Omron ZW-C1*AT, ZW-CE1*T, ZW-C1*T User Manual

Displacement Sensor

ZW series

Confocal Fiber Type

Displacement Sensor

User’s Manual

ZW-CE1@T

Z332-E1-07

Introduction

Thank you for purchasing the ZW.

This manual provides information regarding functions, performance and operating methods that

are required for using the ZW.

When using the ZW, be sure to observe the following:

• The ZW must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Terms and Conditions Agreement

(Please Read)

User's Manual

Basic configuration

Installation and Connections

Basic Operation

Settings for Function

Convenient Functions

Communications with External Devices

1

2

3

4

5

6

Confocal Fiber Type

Displacement Sensor

ZW

Offline Settings

Troubleshooting

Sensor controller operations

APPENDICES

7

8

9

10

Terms and Conditions Agreement

Read and understand this Manual

Please read and understand this catalog before purchasing the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty, Limitations of Liability

Warranties

• Exclusive Warranty

Omron's exclusive warranty is that the Products will be free from defects in materials and workmanship for a

period of twelve months from the date of sale by Omron (or such other period expressed in writing by

Omron). Omron disclaims all other warranties, express or implied.

• Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

•Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally shipped

with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii)

repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price of the

non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity

or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or

inappropriate modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of

Products in combination with any electrical or electronic components, circuits, system assemblies or any

other materials or substances or environments. Any advice, recommendations or information given orally or

in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which

liability is asserted.

2

ZW User's Manual

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply

to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron

will provide applicable third party certification documents identifying ratings and limitations of use which apply

to the Product. This information by itself is not sufficient for a complete determination of the suitability of the

Product in combination with the end product, machine, system, or other application or use. Buyer shall be

solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application,

product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE

RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any

consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user

in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test

conditions, and the user must correlate it to actual application requirements. Actual performance is subject to

the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the Product may be changed

without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications

for your application. Please consult with your Omron’s representative at any time to confirm actual

specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical or proofreading errors or omissions.

ZW User's Manual

3

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

1. Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to high-voltage devices

and power devices.

2. Power Supply and Wiring

• Take care when using a power supply with an overcurrent detector, because this sensor uses DC-DC

converter for its power supply circuit and inrush current may activate the protective circuit for a power supply

with an overcurrent detector.

Recommended power supply: S8VS-06024 (Omron, DC24 V 2.5 A 60 W)

• The supply voltage must be within the rated range (DC24 V ± 10 %).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring them together or

placing them in the same duct may cause induction, resulting in malfunction or damage.

• Use adequate safety measures, for example fail-safe circuits.

• Use a specified-sized wire when wiring. Do not connect wires other than those of the specification to the

terminal block.

• For a power supply, use a DC power supply unit provided with a remedy, for example, safety ultralow voltage

circuit, to prevent a high voltage from being generated.

• Route so that power supply wires are as short as possible.

• Use a power supply dedicated for this product, without sharing it with other products.

• Tighten fixing screws securely at a torque specified in this manual.

• Before performing any of the following activities, be sure to turn off the product, or breakdown may result.

- Connecting or wiring cables

- Connecting or disconnecting connectors

- Installing or removing Calibration ROM

- When inserting or removing an EtherCAT cable, do not put any stress on the calibration ROM.

3. Grounding

• Use a frame ground terminal of the specified size to be grounded. Do not connect a wire with an only twisted

end directly to a terminal block.

- Terminal screw: M4

- Crimp-type terminal:

8.5mm

or less

• Use D-type grounding (ground resistance of 100 or less). Make the ground point as close as possible and

make the ground wire used as short as possible.

• Never a ground wire with other equipment and never ground to building beams. Doing so could cause

negative impacts.

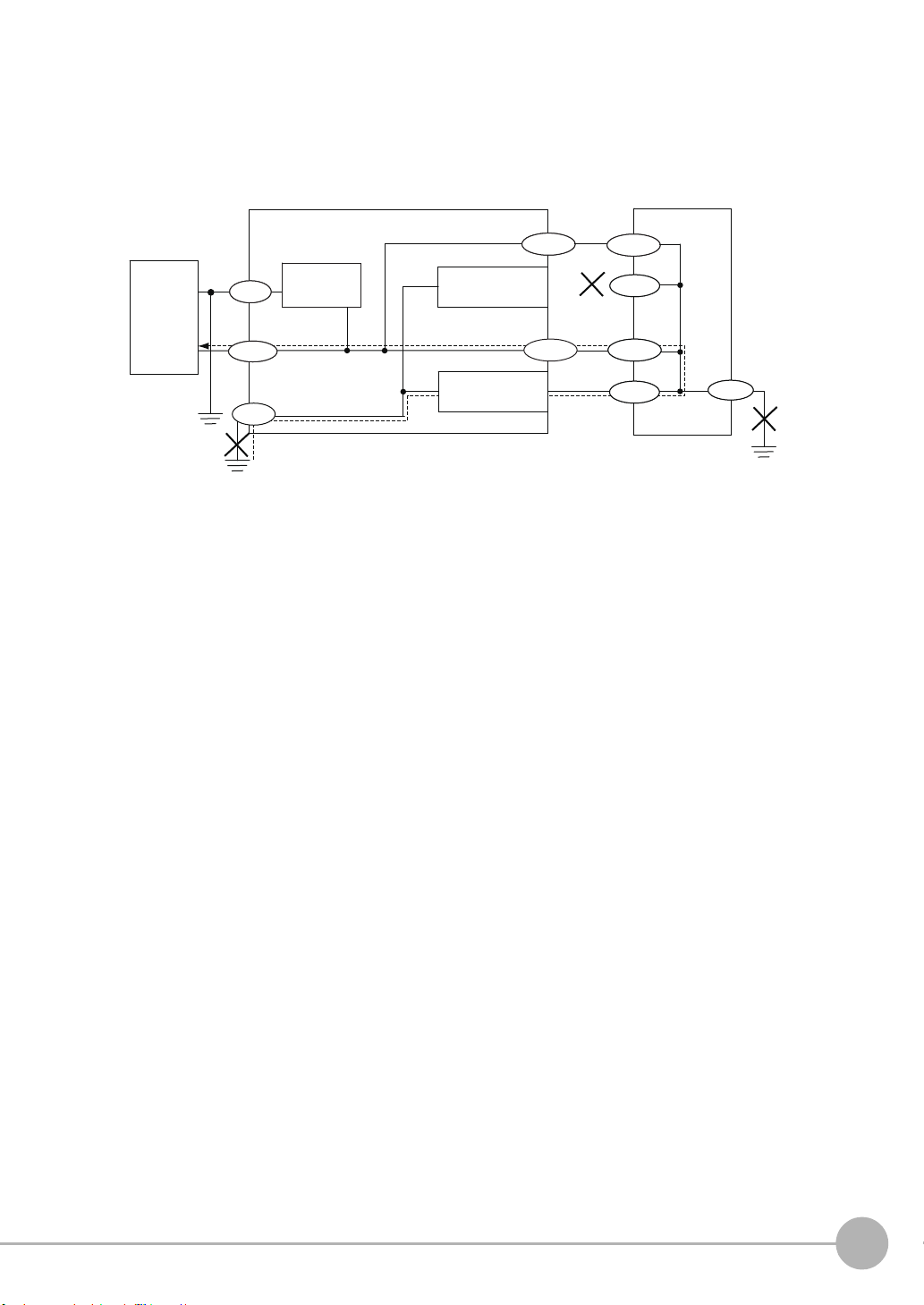

• The power supply circuit of the Sensor Controller is not insulated from the internal circuits.

• When grounding the positive (+) terminal of the 24 VDC power supply, do not connect the Sensor Controller's

frame ground terminal or PLC's frame ground terminal to ground. [(1), (2)]

The PC housing may be internally connected to the SG (0 V), in which case current will flow through the path

shown below and may cause seizure.

4

8.5mm

or less

ZW User's Manual

• If there is no PC, or specifically there is no SG (0 V)/FG short-circuiting path, grounding the Sensor

24V

FG

SG

FG

SG

FG

SG

FG

SG

SG

24 V DC

power

supply

Sensor Controller

24V

PC or PLC

SG: Signal Ground (0 V for 24 V DC power supply)

FG: Frame Ground

FG

(1)

(2)

SG

FG

SG

FG

SG

SG

Power supply

circuit

(3)

RS-232C

connector housing

RS-232C

Ethernet

connector housing

Ethernet

SG

FG

Controller's frame ground terminal will not cause seizure. Wire the PLC after checking the specification of

your PLC.

• The dedicated RS-232C cable (ZW-XRS2/XPT2) has its cable shield isolated from the connector housing.

[(3)]

4. Regulations and Standards

• EN61326-1

• Electromagnetic environment : Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• The following condition is applied to the immunity test of this product.

: There may be cases that current or voltage output fluctuate within ± 3%F.S. when a sensor is experienced

electromagnetic interference.

• Notice for Korea Radio Law

A급 기기 (업무용 방송통신기자재)

이 기기는 업무용 ( A급 ) 전자파적합기기로서 판매자

또는 사용자는 이 점을 주의하시기 바라며 , 가정외의

지역에서 사용하는 것을 목적으로 합니다.

5. Others

• Do not use this product for nuclear facilities, or safety circuits involving human lives.

• Do not attempt to disassemble, repair, modify, apply pressure to deform or burn up the body.

• Dispose of this product as industrial waste.

• Use exclusive devices, including a sensor head, Calibration ROM, fiber cable or RS-232C cable, to connect,

or ignition, burst, false operation or breakdown may be caused.

• Do not cut fiber cable. Glass at the cut section may cause injury. Also, if cut, it will not work normally

anymore.

• Whenever any trouble, including, strange odor smelled, the body overheated or smoke escaped, was found,

immediately stop the operation, and consult an OMRON branch or sales office with the system shut down.

• Do not drop or make a strong impact on the unit.

• Before using any equipment provided with a lock mechanism, make sure that it has been locked.

ZW User's Manual

5

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable effects on

product performance.

1. Installation Site

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85 %

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams, electric arc-welding machines or ultraviolet shine)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes, spray or mist atmospherics

• Strong magnetic or electric field

2. Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the operating environment.

• Before turning ON the power after the product is connected, make sure that the power supply voltage is

correct, there are no incorrect connections (e.g. load short-circuit) and the load current is appropriate.

Incorrect wiring may result in breakdown of the product.

• Use the specified voltage. If voltage exceeding the rating or AC voltage is applied, circuit parts may be burnt

or rupture.

• Use the Extension Fiber Cable (ZW-XF@@R) for extending the fiber cable between the Sensor extension

fiber cable, five total lengths, 2, 5, 10, 20 or 30 m, are available.

• Handling fiber cables

Use them in compliance with the following. This may result in damage to the fiber cable.

-Fiber cable bend radiuses must be at least 20 mm.

- Do not let bending cause stress at the root section of a fiber connector.

- Do not yank hard on a fiber cable.

- Do not step on a fiber cable or place anything heavy on it.

- Do not apply any twisting stress to the fiber cable.

• Be sure to use a Sensor Head and Calibration ROM with the same serial number. A pair with different serial

numbers cannot operate normally.

• Use the configuration software with the combination specified in this manual, or the system may operate

faultily.

• Do not shut down the power supply when saving any data into the memory built in the Sensor Controller, or

the data may be corrupted.

• While a fiber cable is disconnected, be sure to attach the included protective cap on both the Sensor

Controller side and the fiber cable side. Leaving the fiber cable with the protective cap not attached, the

optical fiber may fail due to any adhered foreign matter.

3. Warming Up

After turning ON the power supply, allow the product to stand for at least 30 minutes before use. The circuits

are still unstable immediately after the power supply is turned ON, so measured values may fluctuate gradually.

6

ZW User's Manual

4. Maintenance and Inspection

Important

Note

Optional

Do not use thinner, benzene, acetone or kerosene to clean the Sensor Head, fiber cable and Sensor Controller.

If large dust particles adhere to the emitter/receiver of the Sensor Head or Sensor Controller, use a blower

brush (used to clean camera lenses) to blow them off. Do not blow the dust particles with your mouth.

To remove smaller dust particles, dirt, oil, and fat, wipe gently with a soft cloth (for cleaning lenses). Do not use

excessive force to wipe off dust particles. Scratches on the emitter/receiver may cause false operations or

measuring errors.

For details on the method for cleaning the ends of fiber cables, refer to "Connecting Fiber Cable" (p.38).

Clean the ventilation port periodically to prevent any build up of dirt and dust. If the ventilation port is blocked,

heat builds up inside and can cause breakdown.

5. Sensing Objects

The product sometimes cannot accurately measure the following types of objects: Transparent objects, objects

with an extremely low reflection factor, objects smaller than the spot diameter, objects with a large curvature,

excessively inclined objects, target objects with a thin film on the surface etc.

6. Effect caused by peripheral lights

Do not install the Sensor Head in a place where strong light hits the laser emitter/receiver section of the Sensor

Head. Also, if an object has a shiny surface, the light from the lighting will be reflected and a malfunction may

occur. In such a case, prevent reflection by, for example, covering the light to stop reflection.

Basic precautions for installation p.30

7. Influence by Air Turbulences

Slow air turbulences around the Sensor Head may disperse measured values.

To avoid these possible air turbulences, wrap the Sensor Head with an appropriate cover.

8. Operations Outside Measurement Range

This sensor is highly sensitive, it may operate incorrectly outside the measurement range (too close in). In such

a case, the problem can be solved by reducing the exposure time.

Editor's Note

■ Meaning of Symbols

Menu items that are displayed on the main or sub-display, and windows, dialog boxes and other GUI elements

displayed on the personal computer are indicated enclosed by brackets [ ].

■ Visual Aids

Indicates points that are important to achieve the full product performance, such as operational

precautions.

Indicates application procedures.

Indicates pages where related information can be found.

Indicates that the setting is optional in a configuration procedure.

Copyrights and Trademarks

• Sysmac is a trademark or registered trademark of OMRON corporation in Japan and other countries for our FA

equipment products.

ZW User's Manual

7

• Windows, Windows XP, Windows Vista, Windows 7, and Windows 8 are registered trademarks of Microsoft

Corporation in the USA and other countries.

• EtherCAT is registered trademark and patented technology that is licensed by Beckhoff Automation GmbH,

Germany.

• Other system names and product names that appear in this manual are the trademarks or registered trademarks of

the respective companies.

Notice

• Photocopying, duplication, or copying of all or part of this manual without permission is prohibited.

• Please understand that the specifications and other contents of this manual are subject to change for improvement

without notice.

• Every effort has been made to ensure the accuracy of the contents of this manual, but if you should notice any

mistake, questionable section, or the like in this manual, please contact an OMRON branch or sales office.

• If you do so, please also tell us the manual number, which is found at the end of the manual.

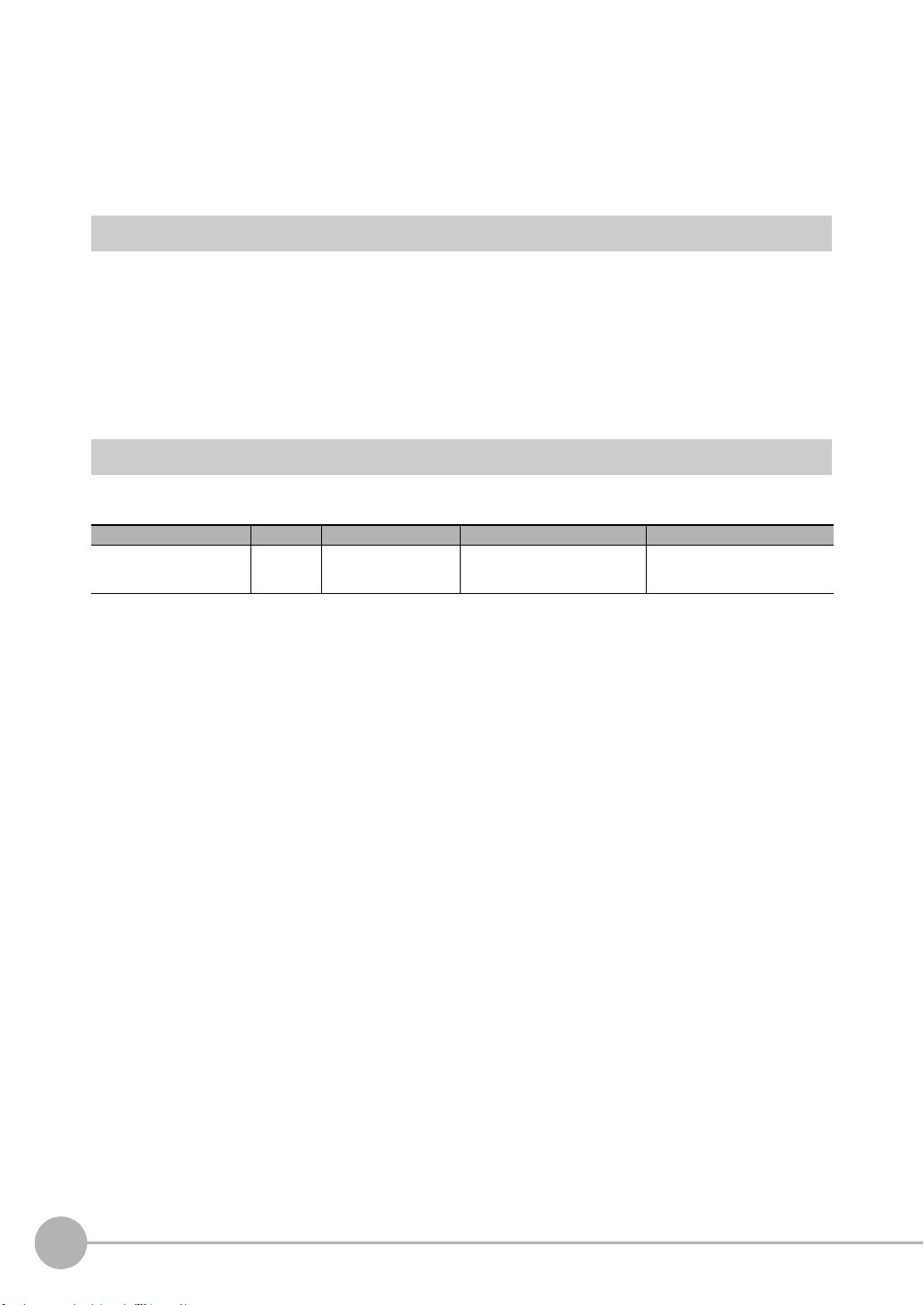

Related Manuals

The following manual is related to the NJ-series Controllers. Use this manual for reference.

Manual name Cat. No. Model numbers Application Description

Sysmac Studio Version 1

Operation Manual

W504 SYSMAC-SE2@@@ Learning about the operating

procedures and functions of

the Sysmac Studio.

Describes the operating procedures of the Sysmac Studio.

8

ZW User's Manual

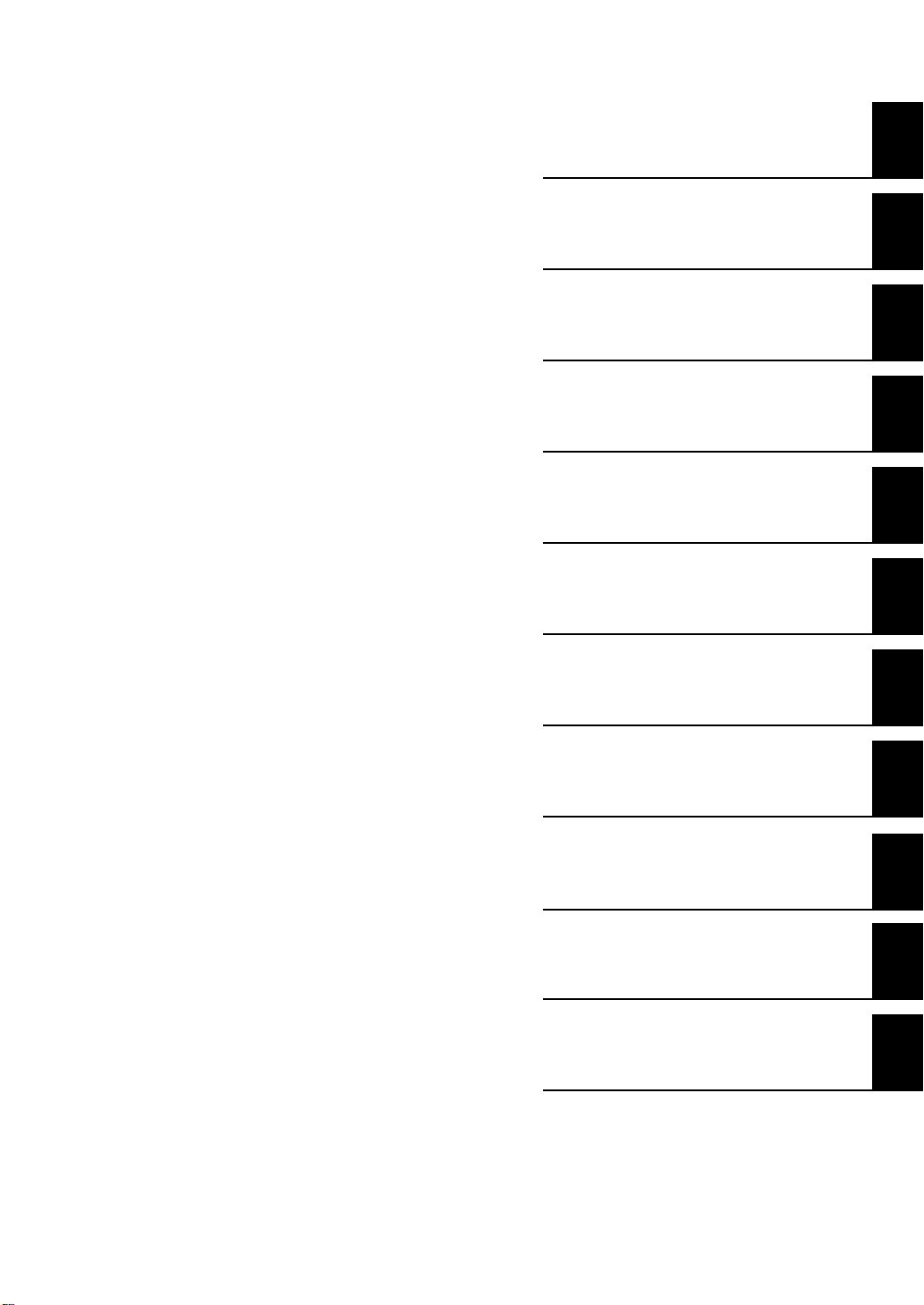

Table of Contents

Editor's Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Copyrights and Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Search from Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.Basic configuration

1-1 ZW-series Displacement Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Types of Sensor Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-2 Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.Installation and Connections

2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connection Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-2 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calibration ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sensor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation of Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation of Sensor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting Calibration ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting Fiber Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibrating Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

32-pole extension connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Analog output terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

24 V input terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-5 Installing the Sysmac Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table of Contents

3.Basic Operation

3-1 Launching a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connecting to the sensor with PC tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ZW User's Manual

9

Entering project information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3-2 Explanation of Screen Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

PC tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3-3 Switching operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-4 Bank switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Multi-task and Bank Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Switching Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

3-5 Perform the Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Zero reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3-6 Setting Threshold Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Threshold Value Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

3-7 Saving a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Saving a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Exporting a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Importing a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-8 Operating with Sensor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.Settings for Function

4-1 Setting Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Selecting the Area Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Setting the Material of the Target to Measure . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Setting the Noise Cut Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Setting Smoothing Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Setting Start Direction of Count Measurement Surfaces . . . . . . . . . . . . . . . . . .78

Setting Exposure Time Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Setting the Measurement Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4-2 Setting Measurement Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

What is a Measurement Item? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Measuring the Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Measuring the Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Performing Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4-3 Setting the Output Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Setting Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Setting Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setting Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Setting the Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4-4 Setting the Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Changing the Bank Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Copying the Bank/System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Saving the Bank/System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Clearing the Bank Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

4-5 Setting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10

ZW User's Manual

Checking Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Making Sensor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Initializing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.Convenient Functions

5-1 Displaying measured values in graphs. . . . . . . . . . . . . . . . . . . . . . . 120

Specifying the sampling start and end conditions . . . . . . . . . . . . . . . . . . . . . .122

Starting and ending sampling before and after the trigger condition is met . . 124

5-2 Saving measured values in a file. . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Outputting the results of sampling as a file . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Exporting the results of sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5-3 Displaying saved measured values. . . . . . . . . . . . . . . . . . . . . . . . . . 128

5-4 Performing internal logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

5-5 Storing the light reception wave form in a file . . . . . . . . . . . . . . . . . 131

5-6 Recovering calibration ROM data . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5-7 Printing the contents of settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

5-8 Controll input signal with PC tool . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6.Communications with External Devices

6-1 Parallel I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

I/O Signal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Settings for Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Settings for Judgment Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Settings for Processing When Measurement Is Not Possible . . . . . . . . . . . . . 148

Settings for Bank Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Settings for Internal Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

6-2 EtherCAT Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Overview of EtherCAT Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

ZW Communications Methods in an EtherCAT Connection . . . . . . . . . . . . . .162

Setting Communications Specifications (EtherCAT Communications) . . . . . . 165

List of I/O Ports for Each Area (PDO Mapping) and Memory Assignments . .166

Timing Chart (EtherCAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Sample Ladder Program (EtherCAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Sysmac Device Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

6-3 EtherNet/IP Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Introduction to EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

ZW Communications for EtherNet/IP Connections . . . . . . . . . . . . . . . . . . . . . 200

Setting Communications Specifications (EtherNet/IP) . . . . . . . . . . . . . . . . . . 203

Tag Data Link Setting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Memory Assignments and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Timing Chart (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Table of Contents

ZW User's Manual

11

Sample Ladder Program (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

6-4 No-protocol Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Outline of No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Setting Up No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Setting Communications Specifications (RS-232C Communications) . . . . . .230

Setting for serial data output after application of measured value . . . . . . . . . 231

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

7.Offline Settings

7-1 Performing Settings Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

7-2 Starting a Project in Offline Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

7-3 Changing between Online and Offline . . . . . . . . . . . . . . . . . . . . . . . 264

7-4 Offline Debugging of the Sensor Control Program and Sensor Opera-

tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

8.Troubleshooting

8-1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Errors for EtherCAT Connection (Sysmac Error Status) . . . . . . . . . . . . . . . . .270

Errors for EtherCAT Connection (SDO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Errors for Ethernet or EtherNet/IP Connection . . . . . . . . . . . . . . . . . . . . . . . . 282

Errors Common to All Communication States . . . . . . . . . . . . . . . . . . . . . . . . . 283

8-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

9.Sensor controller operations

9-1 Search from Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

FUN Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

RUN (run) Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

9-2 Functions of Operating Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

9-3 Digital Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

9-4 Switching operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

9-5 Functions and Operations during Measurement . . . . . . . . . . . . . . . 298

Switching the RUN (Run) Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

9-6 Setting Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Setting the Material of the Target to Measure . . . . . . . . . . . . . . . . . . . . . . . . . 302

Setting Start Direction of Count Measurement Surfaces . . . . . . . . . . . . . . . . .303

Setting Exposure Time Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

9-7 Setting Measurement Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Measuring the Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Measuring the Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Calculating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

12

ZW User's Manual

9-8 Setting the Output Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Setting the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Setting Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Setting Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Setting the Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

9-9 Setting the Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Switching Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .326

Changing the Bank Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Copying the Bank Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .328

Saving the Bank/System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Clearing the Bank Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

9-10 Setting Threshold Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

9-11 Setting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Checking Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Setting the Key Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Calibrating Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Initializing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

9-12 Connecting Parallel I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Settings for Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Settings for Judgment Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .342

Settings for Processing When Measurement Is Not Possible . . . . . . . . . . . . . 344

Setting for Internal Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .346

9-13 Connecting with EtherCAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Setting Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

Setting GATE Signal ON Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

9-14 Connecting with EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Network Settings of the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Setting Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .351

9-15 Connecting by No-protocol Communications . . . . . . . . . . . . . . . . 352

Initial Settings for No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . 352

Setting Communications Specifications (RS-232C Communications) . . . . . .353

Setting Serial Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .354

Set the delimiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Table of Contents

10.APPENDICES

10-1 Specifications and External Dimensions . . . . . . . . . . . . . . . . . . . . 358

Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Sensor controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

PC tools (Sysmac Studio) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .375

EMC Directive Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .379

ZW User's Manual

13

10-2 Firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Use PC tools (Sysmac Studio) to update. . . . . . . . . . . . . . . . . . . . . . . . . . . . .380

Performing the Update on Warp Engine ZW . . . . . . . . . . . . . . . . . . . . . . . . . . 381

10-3 Processing Item Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

10-4 System data list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

10-5 Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Object Dictionary Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Data type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Description Format of Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Communication Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

PDO Mapping Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Sync Manager Communication Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Manufacturer Unique Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

14

ZW User's Manual

1

ZW User's Manual

15

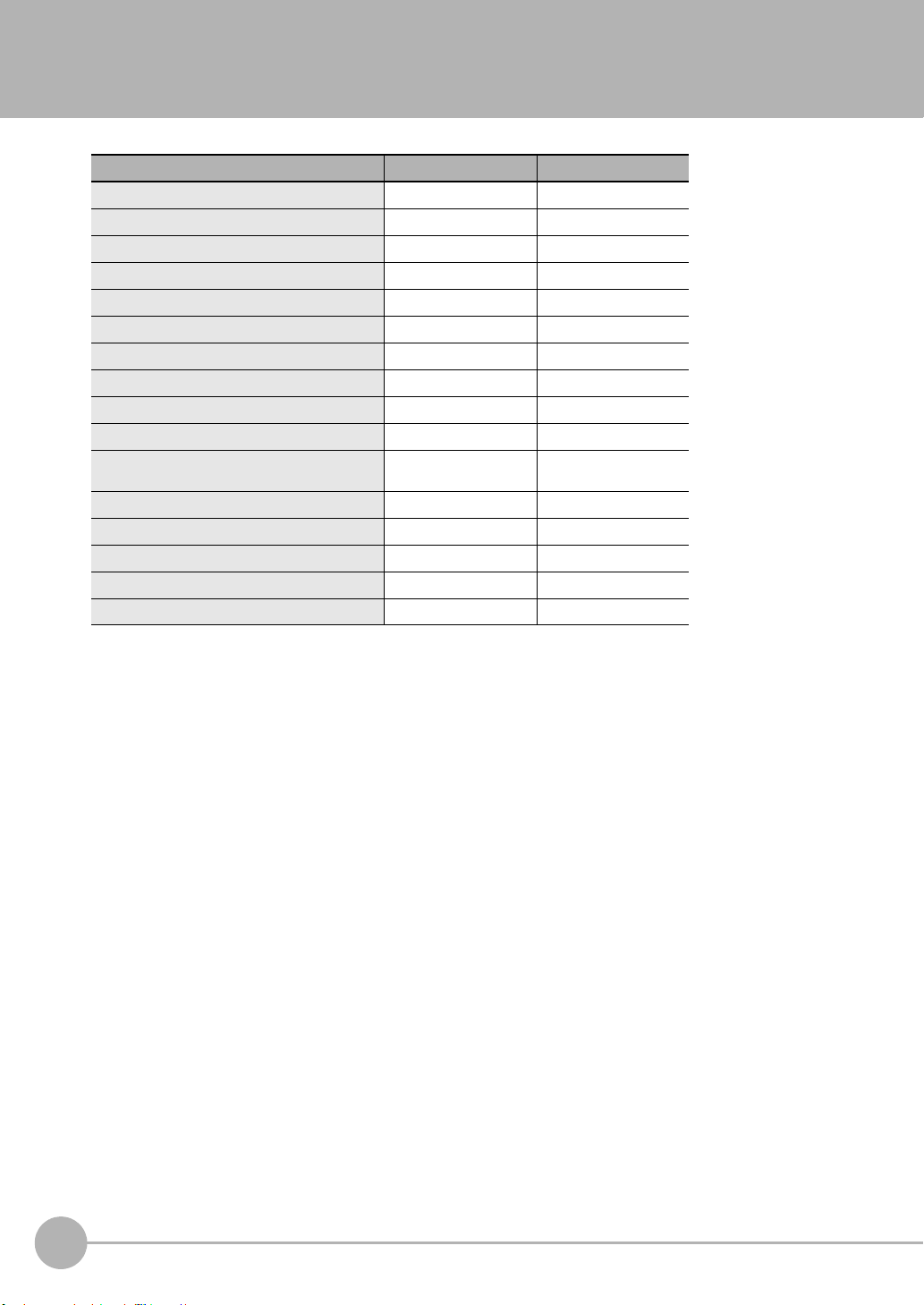

Search from Settings

Settings Set by Sysmac Studio Set by Sensor Controller

Setting the Material for the Target to Measure p.75 p.302

Setting Exposure Time Control Mode p.79 p.304

Measuring the Height p.83 p.305

Measuring the Thickness p.85 p.306

Calculating p.86 p.307

Setting the Filter p.93 p.310

Setting the Scaling p.87 p.314

Setting the Hold p.98 p.318

Setting the Zero Reset p.105 p.322

Changing the Bank Mode p.110 p.327

Copying the Bank/System Settings p.111 p.328

Saving the Bank/System Settings p.112 p.329

Clearing the Bank Settings p.113 p.330

Checking Information p.114 p.334

Setting the Key Lock p.115 p.335

Initializing Settings p.116 p.337

(Bank Settings only)

16

Search from Settings

ZW User's Manual

Basic configuration

1-1 ZW-series Displacement Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1-2 Basic Operation Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1

Basic configuration

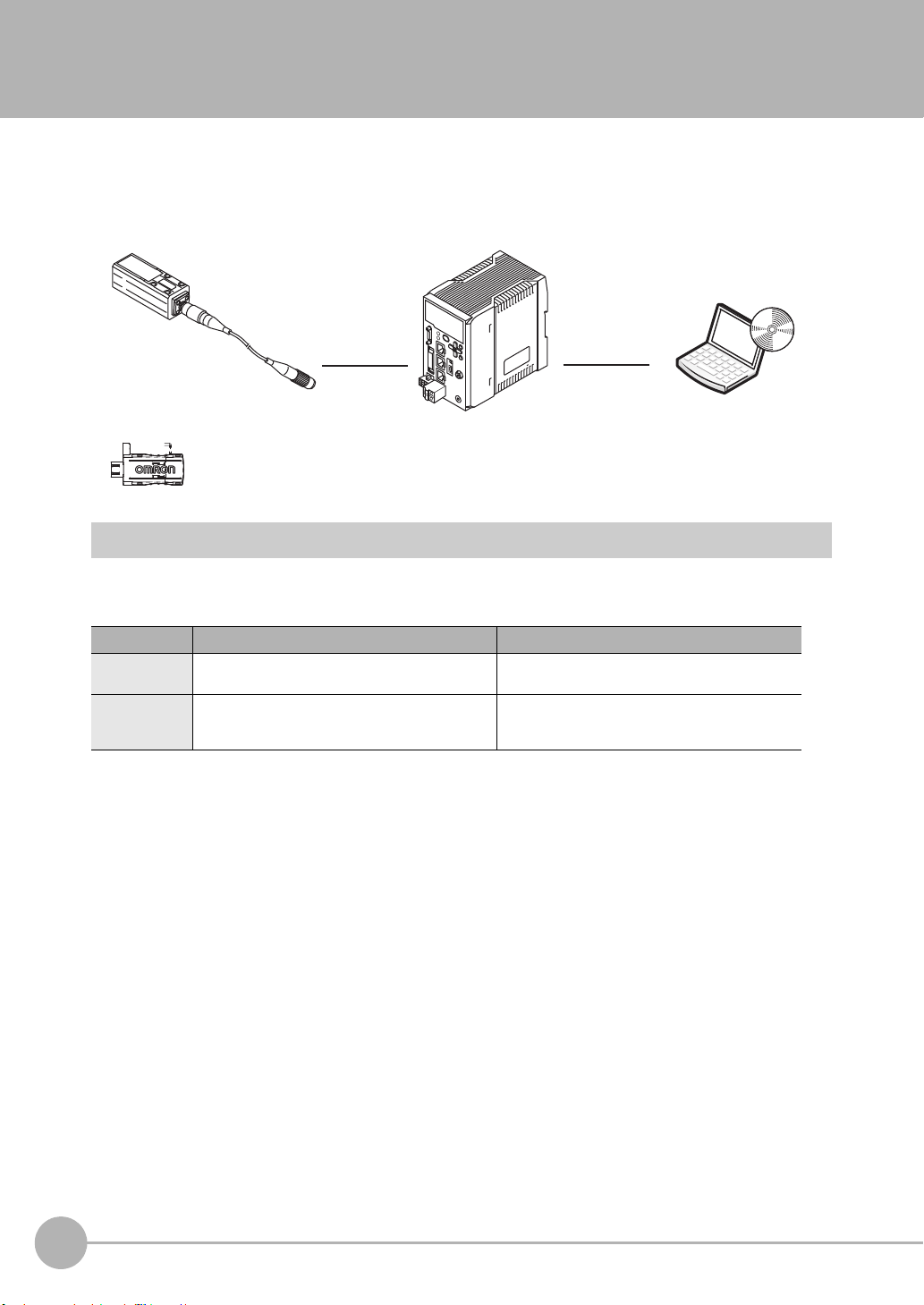

1-1 ZW-series Displacement Sensors

The ZW-series is a line of fiber coaxial displacement sensors.

They consist of Sensor Head and Sensor Controller, calibration ROM, and exclusive setting PC tool which runs

on personal computers for system settings and monitoring.

Sensor head

Detects a target to

measure.

Sensor Controller PC tool

Personal

computer

Calibration ROM

(included with sensor head)

Associated with

the sensor on a

one-to-one basis

Performs measurements

and outputs the result.

Allows making advanced settings

and checking up measured

values easily using exclusive

personal computer software.

Types of Sensor Controllers

The ZW Series has two types of Controllers (hereinafter be referred to as "Sensor Controller" in this

document.). Differences are described below.

Model ZW-C1@T/ZW-C1@AT ZW-CE1@T

I/O

Specifications

PC tool Sysmac Studio (Measurement Sensor Edition)/

EtherCAT and EtherNet/IP not mounted,

Binary output device mounted

Smart MonitorZW version 1.10 or later

EtherCAT and EtherNet/IP mounted,

Binary output device not mounted

Sysmac Studio (Standard Edition)/ Sysmac Studio

(Measurement Sensor Edition)/Smart MonitorZW

version 1.10 or later

18

ZW-series Displacement Sensors

ZW User's Manual

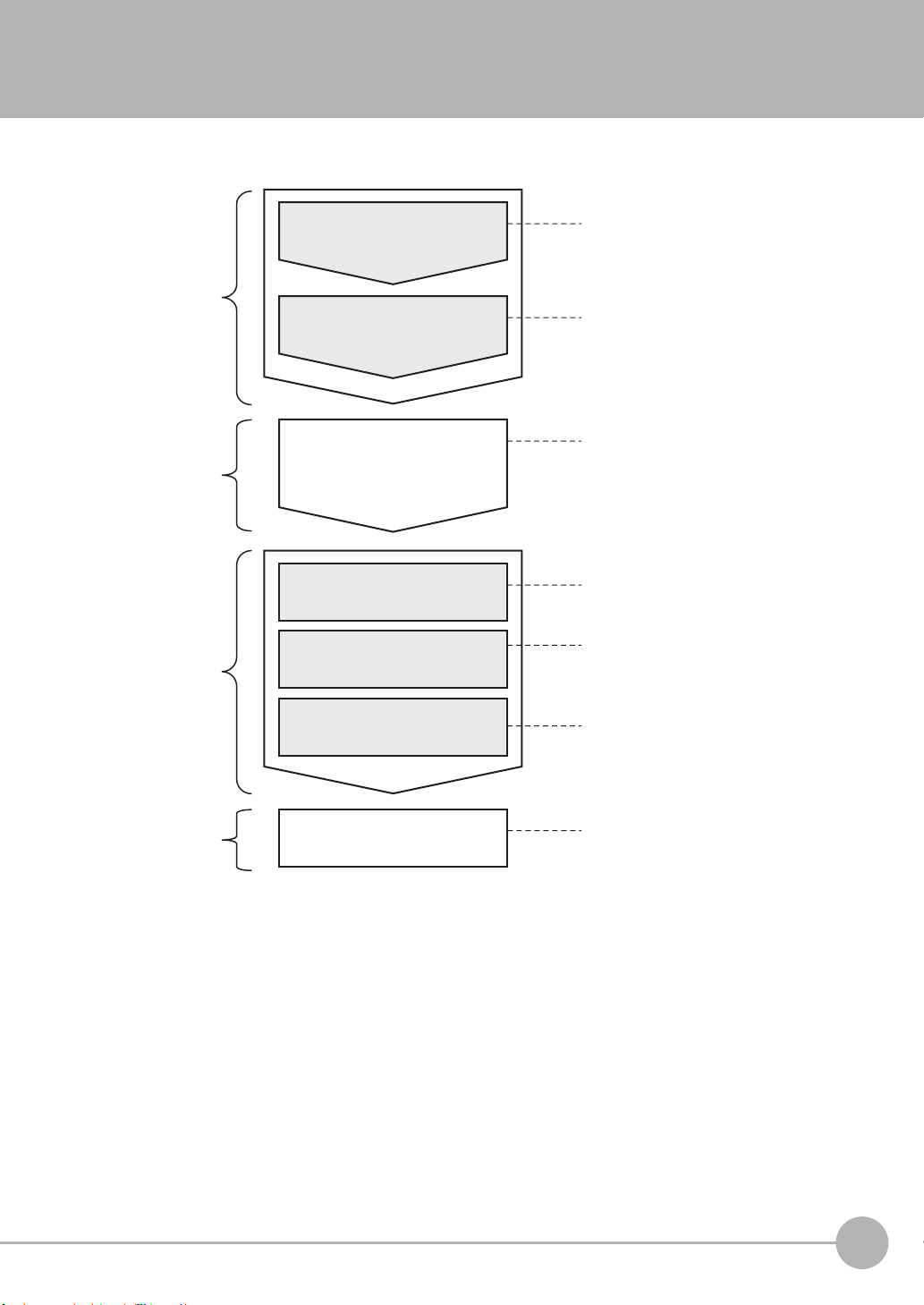

1-2 Basic Operation Flow

Installation and connection

Section 2

4-2

4-3

Preparation

for measurement

Setting

measurement

items

Setting output

processing

Saving settings

Install the sensor head.

Default settings for connecting

the sensor head.

Perform a sensor head calibration.

Setting the scaling

Calibrate the display of the

measured value.

Setting the hold

Set the hold conditions.

Setting the Zero Reset

Set the Zero Reset.

Saving the setting data (*1)

Save the set data.

Setting measurement items

Select task(s) from TASK1 to

TASK4, and set measurement

items, including height, thickness

and calculation.

Setting Measurement Items

Setting the Output Conditions

Installation and Connections

Section 2 Installation and Connections

Section 4 Settings for Functions

Section 4 Settings for Functions

4-3 Setting the Output Conditions

Section 4 Settings for Functions

4-3 Setting the Output Conditions

Section 4 Settings for Functions

3-7 Saving a Project

Section 3 Basic Operation

(*1) After you have made or changed settings,

be sure to save the setup data.

All set data will be cleared if you turn the

power OFF without saving the data.

The following is the basic operation flow for ZW Series.

1

Basic configuration

ZW User's Manual

Basic Operation Flow

19

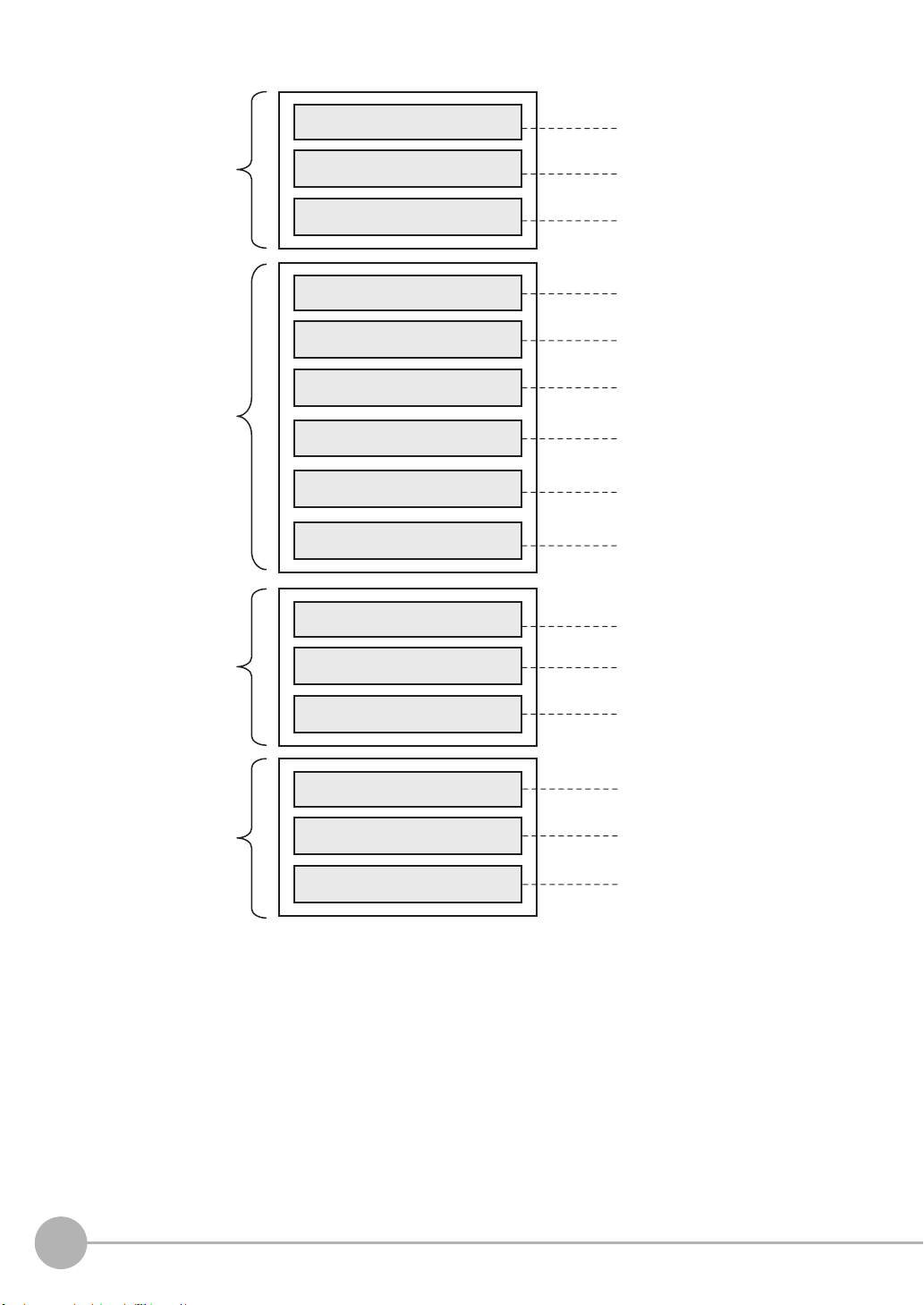

Functions used

during operation

Operations and

settings according

to need

When having

trouble with setting

When you need

help

Setting Threshold Value

Switching Banks

Executing Zero Reset

Changing Material Settings

Changing Exposure Time Control

Mode Settings

Setting Filter

When the Sysmac error status is

displayed

When an error message is

displayed

When it does not work correctly

Setting I/O (analog/judgment)

Using EtherCAT Communications

Using Ethernet/IP Communications

Using Ethernet/

RS-232C Communications

Setting the Banks

Setting the System Environment

3-6 Setting Threshold Value

6-1 Parallel I/O connection

6-2 EtherCAT Connection

6-3 Ethernet/IP Connection

6-4 No-protocol Connection

3-4 Bank Switching

3-5 Perform the Zero Reset

Section 3 Basic Operation

Section 6 Communications with

External Devices

4-4

Setting the Banks

4-5

Setting the System

4-2

Setting Measurement Items

4-1

Setting Sensing

4-3

Setting the Output Conditions

Section 4 Settings for Functions

Section 4 Settings for Functions

8-1

Error Messages

8-1

Error Messages

8-2

Troubleshooting

Section 8 Troubleshooting

20

Basic Operation Flow

ZW User's Manual

Installation and Connections

2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2-2 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2-3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2-5 Installing the Sysmac Studio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2

Installation and Connections

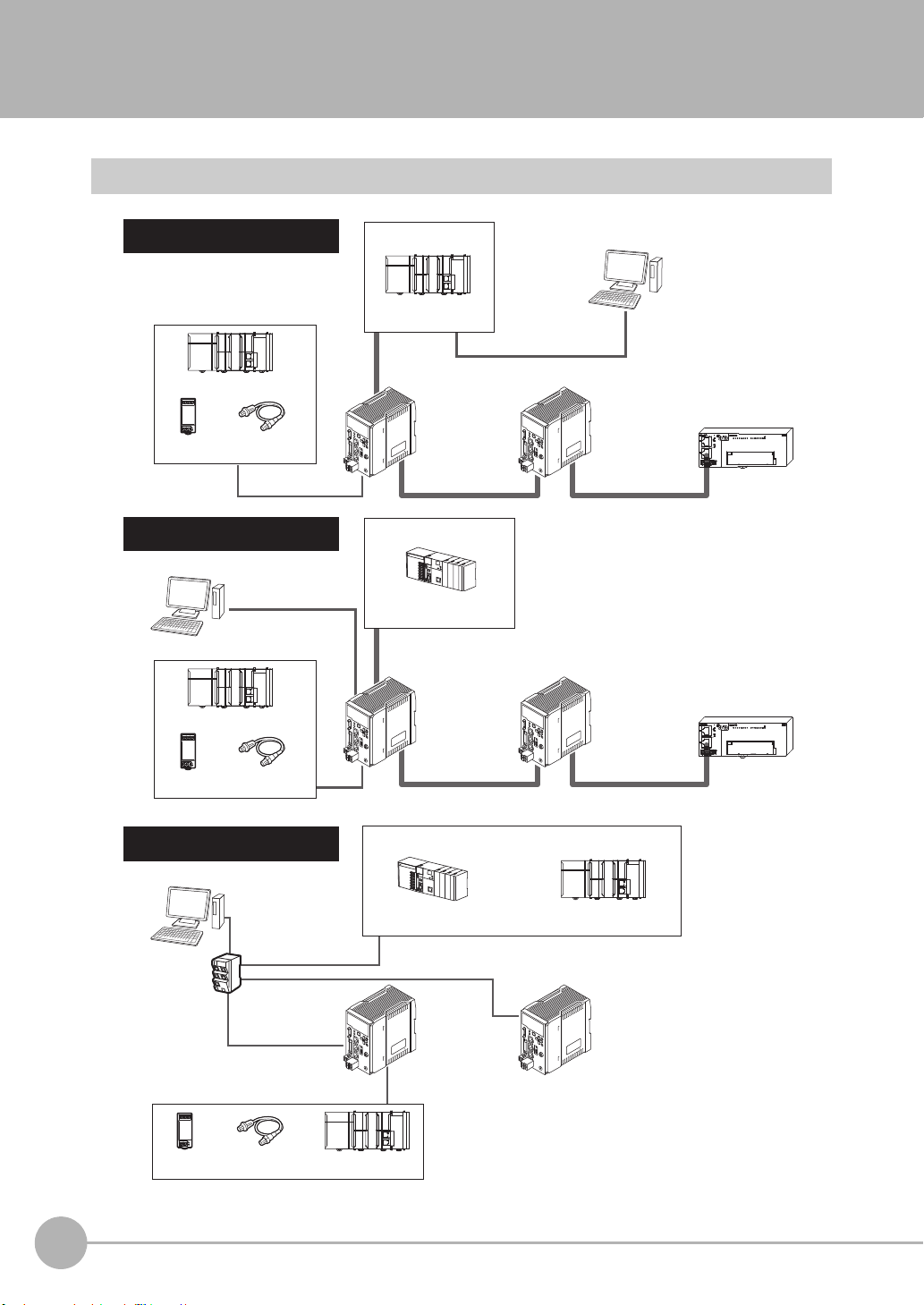

2-1 System Configuration

Ethernet/IP and No-protocol

Ethernet Connections

Control PLC, RC, or MC

Programmable Controller

with CJ2 CPU Unit

Programmable Controller

with CJ2 CPU Unit

ZW-CE1@T

ZW-CE1@T

ZW-CE1@T

Connecting with EtherCAT

(when the master is NJ Series)

Connecting with EtherCAT (when

the master is other than NJ Series)

Special EtherCAT

Cable (RJ45/RJ45)

Special EtherCAT

Cable (RJ45/RJ45)

Special EtherCAT Cable

(RJ45/RJ45)

Special EtherCAT Cable

(RJ45/RJ45)

Special EtherCAT Cable

(RJ45/RJ45)

Other EtherCAT slaves

Special EtherCAT Cable

(RJ45/RJ45)

Other EtherCAT slaves

General-purpose USB Cable

General-purpose Ethernet Cable

Industrial

EtherNet/IP/

Ethernet

Switching Hub

Sysmac Studio

Standard Edition

(*1)

NJ-series Machine

Automation Controller

NJ-series Machine

Automation Controller

EtherCAT Master

EtherCAT Master

Parallel Cable

Parallel Cable

Parallel Cable

If you use Smart Monitor ZW, Connect the PC and the ZW to control.

24-V

power supply

I/O control PLC

Trigger input

sensor

24-V

power supply

I/O control PLC

I/O control PLC

Trigger input

sensor

24-V

power supply

Trigger input

sensor

(*1)

Sysmac Studio

Displacement Sendor

Edition

(*1)

Sysmac Studio

Displacement Sendor

Edition

(*1)

General-purpose

Ethernet Cable

General-purpose

Ethernet Cable

General-purpose

Ethernet Cable

General-purpose

Ethernet Cable

General-purpose

Ethernet Cable

System Configuration

22

System Configuration

ZW User's Manual

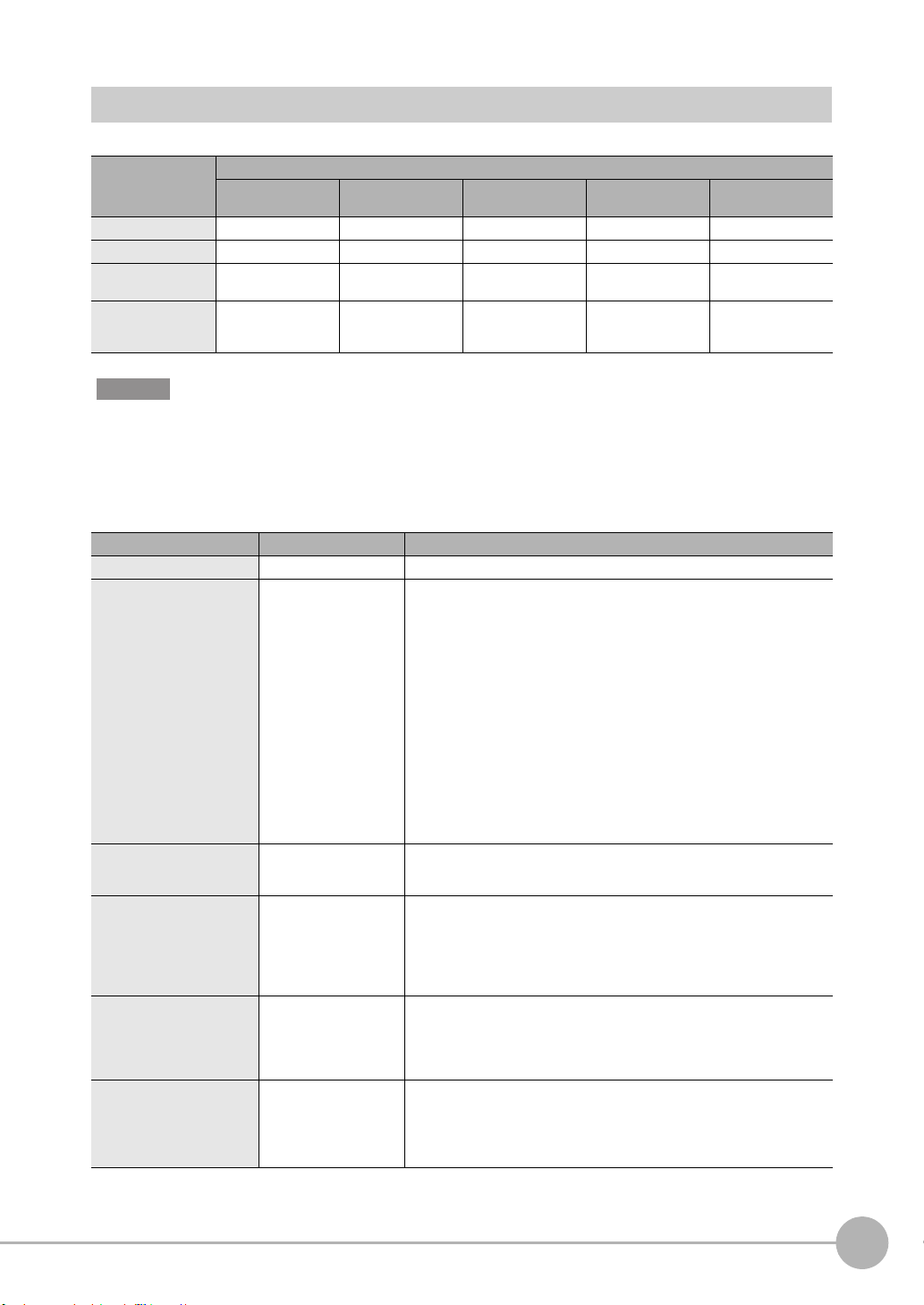

Connection Compatibility

Connected to

ZW-CE1@T

EtherCAT --- Not compatible Compatible Compatible Compatible

EtherNet/IP Not compatible --- Compatible Compatible Compatible

Ethernet

(no-protocol)

Ethernet

(programmable noprotocol)

Other connection

EtherCAT EtherNet/IP Ethernet

Compatible Compatible --- Compatible Compatible

Compatible Compatible Compatible --- Compatible

(no-protocol)

RS-232C

(no-protocol)

I/O Cable

Important

• EtherCAT and EtherNet/IP connections cannot be used at the same time.

• Can be connected simultaneously via Ethernet with PC tools (Sysmac Studio, SmartMonitorZW) and another

device (PLC etc). Can be connected simultaneously via Ethernet with PC tools (Sysmac Studio, SmartMonitorZW)

and another device (PLC etc). The port number for the PC tool is fixed to 9600. When connecting different devices,

set the port number to other than 9600 (default value is 9601).

Product Model Application

ZW ZW-CE1@T This Displacement Sensor performs measurements.

PC Tool Sysmac Studio Standard

Special EtherCAT Cable Refer to 10-1

General-purpose Ethernet

cable

Special I/O Cable For connecting to a PLC

Industrial EtherNet/IP /

Ethernet Switching Hub

Edition

• SYSMAC-SE200D

(no licenses included

(media only))

• SYSMAC-SE201L

(1-license edition)

• SYSMAC-SE2@@L

(multilicense editions

(3, 10, 30, or 50

licenses))

Sysmac Studio

Measurement Sensor

Edition

• SYSMAC-ME2@@L

(1 or 3 licences)

Specifications and

Dimensions

--- Prepare commercially available Ethernet cable

or programmable terminal

•ZW-XPT2

For connecting to a PC

•ZW-XRS2

• W4S1-03B

(3 ports type)

• W4S1-05B

• W4S1-05C

(5 ports type)

This is the setup application. It is part of the Sysmac Studio Package and it

runs on Windows.

The Sysmac Studio comes in two different editions.

• Sysmac Studio Standard Edition

The Sysmac Studio provides an integrated development environment for

the NJ-series Controllers and other Machine Automation Controllers and

EtherCAT Slaves. It supports setup, programming, debugging, operation,

and maintenance.

The Sysmac Studio Standard Edition DVD includes Support Software for

EtherNet/IP, DeviceNet, serial communications, and PT screen design

(CX-Designer). Refer to the Sysmac catalog (Cat. No. PXXX) for details.

• Sysmac Studio Measurement Sensor Edition

This license provides the functions that are required to set up ZW Vision

Sensors from the Sysmac Studio. This model number is for the license

only. You must also purchase the DVD for the Sysmac Studio Standard

Edition Ver.1.05 or higher.

The Special EtherCAT Cable connects the Sensor to another Sensor or to

another EtherCAT device.

satisfying the following requirements:

• Category 5e or more, 30 m or less

• RJ45 connector (8-pin modular jack)

• For direct connection: Select cross cable.

• For connection through an industrial switching hub: Select straight cable.

Connect the sensor with a PLC, programmable terminal, or personal

computer etc..

The Switching Hub connects multiple Sensors to one Touch Finder or one

computer running PC Tool.

2

Installation and Connections

ZW User's Manual

System Configuration

23

Product Model Application

EtherCAT Junction Slave • GX-JC03

(3 ports type)

•GX-JC06

(6 ports type)

Used to connect multiple sensors or PLCs using EtherCAT.

24

System Configuration

ZW User's Manual

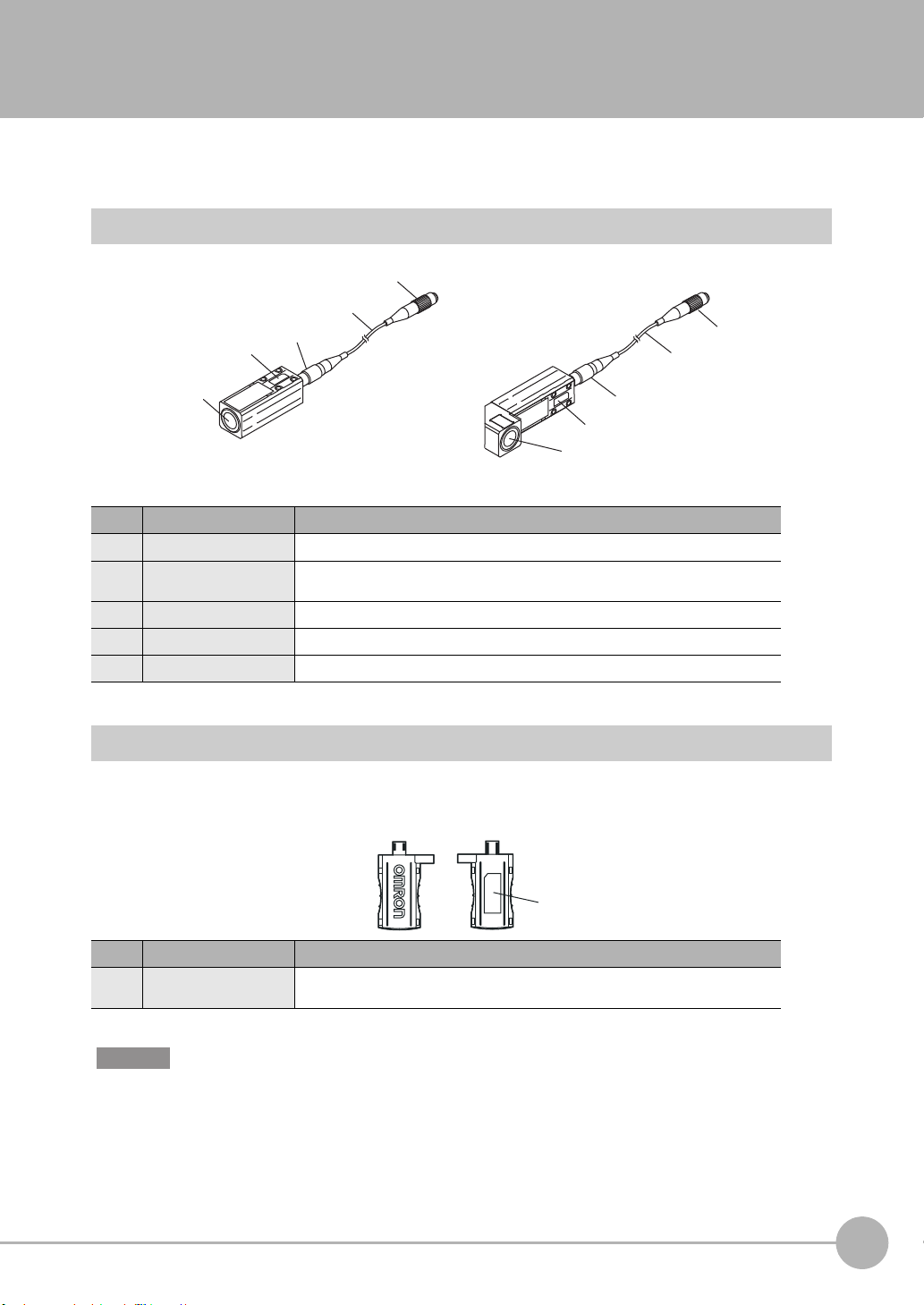

2-2 Part Names and Functions

1

1

5

4

5

4

2

2

Straight type Right angle type

3

3

1

The following describes the names and functions of parts of the Sensor Head, Calibration ROM and Sensor

Controller.

Sensor Head

No. Names Functions

1 Projector/receiver Projects and receives light.

2 Serial number. Serial number.

Only a calibration ROM with the same serial number is available.

3 Fiber interface Interfaces the Sensor Head and optical fiber (unremovable).

4 Fiber Cable Sends or receives light signals to/from the Sensor Controller.

5 Fiber Connector Couples the Sensor Controller and fiber cable.

2

Installation and Connections

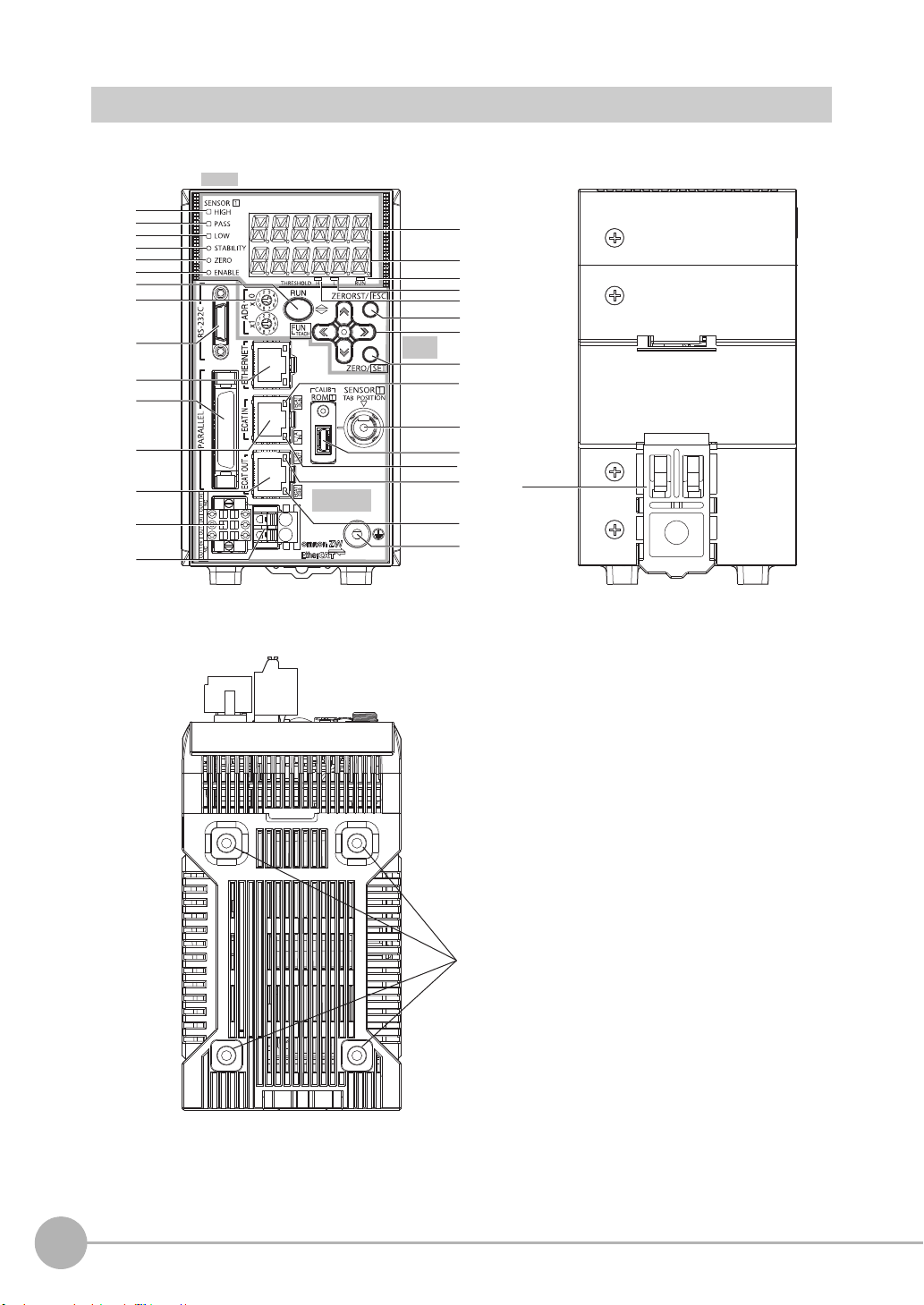

Calibration ROM

This ROM is associated with the sensor on a one-to-one basis, and operates connected to the Sensor

Controller.

No. Names Functions

1 Serial number Serial number.

Important

Use with the Calibration ROM always connected. If the Calibration ROM is not connected, an error is displayed.

ZW User's Manual

Only a Sensor Head with the same serial number is available.

Part Names and Functions

25

Sensor Controller

1

2

3

4

5

6

27

25

9

10

11

17

12

15

22

26

23

24

21

20

19

16

18

30

29

28

13

14

31

8

7

<Front view>

Display

<Rear view>

<Bottom view>

32

Control

Panel

Connectors/

terminals

26

Part Names and Functions

ZW User's Manual

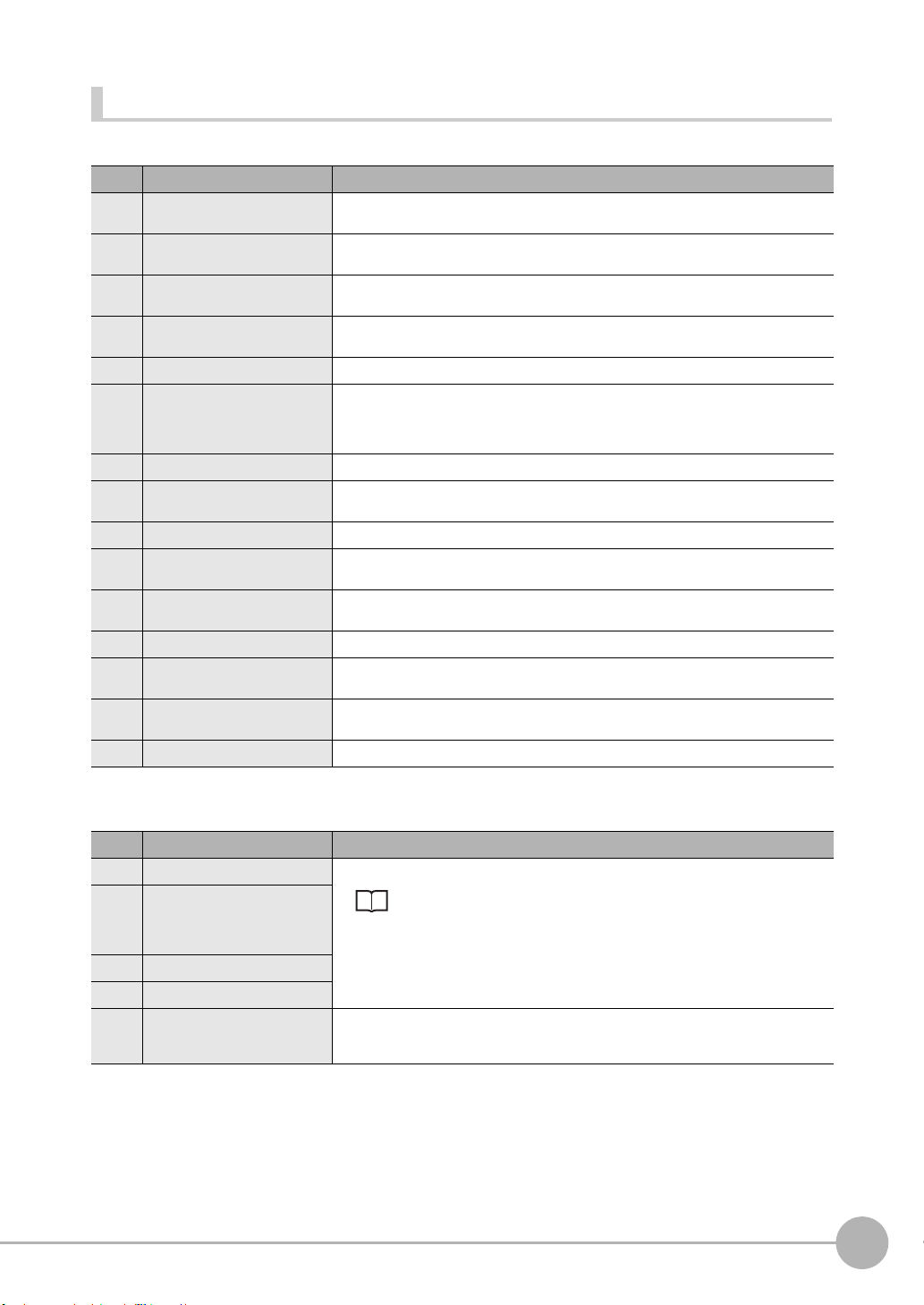

Front view

● Display

No. Names (light color) Functions

1 HIGH indicator (orange) The HIGH indicator is lit while judgment is resulted in HIGH (HIGH threshold value <

2 PASS indicator (green) The PASS indicator is lit while judgment is resulted in PASS (LOW threshold value

3 LOW indicator (orange) The LOW indicator is lit while judgment is resulted in LOW (measured value < LOW

4 STABILITY indicator (green) The STABILITY indicator is lit while a measured value is within the measuring range.

5 ZERO indicator (green) The Zero Reset indicator is lit while the zero reset function is enabled.

6 ENABLE indicator (green) The ENABLE indicator lights when the Sensor is ready for measurement. It goes off when

7 Main display (red) The main display shows measured values and/or function names.

8 Sub-display (green) The sub-display shows additional information for measured values or setting values for

9 RUN indicator (green) The RUN indicator is lit in the RUN mode, and goes out in the FUN mode.

10 THRESHOLD-L indicator

(orange)

11 THRESHOLD-H indicator

(orange)

12 ECAT RUN indicator (green) ECAT RUN indicator lights up when EtherCAT communication is established.

13 L/A IN indicator (green) L/A IN indicator lights up when connected with the EtherCAT device.

14 L/A OUT indicator (green) L/A OUT indicator lights up when connected with the EtherCAT device.

15 ECAT ERROR indicator (red) ECAT ERROR indicator lights up when an EtherCAT communication error occurs.

measured value).

measured value HIGH threshold value).

threshold value).

It goes out if a measured value is out of the measuring range.

measurement is not possible (e.g. when the received light amount is excessive or

insufficient, when the measuring range is exceeded, when the calibration ROM is not

connected, or when measurement is not being performed in FUN mode).

functions.

The LOW threshold value indicator is lit when the Sub-display indicates a LOW threshold

value.

The HIGH threshold value indicator is lit when the Sub-display indicates a HIGH threshold

value.

Flashes when communication (data input) is performed.

Flashes when communication (data output) is performed.

2

Installation and Connections

● Control panel

No. Names Functions

16 ZERORST/ESC key These keys function differently depending on operation modes.

17 (LEFT) key

(RIGHT) key

(UP) key

(DOWN) key

18 ZERO/SET key

19 Mode switching key

20 Node address setting switches These switches are used to set the node address as an EtherCAT communications

ZW User's Manual

device.

The setting range is 01 to 99.

9-2 Functions of Operating Keys p.294

Part Names and Functions

27

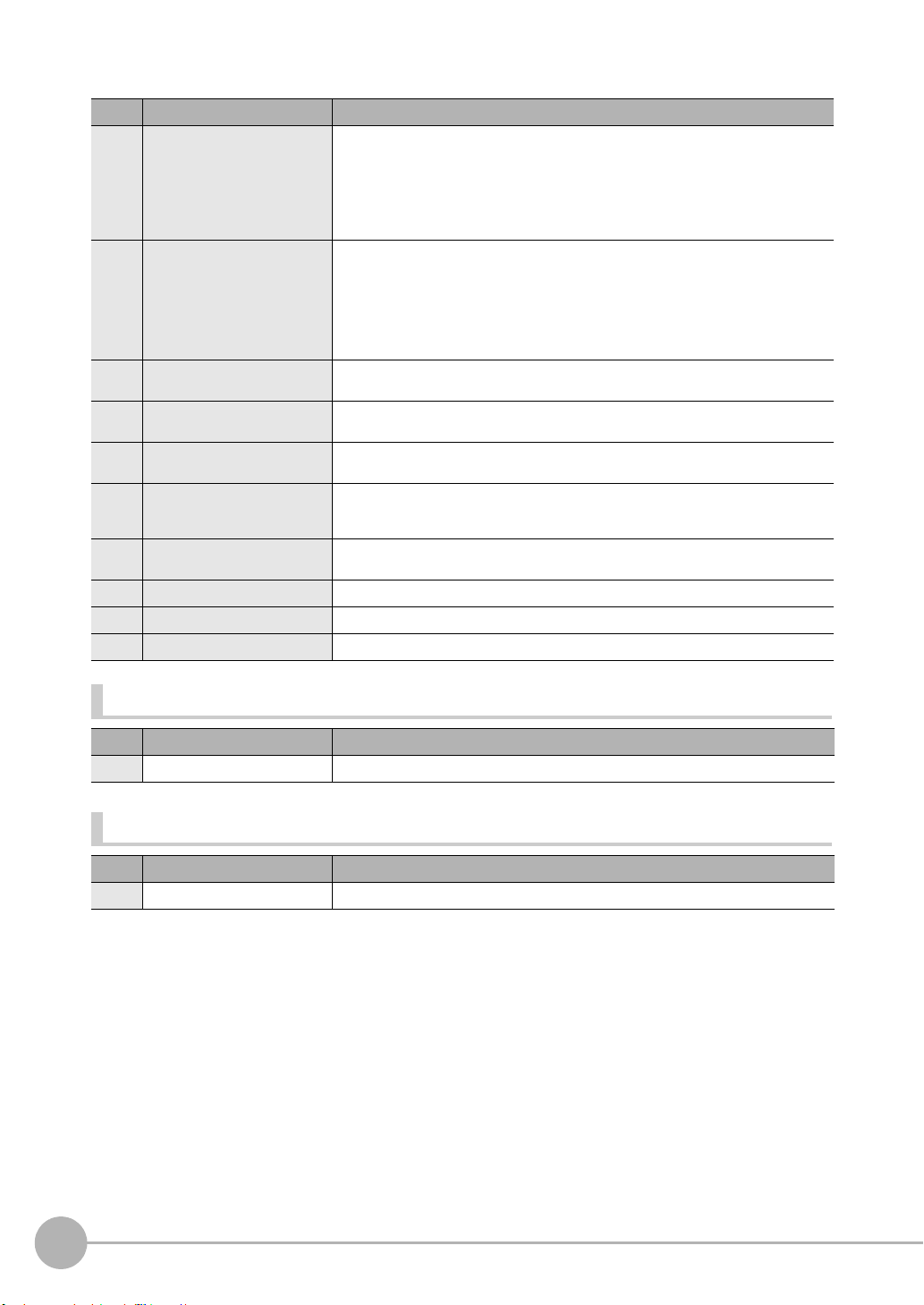

● Connectors/terminals

No. Names Functions

21 RS-232C connector Connect the RS-232C cable when you are connecting the system with a PLC or personal

22 Ethernet connector This connector is used to connect with a personal computer through Ethernet.

23 EtherCAT input connector This connector is used to connect to EtherCAT-compatible devices.

24 EtherCAT input output connector This connector is used to connect to EtherCAT-compatible devices.

25 24 V input terminal block This connector is used to connect to Sensor Controller DC24 V power supply. The length

26 32-pole extension connector This connector connects the parallel I/Os, including output for judgment, ALARM, BUSY

27 Analog output terminal block This connector connects the output for analog voltage and analog current. The length of

28 Fiber connector The fiber connector connects the fiber cable.

29 ROM connector The ROM connector connects the calibration ROM.

30 Frame ground terminal This is the connector for frame ground. It connects grounding wire.

computer through RS-232C.

For the RS-232C cable, please use the following exclusive products:

If you use a cable not included in the exclusive products, a false operation or breakdown

may result.

• For connecting to a PLC or programmable terminal: ZW-XPT2

• For connecting to a PC: ZW-XRS2

Prepare commercially available Ethernet cable satisfying the following requirements:

• Category 5e or more, 30 m or less

• RJ45 connector (8-pin modular jack)

• For one-to-one connection: Select cross cable.

• For connection through an industrial switching hub: Select straight cable.

(Recommended hub: W4S1-0@ (Omron))

Use the recommended EtherCAT cable.

Use the recommended EtherCAT cable.

of Cables should be less than 30 m.

or ENABLE, or input for ZERO, RESET, TIMING, LED-OFF or LOGGING, or bank number output and bank number selection input.

Cables should be less than 30 m.

Rear view

No. Names Functions

31 DIN track attachment hook Used when fixing the Sensor Controller on DIN track.

Bottom view

No. Names Functions

32 Installation screw hole Used when fixing the Sensor Controller with screws.

28

Part Names and Functions

ZW User's Manual

Loading...

Loading...