peripheral interface (SPI) or its associated

parallel input. Each output contains overcurrent protection, open load

detection, and inductive flyback clamps. The device is overvoltage

protected. Overcurrent and open load faults are reported over the SPI

port, and at the STATUS lead.

I/O Control

SPI communication is initiated by asserting CSB low. Data at the SI

lead is transferred on the rising edge of SCLK. The MSB is transferred

first. The outputs become active at the rising edge of CSB. Diagnostic

status bits are transferred out the SO lead at the falling edge of SCLK.

The SO lead is high impedance while CSB is high. An open drain

output, (STATUS) reports a fault (short to V

has occurred at one or more of the outputs.

Protection

Each output independently detects shorts to V

is “on” and open load/short to ground while the output is “off”. The

fault register will be set if a fault occurs at the output. The fault register

will be reset if the fault condition is removed from the output. The

fault data is latched when CSB is asserted low.

If an overcurrent condition or short circuit to V

output goes into a low duty cycle mode for the duration of the fault.

The outputs are disabled during an overvoltage or undervoltage

condition.

Features

• 4.0 MHz Serial Input Bus

• Parallel Input Control

• 1.0 Ω DMOS Drivers (typ)

• Power On Reset

• Internal Flyback Clamps

• Status Output

• Fault Protection

– 46 V Peak Transient

– Power Limiting

– Undervoltage

– Overvoltage

• Fault Reporting

– Open Load

– Short Circuit

• 8 Internally Fused Leads

, GND, or open load)

PWR

while the output

PWR

occurs, the

BATT

http://onsemi.com

SO–24L

DW SUFFIX

CASE 751E

PIN CONNECTIONS AND

MARKING DIAGRAM

1

V

DD

V

PWR

OUT0

IN0

GND

GND

GND

GND

IN1

OUT1

SI

CSB

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

ORDERING INFORMATION

Device Package Shipping

CS1112YDWF24

CS1112YDWFR24

AWLYYWW

CS1112

SO–24L

SO–24L

24

R

OSC

STATUS

OUT3

IN3

GND

GND

GND

GND

IN2

OUT2

SO

SCLK

31 Units/Rail

1000 Tape & Reel

Semiconductor Components Industries, LLC, 2000

October, 2000 – Rev. 10

1 Publication Order Number:

CS1112/D

Page 2

CS1112

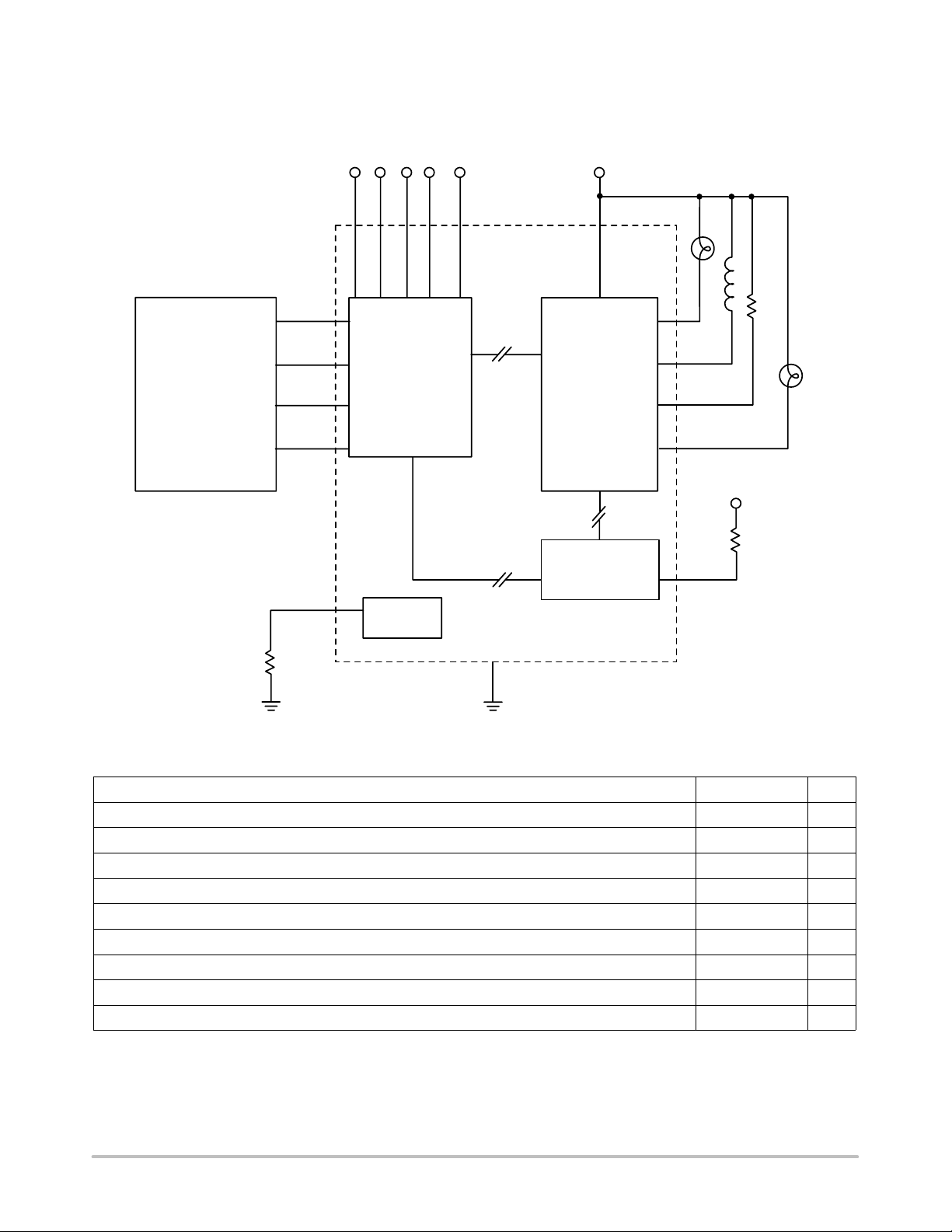

APPLICATION DIAGRAM

Micro Controller

with Bus

CSB

SCLK

R

OSC

IN1 IN2 IN3 IN4 V

SI

Registers and

SO

CMOS

Serial Shift

Latches

Bias

DD

QPOD

4

4

V

PWR

DMOS

Low Side

Switches and

Protection

Circuitry

4

Fault

Reporting

Status

V

DD

10 kΩ

R

OSC

82 kΩ

GND

ABSOLUTE MAXIMUM RATINGS*

Rating Value Unit

DC Supply (V

Output DC Voltage (Out 0, 1, 2, 3) 46 V

VDD Supply Voltage –0.3 to +7.0 V

Peak Transient (1.0 ms rise time, 300 ms period, 32 V Load Dump @ 14 V V

Digital Input Voltage –0.3 to VDD + 0.3 V

Single Pulse Avalanche Energy (I = 450 mA)(Out 0, 1, 2, 3) 50 mJ

Operating Junction Temperature, T

ESD Capability (Human Body Model) 1.5 kV

Lead Temperature Soldering: Reflow: (SMD styles only) (Note 1.) 230 peak °C

1. 60 second maximum above 183°C.

*The maximum package power dissipation must be observed.

) –0.3 to 30 V

PWR

) 46 V

PWR

J

–40 to 150 °C

http://onsemi.com

2

Page 3

CS1112

ELECTRICAL CHARACTERISTICS (9.0 V < V

5.5

V < V

< 25 V, (Outputs Functional); unless otherwise specified.)

PWR

Characteristic

< 17 V, 4.5 V < VDD < 5.5 V, –40°C < T

PWR

Test Conditions Min Typ Max Unit

J <

125°C,

Supply Voltages and Currents

VDD Power On Reset Threshold Outputs Latched Off By Event 2.5 3.0 3.5 V

VDD Power On Reset Hysteresis – – 200 – mV

V

Undervoltage Outputs Latched Off By Event 4.0 4.5 5.0 V

PWR

V

Overvoltage Lockout Outputs Latched Off By Event 30 35 45 V

PWR

Digital Supply Current, I

Analog Supply Current, I

Sleep Current, I

V(PWR)

V(DD)

V(PWR)

All Outputs On (@ 350 mA) – – 5.0 mA

All Outputs On (@ 350 mA) – – 5.0 mA

VDD ≤ 0.5 V – – 10 µA

Digital Inputs and Outputs

VIN High SI, SCLK, CSB, IN0, IN1, IN2, IN3 70 – – %V

VIN Low SI, SCLK, CSB, IN0, IN1, IN2, IN3 – – 30 %V

VIN Hysteresis – – 230 – mV

Input Pulldown Current SI, IN0, IN1, IN2, IN3, VIN = 30% V

Input Pullup Current CSB, VIN = 70% V

Status Low I

= 0.5 mA – 0.1 0.5 V

STATUS

DD

DD

– – 25 µA

– – –25 µA

Fault Detection/Timing

Overcurrent Sense Time, t

SS

Overcurrent Shutdown Time Overcurrent Shutdown Time, R

Overcurrent Sense Time, R

= 82 kΩ 25 62.5 100 µs

OSC

= 82 kΩ 1.60 3.94 6.3

OSC

Fault Duty Cycle After the first fault cycle, Note 1. 1.4 1.56 1.7 %

Open Load Trip Point IN = Low 40 50 60 %V

Open Load Sense Time Open Load Sense Time, R

= 82 kΩ 12.5 – 100 µs

OSC

Power Outputs

V

Clamp ID = 20 mA, t

DRAIN

Drain Leakage Current V

Drain Leakage Current V

R

DS(ON)

= 17 V – – 25 µA

DRAIN

= 46 V – – 400 µA

DRAIN

V

= 13 V, ID = 0.5 A – 1.0 2.0 Ω

PWR

= 100 µs 48 52 64 V

CLAMP

Current Limit Note 2. 3.0 4.5 6.0 A

Reverse Diode Drop Reverse Diode Drop I = 350 mA – – 1.4 V

Fall Time Delay, t

phl

V

PWR

= 13 V, R

LOAD

= 33 Ω,

– – 10 µs

Note 3. (see Figure 2)

Rise Time Delay, t

plh

V

PWR

= 13 V, R

LOAD

= 33 Ω,

– – 15 µs

Note 3. (see Figure 2)

Rise Time, t

Fall Time, t

r

f

V

V

PWR

PWR

= 13 V, R

= 13 V, R

= 33 Ω 0.4 – 10 µs

LOAD

= 33 Ω 0.4 – 10 µs

LOAD

1. Guaranteed by design.

2. A duty cycle mode will initiate at a minimum of 1.0 A and before the current limit.

3. Output turn on delay and turn off delay from rising edge of CSB to the output reaching 50% of V

PWR

.

DD

DD

ms

DD

http://onsemi.com

3

Page 4

CS1112

ELECTRICAL CHARACTERISTICS (continued) (9.0 V < V

5.5

V < V

< 25 V, (Outputs Functional); unless otherwise specified.)

PWR

< 17 V, 4.5 V < VDD < 5.5 V, –40°C < T

PWR

J <

125°C,

Characteristic UnitMaxTypMinTest Conditions

Serial Peripheral Interface V

PWR

= 14 V

SCLK Clock Period CO = 200 pF 250 – – ns

MAX Input Capacitance SI, SCLK, Note 1. – – 12 pF

V

High SO, IOH = 1.0 mA VDD – 1.0 – – V

OUT

V

Low SO, IOL = 1.0 mA – – 0.5 V

OUT

SCLK High Time F

= 4.0 MHz, SCLK = 2.0 V to 2.0 V

SCLK

125 – – ns

(see Figure 1)

SCLK Low Time F

= 4.0 MHz, SCLK = 0.8 V to 0.8 V

SCLK

125 – – ns

(see Figure 1)

SI Setup Time SI = 0.8 V/2.0 V to SCLK = 2.0 V at 4.0 MHz;

25 – – ns

Note 1. (see Figure 1)

SI Hold Time SCLK = 2.0 V to SI = 0.8 V/2 .0 V at 4.0 MHz;

25 – – ns

Note 1. (see Figure 1)

SO Rise Time CLD = 200 pF (0.1 VDD to 0.9 VDD);

– 25 50 ns

Note 1.

SO Fall Time CLD = 200 pF (0.9 VDD to 0.1 VDD);

– – 50 ns

Note 1.

CSB Setup Time CSB = 0.8 V to SCLK = 2.0 V

60 – – ns

(see Figure 1) Note 1.

CSB Hold Time SCLK = 0.8 V to CSB = 2.0 V

75 – – ns

(see Figure 1) Note 1.

SO Delay Time SCLK = 0.8 V to SO Data Valid, VDD = 5.0 V

C

= 200 pF at 4.0 MHz

LD

– 65 125 ns

(see Figure 1); Note 1.

Xfer Delay Time CSB rising edge to next falling edge.

1.0 – – µs

Note 1.

1. Guaranteed by design.

PACKAGE PIN DESCRIPTION

PACKAGE PIN #

24 Lead SOIC

1 V

2 V

3 OUT0 Open drain output one.

4 IN0 Parallel input one.

5, 6, 7, 8

17, 18, 19, 20

9 IN1 Parallel input two.

10 OUT1 Open drain output two.

11 SI SPI serial input.

12 CSB SPI active low chip select.

13 SCLK SPI clock input.

14 SO SPI serial output.

PIN SYMBOL FUNCTION

DD

PWR

Input voltage to bias logic and control circuitry.

Input voltage to bias gate drive circuitry.

GND Ground Reference.

http://onsemi.com

4

Page 5

PACKAGE PIN DESCRIPTION (continued)

PACKAGE PIN #

24 Lead SOIC

15 OUT2 Open drain output three.

16 IN2 Parallel input three.

21 IN3 Parallel input four.

22 OUT3 Open drain output four.

23 STATUS Open drain output, which is asserted when an open load or

24 R

CS1112

overcurrent condition occurs at any of the outputs.

OSC

CIRCUIT DESCRIPTION

82 kΩ resistor tied to ground to set up accurate internal current sources.

FUNCTIONPIN SYMBOL

FUNCTIONPIN SYMBOL

Typical Operation

Control of the CS1112 can be done using the Serial

Peripheral Interface (SPI) port using the Data Input

information in Table 1, or the outputs can be controlled via

the parallel inputs (IN0, IN1, IN2, IN3). IN0 controls OUT0,

IN1 controls OUT1, IN2 controls OUT2, and IN3 controls

TIMING DIAGRAM

CS

SCLK

Don’t Care

SI

OUT3

OUT0

OUT1

Turn ON

OUT3. Turning the output drivers on is an OR function with

the SPI input and the parallel inputs.

Note: To prevent damage to the IC or the output load, V

DD

must be above the Power on Reset threshold (3.5 V) before

IN0, IN1, IN2, or IN3 are asserted high (< 70% VDD).

OUT2

Turn ON

OUT1

Turn OFF

OUT0

Turn ON

OUT2

OUT3

Time

Table 1. SPI Inputs

D7

X X X X OUT3 OUT2 OUT1 OUT0

MSB LSB

X = Don’t Care; MSB is Transferred first.

D6 D5 D4 D3 D2 D1 D0

http://onsemi.com

5

Page 6

CS1112

SERIAL PERIPHERAL INTERFACE TIMING REQUIREMENTS

CSB

SCLK

SI

SO

CSB (Setup)

CSB (Hold)

SI (Setup)

123

SI (Hold)

Xfer Delay

MSB

70% V

MSB

30% V

DD

DD

SO(Delay) SO(Rise,Fall)

Figure 1.

BLOCK DIAGRAM

IN0 IN1 IN2 IN3

CSB

OUT

t

f

t

phl

plh

t

r

X

t

Figure 2.

V

PWR

CSB

SI

SCLK

SO

V

DD

R

OSC

V

DD

10 µA

10 µA

Serial D/O

Line Driver

Power On

Reset

Bias

Serial

Peripheral

Interface

RESET

Data 0

Data 1 to 3

Fault 1 to 3

RESET

OUT

ENABLE

4.0 ms

Fault Timer

Overvoltage/

Undervoltage

Lockout

Fault 0

V

REG

Gate

Drive

Open Load

Data 0

Data 0

Shorted Load

I

LIMIT

OUT0

10 µA

OUT1

OUT2

OUT3

+

R

S

–

–

+

1/2 V

DD

GND

STATUS

http://onsemi.com

6

Page 7

CS1112

APPLICATION INFORMATION

CIRCUIT DESCRIPTION

The CS1112 was developed for use in very noisy and very

harsh environments such as seen in an automobile system.

The device has four low–side switches all controlled

through an 8–bit Serial Peripheral Interface (SPI) port.

Control of the outputs is also OR’d with parallel inputs. This

is a critical feature enhancement over similar devices

because of the ease in which the parallel inputs can be used

to control the outputs in a Pulse Width Modulation (PWM)

mode. Creating a PWM mode using just the serial port input

is not a practical application.

This part uses ON Semiconductor’s POWERSENSE

process technology. POWERSENSE combines the

robustness of Bipolar with the dense logic capability of

CMOS, and the power capabilities of DMOS.

Power consumption is kept to a minimum using

POWERSENSE in comparison to a bipolar technology. A

bipolar process requires DC bias currents to power–up the

integrated circuit. This is needed in many applications

requiring analog circuitry, but is not needed here. Digital

POWERSENSE logic dissipates power only when

switching because that is when transient gate charging

current flows. POWERSENSE logic requires little space,

and is a good economical solution. The DMOS side of the

process provides a robust user interface to the outside world

on each of the outputs. Peak transient capability of each

output is rated at a maximum of 46 V (typical of an

automotive load dump transient).

The CS1112 uses quasi–vertical DMOS transistors

resulting in an output resistance (R

) at each output of

DS(ON)

less than 1.0 Ω @ 13 V and 500 mA @ 25°C.

The part can be put in a sleep mode where the part draws

less than 2.0 µA of bias current from V

. The part enters

PWR

this sleep mode when VDD ≤ 0.5 V. Maximum quiescent

current for the device is 5.0 mA maximum for any

combination of output drivers enabled.

Fault reporting is controlled by the CS1112. Overcurrent

and short to V

are detected when the output is on. Open

BATT

load and short to ground are detected when the output is off.

Faults are reported out of the serial output (SO) pin as a new

8–bit word is being fed into the serial input (SI) pin.

Figure 3 highlights the SPI interface between the

microprocessor and the CS11 12. The SPI control inputs and

all other logic inputs are compatible with 5.0 V CMOS logic

levels.

Parallel

Inputs

µP

Receive Buffer

CS1112

SI

Shift Register

SO

SCLK

CSB

SPI Interface Fault Reporting

2103XXXX

3210

Output Logic

Figure 3.

Control

IN0

IN1

IN2

STATUS

µP

The four communication lines which define the SPI

interface are the SI, SO, CSB, and SCLK. The parallel

inputs, which control the outputs can also connect to the

same microprocessor, a separate microprocessor, or any

other sensor or electrical device which meets the voltage

requirements of the CS1112 (V

= VDD + 0.3 V).

IN(max)

SPI communication is as follows (2 scenarios):

1.

8–Bit Normal Operation

CSB pin is brought low activating the SPI port. Faults

detected since the last CSB low to high transition are

latched into the serial register when CSB goes low. 8

command bits are clocked into the SI pin. The four

fault bits are clocked out of the SO pin. CSB pin is

brought high translating the final 4 bits to the outputs

turning them on or off. Faults are then detected and

saved in the fault register when CSB goes low.

2.

16–Bit Operation For Command Verify

CSB pin is brought low activating the SPI port. 16 bits

are clocked into the SI pin (the last 4 are the 4 control

pins for the four outputs). CSB pin is brought high

translating the last 4 bits to the outputs turning them

on or off.

CSB pin is brought low activating the SPI port. 16

new bits are clocked into the SI pin. As the new bits

are being clocked in, the first 8 bits being clocked out

of the SO pin are the fault bits, followed by the first

8 bits which were clocked in (the verification bits).

The verification bits should replicate the command

bits.

http://onsemi.com

7

Page 8

CS1112

Serial clock frequencies up to 4.0 MHz can be used by the

CS1112.

Internal pull–up circuitry is provided on the Chip Select

Bar (CSB) pin. Internal active pulldowns are provided on the

parallel input pins (IN0, IN1, IN2, IN3, and SI pin).

A product highlight of this part is its ability to be

daisy–chained with other parts which follow the SPI

protocol as defined in Figure 1. Figure 4 displays this aspect.

The serial output of each device is fed into the serial input

of the next device. All data bits are clocked into their

respective registers, while the CSB pin is low. The drivers

are switched to the resulting command when the CSB pin is

brought back high.

µP

CSB SCLK

CS1112

SI

CSB SCLK CSB SCLK

Any IC using

SPI protocol

SO SI SO SI SO

Any IC using

SPI protocol

Figure 4.

Multiple SPI port devices can also be connected in a

parallel fashion (Figure 5) instead of the daisy–chained

connection previously shown. The microprocessor controls

the CS1112 in a multiplex fashion allowing the serial data

input to be input to the device when the device is activated

through the CSB pin. This creates a system whose number

of outputs is a multiple of 4. Figure 5 displays a 12 output

setup.

CS1112

SI

OUT0

SCLK

OUT1

CSB

µP

OUT2

OUT3

1 output with the SPI port, and 3 outputs being controlled

with the parallel inputs allowing them to run in a PWM

mode.

SPI Controlled Outputs

V

BAT

Z0 Z1 Z2 Z3

OUT0

OUT1

OUT2

µP

µP

SPI Port

Parallel Inputs

Control

SPI Port

CSB

SCLK

SI

IN0

IN1

IN2

CSB

SCLK

SI

OUT3

Figure 6.

Parallel Controlled Outputs

V

BAT

Z0 Z1 Z2 Z3

OUT0

OUT1

OUT2

OUT3

SPI Controlled

Outputs

CS1112

OUT0

SI

OUT1

SCLK

OUT2

CSB

OUT3

CS1112

OUT0

SI

OUT1

SCLK

CSB

OUT2

OUT3

Figure 5.

Figure 6 displays the device controlling 4 outputs with the

use of its SPI port. Figure 7 displays the device controlling

http://onsemi.com

Figure 7.

The CS1112 provides a very efficient way of controlling

4 output drivers by minimizing the number of I/O pins

through use of the SPI port, and still provides the flexibility

of pulse width modulating the output drivers where needed.

The use of the SPI also allows the integrated circuit to

communicate directly with the microprocessor.

While designed for an automotive environment, the

CS1112 can be used in other applications in the computer

market, industrial market, telecommunications market, or

any other instance where numerous drivers are needed. All

parts are 100% tested and guaranteed to meet all parameters

specified in the electrical characteristics. These

specifications cover the entire voltage range for V

(9.0 V to 17 V), and VDD (4.5 V to 5.5 V).

8

PWR

Page 9

CS1112

FAULT MODE OPERATION

The CS1112 provides protection for a multitude of system

faults and conditions. These include Overvoltage, Current

Limit, Open Circuit, Output Short to Power, Output Short to

Ground, and Flyback Clamp.

Overvoltage

The IC is constantly monitoring the voltage on the V

PWR

pin. If the voltage on this pin exceeds the Overvoltage

Shutdown Threshold (typically 35 V), all outputs

immediately turn off. The programmed outputs (via serial or

parallel input) turn back on once the voltage is brought back

down below this level.

Current Limit/Short to V

BATT

When the output current exceeds the Overcurrent (4.5 A

typical) for the Short Circuit/Overcurrent Sense Time

(typically 62.5 µs) as it would do during an output short to

V

, its fault status bit will be latched to a logic one. The

BATT

fault status bit remains latched until the rising edge of CSB.

The output will go into a low duty cycle mode (typically

1.56%) as long as the overcurrent condition exists, and the

channel is on. This protects the integrated circuit from

damaging itself due to its thermal limits.

Open Circuit/Short to Ground

Open circuit conditions are detected while the outputs are

off. A fault bit is set when the Open Load “Off” Detection

Voltage (typically 0.5 × V

) is present for the Open Load

DD

“Off” Sense Time (typically 62.5 µs) as it would do during

an output short to ground.

Flyback Clamp

While the flyback clamp is not a fault mode, it is a

protection feature of the CS1112. When driving inductive

loads, it is normal to observe high voltage spikes on the

output pin due to the stored energy in the windings when the

device is turned of f. On–chip clamps on the outputs limit the

voltage amplitude on the pin to prevent damage to the

device. Each output has an Output Clamp which limits the

output voltage to 52 V (typical when measured at 20 mA for

100 µs).

PIN FUNCTION DESCRIPTION

The signal on this pin is clocked from the falling edge of the

SCLK pin. The serial output data provides fault information

for each output and returns most significant bit (bit 7) first.

Bits 0 through 3 are output fault bits for outputs 0 through

3, respectively. In 8–bit SPI mode, bits 0–3, under normal

conditions return all zeros representing no faults. A 1

indicates a fault. The output from this pin conforms to

CMOS logic levels.

R

OSC

An 82 kΩ resistor tied to ground sets up an accurate

internal current source.

CSB

The CSB (Chip Select Bar) is the select pin when the

microprocessor wants to communicate with the CS1112. A

low on this pin enables the SPI communication with the

device and enables the SO pin. After the digital word is

clocked into the IC, a transition from low to high on the CSB

pin translates the last 4 bits of information turning the

outputs on or off. An internal active pull–up is connected to

this input. CMOS logic levels are required on this pin.

SCLK

The SCLK (Serial Clock) clocks the internal shift

registers. This pin controls the data being shifted into the SI

pin, and data being shifted out of the SO pin. CMOS logic

levels are required on this pin.

IN0, IN1, IN2, IN3

These pins control their corresponding numbered output.

These are the parallel input pins which may be used to PWM

the outputs. They have 230 mV of hysteresis. These inputs

are OR’d with their corresponding input bit in the serial

control byte. An internal active pull–down is connected to

these pins. CMOS logic levels are required on these pins.

OUT0, OUT1, OUT2, OUT3

These pins are the output low–side driver pins. They all

have typically 1.0 Ω R

DS(ON)

at V

= 13 V. Current limit

PWR

on these pins has a minimum specification of 3.0 A. A low

duty cycle mode (1.5% typ.) will initiate at a minimum of 1A

and before the current limit.

SI

The SI (Serial Input) receives serial 8–bit or 16–bit words

sent most significant bit first. Data is clocked in on the rising

edge of SCLK. An internal active pull–down is connected to

this input. CMOS logic levels are required on this pin.

SO

The SO (Serial Output) can be connected to the serial data

input pin of the microprocessor, or it can be daisy–chained

to the serial input (SI) of another SPI compatible device.

This pin is tri–stated unless a low CSB pin selects the device.

http://onsemi.com

V

PWR

14 V Battery voltage input. 5.0 mA (max) is needed.

V

DD

5.0 V Supply input. 5.0 mA (max) is needed.

STATUS

Open drain output. This pin goes low when an open load

or overcurrent condition occurs on any of the outputs. This

provides immediate notification to the controller that a fault

is present. The controller can subsequently query the device

(serially) to determine its origin.

9

Page 10

–T–

SEATING

PLANE

CS1112

PACKAGE DIMENSIONS

SO–24L

DW SUFFIX

CASE 751E–04

ISSUE E

–A–

1324

–B–

1

12

D24X

0.010 (0.25) B

M

S

A

T

S

12X

P

0.010 (0.25) B

M

J

M

F

R X 45

C

M

G22X

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 15.25 15.54 0.601 0.612

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

D 0.35 0.49 0.014 0.019

F 0.41 0.90 0.016 0.035

G 1.27 BSC 0.050 BSC

J 0.23 0.32 0.009 0.013

K 0.13 0.29 0.005 0.011

M 0 8 0 8

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

INCHESMILLIMETERS

PACKAGE THERMAL DATA

Parameter

R

Θ

JC

R

Θ

JA

SO–24L Unit

Typical 9 °C/W

Typical 55 °C/W

http://onsemi.com

10

Page 11

Notes

CS1112

http://onsemi.com

11

Page 12

CS1112

POWERSENSE is a trademark of Semiconductor Components Industries, LLC (SCILLC).

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 Toll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (Mon–Fri 2:30pm to 7:00pm CET)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (Mon–Fri 2:00pm to 7:00pm CET)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (Mon–Fri 12:00pm to 5:00pm GMT)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, UK, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Toll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

12

CS1112/D

Loading...

Loading...