Page 1

SERVICE MANUAL

SERVICE MANUAL

BLU-RAY DISC PLAYER

MODEL DV-BD507(B)CDC1N

DV-BD507

Ref. No. 4149

072009 (CDC1N)

Black model

120 V AC, 60HzB CDC1N

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

RC-730DV

Page 2

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

How to Initialize the BLU-RAY Disc Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Manufactured under license from Dolby Laboratories.

Dolby and the double-D symbol are trademarks of Dolby Laboratories.

Page 3

SPECIFICATIONS

1-1-1 E5K50SP

Page 4

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

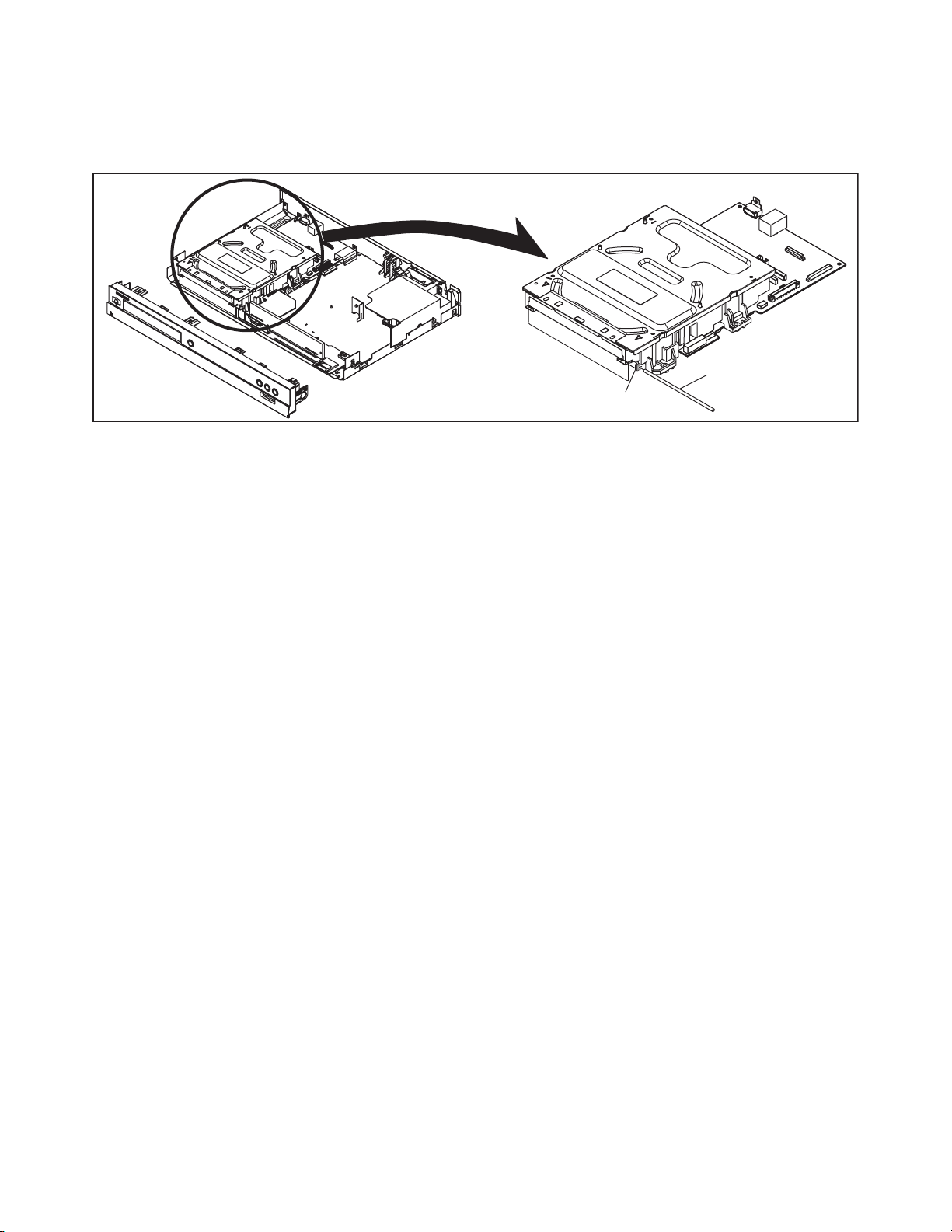

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of BD mechanism.

1-2-1 B2NLBSP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

1-3-1 BDN_ISP

Page 6

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

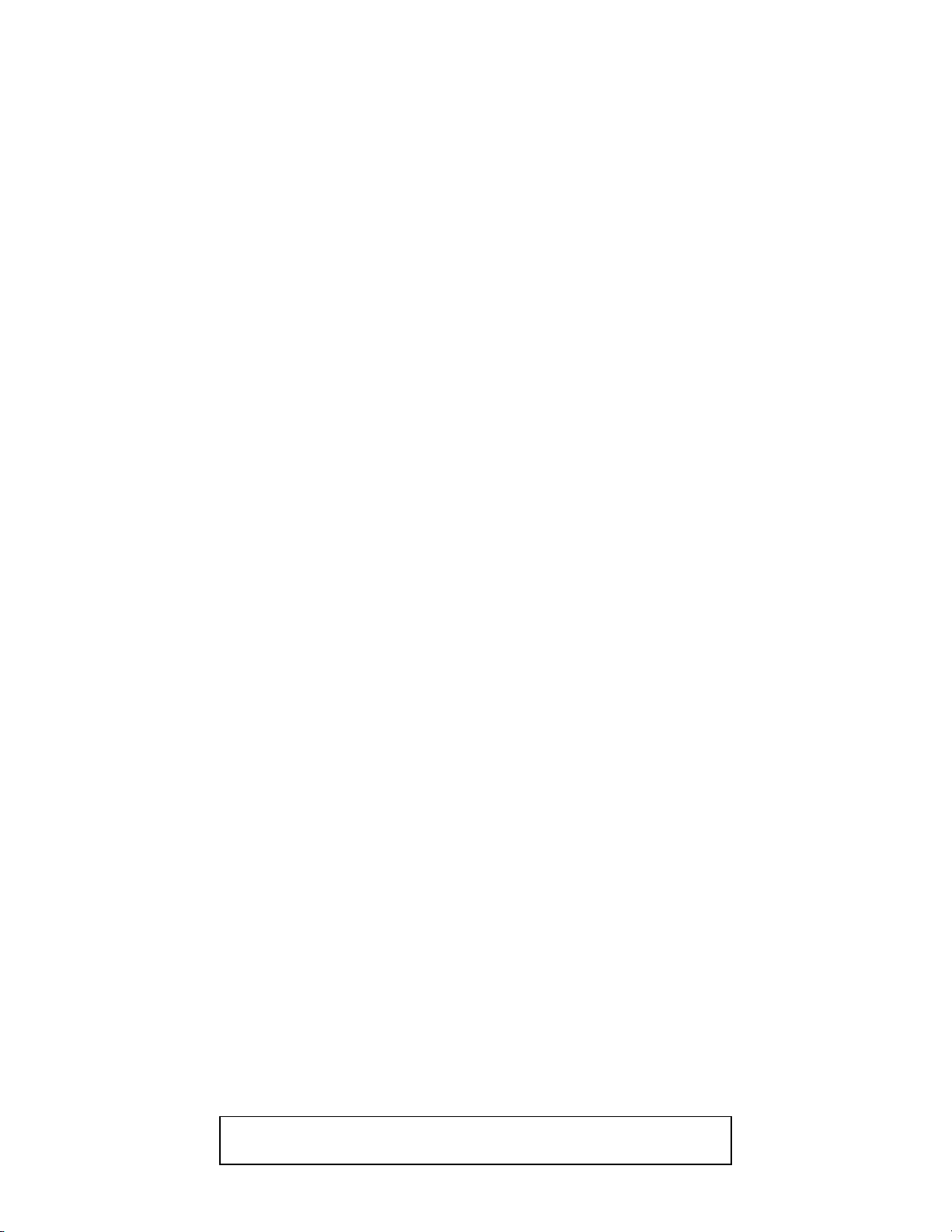

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d’)

120 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

≥ 3mm(d)

≥ 4mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

parallel

120 V

50kΩ RES.

Connected in

parallel

Note:This table is unofficial and for reference only. Be sure to confirm the precise values.

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-3-2 BDN_ISP

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Page 7

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

To p Vi ew

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

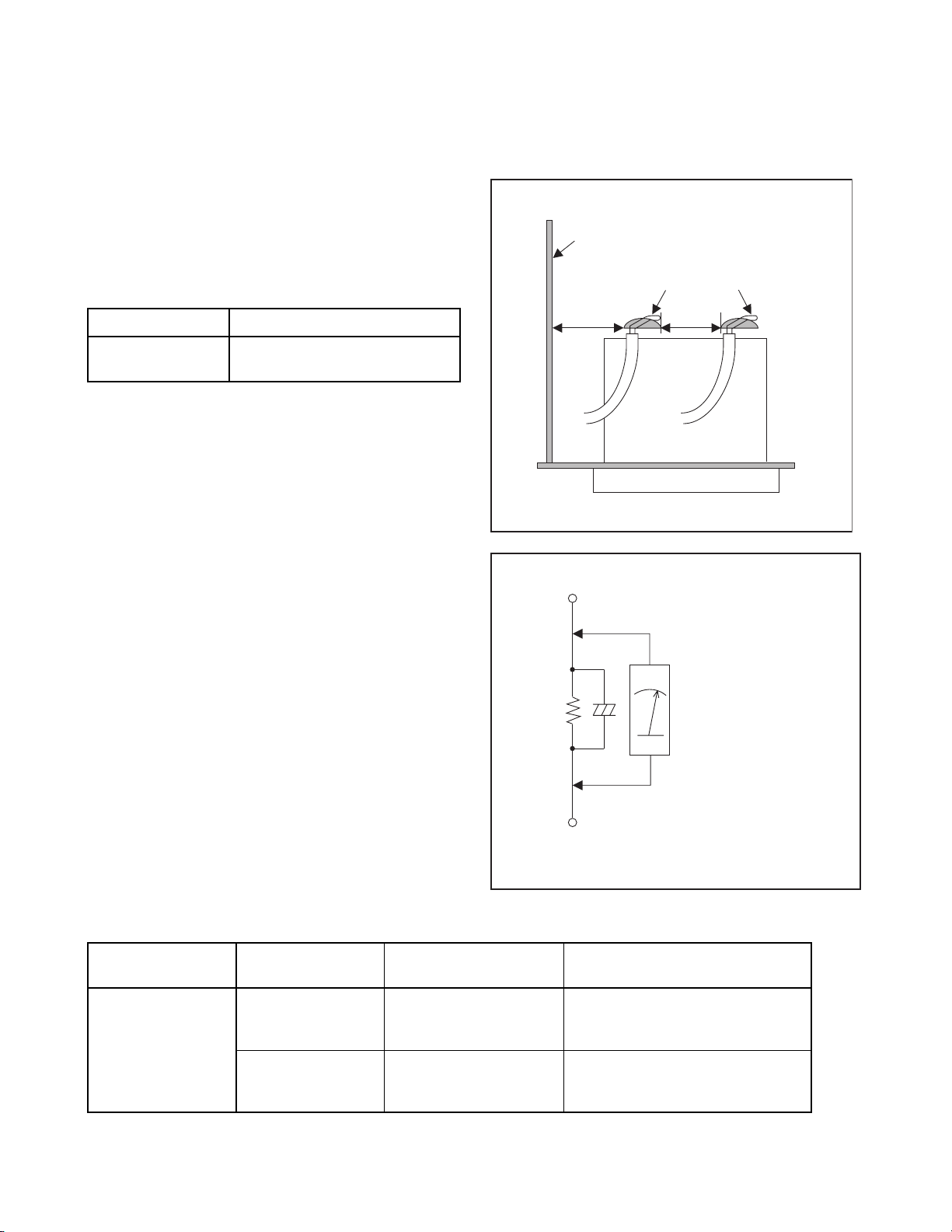

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 BDN_SN

Page 8

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Ta pe

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 BDN_SN

Page 9

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 BDN_SN

Page 10

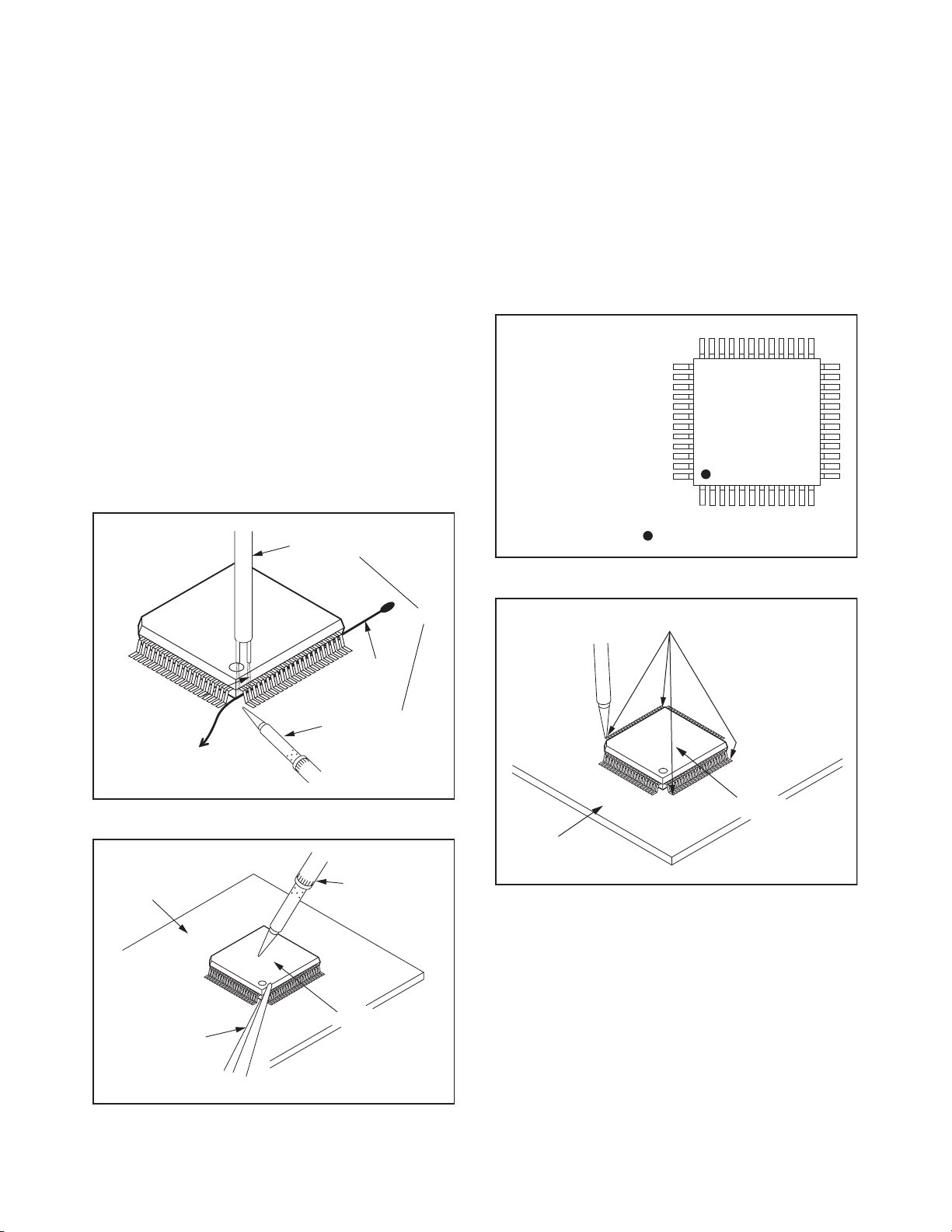

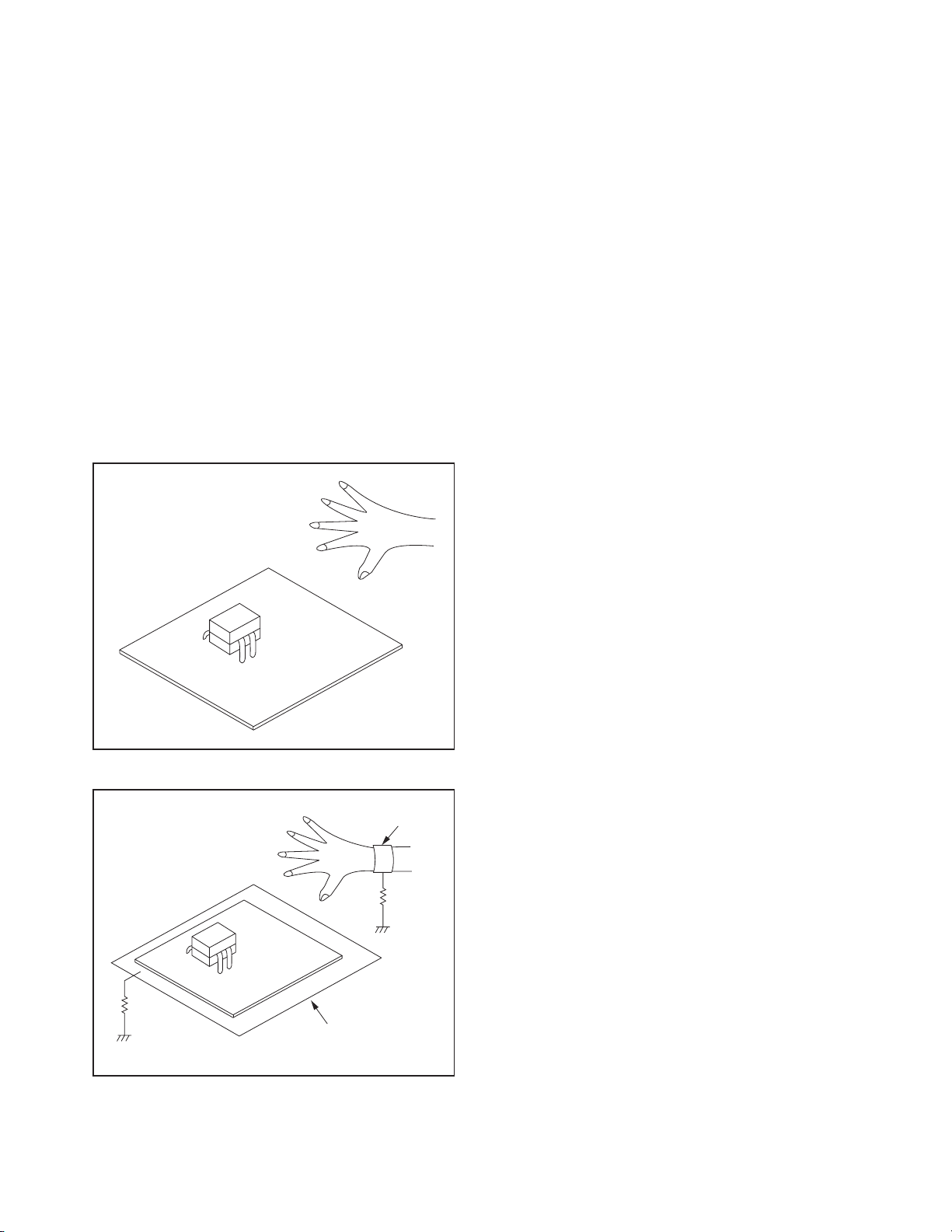

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 BDN_SN

Page 11

CABINET DISASSEMBLY INSTRUCTIONS

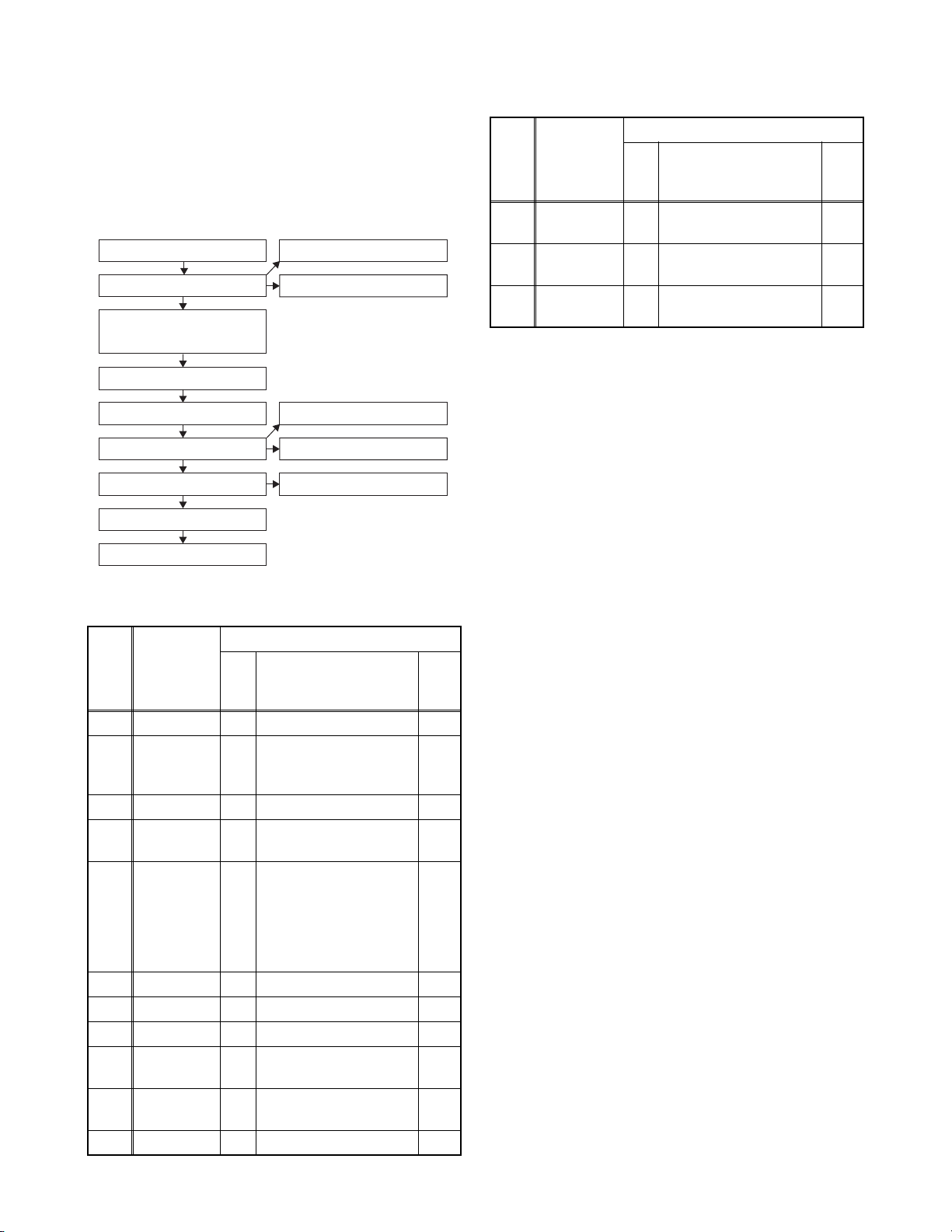

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Top Cover

[2] Front Assembly

[5] BD Main CBA &

BD Mechanism Assembly

[6] SD-A CBA

[7] SD-B CBA

[8] SD-C CBA

[9] Rear Panel

[11] AV CBA

[12] Power Holder

[3] Front CBA

[4] Power SW CBA

[13] Shield Bracket

[14] SD PCB Bracket

[10] Motor DC Fan

2. Disassembly Method

ID/

Loc.

No.

[1] Top Cover D1 9(S-1) ---

[2]

[3] Front CBA D2 --------------- ---

[4]

[5]

[6] SD-A CBA D3 Desolder --[7] SD-B CBA D3 Desolder --[8] SD-C CBA D3 --------------- ---

[9] Rear Panel D4

[10]

[11] AV CBA D5 5(S-11) ---

Part

Front

Assembly

Power SW

CBA

BD Main

CBA & BD

Mechanism

Assembly

Motor DC

Fan

Fig.

No.

*5(L-1), *3(L-2),

D2

*5(S-2) *CN2002,

*CN3001

D2 --------------- ---

(S-3), 2(S-4), 4(S-5),

2(S-6), 4(S-7),

*CN6001, *CN7101,

D3

*CN7601, Main PCB

Earth Plate, Front

Shield

2(S-8), 4(S-9),

2(S-10)

D4 *CN2004, Fan Holder ---

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

1

2

---

ID/

Loc.

No.

[12]

[13]

[14]

↓

(1)

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to “Reference Notes.”

Part

Power

Holder

Shield

Bracket

SD PCB

Bracket

↓

(2)

Fig.

No.

D5 (S-12) ---

D5 4(S-13) ---

D5 (S-14) ---

↓

(3)

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

↓

(4)

Note

↓

(5)

Reference Notes

1. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

2. The BD Main CBA & BD Mechanism Assembly

is adjusted as a unit at factory. Therefore, do

not disassemble it. Replace the BD Main CBA

& BD Mechanism Assembly as a unit.

1-5-1 E5K50DC

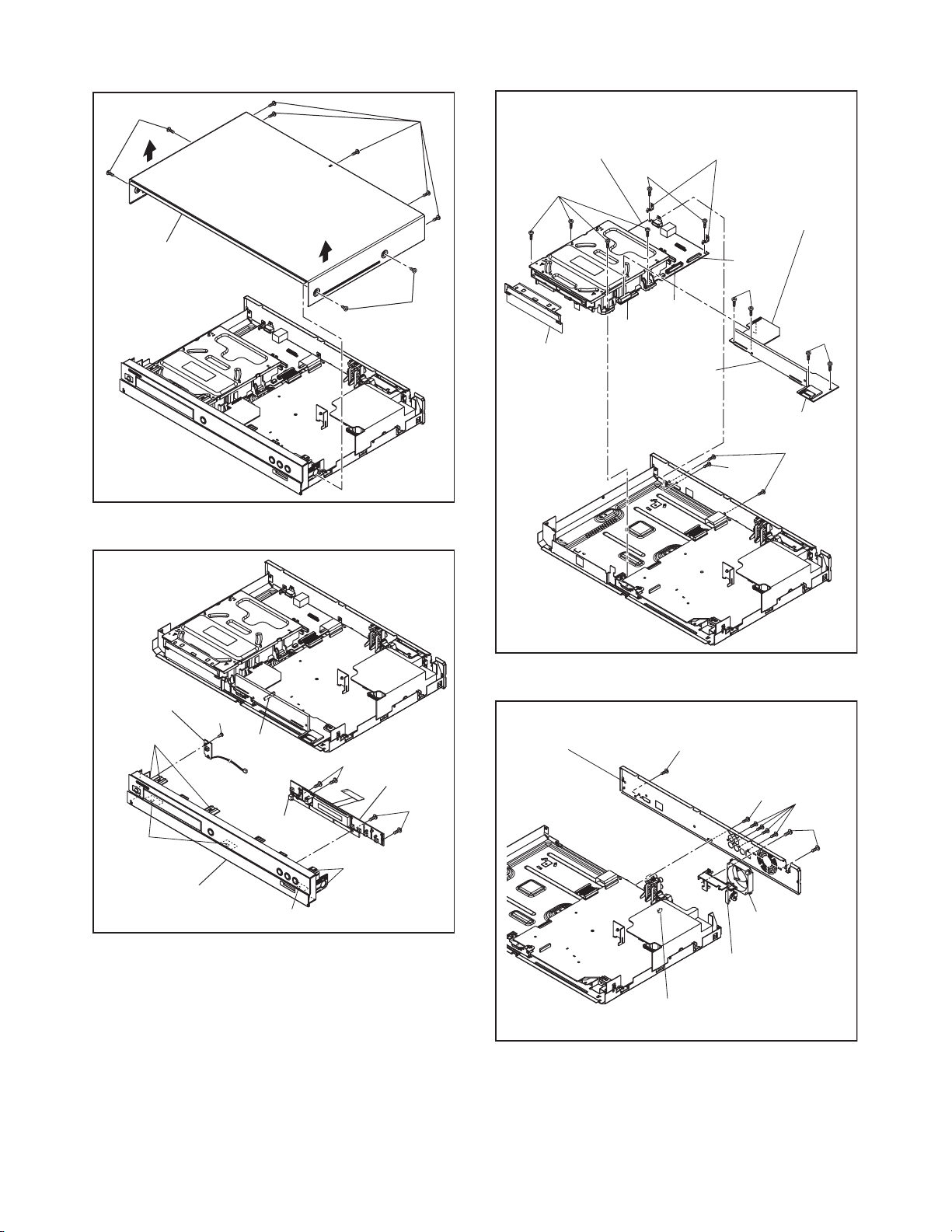

Page 12

(S-1)

(S-1)

[5] *BD Main

CBA & BD

Mechanism

Assembly

(S-5)

Main PCB

Earth Plate

(S-6)

[6] SD-A CBA

[1] Top Cover

[4] Power SW

CBA

(L-1)

(L-2)

(S-2)

CN2002

CN3001

(S-2)

[3] Front CBA

(S-1)

Fig. D1

(S-2)

CN6001

CN7601

Front Shield

[7] SD-B CBA

* See Reference Notes 2.

[9] Rear Panel

(S-8)

CN7101

(S-7)

[8] SD-C CBA

(S-4)

(S-3)

(S-8)

(S-7)

Fig. D3

(S-9)

(S-10)

[2] Front Assembly

(L-2)

(L-1)

Fig. D2

[10] Motor

DC Fan

Fan Holder

CN2004

Fig. D4

1-5-2 E5K50DC

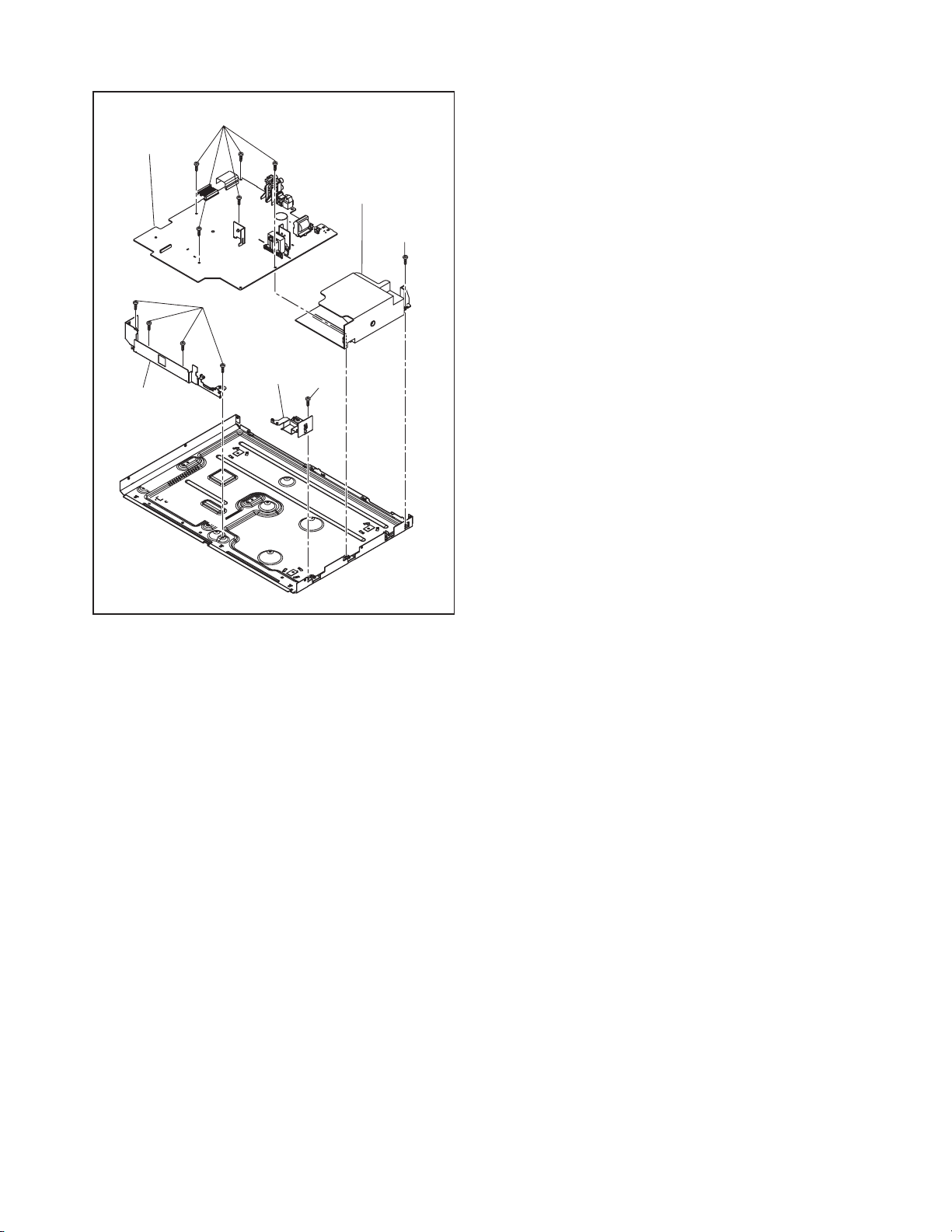

Page 13

[11] AV CBA

[13] Shield

Bracket

(S-11)

(S-13)

[14] SD PCB

Bracket

[12] Power Holder

(S-12)

(S-14)

Fig. D5

1-5-3 E5K50DC

Page 14

3. How to Eject Manually

1. Remove the Top Cover.

2. Insert a screwdriver, etc. into the Hole A straightly so that the Portion A is pushed.

3. Pull the tray out manually and remove a disc.

Portion A

Screwdriver,

hexagon wrench

1-5-4 E5K50DC

Page 15

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. a appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. a

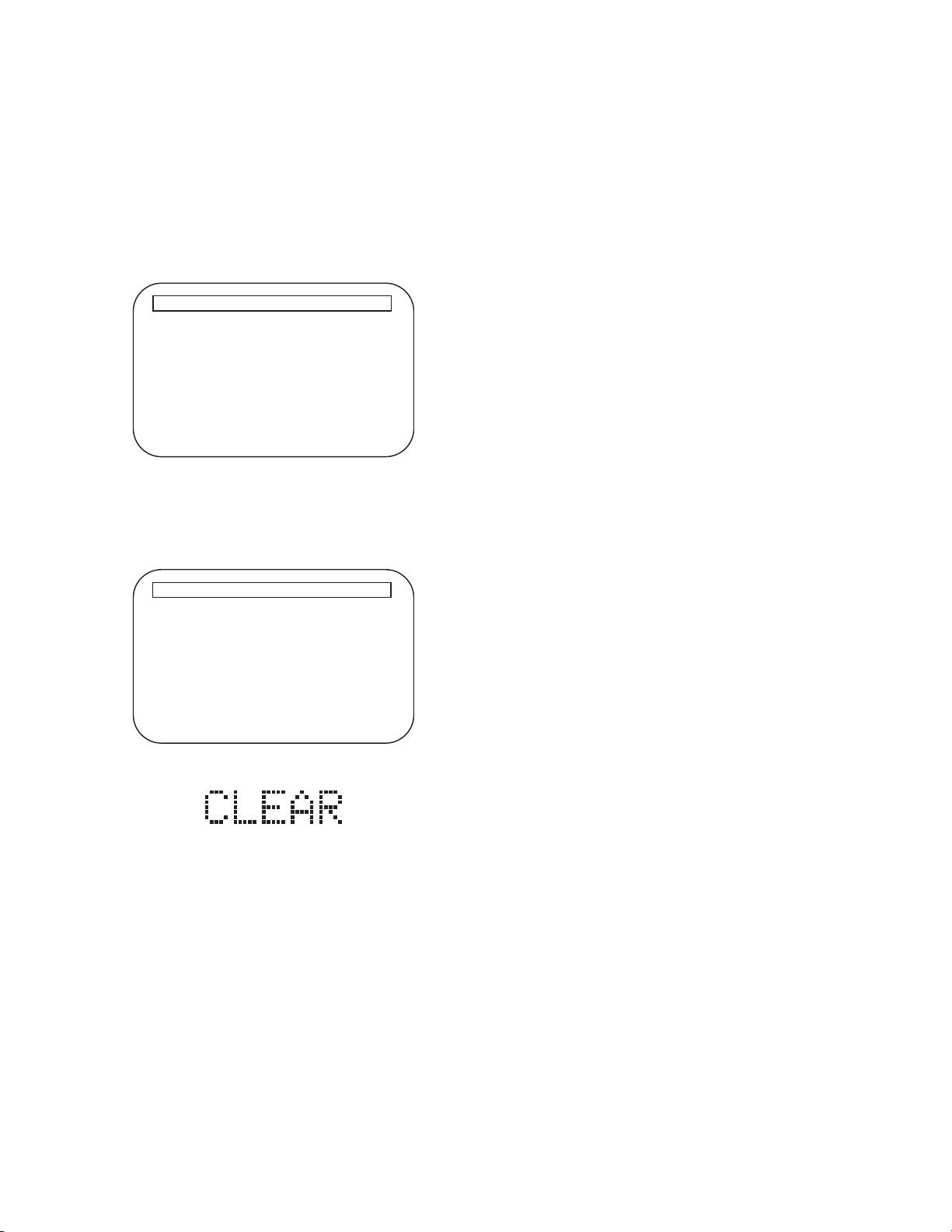

4. Press [ C ] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

EEPROM CLEAR : OK

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. b

Fig. c

5. To exit this mode, press [ON/STANDBY] button.

1-6-1 E5K50INT

Page 16

FIRMWARE RENEWAL MODE

Note: The file extension of the available firmware is

“b20”.

1. Turn the power on and remove the disc on the tray

and close the tray.

2. To put the BD player into version up mode, press

[9], [8], [7], [6], and [POP UP MENU/MENU]

buttons on the remote control unit in that order.

The tray will open automatically.

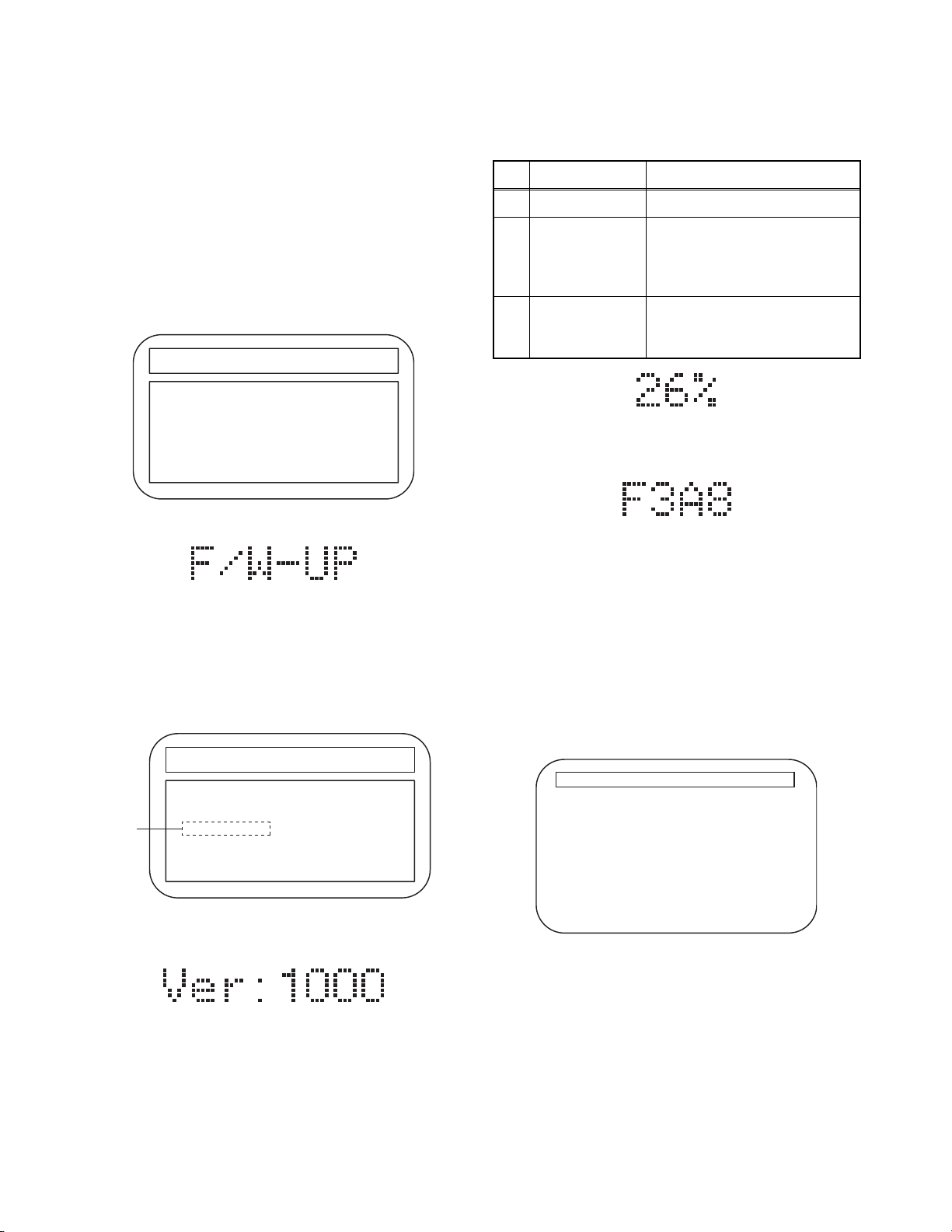

Fig. a appears on the screen and Fig. b appears

on the VFD.

"

" differs depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

Please insert a Disc

for F/W Version Up

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

3. Load the disc for version up.

4. The BD player enters the F/W version up mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD. Make sure to insert the

proper F/W for the state of this model.

"

" differs depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

1. ALL

(*1)

Ver. *.*** ************A*.b20

Now Loading...

The appearance shown in (*1) of Fig. c is

described as follows:

No. Appearance State

1 Now Loading... Loading the disc

Sending files into the

2 Reading...

memory.

After reading, automatically

the tray opens.

Writing new version data,

3 See FL Display

the progress will be displayed

as shown in Fig. e.

Fig. e VFD in Vresion Up Mode

5. After programming is finished, the checksum on

the VFD (Fig. f).

Fig. f

VFD upon Finishing the Programming Mode (Example)

Checksum appears on the VFD then the tray will

open automatically. Remove the disc on the tray.

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug

it again.

7. Turn the power on.

8. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT : POWER

Fig. c Programming Mode Screen (Example)

Fig. d VFD in Programming Mode (Example)

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. g

1-7-1 E5K50FW

Page 17

9. Press [ C ] button on the remote control unit.

Fig. h appears on the screen and Fig. i appears on

the VFD.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. j appears on the screen.

"

" differ depending on the models.

*******

Version Info

EEPROM CLEAR : OK

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. h

Fig. i

10. To exit this mode, press [ON/STANDBY] button.

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. j

4. To exit this mode, press [ON/STANDBY] button.

1-7-2 E5K50FW

Page 18

BLOCK DIAGRAMS

System Control Block Diagram

TO POWER SUPPLY

TO VIDEO

BLOCK DIAGRAM

BLOCK DIAGRAM

TO AUDIO

BLOCK DIAGRAM

EV+5V

SENSOR

REMOTE

RS3000

VFD

FRONT CBA

19 20 21 22

FL3000

KEY

SWITCH

Q3000

CN3001

POWER-LED

1

KEY-1

2

WX3000

1

2

D3007

POWER

POWER

SW3007

POWER SW CBA

(SUB MICRO CONTROLLER)

IC2000

MUTE1

IC2001

MUTE2

21MUTE1

22MUTE2

RESET

14

RESET

EV+3.3V

PWSW1

PWSW2

A33-PW-CONT

4

PWSW137PWSW2

OSC1

8

8MHz

X2000

FL-SW

31

A33-PW-CONT

OSC2

9

X'TAL

FAN-LOCK

32

63

FL-SW

FAN-LOCK

FAN-CONT1

FAN-CONT2

25FAN-CONT1

26FAN-CONT2

AUDIO-MUTE

24AUDIO-MUTE

SWITCHING

Q2620, Q2621

BUFFER

Q2618

CEC-OUT

28 CEC-IN

30

BUFFER

Q2619

CN2001

56

POWER-LED

18 16FL-SDA

CN2002 CN3000

33

FL-SDA

16 14FL-STB

17 15FL-SCL

49

34

FL-SCL

FL-STB

-LED

POWER

64KEY-1

97REMOTE

53

15 13FL-RESET

62

27

50

KEY-1

REMOTE

FL-RESET

SUB-TXD

SUB-RXD

SYS-RESET

3

15

16

TX(+)

123

JK6401

ETHERNET JACK

12

IC6401

(ETHERNET INTERFACE)

39

38

TX(-)

11

36

RX(+)

10

35

RX(-)

6

9

ETHERNET

INTERFACE

33

88SUB-TXD

99SYS-RESET

SCL0

V31

CN7101 CN2001

SDA0

W30

77SUB-RXD

V32

U34

TXD1

RXD1

MII-RXCLK

MII-RXD1

MII-RXD0

J1J3J4

MII-RXD3

MII-RXD2

MII-TXCLK

J2

K2

H4

AE32

XTRST

MII-TXD0

MII-TXD1

H5

G4

T34

XRST

MII-TXD3

MII-TXD2

F4

G5

Q6702

IC6701

Q6701

RESET

2 1

P-ON+1.8V

BD MAIN CBA AV CBA

E5K50BLS

22CEC

CN7101

13

JK7501

CEC

SCL

SDA

IC6903 (EEPROM)

28

23

22

21

20

IC6001

5

(MAIN MICRO CONTROLLER)

6

1-8-1

Page 19

Digital Signal Process 1 Block Diagram

VIDEO SIGNAL AUDIO SIGNAL

TO DIGITAL SIGNAL

PROCESS 2 BLOCK

DIAGRAM

(IC6001)

BD+

CSS

AACS

STREAM

FE

DIGITAL

CONTROL

SIGNAL

PROCESS

COPY

PROTECT

CPRM

(MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

IC6001

B28

A28

20 SE02

18 SE01

MPX

IC201 (FRONT-END PROCESSOR)

97-100

ASENV

H34

G34

61 WBL

59

/LPP

WOB

MATRIX

102-105

107-110

B34

C33

66

655453

RF

EQUALIZER

RF

GENERATOR

868588

TRACKING-CONTROL

FOCUS1-CONTROL

A24

7 6

FOCUS 1

ACTUATOR

DRIVE

18

FOCUS2-CONTROL

D23

8 9

12

FOCUS 2

ACTUATOR

DRIVE

17

16

SD ATA 2

SD ATA 1

SCLK2

SCLK1

J34

J33

SCLK1

SD ATA 1

83 78 79

87

M31

M32

IC604 (OP AMP)

TRACKING

IC603 (MOTOR DRIVE)

212019

E23

1 2

22

ACTUATOR

DRIVE

COLLIMATE

IC602 (MOTOR DRIVE)

236

EXPA-CONTROL

EXPB-CONTROL

B22

D22

132310

LENS

MOTOR DRIVE

5

IC603 (MOTOR DRIVE)

32

SLED1-CONTROL

SLED2-CONTROL

D24

C24

4

30

SLED

MOTOR DRIVE

2

33

TRAY-OUT

TRAY-IN

INLIMIT

LOAD-CONTROL

C22

D21

E21

SPINDLE-CONTROL

B3

E24

SPINDLE-FG

B25

BD MAIN CBA

SPINDLE

MOTOR

DRIVE

4

12

13

LOADING

MOTOR DRIVE

1

14

15

10

IC601 (MOTOR DRIVE)

242119131415161718

CN101

A-D 21-24

E-H 26-29

RF(+) 17

BD MECHANISM

RF(-) 18

BDRF(+) 14

OEIC

(CD/DVD)

TRAY-OUT

CN603

V2

U3

W1

INLIMIT 4

TRAY-IN 1

INNER

SW

TRAY-IN

HU(-) 6

HU(+) 5

SPINDLE

HV(-) 8

HB(-) 11

HV(+) 7

HW(-) 10

HW(+) 9

MOTOR

E5K50BLD1

CN101

TD 3

TR 4

FD1 1

FR1 2

FR2 5

LASER

DIODE

FD2 6

DRIVE

EXPA(-) 7

EXPB(-) 8

EXPA(+) 9

EXPB(+) 10

SCLK2 38

SD ATA 2 4 0

BDRF(-) 15

OEIC

(BD)

CN601

SLD2(+) 4

SLD2(-) 3

SLED

CN602

SLD1(-) 1

LOAD(+) 5

LOADING

MOTOR

LOAD(-) 6

TRAY-OUT 2

SLD1(+) 2

MOTOR

1-8-2

Page 20

Digital Signal Process 2 Block Diagram

TO

VIDEO

BLOCK

DIAGRAM

SCL3

VIDEO

VIDEO SIGNAL AUDIO SIGNAL

C15

VIDEO-Pr/Cr

VIDEO-Y(I/P)

VIDEO-Pb/Cb

F17

B17

D18

VIDEO

DAC

PRMVS

PRMCLK

A2B6B5

CLK

VSYNC

PRMHS

PRMC(0-11)

A4,A8,A9,B4,B9,C5,C9,

C11,D8,D10,E10,E11

HSYNC

DIGITAL

SDA3

PRMY(0-11)

IC6703

R33

U31

A3,A6,A7,B7,C4,C6,C7,

C8,D6,D9,E8,E12

SCL3

SDA3

VIDEO

OUT

2

3

SCL

SDA

(CLOCK GENE.)

AL5

33M CLOCK

I/P CONVERTER

/SCALING

27MHz

OSC

X6701

1

16

CLOCK

GENE.

789

E20

A19

AL34

33M CLOCK

74M CLOCK

27M CLOCK

10

D20

768K CLOCK

TO

AUDIO

BLOCK

DAC-SCK

DAC-BCK

A12

DAC-LRCK

B13

D12

DIAGRAM

SPDIF

B12

MS1

DATA

A13

AC31

TO

VIDEO

BLOCK

DIAGRAM

MC

MD

HDMI-BCK

HDMI-MCK

HDMI-DATA0

HDMI-DATA1

E13

B10

HDMI-LRCK

HDMI-DATA2

HDMI-DATA3

HDMI-SPDIF

AUDIO

OUT

C14

B14

B11

A10

A11

D11

C12

C10

DIGITAL

IC6001 (MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

SD-A CBA

SD-B CBA

CN7601CN4001

11 6SDDAT0

CN4003

11 11SDDAT0

CN4102 CN4101

SD I/F

AF32,AG34,

SD DATA(0-3)

13 4SDDAT1

13 13SDDAT1

SDCLK

AH34

AH33,AJ34

116SDDAT2

314SDDAT3

98SDCLK

11SDDAT2

33SDDAT3

99SDCLK

MEDIA

PROCESSOR

FROM

DIGITAL

SIGNAL

PROCESS 1

BLOCK

DIAGRAM

(IC6001)

Java (BD-J)

(NAND FLASH MEMORY)

IC6902

MPEG-2

DiVX

VC-1

H.264

DECODER

HD (TS)

ED (0-7)

NAND FLASH

MEMORY (64M x 8bit)

SD (PS)

C0DQ (0-31)

(DDR2 SDRAM)

IC6501,IC6502

MEMORY

I/F

C0A (0-12)

DDR2 SDRAM

(1Gbit )

C1DQ (0-31)

(DDR2 SDRAM)

IC6601,IC6602

C1A (0-12)

DDR2 SDRAM

(512Mbit)

115SDDAT2

313SDDAT3

97SDCLK

11 5SDDAT0

13 3SDDAT1

CN4004

BD MAIN CBA

SD-C CBA

CN4002

SD

CARD

SLOT

1-8-3

E5K50BLD2

Page 21

Video Block Diagram

VIDEO OUT

(COMPOSITE)

JK2200

VIDEO-Y

JK2300

OUT

VIDEO-Pb/Cb

OUT

VIDEO-Pr/Cr

OUT

DDC DATA

DDC CLOCK

HOT PLUG

DETECT

191516

HDMI-CONNECTOR

JK7501

T.M.D.S DATA2-

T.M.D.S DATA2+

T.M.D.S DATA1-

T.M.D.S DATA1+

31649

T.M.D.S DATA0-

T.M.D.S DATA0+

7

T.M.D.S CLOCK+

T.M.D.S CLOCK-

10

12

VIDEO SIGNAL AUDIO SIGNAL

AV CBABD MAIN CBA

75Ω

DRIVER

2dB

AMP

LPF 25

4dB

AMP

IC2300 (VIDEO DRIVER)

3

C2323

6.75MHz

75Ω

2dB

LPF

4dB

8 20

DRIVER

AMP

AMP

17

75Ω

DRIVER

2dB

AMP

LPF

13.5/37MHz

13.5/37MHz

4dB

AMP

10

CN2001CN7101

15

75Ω

DRIVER

2dB

AMP

LPF

4dB

AMP

12

13.5/37MHz

MUTE1

2

MUTE1

MUTE2

TO SYSTEM CONTROL

BLOCK DIAGRAM

MUTE2

13

118

DDC

AUTHENT

/CATION

KEY

EXCHANGE

REGISTER

IIC

I/F

113

116

CLK

121

IC7501 (HDMI INTERFACE)

I/F

VS

83

23251921151713

120

119

HS

84

50,51,53-57,59,

87,88,90,91

TMDS

SERIALIZER

TMDS

ENCODER

HDCP

CIPHER/

ENCRYPTOR

AV

CONTROLLER

VIDEO

I/F

70-73,75-78,

92,94,102,103

11

AUDIO

I/F

46454442413936

35

16 16VIDEO-Y(I/P)

14 14VIDEO

VIDEO

VIDEO-Y(I/P)

18 18VIDEO-Pb/Cb

20 20VIDEO-Pr/Cr

VIDEO-Pb/Cb

VIDEO-Pr/Cr

TO DIGITAL

SIGNAL

1-8-4

PROCESS 2

BLOCK DIAGRAM

SCL3

SDA3

PRMCLK

PRMVS

PRMHS

PRMC(0-11)

PRMY(0-11)

HDMI-DATA0

HDMI-DATA1

HDMI-DATA2

HDMI-DATA3

HDMI-MCK

HDMI-BCK

HDMI-LRCK

HDMI-SPDIF

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK DIAGRAM

E5K50BLV

Page 22

Audio Block Diagram

AUDIO SIGNAL

AUDIO(L)-

OUT

JK2200 (REAR)

MUTE-ON

Q2203

DRIVE

Q2200

7

AUDIO(R)-

Q2202

Q2201

1

OUT

MUTE-ON

DRIVE

DIGITAL

JK2100

(REAR)

BUFFER

Q2100

AUDIO OUT

(COAXIAL)

DIGITAL

AUDIO OUT

(OPTICAL)

JK2400 (REAR)

AV CBABD MAIN CBA

IC2200

(OP AMP)

CN7101 CN2001

(L-CH)

6

24 24AUDIO(L)

22 22AUDIO(R)

14

15

(R-CH)

2

55SPDIF

26 26AUDIO(L)-MUTE

25 25AUDIO(R)-MUTE

1

R-CH

MUTE

L-CH

MUTE

AUDIO-MUTE

TO SYSTEM CONTROL

BLOCK DIAGRAM

16

IC7001

(AUDIO D/A CONVERTER)

AUDIO

DAC

3458276

MCMDDAC-SCK

DAC-BCK

DAC-LRCK

TO DIGITAL

SIGNAL

PROCESS 2

MS1

DATA

BLOCK DIAGRAM

1-8-5

SPDIF

E5K50BLA

Page 23

Power Supply Block Diagram

TO BD MAIN

CBA

(CN6001)

AUDIO+3.3V

P-ON+1.2V

P-ON+1.8V

2 P-ON+5V(1)

5,6 P-ON+3.3V

9-11

17-20

23 P-ON+5V(2)

3,4 P-ON+10.5V

CN2000

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

EV+5V

EV+3.3V

TO SYSTEM

CONTROL

BLOCK

DIAGRAM

P-ON+3.3VF1F2

P-ON+5V

FL

FL-SW

PWSW2

FAN-LOCK

FAN-CONT1

FAN-CONT2

PWSW1

A33-PW-CONT

Q2611

Q2013

Q2610

P-ON+14.5V-B

P-ON+14.5V-A

CONTROL

(HIGH SPEED)

FAN

Q2000,Q2001

CN2004

FAN

FAN

Q2002,Q2003

"Ce symbole reprèsente un fusible à fusion rapide."

"This symbol means fast operating fuse."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

F

A V

11

CONTROL

2FAN-LOCK

FAN-VCC 1

Q2204,Q2205

(LOW SPEED)

+3.3V

Q1011

12

SW+3.3V

REG.

15

Q2603

SW+14.5V

13

SW+10.5V

Q2607

Q2602

Q2601

Q2606

SW+5V

Q2608, Q2609

LIMIT

CURRENT

Q2604

SW+5V

Q2605

+3.3V

IC2600

REG.

Q2600

IC2602

REG.

+1.8V

+1.2V

IC2601

REG.

Q2012 Q2101

Q2014

Q2612

AV CBA

Q2613

COLD

REG.

9

10

16

14

1

SHUNT

2

T1001

2

BRIDGE

RECTIFIER

D1001 - D1004

LINE

FILTER

L1001

F

F1001

2A 250V

A V

HOT CIRCUIT. BE CAREFUL.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

AC1001

AC CORD

4

Q1003

5

)

SWITCHING

SWITCHING CONTROL

IC1001

(

CONTROL

2

1

VDD

3

6

1-8-6

4

IC1003

ERROR

7

6

VOLTAGE DET

3

IC1011

ERROR

VOLTAGE DET

HOT

E5K50BLP

Page 24

SCHEMATIC DIAGRAMS / CBA AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “#” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

3

, M = 106).

-6

µF).

1-9-1 BDN_SC

Page 25

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

r

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE

F

A V

SAME TYPE FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D'INCELE N'UTILISER

QUE DES FUSIBLE DE MÊME TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

This symbol means fast operating fuse.

Ce symbole represente un fusible a fusion rapide.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and STOP mode on the schematics are as shown below:

2

1

(Unit: Volt)

The same voltage for

both PLAY & STOP modes

5.0

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mode

STOP mode

5. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line numbe

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

3

AREA D3

2

1

ABCD

AREA B1

1-D3

1-B1

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

1-9-2 BDN_SC

Page 26

AV 1/3 Schematic Diagram

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

F

A V

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

1-9-3

E5K50SCAV1

Page 27

AV 2/3 Schematic Diagram

1-9-4

E5K50SCAV2

Page 28

AV 3/3 Schematic Diagram

1-9-5

E5K50SCAV3

Page 29

Front & Power SW Schematic Diagram

1-9-6

E5K50SCF

Page 30

SD-A, SD-B & SD-C Schematic Diagram

1-9-7

E5K50SCSD

Page 31

BD Main 1/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-8

E5K50SCBD1

Page 32

BD Main 2/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-9

E5K50SCBD2

Page 33

BD Main 3/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-10

E5K50SCBD3

Page 34

BD Main 4/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-11

E5K50SCBD4

Page 35

BD Main 5/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-12

E5K50SCBD5

Page 36

BD Main 6/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-13

E5K50SCBD6

Page 37

BD Main 7/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-14

E5K50SCBD7

Page 38

BD Main 8/11 Schematic Diagram

1-9-15

E5K50SCBD8

Page 39

BD Main 9/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-16

E5K50SCBD9

Page 40

BD Main 10/11 Schematic Diagram

1-9-17

E5K50SCBD10

Page 41

BD Main 11/11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-9-18

E5K50SCBD11

Page 42

AV CBA Top View

"Ce symbole reprèsente un fusible à fusion rapide."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

A V

F

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

1-9-19

BE5K20F01012A

Page 43

AV CBA Bottom View

"Ce symbole reprèsente un fusible à fusion rapide."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

A V

F

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

1-9-20

BE5K20F01012A

Page 44

Front CBA Top View

Power SW CBA Top View

Front CBA Bottom View

Power SW CBA Bottom View

1-9-21

BE5K50F01031A

BE5K50F01031B

Page 45

SD-A CBA Top View

SD-B CBA Top View

SD-C CBA Top View

SD-A CBA Bottom View

SD-B CBA Bottom View

SD-C CBA Bottom View

BE5K10F01021A

1-9-22

BE5K10F01051

BE5K10F01021C

Page 46

Cabinet

EXPLODED VIEWS

See Electrical Parts List

for parts with this mark.

Some Ref. Numbers are

not in sequence.

BD Main CBA &

BD Mechanism Assembly

2L085

2L082

2L049

B32

A3

2L034

A4

2L081

2L084

2L083

2L084

2L082

2L082

2L081

2L070

AC1001

2L071

1B1

Power SW CBA

2L024

A1X

A6

B68

AV CBA

B15

B69

SD-A CBA

SD-B CBA

2L024

2L086

A6

2L051

B70

2L055

2L051

2L024

B47

B13

SD-C CBA

F1001

A6

B5

B4

FM1001

2L026

2L038

A2

A6

A22

Front CBA

1-10-1 E5K50CEX

Page 47

Packing

Lower Side Upper Side

Some Ref. Numbers

are not in sequence.

S1

S3

X14X6

X40 X2-A X2-B

X19

X10

X1-A

X1-B

S2

A21

S1

A21

1-10-2 E5K50PEX

Page 48

MECHANICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a

# have special characteristics important to safety.

Before replacing any of these components, read

carefully the product safety notice in this service

manual. Don't degrade the safety of the product

through improper servicing.

NOTE: Parts that are not assigned part numbers

(---------) are not available.

Ref. No. Description Part No.

A1X FRONT ASSEMBLY E5K50UD 1VM123179

A2 CHASSIS E5K50UD 1VM330278

A3 TOP COVER E5K20UD 1VM122080

A4 REAR PANEL E5K50UD 1VM227696

A6 FOOT ASSEMBLY E5H50UD 1VM430199A

A21 BAR CODE LABEL E5K50UD ----------

A22 LICENSE LABEL E5K12UD ----------

2L024 SCREW P-TIGHT M3X8 BIND HEAD+ GBJP3080

2L026 SCREW C-TIGHT M3X6 E5610UD 0VM412937A

2L034 SCREW C-TIGHT M3X6 E5610UD 0VM412937A

2L038 SCREW C-TIGHT M3X6 E5610UD 0VM412937A

2L049 SCREW C-TIGHT M3X6 E5610UD 0VM412937A

2L051 SCREW C-TIGHT M3X6 E5610UD 0VM412937A

2L070 B-TIGHT SCREW M3X8 E5E00UD 1VM428563

2L071 B-TIGHT SCREW M3X8 E5E00UD 1VM428563

2L081 S-TIGHT SCREW M3X6 E5E00UD 1VM428564

2L082 SCREW TAP TIGHT M3X5 BIND HEAD+BLK NI GBHC3050

2L083 S-TIGHT SCREW M3X6 E5E00UD 1VM428564

2L084 S-TIGHT SCREW M3X6 E5E00UD 1VM428564

2L085 SCREW S-TIGHT M3X10 E5610UD 0VM412936A

2L086 SCREW S-TIGHT M3X5 E5K10UD 1VM431079

B4 POWER HOLDER E5K20UD 1VM225697

B5 FAN HOLDER E6700UD 1VM320504L

B13 SD PCB BRACKET E5K10UD 1VM329203

B15 SHIELD BRACKET E5K10UD 1VM226756

B32 MAIN PCB EARTH PLATE E5K20UD 1VM430800

B68 FRONT SHIELD E5K20UD 1VM328838

B69 PORON SPONGE E5K20UD 1VM431100

FM1001 MOTOR DC FAN 2D57NL100010 MMEZR12XNR05

PAC K IN G

S1 SIDE PAD E5K50UD 1VM123159

S2 GIFT BOX CARTON E5K50UD 1VM330520

S3 SET BAG E7708UA 0DM400731D

ACCESSORIES

X1-A# OWNERS MANUAL(EN) E5K50UD 1VMN27515

X1-B# OWNERS MANUAL(ES/FR) E5K50UD 1VMN27615

X2-A QUICK GUIDE(EN) E5K50UD 1VMN27593

X2-B QUICK GUIDE(ES/FR) E5K50UD 1VMN27616

X6 MANGANESE DRY BATTERY R6UWC/2STA XB0M311MS003

X10 ACCESSORY BAG E5795ED 0VM416059

X14 AV CORD 1000/BLACK WPZ0102TM018

X19 REMOTE CONTROL UNIT NB821UD NB821UD

X40 WARRANTY CARD E5H50UD 1VMN26325

20090604 1-11-1 E5K50CA

Page 49

ELECTRICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a

# have special characteristics important to safety.

Before replacing any of these components, read

carefully the product safety notice in this service

manual. Don't degrade the safety of the product

through improper servicing.

NOTES:

1. Parts that are not assigned part numbers (---------)

are not available.

2. Tolerance of Capacitors and Resistors are noted

with the following symbols.

C.....±0.25% D.....±0.5% F.....±1%

G.....±2% J......±5% K.....±10%

M.....±20% N.....±30% Z.....+80/-20%

BD MAIN CBA & BD MECHANISM

ASSEMBLY

Ref. No. Description Part No.

1B1 BD MAIN CBA & BD MECHANISM ASSEMBLY N77R0BUN

AV CBA

Ref. No. Description Part No.

AV C BA

Consists of the following:

CAPACITORS

C1001 CAP CERAMIC 470pF/2KV/K CA3D471PAN17

C1002# LINE ACROSS CAP. 0.047µF/250V K CT2E473DC016

C1004 CHIP CERAMIC CAP.(1608) CH J 22pF/50V CHD1JJ3CH220

C1005 CHIP CERAMIC CAP.(1608) B K 1000pF/50V CHD1JK30B102

C1006 CHIP CERAMIC CAP.(1608) B K 0.033µF/50V CHD1JK30B333

C1007# SAFETY CAP. 3300pF/250V CCD2EMA0E332

C1008 ELECTROLYTIC CAPACITOR

C1009 ELECTROLYTIC CAP. 47µF/35V/M CEE47RENW016

C1010 METALIZED FILM CAP. 0.0022µF/400V K CT2H222DT034

C1013 CHIP CERAMIC CAP.(1608) B K 0.01µF/50V CHD1JK30B103

C1014 POLYESTER FILM CAP. (PB FREE) 0.0068µF/

C1015 CERAMIC CAP. B K 470pF/500V CCD2JKS0B471

C1016 ELECTROLYTIC CAP. 220µF/10V M CEB221ENW016

C1017# LINE ACROSS CAP. 0.047µF/250V K CT2E473DC016

C1018 ELECTROLYTIC CAP 2200µF/25V/M CED222ENW009

C1019 ELECTROLYTIC CAP 4700µF/6.3V/M CEA472ENW009

C1021 ELECTROLYTIC CAP. 22µF/50V/M CEF22RENW016

C1022 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C1023 ELECTROLYTIC CAP. 220µF/25V/M CED221ENW016

C1024 ELECTROLYTIC CAP 2200µF/25V/M CED222ENW009

C1025 ELECTROLYTIC CAP 4700µF/6.3V/M CEA472ENW009

C1032 ELECTROLYTIC CAP. 100µF/6.3V/M CEA101ENW016

C1033 CHIP CERAMIC CAP.(1608) B K 0.01µF/50V CHD1JK30B103

C1037 ELECTROLYTIC CAP. 47µF/6.3V/M CEA47RENW016

C1140 ELECTROLYTIC CAP. 22µF/50V/M CEF22RENW016

C2000 CHIP CERAMIC CAP.(1608) B K 0.1µF/25V CHD1EK30B104

C2001 ELECTROLYTIC CAP. 100µF/16V/M CEC101ENW016

C2002 CHIP CERAMIC CAP.(1608) B K 0.1µF/25V CHD1EK30B104

C2005 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

ZR200TA221K18EB

100V J

1VSA22027

CA2D221DYG04

CA2A682DT018

Ref. No. Description Part No.

C2007 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2009 CHIP CERAMIC CAP.(1608) CH J 100pF/50V CHD1JJ3CH101

C2011 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2013 CHIP CERAMIC CAP.(1608) B K 0.015µF/50V CHD1JK30B153

C2016 ELECTROLYTIC CAP. 47µF/6.3V/M CEA47RENW016

C2065 CHIP CERAMIC CAP.(1608) B K 1000pF/50V CHD1JK30B102

C2100 CHIP CERAMIC CAP.(1608) B K 0.1µF/25V CHD1EK30B104

C2104 ELECTROLYTIC CAP. 47µF/6.3V/M CEA47RENW016

C2106 CHIP CERAMIC CAP. CH D 8pF/50V CHD1JD3CH8R0

C2108 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2180 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2181 ELECTROLYTIC CAP. 220µF/6.3V/M CEA221ENW016

C2204 ELECTROLYTIC CAP. 47µF/25V/M CED47RENW016

C2205 ELECTROLYTIC CAP. 470µF/6.3V/M CEA471ENW016

C2206 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2207 ELECTROLYTIC CAP. 10µF/16V/M CEC10RENW016

C2208 ELECTROLYTIC CAP. 10µF/16V/M CEC10RENW016

C2209 CHIP CERAMIC CAP. CH J 220pF/50V CHD1JJ3CH221

C2210 CHIP CERAMIC CAP. CH J 220pF/50V CHD1JJ3CH221

C2211 ELECTROLYTIC CAP. 10µF/16V/M CEC10RENW016

C2212 ELECTROLYTIC CAP. 10µF/16V/M CEC10RENW016

C2213 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2215 CHIP CERAMIC CAP. CH J 39pF/50V CHD1JJ3CH390

C2216 CHIP CERAMIC CAP. CH J 39pF/50V CHD1JJ3CH390

C2280 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2281 ELECTROLYTIC CAP. 220µF/6.3V/M CEA221ENW016

C2283 ELECTROLYTIC CAP. 1000µF/6.3V/M CEA102ENW016

C2284 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2286 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2300 ELECTROLYTIC CAP. 100µF/6.3V/M CEA101ENW016

C2301 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2314 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2315 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2316 ELECTROLYTIC CAP. 22µF/6.3V/M CEA22RENW016

C2319 CHIP CERAMIC CAP.(1608) B K 0.1µF/50V CHD1JK30B104

C2320 CHIP CERAMIC CAP.(1608) B K 1µF/10V CHD1AK30B105

C2321 CHIP CERAMIC CAP.(1608) B K 1µF/10V CHD1AK30B105

C2322 ELECTROLYTIC CAP. 33µF/10V/M CEB33RENW016

C2323 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2324 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2325 ELECTROLYTIC CAP. 33µF/10V/M CEB33RENW016

C2326 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2327 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2328 CHIP CERAMIC CAP.(1608) B K 0.1µF/50V CHD1JK30B104

C2329 ELECTROLYTIC CAP. 100µF/6.3V/M CEA101ENW016

C2330 ELECTROLYTIC CAP. 100µF/6.3V/M CEA101ENW016

C2601 ELECTROLYTIC CAP. 1000µF/6.3V/M CEA102ENW016

C2602 ELECTROLYTIC CAP. 1000µF/6.3V/M CEA102ENW016

C2604 ELECTROLYTIC CAP. 10µF/16V/M CEC10RENW016

C2605 ELECTROLYTIC CAP. 47µF/25V/M CED47RENW016

C2606 ELECTROLYTIC CAP. 100µF/6.3V/M CEA101ENW016

C2607 ELECTROLYTIC CAP. 1000µF/6.3V/M CEA102ENW016

C2609 CHIP CERAMIC CAP.(1608) B K 1µF/10V CHD1AK30B105

C2610 CHIP CERAMIC CAP.(1608) B K 0.1µF/25V CHD1EK30B104

C2613 ELECTROLYTIC CAP. 220µF/6.3V/M CEA221ENW016

C2614 CHIP CERAMIC CAP.(1608) B K 0.33µF/10V CHD1AK30B334

C2616 CHIP CERAMIC CAP.(1608) B K 1µF/10V CHD1AK30B105

C2618 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2619 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2620 CHIP CERAMIC CAP. B K 8200pF/50V CHD1JK30B822

20090604 1-12-1 E5K50EL

Page 50

Ref. No. Description Part No.

C2622 CHIP CERAMIC CAP.(2125) B K 10µF/6.3V CHE0KK30B106

C2623 CHIP CERAMIC CAP.(2125) B K 10µF/6.3V CHE0KK30B106

C2627 CHIP CERAMIC CAP.(1608) B K 1µF/10V CHD1AK30B105

C2629 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2630 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C2631 CHIP CERAMIC CAP.(1608) B K 5600pF/50V CHD1JK30B562

C2632 CHIP CERAMIC CAP.(2125) B K 10µF/6.3V CHE0KK30B106

C2633 CHIP CERAMIC CAP.(2125) B K 10µF/6.3V CHE0KK30B106

C2634 CHIP CERAMIC CAP.(2125) B K 10µF/6.3V CHE0KK30B106

C2638 CHIP CERAMIC CAP. CH J 330pF/50V CHD1JJ3CH331

C2639 CHIP CERAMIC CAP. CH J 220pF/50V CHD1JJ3CH221

C2640 CHIP CERAMIC CAP.(1608) B K 0.01µF/50V CHD1JK30B103

C2652 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2653 ELECTROLYTIC CAP. 330µF/6.3V/M CEA331ENW016

C2655 ELECTROLYTIC CAP. 470µF/16V/M CEC471ENW016

C2800 CHIP CERAMIC CAP.(1608) B K 0.01µF/50V CHD1JK30B103

C2801 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

CONNECTORS

CN2000 TWG CONNECTOR 23P TWG-P23P-A1 J3TWA23TG001

CN2001 WIRE ASSEMBLY AV-MAIN 26P WX1E5K20-

CN2002 FFC CONNECTOR IMSA-9615S-16A-PP-A JC96J16ER007

CN2004 PH CONNECTOR TOP 2P B2B-PH-K-S

001

(LF)(SN)

WX1E5K20-001

J3PHC02JG029

DIODES

D1001 DIODE 1N5397-B NDLZ001N5397

D1002 DIODE 1N5397-B NDLZ001N5397

D1003 DIODE 1N5397-B NDLZ001N5397

D1004 DIODE 1N5397-B NDLZ001N5397

D1006 DIODE FR154 NDLZ000FR154

D1007 RECTIFIER DIODE BA157 NDQZ000BA157

D1008 RECTIFIER DIODE BA157 NDQZ000BA157

D1010 RECTIFIER DIODE BA157 NDQZ000BA157

D1012 PCB JUMPER D0.6-P15.0 JW15.0T

D1013 SCHOTTKY BARRIER DIODE SMD SK54 ND1Z0000SK54

D1014 SCHOTTKY BARRIER DIODE SMD SK54 ND1Z0000SK54

D1017 DIODE ZENER 5V1BSB-T26 NDTB5R1BST26

D1018 RECTIFIER DIODE BA157 NDQZ000BA157

D1019 DIODE ZENER 18BSB-T26 NDTB018BST26

D1020 DIODE ZENER 18BSB-T26 NDTB018BST26

D1021 DIODE ZENER 6V8BSB-T26 NDTB6R8BST26

D1022 SCHOTTKY BARRIER DIODE SB140 NDQZ000SB140

D1023 SCHOTTKY BARRIER DIODE SMD SK39 ND1Z0000SK39

D1024 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D1036 DIODE ZENER 27BSB-T26 NDTB027BST26

D1037 DIODE ZENER 27BSB-T26 NDTB027BST26

D1137 RECTIFIER DIODE BA157 NDQZ000BA157

D1138 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2001 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2002 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2003 DIODE ZENER 36BSA-T26 NDTA036BST26

D2004 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2600 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2601 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2602 DIODE 1N5406 NDLZ001N5406

D2605 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2606 DIODE ZENER 11BSC-T26 NDTC011BST26

D2608 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2609 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2610 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2612 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2613 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2614 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

Ref. No. Description Part No.

D2615 DIODE SWITCHING 1N4148-F0021 NDTZ01N4148F

D2620 SCHOTTKY BARRIER DIODE SMD SK34 ND1Z0000SK34

D2621 SCHOTTKY BARRIER DIODE SMD SK34 ND1Z0000SK34

D2624 DIODE ZENER 4V7BSB-T26 NDTB4R7BST26

ICS

IC1001 IC SWITCHING FA5542N-A2-TE1 SOP8 QSZBA0TFD005

IC1003# PHOTOCOUPLER PS2561A-1(W) QPEWPS2561A1

IC1011 IC SHUNT REGULATOR SL431A-AT NSZBA0TAUK01

IC1012 IC SHUNT REGULATOR SL431A-AT NSZBA0TAUK01

IC2000 IC SUB MICON MN101C77A GC QSAA0R0MS010

IC2001 RESET IC S-80930CNMC-G80T2G QSCA0T0SK018

IC2200 IC OP AMP UTC4580TE NSCA0T02H001

IC2300 IC VIDEO DRIVER MM1757EHBE QSCA0T0MM001

IC2600 IC VOLTAGE REGULATOR PQ070XFC1SZF /

IC2601 IC DC-DC CONVERTER BD9323EFJ-E2 QSCA0T0RM002

IC2602 IC DC-DC CONVERTER BD9323EFJ-E2 QSCA0T0RM002

4PIN

QSZBA0RSH083

COILS

L1001# LINE FILTER 27MH 5703 LLBG00ZKT009

L1003 POWER INDUCTORS CWKBNP-220K LLF2200KV002

L1004 RADIAL TYPE CHOKE COIL CW68-470K-

L1005 CHOKE COIL 22µH-K LLBD00PKV021

L2100 INDUCTOR(0.47µH K) LAP02TAR47K LLAXKATTUR47

L2201 POWER INDUCTORS CWKBNP-100K LLF1000KV002

L2202 POWER INDUCTORS CWKBNP-100K LLF1000KV002

L2300 RADIAL TYPE CHOKE COIL CW68-470K-

L2301 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

L2306 PCB JUMPER D0.6-P5.0 JW5.0T

L2400 CHOKE COIL 22µH-K LLBD00PKV021

L2600 CHOKE COIL 22µH-K LLBD00PKV021

L2601 CHOKE COIL 22µH-K LLBD00PKV021

841040NP

841040NP

LLBD00PKV023

LLBD00PKV023

TRANSISTORS

Q1003# FET MOS 2SK3563(Q M) QFQZSK3563QM

Q1011 NPN TRANSISTOR 2SC5344 Y NQSY02SC5344

Q1111 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2000 PNP TRANSISTOR 2SA1980M Y NQSY2SA1980M

Q2001 NPN TRANSISTOR RES-IN SRC1203MAT NQSZSRC1203M

Q2002 PNP TRANSISTOR 2SA1980M Y NQSY2SA1980M

Q2003 NPN TRANSISTOR RES-IN SRC1203MAT NQSZSRC1203M

Q2012 PNP TRANSISTOR 2SA1980M Y NQSY2SA1980M

Q2013 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2014 PNP TRANSISTOR 2SA1981Y-AT NQSY02SA1981

Q2100 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2101 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2200 PNP TRANSISTOR RES-IN SRA2205M NQSZSRA2205M

Q2201 PNP TRANSISTOR RES-IN SRA2205M NQSZSRA2205M

Q2202 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2203 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2204 PNP TRANSISTOR 2SA1980M Y NQSY2SA1980M

Q2205 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2600 NPN TRANSISTOR RES-IN SRC1203MAT NQSZSRC1203M

Q2601 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2602 PNP TRANSISTOR 2SA1980M Y NQSY2SA1980M

Q2603 PNP TRANSISTOR 2SA1981Y-AT NQSY02SA1981

Q2604 PNP TRANSISTOR STB1277LY-AT NQSYSTB1277L

Q2605 NPN TRANSISTOR 2SC5344 Y NQSY02SC5344

Q2606 PNP TRANSISTOR STB1277LY-AT NQSYSTB1277L

Q2607 TRANSISTOR(PB FREE) KTC2026-Y/P NQEYKTC2026P

Q2608 PNP TRANSISTOR 2SA1980MG-AT NQSG2SA1980M

Q2609 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2610 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

20090604 1-12-2 E5K50EL

Page 51

Ref. No. Description Part No.

Q2611 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2612 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2613 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2614 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2618 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2619 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2620 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

Q2621 NPN TRANSISTOR 2SC5343MG-AT NQSG2SC5343M

RESISTORS

R1004 CARBON RES. 1/4W J 75k Ω RCX4JATZ0753

R1005 CARBON RES. 1/4W J 33 Ω RCX4JATZ0330

R1006 CARBON RES. 1/4W J 100k Ω RCX4JATZ0104

R1008 CARBON RES. 1/4W J 56 Ω RCX4JATZ0560

R1009 CARBON RES. 1/4W J 100 Ω RCX4JATZ0101

R1011 CARBON RES. 1/4W J 10 Ω RCX4JATZ0100

R1012 CARBON RES. 1/4W J 4.7k Ω RCX4JATZ0472

R1013 METAL OXIDE FILM RES. 2W J 47k Ω RN02473ZU001

R1014 METAL OXIDE FILM RES. 2W J 0.68 Ω RN02R68ZU001

R1015 CHIP RES. 1/10W J 1 Ω RRXAJR5Z01R0

R1016 CHIP RES. 1/10W J 470 Ω RRXAJR5Z0471

R1017 CHIP RES. 1/10W J 22k Ω RRXAJR5Z0223

R1018 CHIP RES. 1/10W J 1 Ω RRXAJR5Z01R0

R1019 CHIP RES. 1/10W J 680 Ω RRXAJR5Z0681

R1020 CHIP RES. 1/10W F 2k Ω RRXAFR5H2001

R1021 CARBON RES. 1/4W J 10k Ω RCX4JATZ0103

R1022 CARBON RES. 1/4W J 10k Ω RCX4JATZ0103

R1023 CARBON RES. 1/4W J 5.1k Ω RCX4JATZ0512

R1024 CHIP RES. 1/10W F 270 Ω RRXAFR5H2700

R1025 CHIP RES. 1/10W F 1.0k Ω RRXAFR5H1001

R1026 CHIP RES. 1/10W F 1.0k Ω RRXAFR5H1001

R1027 CARBON RES. 1/4W J 10k Ω RCX4JATZ0103

R1039 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R1040 CARBON RES. 1/4W J 100 Ω RCX4JATZ0101

R1041 PCB JUMPER D0.6-P5.0 JW5.0T

R1046 CHIP RES. 1/10W F 1.5k Ω RRXAFR5H1501

R1047 CHIP RES. 1/10W F 100 Ω RRXAFR5H1000

R1048 CHIP RES. 1/10W F 4.7k Ω RRXAFR5H4701

R1142 CHIP RES. 1/10W J 1 Ω RRXAJR5Z01R0

R1143 CHIP RES. 1/10W F 18k Ω RRXAFR5H1802

R1144 CHIP RES. 1/10W F 10k Ω RRXAFR5H1002

R1145 CHIP RES. 1/10W J 330k Ω RRXAJR5Z0334

R2000 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2001 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2002 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2004 CHIP RES. 1/10W J 470 Ω RRXAJR5Z0471

R2005 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2006 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2007 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2008 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2018 CHIP RES. 1/10W J 39k Ω RRXAJR5Z0393

R2019 CHIP RES. 1/10W J 22k Ω RRXAJR5Z0223

R2020 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2024 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2025 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2028 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2029 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2031 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2032 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2033 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2034 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2035 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2039 CHIP RES. 1/10W J 680 Ω RRXAJR5Z0681

Ref. No. Description Part No.

R2050 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2051 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2053 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2056 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2058 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2060 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2061 CHIP RES. 1/10W J 5.6k Ω RRXAJR5Z0562

R2063 CARBON RES. 1/4W J 620 Ω RCX4JATZ0621

R2064 CARBON RES. 1/4W J 620 Ω RCX4JATZ0621

R2065 CARBON RES. 1/4W J 10 Ω RCX4JATZ0100

R2066 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2067 CHIP RES. 1/10W J 5.6k Ω RRXAJR5Z0562

R2069 CARBON RES. 1/4W J 120 Ω RCX4JATZ0121

R2070 CARBON RES. 1/4W J 120 Ω RCX4JATZ0121

R2073 CARBON RES. 1/4W J 620 Ω RCX4JATZ0621

R2074 CARBON RES. 1/4W J 620 Ω RCX4JATZ0621

R2091 CARBON RES. 1/4W J 47k Ω RCX4JATZ0473

R2092 CARBON RES. 1/4W J 47k Ω RCX4JATZ0473

R2093 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2094 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2095 CHIP RES. 1/10W J 3.9k Ω RRXAJR5Z0392

R2100 CHIP RES. 1/10W J 2k Ω RRXAJR5Z0202

R2101 CHIP RES. 1/10W J 2.2k Ω RRXAJR5Z0222

R2102 CHIP RES. 1/10W J 2.2k Ω RRXAJR5Z0222

R2103 CHIP RES. 1/10W J 220 Ω RRXAJR5Z0221

R2104 CHIP RES. 1/10W J 75 Ω RRXAJR5Z0750

R2105 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2109 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2115 CARBON RES. 1/4W J 5.6 Ω RCX4JATZ05R6

R2116 CARBON RES. 1/4W J 5.6 Ω RCX4JATZ05R6

R2117 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2118 CARBON RES. 1/4W J 10 Ω RCX4JATZ0100

R2208 CHIP RES. 1/10W F 24k Ω RRXAFR5H2402

R2209 CHIP RES. 1/10W F 24k Ω RRXAFR5H2402

R2210 CHIP RES. 1/10W J 8.2k Ω RRXAJR5Z0822

R2211 CHIP RES. 1/10W J 8.2k Ω RRXAJR5Z0822

R2212 CHIP RES. 1/10W F 33.0k Ω RRXAFR5H3302

R2213 CHIP RES. 1/10W F 33.0k Ω RRXAFR5H3302

R2214 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2215 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2216 CHIP RES. 1/10W J 820 Ω RRXAJR5Z0821

R2217 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2218 CHIP RES. 1/10W J 820 Ω RRXAJR5Z0821

R2219 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2220 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2221 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2223 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2224 CHIP RES. 1/10W J 2.2k Ω RRXAJR5Z0222

R2226 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2227 CHIP RES. 1/10W J 220 Ω RRXAJR5Z0221

R2228 CHIP RES. 1/10W J 220 Ω RRXAJR5Z0221

R2229 CHIP RES. 1/10W J 2.2k Ω RRXAJR5Z0222

R2230 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2284 CHIP RES. 1/10W J 10 Ω RRXAJR5Z0100

R2285 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2286 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2287 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2288 CHIP RES. 1/10W J 1.8k Ω RRXAJR5Z0182

R2301 CHIP RES.(1608) 1/10W F 82.0 Ω RRXAFR5H82R0

R2302 CHIP RES.(1608) 1/10W F 82.0 Ω RRXAFR5H82R0

R2303 CHIP RES.(1608) 1/10W F 82.0 Ω RRXAFR5H82R0

R2304 CHIP RES.(1608) 1/10W F 82.0 Ω RRXAFR5H82R0

R2305 CHIP RES.(1608) 1/10W F 82.0 Ω RRXAFR5H82R0

20090604 1-12-3 E5K50EL

Page 52

Ref. No. Description Part No.

R2307 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2309 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2310 CHIP RES. 1/10W J 75 Ω RRXAJR5Z0750

R2311 CHIP RES. 1/10W J 75 Ω RRXAJR5Z0750

R2312 CHIP RES. 1/10W J 75 Ω RRXAJR5Z0750

R2313 CHIP RES. 1/10W J 75 Ω RRXAJR5Z0750

R2315 CHIP RES. 1/10W J 27k Ω RRXAJR5Z0273

R2325 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2341 CHIP RES. 1/10W F 4.7k Ω RRXAFR5H4701

R2342 CHIP RES. 1/10W F 2.7k Ω RRXAFR5H2701

R2343 CHIP RES. 1/10W F 1.5k Ω RRXAFR5H1501

R2344 CHIP RES. 1/10W F 1.2k Ω RRXAFR5H1201

R2345 CHIP RES. 1/10W F 1.2k Ω RRXAFR5H1201

R2600 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2601 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2602 CHIP RES. 1/10W J 2.2k Ω RRXAJR5Z0222

R2603 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2604 CARBON RES. 1/4W J 4.7k Ω RCX4JATZ0472

R2606 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2607 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2608 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2609 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2610 CARBON RES. 1/4W J 220 Ω RCX4JATZ0221

R2612 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2613 CHIP RES. 1/10W F 10k Ω RRXAFR5H1002

R2616 CHIP RES. 1/10W F 15k Ω RRXAFR5H1502

R2617 CHIP RES. 1/10W F 2k Ω RRXAFR5H2001

R2620 CHIP RES. 1/10W J 4.7k Ω RRXAJR5Z0472

R2621 CARBON RES. 1/4W J 82 Ω RCX4JATZ0820

R2622 CARBON RES. 1/4W J 82 Ω RCX4JATZ0820

R2636 CARBON RES. 1/4W J 33 Ω RCX4JATZ0330

R2637 METAL OXIDE FILM RES. 1W J 1.2 Ω RN011R2ZU001

R2638 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2639 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2650 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2651 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2652 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2653 CHIP RES. 1/10W J 10k Ω RRXAJR5Z0103

R2654 CHIP RES. 1/10W J 5.1k Ω RRXAJR5Z0512

R2655 CHIP RES. 1/10W J 8.2k Ω RRXAJR5Z0822

R2656 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2657 CHIP RES. 1/10W J 2.7k Ω RRXAJR5Z0272

R2658 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R2659 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2660 CHIP RES. 1/10W F 1.5k Ω RRXAFR5H1501

R2661 CHIP RES. 1/10W F 3.3k Ω RRXAFR5H3301

R2662 CHIP RES. 1/10W F 1.5k Ω RRXAFR5H1501

R2663 CHIP RES. 1/10W F 2.2k Ω RRXAFR5H2201

R2664 CHIP RES. 1/10W F 3.3k Ω RRXAFR5H3301

R2665 CHIP RES. 1/10W J 100 Ω RRXAJR5Z0101

R2667 CHIP RES. 1/10W J 330 Ω RRXAJR5Z0331

R2669 CHIP RES. 1/10W J 27k Ω RRXAJR5Z0273

R2671 CHIP RES. 1/10W J 220k Ω RRXAJR5Z0224

R2673 CHIP RES. 1/10W J 2.2M Ω RRXAJR5Z0225

R2674 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2675 CHIP RES. 1/10W J 220 Ω RRXAJR5Z0221

R2676 CHIP RES. 1/10W J 100k Ω RRXAJR5Z0104

R2678 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R2679 CHIP RES. 1/10W J 47k Ω RRXAJR5Z0473

R2680 CHIP RES. 1/10W J 27k Ω RRXAJR5Z0273

MISCELLANEOUS

2L055 SCREW S-TIGHT M3X8 BIND HEAD+ GBJS3080

Ref. No. Description Part No.

AC1001# AC CORD W/O A GND WIRE UL/CSA/1700/NO/

B47 HEAT SINK E2A00JD 1VM424636E

F1001# FUSE TIME RAG FSL 250V 2A(EM) PDGJAB0NG202

FH1001 FUSE HOLDER MSF-015 LF (B110) XH01Z00LY002

FH1002 FUSE HOLDER MSF-015 LF (B110) XH01Z00LY002

JK2100 RCA JACK(BLACK) MSP-251V-01 NI FE LF JXRL010LY125

JK2200 PIN JACK 3P MSD-243V-48 NI FE LF JXRL030LY167

JK2300 RCA JACK 3PIN MSD-243V-18 NI FE LF JXRL030LY132

JK2400 FIBER OPTIC TRANS.MODULE 0C-0805T*002 JWHHA00JD002

JP2201 PCB JUMPER D0.6-P7.0 JW7.0T

JP2204 PCB JUMPER D0.6-P25.0 JW25.0T

JP2208 PCB JUMPER D0.6-P8.5 JW8.5T

JP2209 PCB JUMPER D0.6-P24.0 JW24.0T

JP2210 PCB JUMPER D0.6-P28.0 JW28.0T

JP2211 PCB JUMPER D0.6-P13.0 JW13.0T

JP2213 PCB JUMPER D0.6-P13.0 JW13.0T

JP2215 PCB JUMPER D0.6-P8.0 JW8.0T

JP2216 PCB JUMPER D0.6-P5.0 JW5.0T

JP2217 PCB JUMPER D0.6-P5.0 JW5.0T

JP2219 PCB JUMPER D0.6-P15.0 JW15.0T

JP2222 PCB JUMPER D0.6-P27.5 JW27.5T

JP2225 PCB JUMPER D0.6-P25.0 JW25.0T

JP2226 PCB JUMPER D0.6-P13.0 JW13.0T

JP2227 PCB JUMPER D0.6-P10.5 JW10.5T

JP2228 PCB JUMPER D0.6-P17.0 JW17.0T

JP2229 PCB JUMPER D0.6-P5.0 JW5.0T

SA1001# VARISTOR 10D 471K SVR NVQZVR10D471

T1001# TRANS POWER 8733 LTT2PC0KT050

X2000 CERAMIC RESONATOR ZTT8.00MT47 FY0805PLN004

BLACK

WAC1720LW001

FRONT ASSEMBLY

Ref. No. Description Part No.

FRONT ASSEMBLY

Consists of the following:

FRONT CBA

POWER SW CBA

FRONT CBA

Ref. No. Description Part No.

FRONT CBA

Consists of the following:

CAPACITORS

C3000 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C3001 ELECTROLYTIC CAP. 22µF/50V/M/H7 CEF22RENW025

C3002 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C3003 ELECTROLYTIC CAP. 100µF/6.3V/M/H7 CEA101ENW025

C3005 CHIP CERAMIC CAP.(1608) B K 1000pF/50V CHD1JK30B102

C3006 CHIP CERAMIC CAP.(1608) F Z 0.1µF/50V CHD1JZ30F104

C3007 ELECTROLYTIC CAP. 100µF/6.3V/M/H7 CEA101ENW025

C3008 CHIP CERAMIC CAP.(1608) B K 0.1µF/50V CHD1JK30B104

CONNECTORS

CN3000 WIRE ASSEMBLY FRONT-AV 16P WX1E5K10-

CN3001 CONNECTOR PRINT OSU S3B-PH-K-

L3001 CHIP INDUCTOR LB 2016T101K LLC101KTU007

Q3000 NPN TRANSISTOR SMD 2SC5343SFG NQ1G2SC5343S

R3000 CHIP RES. 1/10W J 10 Ω RRXAJR5Z0100

002

S(LF)(SN)

COIL

TRANSISTOR

RESISTORS

1VSA22025

----------

----------

----------

WX1E5K10-002

J3PHC03JG030

20090604 1-12-4 E5K50EL

Page 53

Ref. No. Description Part No.

R3001 CHIP RES. 1/10W J 10 Ω RRXAJR5Z0100

R3002 CHIP RES. 1/10W J 12k Ω RRXAJR5Z0123

R3003 CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R3004 CHIP RES. 1/10W J 1k Ω RRXAJR5Z0102

R3005 CHIP RES. 1/10W J 150 Ω RRXAJR5Z0151

R3012 CHIP RES. 1/10W J 180 Ω RRXAJR5Z0181

R3014 CHIP RES. 1/10W J 6.8k Ω RRXAJR5Z0682

R3015 CHIP RES. 1/10W J 220 Ω RRXAJR5Z0221

R3019 CHIP RES. 1/10W J 330 Ω RRXAJR5Z0331

R3020 CHIP RES. 1/10W J 5.1k Ω RRXAJR5Z0512

SWITCHES

SW3003 TACT SWITCH SKQSAB SST0101AL038

SW3004 TACT SWITCH SKQSAB SST0101AL038

SW3005 TACT SWITCH SKQSAB SST0101AL038

SW3006 TACT SWITCH SKQSAB SST0101AL038

MISCELLANEOUS

B70 TAPE HIMERON(60*6) HG470ED 1VM421170

FL3000 FL DM182-GINK TVFD150FT018

RS3000 PHOTO LINK MODULE KSM-713TH2P USESJRSKK061

POWER SW CBA

Ref. No. Description Part No.

POWER SW CBA

Consists of the following:

DIODE

D3007 LED(RED) LTL-1CHEE NPQZLTL1CHEE

SWITCH

SW3007 TACT SWITCH SKQSAB SST0101AL038

MISCELLANEOUS

WX3000 WIRE ASSEMBLY FRONT-SWITCH 3P WIRE

WX1E5K50-001

----------

WX1E5K50-001

SD-B CBA

Ref. No. Description Part No.

SD-B CBA

Consists of the following:

----------

CONNECTORS

CN4101 242 SERIES CONNECTOR 224202115W1 J322C15TG001

CN4102 242 SERIES CONNECTOR 224202115W1 J322C15TG001

SD-C CBA

Ref. No. Description Part No.

SD-C CBA

Consists of the following:

CAPACITORS

C4001 CHIP CERAMIC CAP.(1608) B K 0.1µF/16V CHD1CK30B104