Page 1

Cat. No. Z263-E1-01

ZX-GT Series

Smart Sensor

USER’S MANUAL

Page 2

Introduction

Thank you for purchasing the ZX-GT series.

This manual provides information regarding functions, performance and operating methods that

are required for using the ZX-GT.

When using the ZX-GT, be sure to observe the following:

• The ZX-GT must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

APPRICATION CONSIDERATIONS

(Please read)

User's Manual

BEFORE USE

BASIC OPERATIONS

FUNCTION SETTINGS

COMMUNICATIONS WITH

EXTERNAL DEVICES

APPENDICES

1

2

3

4

5

Smart Sensor

Wide Laser Beam CCD Measurement Sensor

ZX-GT Series

Page 4

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please

consult your OMRON representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials

and workmanship for a period of one year (or other period if specified) from date of

sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS

FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED

THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of

the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR

OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS

CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION,

ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

ZX-GT User’s Manual

Page 5

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED.

THEY ARE NOT DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS,

AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or

regulations that apply to the combination of products in the customer’s application or

use of the product.

At the customer’s request, OMRON will provide applicable third party certification

documents identifying ratings and limitations of use that apply to the products. This

information by itself is not sufficient for a complete determination of the suitability of

the products in combination with the end product, machine, system, or other

application or use.

The following are some examples of applications for which particular attention must

be given. This is not intended to be an exhaustive list of all possible uses of the

products, nor is it intended to imply that the uses listed may be suitable for the

products:

• Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment,

and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A

WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

ZX-GT User’s Manual

3

Page 6

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in

determining suitability and does not constitute a warranty. It may represent the result

of OMRON’s test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on

improvements and other reasons.

It is our practice to change model numbers when published ratings or features are

changed, or when significant construction changes are made. However, some

specifications of the product may be changed without any notice. When in doubt,

special model numbers may be assigned to fix or establish key specifications for

your application on your request. Please consult with your OMRON representative at

any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing

purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be

accurate; however, no responsibility is assumed for clerical, typographical, or

proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable

product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction

with the product. Please notify us before copying or reproducing this document in

any manner, for any other purpose. If copying or transmitting this document to

another, please copy or transmit it in its entirety.

4

ZX-GT User’s Manual

Page 7

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates general prohibitions for which there is no specific symbol.

Indicates the possibility of laser radiation.

Indicates prohibition when there is a risk of minor injury from electrical

shock or other source if the product is disassembled.

ZX-GT User’s Manual

5

Page 8

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

Never look into the laser beam. Doing so continuously will result in

visual impairment.

Do not attempt to dismantle, pressurize, or incinerate the product. Doing

so may cause the laser beam to leak, resulting in the danger of visual

impairment.

6

ZX-GT User’s Manual

Page 9

Precautions for Safe Use

The following points are important to ensure safety, so make sure that they are strictly

observed.

1. Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

• Install the product in such a way that its ventilation holes are not blocked. (excluding

the connecting surface when the products are connected to each other)

• Tighten the mounting screws with a torque specified in this manual.

2. Power Supply and Wiring

• The voltage and AC power supply must be within the rated range (24 VDC +10%, -15%).

• Reverse connection of the power supply is not allowed. Connection to an AC power

supply is also not allowed.

• The output load should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing them in the same duct may cause induction, resulting in

malfunction or damage.

• Use the product within the power supply voltage specified by this manual.

• Use a DC power supply with safety measures against high-voltage spikes (safety extra

low-voltage circuits on the secondary side).

• Use only combinations of the Sensor and Controller specified in this manual.

Controller Specifications p.133

• When connecting Controllers to each other, use only combinations of the Controllers

specified in this manual.

Connecting Controllers to each other p.37

• Connect the exclusive device (Sensor). The product might break down or malfunction

if you use a part not included in the exclusive products.

3. Other

• Do not disassemble, repair, modify, pressurize, or incinerate the product.

• Dispose of this product as industrial waste.

• Should you notice any abnormalities, immediately stop use, turn OFF the power

supply, and contact your OMRON representative.

ZX-GT User’s Manual

7

Page 10

Precautions for Correct Use

Observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

1. Installation Site

Do not install this product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding machines)

• Direct sunlight or near heaters

• Strong magnetic or electric field

Also, do not install this product in locations subjected to the following conditions due to

the degree of protection specified in the ratings:

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Water, oil, or chemical fumes or spray

2. Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG

terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit), and

the load current is appropriate. Incorrect wiring may result in breakdown of the product.

• Before connecting/disconnecting devices, make sure that the Sensor/Controller is

turned OFF. The Sensor or Controller may break down if it is connected/disconnected

while the power is ON.

• Use the extension cable sold separately for extending the cable between the Sensor

(receiver) and the Controller.

p.20

3. Warming Up

After turning the power supply ON, allow the product to stand for at least 10 minutes

before use. The circuits are still unstable just after the power supply is turned ON, so

measurement values may fluctuate gradually.

4. Maintenance and Inspection

Do not use thinner, benzene, acetone or kerosene to clean the Sensor and Controller. If

large dust particles adhere to the filter on the front of the Sensor, use a blower brush

(used to clean camera lenses) to blow them off. Do not use breath from your mouth to

blow the dust off. To remove dust particles from the Sensor, wipe gently with a soft cloth

(for cleaning lenses) moistened with a small amount of alcohol. Do not use excessive

force to wipe off dust particles. Scratches to the filter might cause error.

8

ZX-GT User’s Manual

Page 11

Editor’s Note

■ Meaning of Symbols

Menu items that are displayed on the Controller’s LCD screen, and windows, dialog boxes

and other GUI elements displayed on the PC are indicated enclosed by brackets “[ ]”.

■ Visual Aids

Important

Indicates points that are important to achieve the full product performance,

such as operational precautions.

Note

Indicates application procedures.

Indicates pages where related information can be found.

ZX-GT User’s Manual

9

Page 12

MEMO

10

ZX-GT User’s Manual

Page 13

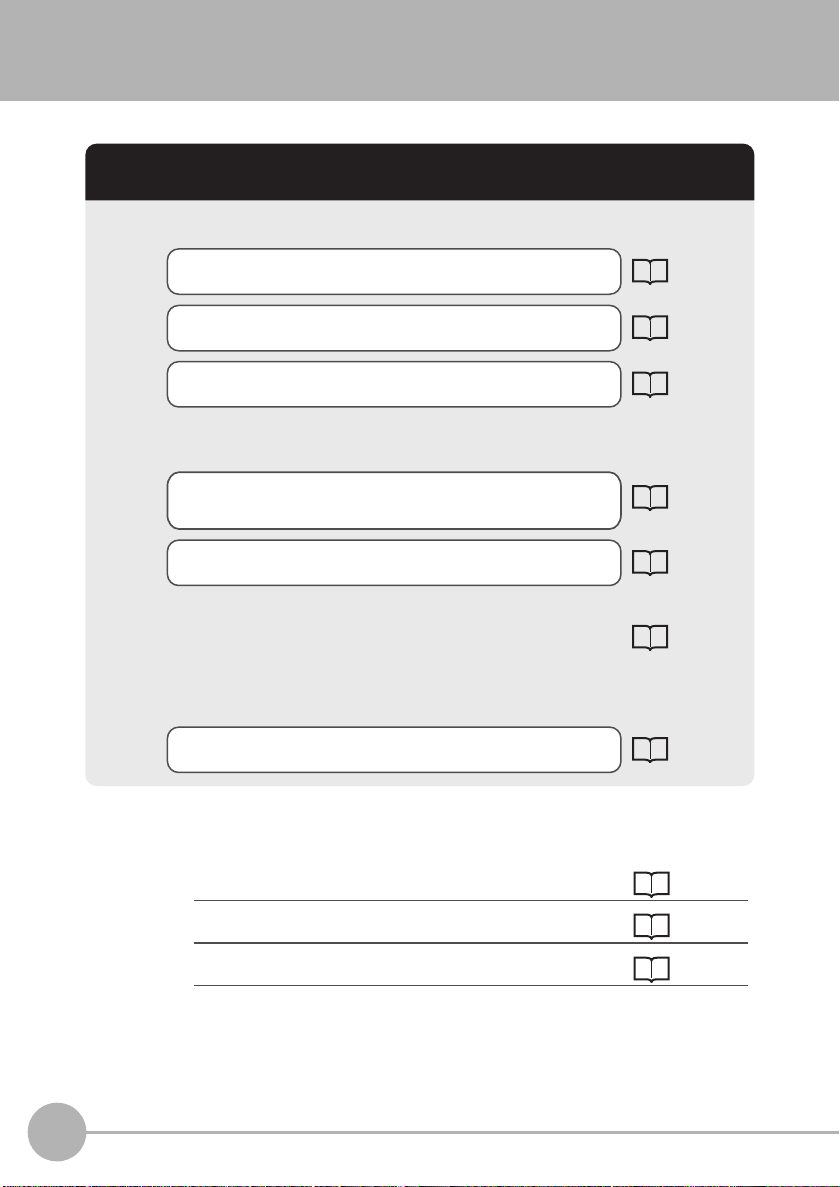

CONTENTS

Operation Step Guide . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.BEFORE USE

ZX-GT Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting and Connecting Devices . . . . . . . . . . . . . . 25

Mounting the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting Controllers to Each Other . . . . . . . . . . . . . . . . 37

Connecting Interface Units . . . . . . . . . . . . . . . . . . . . . . . . . 38

Initializing Controller Settings . . . . . . . . . . . . . . . . . . 39

2.BASIC OPERATIONS

Setting Measurement Conditions - FUN Mode . . . . . 42

Adjusting the Optical Axis and Registering the Standard

Received Light Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Selecting the Measurement Mode . . . . . . . . . . . . . . . . . . . 44

Setting Thresholds - T Mode . . . . . . . . . . . . . . . . . . . 45

Functions and Operations during Operation

- RUN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Switching the Measured Value Display . . . . . . . . . . . . . . . 46

Executing and Canceling a Zero Reset . . . . . . . . . . . . . . . 47

1

CONTENTS

ZX-GT User’s Manual

11

Page 14

3.FUNCTION SETTINGS

Settings Matched to Specific Measurement

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Specific Measurement Requirement and Measurement

Mode Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Explanation of Measurement Modes . . . . . . . . . . . . . . . . . 52

Adjusting Detection Conditions . . . . . . . . . . . . . . . . . 61

Measurement Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Number of Samples to Average . . . . . . . . . . . . . . . . . . . . . 62

Binary Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Edge Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Setting Output Conditions . . . . . . . . . . . . . . . . . . . . . 65

Judgment output timing (timer) . . . . . . . . . . . . . . . . . . . . . . 65

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Analog Output Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Setting Hold Functions . . . . . . . . . . . . . . . . . . . . . . . . 73

Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Delay Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Changing Display Conditions . . . . . . . . . . . . . . . . . . . 77

Reversing the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Changing the Number of Display Digits . . . . . . . . . . . . . . . 78

Adjusting the Display Brightness (ECO mode) . . . . . . . . . . 79

Setting Communication Conditions . . . . . . . . . . . . . . 80

RS-232C Communications Specifications . . . . . . . . . . . . . 80

Setting the Binary Output Cycle . . . . . . . . . . . . . . . . . . . . . 81

Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Zero Reset Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Display during a Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . 83

Key Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Switching Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Displaying the System Version . . . . . . . . . . . . . . . . . . . . . . 87

12

ZX-GT User’s Manual

Page 15

4.COMMUNICATIONS WITH EXTERNAL

DEVICES

Output Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Communications Using the Controller I/O Cable . . . 91

Using the Controller I/O Cable . . . . . . . . . . . . . . . . . . . . . . 91

Binary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Assignments and Functions of Output Signal Wires . . . . . 93

Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

I/O Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

RS-232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Communications on the RS-232C Interface . . . . . . . . . . . 100

Connecting External Devices . . . . . . . . . . . . . . . . . . . . . . 101

About Communications Commands . . . . . . . . . . . . . . . . . 102

Setting Acquisition/Change Commands . . . . . . . . . . . . . . 107

Measurement Control/Measured Value Acquisition

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Bank Control Command . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Utility Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

CONTENTS

5.APPENDICES

Specifications and External Dimensions . . . . . . . . 130

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Calculating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Error Messages and Corrective Actions . . . . . . . . . 140

Setup Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Measurement Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Standard Received Light Intensity Registration Errors . . . 141

Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Basic Knowledge for Operation . . . . . . . . . . . . . . . . 143

ZX-GT User’s Manual

13

Page 16

Reading Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

List of Key Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Label Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Requirements from Regulations and

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Summary of Requirements to Manufactures . . . . . . . . . . 146

Summary of Requirements to User . . . . . . . . . . . . . . . . . 150

Definitions of Laser Classification . . . . . . . . . . . . . . . . . . . 153

Compliance with EC Directives . . . . . . . . . . . . . . . . 154

Quick Reference for Displays . . . . . . . . . . . . . . . . . . 156

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

14

ZX-GT User’s Manual

Page 17

MEMO

CONTENTS

ZX-GT User’s Manual

15

Page 18

Operation Step Guide

Basic Operation Procedure

Mounting and Connections

Mounting the Sensor

Mounting the Controller

Connecting Devices

Preparations for Measurement (FUN)

Adjusting the Optical Axis and Registering the

Standard Received Light Intensity

Selecting the Measurement Mode

Setting Thresholds (T)

Start of Operation (RUN)

Zero Reset

Communications with External Devices

I/O Cable

p.25

p.27

p.28

p.42

p.44

p.45

p.47

p.91

16

Operation Step Guide

Binary Output

RS-232C

p.93

p.100

ZX-GT User’s Manual

Page 19

To Improve Controller Performance

Ignoring Rapid Changes in Measured Values

Adjusting the Number of Samples to Average

Adjusting the Detection Sensitivity

Adjusting the Binary Level

p.62

p.63

(If required)

Adjusting the Edge Filter

Stabilizing Judgment Output

Changing/Adjusting the Timing of Judgment Outputs

Changing the Output Time

Adjusting Hysteresis

Setting the Delay Time

Returning Controller Settings to Their Defaults

Speeding the Measurement Cycle Up

Setting Hold Functions

Reversing the Controller Display

Changing the Number of Controller Display Digits

Operating in the ECO (power-saving) Mode

Holding the Zero Reset Value

p.64

p.65

p.65

p.67

p.75

p.39

p.61

p.73

p.77

p.78

p.79

p.82

Offsetting the Zero Reset Value

Key Lock Function

Switching Banks

ZX-GT User’s Manual

p.83

p.84

p.85

Operation Step Guide

17

Page 20

MEMO

18

Operation Step Guide

ZX-GT User’s Manual

Page 21

BEFORE USE

ZX-GT Series 20

System Configuration 20

Part Names and Functions 21

Mounting and Connecting Devices 25

Mounting the Sensor 25

Mounting the Controller 27

Connecting Devices 28

Connecting Controllers to Each Other 37

Connecting Interface Units 38

Initializing Controller Settings 39

1

BEFORE USE

Page 22

ZX-GT Series

The ZX-GT Series Smart Sensors are a length measurement sensor using a CCD device.

Position, dimensions, and other information can be stably measured by a line beam

comprising a visible semiconductor laser and an optical scale on the CCD line sensor.

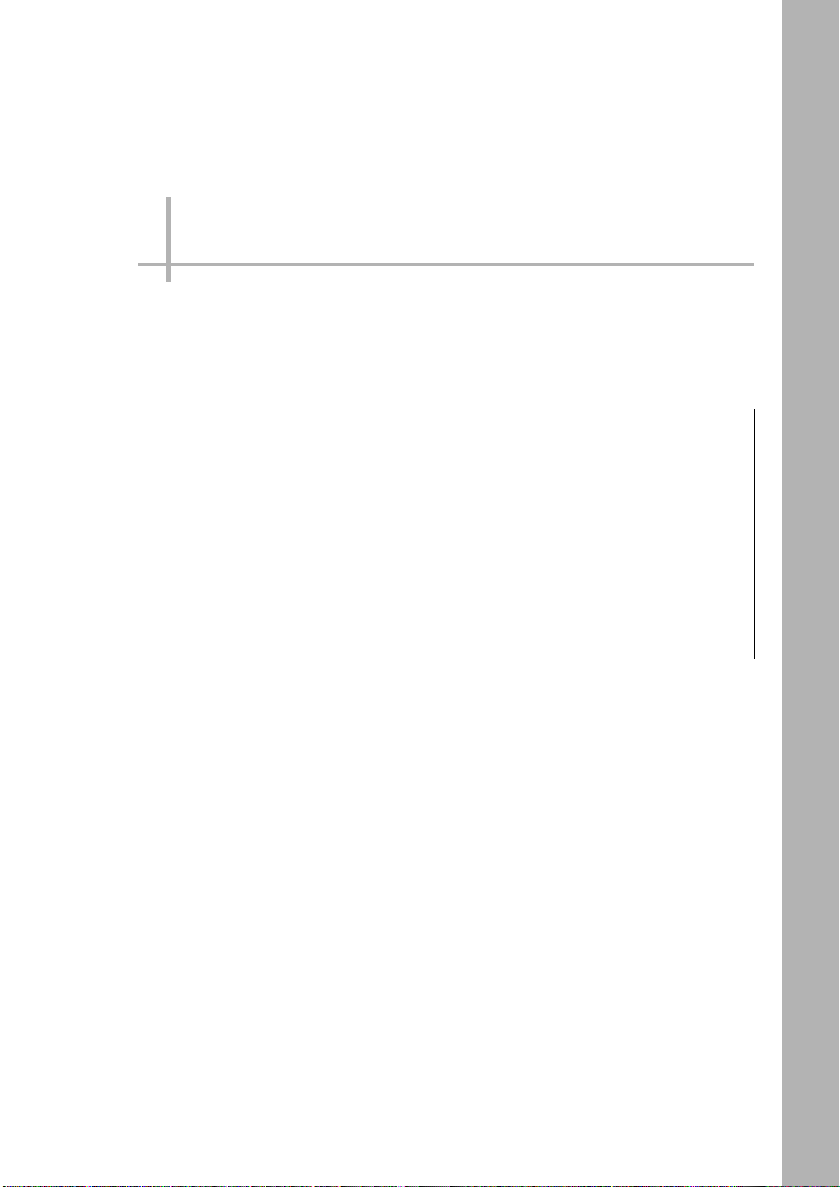

System Configuration

Sensor

ZX-GT28___

Controller

ZX-GTC__

Interface

Unit

ZX-GIF__

SmartMonitor GT

ZX-GSW11

Exclusive PC software

allows complex setups and

verification of measured

values to be performed

with ease.

Analog outputs/judgment outputs

Control input

Binary output

RS-232C

PLC

Measured values and judgments can be

output. Also, the Controller can be controlled

(e.g. switching of measurement conditions

and input of triggers).

PC

Commands can be used to input triggers

and acquire measurement results. Also, the

Controller can be controlled from a PC (e.g.

changing of setup data).

Options

• Receiver-Controller Extension Cable

p.29

Extension cable:

1 m, 2 m, 5 m, 8 m, 20 m

ZX-XGC__A (standard cable)

ZX-XGC__R (flexible cable)

• Calculating Unit

ZX-CAL2

•

Connecting Controllers to Each Other p.37

• Calculation of measurement results p.59

20

ZX-GT Series

ZX-GT User’s Manual

Page 23

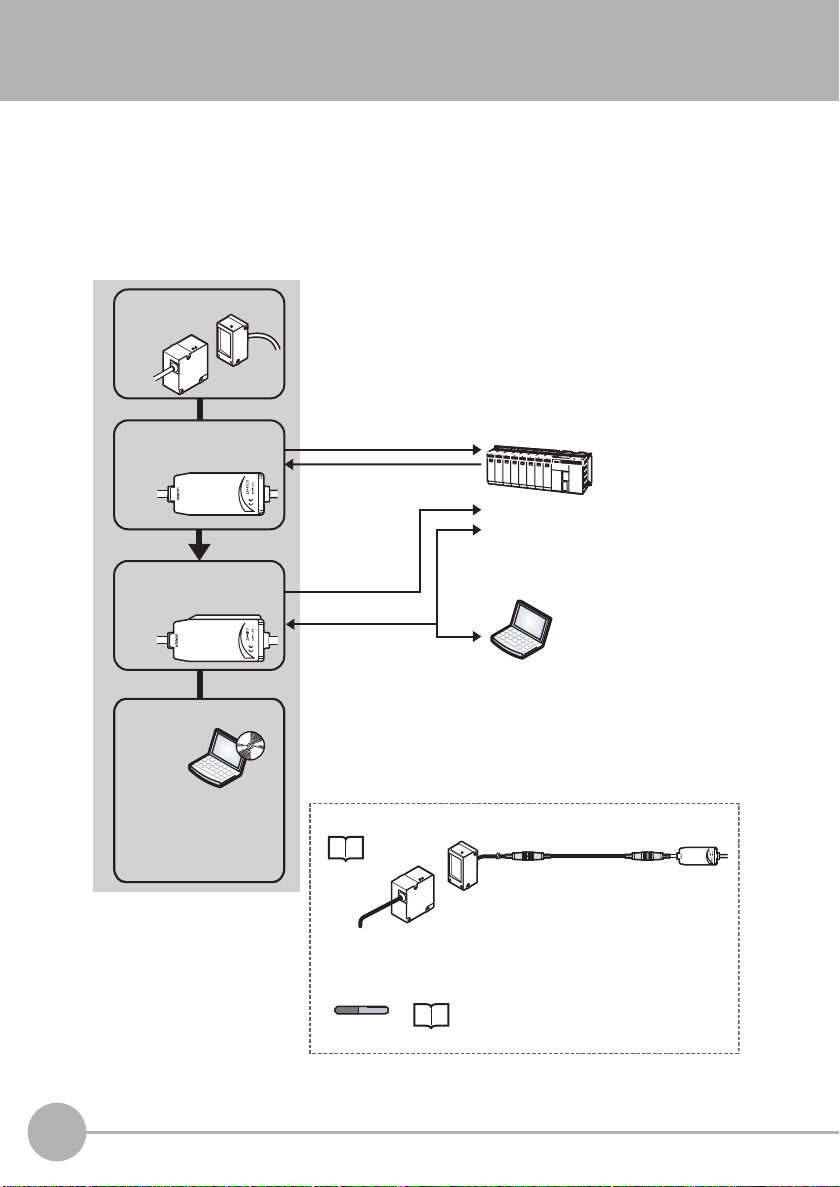

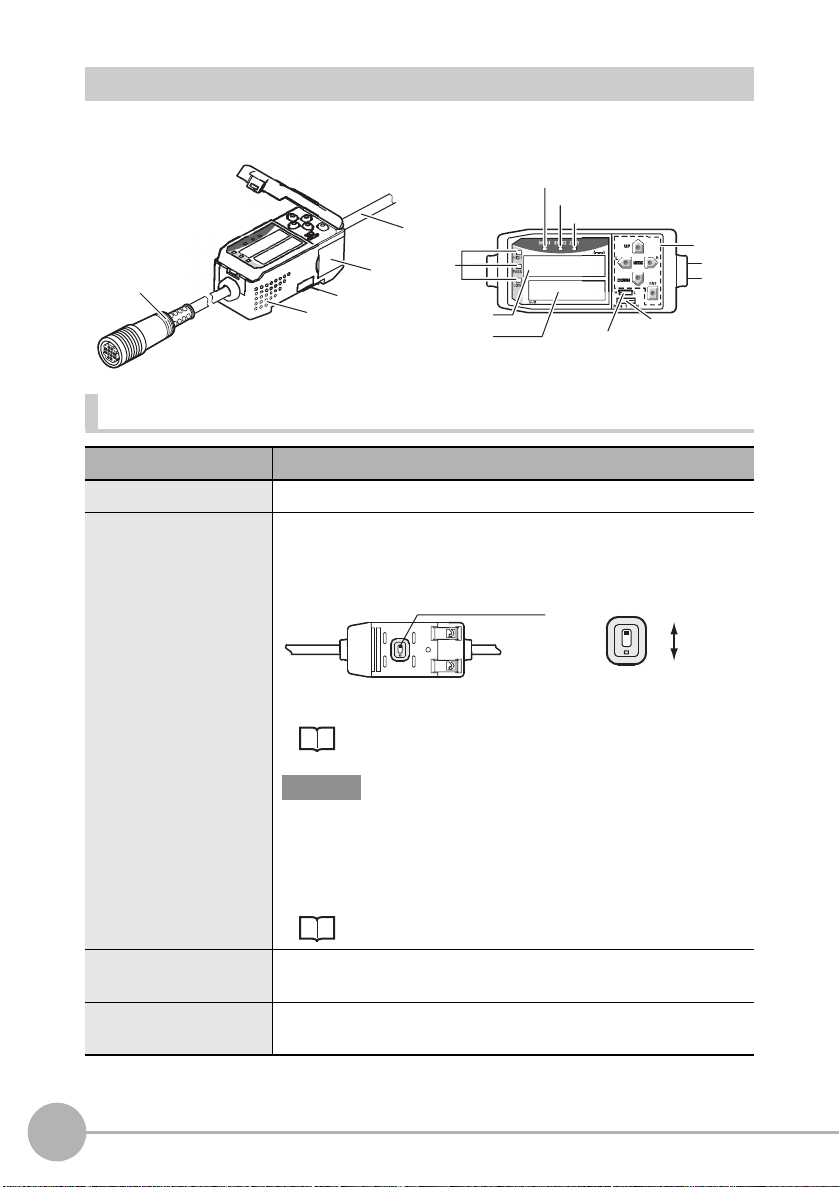

Part Names and Functions

Sensor

Receiver

Emitter

(1)

Name Function

(1) Laser indicators These are laser beam warning indicators. When the laser is being

emitted, the "laser ON indicator (ON, green)" turns ON, and when

the laser has deteriorated, the "laser deterioration alarm indicator

(ALARM, red)" turns ON.

(3)

(2)

Laser ON indicator

Laser deterioration alarm indicator

(5)

(4)

1

BEFORE USE

(2) Laser emitter This emits the laser for measurement.

(3) Laser receiver This receives the laser light emitted from the laser emitter.

(4) Connector This is the connector for connecting to the Controller.

(5) Optical axis setting

indicator

ZX-GT User’s Manual

This indicator turns ON when the laser's optical axis is aligned in

the optical axis adjustment mode.

Optical axis mode p.42

ZX-GT Series

21

Page 24

Controller

(1)

(2)

(3)

(4)

(5)

(6)

e

es

Connector Display and Operation Panel

(1)

(2)

V

ntilation hol

(4)

(3)

(7)

(9)

(8)

Connectors

Name Function

(1) Input cable This is for connecting the Sensor receiver.

(2) Voltage/Current

switch (on rear side)

(3) Controller connector This connector is for connecting Calculating and Interface Units.

(4) Output cable The output cable connects the Controller to the power supply and

This switch is for selecting voltage output or current output as the

analog output.

(default value: voltage output)

Voltage/Current switch

Output scaling settings are also required when switching the output.

Voltage output

Current output

p.68

Important

Before operating this switch, make sure that the Controller is turned

OFF. Make sure that the load connected to "analog output wire (coaxial) - analog GND wire" satisfies the rating of the set state

(voltage or current output) before turning the Controller ON.

Otherwise, the Controller may be damaged.

Rating of Connected Loads (I/O Circuit Diagrams) p.33

(total 2 connectors, one on each side)

external devices, such as timing sensors or PLCs.

22

ZX-GT Series

ZX-GT User’s Manual

Page 25

Display and operation panel

Name Function

(1) Bank 1 indicator This indicator turns ON when bank 1 is selected.

(2) Bank 2 indicator This indicator turns ON when bank 2 is selected.

(3) Zero reset

indicator

(4) Judgment output

indicator

(5) Main display

indicator

(6) Sub-display

indicator

(7) Threshold

switch

(8) Mode

switch

(9) Control keys Use the Control Keys to set the measurement conditions and

This indicator turns ON when the zero reset function is enabled.

HIGH LED : This indicator lights when "the HIGH threshold <

the measured value."

PASS LED : This indicator lights when "the LOW threshold ≤

the measured value ≤ the HIGH threshold."

LOW LED : This indicator lights when "the measured value <

the LOW threshold value."

The main display shows measured values and function names.

Reading Displays p.143

The sub-display shows additional information and function settings

for measurements.

Reading Displays p.143

The threshold switch selects whether to set (or display) the HIGH

or LOW threshold.

The mode switch selects the operation mode.

FUN : Select this mode when setting measurement conditions.

T : Select this mode when setting thresholds.

RUN : Select this mode when performing measurement.

switch the display.

List of Key Operations p.143

1

BEFORE USE

ZX-GT User’s Manual

ZX-GT Series

23

Page 26

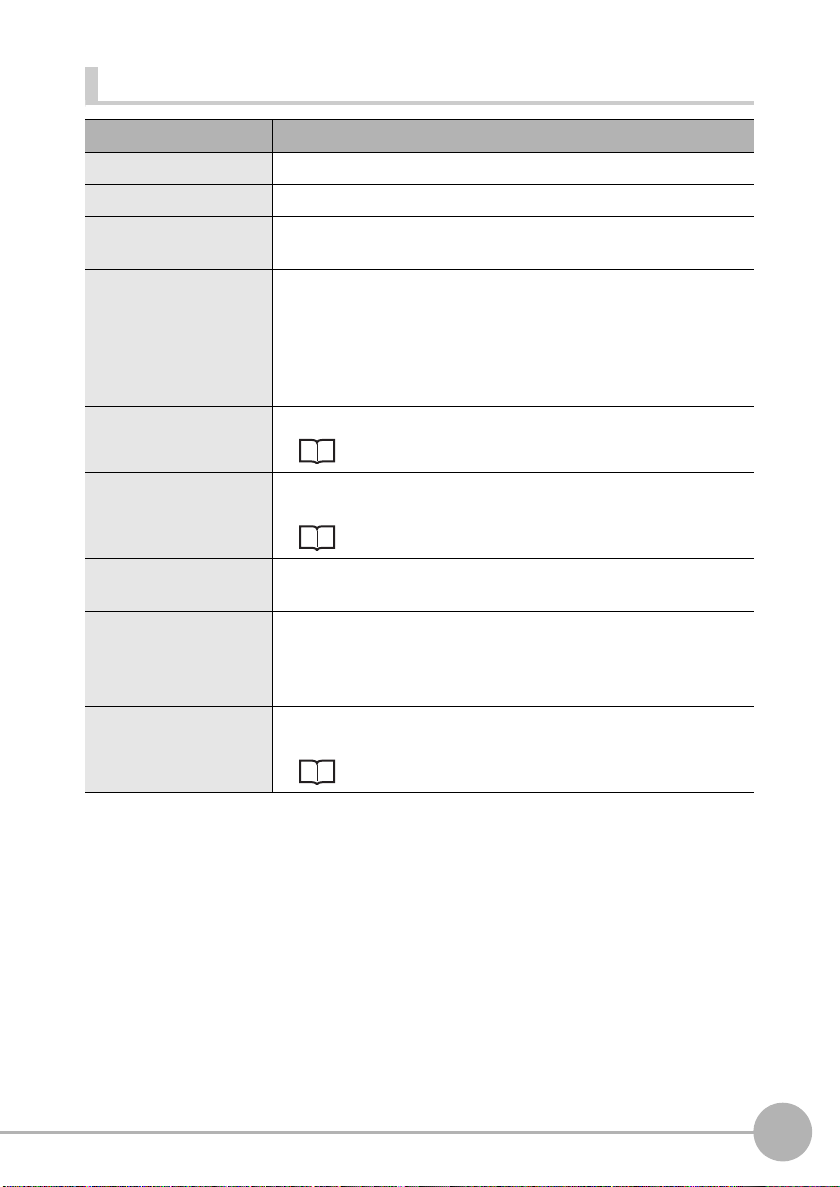

Interface Unit

Connector Display

(3)

(2)

(1)

(2)

(1)

(4)

(3)

(4)

Connector

Name Function

(1) RS-232C connector The RS-232C connector is for connecting the Controller to external

(2) Controller connector This connector is for connecting the ZX-GTC Controllers.

(3) Binary output cable This cable connects external devices such as a PLC so that

(4) Rear switch This switch is not used during measurement. Be sure to leave this

devices, such as a PC or a PLC.

measurement data is output in binary.

switch at its default setting (position in figure below). If this switch

setting is changed, the communications functions will be changed

and the Controller will not operate correctly.

Display

Name Function

(1) Power ON indicator The power ON indicator lights while the power is ON.

(2) Controller

(3)

(4) RS-232C

24

ZX-GT Series

communications

indicator

Binary output indicator

communications

indicator

BUSY: This indicator lights when communications commands are

being issued to the Controller.

ERR : This indicator lights if an error occurs during

communications with the Controller.

This indicator lights during binary output.

BUSY: This indicator lights when RS-232C communications is in

progress.

ERR : This indicator lights if an error occurs during RS-232C

communications.

ZX-GT User’s Manual

Page 27

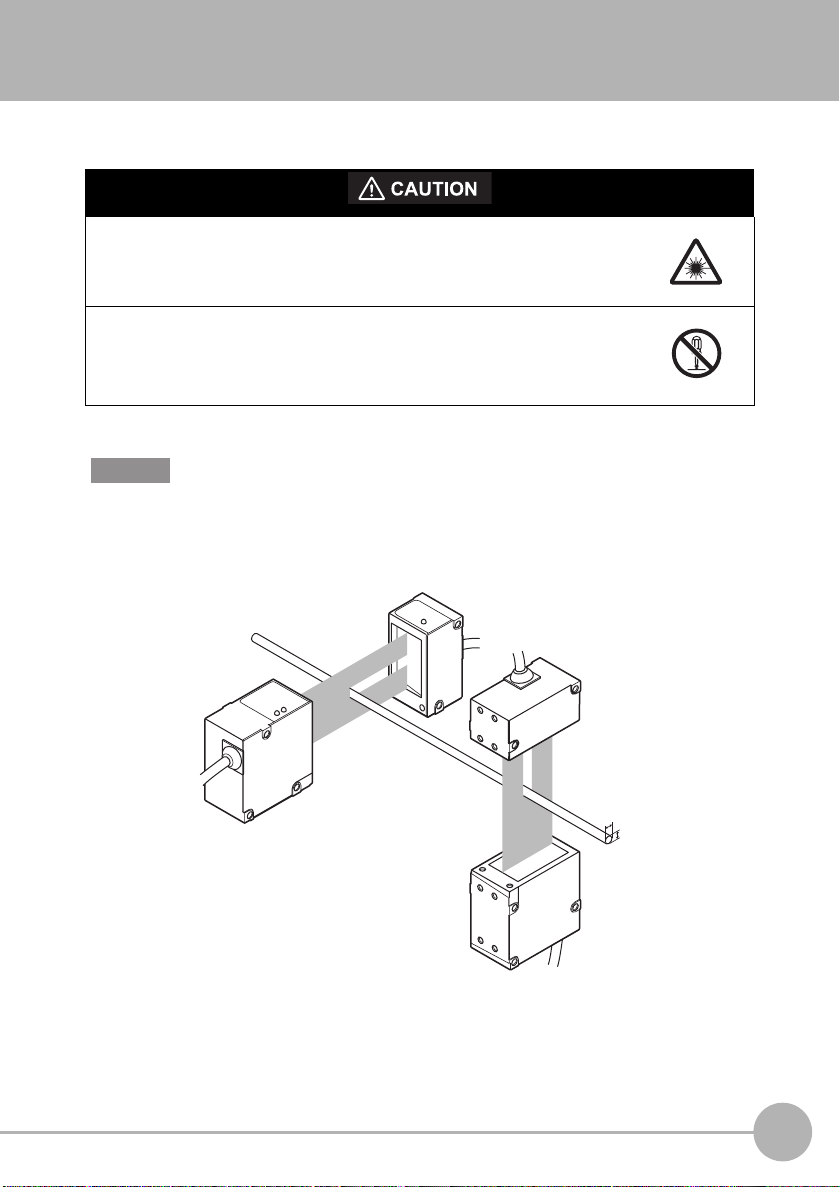

Mounting and Connecting Devices

Mounting the Sensor

Never look into the laser beam. Doing so continuously will result in

visual impairment.

Do not attempt to dismantle, pressurize, or incinerate the product. Doing

so may cause the laser beam to leak, resulting in the danger of visual

impairment.

Important

If a measurement target has a shiny surface, reflected light might adversely influence adjacent

Sensors. Mount the Sensor so that it is not influenced by reflected light.

Example: XY cross measurement

Place the Sensors so that their optical axes do not overlap each other.

1

BEFORE USE

ZX-GT User’s Manual

X

Y

Mounting and Connecting Devices

25

Page 28

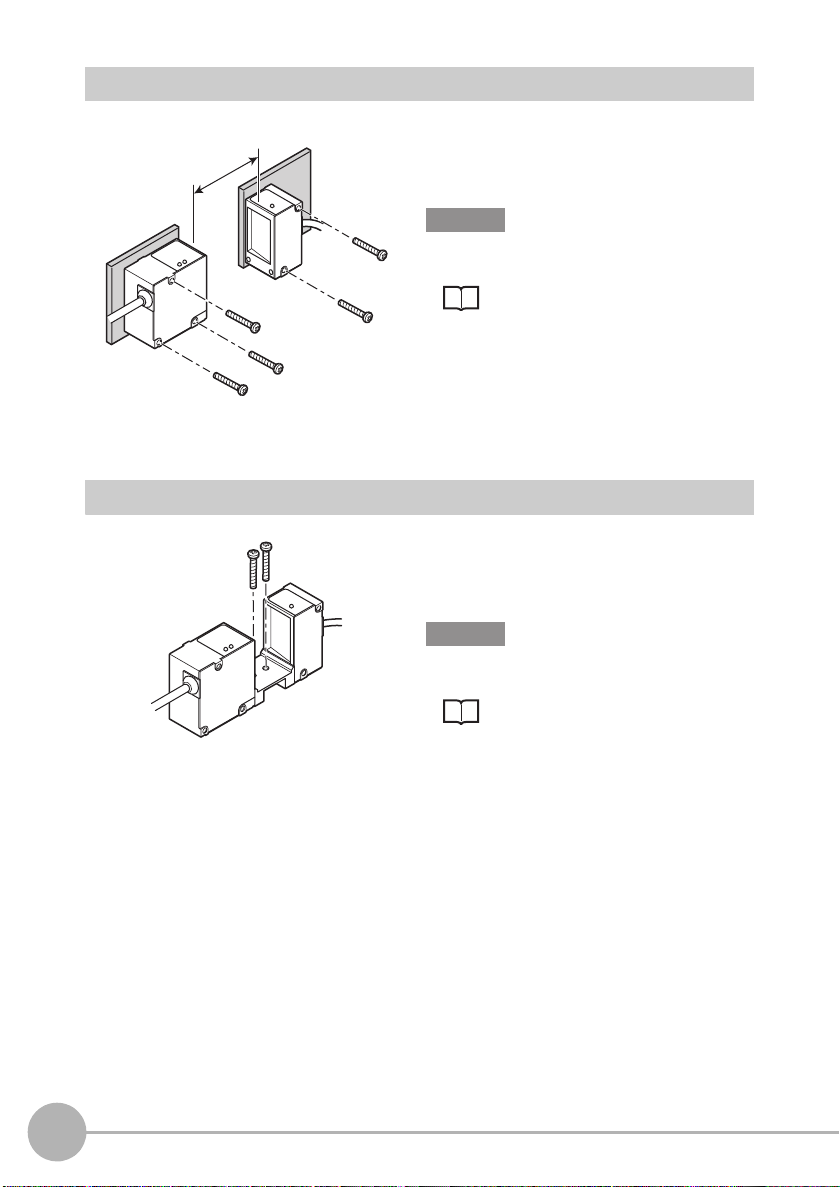

Separate Type (Emitter and Receiver)

Fix the Sensor onto the mounting base with

M4 screws.

0 to 500 (mm)

Tightening torque: 1.2 N•m

Important

For details on the positions of screw holes, check

the external dimensions in "5 APPENDICES."

Integrated Type

Fix the Sensor onto the mounting base with

M3 screws.

Tightening torque: 0.5 N•m

Important

For details on the positions of screw holes, check

the external dimensions in "5 APPENDICES."

• External dimensions p.131

• Adjusting the Optical Axis p.42

External dimensions p.132

26

Mounting and Connecting Devices

ZX-GT User’s Manual

Page 29

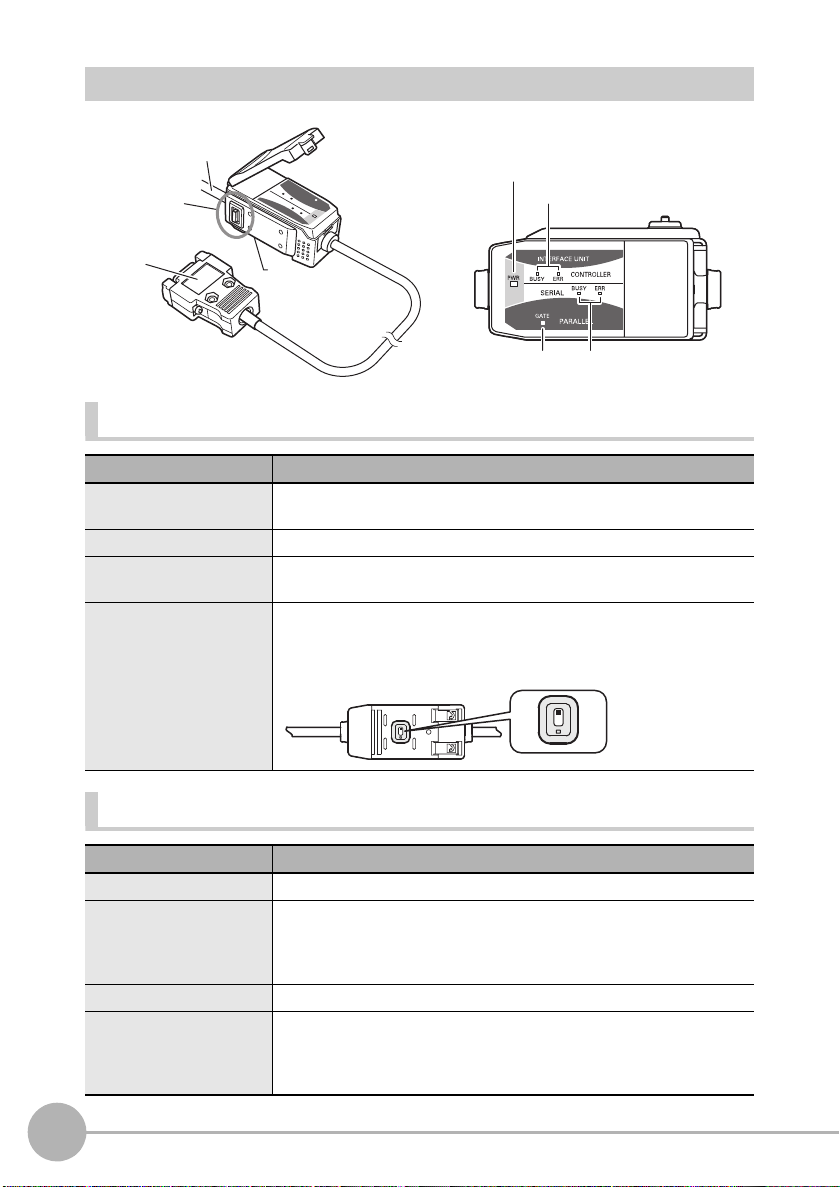

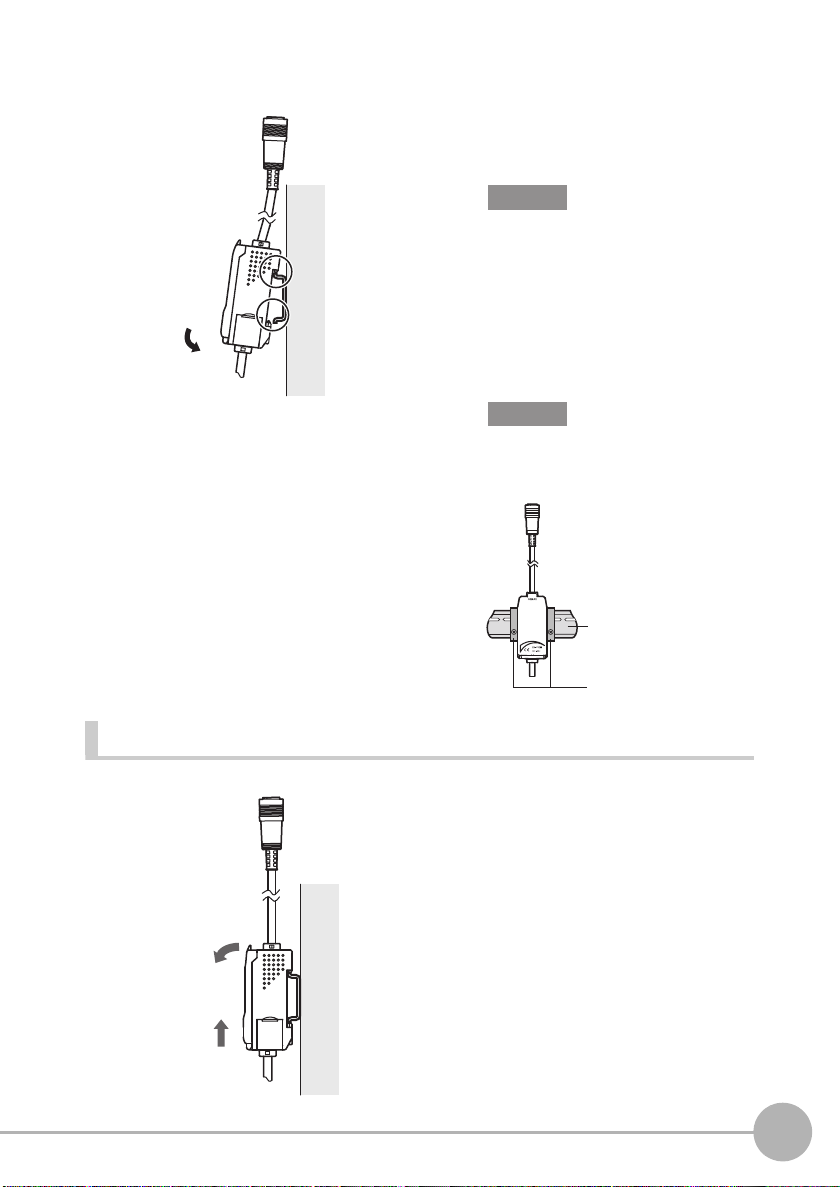

Mounting the Controller

1

1 Hook the connector end of the

Controller onto the DIN track.

Important

Always hook the connector end of the

Controller onto the DIN track first. Mounting

strength may decrease if the I/O cable end

is hooked onto the DIN track first.

1

BEFORE USE

Removal

2

2

2 Push the Controller down onto

the DIN track until the hook on the

I/O cable side is locked.

Important

After mounting the Controller on the DIN

track, attach the end plates (sold

separately) on both sides of the Controller.

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

End plate

1 Push the Controller up towards

the connector side.

2 Lift up the Controller from the

connector end, and remove it

from the DIN track.

1

ZX-GT User’s Manual

Mounting and Connecting Devices

27

Page 30

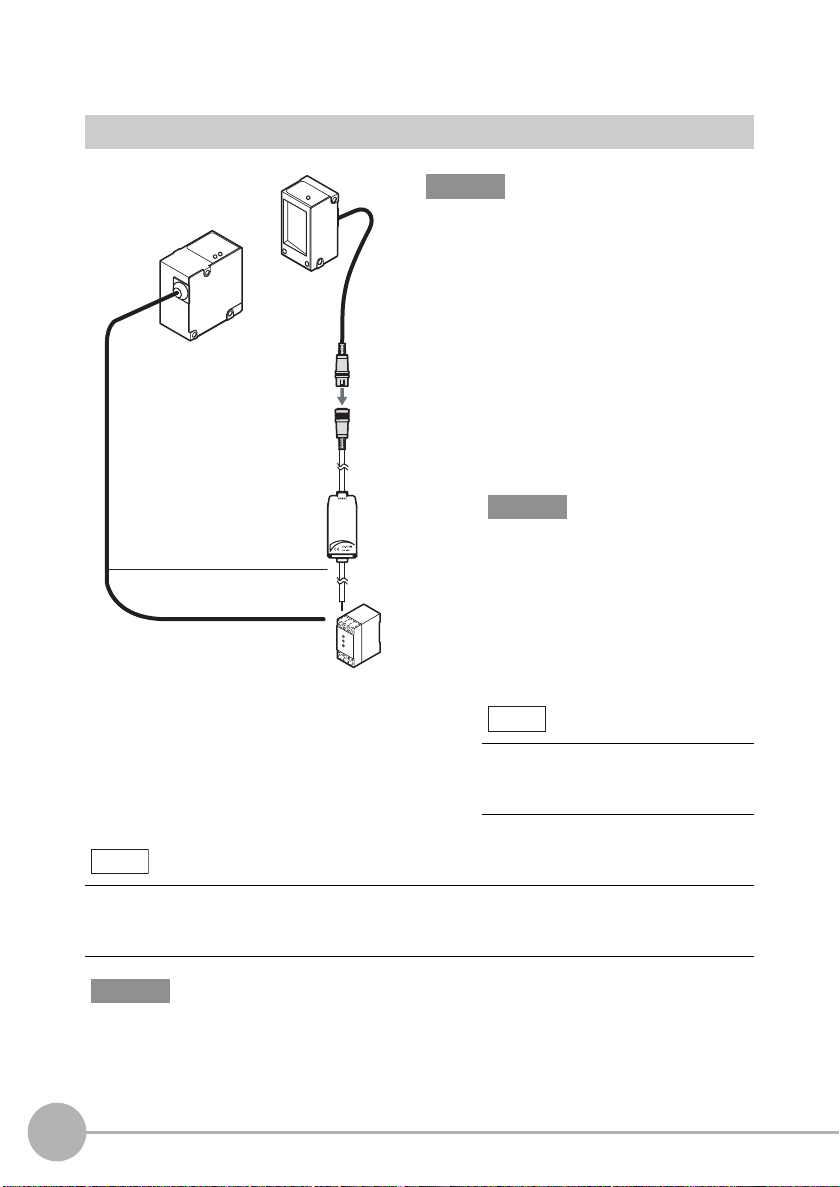

Connecting Devices

3

Connecting Devices in the Basic Configuration

Important

Before connecting/disconnecting the Sensor, make

sure that the Controller is turned OFF. The

Controller may break down if the Sensor is

connected or disconnected while the power is ON.

1 Insert the receiver connector into

the Controller connector.

1

2

3

Note

When the measurement cycle has been changed to the high-speed mode (FAST), wiring of

the sync wires is not required. Note, however, that the Controller becomes more susceptible

to the influence of ambient light in this case.

2 Connect the Controller and

Sensor sync wires.

Controller sync output wire : yellow

Emitter sync input wire : red

Important

The Controller's default mode is the

standard mode. Measurement is not

possible without the sync wires connected.

3

Connect the power wire (brown)

and the GND wire (blue) of the

emitter and the Controller I/O cable.

Note

The following power supply is

recommended:

• S8VS-03024 (24 VDC, 1.3 A)

Important

Do not mount the Controller in such a way that a load is steadily applied on the connector, for

example, with tension applied to the cables.

28

Mounting and Connecting Devices

ZX-GT User’s Manual

Page 31

To extend the connection between the receiver and the Controller

The cable connection between the receiver and the Controller can be extended by up to

30 meters using the extension cable (sold separately). The emitter side can be extended

by up to 30 meters by connecting via the terminal block, for example.

Within 30 m

Cable

Cable

Within

30 m

*1: Up to two extension cables can be connected. However, be sure to limit the total extension cable length

2 m

Connect via terminal block Connect via terminal block

Other than

sync wire

between the receiver and the Controller to 30 meters (including the receiver cable).

2 m

(The sync wire can be extended by up to 30 meters between

the emitter and the Controller.)

Extension cable

: 1 m, 2 m, 5 m, 8 m, 20 m

ZX-XGC__A (standard cable)

ZX-XGC__R (flexible cable)

Sync wire

Within 26 m

(*1)

Cable

0.2 m

Cable

2 m

Other than

sync wire

Wiring the Sensor (emitter)

Wiring diagram

Brown

Blue

Orange

Red

Names and functions

Cable color

Brown Power supply

Blue GND (0V) This is the power supply 0 V terminal.

Orange

Red Laser OFF

Name Function

This is the power supply terminal. Connect the 24 VDC power

(24 VDC)

supply to this terminal.

When using a PNP type Controller, the power supply terminal is

also the common terminal for all I/O.

When using an NPN type Controller, the power supply terminal is

also the common terminal for all I/O.

Laser deterioration

alarm output

This output turns ON when the semiconductor laser deteriorates.

Replace the Sensor when this output turns ON.

Laser emission stops when this output turns ON.

input/sync

input

Synchronized operation is available with this wire connected to the

Controller's sync output, and the influence of ambient light can be reduced.

Laser output can also be turned OFF with this input short-circuited to 0

V (24 V in the case of a PNP type Controller) in this connection state.

Power supply (24 VDC)

GND (0 V)

Laser deterioration alarm output

Laser OFF input/sync input

Within

10 m

1

BEFORE USE

ZX-GT User’s Manual

Mounting and Connecting Devices

29

Page 32

Wiring the Controller

Wiring diagram

Brown

Blue

White

Green

Gray

Co-axial (black)

Co-axial (shield)

Pink

Orange

Purple

Red

Yellow

Light blue

Black

Power supply (24 V)

GND (0 V)

HIGH

PASS

LOW

Analog output

Analog GND

Bank switching input

Zero reset input

Timing input

Reset input

Sync output

Unused

Unused

4 output

terminals

4 input

terminals

Important

• Use a stabilized power supply separate from other devices and power systems for the

Controller, particularly when high resolution is required.

Recommended power supply p.28

• Wire the Controller correctly. Otherwise, the Controller may be damaged. (Pay particular

attention to prevent contact between the analog output and other wires.)

• Use the blue wire (GND (0 V)) for the power supply, and the shielded wire sheath (analog

GND) together with the black wire (analog output) for analog output. Connect analog GND to

GND (0 V) even when analog output is not used.

Names and Functions

Cable color

Name Function

Brown Power supply

(24 V)

Blue GND (0 V)

Co-axial

Analog GND Connect this cable to the input device as the GND for analog output.

(shield)

Yellow Sync output

Assignments and Functions of I/O Signal Wires p.91

30

Mounting and Connecting Devices

This is the power supply terminal. Connect the 24 VDC power supply to

this terminal. When using a PNP type Controller, the power supply

terminal is also the common terminal for all I/O excluding analog output.

This is the power supply 0 V terminal. When using an NPN type Controller,

this terminal is also the common terminal for all I/O excluding analog output.

Normally, wire this cable directly to the sync input wire and run the

Controller in the standard mode (NORM). When the Controller is run in

the high-speed mode (FAST), operation is possible without wiring this

cable. (Note that, in the high-speed mode, the Controller becomes more

susceptible to the influence of ambient light than in the standard mode.)

ZX-GT User’s Manual

Page 33

Wiring the Interface Unit Output Cables

Light blue

Red/white

Black

Yellow

Brown

Blue

Pink

Gray

Green

White

Orange

Red

Purple

Bright green

Assignments and Functions of Output Signal Wires p.93

GATE

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Unused

Binary output

1

BEFORE USE

ZX-GT User’s Manual

Mounting and Connecting Devices

31

Page 34

Sensor (emitter) I/O Circuit Diagrams

NPN type Controller (ZX-GT28E11)

Brown

24 VDC

Internal circuit

PNP type Controller (ZX-GT28E41)

Internal circuit

Orange

Blue

Red

Shielded

Brown

Orange

Blue

Laser deterioration

alarm output

GND (0 V)

Laser OFF input/

sync input

24 VDC

Laser deterioration

alarm output

GND (0 V)

Load

24 VDC

Shield not connected internally

Load

24 VDC

32

Mounting and Connecting Devices

Red

Shield

Laser OFF input/

sync input

Shield not connected internally

ZX-GT User’s Manual

Page 35

Controller I/O Circuit Diagrams

Important

Make sure that the load connected to "analog output wire (co-axial) - analog GND wire"

satisfies the rating of the set state (voltage or current output) before turning the Controller ON.

Otherwise, the Controller may be damaged.

NPN type Controller (ZX-GTC11)

Brown

24 VDC

1

BEFORE USE

Internal circuit

Voltage/Current

switch

Current output

4 to 20 mA

Voltage output

±4 V

Output resistance

100 Ω

HIGH

White

judgment output

Green

PASS judgment output

Gray

LOW judgment output

Blue

GND (0 V)

Pink

Bank switching input

Timing input

Purple

Orange

Zero reset input

Red

Reset input

Co-axial (black)

Co-axial (shield)

Yellow Sync output

Light blue

Black Unused

Analog output

Analog GND

Unused

Load Load Load

Load

24 VDC

Current output: 300 Ω or less

Voltage output: 10 kΩ or more

ZX-GT User’s Manual

Mounting and Connecting Devices

33

Page 36

PNP type Controller (ZX-GTC41)

Brown

24 VDC

White

HIGH judgment output

PASS judgment output

Green

LOW judgment output

Gray

Internal circuit

Voltage/Current

switch

Current output

4 to 20 mA

Voltage output

±4 V

Output resistance

100 Ω

Load Load Load

GND (0 V)

Blue

Bank switching input

Pink

Timing input

Purple

Orange

Zero reset input

Red

Reset input

Co-axial (black)

Co-axial (shield)

Yellow Sync output

Light blue Unused

Black Unused

Analog output

Analog GND

24

VDC

Current output: 300 Ω or less

Load

Voltage output: 10 kΩ or more

34

Mounting and Connecting Devices

ZX-GT User’s Manual

Page 37

Interface Unit I/O Circuit Diagrams

The following circuit configurations are used for data outputs (D0 to D11) and the total of

13 GATE signal outputs.

NPN type

Internal circuit

Bright green

Light blue

Red/white

Black D10

Yellow D9

Brown D8

Blue D7

Pink D6

Gray D5

Green D4

White D3

Orange

Red D1

Purple

GATE

D11

D2

D0

Unused

Same as D0 circuitSame as D0 circuit

Load

1

BEFORE USE

Controller

ZX-GT User’s Manual

Blue GND (0)

12 to 24 VDC

Brown

Mounting and Connecting Devices

35

Page 38

PNP type

Controller

Internal circuit

12 to 24 VDC

Brown

Blue GND (0 V)

Red/white

D11

Black D10

Yellow D9

Brown D8

Blue D7

Pink D6

Gray D5

Green D4

White D3

Orange

D2

Red D1

Purple D0

Load

Same as D0 circuitSame as D0 circuit

36

Mounting and Connecting Devices

Light blue

GATE

Bright green

Unused

ZX-GT User’s Manual

Page 39

Connecting Controllers to Each Other

Controllers are connected to each other via a Calculating Unit.

The number of Controllers that can be connected to each other is as follows:

• When calculating Controller measured values: three Controllers

Calculation can be performed on two of these

Controllers. (One of the calculation targets

must always be CH1.)

• When multiple points are measured and are collectively output from the Interface Unit:

three Controllers or less

1

BEFORE USE

2

1 Open the Controller connector

cover by lifting and sliding it up.

2 Mount the Calculating Unit on a

DIN track.

4

3

1

1

3 Slide the Calculating Unit

and insert it into the connector on

the Controller.

4 Slide the Controller to insert it

into the connector on the

Calculating Unit.

Important

• Provide power to all connected Controllers.

• Connect the emitter sync wires to the respective Controllers.

• Wiring the Sensor (emitter) p.29

• Wiring the Controller p.30

ZX-GT User’s Manual

Mounting and Connecting Devices

37

Page 40

Connecting Interface Units

When outputting measurement data in binary or performing RS-232C communications,

attach the Interface Unit (sold separately).

1 Open the Controller connector

2

cover by lifting and sliding it up.

2 Mount the Interface Unit on a DIN

track.

3

Note

The channel Nos. when Controllers are connected to each other are arranged as follows from

the right "CH1, CH2, CH3".

Note

The RS-232C cable can be fixed to devices, for example, using the cable clamp supplied with

the Controller.

Channels Nos. when Controllers are connected to each other

Interface

Unit

Cable clamp provided with the Controller

Controller

CH3 CH2 CH1

1

Installation

3 Slide the Interface Unit to insert it

into the connector on the

Controller.

38

Mounting and Connecting Devices

Removal

Lift up the tab.

ZX-GT User’s Manual

Page 41

Initializing Controller Settings

Important

The settings of all banks and system settings are initialized regardless of the currently selected

bank No. To save these settings, back them up to a personal computer using the SmartMonitor

GT (ZX-GSW11) before performing initialization.

Default States p.142

1 Initialize Controller settings.

Select [INIT].

Hold down to confirm the selection.

During initialization of the Controller settings,

"-----" is displayed one digit at a time.

When initialization is completed, [OK] is displayed.

SUB

SUB

1

BEFORE USE

ZX-GT User’s Manual

Initializing Controller Settings

39

Page 42

MEMO

40

Initializing Controller Settings

ZX-GT User’s Manual

Page 43

BASIC OPERATIONS

Setting Measurement Conditions FUN Mode 42

Adjusting the Optical Axis and Registering the

Standard Received Light Intensity 42

Selecting the Measurement Mode 44

Setting Thresholds - T Mode 45

Functions and Operations during Operation RUN Mode

Switching the Measured Value Display 46

Executing and Canceling a Zero Reset 47

2

BASIC OPERATIONS

46

Page 44

Setting Measurement Conditions

- FUN Mode

Adjusting the Optical Axis and Registering

the Standard Received Light Intensity

When using an integrated Sensor, adjustment of the optical axis in step 3 is not required.

Important

Connect the Controller and Sensor sync wires.

• Wiring the Sensor (emitter) p.29

• Wiring the Controller p.30

1 Switch to the optical axis adjustment mode.

Select [ALIGN].

SUB

2 Switch to the received light balance display to

show received light balance and light

intensity.

Confirm the selection.

SUB

3 Adjust the emitter while verifying the light intensity.

• Adjusting the received light intensity while

viewing the receiver

Move the emitter in the four directions (left, right,

top and bottom) to adjust the received light

intensity until the optical axis setting indicator

(green) on the receiver lights.

42

Setting Measurement Conditions - FUN Mode

Emitter Receiver

Optical axis

setting indicator

ZX-GT User’s Manual

Page 45

• Adjusting the received light intensity while

viewing the Controller

(1) Received light intensity

The received light intensity is displayed as a

numerical value.

Standard mode (NORM): about 70 or more

High-speed mode (FAST):about 100 or more

Move the emitter to the left and right to adjust

the received light intensity until the display

indicates the above values.

(2) Received light balance

The received light balance of the CCD is displayed.

• When one of the sides of the display is missing

SUB

Received light balance

Received light intensity

2

Move the emitter in the direction in which the

display is missing to adjust.

• When both sides of the display are missing

• Insufficient received light intensity?

Move the emitter to the left and right to increase

the received light intensity.

• Sync output wired?

Wire the Controller sync output and Sensor

sync input.

• When the center of the display is missing

• Insufficient received light intensity?

Move the emitter to the left and right to increase

the received light intensity.

• Dirty emitter surface or object blocking light path?

Clean the emitter surface or remove object

blocking light path.

Note

The received light waveform can be observed in more detail on the exclusive PC

software (SmartMonitor GT (ZX-GSW11)).

4 Register the standard received light intensity.

Hold down for at least three seconds.

When registration of the standard received light intensity ends normally, [OK] is

displayed on the sub-display after "-----".

When registration of the standard received light intensity fails, an error is displayed.

BASIC OPERATIONS

Standard Received Light Intensity Registration Errors p.141

ZX-GT User’s Manual

Setting Measurement Conditions - FUN Mode

43

Page 46

Selecting the Measurement Mode

Select the measurement mode matched to your specific measurement requirements from

the FUN mode menu.

Specific Measurement Requirement and Measurement Mode Used p.50

The following describes, as an example, the basic operation procedure for measuring the

outer diameter.

1 Select the measurement mode.

Select [MODE].

Select [DIA].

Confirm the selection.

44

Setting Measurement Conditions - FUN Mode

SUB

ZX-GT User’s Manual

Page 47

Setting Thresholds - T Mode

In this mode, set the measured values for a PASS (OK) judgment. Both HIGH and LOW

threshold values are set. Three judgment results are output; "HIGH", "PASS" and "LOW".

HIGH threshold

Measured value

LOW threshold

ON

HIGH

OFF

PASS

LOW

ON

OFF

ON

OFF

Output

Note

In the special mode (IC lead pitch or IC lead width judgment mode), the following values are

output:

HIGH:Standard value setting

LOW: Tolerance setting

Measurement Cycle p.61

(ON when measured value > HIGH threshold)

(ON when LOW threshold ≤ measured value

≤ HIGH threshold)

(ON when measured value < LOW threshold)

2

BASIC OPERATIONS

The following describes, as an example, the operation procedure for setting a HIGH threshold.

1 Set the value.

Move from one digit to another.

Change the current value.

SUB

Measured

value

Threshold

Confirm the selection.

Note

Hysteresis can also be set for threshold values. Set hysteresis when judgments are unstable.

Hysteresis p.67

ZX-GT User’s Manual

Setting Thresholds - T Mode

45

Page 48

Functions and Operations during Operation

- RUN Mode

Switching the Measured Value Display

You can switch between the main display and sub-display while operating the Controller

in the RUN mode. This allows you to verify thresholds, resolution and other settings while

viewing measured values according to your specific application.

The measured value is displayed on the main display, and thresholds and other

information are displayed on the sub-display.

SUB SUB SUB

Threshold

*1: In the IC lead pitch and IC lead width judgment modes, standard values and tolerances are displayed

according to the threshold switch setting.

*2: In the IC lead pitch and IC lead width judgment modes, "0V" is displayed at all times.

*3: In the IC lead pitch and IC lead width judgment modes, "4mA" is displayed at all times.

*4: In the IC lead pitch and IC lead width judgment modes, "-----" is displayed at all times.

Special mode p.50

(*1) (*2) (*3)

SUB SUB

Present value

Voltage value Current value

Resolution

(*4)(*4)

46

Functions and Operations during Operation - RUN Mode

ZX-GT User’s Manual

Page 49

Executing and Canceling a Zero Reset

When the zero reset function is used, the measured value can be reset to a reference

value of 0 when the ENT key is pressed or an external signal is input.

Executing/Canceling a Zero Reset by External Signal Input p.126

When the Controller is turned OFF, all settings are cleared from memory (i.e. are returned

to their defaults). This setting can also be changed so that settings are saved in memory

when the power is turned OFF.

Zero Reset Memory p.82

Executing zero reset

1 Set the measurement object to be used as the reference in place.

2 Execute the zero reset.

Hold down for at least one second.

SUB

The zero reset indicator lights, and the current

measured value is registered as "0" (zero).

Note

A value other than 0 can also be set.

Zero Reset Memory p.82

Canceling zero reset

2

BASIC OPERATIONS

1 Cancel the zero reset.

Hold down the R key for at least three

seconds with the ENT key held down.

The zero reset indicator goes out.

ZX-GT User’s Manual

SUB

Functions and Operations during Operation - RUN Mode

47

Page 50

MEMO

48

Functions and Operations during Operation - RUN Mode

ZX-GT User’s Manual

Page 51

FUNCTION SETTINGS

Settings Matched to Specific Measurement Requirements

Specific Measurement Requirement and

Measurement Mode Used 50

Explanation of Measurement Modes 52

50

Adjusting Detection Conditions 61

Measurement Cycle 61

Number of Samples to Average 62

Binary Level 63

Edge Filter 64

Setting Output Conditions 65

Judgment output timing (timer) 65

Hysteresis 67

Analog Output Conditions 68

Setting Hold Functions 73

Hold 73

Delay Hold 75

Changing Display Conditions 77

Reversing the Display 77

Changing the Number of Display Digits 78

Adjusting the Display Brightness (ECO mode) 79

Setting Communication Conditions 80

RS-232C Communications Specifications 80

Setting the Binary Output Cycle 81

Special Functions 82

Zero Reset Memory 82

Display during a Zero Reset 83

Key Lock 84

Switching Banks 85

Displaying the System Version 87

3

FUNCTION SETTINGS

Page 52

Settings Matched to Specific Measurement Requirements

Specific Measurement Requirement and Measurement Mode Used

Mode Used

Edge position

Center position

Position

Thin wire position

Outer diameter

dimension

Gap

Specified edge

measurement

Dimension

Thick diameter

Regular positioning

Position of round bar

Position of wire

Round bar diameter

Internal diameter measurement

Can be freely specified.

1

2

3

4

5

6

Measuring between 2 sensors

Interrupted beam width measurement mode

SUB

Incident beam width measurement mode

SUB

Center position measurement mode

SUB

Wire position measurement mode

SUB

Outer diameter measurement mode

SUB

Incident beam width measurement mode

SUB

Specified edge measurement mode

SUB

Calculation of measurement results

Glass edge

position

IC lead pitch

Special

Special

IC lead width

50

Settings Matched to Specific Measurement Requirements

SUB

Glass edge measurement mode

SUB

IC lead pitch judgment mode

SUB

IC lead width judgment mode

SUB

ZX-GT User’s Manual

Page 53

ReferenceExplanation

The width up to the end of the first interrupted beam section is measured.

The width up to the end of the first incident beam section is measured.

The width from the top edge of the beam up to the center of the first

and last edges of the measurement object is measured.

Thin wire of up to 0.1 mm in diameter is measured. Measurement

details are the same as

mode."

The width from the first edge of the measurement object up to the last

edge is measured.

The width up to the end of the first incident beam section is measured.

The width between two specified edges is measured.

The interrupted beam width of two Sensors is calculated to measure the

diameter.

those for the "center position measurement

p.52

p.52

p.58

3

p.53

FUNCTION SETTINGS

p.58

p.53

p.52

p.56

The edge position of glass sheets is measured. In this mode, the

distance from the beam top edge to the edge of the transparent

material is measured

The distance between IC lead centers is measured, and whether or not

the pitch is within the tolerance is judged.

The IC lead width (multiple IC leads OK) is measured, and whether or

not the diameter is with

ZX-GT User’s Manual

.

in the tolerance is judged.

Settings Matched to Specific Measurement Requirements

p.59

p.54

p.55

51

Page 54

Explanation of Measurement Modes

Interrupted Beam Width Measurement Mode [DK.WID]

This mode is for measuring the width up to

the end of the first interrupted beam section.

How to select the measurement

mode p.44

SUB

Note

In cases such as the following, the width of the first interrupted beam section is measured

from the side of the Sensor where the LED is located.

This width is measured.

Beam

Incident Beam Width Measurement Mode [LT.WID]

light

Received

This mode is for measuring the width up to

the end of the first incident beam section.

How to select the measurement

mode p.44

SUB

Note

In cases such as the following, the width of the first incident beam section is measured from

the side of the Sensor where the LED is located.

This width is measured.

Beam

52

Settings Matched to Specific Measurement Requirements

light

Received

ZX-GT User’s Manual

Page 55

Outer Diameter Measurement Mode [DIA]

This mode is for measuring the width from

the first edge of the measurement object up

to the last edge.

How to select the measurement

mode p.44

SUB

Note

In cases such as the following, the width from the first edge up to the last edge is measured

from the side of the Sensor where the LED is located.

3

Beam

light

Received

This width is measured.

Center Position Measurement Mode [POSN]

This mode is for measuring the width from the

top edge of the beam up to the center of the

measurement object.

How to select the measurement

mode p.44

SUB

Note

In cases such as the following, the width from the first edge up to the center of the first and

last edges is measured from the side of the Sensor where the LED is located.

This width is measured.

Beam

light

Received

FUNCTION SETTINGS

ZX-GT User’s Manual

Settings Matched to Specific Measurement Requirements

53

Page 56

IC Lead Pitch Judgment Mode [PIN-P]

This mode is for measuring the pitch

between IC leads, and for judging whether

the pitch is within the tolerance.

How to select the measurement

mode p.44

SUB

Description Range

Number of IC leads (A)

IC lead pitch (B) Set the IC lead pitch to be used as the standard. 0.6 to 28 (mm)

IC lead pitch

tolerance

After selecting the measurement mode, make the following settings.

Set the number of IC leads of the measurement object. 2 to 14 (IC leads)

Set the tolerance of the measured value with respect to

the reference value.

0 to 28 (mm)

1 Set the number of IC leads.

Change the selection.

Confirm the selection.

SUB

2

Set the IC lead pitch to be used as the standard.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

3 Set the IC lead pitch tolerance.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

54

Settings Matched to Specific Measurement Requirements

SUB

SUB

ZX-GT User’s Manual

Page 57

IC Lead Width Judgment Mode [PIN-D]

This mode is for measuring the width of

multiple IC leads, and for judging whether

the diameter is within the tolerance.

How to select the measurement

mode p.44

SUB

Description Range

Number of IC leads (A) Set the number of IC leads of the measurement

object.

IC lead width (B) Set the IC lead width to be used as the standard. 0.3 to 28 (mm)

IC lead width tolerance Set the tolerance of the measured value with

respect to the reference value.

After selecting the measurement mode, make the following settings.

1 to 14

(IC leads)

0 to 28 (mm)

1 Set the number of IC leads.

Change the selection.

Confirm the selection.

SUB

3

FUNCTION SETTINGS

2

Set the IC lead width to be used as the standard.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

3 Set the IC lead width tolerance value.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

ZX-GT User’s Manual

Settings Matched to Specific Measurement Requirements

SUB

SUB

55

Page 58

Specified Edge Measurement Mode [EDGE]

This mode is for measuring the width

1

2

3

4

5

6

between two specified edges.

How to select the measurement

mode p.44

SUB

Description Range

Edge No. Set the edge of the measurement

target.

1 to 30, 49, 50

For details, see "How to

count edge Nos."

After selecting the measurement mode, make the following settings.

1 Set the 1st edge.

Change the selection.

Confirm the selection.

SUB

p.57

2 Set the 2nd edge.

Change the selection.

Confirm the selection.

56

Settings Matched to Specific Measurement Requirements

SUB

ZX-GT User’s Manual

Page 59

Note

How to count edge Nos.

General measurement

Edge Nos. are assigned from 1 to 30.

In the specified edge measurement mode, the top edge of the beam is always 1, and the

bottom edge is always the last edge.

Beam

1

2

3

4

5

6

7

Received light

8

Edge No.

Beam

1

2

3

4

5

6

7

Received light

8

Edge No.

Special measurement

How the edge No. is counted differs according to measurement of (a) to (c) in the figure

below.

(a) Width from top edge of beam to last interrupted beam section (distance from edge 1 to

50)

(b) Width from first interrupted beam section to last interrupted beam section (distance from

edge 2 to 50)

(c) Width of last interrupted beam section (distance from edge 49 to 50)

Though edge Nos. are generally assigned within the range 1 to 30, 49 is set when setting the

top edge of the last interrupted beam section, and 50 is set when setting the bottom edge of

the last interrupted beam section.

1

2

Beam

ab

c

49

50

Received light

3

FUNCTION SETTINGS

Edge No.

Important

• Set different edges for the 1st and 2nd edges.

• The 1st and 2nd edges can also be set and measured in the reverse order. Note, however,

that the following restrictions apply:

- The same edge No. cannot be set twice.

- When "49" is set to one edge, be sure to set "50" to the other edge.

- When "50" is set to one edge, be sure to set "1", "2" or "49" to the other edge.

ZX-GT User’s Manual

Settings Matched to Specific Measurement Requirements

57

Page 60

Wire Position Measurement Mode [THIN]

This mode is for measuring thin wire of up to 0.1 mm

in diameter. Measurement details are the same as

those for the "center position measurement mode."

How to select the measurement

mode p.44

Glass Edge Measurement Mode [GLASS]

This mode is for measuring the edge

position of glass sheets. In this mode, the

distance from the beam top edge to the

edge of the glass sheets is measured.

How to select the measurement

mode p.44

SUB

SUB

Setting value Description

TOP Set from which direction the measurement object will be inserted.

BOTTM

TOP (default value)

From side of Sensor on which LED indicator is located

BOTTOM

From side of Sensor on which LED indicator is not located

After selecting the measurement mode, make the following settings.

1 Set the edge detection direction.

Change the selection.

Confirm the selection.

58

Settings Matched to Specific Measurement Requirements

SUB

ZX-GT User’s Manual

Page 61

Calculating the Measurement Result [CALC]

Measurement results can be calculated

between two Controllers. Set the expression

on the Controller having the larger CH No.

The calculation result also is output from the

Controller having the larger CH No.

CH2 CH1

3

Setting value Description

OFF The measurement result is not calculated. (default value)

A+B Calculates the sum of the measurement results for two Controllers.

A-B Calculates the difference between the measurement results for two

Controllers.

WIDTH Measures the width of a large measurement object exceeding 28

mm.

After selecting this value, set a measurement target of known width

to the measured state and enter the width.

Range: 0.00 to 599.99 (mm)

Important

When [WIDTH] is set, the range of the measured value becomes 0.00 to 599.99 mm.

Note

Set the expression on the Controller having the larger CH No.

The calculation result also is output from the Controller having the larger CH No.

One of the calculation targets is always CH1.

When three Controllers are connected to each other

FUNCTION SETTINGS

Output Data List p.90

ZX-GT User’s Manual

Settings Matched to Specific Measurement Requirements

59

Page 62

1 Select the type of calculation.

Select [CALC].

Change the selection.

Confirm the selection.

When [WIDTH] is set

2 Set the width of the standard object.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

SUB

SUB

Note

Flow of measurement during calculation

The value after averaging of each CH is calculated.

CH1 CH2

Measurement processing Measurement processing

Averaging Averaging

2-sensor operation processing

Hold processing Hold processing

Zero reset processing Zero reset processing

Judgment processing Judgment processing

Output processing Output processing

The measurement result is

taken as the analog output.

60

Settings Matched to Specific Measurement Requirements

Hold processing is

executed on measured

result of CH1.

Zero reset processing is

executed on measured

result of CH1.

Judgment processing is

executed on measured

result of CH1.

Calculation results of

CH1 and CH2 are taken

as the analog output.

Data of CH1 is acquired to execute

calculation.

Hold processing is executed on

calculation result.

Zero reset processing is executed on

calculation result.

Judgment processing is executed on

calculation result.

ZX-GT User’s Manual

Page 63

Adjusting Detection Conditions

Measurement Cycle

Normally, set the measurement cycle to the stand ar d m ode [NORM].

If the high-speed mode [FAST] is set, the measurement cycle speeds up but the

Controller become s m or e susceptible to the influence of ambient light.

Setting value Description

NORM (Standard mode) This mode is for performing measurement with laser emission from

the emitter synchronized with the measurement timing of the

receiver. However, the Controller becomes more resistive to the

influence of ambient light. (default value)

Important

Make sure that the Controller and Sensor sync wires are

connected.

FAST (High-speed

mode)

This mode is for performing measurement at high speed. Note,

however, that the Controller becomes more susceptible to the

influence of ambient light.

1 Select the measurement cycle.

Select [SPEED].

Change the selection.

Confirm the selection.

3

FUNCTION SETTINGS

SUB

ZX-GT User’s Manual

Adjusting Detection Conditions

61

Page 64

Number of Samples to Average

The average of the set number of samples can be output as the measured value. Set this

function to disregard sudden changes in the waveform.

Setting value Description

1, 2, 4, 8, 16, 32, 64,

128, 256, 512, 1024,

2048, 4096

Setting the number of samples to average. (default value: 16)

1 Setting the number of samples to average.

Select [AVE].

Change the selection.

Confirm the selection.

SUB

62

Adjusting Detection Conditions

ZX-GT User’s Manual

Page 65

Binary Level

Adjust the binary level to suit the optical transmittance of the measurement object.

Reference settings are as follows:

• Non-transparent object: 25% (default value)

• Transparent object/non-transparent object: 50% or more

Note

When the measurement mode is the wire position measurement mode or the glass edge

measurement mode, the binary level is automatically set to 50%.

Important

The edge detection state changes when the binary level is changed.

The edge detection state can be verified by the EDGEPOS command.

p.123

Setting value Description

25 to 90 (%) Set the binary level. (default value: 25)

3

FUNCTION SETTINGS

1 Select the special setting.

Select [SPCL].

Select [M-LV] or [ALL].

Confirm the selection.

2 Set the binary level.

Select [BIN.LV].

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

ZX-GT User’s Manual

SUB

SUB

Adjusting Detection Conditions

63

Page 66

Edge Filter

CCD

Edge filter: 3

The edge filter for judging the interrupted

beam section can be adjusted to suit your

specific measurement requirements and the

All judged as interrupted beam sections

The Controller becomes

more susceptible to the

noise.

CCD

Though the Controller

becomes more

susceptible to the

influence of noise,

the edge detection

sensitivity increases.

Edge filter: 7

Processed as noise

Judged as interrupted

beam section

measurement object.

On the ZX-GT, the interrupted beam section

is judged according to how many continuous

pixels of the CCD's 2000 pixels in the

receiver are blocked. These continuous

pixels act as the edge filter. By adjusting this

number of edge pixels, you can prevent

noise and increase detection sensitivity.

Setting value Description

3 to 7 (pixels) Set the number of pixels to function as the edge filter.

The setting differs according to the measurement mode.

• When the wire position measurement mode or glass edge

measurement mode is selected

3 to 7 (default value: 4)

• When another measurement mode is selected

7 (fixed)

1 Select the special setting.

Select [SPCL].

Select [M-LV] or [ALL].

Confirm the selection.

2 Set the edge filter.

Select [EG.FLT].

Change the current value.

Confirm the selection.

64

Adjusting Detection Conditions

SUB

SUB

ZX-GT User’s Manual

Page 67

Setting Output Conditions

Judgment output timing (timer)

The timing for judgment outputs can be adjusted to match the operation of external

devices.

Setting value Description

OFF Outputs the judgment as soon as the judgment result has been

confirmed. (default value)

Measured value

HIGH threshold

LOW threshold

HIGH output

PASS output

LOW output

OFF-D (OFF delay) After the judgment result has been confirmed, delays the time required

for the PASS output to turn OFF by the time set to timer. (Also delays

turning OFF the HIGH and LOW outputs.)

HIGH threshold

LOW threshold

HIGH output

PASS output

LOW output

ON

OFF

ON

OFF

ON

OFF

Measured value

ON

OFF

ON

OFF

ON

OFF

Time set to timer

3

FUNCTION SETTINGS

ON-D (ON delay) After the judgment result has been confirmed, delays the time required

for the PASS output to turn ON by the time set to timer. (Also delays

turning ON the HIGH and LOW outputs.)

Measured value

HIGH threshold

LOW threshold

HIGH output

PASS output

LOW output

ZX-GT User’s Manual

ON

OFF

ON

OFF

ON

OFF

Time set to timer

Setting Output Conditions

65

Page 68

Setting value Description

1-SHT (One-shot) When the measured value changes from HIGH to PASS or from LOW

to PASS, turns ON the PASS output with a pulse width equivalent to the

time set to the timer. Neither the HIGH nor the LOW output are output.

Range: 0 to 5999 ms

Measured value

HIGH threshold

LOW threshold

HIGH output

PASS output

LOW output

ON

OFF

ON

OFF

ON

OFF

Time set to timer

1 Select the judgment output timing.

Select [TIMER].

Change the selection.

Confirm the selection.

SUB

When other than [OFF] is set

2 Set the timer setting.

Select [T-TIM].

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

66

Setting Output Conditions

SUB

ZX-GT User’s Manual

Page 69

Hysteresis

Set the hysteresis width (difference between operation point and return point) for the

upper and lower limits of the judgments if the HIGH, PASS, or LOW judgment is unstable

near the threshold values.

HIGH threshold

Measured value

LOW threshold

Output

HIGH

PASS

LOW

ON

OFF

ON

OFF

ON

OFF

Hysteresis

Operation point

Return point

Setting value Description

00.000 to 59.999 (mm) Sets the hysteresis width. (default value: 00.100)

1 Select the hysteresis setting.

Select [HYS].

Confirm the selection.

SUB

3

FUNCTION SETTINGS

2 Change the current value.

The sub-display flashes.

Move from one digit to another.

Change the current value.

Confirm the selection.

ZX-GT User’s Manual

Setting Output Conditions

67

Page 70

Analog Output Conditions

Setting Output Scaling

With analog output, the relationship between the displayed measured value and output

value can be freely set as the measurement result is converted to a current of 4 to 20 mA

or a voltage of -5 to +5 V, and is then output. Match the settings to suit the connected

external device.