Page 1

CD RECEIVER

MODEL CR-305X

CR-305X

Ref.NO.3654

082000

UDD,UDT

UPP

UGT,UGR

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST

ARE CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK. REPLACE THESE COMPONENTS

WITH ONKYO PARTS WHOSE PARTS NUMBERS

APPEAR AS SHOWN IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED PARTS ARE ACCEPTABLY INSULATED FORM

THE SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

Silver models

120 V AC,60 Hz

230 V AC,50 Hz

220 - 230 V AC,50/60Hz

TABLE OF CONTENTS

Specifications ----------------------------------------------------------Caution on replacement of optical pickup --------------------------

Protection of eyes from laser bam during servicing ---------------

Service procedures -----------------------------------------------------

Front panel view ------------------------------------------------------

Rear panel view -------------------------------------------------------

Remote controller ----------------------------------------------------

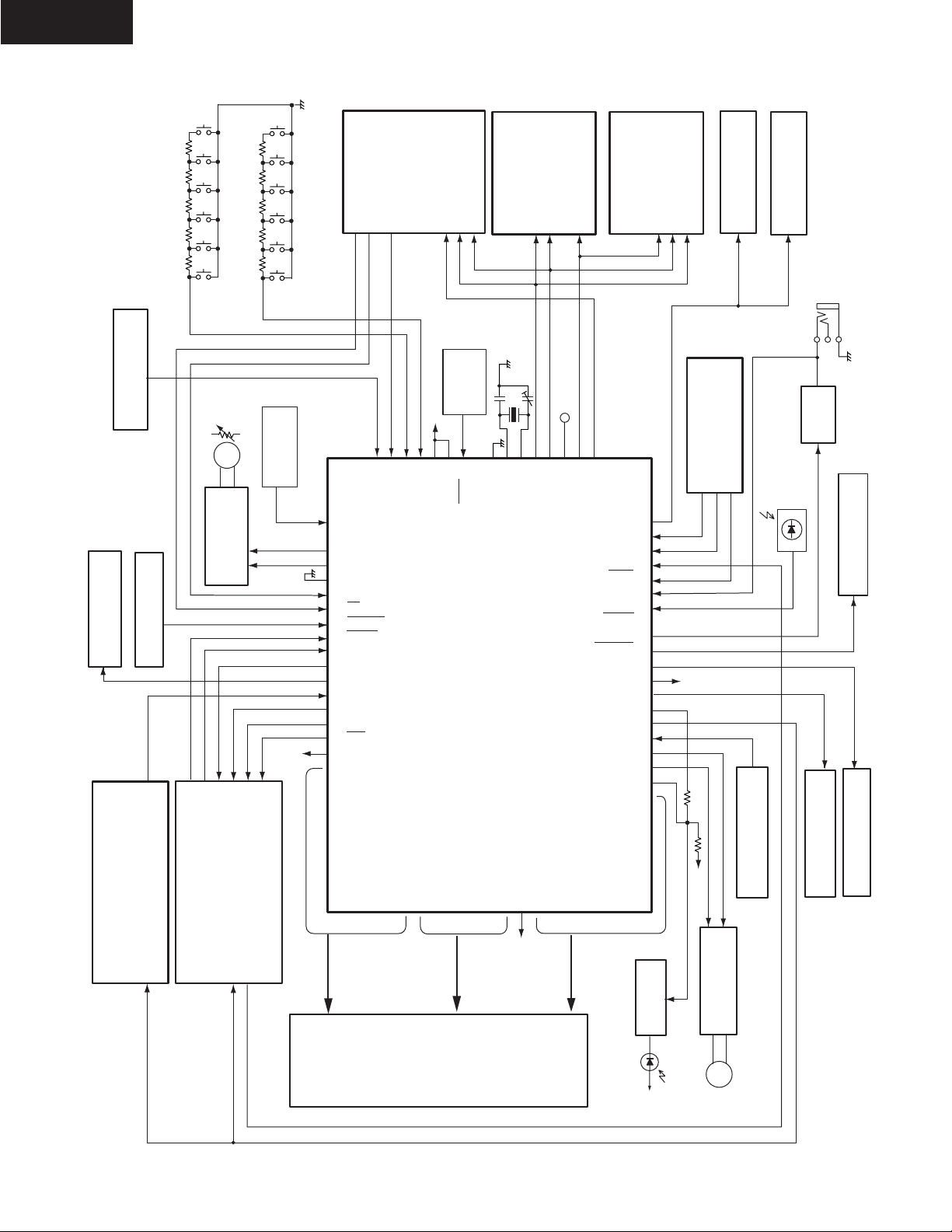

Microprocessor connection diagram --------------------------------

Microprocessor terminal descriptions ------------------------------

IC Block diagram and descriptions ---------------------------------

CD Mechanism exploded view --------------------------------------

Replacement of optical pickup ---------------------------------------

Chassis exploded view parts list -------------------------------------

Chassis exploded view -----------------------------------------------

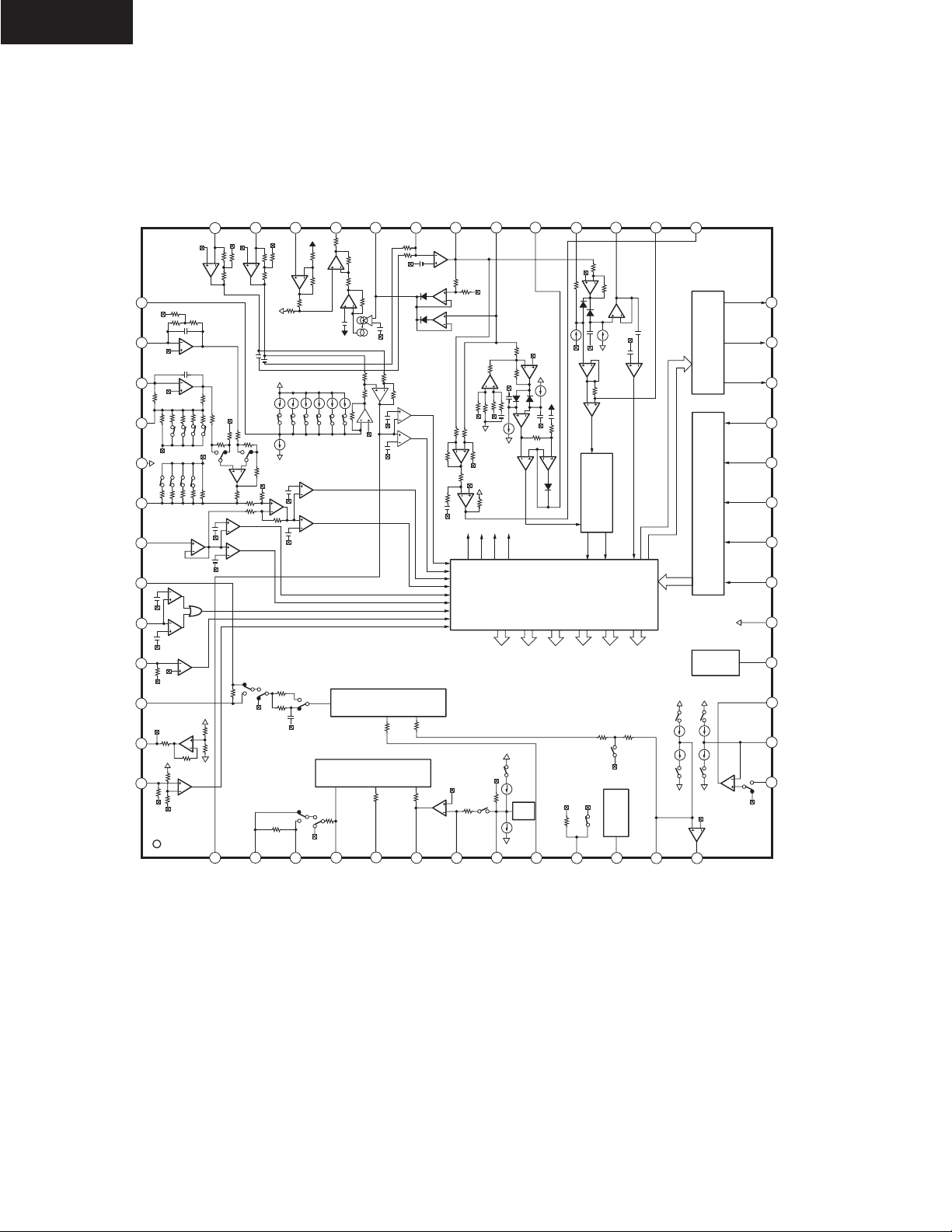

Block diagram ---------------------------------------------------------

Wiring view ------------------------------------------------------------

Printed circuit board view parts list --------------------------------7

Schematic diagram (Amplifier section) -----------------------------

Printed circuit board view 1-------------------------------------------

Schematic diagram (CD & Microprocessor section) -------------

Printed circuit board view 2-------------------------------------------

Printed circuit board view 3-------------------------------------------

CD Adjustment procedures ------------------------------------------

Clock adjustment procedures ----------------------------------------

Assembling of pad ---------------------------------------------------

packing view ---------------------------------------------------------

2

2

3

4

5

6

7

8

9

10

19

21

22

23

25

26

27

29

31

33

35

37

39

40

41

42

Page 2

CR-305X

SPECIFICATIONS

AMPLIFIER

Power Output:

Dynamic Power: 2 x 24 watts at 4 ohms

Total Harmonic Distortion: 0.2 % at 10 watts output

IM Distortion: 0.2 % at 10 watts output

Damping Factor: 25 at 8 ohms

Sensitivity and Impedance: TAPE/CDR/MD IN : 150 mV, 50 kohms

Frequency Response: 10 to 50,000 Hz : +0 / –3 dB

Acoustic Presence: 1 40 Hz +6.0 dB

Single–to–Noise Ratio: 100 dB (IHF A)

Muting –55 dB

CD PLAYER

Signal Readout System: Optical non–contact

Reading Rotation: About 500 – 200 r.p.m.

Linear Velocity: 1.2 – 1.4 m / s

Error Correction System: Cross Interleave Reed Solomon code

D / A Converter: 1 bit

Digital Filter: 352.8 kHz 8 times over sampling

Number of Channels: 2 (stereo)

Frequency Response: 5 Hz – 20 kHz

2 x 20 watts at 4 ohms 1 kHz DIN

2 x 17 watts at 6 ohms 1 kHz DIN

2 x 15 watts at 8 ohms 1 kHz DIN

2 x 20 watts min, RMS at 4 ohms 1 kHz

no more than 1 % THD (FTC rating)

2 x 25 watts at 4 ohms EIAJ

2 x 18 watts at 8 ohms

2 80 Hz +7.5 dB

3 40 Hz +10 dB

80 Hz +8.0 dB

4 40 Hz +10 dB

80 Hz +8.0 dB

10 kHz +4.5 dB

(constant linear velocity)

TUNER

Tuning range

FM: 87.9 to 107.9 MHz (200 kHz steps)

(U.S. & Canadian models)

87.5 to 108.00 MHz (50 kHz steps)

(Other area models)

Usable sensitivity

FM: Mono 11.2 dBf,

1.0 µV (75 ohms IHF)

0.9 µV (75 ohms DIN)

Stereo 17.2 dBf,

2.0 µV (75 ohms IHF)

23.0 µV (75 ohms DIN)

50 dB Quieting sensitivity

FM: Mono 17.2 dBf, 2.0 µV (75 ohms)

Stereo 37.2 dBf, 20.0 µV (75 ohms)

Capture ratio

FM: 2.0 dB

Image rejection ratio

FM: 40 dB (U.S. & Canadian models)

85 dB (Other area models)

IF rejection ratio

FM: 90 dB

Signal to noise ratio

FM: Mono 73 dB, IHF

Stereo 67 dB, IHF

Selectivity

FM: 50 dB DIN

(±300 kHz at 40 kHz Devi.)

AM Suppression Ratio: 50 dB

Harmonic distortion

FM: Mono 0.2%

Stereo 0.3%

Frequency response

FM: 30 to 15,000 Hz (±1.5 dB)

Stereo separation

FM: 35 dB at 1,000 Hz

25 dB at 100 to 10,000 Hz

Stereo threshold

FM: 17.2 dBf, 2.0 µV (75 ohms)

AM: 530 to 1710 kHz (10 kHz steps)

(U.S. & Canadian models)

522 to 1611 kHz (9 kHz steps)

(Other area models)

AM: 30 µV

AM: 40 dB

AM: 40 dB

AM: 40 dB

AM: 0.7 %

GENERAL

Power Supply:

Power Consumption: 60 W (U.S. & Canadian models)

Dimensions:

W

eight: 4.0 kg (8.8 lbs)

Specifications and features are subject to change without notice

Power supply and voltage vary depending on the area in which the unit is

AC 120 V, 60 Hz (U.S. & Canadian models)

(Some Asian models)

AC 230 V, 50 Hz (European models)

AC 220-230 V, 50/60 Hz (Other area models)

(Some Asian models)

55 W (Other area models)

205 W x 103 H x 362 D mm

(8-1/6" x 4-1/16" x 14-1/4")

purchased.

CAUTION ON REPLACEMENT OF OPTICAL PICKUP

The laser diode in the optical pickup block is so sensitive to

static electricity, surge current and etc., that the components

are liable to be broken down or its reliability remarkably

deteriorated.

PRECAUTIONS

1.Ground for the work-desk.

Place a conductive sheet such as a sheet of copper

(with impedance lower than 10Mohm) on the workdesk and place the set on the conductive sheet so that

the chassis can be grounded.

2.Grounding for the test equipments and tools.

Test equipments and toolings should be grounded in

order that their ground level is the same the ground of

the power source.

㧙

During repair,carefully take the following precautions.

(The following precautions are included in the service

parts.)

3. Grounding for the human body.

Be sure to put on a wrist-strap for grounding whose

other end is grounded.

Be particularly careful when the workers wear

synthetic fiber clothes, or air is dry.

4. Select a soldering iron that permits no leakage and

have the tip of the iron well-grounded.

5. Do not check the laser diode terminals with the

probe of a circuit tester or oscilloscope.

㧙

1

.

Page 3

CR-305X

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs a laser. Therefore, be sure to follow carefully

the instructions below when servicing.

WARNING!!

SERVICE WARNING : DO NOT APPROACH THE

LASER EXIT WITH THE EYE TOO CLOSELY.

IN CASE IT IS NECESSARY TO CONFIRM LASER

BEAM EMISSION, BE SURE TO OBSERVE FROM

A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE

OPTICAL PICK-UP BLOCK.

LASER WARNING LABEL

The label shown below are affixed.

1. Warning label

Laser Diode Properties

Material: GaAS/GaALAs

Wavelength: 780nm

Laser output: max. 0.5mW*

Emission Duration: continuous

*This output is the value measured at a distance about 1.8mm

from the objective lens surface on the Optical Pick-up Block.

1. Class 1 label

"CLASS 1 LASER

PRODUCT"

LUOKAN 1

LASERLAITE

KLASS 1

LASER APPARAT

㧙

㧙

3

Page 4

CR-305X

SERVICE PROCEDURE

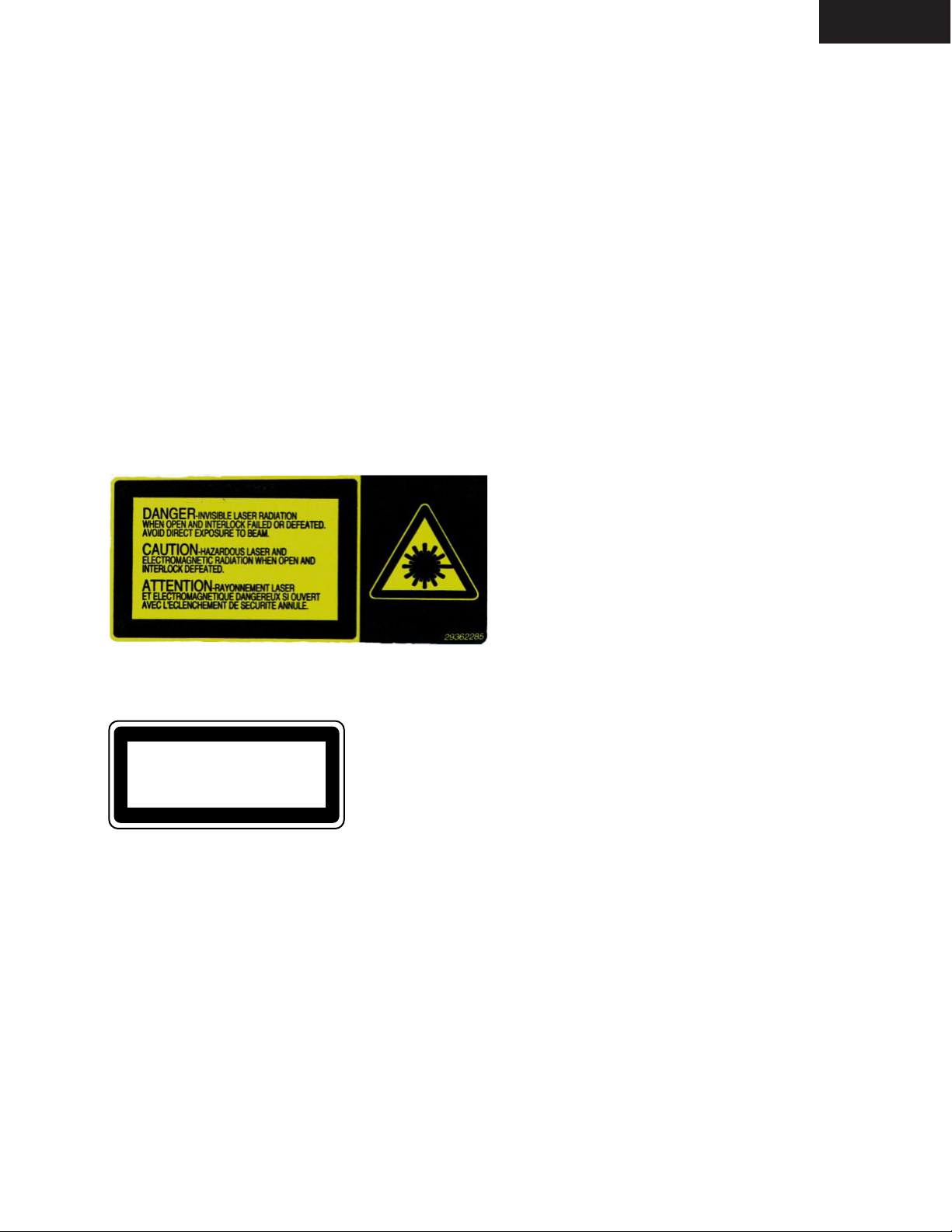

1. Replacing the fuses

This symbol located near the fuse indicates that the

fuse used is show operating type, For continued protection against

fire hazard, replace with same type fuse , For fuse rating, refer to

the marking adjest to the symbol.

Ce symbole indique que le fusible utilise est e lent.

Pour une protection permanente, n'utiliser que des fusibles de meme

type. Ce demier est indique la qu le present symbol est apposre.

REF.NO.

F901

PART NO.

252157

252083

NOTE : <D, DT> : 120 V model only

<P,GR, GT> : 230 V model only

DESCRIPTION

1.25A-UL/T-237, Fuse <D, DT>

0.4A-SE-EAW, FUSE <P,GR, GT>

2. To initialize the unit

1. Press and the hold down the MEMORY button , then press the

After "all lighting " is displayed

2. Press the standby/on button.

After " CLEAR " is displayed, the preset memory and each mode

stored in the memory, are initialized and will return to the

factory settings.

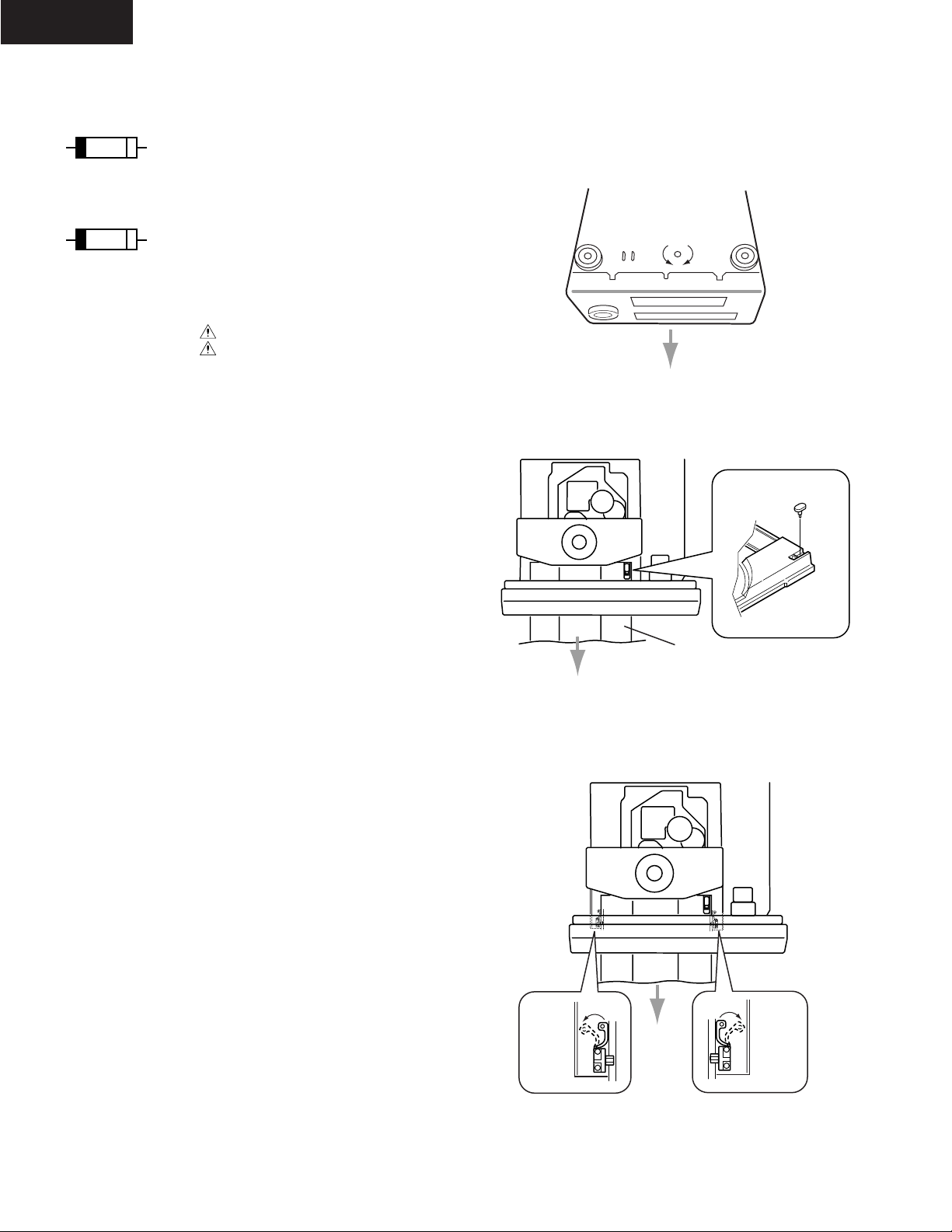

5. Removement of tray

1.Remove the top cover

2.Turn the locked screw to the clockwise to release the lock of gear.

(Refer to fig-1)

Fig-1

Bottom side

Lock

Unlock

Front

3.Pull out the tray.

4.Remove the stopper. (Refer to fig-2)

Fig-2

Stopper

3. Safety-check out

(Only U.S.A. model)

After correcting the original service problem perform the

follwing safety check before releasing the set to the customer

Connect the insulating-resistance tester between the plug of

power supply cord and terminal GND on the back panel.

Specifications: More than 10Mohm at 500V

4. Memory Preservation

This unit does not require memory preservation batteries. A built-in

memory power back-up system preserves the contents of the

memory during power failures and even when the unit is un-plugged.

The unit must be plugged in order to charge the back-up

system.

The memory preservation period after the unit has been unplugged

varies depending on climate and placement of the unit. On the

average, memory contents are protected over a period of a few

weeks after the last time the unit has been unplugged. This pe-riod

is shorter when the unit is exposed to a highly humid cli-mate.

5. Changing the AM band step

With the exception of the worldwide models, a tuning step selector

switch is not provided. When you change the band step, change

the parts as shown below.

To 10kHz To 9kHz

R705 3.3k 10k

R706 5.6k open

Tray

Front

5.Press teh tray stopper to the arrow mark direction and remove

the tray ass'y. (Refer to fig-3)

Fig-3

Tray

stopper

Front

Tray

stopper

㧙

㧙

4

Page 5

CR-305X

DETECTOR SWITCH

CD TRAY OPEN/CLOSE

Q703

Q184-Q186

SYSTEM RESET

CD MUTNG SWITCH

26 SENS2

Q101

CXA1992BR

SERVO AMP

RF SIGNAL PROCESSING

23 XRST

KEY SWITCH

S762 S761 S760 S759 S758 S757

VOLUME

M

Q704

MOTOR DRIVE IC

SENS 6

SQSO 5

SQCK 4

Q301

CXD2589Q

CD DIGITAL

SIGNAL PROCESSOR

FR FF PLAY STOP OPEN MEMORY

TA7291S

DATA 7

XLAT 8

57 SCOR

79 XRST

STBY

AUTO

/MONO

DISPLAY

SD

STEREO

INPUT<

INPUT>

S756 S755 S754 S753 S752 S751

AP

(FM/AM BAND)

INITIALIZING

24

AREA

23

22

21

20

AVSS

19

SD

18

17

16

SQSO

15

SENS

14

SQCK

13

12

11

10

XLT

9

+5V

8

VDD

7

10G

6

9G

5

8G

4

GRID

IG - 10G

7G

3

6G

2

5G

1

4G

CLOK 9

U10

TUNER UNIT

K1

K0

P17

+5V

AVDD

P16

PLL

POWER

AVREF

P15

P11-P17

SEGMENT

SIGNAL

252627282930313233343536373839

IN/OUT

SIGNAL

VOLUP

VOLDOWN

STEREO

RESET

DSPMUT

SENS20

CDDATA

CDCLK

3G2G1G

807978777675747372717069686766

Q401

TC9273N-007

RDATA

DETECTOR

XT2

VSS

X1

INPUT SELECTOR

C703

( CLOCK ADJUST)

X2

RCLK

14 CK

RDATA

15 DATA

RCLK

FAILURE

POFF

Q701

MICROPROCESSOR

MPD78045FGF-119-3B9

P14

P13

P12

P11

VLOAD

P10P9P8P7P6

-VP

SEGMENT

TP-01

FREQCAL

P1 - P10

16 ST

( CLOCK ADJUST )

40

FCE

PLLCE

65

Q402

SELECTOR IC

ACOUSTIC PRESENCE

13 ST

15 CK

16 DATA

POWERAMP

41

RDSDATA

42

RDSSIG

43

SCOR

44

RDSCLK

45

SYSIN

46

REMIN

47

IC

48

SYSOUT

49

TUMUT

50

ANGMUT

51

VDD

52

POWERCD

53

LED1

54

XRST

55

CDAUTOADJ

56

OPEN

57

CLOSE

58

LED2

59

P1

60

P2

61

P3

62

P4

63

P5

64

Q702

+5V

LED DRIVE

Q601,Q602

POWER AMP SWITCH

Q180

BU1923

RDS DECODER

2 RDATA

16 RCLK

1 QUAL

+5V

Q704

TA7291S

MOTOR DRIVE IC

Q904

POWER

RELAY DRIVE

U751

REMOTE

INITIALIZING

(CD AUTO ADUST ON/OFF)

Q702

BUFFER

SENSOR

Q110,Q111

CD POWER SWTCH

RI

Q181-Q183

TUNER MUTE SWITCH

Q405,Q406

INPUT MUTE SWITCH

Q751

FL TUBE

10-BT-167GK

D782

ACOUSTIC

MICROPROCESSOR CONNECTION DIAGRAM

㧙

㧙

8

PRESENCE

+5V

M

CD TRAY

OPEN/CLOSE

Page 6

Description

CR-305X

P11)

㨪

Output pin for power supply control of power amplifier

Data input pin from RDS decoder IC.

Signal input pin from RDS decoder IC.

Sub code frame detection input pin from signal processing IC(CXD2589Q).

Clock input pin from RDS decoder IC.

System code input pin.

Signal input pin for remote controller.

Internal connection pin. Not used.

System code output pin.

Muting control signal output pin for tuner section.

Muting control signal output pin for amplifier section.

Power supply pin.

Output pin for power supply control of CD section.

Acoustic presence indicator (red) control output pin.

Reset signal output pin of signal processing IC and servo IC.

Set pin of self adjustment ON/OFF of CD

CD tray open control output pin.

CD tray close control output pin.

Acoustic presence indicator (green) control output pin.

I

I

I

I

I

I

O

I/O

Function

POWER AMP

RDSDATA

RDSSIG

SCOR

RDSSCK

414243444546474849505152535455565758596061626364656667686970717273747576777879

NO.

I

SYSIN

REMINICSYSOUT

OOOIOOOIOOO

TUMUT

ANGMUT

VDD

POWERCD

LED1

XRST

CDAUTOADJ

OPEN

CLOSE

LED2P1P2P3P4P5P6P7P8P9P10

Segment output pins. (P1

Power supply pin for FL tube.

P11

VLOAD

P17)

㨪

Segment output pins. (P12

P12

P13

P14

P15

P16

3G)

㨪

Grid output pins. (1G

P171G2G

3G

80

Description

10G)

㨪

Grid output pins. (4G

OOOOOOOIOOOIO

I/O

Function4G5G6G7G8G9G

MICROPROCESSOR TERMINAL DESCRIPTION (Q701 : MPD78042GF-3B9)

123456789

NO.

Power supply pin.

Command output pin to transfer the clock signal to signal processing IC(CXD2589Q).

Command output pin to transfer the latch signal to signal processing IC(CXD2589Q).

Command output pin to transfer the data signal to signal processing IC(CXD2589Q).

Sense signal input pin from servo IC(CXA1992)

Digital mute output pin to signal processing IC(CXD2589Q).

Subcode reading clock output pin to signal processing IC(CXD2589Q).

Sense signal input pin from signal processing IC(CXD2589Q).

Subcode data input pin from signal processing IC(CXD2589Q).

System reset input pin.

FM stereo broadcast detection input pin.

Broadcast detection input pin.

Ground pin for A/D converter.

Volume control output pin.

Volume control output pin.

Not used.

Initialization input pin for destination switch.

Input pin for CD tray open/close detection switches.

Signal level input pin for automatic memory.

Operation key connection pin.

Operation key connection pin.

I

I

10G

SENS

III

SQSO

RESET

O

VDD

CDCLK

XLT

CDDATA

SENS20

DSPMUT

SQCK

10111213141516171819202122232425262728293031323334353637383940

I

STEREOSDAVSS

㧙

9

O

VOLDOWN

㧙

-

O

VOLUP

I

I

AREA

IN/OUT

I

I

I

SIGNALK1KO

Power supply pin for A/D converter.

I

AVDD

Reference voltage input pin for A/D converter.

I

AVREF

Power failure input pin.

Sub clock connection pin. Not used.

Gound pin.

Master clock connection pin.

Master clock connection pin.

Serial clock output pin to PLL and function switch ICs (TC9273,TC9162).

Serial data output pin to PLL and function switch ICs(TC9273,TC9162).

Frequency output terminal for clock adjustment

Serial latch output pin to function switch ICs(TC9273,TC9162).

IOI

POFF

XT2

VSSX1X2

I

I

OOOOO

RCLK

RDATA

FREQCAL

FCE

Serial latch output pin to PLL IC.

PLLCE

Page 7

CR-305X

IC BLOCK DIAGRAM AND DESCRIPTIONS

Q101:CXA1992BR (RF Signal Processing Servo Amplifier)

Block Diagram

FE-BIAS

V

TEO

LPFI

TEI

ATSC

TZC

TDFCT

VC

FZC

O

-

RF

M

-

FE

LDON

VEE

LEVEL S

VCC

LPCL

FS2

323334353637

LPC

DFCTO IFB1-6

FS1

8

I

-

RF

CP

31

VCC

VEE

VEE

MIRR

TGFL

IIL DATA REGISTER

INPUT SHIFT REGISTER

ADDRESS DECODER

SENS SELECTOR

OUTPUT DECODER

FS1-4 TG1-2

BAL1-4

TOG1-4

VCC

Charge

up

VEE

9

TGU

SRCH

30

TG2

10

CB

MIRR

TG2

V

CC

DFCT

IIL

↓

TTL

TN1-7 PS1-4

TM3

FSET

11

CC1

DFCT1

FSET

FOK

CC2

2829

27

26

SENS2

IIL

↓

TTL

TTL

↓

IIL

CC1

ISET

VCC

VCC

TM4

TM6

TM3

TM5

VEE

VEE

12

13

O

M

-

TA

TA

25

SENS1

24

C.OUT

23

XRST

22

DATA

XLT

21

CLK

20

LOCK

19

VCC

TM2

CC

V

18

ISET

17

16

SL-O

15

SL-M

14

SL-P

M

-

RFTC

RF SUMMING AMP

FO.BIAS

WINDOW COMP.

RF

FOK

FOH

FOL

TGH

TGL

BALH

BALL

ATSC

TZC

FZC

PD

VEE

APC

LASER POWER CONTROL

IFB5

IFB3

IFB4

TRK.GAIN

WINDOW COMP

LD

VEE

FE AMP

IFB6

PD1

PD2

3839

PD1 IV

PD2 IV

AMP

AMP

40

41

F

42

E

EI

43

EE

44

F IV AMP

E IV AMP

BAL1

BAL2

BAL3

VEE

TOG1

BAL4

TOG2

TOG3

TOG4

TGFL

VCC

VCC

IFB2

IFB1

VEE

45

E-F BALANCE

46

WINDOW COMP.

47

48

ATSC

WINDOW

COMP.

TZC COMP.

49

50

VCC

DFCT

TM1

TG1

TRACKING

PHASE COMPENSATION

51

VCC

VEE

52

FZC COMP.

12

FEI

FEO

FOCUS

PHASE COMPENSATION

DFCT

FS4

45

3

FDFCT

FGD

FLB

6

7

O

-

FE

㧙

㧙

10

Page 8

Terminal description

CR-305X

Pin

Symbol

No.

1 FEO O

2 FEI Focus error input. I

34FDFCT

FGD I

5 FLB

6 FE_O

7

FE_M

8 SRCH

9

TGU

10

TG2

11

FSET

12 TA_M I Tracking amplifier inverted input.

TA_O

13

14

SL_P

15

SL_M

16 SL_O O Sled drive output.

17 ISET I Connect an external capacitance to set the current

18

VCC

19 LOCK I

20 CLK

XLT

21

22 DATA

XRST I Reset input; resets at Low. (no pull-up resistance)

23

24 C. OUT

SENS1

25

I/O

Focus error amplifier output.

Connected internally to the window comparator input

for bias adjustment.

I

Capacitor connection pin for defect time constant.

Ground this pin through a capacitor for cutting the

focus servo high-frequency gain.

External time constant setting pin for boosting the

I

focus servo low-frequency.

O

Focus drive output.

I Focus amplifier inverted input.

I

External time constant setting pin for generating

focus search waveform.

I External time constant setting pin for switching track-

ing high-frequency gain.

External time constant setting pin for switching track-

I

ing high-frequency gain.

Peak frequency setting pin for focus and tracking

I

phase compensation amplifier.

O Tracking drive output.

I Sled amplifier non-inverted input.

I Sled amplifier inverted input.

which determines the Focus search, Track jump, and

Sled kick heights.

I Positive power supply.

The sled overrun prevention circuit operates when

this pin is Low. (no pull-up resistance)

I

Serial data transfer clock input from CPU.

(no pull-up resistance)

I

Latch input from CPU. (no pull-up resistance)

Serial data input from CPU. (no pull-up resistance)

I

O

Track number count signal output.

O

Outputs FZC, DFCT1, TZC, BALH, TGH, FOH,

ATSC, and others according to the command from

CPU.

Description

Pin

Symbol

No.

26 SENS2 O

27

FOK

28

CC2 I

CC1

29

30 CB

31 CP

32

RF_I I

33 RF_O

34 RF_M

35 RFTC

LD O APC amplifier output.

36

PD I APC amplifier input.

37

PD1

38

39

PD2

40

FE_BIAS

41

F

42IE

43 EI

44

VEE

45 TEO O

46 LPFI I Comparator input for balance adjustment.

47

TEI

ATSC

48

49

TZC

50

TDFCT

51

VC

52 FZC

I/O

Outputs DFCT2, MIRR, BALL, TGL, FOL, and

others according to the command from the CPU.

O Focus OK comparator output.

Input for the defect bottom hold output with capacitance coupled.

O Defect bottom hold output. Connected internally to

the interruption comparator input.

Connection pin for defect bottom hold capacitor.

I

Connection pin for MIRR hold capacitor.

I

MIRR comparator non-inverted input.

Input for the RF summing amplifier output with capa-

citance coupled.

RF sunning amplifier output. Eyepattern check point.

O

RF summing amplifier inverted input.

I

The RF amplifier gain is determined by the resistance

connected

between this pin and RFO pin.

I

External time constant setting pin during RF level

control.

I

RF I-V amplifier inverted input. Connect these pins

to the photo diode A + C and B + D pins.

I

I

Bias adjustment of focus error amplifier.

Leave this pin open for automatic adjustment.

I

F I-V and E I-V amplifier inverted input.

Connect these pins to photo diodes F and E.

—

I-V amplifier E gain adjustment.

(When not using automatic balance adjustment)

—

Negative power supply.

Tracking error amplifier output. E-F signal is output.

(Input from TEO through LPF)

Tracking error input.

I

Window comparator input for ATSC detection.

I

I

Tracking zero-cross comparator input.

I

Capacitor connection pin for defect time constant.

O (VCC + VEE)/2 direct voltage output.

I

Focus zero-cross comparator input.

Description

㧙

㧙

11

Page 9

CR-305X

Q301:CXD2589Q (CD Digital Signal Processor)

Bloch Diagram

XTSL

VPCO

VCKI

V16M

VCTL

XUGF

GFS

EMPH

EFM

WFCK

56

54

C4M

RF

ASYI

ASYO

BIAS

XPCK

FILO

FILI

PCO

CLTV

52

52

35

35

37

37

38

38

36

36

48

48

30

30

31

31

29

29

33

33

51

51 25 26 27 28 47 49 54 56 50 39 41 43 55 40 42 44 62

25

Clock

28

26

27

49

47

OSC

Generator

demodurator

Asymmetry

Corrector

Digital

PLL

Sub Code

Processor

Error

Corrector

16K

RAM

C2PO

LRCK

39

41

50

D/A

Interface

Digital

OUT

PCMD

BCK

EMPHI

LRCKI

40

55

Serial-In

Interface

Over Sampling

Digital Filter

PWM

PCMDI

BCKI

SYSM

424344

62

Timing

Logic

3rd-Order

Noise Shaper

PWM

24

24

23

23

79

79

3

3

2

2

70

70

71

71

TES1

TEST

XRST

RMUT

LMUT

XTAI

XTAO

FOK

SEIN

CNIN

18

18

Servo

10

10

11

11

Auto

Sequencer

12 13 14 6 7 8 9 15 16 17 57 58 59 5 4 21 22 53 74 75 76 67 66 65

14

13

12

DATO

CLKO

XLTO

CPU

Interface

65

7

SENS

15 16 17

XLAT

DATA

CLOK

SPOA

XLON

SPOB

57

58

SCOR

9

8

59

EXCK

SBSO

4

SQCK

SQSO

Digital

CLV

21

MDP

22

PWMI

53

DOUT

74

LOUT2

75

76

AIN2

AOUT2

67

66

AIN1

LOUT1

65

AOUT1

㧙

㧙

12

Page 10

Terminal description

Pin

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

1

2

3

4

5

6

7

8

9

Symbol

VSS

LMUT

RMUT

SQCK

SQSO

SENS

DATA

XLAT

CLOK

SEIN

CNIN

DATO

XLTO

CLKO

SPOA

SPOB

XLON

FOK

VDD

VSS

MDP

PWMI

TEST

TES1

VPCO

VCKI

V16M

VCTL

PCO

FILO

FILI

AVSS

CLTV

AVDD

RF

BIAS

ASYI

ASYO

LRCK

LRCKI

PCMD

PCMDI

I/O

GND

—

Left-channel zero detection flag.

O

Right-channel zero detection flag.

O

SQSO readout clock input.

I

Sub Q 80-bit serial output.

O

SENS output to CPU.

O

Serial data input from CPU.

I

Latch input from CPU. Serial data is latched at the

I

falling edge.

Serial data transfer clock input from CPU.

I

SENS input from SSP.

I

Track jump count signal input.

I

Serial data output to SSP.

O

Serial data latch output to SSP. Latched at the falling

O

edge.

Serial data transfer clock output to SSP.

O

Microcomputer extended interface (input A).

I

Microcomputer extended interface (input B).

I

Microcomputer extended interface (output).

O

Focus OK input.

I

Used for SENS output and the servo auto sequencer.

Power supply (+5V).

—

GND

—

Spindle motor servo control.

O

Spindle motor external control input.

I

TEST pin; normally GND.

I

TEST pin; normally GND.

I

Charge pump output for the wide-band EFM PLL.

O

VCO2 oscillation input for the wide-band EFM PLL.

I

VCO2 oscillation output for the wide-band EFM

O

PLL.

VCO2 control voltage input for the wide-band EFM

I

PLL.

Master PLL charge pump output.

O

Master PLL (slave = digital PLL) filter output.

O

Master PLL filter input.

I

Analog GND.

—

Master VCO control voltage input.

I

Analog power supply (+5V).

—

EFM signal input.

I

Constant current input of the asymmetry circuit.

I

Asymmetry comparator voltage input.

I

EFM full-swing output (low = VSS, high = VDD).

O

D/A interface. LR clock output f = Fs.

O

LR clock input.

I

D/A interface. Serial data output (two's complement,

O

MSB first).

D/A interface. Serial data input (two's complement,

I

MSB first).

Description

Pin

No.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Symbol

BCK

BCKI

VSS

VDD

XUGF

XPCK

GFS

C2PO

XTSL

C4M

DOUT

EMPH

EMPHI

WFCK

SCOR

SBSO

EXCK

VSS

VDD

SYSM

AVSS

AVDD

AOUT1

AIN1

LOUT1

AVSS

XVDD

XTAI

XTAO

XVSS

AVSS

LOUT2

AIN2

AOUT2

AVDD

AVSS

XRST

VDD

I/O

D/A interface. Bit clock output.

O

D/A interface. Bit clock input.

I

GND

—

Power supply (+5V).

—

XUGF output. Switched to MNT1 or RFCK output

O

by a command.

XPLCK output. Switched to MNT0 output by a com-

O

mand.

GFS output. Switched to MNT3 or XRAOF output

O

by a command.

C2PO output. Switched to GTOP output by a com-

O

mand.

Crystal selector input. Low: 16.9344MHz;

I

high: 33.8688MHz.

4.2336MHz output. 1/4 frequency-divided VCKI out-

O

put in CAV-W mode.

Digital Out output.

O

Outputs a high signal when the playback disc has

O

emphasis, and a low signal when there is no emphasis.

Inputs a high signal when de-emphasis is on, and a

I

low signal when de-emphasis is off.

WFCK output.

O

Outputs a high signal when either subcode sync S0

O

or S1 is detected.

Sub P to W serial output.

O

SBSO readout clock input.

I

GND

—

Power supply (+5V).

—

Mute input. Active when high.

I

Analog GND.

—

Analog power supply (+5V).

—

Left-channel analog output.

O

Left-channel operational amplifier input.

I

Left-channel LINE output.

O

Analog GND.

—

Power supply for master clock.

Crystal oscillation circuit input. Input the external

I

master clock via this pin.

Crystal oscillation circuit output.

O

GND for master clock.

Analog GND.

—

Right-channel LINE output.

O

Right-channel operational amplifier input.

I

Right-channel analog output.

O

Analog power supply (+5V).

—

Analog GND.

—

System reset. Reset when low.

I

Power supply (+5V).

—

Description

CR-305X

Notes)

• PCMD is an MSB first, two's complement output.

• GTOP is used to monitor the frame sync protection status. (High: sync protection window open.)

• XUGF is the frame sync obtained from the EFM signal, and a negative pulse. It is the signal before

sync protection.

• XPLCK is the inverse of the EFM PLL clock. The PLL is designed so that the falling edge of XPLCK

and the EFM signal transition point coincide.

• GFS goes high when the frame sync and the insertion protection timing match.

• RFCK is derived with the crystal accuracy. This signal has a cycle of 136µs (during normal speed).

• C2PO represents the data error status.

• XRAOF is generated when the 16K RAM exceeds the ±4F jitter margin.

㧙

㧙

13

Page 11

CR-305X

Q401:TC9273N-007 (Analog function switch)

VSS

VDD

128

2

S1

3

S2

4

S3

5

S4

6

S5

7

S6

8

S7

9

OUT

10

S8

11

S9

12

OUT

GND CK DATA STB

Q402:TC9162AF Analog function switch

2

S1

10BITS LATCH CIRCUIT

LEVEL SHIFT AND

SHIFT REGISTER

13 14 15 16

VSS

GND

1

14

10BITS LATCH CIRCUIT

VDD

28

27

26

25

24

23

22

21

20

19

18

17

S1

S2

S3

S4

S5

S6

S7

OUT

S8

S9

OUT

27

S1

S2

S3

COM1

S4

S5

S6

COM2

S7

S8

COM3

ST

11

12

13

10

S2

16

26

25

24

23

22

21

20

19

18

17

15

S3

COM1

S4

S5

S6

COM2

S7

S8

COM3

DATA

CK

3

4

5

6

7

8

9

LATCH CIRCUIT

LEVEL SHIFTER

SHIFT REGISTER

㧙

㧙

14

LATCH CIRCUIT

LEVEL SHIFTER

Page 12

CR-305X

CMP

VSS3

(8)

(7)

ǡ

100 k

(4)

MUX

Comparator

8ch Switched

capacitor filter

+

anti-aliasing

ǡ

100 k

ǡ

(3)

120 k

filter

VREF

RCLK

(16)

(5)

QUAL

(1)

Analog

Power supply

(6)

VDD1

RDATA

(2)

PLL

PLL

VSS1

decoder

Differential

decoder

Bi-phase

1187.5 Hz

57 kHz

RDS/ARI

Digital

power supply

(12)

VDD2

circuit

Measurement

clock

Reference

(11)

VSS2

(9)

(10)

(13) (14)

XO

X1

T2T1

㧙

16

Function

Good data : High , bad data : Low

Refer to output data trimming

1/2 VDD1

Composite signal input

4.5 V to 5.5 V

Pin name

Demodulator quality

Demodulator data

Reference voltage

Input

Analog power supply

Vref

Vss1

MUX

QUAL

Symbol

RDATA

123456789

Pin No.

VDD1

-

C-junction

Open or connected to ground

4.5 V to 5.5 V

GND

Comparator input

Test input

Digital power supply

T2

T1

Vss3

CMP

VDD2

10111213141516

Connects to 4.332 MHz oscillator

-

1187.5 Hz clock

Crystal oscillor

-

Demodulator clock

XI

XO

Vss2

(NC)

RCLK

㧙

Q180:BU1923 (RDS Decoder(

16

RES

17

CD

18

VIN3

19

VG3

20

Vo5

21

Vo6

22

GND

23

GND

24

GND

25

Vo7

26

Vo8

27

VG4

28

VIN4

29

Vref

30

Vcc

RESET

Level shift

BTL AMP

BTL AMP

Level shift

2

2

1

1

3

3

Vcc

4

4

Regulator

Level shift

BTL AMP

BTL AMP

Level shift

15

Reg IN

14

Reg OUT

13

VI2

12

VG2

11

Vo4

10

Vo3

9

GND

8

GND

7

GND

6

Vo2

5

Vo1

4

VG1

3

VIN1

2

Mute

1

Vcc

Power supply (shorted with pin 30)

1 BTL AMP 1 input

1 BTL AMP 1 output (non-inverting side)

2 BTL AMP 1 output (inverting side)

O

CC

O

IN

3 BTL AMP 2 output (inverting side)

O

4 BTL AMP 2 output (non-inverting side)

O

2 BTL AMP 2 input

IN

Reset output

Reset output delay time setting (with capacitor)

3 BTL AMP 3 input

D

IN

5 BTL AMP 3 output (non-inverting side)

O

6 BTL AMP 3 output (inverting side)

O

7 BTL AMP 4 output (inverting side)

O

8 BTL AMP 4 output (non-inverting side)

O

4 BTL AMP 4 input

IN

Reference voltage input for level shift circuit

REF

㧙

15

㧙

Power supply (shorted with pin 1)

CC

2 Mute ON/OFF control for all BTL AMP outputs

3V

4 VG1 BTLAMP 1 input (for gain control)

1V

Pin No. Pin Name Description (Function)

5V

Q102:LA6541D (4-channel ridge Driver for Compact Dizcs)

6V

7 GND GND (minimum electric potential)

8 GND GND (minimum electric potential)

9 GND GND (minimum electric potential)

11 V

12 VG2 BTL AMP 2 input (for gain control)

10 V

17 C

15 REG IN Connection for base of external transistor (PNP)

16 RES

18 V

19 VG3 BTL AMP 3 input (for gain control)

21 V

22 GND GND (minimum electric potential)

23 GND GND (minimum electric potential)

24 GND GND (minimum electric potential)

25 V

20 V

26 V

13 V

14 REG OUT Connection for collector of external transistor (PNP); 5 V supply output

27 VG4 BTL AMP 4 input (for gain control)

30 V

28 V

29 V

Page 13

b

c

k

n

j

a

m

g

r

S.BASS

MUTING

STEREO

MIN

kHz

ST

RDS

PMAM

e

p

DIRECT

MHz

d

(9G - 2G)

h

f

MIN

S.BASS

MUTING

MHz

kHz

DIRECT

T STEREO

--

-

Dp

Col

㧙

18

㧙

CR-305X

CR-305X

MONOAUTOTRACKTIMER

CD

MEMORY

REPEAT

W.DAY

W.END

RANDOM

REC

SLEEP

10G 9G 8G 7G 6G 5G 4G 3G 2G 1G

Q751 : 10BT-167GK (FL TUBE)

STOP

MODE

CW/CCW

LHL

п

OUT2

OUTPUT

H

п

OUT1

001

IN2

INPUT

010

IN1

jjjjjjjj

hhhhhhhh

10G 9G 8G 7G 6G 5G 4G 3G 2G 1G

W.END

W.DAY

P1- aaaaaaaa -

P2

P3

BRAKE

CCW/SW

L

L

1

1

CCW : Counter clockwise diection

CW : Clockwise diection

----

kkkkkkkk

MEMORY

P4

P5- bbbbbbbb -

P6- ffffffff -

P7- gggggggg -

nnnnnnnn

REPEAT

P9- cccccccc -

P10- eeeeeeee -

P11

r r r r rr r r r

RANDOM

P12

P13- pppppppp -

mmmmmmmm

REC

P8

-----

CD

SLEEP

TIMER TRACK AUTO MONO AM PM RDS S

P17

P14- dddddddd -

P15

P16

Vss

6

Vref

Vcc

8

2

REG

Q103:TA7291S (motor driver)

OUT1

7

ً

ً

OUT2

3

PROTECTOR

AY

L H

H L

Truth table

㧙

17

㧙

ً

Vcc

1Y

3A

2Y

6

7

8

ً

159

1

1A

IN1 IN2 GND

2

3Y

3

45

2A

GND

Q691:TC7WU04FU (triple inverters)

Page 14

p

p

p

CR-305X

61

59

62

54

60

63

51

tion

51 X2625-984-1 Motor chassis ass'y

52 X2625-769-1 Motor gear ass'y

53 2656-908-01 Sled shaft

54 2625-188-02 Gear A

55 7621-255-15 P2x3, Screw

56 1572-085-11 Leaf switch

57 1639-678-12 Motor PC board

58 1564-722-11 Socket

59 2627-003-02 Gear B

60 2625-191-01 Coil spring

61 2625-477-01 Center ring

62 2641-386-01 Special screw, 2*5

63 2625-625-01 Reinforcement board

Ref. No. Part No. Descri

The mechanical parts with no part number

in the exploded views are not supplied.

56

64 8848-483-05 KSS-213C, Pickup

57

tion

16 2627-234-01 Insulator

17 KSM-213CCM

Ref. No. Part No. Descri

18 2625-552-06 Main chassis

19 3319-501-51 PTPWH2.6*16, Screw

20 2625-547-01 Drive Gear

21 2625-545-04 Control cam

22 1692-667-11 Leaf switch

23 1564-721-11 Socket

24 1640-523-11 Loading motor ass'y

25 X2625-117-1 Loading motor

26 2625-274-02 Middle gear

27 2625-536-02 Loading pulley

28 3653-387-00 LM belt

29 B2.6*2.5, Screw

㧙

20

㧙

55

53

64

pickup drive unit

CD MECHANISM EXPLODEE VIEW(2)

6

16

6

11

6

17

16

131415

121415

16

121415

21

52

58

tion

1 2646-290-01 Tray

2 Stopper

3 2625-544-01 Gear cover

4 2625-535-01 Tray Gear

5 2625-546-01 Chucking plate

6 PTPWH2.6*7,Screw

7 2625-537-01 Chucking yoke

8 1452-493-21 Magnet

9 2625-541-02 Damper

10 2646-291-01 Chucking pulley

11 2646-288-01 Sub chassis

12 2627-236-01 Coil spring (front)

13 2627-235-01 Coil spring (back)

14 2646-289-01 Washer

Ref. No. Part No. Descri

18

22

23

25

24

15 P2.6*10,Screw

7

9

8

10

13

141516

282726

㧙

19

㧙

29

6

5

20

19

4

3

2

1

CD MECHANISM EXPLODEE VIEW(1)

Page 15

DESCRIPTION

NAAF-6874-1A, Selector circuit PC board ass'y <D>

NAAF-6874-1B, Selector circuit PC board ass'y <P>

NAAF-6874-1C, Selector circuit PC board ass'y <DT>

NAAF-6874-1D, Selector circuit PC board ass'y <GR, GT>

NAPS-6878-1A, Power supply PC board ass'y <D>

NAPS-6878-1B, Power supply PC board ass'y<P>

NAPS-6878-1C, Power supply PC board ass'y <DT>

NAPS-6878-1D, Power supply PC board ass'y<GR, GT>

NADIS-6879-1A, Display circuit PC board ass'y <D>

NADIS-6879-1B, Display circuit PC board ass'y<P>

NADIS-6879-1C, Display circuit PC board ass'y <DT>

NADIS-6879-1D, Display circuit PC board ass'y<GR, GT>

NAAF-6880-1A, Power amplifier PC board ass'y <D>

NAAF-6880-1B, Power amplifier PC board ass'y<P>

PART NO.

H445574-1A

1H445574-1B

1H445574-1C

1H445574-1D

1H445578-1A

1H445578-1B

1H445578-1C

1H445578-1D

1H445579-1A

1H445579-1B

1H445579-1C

1H445579-1D

1H445580-1A

1H445580-1B

U1

U2

U3

REF.NO.

DESCRIPTION

Front brakcet

3TTB+8B, Self tapping screw

Chassis

KGLS-6RF, Holder

KGPS-6RF, Holder

Hoder, M

Leg

Busing, cord

ÅI

U4

4TTC+6C(BC), Self tapping screw

3TTW+8B(BC), Self tapping screw

Cover, HT

Top cover

3TTB+8B(UN), Self tapping screw

Knob, volume

NAAF-6880-1C, Power amplifier PC board ass'y <DT>

NAAF-6880-1D, Power amplifier PC board ass'y<GR, GT>

NAETC-6881-1A, Speaker terminal PC board ass'y <D>

NAETC-6881-1B, Speaker terminal PC board ass'y<P>

NAETC-6881-1C, Speaker terminal PC board ass'y <DT>

NAETC-6881-1D, Speaker terminal PC board ass'y<GR, GT>

NAETC-6882-1A, Digital output PC board ass'y <D>

NAETC-6882-1B, Digital output PC board ass'y<P>

1H445580-1C

1H445580-1D

1H445581-1A

1H445581-1B

1H445581-1C

1H445581-1D

1H445582-1A

1H445582-1B

U5

U6

Tray panel, CD

Shield plate

Rear panel<D>

Rear panel<P, GR, DT, GT>

3TTB+6B(BC), Self tapping screw

Front panel<D, GR, DT, GT>

Front panel<P>

Guide, volume

NAETC-6882-1C, Digital output PC board ass'y <DT>

NAETC-6882-1D, Digital output PC board ass'y<GR, GT>

NCETC-6900, PC board for holder <P, GR, GT>

NAAR-6875-1A, CD circuit PC board ass'y<D>

NAAR-6875-1B, CD circuit PC board ass'y<P>

NAAR-6875-1C, CD circuit PC board ass'y<DT>

NAAR-6875-1D, CD circuit PC board ass'y<GR, GT>

NAETC-6883-1A, Connector PC board ass'y<D>

NAETC-6883-1B, Connector PC board ass'y<P>

NAETC-6883-1C, Connector PC board ass'y<DT>

NAETC-6883-1D, Connector PC board ass'y<GR, GT>

TFCE1U114A, Tuner unit<D>

TFCE1E512A, Tuner unit<GR, GT, P DT>

1H445582-1C

1H445582-1D

25136900

1H445575-1A

1H445575-1B

1H445575-1C

1H445575-1D

1H445583-1A

1H445583-1B

1H445583-1C

1H445583-1D

240134

240135

U9

U8

Label, Spec.<GR>

Label, Spec.<DT>

Label, Spec.<GT>

Label, Spec.<P>

Label, Warning <D>

Label, Warning<P, GR, GT, DT>

Label<GR, GT, P>

U10

Label

1.25A-UL/T-237, Fuse<D, DT>

0.4A-SE-EAW, Fuse<P,GR, GT>

ÅI

ÅI

NSAS-10P0654, Socket

NSAS-12P0723, Socket

Facet

Clear plate

U7

Plastic rivet, NRP-345<P, GR, GT>

Label, Spec.<D>

THE COMPONENTS IDENTIFIED BY THE MARK ARE

NOTE :

NCFC7-161012, Flexible flat cable

NCFC2-161022, Flexible flat cable

NCFC7-360612, Flexible flat cable

NCFC7-151012F,lexible flat cable

USA & Canadian models only

:

: Taiwanese model only

: European model only

: Chinese model only

<D>

<DT>

<P>

<GR>

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE ONLY WITH PART NUMBER SPECIFIED.

AS-UC-2#18, Power supply cord<D, DT>

AS-CCEE, Power supply cord<GR>

AS-CEE, Power supply cord<P, GT>

2SC3851-Y or

2SC3851-O, Transistor

2SA1488-Y or

2SA1488-O, Transistor

Heat sink

ÅIÅIÅI * * * *

ޓޓޓޓޓޓ

,if necessary, must be

*

: Asian model only

<GT>

made from the same beta group(HFE) as the original type.

CAUTION : Replacement of the transistor of mark

3SMS8W.SW+14B(BC), Special screw

NPT-1391D, Power transformer<D, DT>

NPT-1391G, Power transformer<GR, GT>

NPT-1391P, Power transformer<P>

NCD-170S, CD mechanism

Boss, PCB

Boss, PCB3

2TTB+8P, Self tapping screw

2.6TTB+8B(BC), Self tapping screw

ÅIÅIÅI

㧙

22

㧙

CR-305X

CR-305X

PART NO.

27111168

838130088

16789

REF.NO.

27100384

27190693A

27191112

27191110

27175253-1A

27300750

830440069

831430088

28184781

28184782

838930088

28325775A

28148447

27150456

27122738

27122739

838430068

10121415162022232425263133414346475052

J293

NAETC-6883

(Fig-4)

Connect J293 (or LD short terminal 2) on CD

Connector PC board (NAETC-6883) first when

you replace an optical pickup. (Fig-4)

NAETC-6883

(Soldering side)

(Component side)

(3)

27212217

27212218

27268027A

28198909

28191888

880009

LD short terminal 2

29362650

29362700

29362651

29362699

29362652

29362572A

29362571

29360687

29362285

252157

252083

2009990500

535455

F901

P302

(NAAR-6875)

to main PC board

P351

NAETC-6883

(Fig-5)

Remove socket P351 between the CD

Connector PC board and the Main circuit

PC board.(Fig-5)

(4)

20022391210

2047161012

2042161022

2047360612

2047151012

253294HDK

253287HIT

253237HIT

2203384 or

2203383

2203394 or

2203393

27160468

801433

2301452

2301454

P303

P351

P352

P701

P778

P901

Q557,Q558

P352

to CD mechanism

(5) Solder the LD short terminal 1 on mechanism

LD short terminal 1

(Fig-6)

(Fig-6)

(6) Disconnect the flexible flat cable P352. (Fig-6)

Q557A

Q559,Q560

T901

Q557B

P352

to NAETC-6883

2301453

24800018A

24840133

24840135

838120080

838426088

Z1Z2Z3Z5Z6

Cut J293.(or Unsolder the LD terminal 2) (Fig-4)(11)

Connect the socket P351 between CD Connector

and Main circuit PC boards (NAAR-6875).

(Fig-5)

(7) Replace the optical pickup.

(10)

(8) Connect the flexible flat cable P352. (Fig-6)

(9) Unsolder the LD terminal 1 on mechanism. (Fig-6)

㧙

21

㧙

screw

The machine screw of four points which is the fixation

The laser diode in the optical pickup block is so sensitive to static electricity,surge current and etc.

That the components are liable to be broken down or its reliability remarkably deteriorated.

During repair,carefully take the following precautions.

of mechanism is removed, mechanism is upset, and

Do not touch the optical pickup object lens with the hands.

(1)

(Fig-1)

PC which is about the bottom of mechanism is seen.

(Fig-1,Fig-2)

CD Mechanism

screw

(Fig2)

REPLACEMENT OF OPIAL PICKUP CHASSIS EXPLODED VIEW PARTS LIST

CD mechaniam

(Fig-3)

The machine screw is removed and CD connector

PC board(NAETC-6883) is removed from the main body

of CD mechanism.(Fig-3)

screw

CD connector PC board

(NAETC-6883)

(2)

Page 16

CR-305X

24

41

23

25

Z1

53

22

43

46

6

㧙

1

24

㧙

47

U3

6

12

P302

6

6

10

P303

P351

U1

P701

U8

7

6

9

P352

P901

(P,GR,GT type)

P901

(D,DT type)

14

Z2

Z3

Z5

52

Z6

U9

31

33

20

26

6

U10

6

P778

U5

Q557

U6

Q558

Q557A

15

Q559

Q557B

U4

Q560

6

T901

F901

U2

8

9

55

50

U7

16

㧙

23

㧙

CHASSIS EXPLODED VIEW

6

Page 17

BLOCK DIAGRAM

REC

TAPE

PLAY

REC

CDR

PLAY

REC

MD

PLAY

Excluding

U692

㧙

25

㧙

USA &

Canadian

models

OPTICAL

OUTPUT

FM

AM

LD

CD MECHANISM

FOCUS

COIL

TRACKING

COIL

SPINDLE

MOTOR

SLED

MOTOR

TRAY

MOTOR

OPEN/

CLOSE

U691

SSTOP

E

A

D

M

M

M

B

C

F

+

+

+

TUNER UNIT

A,C

B,D

E,F

FOCUS

GAIN ADJ.

Q691

BUFFER

TC7W04

RCLK

RDATA

RDS

STEREO

SIGNAL

OUT

PLL

SD

36 LD

37 PD

38 PD1

39 PD2

41,42

1 FEO

5 VO1+

6 VO1 10 VO2+

11 VO2-

20 VO3+

21 VO3-

25 VO4+

26 VO4-

3 OUT2

TRAY MOTOR DRIVER

7 OUT1

Q101

RF SIGNAL

PROCESSING

SERVOAMP.

CXA1992BR

6 FEO

16 SLO

13 TAO

FC

TR

SLD

VIN1 3

VIN2 13

VIN4 28

Q105

FOCUS/TRACKING &

SLED/SPINDLE

MOTOR DRIVER

LA6541D

Q103

TA7291S

Q401 INPUT SELECTOR

TC9273N-007

CK 14

DATA 15

ST 16

Q181-Q183

TUNER MUTE

CLK 20

XLT 21

DATA 22

COUT 24

SENS1 25

FOK 27

XRST 79

SENS2 26

VCC 18

VCC

Q110

,Q111

SPDL

VG3 19

Q184-Q186

CD MUTE

15 SPOA

14 CLK

13 XLT

12 DAT

11 CNIN

10 SEIN

18 FOK

5.6V

Q403,Q404

ACOUSTIC PRESENCE CONTROL

13 ST

15 CK

16 DATA

Q180

4

RDS DECODER

BU1923

European Model only

Rch

DOUT 53

LOUT1 67

LOUT2 74

Q301

CD DIGITAL SIGNAL

PROCESSOR

CXD2589Q

21 MDP

Q402

ACOUSTIC PRESENCE

CONTROL

TC9162

2

1

16

CLOCK

9

XLAT

8

DATA

7

SENS

6

SQCK

4

SQSO

5

SCOR

57

XRST 23

40 PLL

36 RCLK

37 RDATA

39 FCE

13 DSP MUTE

50 TU MUTE

42 RDS DATA

43 RDS SIG

45 RDSCLK

18 STEREO

19 SD

26 SIGNAL

9

10

11

15

14

16

44

55 XRST

12 SENS20

53 POWER CD

57 OPEN

58 CLOSE

25 IN/OUT

Q751

FL TUBE

10-BT-167GK

VOLUME

R425

M

Q704

MOTORVOLUME

DRIVER TA7291S

VOLUP 22

VOLDN 21

Q701

MICROPROCESSOR

MPD78045GF-119-3B9

60-77 P1-P10

1-7,78-80 G1-G9

ANG MUTE 51

POWER 41

POFF 31

SYS IN 46

SYS OUT 49

REMIN 47

27 K0

S751-S762

KEY SWITCH

Q603,Q405

MUTING

38 K1

-27V

+12V

+22V

-22V

+5.6V

POWERAMP.

Q601,Q602

AMP. MUTE

Q902

Q901

78M12

Q903

78M56

POWER

FAILURE

DETECTOR

Q702

BUFFER

REMOTE

SENSOR

U751

+12V

Q902

RL901

TO FL TUBE

L

P551

SPEAKERS

R

USA & Canadian models only

P405

SUBWOOFER

PREOUT

T901

POWER

TRANSFORMER

F901

RI

P553

PHONES

P901

AC IN

CR-305X

WIRING VIEW

㧙

AC INPUT

26

㧙

SPEAKERS

U5

SPEAKER TERMINAL PC BOARD

(NAETC-6881)

JL552A

U4

POWER AMPLIFIER

PC BOARD

(NAAF-6880)

L

L

GND

R

R

+B-BDGND

JL504B

+B

JL504B

P30

L

GND

JL551B

L

GND

P30

GND

GND

GND

-B

GND

GND

GND

DGND

P902

T901

Power transformer

U2

POWER SUPPLY PC BOARD

(NAPS-6878)

P30

GND

R

R

GND

POW.AMP

JL551A

JL903

GND

GND

GND

P901B

+12V

FL1

FL2

-VP

+5.6V

GND

GND

POFF

JL405B

GND

JL501B

+B

L+

LNF

LGND

GND

R-

RNF

R-

-B

CR-305X

PC board

SP+

SP-

SP-

SP+

P29

U10

TUNER UNIT

SL+

SL-

SSTOP

SL-

SL+

SSTOP

OPTICAL

2

GND

GND

P16

P15

1

P405B

MDREC-L

GND

DREC-R

GND

MDPLAY-L

GND

MDPLAY-R

GND

+B

DOUT

STEREO

SD

TUMUTE

TU-R

GND

TU-L

RDS

+12V

+5V

SIGNAL

GND

STB

RCLK

DATA

PLL

PICKUP UNIT

FC-

TR-

TR+

FC+POGND

PO

FC-

TR-

FC+

TR+

GND

P351B

PO

FC-

TR-

FC+

TR+

GND

P351A

P14

P13

P12

P11

P10P9P8P7P6P5P4P3P2P1F1F2GND

GNDLDFCBADF+5V

F

F

C

B

A

D

LD

GND

F

F

C

B

A

D

LD

GND

VC

P352A

VC

+5V

VC

+5V

GND

+5V

REMOK1K0

AP

P405A

MDREC-L

GND

DREC-R

GND

MDPLAY-L

GND

MDPLAY-R

GND

+B

DOUT

P778A

STEREO

SD

TUMUTE

TU-R

GND

TU-L

RDS

+12V

+5V

SIGNAL

GND

MDREC-R

STB

RCLK

MDREC-L

DATA

PLL

MDPLAY-R

P393

MDPLAY-L

GND

GND

GND

U9

CONNECTOR

PC BOARD

(NAETC-6883)

P33

VOL DOWN

VOL UP

POWER

U8

CD & MICROPROCESSOR

CIRCUIT PC BOARD

(NAAR-6875)

P33

P403A

TU-R

GND

TU-L

GND

GND

GND

GND

GND

CD-L

GND

CD-R

GND

P404

NC

CLK

DATA

MUTE

+B

-B

ST

RI

SW PREOUTMD

USA & Canadian

JL405A

L

GND

R

models only

U6

DIGITAL OUTPUT

PC BOARD

(NAETC-6882)

Excluding USA & Canadian models

L

R

Excluding USA & Cana

-dian models only

FM

AM

CD MACHANISM

P901A

+12V

FL1

FL2

-VP

+5.6V

GND

GND

POFF

POW.AMP

Loading motor

PC board

P302B

LD-

LD-

P302A

LD-OPGND

LD-

Spindle motor

CL

P303B

OP

CL

GND

P303A

10G9G8G7G6G5G4G3G2G1GP17

P701A

CDR

TAPE

JL501A

+B

L+

LNF

LGND

GND

RRNF

R-

-B

P403B

TU-R

GND

TU-L

GND

MDREC-R

GND

MDREC-L

GND

MDPLAY-R

GND

MDPLAY-L

GND

CD-L

GND

CD-R

+B

GND

-B

P404B

NC

CLK

DATA

ST

RI

VOL DOWN

VOL UP

MUTE

POWER

U1

SELECTOR CIRCUIT

PC BOARD

(NAAF-6874)

P29

RI

JL552B

L

L

GND

R

R

PHONES

9G8G7G6G5G4G3G2G1G

10G

P701B

P17

P16

P15

P14

FL TUBE

P9P8P7P6P5P4P3P2P1F1F2

P13

P12

P11

P10

K1

K0

AP

+5V

GND

GND

REMO

U3

DISPLAY CIRCUIT PC BOARD

(NADIS-6879)

P29

Volume

Page 18

CR-305X

DESCRIPTION

1SS352

1SR154-400

UDZ5.6B, Zener

PART NO.

Diodes

223234R2

22380284R2

224490560R2

CIRCUIT NO.

D101,D703,D707

D701,D702,D704

D705

5 %, 50 V, Plastic

Ǵr

F, 16 V, Elect.

Ǵ

DESCRIPTION

10

0.047

PART NO.

Capacitors

355741009

371124734

Resistors

CIRCUIT NO.

C551,C552

C553,C554

UDZ5.1B, Zener

NCH-1475

HC-49/U034.332 MHz <P>

224490510R2

Coils

231237K100R2

Crystals

3010321

D791

L101,L351

X181

5 %, 2 W, Metal oxide

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

ǡr

ǡr

ǡr

100

0.22

8.2

NSCT-10P881

443521014

452732294F

453530824

Sockets

25051094

R557,R558

R559-R562

R563,R564

JL501B

5 %, 50 V, Plastic

5 %, 50 V, Plastic

5 %, 50 V, Plastic

r

r

r

F,

F,

F, 6.3 V, Elect.

Ǵ

Ǵ

Ǵ

HC-49/U0316.9344M

HC-49/U03 4.19M10P

100

0.01

0.47

2200 pF,

3010308

3010261

Capacitors

355721019

374721034

374724744

374722224

X351

X701

C102,C129,C135

C104,C105,C115

C106,C109

C107,C124,C133

NSCT-6P897

NSCT-4P875

DESCRIPTION

25051110

25051088

PART NO.

Coils

(NAETC-6881-1A/-1B/-1C/-1D)

JL504A

JL551A

SPEAKER TERMINAL PC BOARD

CIRCUIT NO.

5 %, 50 V, Plastic

5 %, 50 V, Plastic

r

r

F,

F, 50 V, Elect.

F, 35 V, Elect.

Ǵ

Ǵ

Ǵ

0.1

4.7

33

1000 pF,

374721024

374721044

355780479

355763309

C108

C110,C111,C113

C112

C117,C794,C795

5%, 1/2 W, Metal oxide

ǡr

S-1.3C

5.6

231176S

Resistors

453530564

Sockets

L551,L552

R565,R566

5 %, 50 V, Plastic

5%, 50V, Plastic

5 %, 50 V, Plastic

r

r

r

F,

F,

F,

F, 6.3 V, Elect.

F, 50 V, Elect.

Ǵ

Ǵ

Ǵ

Ǵ

Ǵ

3.3

0.033

0.01

0.01

470

355780339

374723334

374721034

374721034

354724719

C118,C191,C192

C120

C121,C123

C125,C128 ,C352

C134

NSCT-3P874<D>

NSCT-4P875

NPLG-5P588

NTM-4PDML230, Speaker

25051087

25051088

25055626

Terminal

25060299

JL405A

JL551B

JL552A

P551

5 %, 50 V, Plastic

r

5 %, 50 V, Plastic

F,

r

F, 6.3 V, Elect.

Ǵ

F, 50 V, Elect.

Ǵ

Ǵ

100

0.022

2.2

355721019

374722234

355780229

C136,C145,C151

C137

C139,C181,C708

(NAETC-6882-1A/-1B/-1C/-1D)

DIGITAL OUTPUT TERMINAL PC BOARD

F, 50 V, Elect.

F, 6.3 V, Elect.

F, 50 V, Elect. <P>

F, 35 V, Elect.

Ǵ

Ǵ

Ǵ

Ǵ

100

2.2

680 pF,

22

0.47

355721019

355780229

374726814

355762209

355784799

C180,C350,C712

C185

C333,C334

C335,C336

C351

DESCRIPTION

GP1FA550TZ

GP1FA550TZ<P,DT,GR,GT,PT>

PART NO.

Photo couplers

24120082

24120082IC22240935R2

CIRCUIT NO.

U691

U692

5%, 50 V, Plastic

5 %, 50 V, Plastic

r

r

F,

F, 6.3 V, Elect.

Ǵ

Ǵ

NTC-20P09, Trimming capacitor (Clock adj.)

100

0.047

1500 pF,

DX-5R5L104, Super capacitor

N06HR20KBC, Trimming register

374724734

374721524

3060010

354721019

3000078

Resistor

5210263

Sockets

C354

C355

C703

C710

C711

R123

F, 16 V, Elect.

Ǵ

TC7WU04FU<P,DT,GR,GT,PT>

NCH-1477

100

NPLG-3P586<D>

Coil

231237K220R2

Capacitor

354741019

Plug

25055624

Socket

Q691

L691

C691

JL405B

NSCT-3P874

NSCT-16P2109

NSCT-36P2129

NSCT-15P2108

25051087

25052212

25052232

25052211

JL903A

P351A

P701A

P778

NSCT-10P1025

NPJ-1PDBL382<D>

NPJ-4PDRW389<P,DT,GR,GT,PT>

25051235

Jack

25045567

25045575

P405B

P406

NSAS-18P0666

NPLG-4P33

NPLG-2P29

NPLG-5P133

NPLG-6P134

NPLG-18P763

NPLG-9P661

2002391815

Plugs

25055045

25055038

25055149

25055150

25055807

25055705

P901A

P104

P105

P302A

P303A

P403A

P404A

DESCRIPTION

CXA1992BR

LA6541D

TA7291S

BU1923 <P>

PART NO.

ICs

22241499R3

22241247

22240239

22241302

CD CIRCUIT PC BOARD (NAAR-6875-1A/-1B/-1C/-1D)

CIRCUIT NO.

Q101

Q102

Q103

Q180

NPLG-10P662

Terminal PC (clock /adjust)

DESCRIPTION

NSCT-16P2146

25055706

Terminal

25060061

PART NO.

Sockets

25052249

P405A

TP01

CONNECTOR PC BOARD (NAETC-6883-1A/-1B/-1C/-1D)

CIRCUIT NO.

P351B

CXD2589Q

MPD78045FGF-119-3B9

TA7291S

2SB1068-K

RN1404

2SA950-Y

22241500R3

22241502R3

22240239

Transistors

2212853

2214490R2

2211504

Q301

Q701

Q704

Q110,Q112

Q111,Q703

Q114

NSCT-16P1583

25051796A

THE COMPONENTS IDENTIFIED BY THE MARK ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE ONLY WITH PART NUMBER SPECIFIED.

P352A

RN2404

RN1441

RN1441

2SC2712-O <P>

RN2403

2214550R2

2215410R2

2215410R2

2213143R2

2214540R2

Q181,Q184

Q182,Q183

Q185,Q186

Q191

Q702

,if necessary, must be

*

USA & Canadian models only

:

: Taiwanese model only

: European model only

: Chinese model only

: Asian model only

<D>

<DT>

<P>

<GR>

<GT>

㧙

made from the same beta group(HFE) as the original type.

28

㧙

CAUTION : Replacement of the transistor of mark

F,35V, Elect.

F, 35 V, Elect.

F, 16 V, Elect.

Ǵ

Ǵ

Ǵ

100

DESCRIPTION

3300

10

PART NO.

Capacitors

354763329S

354741009

354761019

CIRCUIT NO.

C904,C905

C907

C909

DESCRIPTION

TC9273N-007

TC9162AF

NJM4565M-D

PART NO.

ICs

22241072

22240981R2

22241383R2

SELECTOR CIRCUIT PC BOARD (NAAF-6874-1A/-1B/-1C/-1D)

CIRCUIT NO.

Q401

Q402

Q403,Q404

PRINTED CIRCUIT BOARD VIEW PARTS LIST

F, 16 V, Elect.

F, 50 V, Elect.

F, 35 V, Elect.

Ǵ

Ǵ

Ǵ

6800

100

47

354764709

3500173S

354781019

C913

C914

C918

RN1441

RN1402

Transistors

2215410R2

2214470R2

Q405, Q406

Q409, Q603

5 %, 50 V, Plastic

r

5 %, 1/2 W, Metal oxide

5 %, 1 W, Metal oxide

F

Ǵ

ǡr

ǡr

22

2.2

0.22

374722244

Resistors

443622204

453530224

C920-C924

R901

R903,R913

2SC1622A-L

2SC2712-O

2SA1015-GR or

KTA1266-GR

2216156R2

2213143R2

2211455 or

2215975

Q501-Q504

Q505-Q508

Q509-Q512

20 %,1/2 W,Solid <D,DT>

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

5%, 1/2 W, Metal oxide

ǡr

ǡr

ǡr

ǡr

0.47

1 k

27

3.3 M

453534794

443521024

443522704

431533355

!

R907

R908

R911

R912

2SA1015-GR or

KTA1266-GR

2SC2712-O

2SA1162-GR

2211455 or

2215975

2213143R2

2214375R2

Q515-Q518

Q601

Q602

NRL-2P5A-DC12-155 <D,DT>

NRL-2P3A-DC12-148 or

NRL-2P8A-DC12-147 <P,GR,GT,PT>

NPLG-3P586

NPLG-9P137

NPLG-2P632

Relay

25065607

25065598 or

25065597

Plug

25055624

25055153

25055676

Socket

ÅI

RL901

JL903B

P901B

P902

5 %, 50 V, Plastic

5 %, 50 V, Plastic

r

r

F,

F,

Ǵ

Ǵ

F, 16 V, Elect.

F, 50 V, Elect.

Ǵ

22

0.068

Capacitors

354742209

371126834

C409,C410

C415-C418

Ǵ

0.015

1

371121534

354780109

C421,C422

C423,C424,C603

UDZ13B

1SS352

Diodes

224491300R2

223234R2

D491,D492

D501-D504

1SS352

223234R2

D601

NSCT-6P98

YSH403T

25050270

Fuse holder

25050065

!

JL504B

F901A,F901B

5 %, 50 V, Plastic

r

F,

F, 16 V, Elect.

F, 16 V, Elect.

Ǵ

Ǵ

Ǵ

0.15

22

220

371121544

354742209

354742219

C425,C426

C429,C430

C491,C492

T400MAL250V, Fuse label <P,GR,GT,PT>

Fuse label

29361919

Clamp

F901A

F, 16 V, Elect.

F, 35 V, Elect.

F, 16 V, Elect.

Ǵ

Ǵ

Ǵ

100

100

10

354741019

354761019

354741009

C493,C494

C495,C496

C501,C502

UA-0 V0

RAD-81

3P+10FN(BC)

27190608-1

Heat sink

27160250

82143010

P901C

Q903A

Q903B

F, 6.3 V, Elect.

F, 16 V, Elect.

F, 16 V, Elect.

Ǵ

Ǵ

Ǵ

47

220

10

N16RG100KBT25F,Volume

354744709

354722219

354741009

Resistors

5104333

C505,C506,C601

C509-C510

C515,C516

R427

DESCRIPTION

10BT-167GK

PIC-26043TE2

RN1404

PART NO.

FL Tube

212141

Remote sensor

241330

Transistor

2214490R2

LED

DISPLAY CIRCUI PC BOARD (NADIS-6879-1A/-1B/-1C/-1D)

CIRCUIT NO.

Q751

U751

Q782

5 %, 1 W, Metal oxide

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

5 %, 1/2 W, Metal oxide

ǡr

ǡr

ǡr

1k

820

39

443521024

443528214

443523904

R495

R496

R519-R522

5 %, 1/2 W, Metal oxide

ǡr

ǡr

33

39

443523304

443523904

Jacks

R533,R534

R535,R536

NPJ-4PDRW389

25045575

P400, P401

ǡr

ǡr

560

22

443625614

443522204

R491,R492

R493,R494

5 %, 1/2 W, Metal oxide

F, 6.3 V, Elect.

Ǵ

ǡr

SEL2210R-TP1

100

330

LGT1516-0101, Head phone jack

225381

Capacitor

353721019

Resistors

443523314

Jack

25045396

Sockets

D782

C752

R567,R568

P553

HSJ1501-010010, RI Jack

NSCT-18P1316

NSCT-9P1024

NPLG-10P593

25045581R0

Sockets

25051529

25051234

Plug

25055631

P402

P403B

P404B

JL501A

POWER SUPPLY PC BOARD (NAPS-6878-1A/-1B/-1C/-1D)

NSCT-5P876

NSCT-36P2129

NPS-111-S662

25051089

25052232

Push switches

25035699

FL Holder

JL552B

P701B

S751- S762

DESCRIPTION

78M12HF

78M56

PART NO.

ICs

222780125

222780565

Transistors

CIRCUIT NO.

Q901

Q903

FL Holder

DESCRIPTION

2SC1740S-R or

KTC3199-GR

27191111

PART NO.

Transistors

2213284 or

2215864

Q751A

POWER AMPLIFIER PC BOARD (NAAF-6880-1A/-1B/-1C/-1D)

CIRCUIT NO.

Q551,Q552

2SA950-O or

2SA950-Y

DTC123JS

RBV402 or

D3SBA20

RL1N4003 or

2211503 or

2211504

2213640

Diodes

22380022F or

22380271F

22380260 or

Q902

Q904

D901

D902-D908

2SC2235-O or

2SC2235-Y

2SA965-O or

2SA965-Y

2211653 or

2211654

2211643 or

2211644

Q553,Q554

Q555-Q556

GP104003E

UDZ27B

UDZ5.1B

1SS352

22380035

224492700R2

224490510R2

223234R2

D909

D910

D911

㧙

27

㧙

Page 19

H

5-A

P2 9

5-B

P2 9

㧙

30

㧙

CR-305X

CR-305X

3-G

4-C

P3 3

5-G

P3 4

P3 4

㧙

29

㧙

3-G

2-H

P3 0

P3 4

ABCDEFG

SCHEMATIC DIAGRAM (AMPLIFIER SECTION)

1

1-H

P3 0

5-G

P3 4

2

3

4

5

Page 20

CR-305X

Soldering side

Component side

SPEAKER TERMINAL PC BOARD (NAETC-6881)

Soldering side

U5

Component side

DIGITAL OUTPUT PC BOARD (NAETC6882)

Soldering side

U6

㧙

32

㧙

Component side

POWER SUPPLY PC BOARD (NAPS-6878)

U2

ABCDEFG

PRINTED CIRCUIT BOARD VIEW 1

1

2

Component side

SELECTOR CIRCUIT PC BOARD (NAAF-6874)

U1

3

Soldering side

4

㧙

31

㧙

5

Page 21

3-A

P2 9

CR-305X

CR-305X

3-B

P2 9

5-E

P3 0

4-B

P3 3

3-B

P2 9

㧙

34

㧙

ABCDEFG

SCHEMATIC DIAGRAM (CD & MICROPROCESSOR SECTION)

1

2

3

4-D

P2 9

㧙

33

㧙

5-G

P3 4

4

5

Page 22

CR-305X

Component side

CD CIRCUIT PC BOARD (NAAR-6875)

㧙

36

㧙

U8

㧙

35

㧙

Component side

ABCDEFG

DISPLAY CIRCUIT PC BOARD (NADIS-6879)

Soldering side

U3

PRINTED CIRCUIT BOARD VIEW 2

1

2

3

4

5

Page 23

CR-305X

CR-305X

Soldering side

CD CIRCUIT PC BOARD (NAAR-6875)

U8

㧙

38

㧙

Component side

POWER AMPLIFIER PC BOARD (NAAF-6880)

U4

ABCDEFG

PRINTED CIRCUIT BOARD VIEW 3

Component side

CONNECTOR PC BOARD

(NAETC-6883)

U9

1

2

Soldering side

Soldering side

3

㧙

37

㧙

4

5

Page 24

CR-305X

reqency counter

F

524,287 524,289 Hz

Trimmer capacitor C703

TP01

C703

1. Connect the frequency counter to the terminal TP01 on main PC board (NAAR-6875)

2. Press and hold down the MEMORY button , then press the DISPLAY button.