Page 1

SERVICE MANUAL

SERVICE MANUAL

DVD PLAYER

MODEL DV-SP404

(For USA/Canada, Black/ Silver)

DV-SP404

Ref. No. 3947

072006

ON STANDBY

OPEN/

CLOSE

PLAY

MODE

123

DISPLAY

6

45

789

CLEAR

0

ENTER

AUDIO ANGLE SUBTITLE ZOOM

MENU

SETUP

TOP MENU

RETURN

Black and Silver models

BTUA, STUA

BTDD, STDD

110-240V AC, 50/60Hz

120V AC, 60Hz

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

RC-616DV

RC-616DV

Page 2

CAUTION

THIS DIGITAL VIDEO PLAYER EMPLOYS A LASER SYSTEM.

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SERVICE MANUAL CARE-

FULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCATION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY TO OPEN THE ENCLOSURE.

VISIBLE LASER RADIATION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

STARE INTO BEAM.

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, the life of the product may be shortened.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

at the time of repair.

• Place the unit on a workstation equipped to protect against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-1

Page 3

IMPORTANT SERVICE SAFETY INFORMATION

Safety precautions to be followed during servicing:

1.

Parts marked with an are critical parts for safety. Replace only with the one described in the parts

list.

2.

Before returning the DVD product to the customer, make the appropriate leakage current check or

resistance measurements to ensure that exposed parts are properly insulated from the supply circuit.

A leakage current check is recommended for this unit. Plug the AC line cord directly into a 120V 60Hz AC

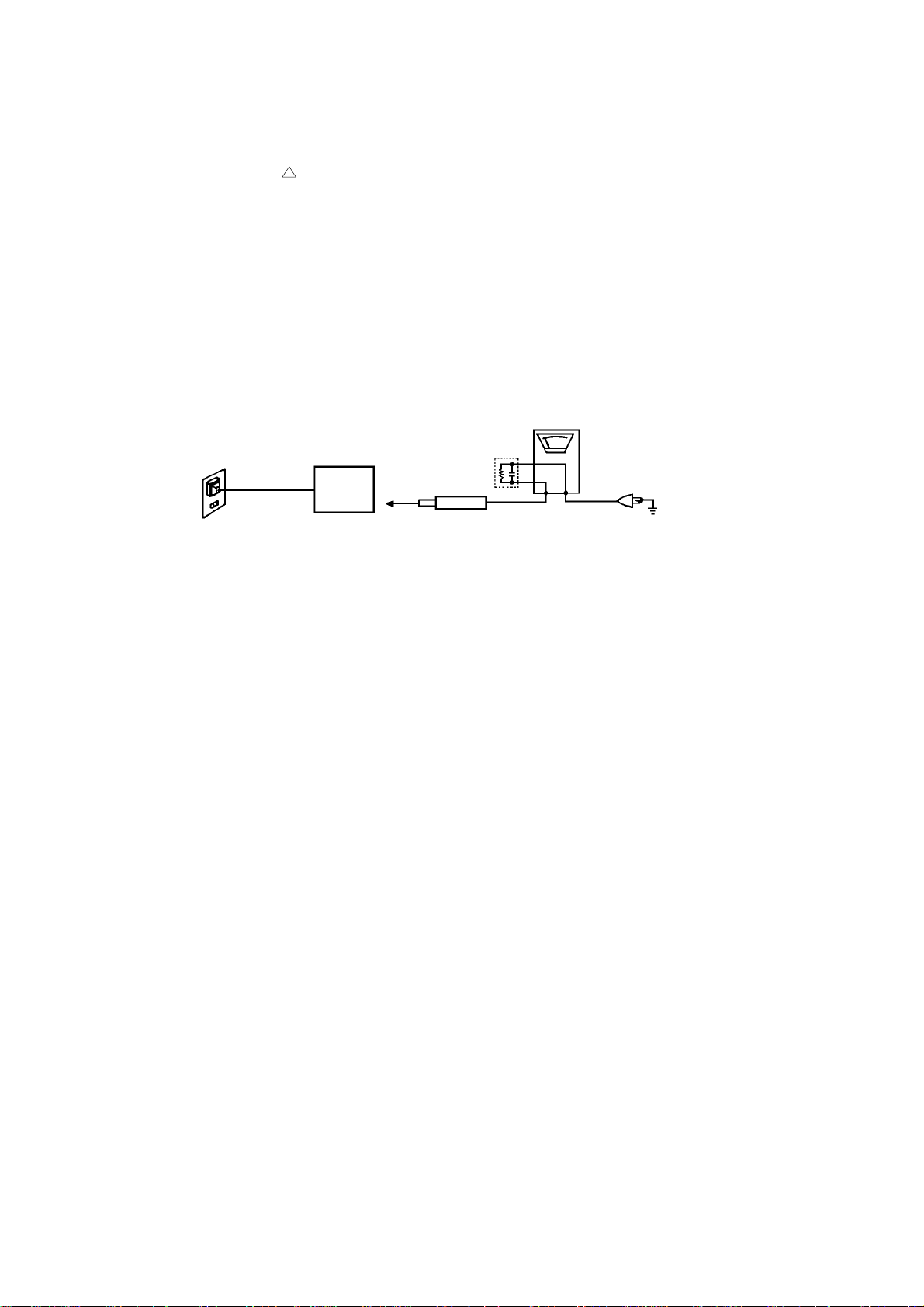

outlet (do not use an isolation transformer for this check). Use a leakage current tester (Fig. 1) or a

metering system which complies with Underwriters Laboratories (UL 1492). Measure for current from all

exposed metal parts of the cabinet to a known earth ground: particularly, any exposed metal part having a

return path to the chassis. Any current measured must not exceed 0.5mA. Any measurement not within

the limits outlined above are indicative of a potential shock hazard and corrective action must be taken

before returning the unit to the customer.

(Reading should not be above 0.5mA)

Leakage Current Tester

PRODUCT UNDER TEST

1.5K ohm

0.15 µF

2-Blade polarized

type cord set

Test all exposed

metal surfaces

TEST PROBE

Fig. 1 AC Leakage Test

KNOWN EARTH

GROUND

A1-2

Page 4

IMPORTANT SAFEGUARDS

1.

READ INSTRUCTIONS

All the safety and operating instructions should be read before the unit is operated.

2.

RET AIN INSTRUCTIONS

The safety and operating instructions should be retained for future reference.

3.

HEED WARNINGS

All warnings on the unit and in the operating instructions should be adhered to.

4.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

5.

CLEANING

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp

cloth for cleaning.

6.

A TTACHMENTS

Do not use attachments not recommended by the unit’s manufacturer as they may cause hazards.

7.

WATER AND MOISTURE

Do not use this unit near water. For example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

8.

ACCESSORIES

Do not place this unit on an unstable cart, stand, tripod, bracket, or table. The

unit may fall, causing serious injury, and serious damage to the unit. Use only

with a cart, stand, tripod, bracket, or table recommended by the manufacturer.

8A.

An appliance and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the appliance and cart

combination to overturn.

9.

VENTILATION

Slots and openings in the cabinet and in the back or bottom are provided for ventilation, to ensure reliable

operation of the unit, and to protect it from overheating. These openings must not be blocked or covered. The

openings should never be blocked by placing the unit on a bed, sofa, rug, or other similar surface. This unit

should never be placed near or over a radiator or heat source. This unit should not be placed in a built-in

installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

10.

POWER SOURCES

This unit should be operated only from the type of power source indicated on the rating plate. If you are not sure

of the type of power supply to your home, consult your appliance dealer or local power company . For units

intended to operate from battery power, or other sources, refer to the operating instructions.

11.

GROUNDING OR POLARIZA TION

This unit is equipped with a polarized alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way . This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the polarized plug. If your unit is equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin, this plug will only fit into a grounding-type power

outlet. This too, is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to

replace your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

12.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon

or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they

exit from the appliance.

13.

LIGHTNING

To protect your unit from a lightning storm, or when it is left unattended and unused for long periods of time,

unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the unit

due to lightning and power line surges.

14.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light or

power circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system,

extreme care should be taken to keep from touching such power lines or circuits, as contact with them might be

fatal.

15.

OVERLOADING

Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

16.

OBJECT AND LIQUID ENTRY

Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short out

parts that could result in fire or electric shock. Never spill or spray any type of liquid into the unit.

PORT ABLE CAR T WARNING

(symbol provided by RETAC)

S3125A

A1-3

Page 5

IMPORTANT SAFEGUARDS (CONTINUED)

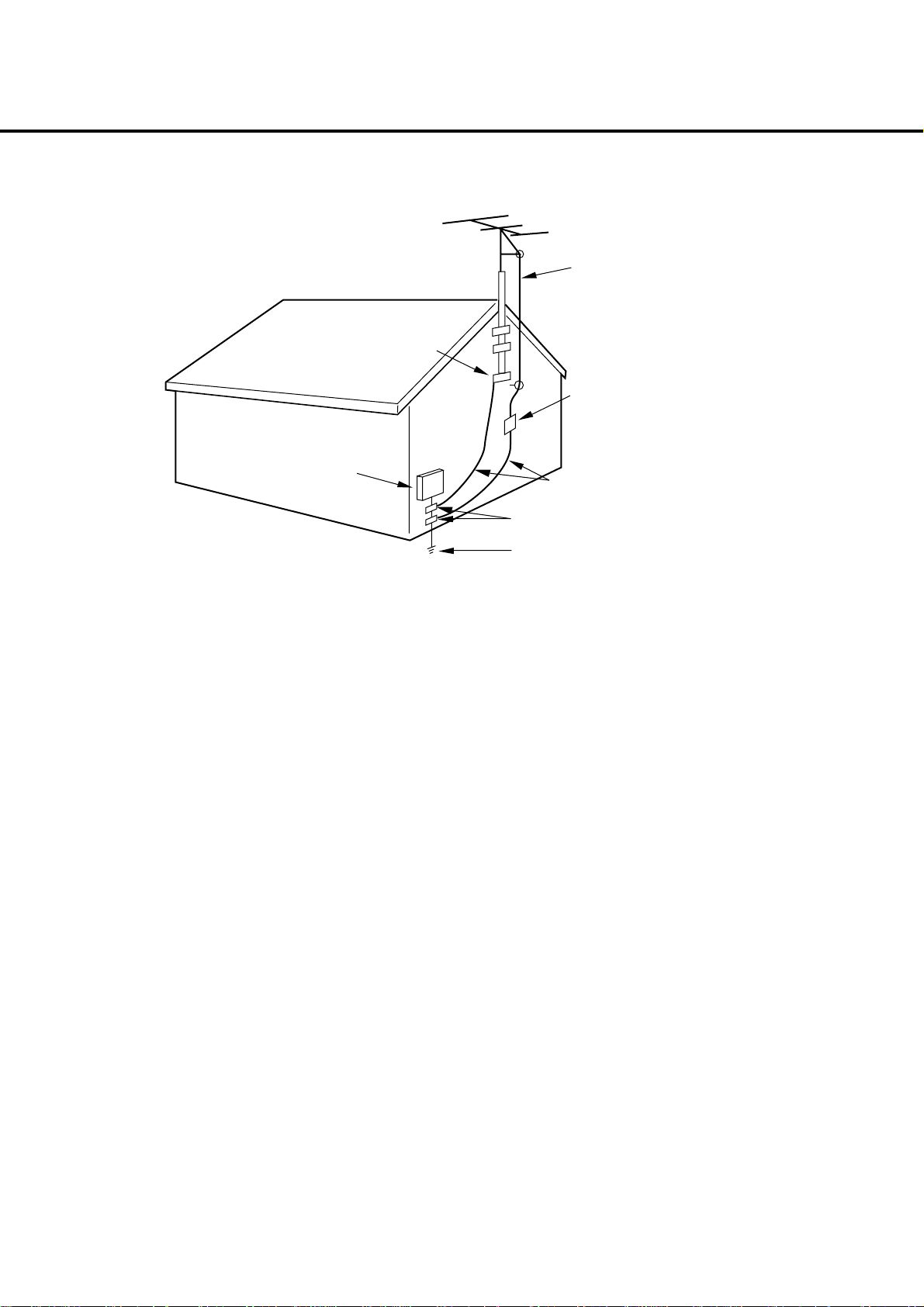

OUTDOOR ANTENNA GROUNDING

17.

If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is grounded

so as to provide some protection against voltage surges and built-up static charges. Section 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with respect to proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors, location of

antenna discharge unit, connection to grounding electrodes, and requirements for the grounding electrode.

SERVICING

18.

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage

or other hazards. Refer all servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

19.

Unplug this unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

a.

When the power-supply cord or plug is damaged.

b.

If liquid has been spilled, or objects have fallen into the unit.

c.

If the unit has been exposed to rain or water.

d.

If the unit does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions, as an improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to restore the unit to its normal

operation.

e.

If the unit has been dropped or the cabinet has been damaged.

f.

When the unit exhibits a distinct change in performance, this indicates a need for service.

REPLACEMENT PARTS

20.

When replacement parts are required, be sure the service technician uses replacement parts specified by the

manufacturer or those that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK

21.

Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks to

determine that the unit is in proper operating condition.

WALL OR CEILING MOUNTING

22.

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

HEAT

23.

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

DISC TRAY

24.

Keep your fingers well clear of the disc tray as it is closing. It may cause serious personal injury.

CONNECTING

25.

When you connect the product to other equipment, turn off the power and unplug all of the equipment from the

wall outlet. Failure to do so may cause an electric shock and serious personal injury. Read the owner's manual of

the other equipment carefully and follow the instructions when making any connections.

SOUND VOLUME

26.

Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume sound

may cause hearing or speaker damage.

SOUND DISTORTION

27.

Do not allow the product output distorted sound for a longtime. It may cause speaker overheating and fire.

HEADPHONES

28.

When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously

with high volume sound, it may cause hearing damage.

LASER BEAM

29.

Do not look into the opening of the disc tray or ventilation opening of the product to see the source of the laser

beam. It may cause sight damage.

DISC

30.

Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious

personal injury and product malfunction.

NOTE TO CATV SYSTEM INSTALLER

31.

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the

grounding system of the building, as close to the point of cable entry as practical.

A1-4

Page 6

IMPORTANT SAFEGUARDS (CONTINUED)

EXAMPLE OF ANTENNA GROUNDING AS PER THE NATIONAL ELECTRICAL CODE

ANTENNA LEAD

IN WIRE

GROUND

CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

ELECTRIC SERVICE

EQUIPMENT

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

NEC-NATIONAL ELECTRICAL CODE

S2898A

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

A1-5

Page 7

DV-SP404 (For USA/CANADA, SILVER)

SERVICE MANUAL

DVD VIDEO PLAYER

This SUPPLEMENT must be used together SERVICE MANUAL for DV-SP404 (For USA/CANADA,

BLACK).

All other test and repair procedures are as shown in the ORIGINAL MANUAL.

Please file this SUPPLEMENT with the ORIGINAL VERSIONS.

SUPPLEMENT

MFR'S VERSION A

Design and specifications are subject to change without notice.

Page 8

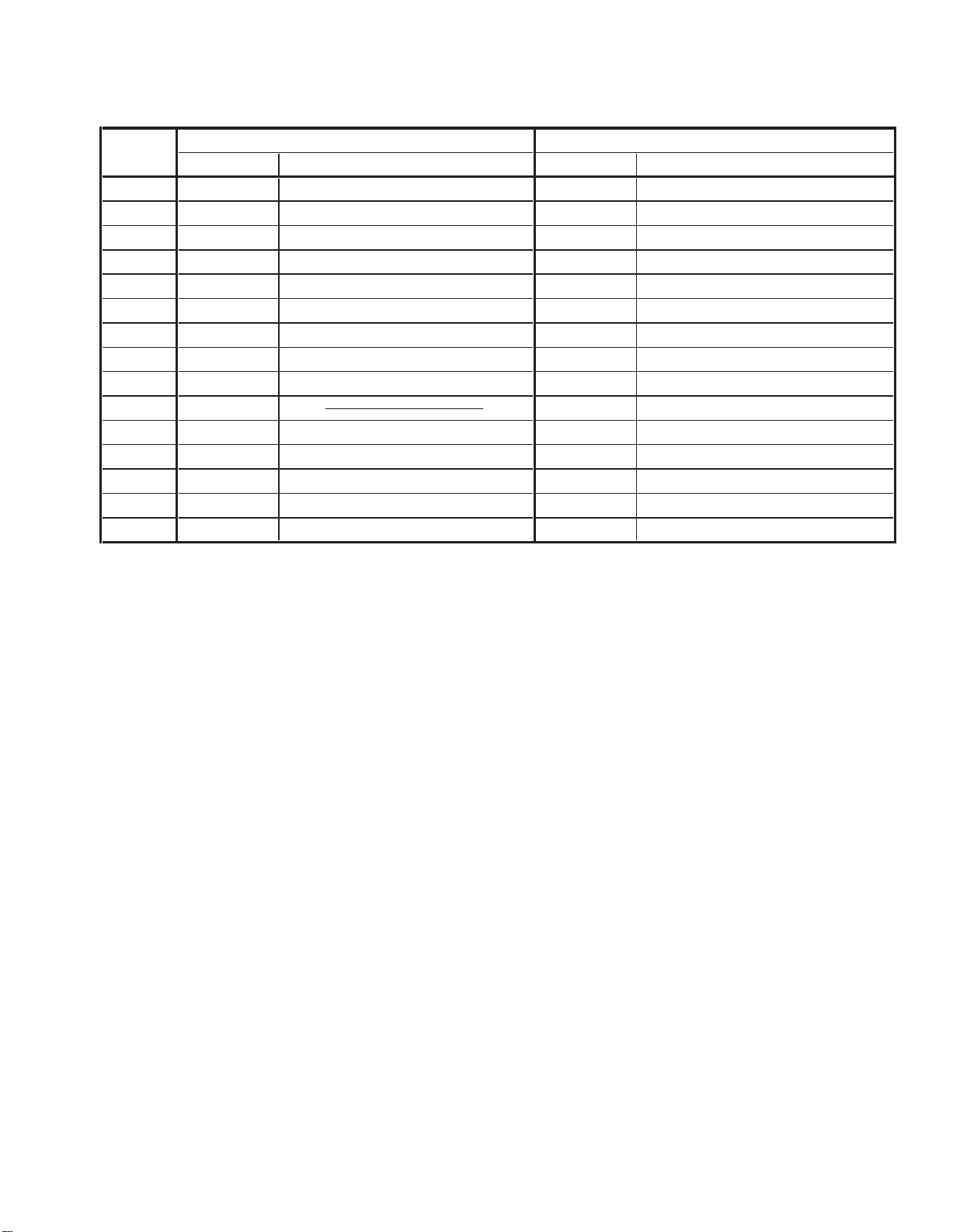

MECHANICAL REPLACEMENT PARTS LIST

DV-SP404 (For USA/CANADA, BLACK) DV-SP404 (For USA/CANADA, SILVER)

REF. NO.

101 7A701A785A FRONT CABI ASS'Y 7A701A798A FRONT CABI ASS'Y

101A 701WPBA069 CABINET FRONT 701WPBA073 CABINET FRONT

101B 701WADA004 PANEL FRONT 701WADA005 PANEL FRONT

101C 711WPAA143 PLATE DISPLAY 711WPAA146 PLATE DISPLAY

101D 712WPJC280 FLAP DVD 712WPJC283 FLAP DVD

101F 723656A002 BADGE BRAND 723656A003 BADGE BRAND

101H 737WPAA018 BUTTON CAP 737WPEA020 BUTTON CAP

101I 737WPA0027 BUTTON CAP EJECT 737WPE0033 BUTTON CAP EJECT

101L 738WPJA030 BUTTON FRAME 1 738WPJA035 BUTTON FRAME 1

101N 724000A009 SHEET PC

110 702WSBA071 CABINET TOP 702WSBA070 CABINET TOP

206 8109K3060S SCREW TAP TITE(B) BIND(3D) 3x6 8109K3060U SCREW TAP TITE(B) BIND(3D) 3x6

208 811022680S SCREW TAP TITE(P)BIND 2.6x8 811022680U SCREW TAP TITE(P)BIND 2.6x8

--- 723000D382 CARTON LABEL 723000D388 CARTON LABEL

--- 793WCDD254 GIFT BOX 793WCDD275 GIFT BOX

PART NO. DESCRIPTION PART NO. DESCRIPTION

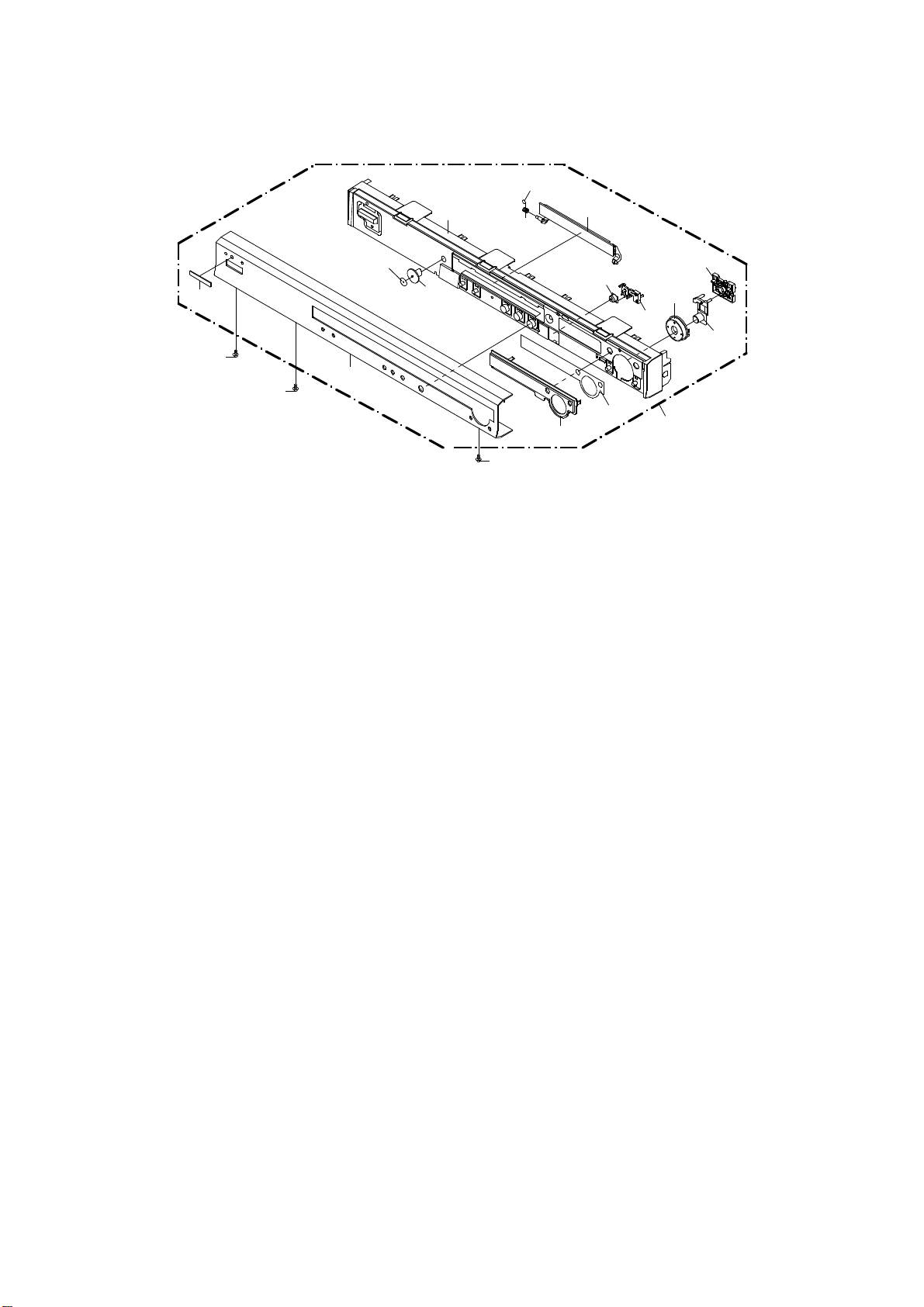

Page 9

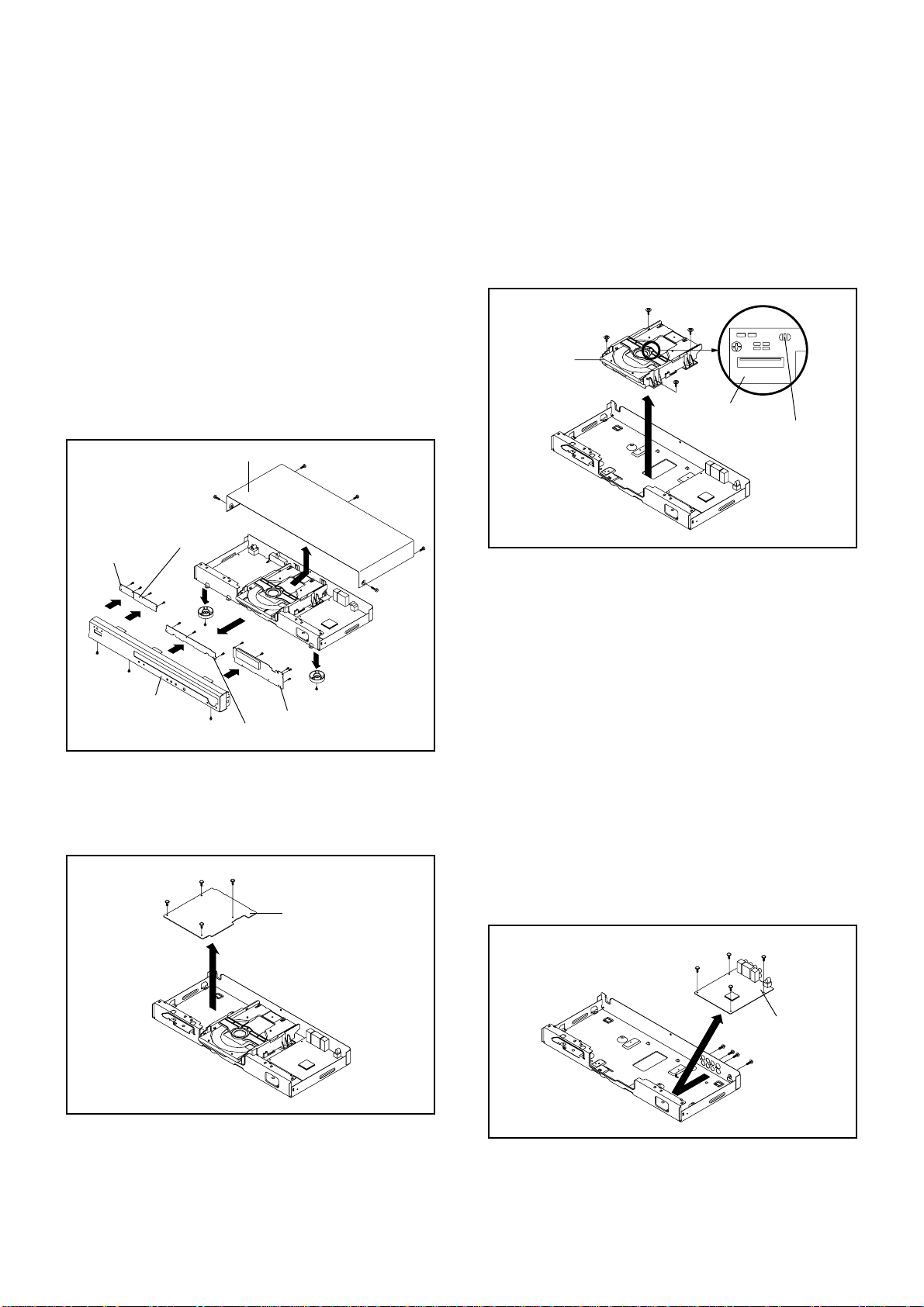

MECHANICAL EXPLODED VIEW

DV-SP404 (For USA/CANADA, SILVER)

101M

101F

208

208

101B

101G

101E

101A

208

101C

101D

101I

101N

101J

101H

101K

101L

101

ADD: 101N

Page 10

WHEN REPLACING DVD DECK

[ When removing the DVD Deck ]

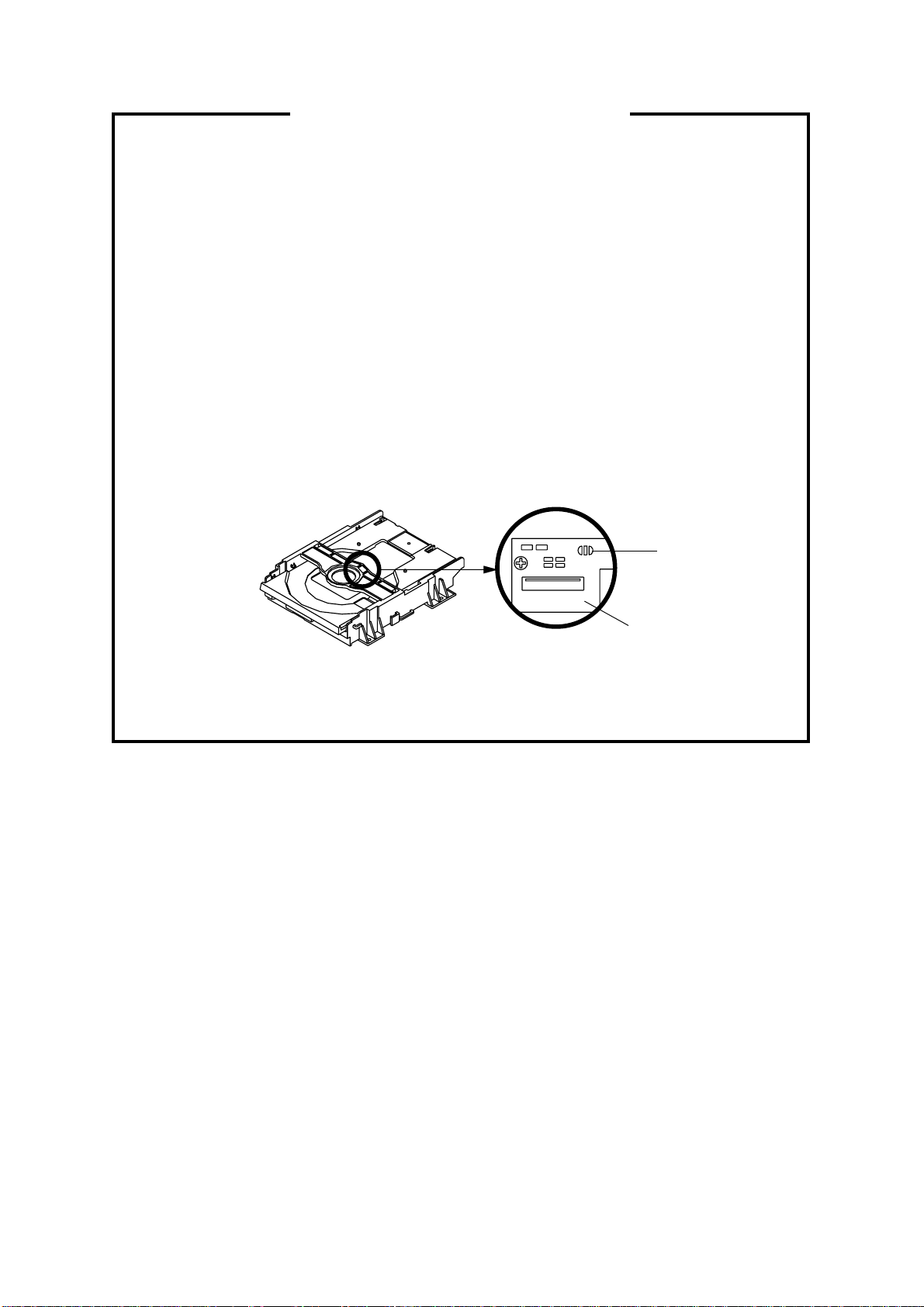

Before removing Pick Up PCB and DVD PCB connector, the short circuit the position shown in Fig. 1

using a soldering iron. If you remove the DVD Deck with no soldering, the Laser may be damaged.

[ When installing the DVD Deck ]

Remove all the soldering on the short circuit position after the connection of Pick Up PCB and DVD

PCB connector.

NOTE

Before your operation, please read “PREPARATION OF SERVICING”.

•

Use the Lead Free solder.

•

Manual soldering conditions

•

• Soldering temperature: 320 ± 20˚C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the draw in equipment over the Pick Up Unit to keep the

•

Flux smoke away from it.

Short circuit using a

soldering iron.

Fig. 1

Pick Up PCB

A1-6

Page 11

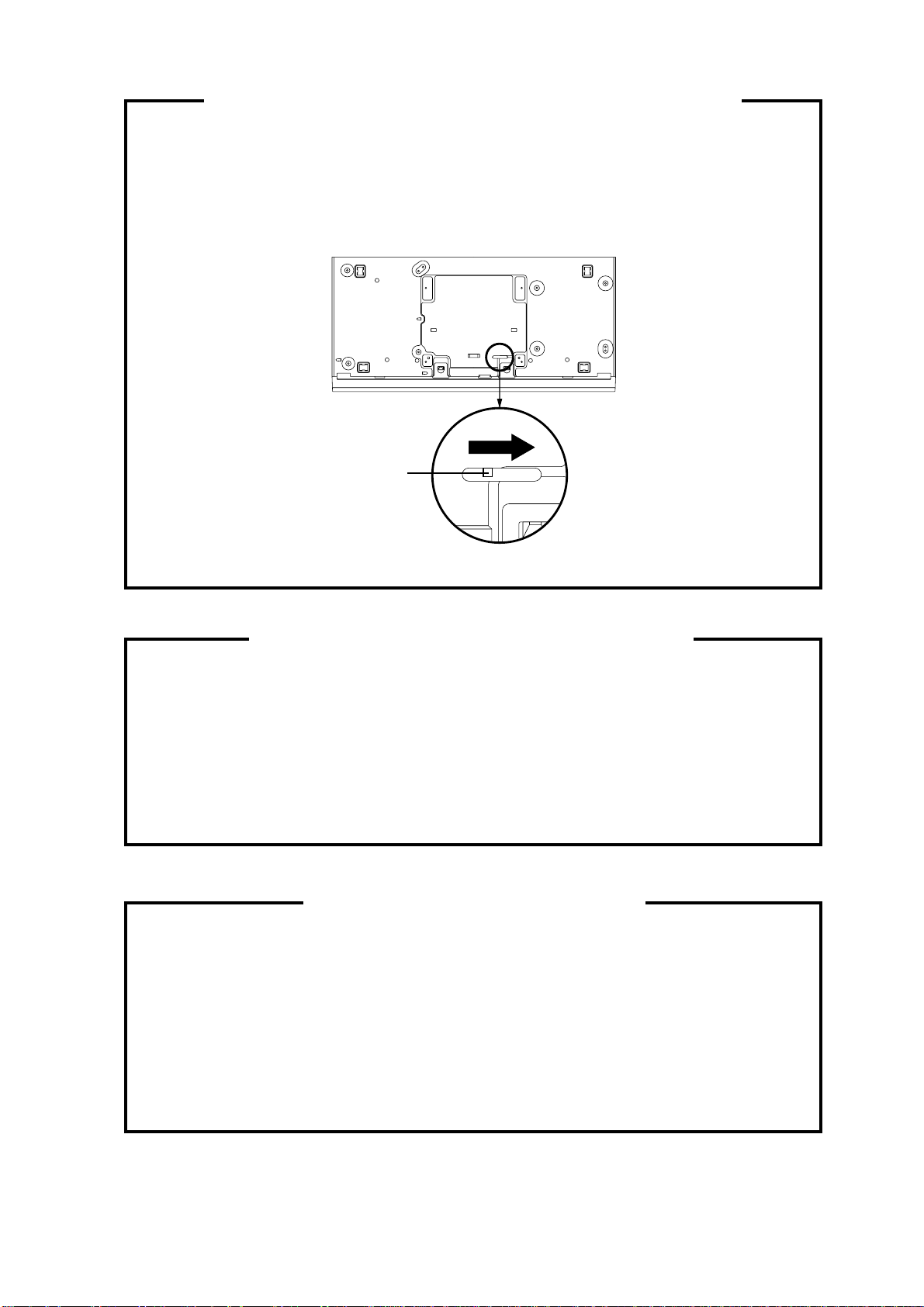

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.

Slide the Rack Loading (White) toward the arrow direction by using a minus driver to release the lock.

(Refer to Fig. 1)

2.

Manually open the Tray.

NOTE:

Please strongly pushing Rack Loading (White) to release the lock because the tray doesn't go out

easily.

DVD Player (Bottom Side)

Rack Loading (White)

Fig. 1

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps

below.

Set the DVD to the Stand-by Mode.

1.

Press and hold the 'STOP' key on the front panel.

2.

Simultaneously press and hold the POWER key on the front panel.

3.

The 4 digit password has now been cleared.

4.

NOTE: The above procedure will reset ALL of the player's settings to the default factory state.

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is

received at the time of repair, the life of the product may be shortened.

Please perform the following measure against static electricity, be careful of destruction of a

laser diode at the time of repair.

• Place the unit on a workstation equipped to protect against static electricity, such as

conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-7

Page 12

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

Pb free solder has a higher melting point than standard solder;

•

Typically the melting point is 86°F~104°F(30°C~40°C) higher.

Please use a soldering iron with temperature control and adjust it to 650°F ± 20°F (350°C ± 10°C).

In case of using high temperature soldering iron, please be careful not to heat too long.

Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

•

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

A1-8

Page 13

TABLE OF CONTENTS

CAUTION .............................................................................................................................................................

IMPORTANT SERVICE SAFETY INFORMATION .............................................................................................

IMPORTANT SAFEGUARDS..............................................................................................................................

WHEN REPLACING DVD DECK ........................................................................................................................

DISC REMOVAL METHOD AT NO POWER SUPPLY........................................................................................

PARENTAL CONTROL- RATING LEVEL ..........................................................................................................

PREPARATION OF SERVICING ........................................................................................................................

ABOUT LEAD FREE SOLDER (PbF).................................................................................................................

TABLE OF CONTENTS.......................................................................................................................................

GENERAL SPECIFICATIONS ............................................................................................................................

DISASSEMBLY INSTRUCTIONS

1.REMOVAL OF MECHANICAL PARTS AND P.C. BOARDS .........................................................................

2.REMOVAL OF DVD DECK PARTS ...............................................................................................................

3.REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ...........................................................................

SERVICING FIXTURES AND TOOLS ................................................................................................................

RE-WRITE FOR DVD FIRMWARE .....................................................................................................................

TROUBLESHOOTING GUIDE ............................................................................................................................

BLOCK DIAGRAMS

DVD LOADER/MPEG .......................................................................................................................................

POWER ............................................................................................................................................................

OVERALL BLOCK DIAGRAM .............................................................................................................................

PRINTED CIRCUIT BOARDS

DVD MT ............................................................................................................................................................

POWER/OPERATION/OPERATION 2/OPERATION 3/OPERATION 4 ...........................................................

LOADING MOTOR/SW .....................................................................................................................................

SCHEMATIC DIAGRAMS

MPEG/MICON/DSP ..........................................................................................................................................

MEMORY ..........................................................................................................................................................

LOADER/MOTOR DRIVE .................................................................................................................................

AUDIO JACK.....................................................................................................................................................

VIDEO JACK .....................................................................................................................................................

HDMI .................................................................................................................................................................

POWER PORT..................................................................................................................................................

POWER.............................................................................................................................................................

DISPLAY ...........................................................................................................................................................

LOADING MOTOR/SW .....................................................................................................................................

INTERCONNECTION DIAGRAM .........................................................................................................................

WAVEFORMS ......................................................................................................................................................

MECHANICAL EXPLODED VIEW .......................................................................................................................

DVD DECK EXPLODED VIEW ............................................................................................................................

MECHANICAL REPLACEMENT PARTS LIST ...................................................................................................

DVD DECK REPLACEMENT PARTS LIST .........................................................................................................

ELECTRICAL REPLACEMENT PARTS LIST .....................................................................................................

A1-1

A1-2

A1-3~A1-5

A1-6

A1-7

A1-7

A1-7

A1-8

A2-1

A3-1~A3-5

B1-1

B2-1~ B2-4

B3-1, B3-2

C-1

C-1

D-1~D-6

E-1, E-2

E-3, E-4

E-5, E-6

F-1, F-2

F-3, F-4

F-5, F-6

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

H-1

I1-1, I1-2

I2-1

J1-1

J2-1

J3-1~J3-4

A2-1

Page 14

GENERAL SPECIFICATIONS

G-1 DVD System Color System NTSC

Disc

Disc Diameter 120 mm , 80 mm

Drive DM4PB

Search speed Fwd 4 step

Fwd-Actual 4, 8, 16, 32 times

Rev 4 step

Rev-Actual 4, 8, 16, 32 times

Slow speed Fwd 4 step

Fwd-Actual 1/16, 1/8, 1/4, 1/2 times

Rev 4 step

Rev-Actual 1/16, 1/8, 1/4, 1/2 times

Zoom Zoom 2 step

Zoom-Actual 2, 4 times

G-2 Power Power Source AC 120V 60Hz

DC --

Power Consumption 7 W

Stand by 0.9 W

Per Year -- W

Energy Star No

Protector Power Fuse Yes

Safety Circuit Yes

IC Protector (Micro Fuse) No

G-3 Regulation Safety UL/CSA(C-UL)

Radiation FCC/IC

Laser DHHS

G-4 Temperature Operation 5 oC - 40 oC

Storage -20 oC - 60 oC

G-5 Operating Humidity Less than 80% RH

G-6 Signal Video Signal Output Level 1 V p-p / 75 ohm

S/N Ratio (Weighted) 65 dB

Horizontal Resolution at DVD 500 Lines

RGB Signal Output Level -Component Video Output Level (Y) 1.0V p-p / 75 ohm

Output Level (Cb, Cr) 0.7V p-p / 75 ohm

Audio Signal Input Level Microphone --- dBm / --- ohm

Output Level Line

S/N Ratio at (Weighted) 90dB

Harmonic Distortion : 0.0065% (1KHz)

Frequency Response : at DVD 4 Hz - 44 KHz (96KHz)

Frequency Response : at SVCD 4 Hz - 20 KHz

Frequency Response : at VIDEO CD 4 Hz - 20 KHz

Frequency Response : at CD 4 Hz - 20 KHz

Frequency Response : at DVD Audio --

Frequency Response : at SACD -Digital Audio Signal Output Level

G-7 OSD Language English/French/Spanish/German/Italian

DVD, CD-DA, CD-R/RW, Video CD, SVCD

DVD-R/RW, DVD+R/+RW (w/o VCPS)

-12 dBm/ 1k ohm (-20dBFs, 0dBFs=2.0Vrms)

0.5 V p-p / 75 ohm

A3-1

Page 15

GENERAL SPECIFICATIONS

G-8

Remote Control Unit

Unit RC-LP

Glow in Dark Remocon No

Remocon Format ONKYO

Format NEC

Custom Code D2-2B

Power Source Voltage (D.C) 3V

UM size x pcs UM-3 x 2 pcs

Total Keys 36 Keys

Power ON Yes

Power Off (STAND BY) Yes

Open/Close Yes

Audio Yes

Subtitle Yes

Angle Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

Clear Yes

Enter Yes

Top Menu Yes

Menu Yes

Set up (Home Menu) Yes

Return Yes

Up Yes

Down Yes

Right Yes

Left Yes

Enter No

<< (Scan/Slow/Step) Yes

>> (Scan/Slow/Step) Yes

Play Yes

|<< (Search) Yes

>>| (Search) Yes

Pause Yes

Stop Yes

Play Mode Yes

Surround No

Zoom Yes

Display Yes

Key Control b No

Key Control # No

A3-2

Page 16

GENERAL SPECIFICATIONS

G-9

G-10

DVD Features

Accessories

Progressive Video Out Yes

Echo No

Mic Mixing No

Digital Out (Dolby Digital) Yes

(MPEG) Yes

(PCM) Yes

(DTS) Yes

Down Mix Out (Dolby Digital) Yes

(DTS) No

(SACD) No

(DVD Audio) No

Surround MTK original Surround

Screen Saver Yes

Auto Stop No

BNR No

Dynamic Range Control Yes

Disc Navigator Yes

Video CD Playback Yes

SVCD Playback Yes

SACD Playback No

DVD Audio Playback No

DivX Playback Yes

DMF Support No

VR Format Playback Yes

Fujicolor CD Yes

KODAK Picture CD Yes

MP3 Playback Yes

WMA Playback Yes

JPEG Playback Yes

Audio DAC 96kHz / 24bit

Auto Power Off Yes

Closed Caption signal in VBI (DVD Playback)

Owner's Manual Language English

w/Guarantee Card No

Remote Control Unit Yes

Guarantee Card Yes

Warning Sheet No

Service Station List No

Important Tag No

AC Plug Adapter No

Quick Set-up Sheet No

Battery Yes

UM size x pcs UM-3 x 2 pcs

OEM Brand No

AC Cord No

AV Cord Yes (1.2m)

1Pin RCA Cable Yes (1.2m)

HDMI Cable No

S-Video Cable No

21pin Cable (Double Shield) No

800 No Sticker No

Toll Free Insert Sheet No

Safety Tip No

Security Tag No

Sheet Information (Return) No

Registration Card No

Netflix Sheet No

Helpline Sheet No

Helpline Sticker No

Information Sheet No

Yes

A3-3

Page 17

GENERAL SPECIFICATIONS

G-11 Interface Switch-Front Standby/On Yes

Play Yes

Open/Close Yes

Skip (>>|) Yes

Skip (|<<) Yes

Pause Yes

Stop Yes

Top Menu Yes

Home Menu Yes

Menu Yes

Return Yes

Enter Yes

Up Yes

Down Yes

Right Yes

Left Yes

Shuttle (Search/REV/FWD) No

Main Power SW No

Display Yes

DISPLAY Type Fluorescent Indicator

Pause/Play Yes

Progressive Yes

DVD No

Remain Yes

Surround No

Track No

A No

-B No

Video No

CD No

All No

PROG No

Mic Mark No

Title Yes

Repeat Yes

Angle Yes

Chapter Yes

Music Calendar (1-14, Play) No

7-seg Digit (8) Yes

Terminals-Front Mic In No

Volume Control No

Echo Control No

Terminals-Rear Video Output RCA x 1

S-Video Output S-Jack x1

Component Video Output RCA x3 (Y, Cr, Cb)

D1 No

Audio Output RCA x 2 (Stereo)

Euro Scart No

Digital Audio Output RCA x 1 (Digital Audio)

5.1ch Audio Output No

HDMI Output Yes

AC Inlet No

Indicator HDMI Yes(Red)

G-12 Set Size Dimensions (Approx.) W x D x H (mm) 435 x 208 x 60.5

G-13 Weight Net (Approx.) 1.9kg ( 4.2 lbs)

Gross (Approx.) 2.8kg ( 6.2 lbs)

A3-4

Page 18

GENERAL SPECIFICATIONS

G-14 Carton Master Carton No

Content --- Sets

Material --- / ---

Dimensions W x D x H (mm) ---

Description of Origin --Gift Box Material Single/Brown

W/Color Photo Label No

Dimensions W x D x H (mm) 507 x 290 x 130

Description of Origin Yes

Natural Dropping At 1 Corner / 3 Edges /

6 Surface

Green procurement of Pioneer

G-15

G-16

Cabinet Material

Environment

Drop Test

Height (cm) 80cm

Container Stuffing 3,220 Sets/40' container

Cabinet Front PS 94V2 or More / NON DECABROM

PCB Non-Halogen Demand No

Eyelet Demand No

Environmental standard requirement (by buyer)

WEEE No

Pb-free Phase3 (Phase3A)

Measures for Whisker Yes

A3-5

Page 19

DISASSEMBLY INSTRUCTIONS

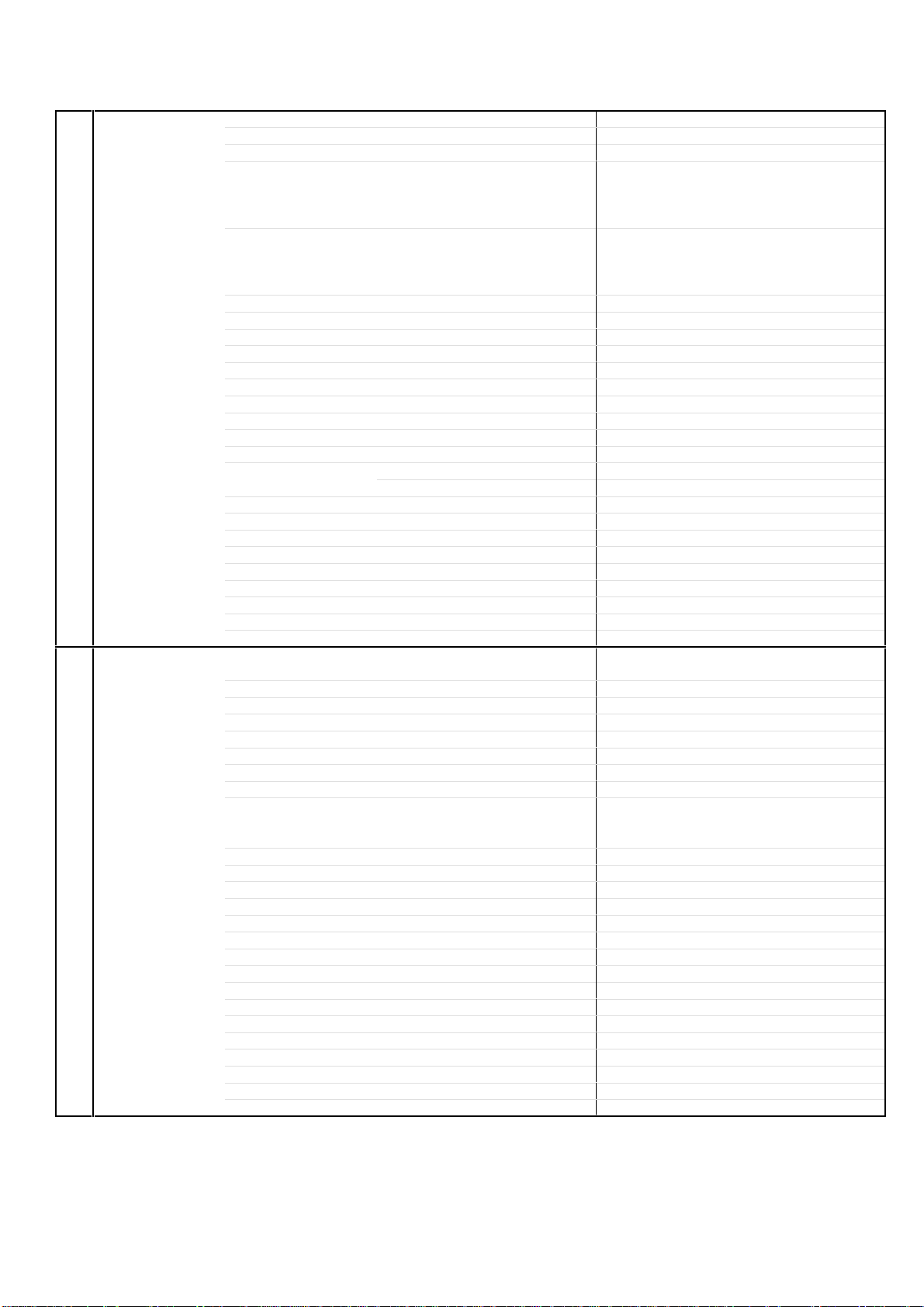

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

1-1:

TOP CABINET/FRONT CABINET/OPERATION 1/2/

3/4 PCB (Refer to Fig. 1-1)

1.

Remove the 5 screws 1.

2.

Remove the Top Cabinet in the direction of arrow (A).

3.

Remove the 2 screws 2.

4.

Remove the Leg in the direction of arrow (B).

5.

Remove the 3 screws 3.

6.

Disconnect the following connector: (CP4002).

7.

Unlock the 2 supports 4.

8.

Remove the Front Cabinet in the direction of arrow (C).

9.

Remove the 10 screws 5.

10.

Remove the 2 screws 6.

11.

Remove the Operation 1/2/3/4 PCB in the direction of

arrow (C).

Top Cabinet

1

(D)

Operation 4 PCB

6

5

5

5

(D)

3

Front Cabinet

(B)

5

(C)

5

2

5

5

(D)

(D)

4

3

Operation 2 PCB

Operation 3 PCB

4

3

1-2: POWER PCB (Refer to Fig. 1-2)

1.

Disconnect the following connector: (CP502).

2.

Remove the 4 screws 1.

3.

Remove the Power PCB in the direction of arrow.

1

1

1

1

1

(A)

5

5

6

5

2

Operation 1 PCB

Power PCB

1

1

(B)

Fig. 1-1

1-3: DVD DECK (Refer to Fig. 1-3)

1.

Short circuit the position shown in Fig. 1-3 using a

soldering iron. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

2.

Disconnect the following connectors:

(CP2301, CP2302, CP2303).

3.

Remove the 4 screws 1.

4.

Remove the DVD Deck in the direction of arrow.

1

1

DVD Deck

1

1

1

Pick Up PCB

Short circuit using a

soldering iron.

Fig. 1-3

NOTE

Before your operation, please read “PREPARATION

1.

OF SERVICING”.

Use the Lead Free solder.

2.

Manual soldering conditions

3.

• Soldering temperature: 320 ± 20˚C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the drawing

4.

equipment over the Pick Up Unit to prevent the Flux

smoke from it.

When installing the DVD Deck, remove all the soldering

5.

on the short circuit position after the connection of Pick

Up PCB and DVD MT PCB connector.

1-4: DVD MT PCB (Refer to Fig. 1-4)

1.

Remove the 3 screws 1.

2.

Remove the screw 2.

3.

Remove the 4 screws 3.

4.

Remove the DVD MT PCB in the direction of arrow.

Fig. 1-2

B1-1

3

1

3

1

1

3

DVD MT PCB

2

3

Fig. 1-4

Page 20

DISASSEMBLY INSTRUCTIONS

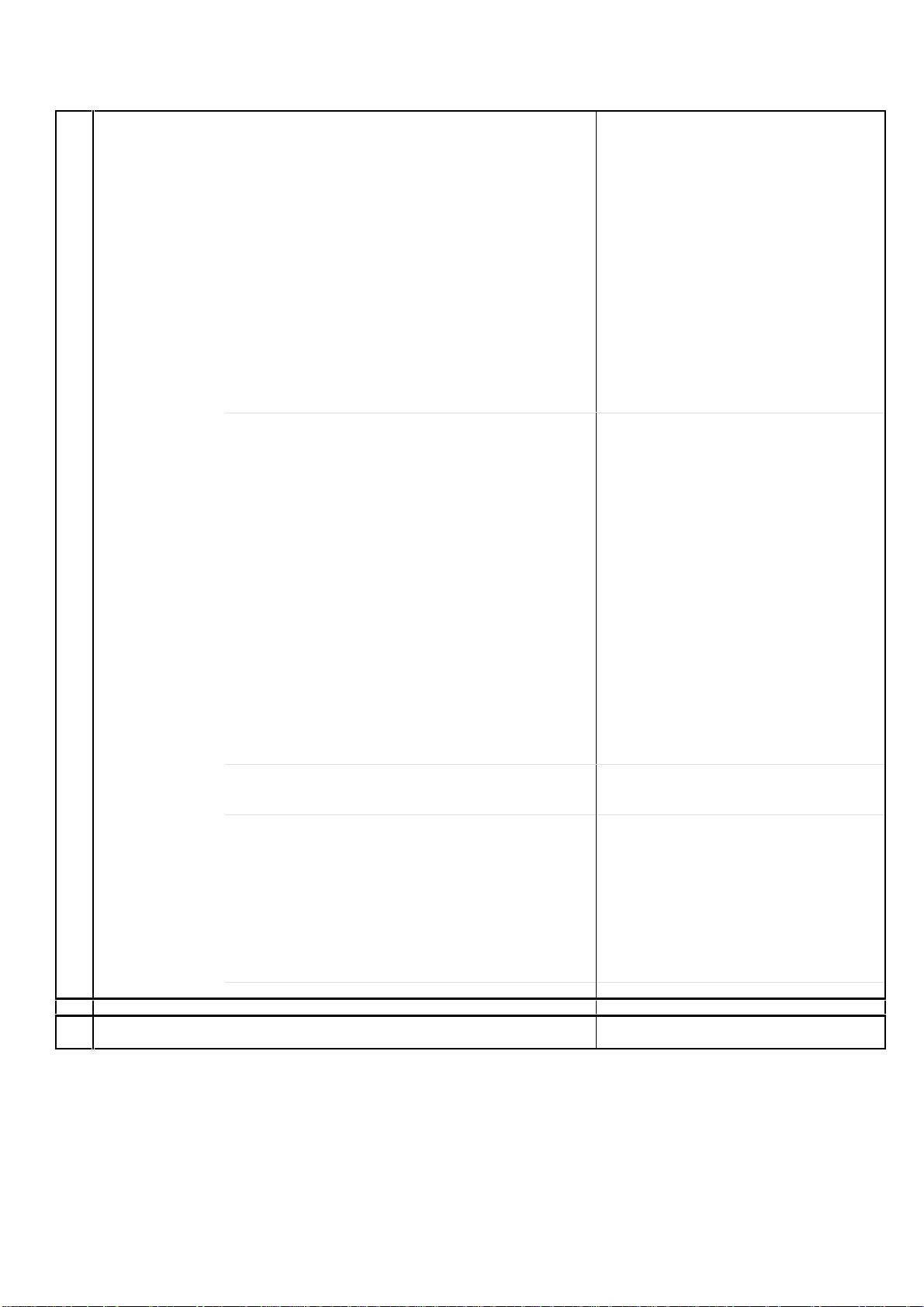

2. REMOVAL OF DVD DECK PARTS

NOTE

1. Disassemble only the DVD DECK PARTS parts listed

here. Minute adjustments are needed if the

disassembly is done. If the repair is needed except

listed parts, replace the DVD MECHA ASS'Y.

2-1: TRAY (Refer to Fig. 2-1-A)

Set the Tray opened. (Refer to the DISC REMOVAL

1.

METHOD AT NO POWER SUPPLY)

Unlock the 2 supports 1 and draw it while sagging the

2.

Tray.

Loader Ass'y

Push to Sag

Tray

NOTE

In case of the Tray installation, install them as the circled

1.

section of Fig. 2-1-B so that the each markers are met.

1

1

Push to Sag

Fig. 2-1-A

NOTE

In case of the Traverse Ass'y, install it from (1) to (4) in

1.

order. (Refer to Fig. 2-2-B)

In case of the Traverse Ass'y installation, hook the wire

2.

on the Loader Ass'y as shown Fig. 2-2-C.

Loader Ass'y (Bottom Side)

(3)

(3)

(3)

(2)

(4)

Check Lock

(4)

Loader Ass'y

(3)

(1)

Rack Loading

Holder Traverse

Traverse Ass'y

Fig. 2-2-B

Loader Ass'y

Tray

Fig. 2-1-B

2-2: TRAVERSE ASS'Y (Refer to Fig. 2-2-A)

Remove the screw 1.

1.

Unlock the 2 supports 2.

2.

Remove the Insulator (R) from the Loader Sub Ass'y.

3.

Remove the Traverse Ass'y.

4.

1

2

2

Loader Sub Ass'y

Insulator (R)

Traverse Ass'y

• Screw Torque: 2.0 ± 0.3kgf•cm

Fig. 2-2-A

Check Hook

Fig. 2-2-C

2-3: LOADING MOTOR PCB ASS'Y/ LOADING BELT

(Refer to Fig. 2-3-A)

1.

Remove the Loading Belt.

2.

Remove the screw 1.

3.

Remove the Loading Motor PCB Ass'y.

4.

Remove the 2 screws 2.

5.

Remove the Loading Motor.

6.

Remove the Gear Pulley.

Loading Belt

• Screw Torque: 2.5 ± 0.3kgf•cm (Screw 1)

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw 2)

2

2

Gear Pulley

Loading Motor

Loading Motor PCB Ass’y

1

Loader Sub Ass'y

Fig. 2-3-A

B2-1

Page 21

DISASSEMBLY INSTRUCTIONS

NOTE

1.

In case of the Pulley Motor installation, check if the value

of the Fig. 2-3-B is correct.

2.

When installing the wire of the Loading Motor PCB Ass'y,

install it correctly as Fig. 2-3-C.

Manual soldering conditions

• Soldering temperature: 320 ± 20˚C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

3.

When installing the Loading Motor PCB Ass'y, install it

correctly as Fig. 2-3-D.

4.

In case of the Loading Motor PCB Ass'y installation, hook

the wire on the Loader Sub Ass'y as shown Fig. 2-3-E.

Pulley Motor

Loading Motor

Safety surface for pressing

of the insert.

BROWN (1)

WHITE (2)

• Install wire from (1) to (2) in order.

7.0 ± 0.1mm

Fig. 2-3-B

2-4: RACK LOADING/MAIN GEAR/PULLEY GEAR

(Refer to Fig. 2-4-A)

1.

Unlock the support 2 and remove the Gear Pulley.

2.

Remove the Gear Main.

3.

Press down the catcher 1 and slide the Rack Loading.

Gear Pulley

Gear Main

2

1

Rack Loading

Loader Sub Ass’y

Fig. 2-4-A

NOTE

1.2.In case of the Rack Loading installation, hook the Rack

Loading on the Loader Sub Ass'y as shown Fig. 2-4-B.

When installing the Gear Main, take care the direction

of up or down as shown Fig. 2-4-C.

Rack Loading

Rack Loading

Check Hook

Loading Motor PCB Ass’y

AB

The Lever should be position

between A and B.

Check Hook

Fig. 2-3-C

Fig. 2-3-D

Loader Sub Ass'y (Bottom Side)

Check Hook

Fig. 2-4-B

Up Side

Main Gear

Down Side

Fig. 2-4-C

2-5: CLAMPER ASS'Y (Refer to Fig. 2-5-A)

Press the Clamper and rotate the Plate Clamper clockwise,

1.

then unlock the 3 supports 1.

Remove the Plate Clamper, Magnet Clamper and Clamper.

2.

Plate Clamper

Magnet Clamper

Main Frame

Check Hook

Loading Motor PCB Ass’y

Fig. 2-3-E

B2-2

1

1

Clamper

1

Fig. 2-5-A

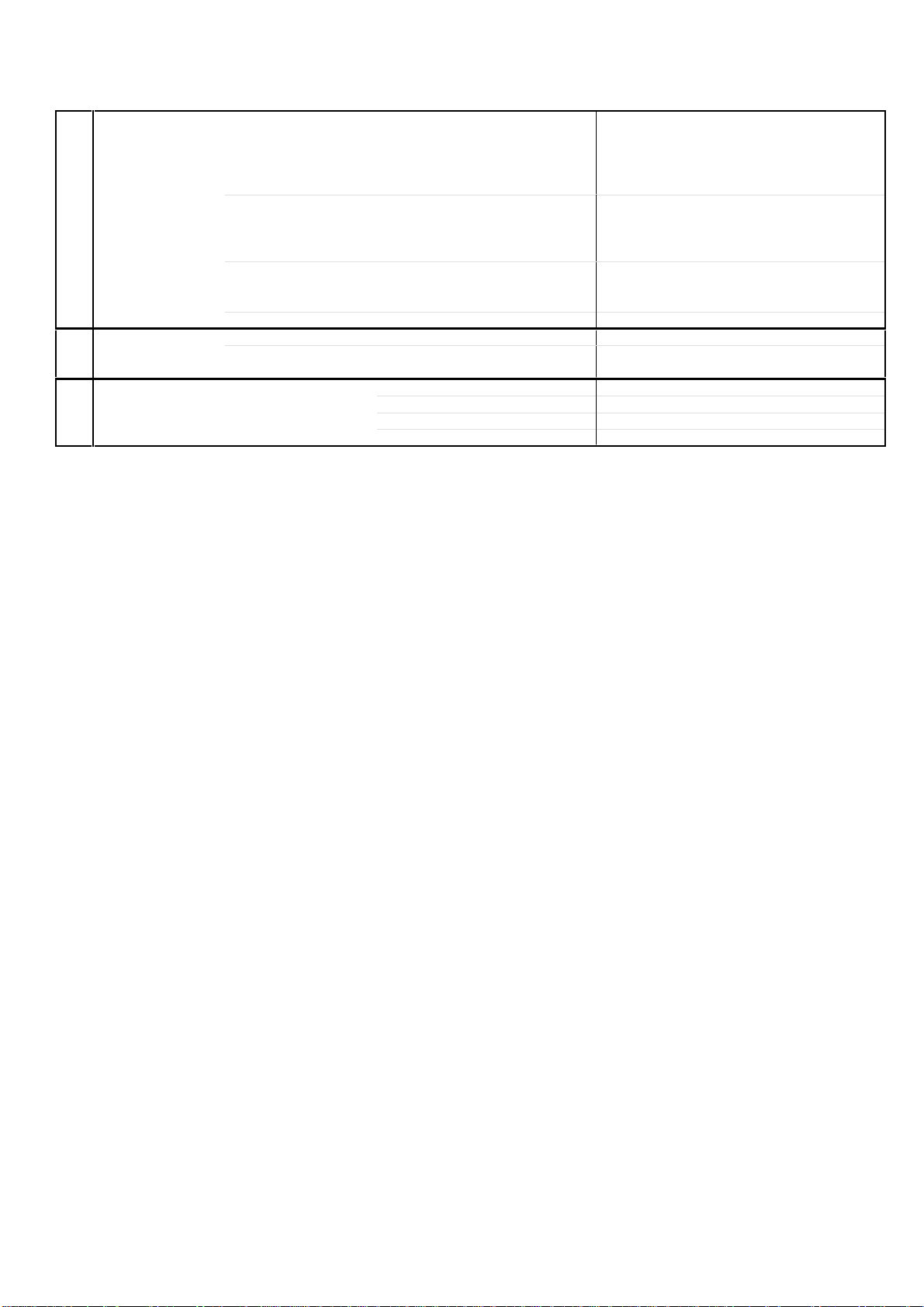

Page 22

DISASSEMBLY INSTRUCTIONS

NOTE

1. In case of the Clamper Ass'y installation, install

correctly as Fig. 2-5-B.

Feed Motor

Gear Motor

Plate Clamper

Clamper

Check Lock

Fig. 2-5-B

2-6:

HOLDER TRAVERSE/INSULATOR (F)/INSULATOR

(R) (Refer to Fig. 2-6-A)

Remove the Holder Traverse.

1.

Remove the 2 Insulator (F).

2.

Remove the Insulator (R).

3.

Insulator (R)

Traverse Ass'y

Insulator (F)

Holder Traverse

Insulator (F)

Fig. 2-6-A

NOTE

1. In case of the Insulator (F) installation, install correctly

as Fig. 2-6-B.

Insulator (F)

5

Traverse Ass'y

Rack Feed Ass'y

• Screw Torque: 1.3 ± 0.3kgf•cm (Screw 2)

• Screw Torque: 3.0 ± 0.3kgf•cm (Screw 3)

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw 4, 5)

1

5

Gear Feed

4

Gear Middle

2

Switch PCB Ass'y

3

Fig. 2-7-A

NOTE

1.

When installing the Rack Feed Ass'y, push both ends to

align the teeth as shown Fig. 2-7-B. Then install it.

2.

In case of the Gear Motor installation, check if the value

of the Fig. 2-7-C is correct.

3.

When installing the wire of the Switch PCB Ass'y, install

it correctly as Fig. 2-7-D.

Manual soldering conditions

• Soldering temperature: 320 ± 20˚C

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

4.

After the assembly of the Traverse Ass'y, hook the wire

on the Traverse Ass'y as shown Fig. 2-7-E.

Rack Feed Ass'y

Traverse Holder

Fig. 2-6-B

2-7:

SWITCH PCB ASS'Y/GEAR MIDDLE/GEAR FEED/RACK

FEED ASS'Y/FEED MOTOR (Refer to Fig. 2-7-A)

Unlock the support 1.

1.

Remove the Gear Middle.

2.

Remove the screw 2.

3.

Remove the Rack Feed Ass'y.

4.

Remove the screw 3.

5.

Remove the Switch PCB Ass'y.

6.

Remove the screw 4.

7.

Remove the Gear Feed.

8.

Remove the 2 screws 5.

9.

Remove the Feed Motor.

10.

Remove the Gear Motor.

11.

B2-3

Push

Gear Motor

Feed Motor

[OK] [NG]

Safety surface for pressing

of the insert.

Push

Fig. 2-7-B

8.0 ± 0.2mm

Fig. 2-7-C

Page 23

DISASSEMBLY INSTRUCTIONS

Switch PCB Ass'y

~ SPINDLE MOTOR ~

Check Hook

Check Hook

• Loosen the wire in the direction of the arrow.

YELLOW (2)

GREEN (1)

Traverse Ass'y

Check Hook

Check Hook

2-8: FFC WIRE HANDLING

~ FEED MOTOR ~

WHITE (4)

BROWN (3)

• Install wire from (1) to (4) in order.

Fig. 2-7-D

Fig. 2-7-E

1.

When installing the FFC, fold it correctly and install it as

shown from Fig. 2-8.

NOTE

Do not make the folding lines except the specified

1.

positions for the FFC.

[ 24 pin FFC ]

Printing Surface

79 ± 1mm

Fold

Reinforcement Plate

To Pick Up PCB

Fig. 2-8

B2-4

Page 24

DISASSEMBLY INSTRUCTIONS

3.

REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

REMOVAL

Put Masking Tape (cotton tape) around the Flat Pack-

1.

age IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

When IC starts moving back and forth easily after

3.

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 3-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering

machine

Masking Tape

(Cotton Tape)

Heat the IC leads using a blower type IC desoldering

2.

IC

machine. (Refer to Fig. 3-2.)

NOTE

Do not rotate or move the IC back and forth , until IC

can move back and forth easily after desoldering the

leads completely.

Blower type IC

desoldering machine

Fig. 3-1

Tweezers

IC

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the Braided

5.

Shield Wire. (Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 3-3

Braided Shield Wire

Soldering Iron

IC

Fig. 3-2

IC pattern

Fig. 3-4

B3-1

Page 25

DISASSEMBLY INSTRUCTIONS

INSTALLATION

Take care of the polarity of new IC and then install the

1.

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

Soldering Iron

Solder temporarily

Supply the solder from the upper position of IC leads

2.

Solder temporarily

sliding to the lower position of the IC leads.

(Refer to Fig. 3-6.)

Fig. 3-5

When bridge-soldering between terminals and/or the

4.

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 3-8.)

Thin-tip Soldering Iron

IC

Fig. 3-8

Finally, confirm the soldering status on four sides of the

5.

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, always be sure to replace the IC in this

case.

Soldering IronSolder

IC

Absorb the solder left on the lead using the Braided

3.

Supply soldering

from upper position

to lower position

Shield Wire. (Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 3-6

Fig. 3-7

B3-2

Page 26

SERVICING FIXTURES AND TOOLS

Remote control JIG

Ref. No.

–––

Part No.

–––

JG176 Up-Date Disc

Parts Name

Remote control JIG

Check for the Firmware version

Up-Date of the Firmware

JG176

APJG176112

Up-Date Disc

Up-Date of the Firmware

RE-WRITE FOR DVD FIRMWARE

Turn on the power.

1.

Open the DVD tray.

2.

Place the Up-Date Disc and close the tray. (Refer to SERVICING FIXTURE AND TOOLS)

3.

The reading will start and the Fig. 1 screen will appear.

Upgrade File DETECTED

Upgrade?

Press Play To Start

Remarks

Fig. 1

Press the PLAY key on the set.

4.

The data reading will start.

And, "File Copying" appears on the TV monitor.

After the finishing of the data reading, tray will open automatically.

The display will change to “CLEAR”.

Remove the Up-Date Disc.

5.

CHECK FOR THE FIRMWARE VERSION

6.

Turn on the power, then press "CHECK SUM" key on the remote control JIG for more than 1 second.

Firmware version will be displayed on the screen.

When the changed version displays, the Re-write will be completed.

REAGION: 1

Y E B 6 4 2 0 A

Fixed

Released times on the same date

Release date (Example: 2006.4.20)

A = October

ROM NUMBER

REG CHK

SUM CHK

FL VERSION

CHIP VERSION

AREA: WY

YEB6420A

10

02A5

1.16

1389FE

Fig. 2

B = November

Turn off the power

7.

C = December

C-1

Page 27

POWER DOES NOT TURN ON

TROUBLESHOOTING GUIDE

Is the voltage at pin 8 and

pin 9 of CP502 about

3.3V and at pin 5 of

CP502 about 5V?

Yes

Is there waveform at

X4001 about 3.0Vp-p ?

Yes

Write DVD FIRMWARE DATA.

No

No

Check AT+3.3V line of POWER BLOCK.

Check Q515 and peripheral circuit.

Check X4001, IC4001 and

peripheral circuit.

D-1

Page 28

DECK DOES NOT ACCEPT

OPEN/CLOSE

TROUBLESHOOTING GUIDE

Is the voltage at pins 3,18 and

19 of IC2301 about DC6V ?

Yes

Is the lose connection

at CP2302 to DECK ?

No

Change DVD LOADER.

No

Yes

Check P.CON 6V line of

POWER BLOCK.

Check CP2302

connection to DECK.

D-2

Page 29

TROUBLESHOOTING GUIDE

DOES NOT LIGHT ON DISPLAY

Is the voltage at pin 13

and pin 43 of IC651

about 3V ?

Yes

Replace V651 or IC651.

No

Check AT+3.3V line of

POWER BLOCK.

D-3

Page 30

NO PLAYBACK PICTURE OF AV

JACK

TROUBLESHOOTING GUIDE

Is there a voltage

(beam current) at

JG008 and JG009 ?

Yes

Is there a signal at

pin 164 of IC4001 ?

Yes

Is there video signal at

pin 33 of IC7301 ?

No

Change IC7301.

No

No

Yes

Check LOADER BLOCK.

Check IC4001 and

peripheral circuit.

Check J7302 and peripheral

circuit.

D-4

Page 31

NO DIGITAL AUDIO ON

PLAYBACK OF COAXIAL JACK

TROUBLESHOOTING GUIDE

Is there waveform at pin 7

of J7301 about 0.3Vp-p?

No

Is there waveform at

pin 159 of IC4001

about 0.3Vp-p ?

No

Change IC4001.

Yes

Yes

Check connection at RCA

Cable.

Check Q8005 and

peripheral circuit.

D-5

Page 32

NO ANALOG AUDIO ON

PLAYBACK

TROUBLESHOOTING GUIDE

Is there AUDIO signal

at pins 1 and 7 of

IC8003 ?

No

Is there AUDIO signal at

pins 2 and 6 of IC8003 ?

No

Change IC8003.

Yes

Yes

Check J8003 and peripheral

circuit.

Check AT pins 184 and

186 of IC4001.

D-6

Page 33

DVD LOADER/MPEG BLOCK DIAGRAM

DVD

Loader

(DM-4)

OPU

SPINDLE/

STEPING/

SLED

MOTOR

C

IOA, V20

RF, A, B, C, D, E, F, MDI1

LD_DVD, LD_CD

T+/-, F+/-,

LOAD+/-,

MOT_SLED+/-,

MOT_SPDL+/-

A

Q2302~2305

LD DRIVE

D

MOTOR DRIVER IC

IC2301

LA6565VR-TLM-E

LIMIT, TRIN, TROUT,

OPO, OP+/-

A0~A20, AD0~AD7,

PRD#, PCE#, PWR#

MA0~MA11, DQ0~DQ15,

DQM0, DQM1, DBA0, DBA1,

SDCLK, SDCKE, DWE#,

DRAS#, DCAS#, DCS#

LDO1, LDO2

DMSO, FMSO,

TROPEN, TRCLOSE,

TRSO, FOSO,

STBY, V1P4

X4001

27MHz

MPEG/MICON IC

IC4001

MT1389FE/E-L

RESET

LETTER, SQUEEZE, VSEL1,

I/XP, R/CR, B/CB, G/Y, C/V

A, B

AUDIO L, R

RESET IC

IC4003

BD5229G-TR

ASPDIF

C

F

A

VIDEO DRIVER 6CH IC

IC7301

LA73054-TLM-E

AUDIO AMP IC

IC8003

RC4580IDR

AUDIO R

AUDIO L

S+COAXIAL JACK

J7301

7

C

4

Y

3

VIDEO JACK

J7302

Y

5

U

3

V

2

CVBS

6

AUDIO JACK

J8003

R

2

L

3

E-1

A

S29AL016D70TFI020

HDMI CONNECTOR

CP5901

1

D2+

3

D2-

4

D1+

6

D1-

7

D0+

9

D0-

10

CLK+

12

CLK-

19

HOTPLUG

18

POWER

15

SCL

16

SDA

16Mbit FLASH

IC4004

H

64Mbit SDRAM

IC4005

EM638165TS-7G

HDMI TRANSMITTER IC

IC5901

MT1392E/C-L

A

A

EEPROM IC

IC4002

BR24L08FJ-WE2

A, B

SDA

SCL

92_Y0~Y7

92_VCK, 92_ACLK, XO

HDMI_SCL

HDMI_SDA

SDA

SCL

FP_DI, FP_DO,

FP_SCK, STB

IR

IR RECEIVER (OS651)

IR

ROM-N338TAO

FIP DRIVER IC

IC651

PT6315

A

A

GR1 ~ GR8,P1~P16

FIP (V651)

HNV-08SS44T

G

A.......AT+3.3V

B.......+1.8V

C.......P.CON+5V

D.......P.CON+6V

E.......AT+12V

F.......P.CON+12V

G.......-28V

H.......V+5H

E-2

Page 34

PHOTO COUPLER

IC504

PS2561AL1-1-V (W)

POWER BLOCK DIAGRAM

VOLTAGE CTL

IC501

KIA431A-AT

AC IN

POWER CTL

IC502

STR-A6131M

SWITCHING

TRANS

T501

REG+1.8V

IC4006

LM1117S-ADJ

6V REG

IC503

PQ070XF01SZH

Q505

P.CON SW

Q504

FL+ P.CON SW

Q515

P.CON +5V SW

Q510

P.CON +12V SW

HDMI+5V REG IC

IC5902

PQ1K503M2ZPH

+1.8V

AT+12V for mute

P.CON+12V

P.CON+5V

P.CON+6V

V+5H

P.ON-H

AT+3.3V

FL DC -

FL DC +

E-3

Q502

-28V P.CON SW

-28V

E-4

Page 35

OVERALL BLOCK DIAGRAM

KEY

IR

IR RECEIVER (OS651)

ROM-N338TAO

FIP

HNV-08SS44T

FIP DRIVER IC

IC651

PT6315

IR

SERVO

FP,STB

8K EEPROM

BR24L08FJ-WE2

27MHz

MPEG/MICON BLOCK

IC4001

MT1389FE/E-L

RF

IC4002

SDA, SCL

MPEG-1/2/

JPEG

VIDEO

DECORDER

AUDIO AMP IC

IC8003

RC4580IDR

AUDIO_L,

AUDIO_R

AUDIO CODEC/

INTERNAL DAC

TV Encoder

108MHz

AMUTE

CH VIDEO DAC

ASPDIF

RESET

AMP_AUDIO_L/R

VIDEO DRIVER 6CH IC

IC7301

LA73054-TLM-E

RESET IC

IC4003

BD5229G-TR

S_VIDEO

COAXIAL

R

L

Y

U

V

CVBS

S

CO

MOTOR DRIVER

LA6565VR-TLM-E

SERVO

AC120V

IC2301

RF

DVD LOADER

(DM4)

POWER

SUPPLY

LD_DVD,

LD_CD

16Mbit FLASH

IC4004

S29AL016D70TFI020

P.CON+12V

P.CON+5V

P.CON+6V

+1.8V

AT+3.3V

AT+12V for mute

-28V

FLDC+/-

A0~A20,

AD0~AD7

MA0~MA11,

DQ0~DQ15

64Mbit SDRAM

IC4005

EM638165TS-7G

92_Y0~Y7,

92_VCK,

92_ACLK

HDMI TRANSMITTER IC

IC5901

MT1392E/C-L

TX0+/-,

TX1+/-,

TX2+/-,

TXC+/-

HDMI

CONNECTOR

CP5901

E-5

E-6

Page 36

PRINTED CIRCUIT BOARDS

C5921

CP5901

J7301

C5920

J7302

R5928

B5902

L5904

L5903

L5902

L5901

W850

R8040

R5919

R5916

W830

C8042

J8003

R5920

C5910

C5911

C5912

C5913

C5914

C5915

W831

C8038

C7324

R7324

R7322

R7323

R7316

B7305

R7315

R7318

R7317

R8079

R8084

Q8019

C8078

R8078

Q8018

C8077

R8085 R8080

W840

61

C5916

B7304

R5918

R8038

Q8005

R8039

C7317

C7325

C8074

R8081

C5917

C7316

R8074

R8073

C5918

IC5901

R8036

R8037

C8070C8073

R8056

R8035C8036

Q8014

Q8013

2141

1

C7319

C5901

C7318

R8051

C5903

B8004

C5925

R8014

C5902

C5919

W829

W877

R5906

C5905

R8063

C5904

B5905

C5908

W887

C8067

C8072

R8067

C8069

W888

C7313C7304

IC8003

R5923

C7303

W878

R7306

R8061

R8066

W851

DVD MT (TOP SIDE)

R5922

R4052

R4051

W805

W868

R4049 R4050

W832

Q4001

Q7302

C7311

IC7301

W873

W871 W872

W834

R8049R8059

R8048

C8059

C8057

C8056

C8058

R8060

R8069

R8057

C8066

W880

R7302

C7312

C7310

C7309

C7308

C7307

C7305

C7306

W833

W886

C8051C8053

W838

R8044

Q8010

R4027

R4022

W837

W826

C4104

R4021

X4001

C4035

R5921

IC5902

R8065

B4002

C5922

C4122

C4039

C4032

C5924

R5901

R4035

C4047

C4037

C4033

C4030

C5923

C4087

C4078

R4024

C4031

C4027

C4064

R4008

C4038

R4025

C4029

R4020

C4065

C4036

C4025

R4058

C4105

C4098

C4093

B4010

C4059

C4034

C4028

C4026

C4099

C4058

C4066

R4045

R4046

C4063

C4024

R4011

CP4003

C4046

C4020

C4022

C4100

R4012

C4112

R4018

C4019

C4011

NR4003

B4007

C4072

C4018

B4001

IC4006

C4086

C4067

1

C4012

R4013

C4056

R4053

R4057

C4013

W820

C4096

C4014

W821

C4055

R4062

C4094

W822

R4054

C4075

C4002

C4095

R4065

R4066

IC4001

C2303

R4072

C4073

C4003

C4088

Q2301

R4073

C4074

C4006

R2309

R2308

IC4005

NR4002

C4007

Q2306

C4049

R2307

R4006

C4005

R2306

109163

R4061

R4007

C2321

R2323

R2321

Q2307

CP2301

55

C4001

R4014

C4010

Q2305

R4009

C4089

C2320

C4052

C4090

R2322

Q2303

C2306

W807

C4071

R4055

R4001

R2320

W865

C2301C2302

R4030

R4056

C4080

C2314

Q2304

Q2302

C4023

R4010

C4101

C4048

C4051

C4102

W864

R2327

R2325

IC4002

R4074

R2330

R2328

R2326

C4060

C4103

R2343

R4034

C4057

R4040

R4003

R2341

R2318

C4016

R4039

R4036

C2307

R2316R2317

CP2303

NR4001

C4040

IC2301

W842

R4002

R4004

IC4004

C2313

C4050

R4076

C4062

R4015

R2312

C2305

R2338

C4081

C4082

R4037

C4116

C2312

C4114

B4011

R2311R2313

3

2

P

C

R2337

R2310

R2335

C2311

C4077

2

0

4002

P

C

IC4003

C4084

R4029

C4083

R2332

R2333

C2309

C2308

R2334

C2310

C4079

R4075

DMF073A

C2323

C2322

R2342

R2331

R2319

R2329

DVD MT (BOTTOM SIDE)

DMF073A

F-1

F-2

Page 37

PRINTED CIRCUIT BOARDS

W804

CP501

FH501_1

POWER (INSERTED PARTS)

SOLDER SIDE

R503

FIRE

D503

D506

D502

D505

AS

MARKED

W013

C522

W037

D525

D531

F501

C502_1

IC503

R546

D517

DPF010A

FH502_1

R524

C536

C535

D534

W023

D532

W012

C531

L503

W814

W036

C527

W024

R542

Q515

L501

C538

C526

L505

W019

R540

Q510

W817

D510

CP502

-

RISK

REPLACE

OF

C523

W015

D512

C521

W018

W016

C516

.

D527

W008

R502

D535

D528

Q502

W007

T501

D519

D511

R

5

1

IC502

R510_1

1

R539

W038

W010

R529

W011

C511

R505

D515

C520

C509

IC501

C517

C519

Q504

C528

C506

B501

D523

R528

C513

D536

W003

D509_1

D508

D513

D516

D520

D522

W004

W006

C515_1

R530

D533

W005

R513

C540

W002

W001

R534

R512_1

IC504

C518

R507

R514

R517

D521

R527

W803

R538

Q506

R516

Q501

R523

R506

R548

R536

R537

R531

R544

R515

Q503

Q513

C503

Q512

C508

POWER (CHIP MOUNTED PARTS)

SOLDER SIDE

C507

C541

R518

R504

R543

Q511

Q509

R547

R509

R541

R519

Q505

DPF010A

R525

C501

R526

R545

F-3

OPERATION/OPERATION 2/OPERATION 3/OPERATION 4 (INSERTED PARTS)

SOLDER SIDE

SW656

SW655

D660

W001

SW654

D651

SW664

SW652

SW657

SW653

SW659

R664

SW662

SW661

DEF085B

W809

SW658

DEF095B

W009

W008

W004

CP601

W006

CP603CP604

W804

D667

C653

SW660

W012

W013

DEF084B

W807

W808

V651

W003

CP605

W010

SW665

CP602

D659

D658

D657

D656

D655

D654

D652

SW663

W002

SW667

R666

W805

SW666

DEF086B

C674

OS651

OPERATION/OPERATION2 (CHIP MOUNTED PARTS)

SOLDER SIDE

DEF095B

DEF086B

DEF084B

C651

R657

R656

R655

R651

C676

R652

R653

R658

R662

R654

C675

IC651

C604

C605

C658

DEF085B

C668

F-4

Page 38

PRINTED CIRCUIT BOARDS

LOADING MOTOR (INSERTED PARTS)

SOLDER SIDE

SW1

DED021A

SW

SOLDER SIDE

LOADING MOTOR (CHIP MOUNTED PARTS)

SOLDER SIDE

DED021A

BR

M2603

WH

CD2302

15

F-5

SW2

DED020A

CD2301

WH

BR

M2602 M2601

YE

GR

F-6

Page 39

ABC D E F GH

8

FROM/TO LOADER/MOTOR DRIVE

7

TRCLOSE R/CR

TROPEN B/CB

6

FROM/TO MEMORY

5

4

3

2

1

MPEG/MICON/DSP SCHEMATIC DIAGRAM

XO

C4035

R4022

9PCH

750K

3.3

PLLVDD3

AD1

1.5

TP4023

TP4022

AD1

R4027

C4034

0.0

0.1

PLLVSS

IDACEXLP

AD2

DVSS(1.8)

0.0

1.1

AD2

68

100GT02720

0.1 B

1.0

1.3

JITFN

AD3

1.0

1.5

TP4024

TP4025

AD3

AD4

X4001

27MHz

R4024

100K

R4025 68

0.9

JITFO

AD4

1.6

TP4026

AD5

V+1R8

MDI1

V20

STBY

A

B

C

D

E

F

LDO1

LDO2

DMSO

FMSO

TRSO G/Y

FOSO C/V

OPO SQUEEZE

OP+ LETTER

OP- I/XP

IOA VSEL1

TRIN

TROUT

LIMIT

V1P4

RF

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

PWR#

PRD#

PCE#

DQM0

DQM1

DWE#

DCAS#

DRAS#

DCS#

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DBA0

DBA1

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

SDCKE

SDCLK

V+3

C4016

0.0

1.5

1.5

1.5

1.5

1.7

NC

2.1

2.1

2.1

2.1

NC

NC

NC

NC

NC

NC

2.1

2.1

0.2

0.2

2.5

3.3

3.5

3.4

2.1

0.0

2.8

2.0

1.4

1.3

1.3

1.3

2.5

1.6

1.4

2.1

1.3

0.0

1.4

1.4

1.4

2.5

3.4

0.0

3.3

2.2

1.8

1.8

2.2

1.6

2.7

1.9

2.2

0.1 B

C4101

C4011 1 B

C4012 1 B

C4013 1 B

C4014 1 B

C4088 1 B

CS

TP4008

TP4009

RFLV

FE

TP4010

TP4011

TE

C4102

470PCH

470P CH

3.3

VCC

NC

1234

0.0

R4061

EEPROM IC

C4006 0.1 B

R4006 10K

R4007 15K

R4009 12K

R4010 12K

TP4001

TP4002

TP4003

TP4004

TP4005

TP4006

TP4007

10K

C4010

IC4002

BR24L08FJ-WE2

220P CH

D

A

B

C

RF

C4005

0.1 B

E MA4

F MA5

MDI1 MA6

V20 MA7

LDO2 MA8

LDO1 MA9

OPO

OP- DBA0

OP+

DMSO

FMSO

TROPEN DWE#

ADIN

TRSO DQ8

FOSO DQ9

LIMIT

IOA DQ10

TRCLOSE DQ11 D_GND

STBY DQ12

A2 DQ13

A3 DQ15

A4 DQ0

A5 DQ1 STB

A6 DQ2

A7 DQ3

A8 DQ4

(V+3D)

SCL

SDA

TP4036

TP4037

C4002 0.1 B

C4007 0.1 B

C4003

R401510K

R401410K

C4001

0.1 B

0.1

B

R4003

C4103

0.0022 B

R4002

3.3

5678

0.0

1.8V

680K

SDA

GND

C4089

10K

R4004

0.015 B

C4090

R4001 33

10K

3.3

SCL

NC

0.0

0.1 B

0.0

WP

NC

0.0

R4018 15K

V+3RF

C4018

0.1 B

1.4

0.9

3.3

110

AGND

DVDA

3

DVDB

4

DVDC

5

DVDD

6

DVDRF IP

DVDRF IN

MA

MB

MC

MD

111213141516171819 22021222324

SA

SB

SC

SD

CDFON

CDFOP

TNI

TPI

MDI1

MDI2

LDO2

LDO1

SVDD3

CSO/RFOP

2526272829

RFLV/RFON

SGND

V2REFD

V2D

VREFD

30313233343536373839

FEO

TEO

TEZISLV

OP_OUT

OP_INN

OP_INP

DMO

FMO

TROPENPWM

PWMOUT1/ADIN0

40414243444546474849

TRO

FOO

FG/ADIN1/GPIO (PU)

GPIO0/VSYN/YUV1

GPIO1/HSYN/INT4#/YUV2

GPIO2/SPMCLK

IOA2 (PU)

DVDD18

IOA3 (PU)

IOA4 (PU)

50

IOA5 (PU)

51525354

IOA6 (PU)

IOA7 (PU)

HIGHA0(PU)

55

56 57 58 59

0

0.2

3.300.5

TP4012

TP4013

PWR#

A18

A19

C4019 0.1 B

RFGC

V1P4

390P CH

C4032

C4030

C4028

0.1 B

C4026 0.1 B

1.6

3.3

0.0

ADCVSS

ADCVDD3

IOA20/YUV0 (PD)

HIGHA1 (PU)

0.1

0.0

0.5

TP4020

PCE#

0.47 B

1025V KA

C4033

C4029

0.047 B

C4031

1.6

1.6

LPFIP

LPFIN

LPFOP

IOCS# (PU)

IOA1 (PU)

IOOE#

1.8

0.0

PRD#

0.047 B

1.8

LPFON

AD0

1.2

TP4021

R4020

100K

C4027

22P CH

C4024 0.1 B

C4022 0.033 B

C4020 0.1 B

1.7

OSN

A16

C4025

0.001 B

1.7

3.3

1.4

1.5

2.0

0.0

1.7

OSP

HRFZC

RFGND

CRTPLP

RFVDD3

RFRPDC

RFRPAC

AVDD3216

IREF

215

55

IOA18 (PD)

56

IOA19 (PD)

57

IOWR# (PU)

A16 (PU)

58

HIGHA7 (PU)

DVDD3

HIGHA6 (PU)

HIGHA5 (PU)

HIGHA4 (PU)

HIGHA3 (PU)

0.9

TP4015

TP4016

0.1 B

A14

2.8

A13

HIGHA2 (PU)

2.7

2.7

1.8

TP4017

TP4018

TP4019

A12

A11

A10A9A20A1AD0

60 61 62 63 64 65 66 67 68 69770 71 72 73 74 75 76 77 78 79880 81 82 83 84 85 86 87 88 89990 91 92 93 94 95 96 97 98 99

3.3

TP4014

C4023

A15

1

C4047

C4037

11P CH

W832

C4036

0.1 B

0.0

1.8

0.7

3.3

XTALI

XTALO

RFGND18

RFVDD18

ADACVDD2(A)

MPEG/MICON IC

MT1389FE/E-L

AD5

AD6

ALE (PU)

AD7

IOA21/YUV7/GPIO (PD)

0

1.6

1.0

1.701.8

TP4027

TP4029

AD6

AD7

22

R4056

(A21)

92_Y7

V+3A

10006.3V YK

C4046 0.0068 B

C4038

0.0

3.3

3.3

ADACVDD1(A)

ALF(CTR)/GPIO(A)

IC4001

IOA0 (PU)

A17 (PU)

2.0

TP4030

A0

A17

SDA

SCL

AMUTE

LE

1B

1.6

ALS/SDATA0/GPIO(A)

DVDD18

2.6

C4057 0.1 B

C4060

LETTER

SQUEEZE

SQ

TP4043

TP4042

C4039

3.3

1.6

1.0

AVCM(A)

ARS/GPIO(A)

AL/SDATA2(A)

AR/SDATA1(A)

DVDD3

UWR# (PU)

URD# (PU)

UP1_2 (PU)

3.3

3.2

3.1

NCNCNC

R4034 10K

R4036 10K

R4037 10K

R4039 10K

33

R4030

B4011

0.1 B

92_VCK

V+3

I/XP

1025V KA

0.0

0.0

0.0

3.3

ADACVSS1(A)

ADACVSS2(A)

ARF(SW)/GPIO(A)

UP1_3 (PU)

UP1_4 (PU)

GPIO6/YUVCLK (PD)

2.9

0.0

3.1

3.0

33

R4029

MMZ1608

R102CT

FP_DI

FP_SCK

W805

C4063

0.1 B

C4059

0.0015 B

3.3

1.0

APLLVDD(A)

APLLCAP(A)

APLLVSS(A)

162

161

160

159 SPDIF

UP1_6/SCL (PU)

UP1_7/SDA (PU)

UP1_5 (PU)

3.3

3.3

NR4001

4D03WGJ0330T5E

STB

FP_DO

B4010

MMZ1608R102CT

NC NC NC

0.1

1.4

0.1

3.3

AKIN2(A)

ADVCM(A)

AKIN1(A)

AADVDD(A)

FS(V)

VREF(V)

DACVDDC(V)

107

RD5

DVDD3

108

UP3_0/RXD (PU)

UP3_1/TXD (PU)

UP3_5/TXD/SDA (PU)

UP3_4/RXD/SCL (PU)

0.0

2.6

3.3

2.6

RXD

HDMI_SCL

C4064

0.1 B

0.0

0.0

HDMI_SDA

3.3

0.7

0.0

0.7

0.7

G/Y(V)

R/CR(V)

B/CB(V)

AADVSS(A)

GPIO7/YUV3 (PD)

100

TXD

DACVDDA(V)

DACVSSA(V)

MC_DATA/INT2#/YUV0/GPIO

(PD) ASDATA3/YUV6/GPIO

(PD) ASDATA2/YUV5/GPO

(PD) ASDATA1/YUV4/GPO

(PD) ASDATA0/YUV2/GPO

(PD) ALRCLK/YUV1/GPO

ACLK/YUV0/GPIO

ABCK/YUV0/GPIO

GPIO5/INT3#/SPBCK

GPIO4/SPLRCK

GPIO3/INT1#/SPDATA

ICE (PD)

PRST# (PU)IRDQM0#

INT0# (PU)

101102103104105 106107 108

0.1

3.3

1.9

3.3

2.6

NC

TP4033

TP4078

DQM0

22

R4055

92_Y3

C4065

0.1 B

3.3

0.0

DACVSSB(V)

DVSS(3.3)

DVDD18

(PD) RA11

DVDD18

DVSS(1.8)

RD7

1.9

1.9

TP4077

DQ7

DQ6

R4076

100

(DVD MT PCB)

V+3V

C4058

0.1 B

R4045 15K

R4046

2.7K

+-1%

0.0

0.7

163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208209210211212213214215216

1.3

1.3

3.3

1.6

CVBS/C(V)

DACVSSC(V)

DACVDDB(V)

3.3

0.0

0.0

3.3

1.6

1.6

1.6

1.6

1.9

0.0

0.0

0.0

C4075100P CH

1.8

1.2

RA4

1.2

RA5

1.2

RA6

1.2

RA7

1.2

RA8

1.2

RA9

1.2

1.9

CKE

3.3

DVDD3

RD6

RCLK

RA10

RCS#

RAS#

CAS#

RWE#

DQM1

RD8

RD9

RD10

RD11

RD12

RD13

RD14

RD15

RD0

RD1

RD2

RD3

RD4

1.9

DQ5

RA3

RA2

RA1

RA0

BA1

BA0

3.3

C4071

1.7

1.5

2.0

1.2

1.8

1.1

0.1

1.6

1.6

2.0

1.5

3.0

3.3

1.9

1.9

1.9

0.0

1.9

1.9

1.9

1.9

0.0

1.9

1.9

1.9

1.9

1.9

1.9

109110111112113 114115 116117 118119 120121 122123 124125126127128129130131132133134135136 137138 139140 141142 143144 145146 147148149150151152153154155156157158159160161 162

0.1 B

C4073 0.1 B

C4074 0.1 B

R4074

33

IR

ANALOG VIDEO OUTPUT!! NECESSARY SHIELD

R4050

R4051

R4052

150 +-1%

150 +-1%

B4007

MMZ1608R102CT

NR4003

4D03WGJ0220T5E

R4053 22

R4054 22

R4062 10

TP4055

TP4056

TP4057

TP4058

TP4059

TP4060

TP4061

TP4062

TP4063

TP4064

TP4065

TP4066

TP4067

NR4002

CT

V_OUT

R4075

1K

3.3

C4079

NC

45

VDD

0.0

0.1 B

1.9

123

3.3

150 +-1%

TP4095

VSS NC

C4072

100P CH

C4066

1B

C4067

0.1 B

R4049

0.0082 B

TP4035

150 +-1%

R4057 10K

C4077

RESET IC

IC4003

RESET

R4065 33

R4066 33

R4072 33

R4073 33

4D03WGJ0330T5E

BD5229G-TR

R/CR

B/CB

G/Y

C/V

PWDN#

1.8V

ASPDIF

92_Y6

92_Y5

92_Y4

92_Y2

92_Y1

92_Y0

92_ACLK

TROUT

VSEL1

SDCKE

SDCLK

W842

C4080

AL

AR

3

TRIN

MA11

MA3

MA2

MA1

MA0

MA10

DBA1

DCS#

DRAS#

DCAS#

DQM1

DQ14

2206.3V YK

V+3D

8

FROM/TO POWER PORT

V+3E

V+3

V+1R8

PWDN#

-28V

FLDCFLDC+

ADAC_GND

D_GND

7

TO VIDEO JACK

FROM/TO HDMI

XO

URST#

92_Y7

92_Y6

92_Y5

92_Y4

92_Y3

92_Y2

92_Y1

92_Y0

92_VCK

92_ACLK

92_ABCK

92_ALRCK

92_SDATA0

SCL

SDA

HDMI_SCL

TP4087

TP4088

TP4089

TP4081

TP4082

TP4083

TP4084

TP4085

TP4086

HDMI_SDA

TO AUDIO JACK

AL

AR

AMUTE

ASPDIF

GND

6

FROM/TO DISPLAY

CP4002

(CP601)

00_6232_011_006_800+

FLDC-

-28V

FLDC+

DGND

DGND

V+3E

IR

DO (F to M)

STB

DI (M to F)

CLK

TP4091

TP4092

TP4093

TP4094

PCB130

DMF073

11

10

9

8

7

6

5

4

3

2

1

2

W834

W833

FLDC-

-28V

FLDC+

1B

V+3E

IR

FP_DO

FP_DI

FP_SCK

C4081 33P CH

C4082 100PCH

C4083 33P CH

C4084 100PCH

RXD

TXD

V+3

C4114

6

5

4

3

2

1

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

ABC D E F GH

G-2G-1

Page 40

ABC D E F GH

MEMORY SCHEMATIC DIAGRAM

8

16Mbit FLASH

7

FROM/TO MPEG/MICON/DSP

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

6

5

4

3

DQ13

DQ14

DQ15

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8