Omron ZW, ZW-S20, ZW-S40 User Manual

Displacement Sensor

Confocal Fiber Type

ZW Series

User’s Manual

Cat. No.

Z322-E1-01A

Introduction

This manual provides information regarding functions, performance and operating methods that

are required for using the ZW Series.

• The ZW Displacement Sensor must be operated by personnel knowledgeable in electrical

engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

䈲 䈛 䉄䈮 ╙㩷㪈㩷┨ ╙㩷㪉㩷┨ ╙㩷㪊㩷┨ ╙㩷㪋㩷┨

INTRODUCTION

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

㪘㪧㪧㪣㪠㪚㪘㪫㪠㪦㪥㩷㪚㪦㪥㪪㪠㪛㪜㪩㪘㪫㪠㪦㪥㪪㩷㩿㪧㫃㪼㪸㫊㪼㩷㪩㪼㪸㪻㪀

㪤㪜㪘㪪㪬㪩㪜㪤㪜㪥㪫㩷㪪㪜㪫㪬㪧

㪙㪘㪪㪠㪚㩷㪦㪧㪜㪩㪘㪫㪠㪦㪥

㪪㪜㪫㪫㪠㪥㪞㪪㩷㪝㪦㪩㩷㪝㪬㪥㪚㪫㪠㪦㪥㪪

㪠㪆㪦㩷㪪㪜㪫㪫㪠㪥㪞㪪

㪜㫋㪿㪼㫉㫅㪼㫋㪆㪩㪪㪄㪉㪊㪉㪚㩷㪚㪦㪤㪤㪬㪥㪠㪚㪘㪫㪠㪦㪥

Introduction

Chapter 1 Chapter 2 Chapter 3 Chapter 4 Chapter 5 Chapter 6 Chapter 7

㪪㪧㪜㪚㪠㪝㪠㪚㪘㪫㪠㪦㪥㪪㩷㪘㪥㪛㩷㪜㪯㪫㪜㪩㪥㪘㪣㩷㪛㪠㪤㪜㪥㪪㪠㪦㪥㪪

㪘㪧㪧㪜㪥㪛㪠㪯

User's Manual

Confocal Fiber Displacement Sensor

ZW Series

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

ZW

2

User's Manual

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

Introduction

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

User’s Manual

ZW

3

Introduction

Warning

Caution

Meanings of Signal Words

Introduction

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or in property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates general prohibitions for which there is no specific symbol.

Indicates prohibition when there is a risk of minor injury from electrical

shock or other source if the product is disassembled.

Indicates the possibility of fire under specific conditions.

Indicates the possibility of explosion under specific conditions.

Indicates the possibility of LED radiation.

ZW

4

User's Manual

Meanings of Alert Symbols

Warning

Meanings of Alert Symbols

The following alert symbols are used in this manual.

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

Doing so may cause high-voltage section to be exposed, resulting in the

electrical shock, and may cause burn from a high temperature.

Never attempt to disassemble, repair, modify, apply pressure to deform

or burn up the body.

Introduction

Introduction

Caution

Doing so may cause breakdown or ignition.

Do not operate the product in excess of the rated voltage.

Doing so may cause an explosion.

Never operate the product with an AC power supply.

If you keep looking at LED light, in rare cases visual impairment may

occur.

Do not look directly at LED light.

User’s Manual

ZW

5

Introduction

Precautions for Safe Use

Introduction

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

(1) Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

(2) Power Supply and Wiring

• Take care when using a power supply with an overcurrent detector, because this

sensor uses DC-DC converter for its power supply circuit and inrush current may

activate the protective circuit for a power supply with an overcurrent detector.

Recommended power supply: S8VS-06024 (Omron, DC24 V 2.5 A 60 W)

• The supply voltage must be within the rated range (DC24 V ± 10 %).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing them in the same duct may cause induction, resulting in

malfunction or damage.

• Use adequate safety measures, for example fail-safe circuits.

• Attach a specified-sized crimp-type terminal at the end of a wire. Do not connect a

wire with an only twisted end directly to a power supply or terminal block.

• For a power supply, use a DC power supply unit provided with a remedy, for example,

safety ultralow voltage circuit, to prevent a high voltage from being generated.

• Route so that power supply wires are as short as possible.

• Use D-type grounding (ground resistance of 100 or less). Make the ground point as

close as possible and make the ground wire used as short as possible.

• Never a ground wire with other equipment and never ground to building beams. Doing

so could cause negative impacts.

• Use a power supply dedicated for this product, without sharing it with other products.

• Tighten fixing screws securely at a torque specified in this manual.

• Before performing any of the following activities, be sure to turn off the product, or

breakdown may result.

- Connecting or wiring cables

- Connecting or disconnecting connectors

- Installing or removing Calibration ROM

(3) Others

• Do not use this product for nuclear facilities, or safety circuits involving human lives.

• Do not attempt to disassemble, repair, modify, apply pressure to deform or burn up the

body.

• Dispose of this product as industrial waste.

ZW

6

User's Manual

Introduction

Precautions for Safe Use

• Use exclusive devices, including a sensor head, Calibration ROM, fiber cable or RS232C cable, to connect, or ignition, burst, false operation or breakdown may be

caused.

•Do not cut fiber cable. Glass at the cut section may cause injury. Also, if cut, it will not

work normally anymore.

• Whenever any trouble, including, strange odor smelled, the body overheated or

smoke escaped, was found, immediately stop the operation, and consult an OMRON

branch or sales office with the system shut down.

• Do not drop or make a strong impact on the unit.

• Before using any equipment provided with a lock mechanism, make sure that it has

been locked.

(4) Regulations and Standards

This sensor conforms to the following EMC directive and EN standard:

• EMC directive, No. 2004, 108, EC

• EN standard, EN61326

(5) Notice for Korea Radio Law

匏匶匶 ా櫋怺殯愯暧皻柦匶沖沲ి

決匶匶垚櫋怺殯 匏 洊沖砒洇穯匶匶嵢昢砖廪沖

嬖垚斲殯沖垚決洖汊渂汞穞柢匶愚岂彶 儆洛歾汞

滆櫳櫖昢斲殯穞垚冉汊徯洇求嵢穯城埪

Introduction

User’s Manual

ZW

7

Introduction

Precautions for Correct Use

Introduction

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable

effects on product performance.

(1) Installation Site

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85 %

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams, electric arc-welding machines

or ultraviolet shine)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes, spray or mist atmospherics

• Strong magnetic or electric field

(2) Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG

terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit)

and the load current is appropriate. Incorrect wiring may result in breakdown of the

product.

• Use the specified voltage. If voltage exceeding the rating or AC voltage is applied,

circuit parts may be burnt or rupture.

• Use the Extension Fiber Cable (ZW-XF_ _R) for extending the fiber cable between

the Sensor extension fiber cable, five total lengths, 2, 5, 10, 20 or 30 m, are available.

• Handling fiber cables

Use them in compliance with the following.

-Fiber cable bend radiuses must be at least 20 mm.

- Do not let bending cause stress at the root section of a fiber connector.

-Do not yank hard on a fiber cable.

-Do not step on a fiber cable or place anything heavy on it.

• Be sure to use a Sensor Head and Calibration ROM with the same serial number. A

pair with different serial numbers cannot operate normally.

• Use the configuration software with the combination specified in this manual, or the

system may operate faultily.

• Do not shut down the power supply when saving any data into the memory built in the

controller, or the data may be corrupted.

ZW

8

User's Manual

Introduction

Precautions for Correct Use

• While a fiber cable is disconnected, be sure to attach the included protective cap on

both the controller side and the fiber cable side. Leaving the fiber cable with the

protective cap not attached, the optical fiber may fail due to any adhered foreign

matter.

(3) Warming Up

After turning ON the power supply, allow the product to stand for at least 30 minutes

before use. The circuits are still unstable immediately after the power supply is turned

ON, so measured values may fluctuate gradually.

(4) Maintenance and Inspection

Do not use thinner, benzene, acetone or kerosene to clean the Sensor Head, fiber

cable and controller. If large dust particles adhere to the emitter/receiver of the Sensor

Head or controller, use a blower brush (used to clean camera lenses) to blow them off.

Do not blow the dust particles with your mouth.

To remove smaller dust particles, dirt, oil, and fat, wipe gently with a soft cloth (for

cleaning lenses). Do not use excessive force to wipe off dust particles. Scratches on

the emitter/receiver may cause false operations or measuring errors.

For details on the method for cleaning the ends of fiber cables, refer to "Connecting

Fiber Cables" (p.1-15).

Introduction

(5) Sensing Objects

The product sometimes cannot accurately measure the following types of objects:

Transparent objects, objects with an extremely low reflection factor, objects smaller

than the spot diameter, objects with a large curvature, excessively inclined objects,

target objects with a thin film on the surface etc.

(6) Effect caused by peripheral lights

Do not install the Sensor Head in a place where strong light hits the laser emitter/

receiver section of the Sensor Head. Also, if a workpiece has a shiny surface, the light

from the lighting will be reflected and a malfunction may occur. In such a case, prevent

reflection by, for example, covering the light to stop reflection.

p.1-8

(7) Influence by Air Turbulences

Slow air turbulences around the Sensor Head may disperse measured values.

To avoid these possible air turbulences, wrap the Sensor Head with an appropriate

cover.

User’s Manual

ZW

9

Introduction

╙㩷 㩷

╙㪋┨ 䇭㪠㪆㪦⸳ቯ

ജ䈮㑐䈜 䉎⸳ቯ

ജ䈮㑐䈜 䉎 ⸳ቯ

4-12

Chapter 4 I/O SETTINGS

ZW

User’s Manual

Settings for Analog Output

The following describes the settings for outputting the current measurement results from

the analog output of the 20-pole terminal block.

Output destination setting

With analog output, the measurement results can be output converted into a current

from 4 to 20 mA or a voltage from -10 to +10 V.

Selects which to output, the current or the voltage.

The same output destination is set for all banks. The output destination cannot be set separately for

individual banks.

As an example, here is an explanation of the procedure for outputting the voltage.

RUN

FUN

TEACH

L

H L

RUN

RUN

FUN

TEACH

L

ZERORST/

ESC

ZERO/

SET

ZERO/

SET

SET

ZERO/

SET

ZERO/

SET

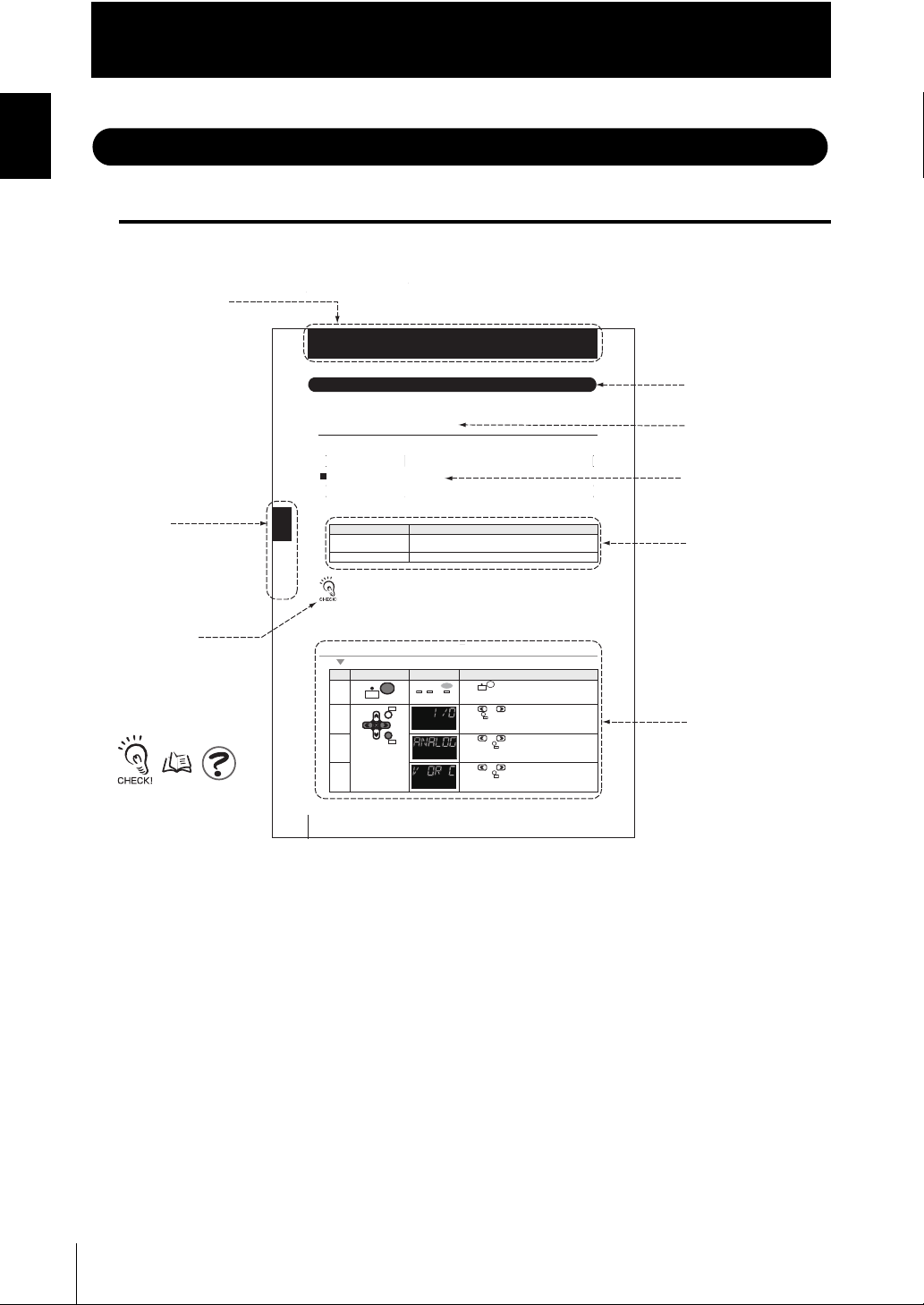

Title of each chapter

Header

Index label

Supplementary

Explanation

Explanation of

Explanation of options

Explanation of

Operating

procedure

Cross-header

Indicates the chapter

number and title.

Helpful information

regarding operation

and reference pages

are introduced here

using symbols.

Quasi Cross-header

Editor's Note

Introduction

Editor's Note

Page Format

Chapter 4

Settings for I/O

Settings for I/O

The following describes settings for I/O.

╙

┨

Setting [Display] Description [Display]

Voltage output [VOLT]

(Default value)

Current output [CUR.] Current output

Voltage output

Operating procedure

Steps

Key operation Display Description

RUN

FUN

TEACH

ESC

ZERORST/

SET

ZERO/

UNLIT

mode.

RUN

press key.

and press

and press key.

RUN

FUN

TEACH

ZERO/

es ot syek ro sserP3 lect either of "ANALOG"

key.

SET

ZERO/

SET

ZERO/

NUF eht retne ot sdnoces owt rof yek sserP1

dna "O/I" fo rehtie tceles ot syek ro sserP2

"C RO V" fo rehtie tceles ot syek ro sserP4

■ Meaning of Symbols

Menu items that are displayed on the main or sub-display, and windows, dialog boxes

and other GUI elements displayed on the personal computer are indicated enclosed by

brackets [ ].

ZW

10

User’s Manual

■ Visual Aids

Mark Means

Introduction

Editor's Note

Introduction

Indicates points that are important to ensure full product performance, such as operational precautions and application procedures.

Indicates pages where related information can be found.

Indicates information helpful in operation.

Optional

Indicates that the setting is optional in a configuration procedure.

User’s Manual

ZW

11

Introduction

Editor's Note

Introduction

Notice

•Photocopying, duplication, or copying of all or part of this manual without permission is

prohibited.

•Please understand that the specifications and other contents of this manual are sub-

ject to change for improvement without notice.

•Every effort has been made to ensure the accuracy of the contents of this manual, but

if you should notice any mistake, questionable section, or the like in this manual,

please contact an OMRON branch or sales office.

•If you do so, please also tell us the manual number, which is found at the end of the

manual.

12

ZW

User’s Manual

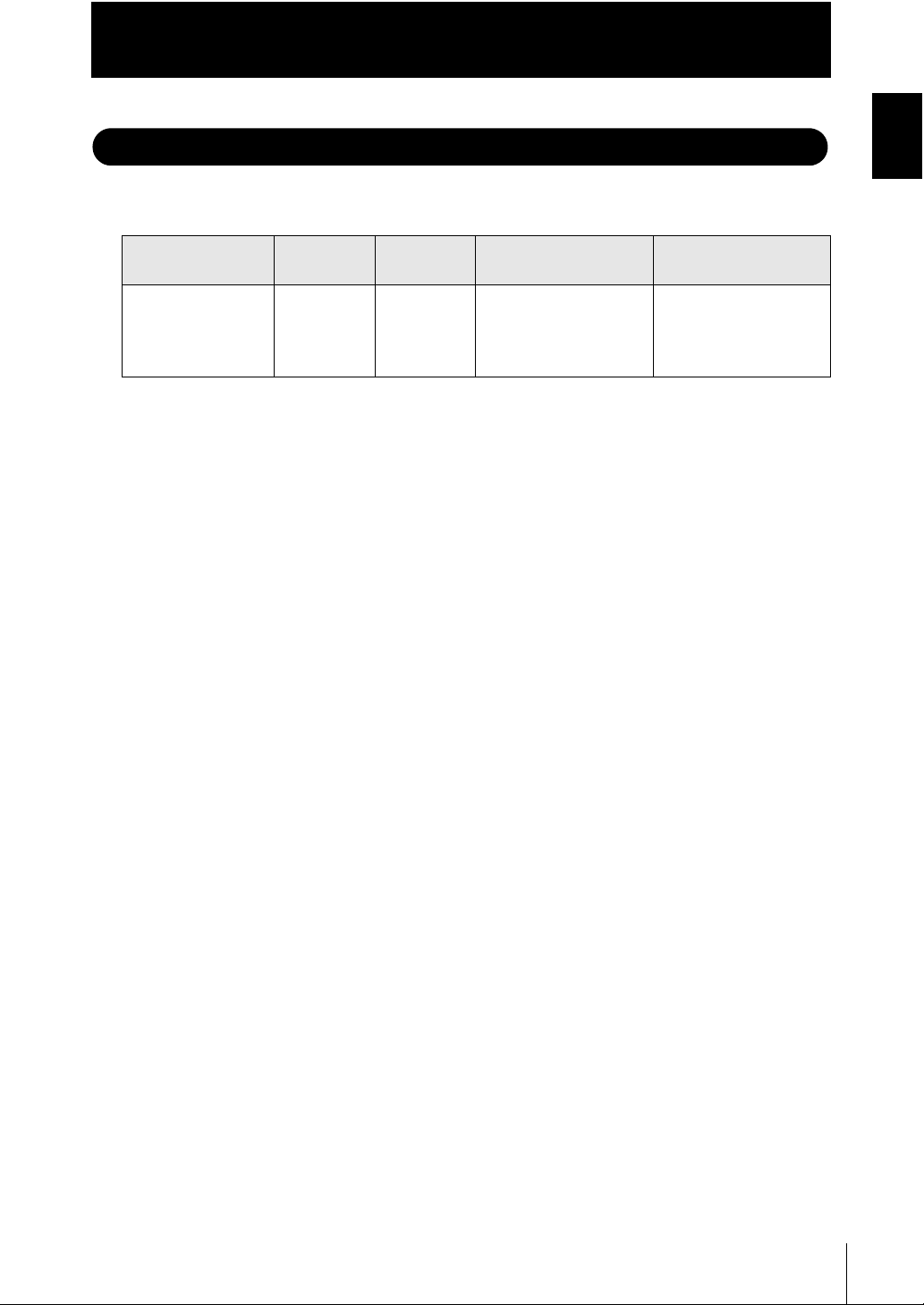

Related Manuals

The following manual is related to the ZW series. Use this manual for reference.

Introduction

Related Manuals

Introduction

Manual name Cat. No.

Smart Monitor ZW

Operation manual

Z323-E1-01 ZW-SW_ _ To learn about the

Model

numbers

Application Description

This describes the

operation methods and

functions of the Smart

Monitor ZW

operation methods for

the Smart Monitor ZW.

User’s Manual

ZW

13

Introduction

Related Manuals

Introduction

14

ZW

User’s Manual

Introduction

CONTENTS

Meanings of Signal Words 4

Meanings of Alert Symbols 4

Meanings of Alert Symbols 5

Precautions for Safe Use 6

Precautions for Correct Use 8

Editor's Note 10

Page Format 10

Notice 12

Related Manuals 13

Search from Menu Tree 20

Section 1 MEASUREMENT SETUP 1-1

CONTENTS

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9

System Configuration 1-2

Part Names and Functions 1-3

Sensor Head 1-3

Calibration ROM 1-3

Controller 1-4

About Installation and Connection 1-7

Installation of Sensor Head 1-7

Installation of Controller 1-10

Connecting Calibration ROM 1-14

Connecting Fiber Cable 1-15

Calibrating Sensor Head 1-19

Smart Monitor ZW 1-21

Operating Environment 1-22

Installation/Uninstallation Method 1-23

Settings when Connecting Personal Computer with Controller 1-25

Starting and Exiting 1-29

Section 2 BASIC OPERATION 2-1

Overview of Setting and Measurement 2-2

Operation Modes 2-2

ZW

User’s Manual

15

Introduction

CONTENTS

Section 3 SETTINGS FOR FUNCTIONS 3-1

Functions of Operating Keys 2-3

Digital Displays 2-4

Multi-task and Bank Data 2-6

Setting Flow 2-8

Functions and Operations during Measurement 2-10

Switching the Display during RUN mode 2-10

Zero Reset 2-14

Setting Threshold Value 2-17

Bank Switching 2-20

Setting Sensing 3-2

Setting the Material for the Target to Measure 3-2

Setting Exposure Time Control Mode 3-3

Setting Measurement Items 3-5

Measuring the Height 3-6

Measuring the Thickness 3-8

Calculating 3-10

Setting the Output Conditions 3-14

Setting the Filter 3-14

Setting the Scaling 3-21

Setting the Hold 3-28

Setting the Zero Reset 3-37

Setting the Banks 3-43

Changing the Bank Mode 3-43

Copying the Bank Settings 3-44

Saving the Bank/System Settings 3-45

Clearing the Bank Settings 3-46

Setting the System 3-47

Checking Information 3-47

16

Setting the Key Lock 3-49

Initializing Settings 3-50

ZW

User’s Manual

Introduction

Section 4 I/O SETTINGS 4-1

I/O Terminal Names and Functions 4-2

I/O Terminal Functions 4-2

Electrical Specifications 4-5

I/O Signal Functions 4-7

Settings for I/O 4-12

Settings for Analog Output 4-12

Settings for Judgment Output 4-18

Settings for Binary Output 4-22

Settings for Processing when Measurement Cannot be Performed 4-28

Settings for I/O Signals 4-31

Timing Charts 4-33

Section 5 Ethernet/RS-232C COMMUNICATION 5-1

CONTENTS

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9

Overview 5-2

Ethernet Communication 5-2

RS-232C Communication 5-4

Connecting Using Ethernet Cable 5-5

Connection Method 5-5

Communication Settings 5-5

Connecting Using RS-232C Cable 5-7

Connection Method 5-7

Communication Settings 5-10

Communication Command List 5-12

Command format 5-14

Section 6 SPECIFICATIONS AND EXTERNAL DIMENSIONS 6-1

Sensor Head 6-2

Specifications

External Dimensions 6-3

Spot Diameter 6-4

Linearity Characteristic by Materials 6-5

Angle Characteristic 6-6

Controller 6-8

ZW

User’s Manual

17

Introduction

CONTENTS

Section 7 APPENDIX 7-1

Specifications

Status Indicators for Controller 6-10

External Dimensions 6-11

Accessories 6-12

Extension Fiber Cable 6-12

Connecting Adapter (For Fiber Cable Connection) 6-13

RS-232C Cable 6-14

Parallel Cable 6-15

Troubleshooting 7-2

Error Messages and Countermeasures 7-5

EMC Directive Conformity 7-7

Updating Firmware 7-8

Flow of Updating Firmware 7-8

Processing Item Data List 7-13

Index 7-19

Revision History 7-23

18

ZW

User’s Manual

Introduction

CONTENTS

User’s Manual

ZW

19

CONTENTS

Introduction

CONTENTS

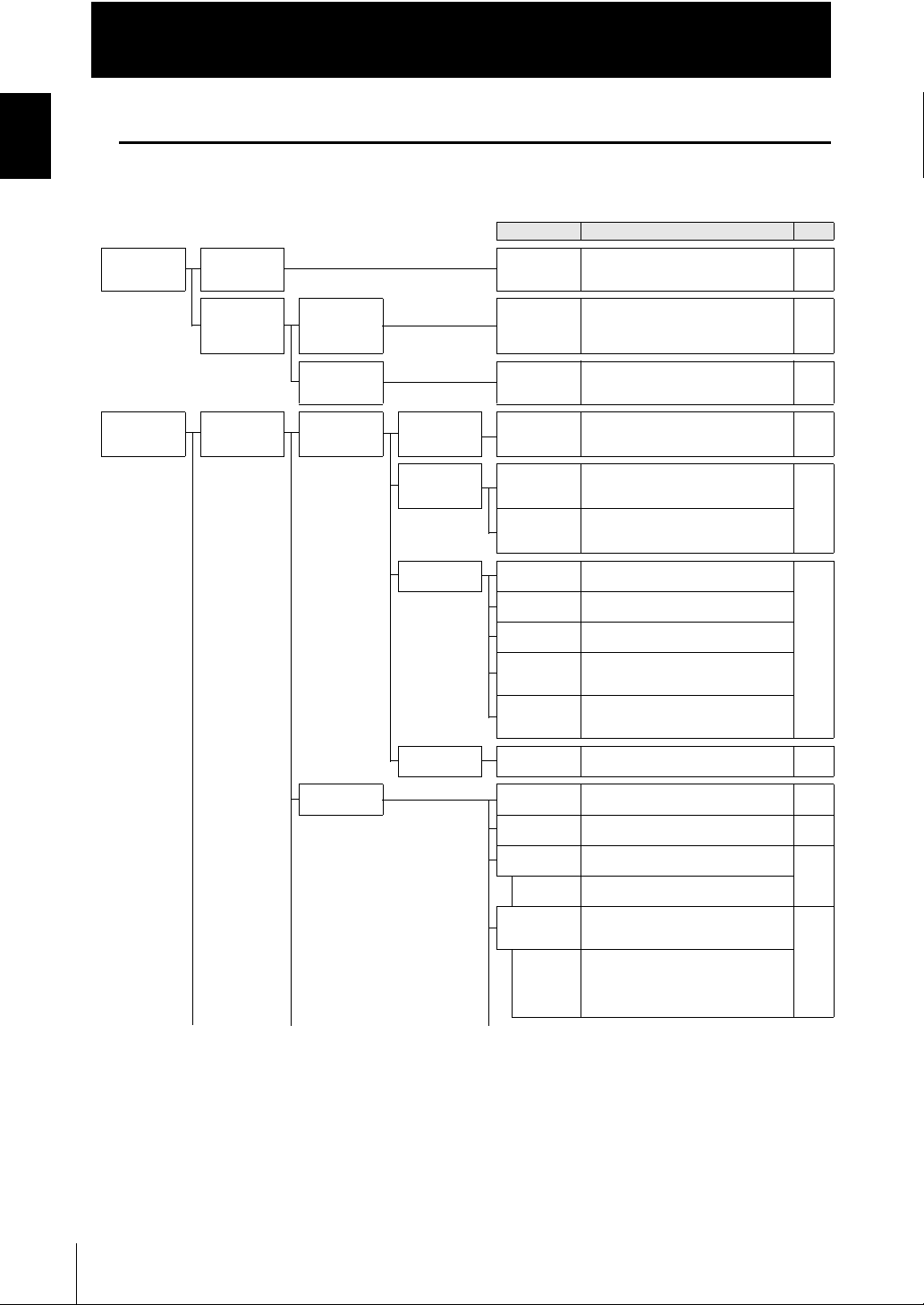

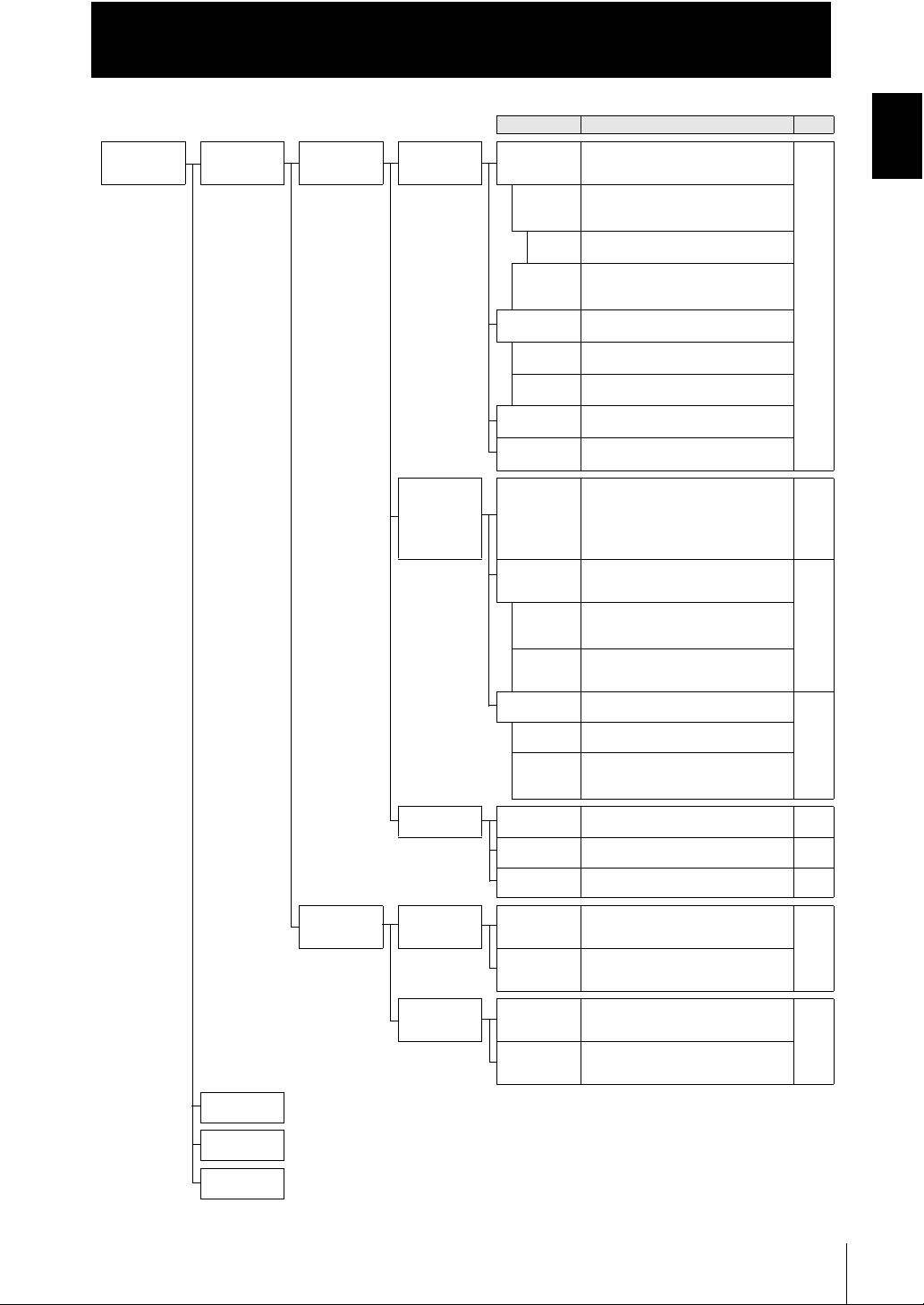

Search from Menu Tree

■FUN mode

Sensing

setting

[SENS]

Measurement

setting

[MEAS]

Material

[OBJECT]

Exposure

Time Control

Mode

[EXPOSE]

TAS K1

[TASK1]

*

Auto

[AUTO]

Manual

[MANUAL]

Measurement

item

[ITEM]

Filter

[FILTER]

Height

[HEIGHT]

Thick

[THICK]

Calculation

[CALC]

None

[NONE]

* - Default value

Setting Option/Setting range Pages

Material

[OBJECT]

Upper limit

[UPPER]

Fixed

exposure time

[TIME]

Measurement

Surface

[SUR]

Surface 1

[TOP]

Surface 2

[END]

Parameter K

[PARAM.K]

Parameter m

[PARAM.M]

Parameter n

[PARAM.N]

Parameter X

[PARAM.X]

Parameter Y

[PARAM.Y]

Median

[MEDIAN]

Average

[AVE]

Differ

[DIFFER]

Differ cycle

[CYCLE]

Frequency

[FREQ]

Cutoff

frequency

[CUTOFF]

Normal [NORMAL]

[MIRROR]/Diffusion surface [DIFF]

1 to 5000 ms (Default: 1000) p.3-3

1 to 5000 ms (Default: 1000) p.3-3

Edge 1st [EDGE1]/Edge 2nd

[EDGE2]/Edge 3rd [EDGE3]/Edge

4th [EDGE4]/

Edge 1st [EDGE1]/Edge 2nd

[EDGE2]/Edge 3rd [EDGE3]/Edge

4th [EDGE4]/

Edge 1st [EDGE1]/Edge 2nd

[EDGE2]/Edge 3rd [EDGE3]/Edge

4th [EDGE4]/

-999.999999 to 999.999999 mm

(Default: 0)

-10.0 to 10.0 (Default: 0)

-10.0 to 10.0 (Default: 0)

None [OFF]

TASK2 [TASK2]/TASK3 [TASK3]/

TASK4 [TASK4]

None [OFF]

TASK2 [TASK2]/TASK3 [TASK3]/

TASK4 [TASK4]

- - p.3-5

OFF [OFF]

[MID]/HIGH [HIGH]

1/2/4/8/16/32/64/128/256

1024/2048/4096

Off [OFF]

1 to 5000 ms (Default: 1)

OFF [OFF]

Highpass [HIPASS]/Bandpass

[BDPASS]

Lowpass/Highpass: 0.001 to

999.999 Hz (Default: 0.001)

Bandpass: 0.001 to 999.999 Hz

(Default: Upper limit 999.999/

Lower limit: 0.001)

*

/Mirror surface

Light Peak

Light Peak

Light Peak

*

/TASK1 [TASK1]/

*

/TASK1 [TASK1]/

*

/LOW [LOW]/MID

*

/On [ON]

*

/Lowpass [LOPASS]/

[PEAK]

[PEAK]

[PEAK]

*

/512/

*

*

*

p.3-2

p.3-6

p.3-8

p.3-10

p.3-15

p.3-16

p.3-17

p.3-19

20

ZW

User's Manual

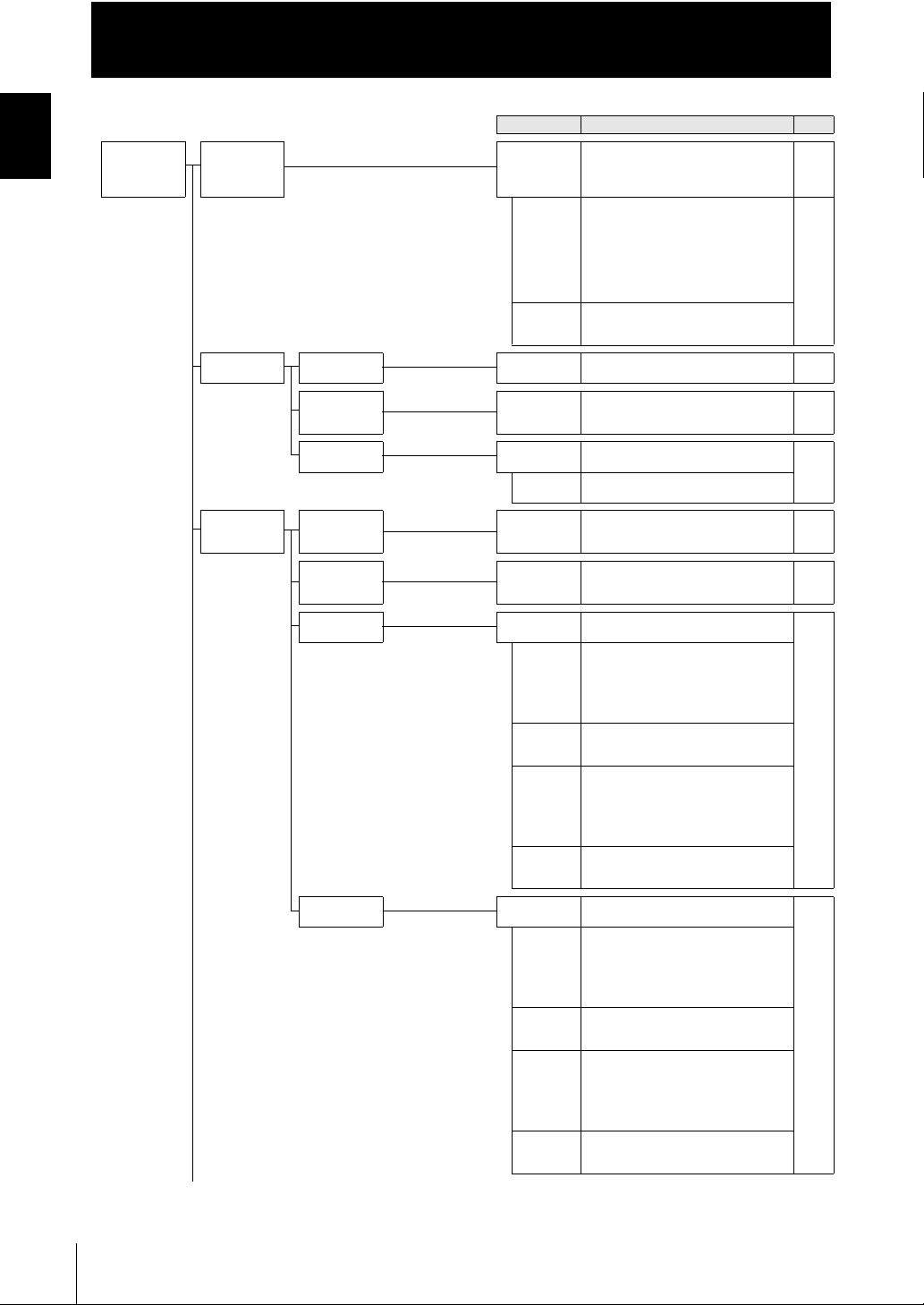

Measurement

setting

[MEAS]

TAS K1

[TASK1]

Output

[OUTPUT]

Scaling

[SCALE]

(Cont'd) (Cont'd) One-point

Hold

[HOLD]

Zero reset

[ZERO]

TAS K2

[TASK2]

TAS K3

[TASK3]

TAS K4

[TASK4]

Threshold

[JUDGE]

(same as TASK1)

(same as TASK1)

(same as TASK1)

Teaching

[TEACH]

Direct

[DIRECT]

Introduction

CONTENTS

Setting Option/Setting range Pages

Auto

[AUTO]

scaling

[1PT]

Direction

Two-point

scaling

[2PT]

Manual

[MANUAL]

Span

[SPAN]

Offset

[OFFSET]

Thick

[THICK]

Off

[OFF]

Type

[TYPE]

Trigger

[TRIG]

Trigger

[LEVEL]

Trigger hys

[HYS]

Delay

[DELAY]

Delay time

[DLY.TIM]

Sampling

[SMP.TIM]

Type

[TYPE]

Offset

[OFFSET]

Status

[STATUS]

High

threshold

[H.JUDGE]

Low threshold

[L.JUDGE]

High

threshold

[H.JUDGE]

Low threshold

[L.JUDGE]

-

-

Forward [FWD]

[DIR]

-

-

-2.0000 to 2.0000 (Default: 1.0000)

-999.999999 to 999.999999 mm

(Default: 0)

-

-

*

Off [OFF]

[BOTTOM]/Peak to peak [P-P]/Auto

peak [AUTOPK]/Auto bottom

[AUTOBT]/Auto peak to peak

[AUTOPP]/Average [AVE]/Sample

[SAMPLE]

Timing [TIMING]

[SELF-U]/Selfdown trigger [SELFD]

-999.999999 to 999.999999 mm

level

(Default: 0)

0 to 999.999999mm

(Default: 0.05 % of measurement

range)

Off [OFF]

*

/Peak [PEAK]/Bottom

*

/On [ON]

1 to 5000 ms (Default: 1 ms)

time

1 to 5000 ms (Default: 100 ms)

Real value [REAL]

[HOLD]

-999.999999 to 999.999999 mm

(Default: 0)

Off [OFF]/On [ON]

-999.999999 to 999.999999 mm

(Default: +25 % of measurement

range)

-999.999999 to 999.999999 mm

(Default: -25 % of measurement

range)

-999.999999 to 999.999999 mm

(Default: +25 % of measurement

range)

-999.999999 to 999.999999 mm

(Default: -25 % of measurement

range)

*

/Reverse [REV]

*

/Selfup trigger

*

/Hold value

*

CONTENTS

p.3-21

p.3-28

p.3-32

p.3-35

p.3-37

p.3-39

p.3-40

p.2-18

p.2-19

User’s Manual

ZW

21

CONTENTS

Introduction

CONTENTS

Setting Option/Setting range Pages

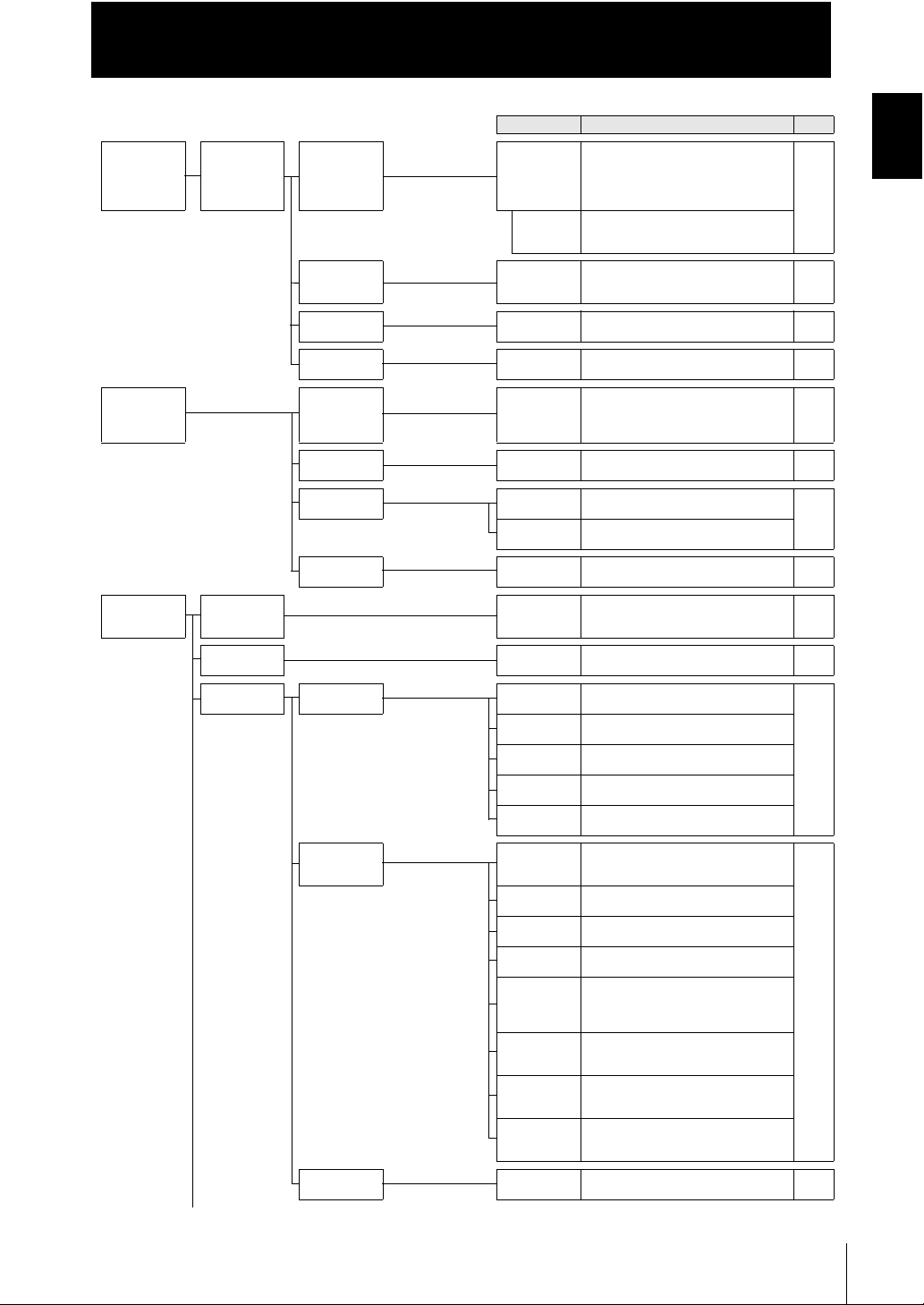

I/O setting

[I/O]

*

The same output destination is set for all banks. The output destination cannot be set separately for individual banks.

Non

measurement

setting

[HLD.RST]

Judgment

[JUDGE]

Analog output

[ANALOG]

Output object

[OUTPUT]

Hysteresis

[HYS]

Timer

[TIMER]

Voltage or

*

current

[V OR C]

Output object

[OUTPUT]

Focus

[FOCUS]

Calibration

[CALIB]

Non

measurement

setting

[HLD.RST]

Analog

output

[ANALOG]

Binary

output

[BINARY]

Output object

[OUTPUT]

Hysteresis

[HYS]

Timer

[TIMER]

Timer time

[TIME]

Voltage or

current

[V OR C]

Output object

[OUTPUT]

Focus

[FOCUS]

Focus

Current/

Voltage 1

[CUR1]/

[VOLT1]

Measurem

ent value 1

[MEAS1]

Focus

Current/

Voltage 2

[CUR2]/

[VOLT2]

Measurem

ent value 2

[MEAS2]

Calibration

[CALIB]

Calibration

Current/

Voltage 1

[CUR1]/

[VOLT1]

Calibration

value 1

[ADJ1]

Calibration

Current/

Voltage 2

[CUR2]/

[VOLT2]

Calibration

value 2

[ADJ2]

Keep [KEEP]/Clamp [CLAMP]

Current output: MIN [MIN]

(Approx. 3.4 mA)/4 mA/5 mA/.../19

mA/20 mA/MAX [MAX]

(Approx. 21 mA) (Default: MAX)

Voltage output: MIN [MIN]

(Approx. -10.8 V)/-10 V/-9 V/.../9 V/

10 V/MAX [MAX] (Approx. 10.8 V)

(Default: MAX)

*

MAX [MAX]

TASK1 [TASK1]

TASK3 [TASK3]/TASK4 [TASK4]

0 to 99.9999 mm

(Default: 0.05 % of measurement

range)

*

Off

delay [ONDLY]/1 shot [1SHOT]

/MIN [MIN]

*

/TASK2 [TASK2]/

[OFF]/Off delay [OFF.DLY]/On

1 to 5000 ms (Default: 1)

*

Voltage output

OFF [OFF]/TASK1 [TASK1]

TASK2 [TASK2]/TASK3 [TASK3]/

TASK4 [TASK4]

Off [OFF]

Current: 4/5/6/7/8/9/10/11/12/13/14/

15/16/17/18/19/20 mA

(Default: 4 mA)

Voltage: -10/-9/-8/-7/-6/-5/-4/-3/-2/1/0/1/2/3/4/5/6/7/8/9/10 V

(Default: -10 V)

-999.999999 to 999.999999 mm

(Default: -0.5)

Current: 4/5/6/7/8/9/10/11/12/13/14/

15/16/17/18/19/20 mA

(Default: 20 mA)

Voltage: -10/-9/-8/-7/-6/-5/-4/-3/-2/1/0/1/2/3/4/5/6/7/8/9/10 V

(Default: 10 V)

-999.999999 to 999.999999 mm

(Default: 0.5)

*

/On

Off

Current: 4/5/6/7/8/9/10/11/12/13/14/

15/16/17/18/19/20 mA

(Default: 4 mA)

Voltage: -10/-9/-8/-7/-6/-5/-4/-3/-2/1/0/1/2/3/4/5/6/7/8/9/10 V

(Default: -10 V)

/Current output

*

/On [ON]

-999 to 999 (Default: 0)

Current: 4/5/6/7/8/9/10/11/12/13/14/

15/16/17/18/19/20 mA

(Default: 20 mA)

Voltage: -10/-9/-8/-7/-6/-5/-4/-3/-2/1/0/1/2/3/4/5/6/7/8/9/10 V

(Default: 10 V)

-999 to 999 (Default: 0)

*

p.4-28

p.4-30

p.4-18

p.4-18

p.4-19

p.4-12

*

/

p.4-13

p.4-14

p.4-16

22

ZW

User's Manual

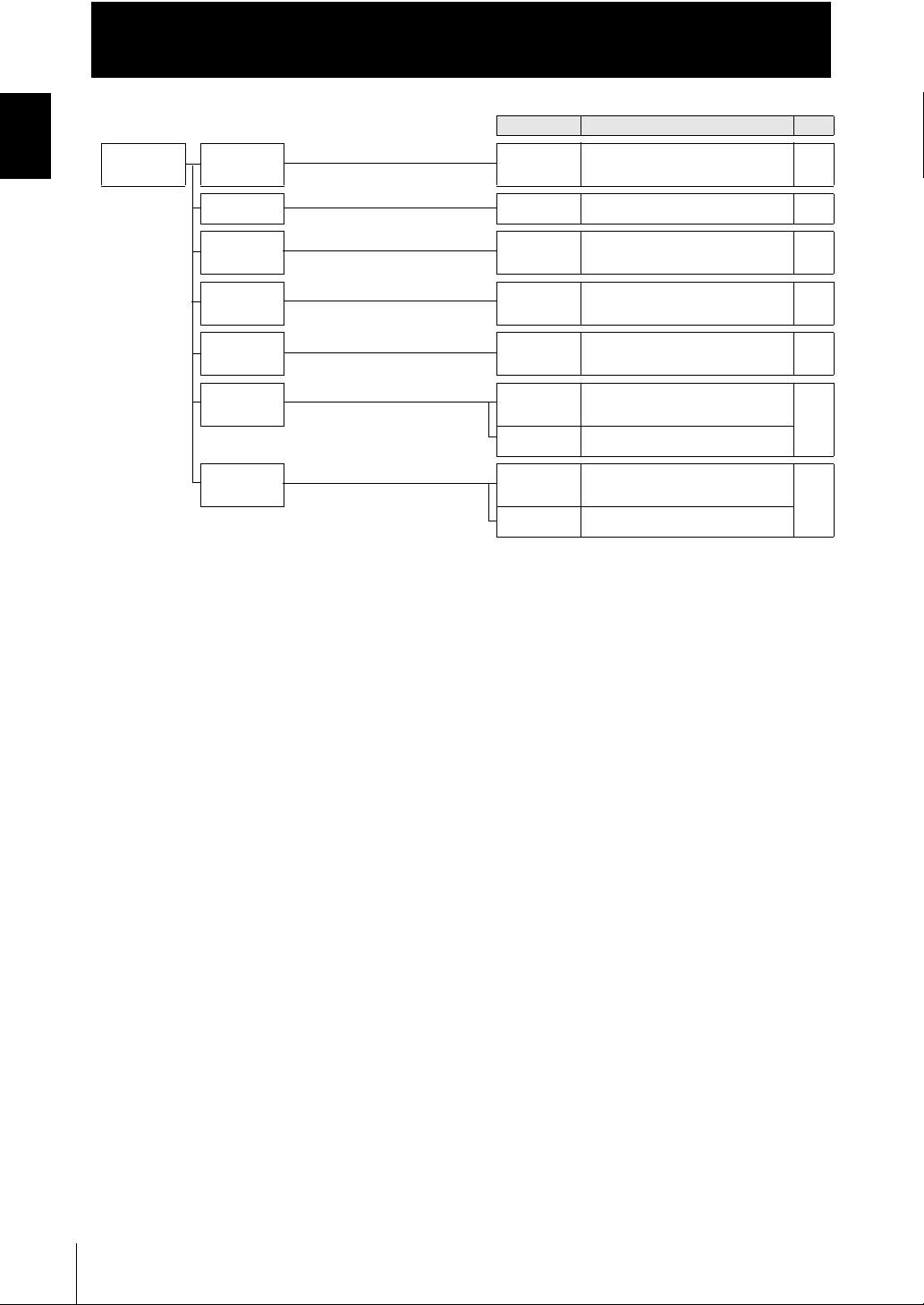

I/O setting

[I/O]

Binary output

[BINARY]

Output object

[OUTPUT]

Output object

(Cont'd) TASK1 to 4

Bank setting

[BANK]

System

setting

[SYSTEM]

Save

[SAVE]

Initialize

[INIT]

Communication

[COM]

Decimal point

digit

[DEC.NUM]

Output cycle

[CYCLE]

GATE Period

[GATE]

Bank change

[BK.CHG]

Bank mode

[BK.MODE]

Bank copy

[BK.COPY]

Bank clear

[BK.CLR]

RS-232C

[RS232C]

Ethernet

[ETN]

Decimal point

GATE Period

Bank number

Subnet mask

Subnet mask

Subnet mask

Subnet mask

Delimiter

[DELIMI]

Introduction

CONTENTS

Setting Option/Setting range Pages

[OUTPUT]

[TASK1] to

[TASK4]

digit

[DEC.NUM]

Output cycle

[CYCLE]

[GATE]

[BANK]

Bank mode

[BK.MODE]

From

[FROM]

To

[TO]

Bank clear

[BK.CLR]

Save

[SAVE]

Initialize

[INIT]

Data length

[DATA]

Parity

[PARITY]

Stop bit

[STOP]

Baud rate

[BAUD.RT]

CS/RS

[CS/RS]

IP address 1

[IPADDR]

[IP1]

IP address 2

[IP2]

IP address 3

[IP3]

IP address 4

[IP4]

1

[SUBNET]

[SUB1]

2

[SUB2]

3

[SUB3]

4

[SUB4]

Delimiter

[DELIMI]

Measurement value 1 [MEAS1]

(TASK1(ON

TAS K4 (O N/OFF

value 2 [MEAS2]/Judgment value

[JUDGE]/Off [OFF]

Off [OFF]

0 [0DIG] to 6 [6DIG] (Default: 5

[5DIG])

1 to 100 (Default: 1) p.4-26

0.1 to 100.0 ms (Default: 0.1) p.4-27

BANK1 [BANK1] to BANK8

[BANK8] (Default: BANK1)

If bank mode is "Judge mode",

selection is possible to BANK32.

Normal mode [NORMAL]

mode [JUDGE]

BANK1 [BANK1] to BANK8

[BANK8]

BANK1 [BANK1] to BANK8

[BANK8]

OK [OK]/Cancel [CAN] p.3-46

OK [OK]/Cancel [CAN] p.3-45

OK [OK]/Cancel [CAN] p.3-50

7 bit [7BIT] /8 bit [8BIT]

None [OFF]

Even [EVEN]

1 bit [1BIT]

9600/19200/38400

Off [OFF]

1 to 223 (Default: 192)

0 to 255 (Default: 168)

0 to 255 (Default: 250)

1 to 255 (Default: 50)

0 to 255 (Default: 255)

0 to 255 (Default: 255)

0 to 255 (Default: 255)

0 to 255 (Default: 255)

CR [CR]

*

/OFF), TASK2 to

*

))/Measurement

*

*

/On [ON]

*

/Judge

*

*

/Odd [ODD]/

*

/2 bit [2BIT]

*

/57600/115200

*

/On [ON]

*

/LF [LF]/CR+LF [CRLF]

CONTENTS

p.4-22

p.4-25

p.2-20

p.3-43

p.3-44

p.5-10

p.5-5

p.5-11

User’s Manual

ZW

23

CONTENTS

Introduction

CONTENTS

System

setting

[SYSTEM]

(Cont'd)

Sensor head

calibration

[H.CALIB]

Key lock

[LOCK]

Zero reset

memory

[ZER.MEM]

Timing/Reset

key input

[KEY.IN]

Measurement

cycle

[CYCLE]

Controller

information

[C.INFO]

Sensor head

information

[H.INFO]

Setting

Sensor head

calibration

[H.CALIB]

Key lock

[LOCK]

Zero reset

memory

[ZER.MEM]

Timing/Reset

key input

[KEY.IN]

Measurement

cycle

[CYCLE]

Vers ion

[VER]

MAC address

[MAC.ADR]

Model

[MODEL]

Serial No.

[SER.NO]

Option/Setting range

OK [OK]/Cancel [CAN] p.1-19

*

Off [OFF]

Off [OFF]

Off [OFF]

Display current measurement cycle

500 to 10000 s (Default: 500)

Display version

Display current MAC address

Display model

Display serial No.

/On [ON]

*

/On [ON]

*

/On [ON]

Pages

p.3-49

p.3-41

p.3-34

p.3-47

p.3-47

p.3-47

24

ZW

User's Manual

Introduction

CONTENTS

■RUN mode

Setting [Display] Option/Setting range [Display] Pages

Display target task [DISP] TASK1/TASK2/TASK3/TASK4 p.2-12

HIGH threshold value

[H.JUDGE]

LOW threshold value

[L.JUDGE]

Decimal point digit

[DEC.NUM]

Controller: -999.99 to 999.999

Smart Monitor ZW: -999.999999 to 999.999999

Controller: -999.99 to 999.999

Smart Monitor ZW: -999.999999 to 999.999999

0 [0DIG]/1 [1DIG]/2 [2DIG]/3 [3DIG]/4 [4DIG]/5 [5DIG] p.2-12

CONTENTS

p.2-13

p.2-13

User’s Manual

ZW

25

Introduction

CONTENTS

CONTENTS

26

ZW

User’s Manual

Chapter 1 MEASUREMENT SETUP

System Configuration 1-2

Part Names and Functions 1-3

Sensor Head 1-3

Calibration ROM 1-3

Controller 1-4

About Installation and Connection 1-7

Installation of Sensor Head 1-7

Installation of Controller 1-10

Connecting Calibration ROM 1-14

Connecting Fiber Cable 1-15

Calibrating Sensor Head 1-19

Smart Monitor ZW 1-21

Chapter 1 MEASUREMENT SETUP

Operating Environment 1-22

Installation/Uninstallation Method 1-23

Settings when Connecting Personal Computer with

Controller 1-25

Starting and Exiting 1-29

User’s Manual

ZW

1-1

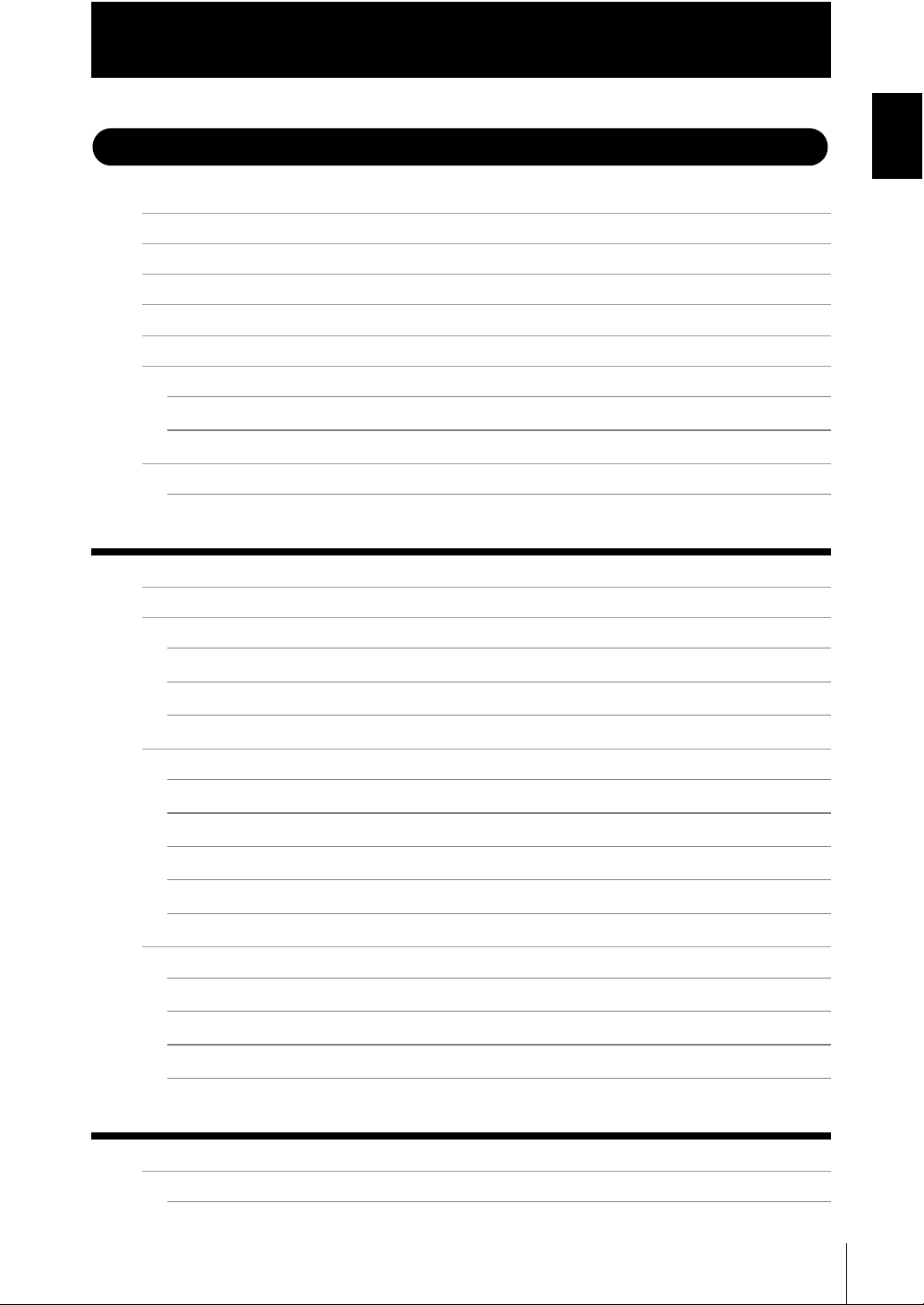

Chapter 1

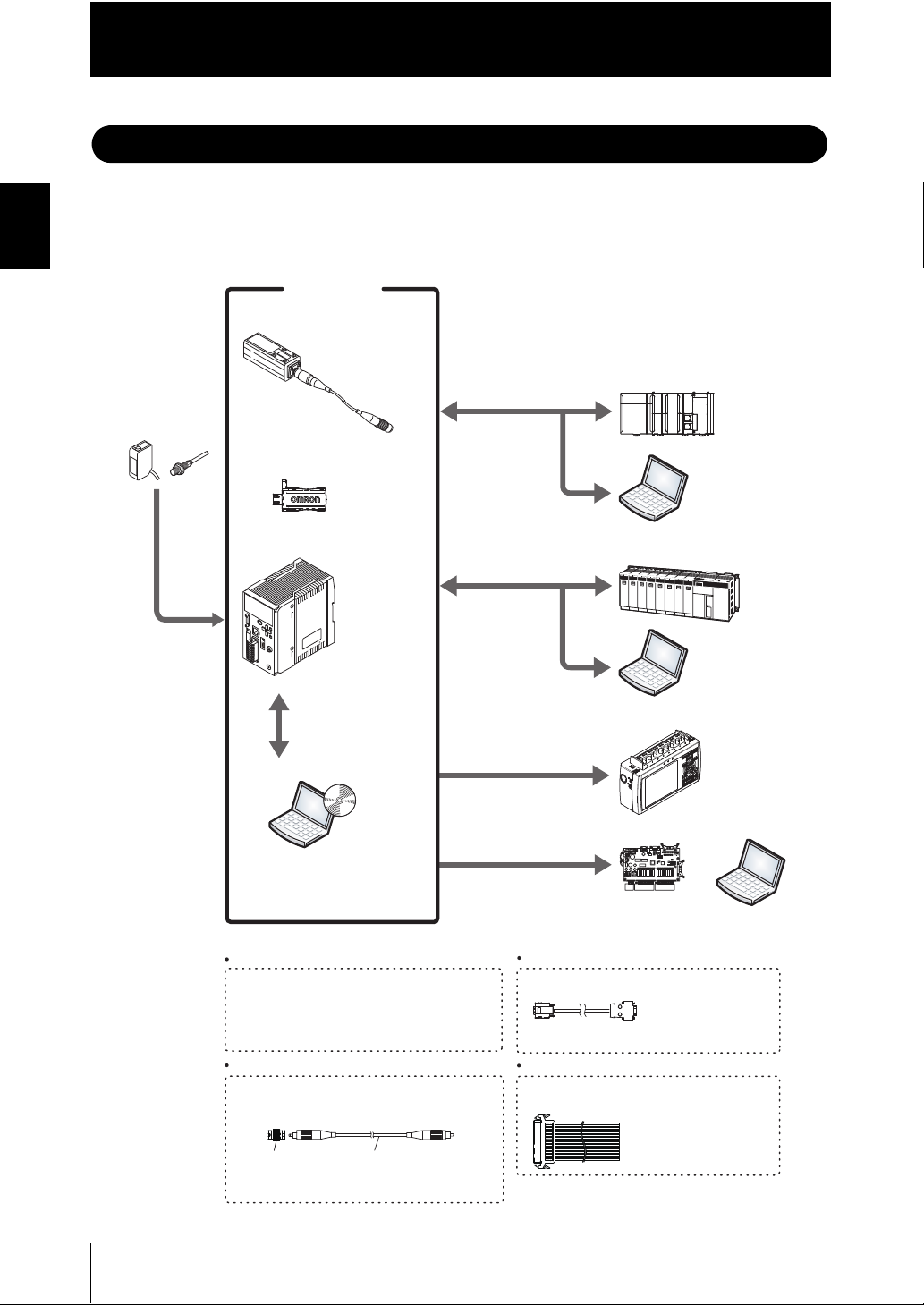

System Configuration

System Configuration

Chapter 1 MEASUREMENT SETUP

In addition to operations with the basic configuration, ZW series displacement sensors can

support various measurement applications when combined with numerous peripheral

devices.

Photoelectric and

adjacent sensors

The system receives

trigger signals to

control measuring

timings.

ZW series

Basic configuration

Sensor head

Detects a target to

measure.

ZW-S20

ZW-S40

Calibration ROM

(included with sensor head)

Associated with

the sensor on a

one-to-one basis

Controller

Perfor ms

measurements

and outputs the

result.

ZW-C10T/C10AT

ZW-C15T/C15AT

Measurement data can be easily loaded

into a PLC or personal c omputer through

Ethernet connections.

The Controlle r can be remotely contr olled

from a personal computer; including switching

between or changing setting data and entering

measuring triggers.

(Communication with multiple devices

simultaneously cannot be achieved via Ethernet.)

Ethernet (note1)

Various Controll er operations,

including, taking measured values

and judgment results, switching

between or changing setting data

or entering measuring triggers, are

available.

RS-232C cable

䇭䇭䇭䇭䇭䇭(note 2)

PLC

PC

PLC

PC

Ethernet (note1)

Smart Monitor ZW

(Exclusive personal

Personal

computer

Allows making advanced settings and

checking up measured values easily using

exclusive personal computer software.

Accessory for the Controller

ZW-C10T/C15T.

(Note1)㩷Ethernet cable (sold separately)

Prepare commercially available Ethernet cable

satisfying the following requirements:

- Category 5e or more, 30 m or less

- RJ45 conne ctor (8-pin modular jack)

- For direct connection: Select cross cable.

- For connection through a netwo rk hub: Select strai ght

cable.

Extension fiber cable (optional)

A exclusive extension fiber cable is available to

place the Sensor Head and Controller far apart than

the normal distance to each other.

Use the exclusive product for correct measurements.

Connecting adapter

(included with the fiber

cable for extension)

ZW-XFC

computer software)

ZW-SW_ _

Extension f iber cable

ZW-XF_ _R

(2 m/5 m/10 m/20 m/30 m)

Displaying analog signals in

waveform from measured values

or judgment results in color is

available.

Analog output

Outputting measured values

or judgment results at a high

speed in parallel is available.

Parallel output (note3)

Data loggers, etc.

High-speed

input board

(Note2)㩷RS-232C cable (optional)

Depending on connecting devices, exclusive cables

may be supplied.

For PLC/programmable terminal: ZW-XPT2

For personal computer: ZW-XRS2

(Note3)㩷Parallel cable (optional)

A parallel cabl e for 52-pole extensio n connector

(ZW-XCP2) with 2 m cable is available.

PC

1-2

ZW

User’s Manual

Loading...

Loading...