Page 1

Displacement Sensor

ZW-8000/7000/5000 series

Confocal Fiber Type

Displacement Sensor

User’s Manual for Communications Settings

ZW-8000@

ZW-7000@

ZW-5000@

Z363-E1-06

Page 2

Introduction

Thank you for purchasing the ZW-8000/7000/5000 Series.

This manual provides information regarding functions, performance and operating methods that

are required for using the ZW-8000/7000/5000 Series.

When using the ZW-8000/7000/5000 Series, be sure to observe the following:

• The ZW-8000/7000/5000 Series must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

Terms and Conditions Agreement

(Please Read)

User’s Manual for

Communications

Settings

Overview of Communication Specifications

Parallel I/O Connection

EtherCAT Connection

EtherNet/IP Connection

No-protocol Connection

Sensor Controller Operations

1

2

3

4

5

6

Confocal Fiber Type

Disp

laceme

ZW-8000/7000/5000 Series

nt Sensor

Troubleshooting

Appendices

7

8

Page 4

Terms and Conditions Agreement

Read and understand this Manual

Please read and understand this catalog before purchasing the products. Please consult your OMRO N

representative if you have any questions or comments.

Warranties

• Exclusive Warranty

Omron’s e xc lus ive warranty is that the Products will be free from defects in materials and workmanship for a

period of twelve months from the date of sale by Omron (or such other period expressed in writing by

Omron). Omron disclaims all other warranties, express or implied.

• Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

i

nfringeme

obligation hereunder shall be, at Omro n’s election, to (i) replace (in the form originally shipped with Buyer

responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Prod

to the purchase price of the non-comply ing Product; pro vid ed that in no event shall Omron be responsib le for

warranty, repair , indemnity or any other claims or expenses regarding the Products unless Omron’s analysis

confirms that the Products were properly handled, stored, installed and maintained and not subject to

contamination, abuse, mis use or inappropriate modification. Return of any Products by Buyer must be

approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with any electrical or electronic

components, circuits, syst em assemb li es or an y othe r materials or substa nces or en vironme nts . An y advice,

recommendations or information given orally or in writing, are not to be construed as an amendment or

addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

nt by the Products or otherwise of any intell ectual property right. (c) Buyer Remedy. Omron’s sole

uct, or (iii

) repay or credit Buyer an amount equal

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which

l

is asserted.

iability

Suitability of Use

Omron Companies shall not be responsible f or conf ormity with any standards , codes or regulations which apply

to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron

will provide applicable third party certification documents identifying ratings and limitations of use which apply

to the Product. This information by itself is not sufficient for a complete determination of the suitability of the

Product in combination with the end product, machine, system, or other application or use. Buyer shall be

solely responsible f or determining appropriateness of the particular Product with respect t o Buyer’s application,

product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

2

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 5

OR IN LARGE QUANT ITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN

DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any

consequence thereof.

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user

in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test

conditions, and the user must correlate it to actual application requirements. Actual performance is subject to

the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or when

significant construction changes are made. Ho wever, some specifications of the Product may be changed

without any notice. When i n doubt, special part numbers may be assigned to fix or establish key specifications

for your application. Please consult with your Omron’s representative at any time to confirm actual

specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typog raphical or proofreading errors or omissions.

ZW-8000/7000/5000

User’s Manual for Communications Settings

3

Page 6

Precautions on Safety

For details on the precautions on safety, refer to the following manual:

"Precautions on Safety" described in Displac ement Se nsor ZW-8000/7000/5000 series Confocal Fiber

Type Displacement Sensor User's Manual (Z362)

Precautions for Safe Use

For details on the precautions for safe use, refer to the following manual:

"Precautions for Safe Use" described in Displacement Sensor ZW-8000/7000/5000 series Confocal

Fiber Type Displacement Sensor User's Manual (Z362)

Precautions for Correct Use

For details on the precautions for correct use, refer to the following manual:

"Precautions for Correct Use" described in Displacemen t Sensor ZW-8000/7000/5000 series Confocal

Fiber Type Displacement Sensor User's Manual (Z362)

Editor's Note

● Meaning of Symbols

Menu items that are displa yed on the main or sub-display, and windows, dialog boxes and other GUI elements

displayed on the personal computer are indicated enclosed by brackets [ ].

●

Visual Aids

Important

Note

Optional

Indicates points that are important to achie ve the full product performance, such as oper a tiona l

precautions.

Indicates application procedures.

Indicates pages where related information can be found.

Indicates that the setting is optional in a configuration procedure.

Copyrights and Trademarks

• Sysmac is a trademark or registered trademark of OMRON corporation in Japan and other countries for our FA

equipment products.

• Windows, Windows XP, Windows Vista, Windows 7, and Windows 8 are registered tr

Corporation in the USA and other countries.

• EtherCAT

Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• Microsoft product screen shots reprinted with p

• Other system names and product names that appear in this manual are the trademarks or

the respective companies.

®

is registered trademark and patented technology that is licensed by Beckhoff Automation GmbH,

ermission from

Microsoft Corporation.

ademarks of Microsoft

registered trademarks of

4

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 7

Notice

• Photocopying, duplication, or copying of all or part of this manual without permission is prohibited.

• Please understand that the specifications and other contents of this manual are subject to change f

without notice.

• Every effort has been made to ensure the accuracy of the contents of this manual, but if you should notice an

mistake, questionable section, or the like in this manual, please contact an OMRON branch or sales office.

If you do so, please also tell us the manual number, which is found at the end of the manual.

or improvement

y

ZW-8000/7000/5000

User’s Manual for Communications Settings

5

Page 8

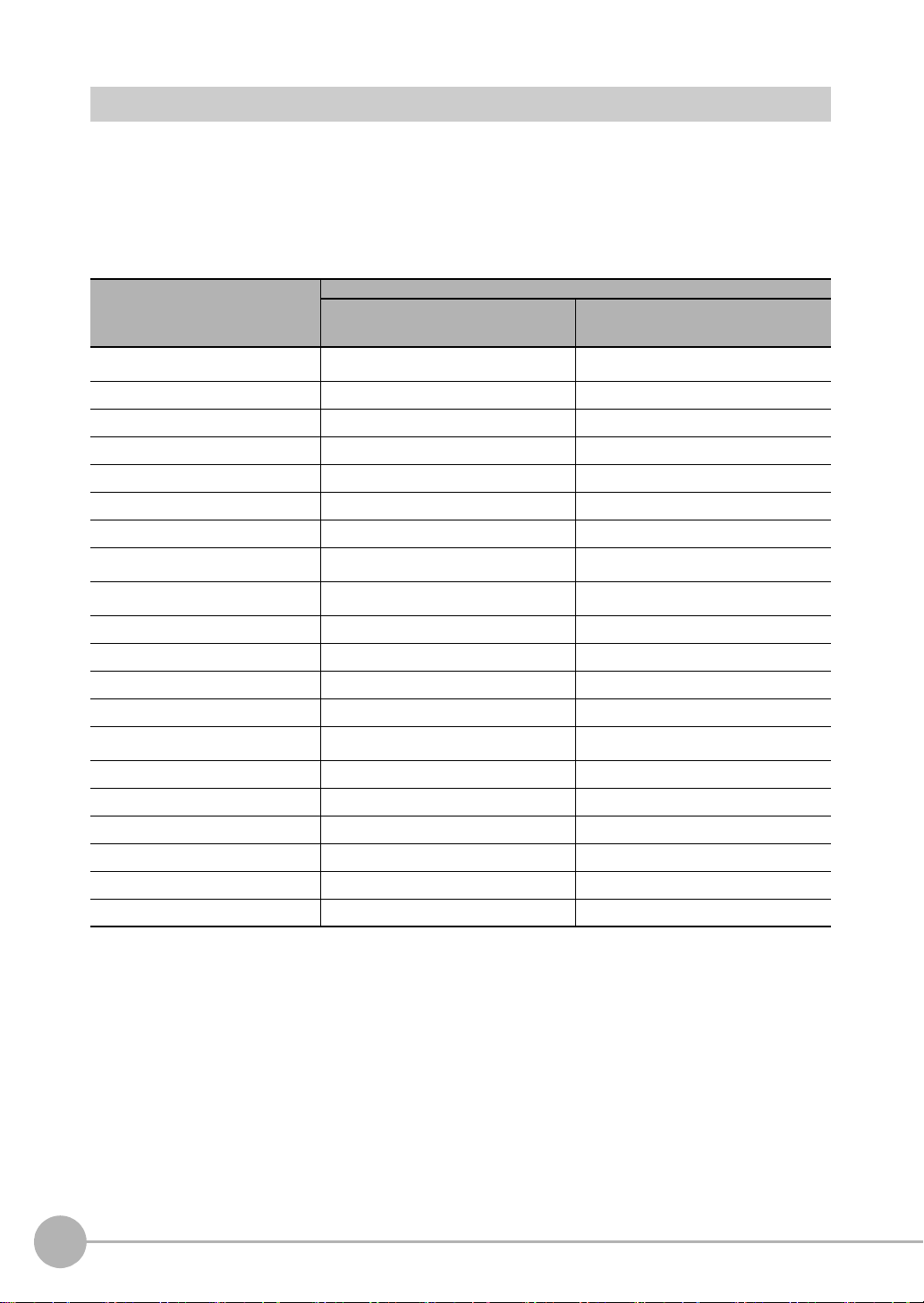

Relevant Manuals

The following table provides the relevant manuals for the ZW-8000/7000/5000 series Conf ocal Fiber Type

Displacement Sensor.

Read all of the manuals that are relevant to your system configuration and application before you use the ZW8000/7000/5000 series Confocal Fiber T ype Displacement Sensor.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the “Sysmac Studio

V ersion 1 Operation Manual (Cat. No. W504)” for information on the Sysmac Studio.

Purpose of use Manual

Overview of ZW-8000/7000/5000

series

Setup and Wiring

Basic Operation

Function Setting

Offline Setting

Confirm the Menu List

Connecting to the Sensor Controller

Connecting to the Sensor Controller for

Communication Settings

Overview of Communication Specifica-

tions

Parallel I/O

EtherCAT

EtherNet/IP

No-protocol

Specifications and External Dimen-

sions

Processing Item List

System Data List

Object Dictionary

Update the Firmware

Troubleshooting

Error Messages

ZW-8000/7000/5000 series Confocal Fiber

Type Displacement Sensor User's Manual

●

●

●

●

●

●

●

●

●

●

ZW-8000/7000/5000 series Conf o cal Fiber

Type Displacement Sensor User's Manual

for Communications Settings

●

●

●

●

●

●

●

●

●

●

6

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 9

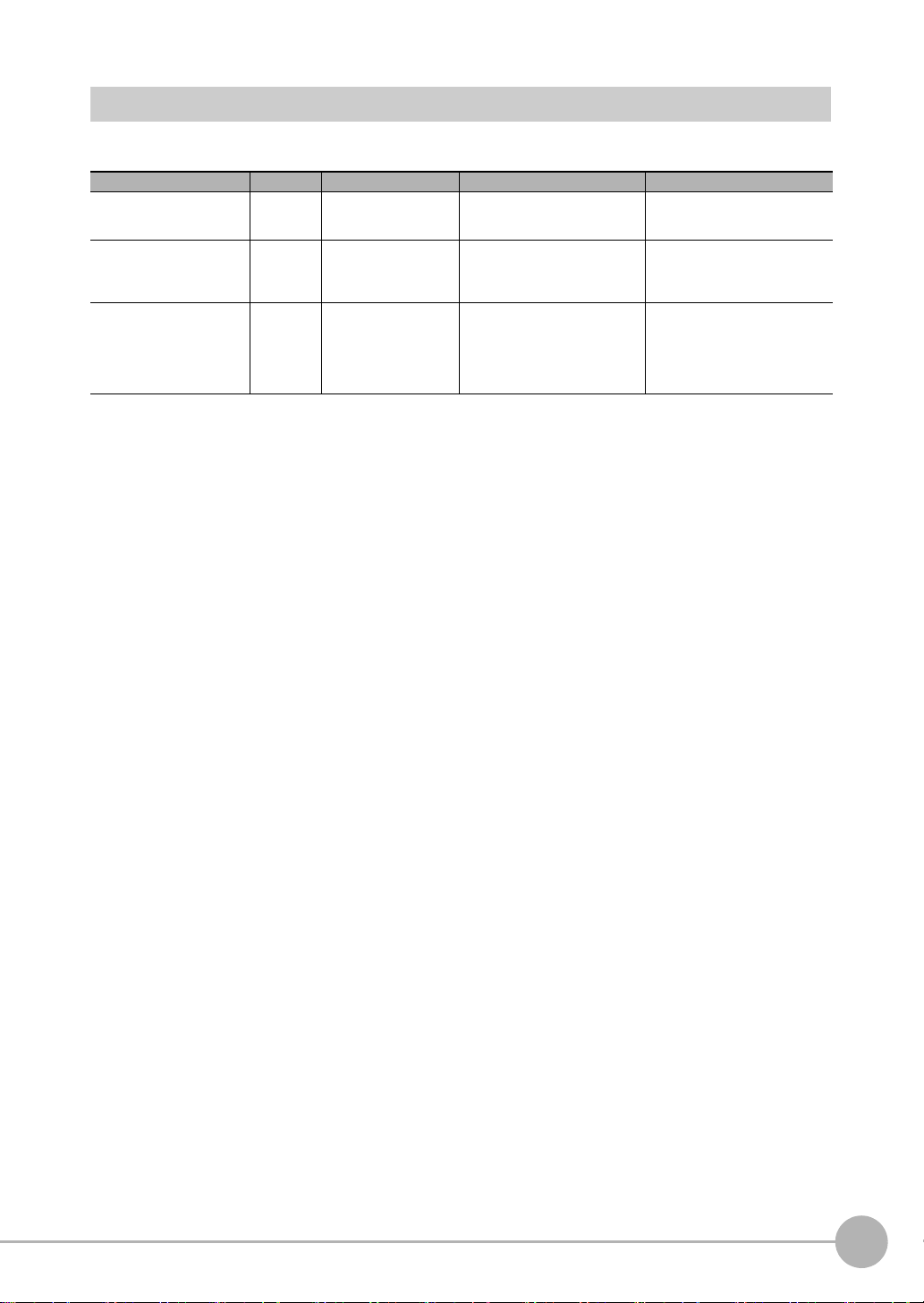

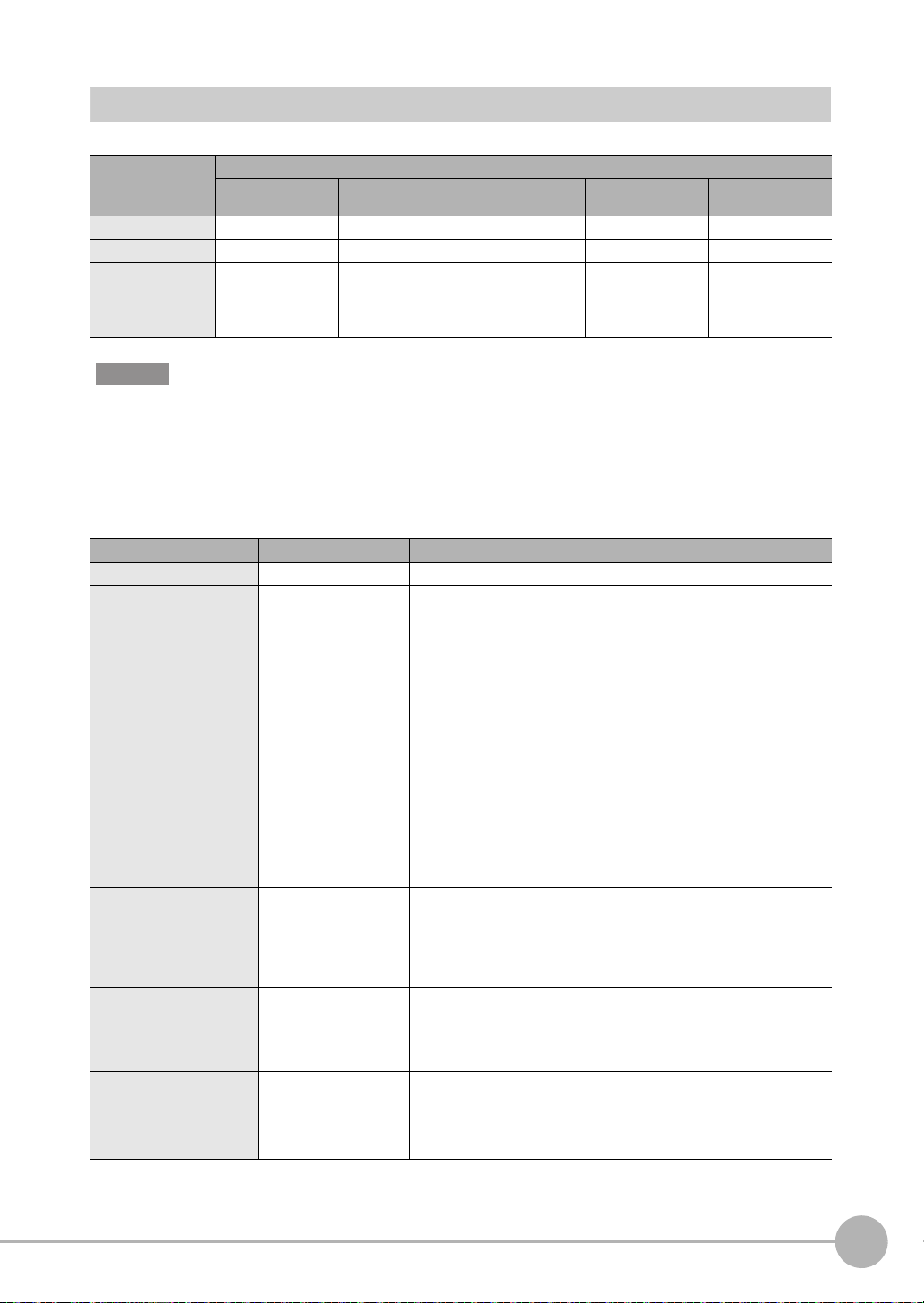

Related Manuals

The related manuals are described the below tables. Please check the manuals.

Manual name Cat. No. Model numbers Application Description

Sysmac Studio Version 1

Operation Manual

Confocal Fiber Type

Displacement Sensor

ZW-8000/7000/5000

series User's Manual

Confocal Fiber Type

Displacement Sensor

ZW-8000/7000/5000

series User's Manual for

Communication Settings

(This manual)

W504 SYSMAC-SE2@@@ Learning about the operating

Z362 ZW-8000@

Z363 ZW-8000@

ZW-7000@

ZW-5000@

ZW-7000@

ZW-5000@

procedures and functions of

the Sysmac Studio.

To learn how to set-up of Confocal Fiber Type Displacement

Sensor of ZW-8000/7000/5000

series.

To learn how to use communication settings of Confocal

Fiber Type

Displacement Sensor of ZW8000/7000/5000 series.

Describes the operating procedures of the Sysmac Studio.

Describes how to set-up of

Confocal Fiber Type

Displacement Sensor of ZW8000/7000/5000 series.

Describes how to use communication settings of Confocal

Fiber Type

Displacement Sensor of ZW8000/7000/5000 series.

ZW-8000/7000/5000

User’s Manual for Communications Settings

7

Page 10

8

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 11

Table of Contents

Editor's Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Copyrights and Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Relevant Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.Overview of Communication Specifications

1-1 Overview of Communication Specifications . . . . . . . . . . . . . . . . . . . 14

Overview of Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1-2 Checking the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connection Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.Parallel I/O Connection

2-1 Parallel I/O Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

I/O Signal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Settings for Parallel Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Settings for Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Settings for Judgment Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Settings for Bank Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table of Contents

3.EtherCAT Connection

3-1 EtherCAT Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Overview of EtherCAT Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Communication Methods for Measurement Sensor when Connect ed via EtherCAT

48

Setting Communications Specifications (EtherCAT Communications) . . . . . . .51

List of I/O Ports for Each Area (PDO Mapping) and Memory Assignments . . . 52

Timing Chart (EtherCAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Sample Ladder Program (EtherCAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Sysmac Device Features (EtherCAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.EtherNet/IP Connection

4-1 EtherNet/IP Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ZW-8000/7000/5000

User’s Manual for Communications Settings

9

Page 12

Introduction to EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Communication Methods for Measurement Sensor when Connect ed vi a EtherNe t/

IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Setting Communications Specifications (EtherNet/IP) . . . . . . . . . . . . . . . . . . .95

Tag Data Link Setting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Memory Assignments and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Timing Chart (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Sample Ladder Program (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

5.No-protocol Connection

5-1 No-protocol Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Outline of No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Setting Communications Specifications (Ethernet Co mmunications) . . . . . . .121

Setting Communications Specifications (RS-232C Communications) . . . . . .123

Setting for serial data output after application of measured valu e . . . . . . . . .124

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

6.Sensor Controller Operations

6-1 Connecting Parallel I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Settings for Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Settings for Judgment Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Settings for Processing When Measurem e nt Is No t Po ssi b le . . . . . . . . . . . . .166

Settings for Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Settings for Parallel Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Settings for TIMING Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Setting for Internal Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

6-2 Connecting with EtherCAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Setting Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Setting GATE Signal ON Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

6-3 Connecting with EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Network Settings of the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Setting Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

6-4 Connecting by No-protocol Communications . . . . . . . . . . . . . . . . . 179

Initial Settings for No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . .179

Setting Communications Specifications (RS-232C Communications) . . . . . .180

Setting Serial Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Set the delimiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

7.Troubleshooting

7-1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

10

Errors for EtherCAT Connection (Sysmac Error Status) . . . . . . . . . . . . . . . . .184

Errors for EtherCAT Connection (SDO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 13

Errors for Ethernet or EtherNet/IP Connection . . . . . . . . . . . . . . . . . . . . . . . .197

Errors Common to All Communication States . . . . . . . . . . . . . . . . . . . . . . . . .198

7-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

8.Appendices

8-1 Processing Item Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

8-2 System data list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

8-3 Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Object Dictionary Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Data type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Description Format of Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Communication Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

PDO Mapping Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Sync Manager Communication Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Manufacturer Unique Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Table of Contents

ZW-8000/7000/5000

User’s Manual for Communications Settings

11

Page 14

12

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 15

1

Overview of Communication Specifications

Overview of Communication Specifications

1-1 Overview of Communication Specifications . . . . . . . . . . . . . . . . . . . .14

1-2 Checking the System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 16

1-1

Overview of Commu nication Specifications

Overview of Communication Specifications

This chapter provides a general description of the communication specifications and sensor control method,

which is necessary to know before setting up the communication between the ZW-8000/7000/5000 series and

an external device.

14

Overview of Communication Specifications

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 17

1-2 Checking the System Configuration

This product is a displacement sensor of the confocal fiber type.

The connection with an external de vice such as a PLC and a personal computer allows a measurement

command to be input and measurement results to be output from the external device.

1

Overview of Communication Specifications

ZW-8000/7000/5000

User’s Manual for Communications Settings

Checking the System Configuration

15

Page 18

System Configuration

Connecting with EtherCAT

(when the master is NX/NJ Series)

EtherCAT Master

Sysmac Studio

Standard Edition

I/O control PLC

Trigger input

sensor

24-V

power supply

Power Cable

Parallel Cable

Connecting with EtherCAT (when the

master is other than NX/NJ Series)

Sysmac Studio

Displacement Sendor

Edition

General-purpose

Ethernet Cable

I/O control PLC

Trigger input

sensor

24-V

power supply

Power

Cable

Parallel Cable

NX/NJ-series Machine

Automation Controller

Special EtherCAT

Cable (RJ45/RJ45)

Special EtherCAT Cable

(RJ45/RJ45)

EtherCAT Master

Programmable Controller

with CJ2 CPU Unit

Special EtherCAT

Cable (RJ45/RJ45)

Special EtherCAT Cable

(RJ45/RJ45)

General-purpose USB Cable

General-purpose Ethernet Cable

ZW-8000@/7000@/5000@

Special EtherCAT Cable

ZW-8000@/7000@/5000@

Special EtherCAT Cable

Other EtherCAT slaves

(RJ45/RJ45)

Other EtherCAT slaves

(RJ45/RJ45)

EtherNet/IP and No-protocol

Ethernet Connections

Sysmac Studio

Displacement Sendor

Edition

General-purpose

Ethernet Cable

Industrial

EtherNet/IP/

Ethernet

Switching Hub

24-V

power supply

16

Checking the System Configuration

Power Cable

Control signal

input sensor

General-purpose

Ethernet Cable

General-purpose

Ethernet Cable

I/O control PLC

Control PLC, RC, or MC

Programmable Controller

with CJ2 CPU Unit

General-purpose

Ethernet Cable

Parallel Cable

NX/NJ-series Machine

Automation Controller

ZW-8000@/7000@/5000@

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 19

Connection Compatibility

Connected to

ZW-8000@/7000@/

5000@

EtherCAT --- Not compatible Compatible Compatible Compatible

EtherNet/IP Not compatible --- Compatible Compatible Compatible

Ethernet

(no-protocol)

RS-232C

(no-protocol)

Other connection

EtherCAT EtherNet/IP Ethernet

Compatible Compatible --- Compatible Compatible

Compatible Compatible Compatible --- Compatible

(no-protocol)

RS-232C

(no-protocol)

Parallel I/O Cable

Important

• EtherCAT and EtherNet/IP connections cannot be used at the same time.

• Can be connected simultaneously via Ethernet with PC tools (Sysmac Studio, Sma

rtMonitorZW) and another

device (PLC etc). Can be connected simultaneously via Ethernet with PC tools (Sysmac Studio, SmartMonitorZW)

and another device (PLC etc). The port number for the PC tool is 9600 (fixed) and 9602 (fixed). When connecting

different devices, set the port number to other than 9600 and 9602 (default value is 9601).

• When the measurement cycle is 40µs or less and ETherCA

Product Model Application

ZW ZW-8000@/7000@/5000@ This Displacement Sensor performs measurements.

PC Tool Sysmac Studio Standard

Special EtherCAT Cable * The Special EtherCAT Cable connects the Sensor to another Sensor or to

General-purpose Ethernet

cable

Special RS-232C Cable For connecting to a PLC or

Industrial EtherNet/IP /

Ethernet Switching Hub

Edition

• SYSMAC-SE200D

(no licenses included

(media only))

• SYSMAC-SE201L

(1-license edition)

• SYSMAC-SE2@@L

(multilicense editions

(3, 10, 30, or 50

licenses))

Sysmac Studio

Measurement Sensor

Edition

• SYSMAC-ME00@L

(1 or 3 licences)

--- Prepare commercially available Eth ernet cable

programmable terminal

•ZW-XPT2

For connecting to a PC

•ZW-XRS2

• W4S1-03B

(3 ports type)

• W4S1-05B

• W4S1-05C

(5 ports type)

This is the setup application. It is part of the Sysmac Studio Package and it

runs on Windows.

The Sysmac Studio comes in two different editions .

• Sysmac Studio Standard Edition

• Sysmac Studio Measurement Sensor Edition

another EtherCAT device.

satisfying the following requirements:

• Category 5e or more, 30 m or less

• RJ45 connector (8-pin modular jack)

• For direct connection: Select cross cable.

• For connection through an industrial switching hub: Select straight cable.

Connect the sensor with a PLC, programmab le terminal, or personal

computer etc..

The Switching Hub connects multiple Sensors to one Touch Finder or one

computer running PC Tool.

T is connected, analog output is not e

The Sysmac Studio provides an integrated development environment for

the NX/NJ series Controllers and other Machine Automation Controllers

and EtherCAT Slaves. It supports setup, programming, debugging,

operation, and maintenance.

The Sysmac Studio Standard Edition DVD includes Support Software for

EtherNet/IP, DeviceNet, serial communications, and PT screen design

(CX-Designer). Refer to the Sysmac catalog (Cat. No. P072) for details.

This license provides the functions that are required to set up ZW-8000/

7000/5000 Series Vision Sensors from the Sysmac Studio. This model

number is for the license only. You must also purchase the DVD for the

Sysmac Studio Standard Edition Ver.1.22 or higher.

xecuted.

1

Overview of Communication Specifications

ZW-8000/7000/5000

User’s Manual for Communications Settings

Checking the System Configuration

17

Page 20

Product Model Application

EtherCAT Junction Slave • GX-JC03

(3 ports type)

•GX-JC06

(6 ports type)

Used to connect multiple sensors or PLCs using EtherCAT.

*: Refer to Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor User's

Manual (Z362) "9-1 Specifications and External Dimensions".

18

Checking the System Configuration

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 21

Parallel I/O Connection

2-1 Parallel I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2

Parallel I/O Connection

Page 22

2-1 Parallel I/O Connection

I/O Signal Functions

The following describes the functions of I/O signals.

Analog Output Terminals

Analog output

Name Description

Analog voltage output This outputs the measured value from -10 V to +10 V as the voltage value.

Analog current output This outputs the measured value, from 20 mA to 4 mA as the current value.

32-pole expansion connector

Judgment output

Name Description

HIGH output Judgment result HIGH (HIGH threshold value < measured value) is output.

PASS Output Judgment result PASS (LOW threshold v alue ≤ measured value ≤ HIGH threshold value) is

LOW output Judgment result LOW (LOW threshold value > measured value) is output.

When measurement not possible: Approx. 10.8V (default value, can be selected by user)

At alarm: Approx. 10.8V

When measurement not possible: Approx. 21 mA (default value, can be selected by user)

At alarm: Approx. 21 mA

output.

ALARM output

Name Description

ALARM output This turns ON when there is a system error.

BUSY output

Name Description

BUSY output This turns ON during sampling with the hold function enabled.

It allows you to check whether or not the self-tr

It also turns ON during bank switching.

This signal is turned ON in FUNC mode.

ENABLE output

Name Description

ENABLE output This turns ON when the sensor is ready for measurement.

20

Parallel I/O Connection

This output is interlocked with the ENABLE indicator.

igger is functioning correctly.

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 23

SYNCFLG/TRIGBUSY output

Name Description

SYNCFLG/TRIGBUSY output In the internal/PDO synchronized mode , this output sig nal operates a s SYNCFLG. This turns ON

when measurement synchronization processing is execut ed by SYNC input and the state

changes to one where normal measurement values can be output.

In the external synchronous measurement mode, t

turns ON while a measurement by TRIG input is being performed. The next TRIG input cannot

be turned ON until this turns OFF.

his output signal

operates as TRIGBUSY. This

STABILITY output

Name Description

STABILITY output Turns ON when the 1 surface is in the measuring range.

LOGSTAT output

Name Description

LOGSTAT output This turns ON while internal logging is in execution.

LOGERR output

Name Description

LOGERR output Turns ON when memory for Internal logging is full and the executes Internal logging.

2

Parallel I/O Connection

TASKSTAT output

Name Description

TASKSTA T output This turns ON when the measurement value is finalized.

ZERO input

Name Description

ZERO input This is used to execute and clear a zero reset.

RESET input

Name Description

RESET input This resets all executing measurements and outputs.

While a RESET is being input, judgment output conforms to the non-measurement setting.

If this RESET input switches ON while the hold function is us

hold function was set will be restored.

ed, the state in effect before the

TIMING input

Name Description

TIMING input This timing input is for signal input from external devices. Use it for hold function timing.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

21

Page 24

LIGHT OFF input

Name Description

LIGHT OFF input Turns OFF the light for measurement.

While LIGHT OFF is being input, the analog output and judgment output conform to the nonmeasurement sett

ing.

LOGGING input

Name Description

LOGGING input This is used to start internal logging.

SYNC/TRIG input

Name Description

SYNC input This is used to synchronize imaging between multiple ZW. With e x ternal synchronous

Important

When the Internal synchronous measurement mode is External synchronous measurement mode, updates each input

signals by inputting the TRIG input signal. To be enabled each input signal, enter the TRIG input signal.

measurement mode selected, this signal works as TRIG input.

For the following conditions, it performs as a SYNC input.

• [Fieldbus] setting: When either [OFF] or [EtherNet/IP] is selected.

• [Synchronous measurement mode] setting: When

selected.

For the following conditions, it performs as a TRIG input.

• [Internal synchronous measurement mode] setting: When select [External synchronous measurement mode].

Inter

nal/PDO synchronized mode is

Settings for Parallel Input

Used for preventing chattering in parallel input and malfunction due to noise .

Item Setting item Setting value Description

I/O settings Width of input signal

filter

5 μs/10 μs/20 μs/50 μs/

100 μs/200 μs/500 μs/

1000 μs

100 μs (default value)

Set the width of filter.

Multi View Explore : [Bank Gr oup] | [(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [I/O Settings]

1 Set [Width of input signal filter].

22

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 25

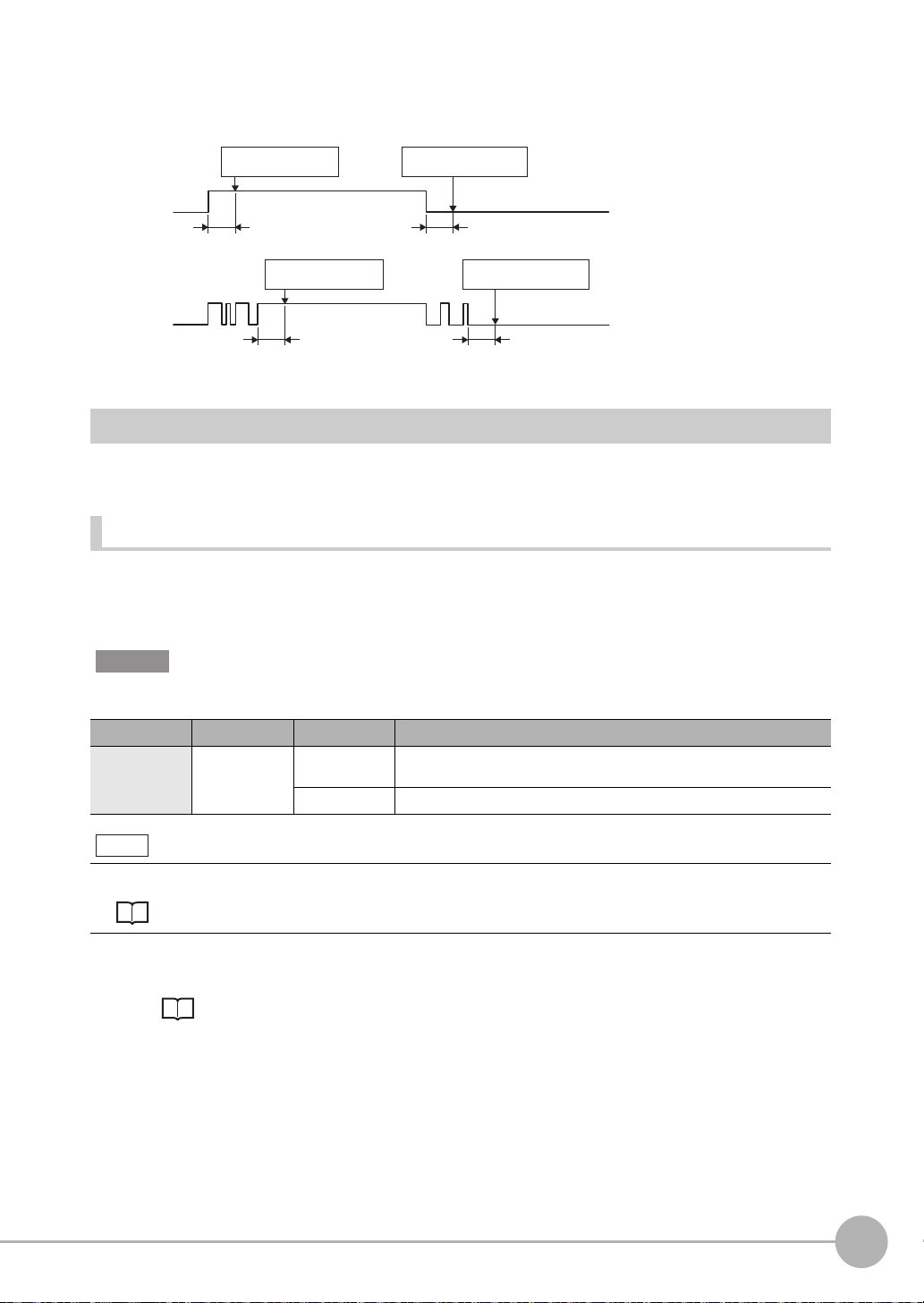

Example) When the filter setting value is 100μs (default value)

As an ON state persists for 100μs, an ON or OFF state of TIMING signal is detected. Therefore, a delay in the

detection of TIMING signal occurs for a period of time equivalent to the set filter value.

Without chattering

TIMING

With chattering

TIMING

ON

OFF

ON

OFF

ON state is detected as ON

state persists for 100µs.

100µs

ON state is detected as ON

state persists for 100µs.

100µs 100µs

OFF state is detected as OFF

state persists for 100µs.

100µs

OFF state is detected as OFF

state persists for 100µs.

Settings for Analog Output

The following describes the settings for outputting the current measurement results from the analog output of

the analog output terminal block.

Setting the analog output destination

With analog output, the measurement re sults can be outp ut con v erted to a current from 4 to 20 mA or a v oltage

from -10 to +10 V.

Selects which to output, the current or the voltage.

2

Parallel I/O Connection

Important

The same output destination is set for all banks. The output destination cannot be set separately for individual banks.

Item Setting item Setting value Description

Sensor settings Analog output Voltage output

(default value)

Current output Current output

Voltage output

Note

The analog output destination can also be set with key operations on the Sensor Controller.

Setting the analog output destination p.160

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

23

Page 26

Multi View Explore : [Device Group] | [(Sensor Name)] | [System] |

[System Data] (double-click)

→ Edit pane : [Sensor settings] icon ( )

2 Select the output destination from [Analog

output].

Important

When satisfies the following conditions, the analog output is disabled. A clamp value is output.

• Measurement cycle is 40 µs or less.

• EtherCAT communication is selected in the Fieldbus.

24

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 27

Assigning Analog Output

Set the task for which to output the result s as analog.

Item Setting item Setting value Description

Analog output Output object None/TASK1/TASK2/TASK3/

TASK4

Select the task to output as analog.

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

Multi View Explore : [Bank Gr oup] | [(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [Analog output]

2 Select the task from [Output object].

You can select from the above setting values.

None/TASK1/TASK2/TASK3/TASK4

2

Parallel I/O Connection

Note

Analog output can also be assigned with key operations on the Sensor Controller.

Assigning Analog Output p.161

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

25

Page 28

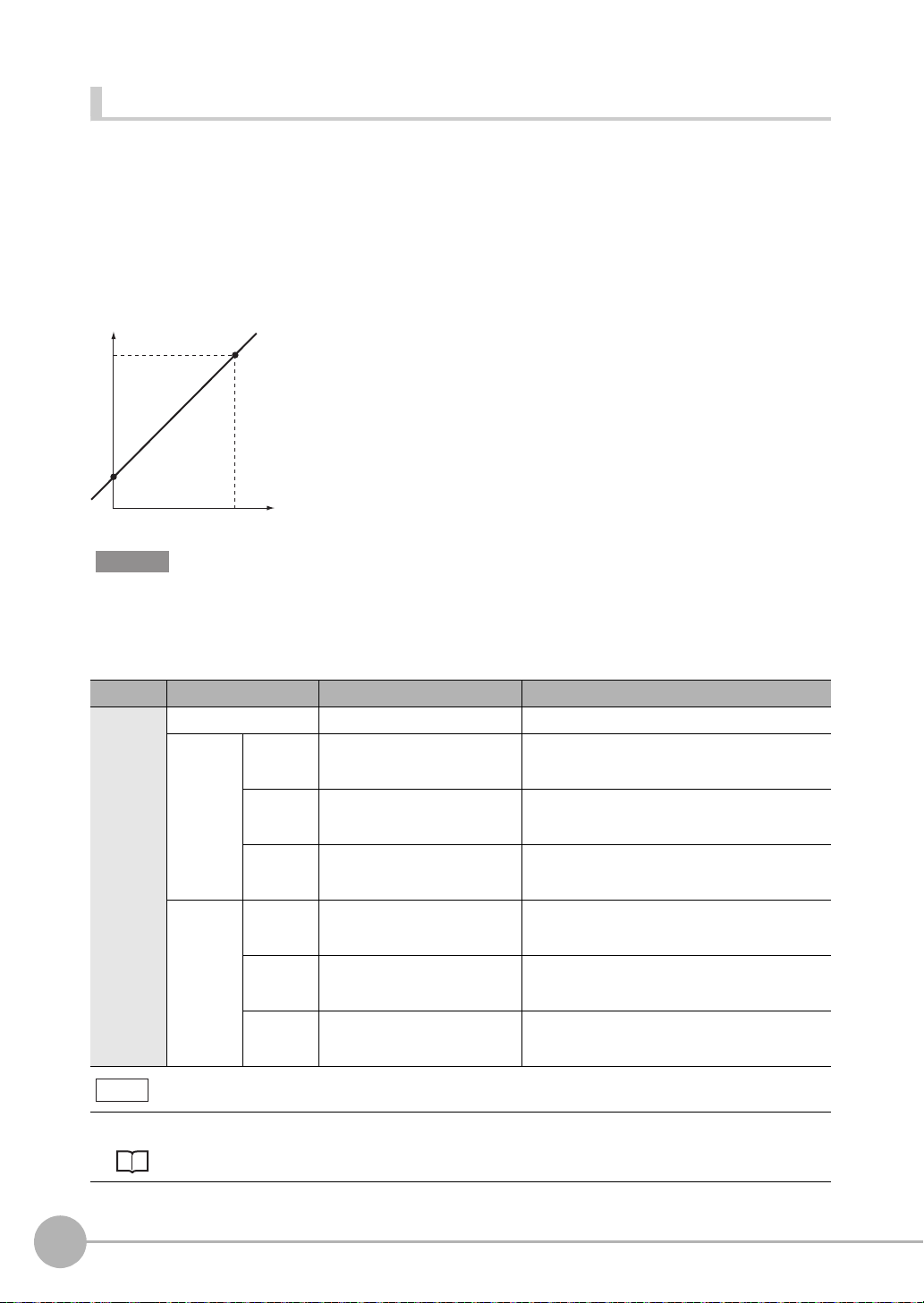

Setting Monitor Focus

With analog output, the relationship between the output value and measured value to be displ ayed can be set

as desired to convert the measurement result to 4 to 20 mA current or -10 to +10 V voltage before output.

Set the focus to match the connected external device.

The output range can be set by entering the output value for the current or voltage values for any two points.

Example: When setting 4 mA output (1st point) for measured value of 0 mm and 20 mA output for measured

value of 1 mm (2nd point) (current output)

Output current

(mA)

20

4

0

Point 1

0

Point 2

1

Measured value

(mm)

Important

• Separate the two specified points by at least 1% of the rated measuring range of the connected Sensor Head or 40

μm.

• After executing functions that add/subtract the span and offset values to/from the measurement value

, execute the

monitor focus.

Item Setting item Setting value Description

Monitor

focus

Monitor focus ON/OFF (default value) Sets monitor focus ON/OFF.

Point1 Distance

Point2 Distance

value

Current

output value

Voltage

output value

value

Current

output value

Voltage

output value

-999.999999 to 999.999999 [mm] Sets the reference measured value for output.

4 (default value) to 20 [mA] When the analog output destination is set to current,

-10 (default value) to 10 [V] When the analog output destination is set to v oltage,

-999.999999 to 999.999999 [mm] Sets the reference measured value for output.

4 (default value) to 20 [mA] When the analog output destination is set to current,

-10 (default value) to 10 [V] When the analog output destination is set to v oltage,

The default setting diff ers depending on the Sensor

Head.

sets the current to be output when the distance valu e is

measured.

sets the voltage to be output when the distance value

is measured.

The default setting diff ers depending on the Sensor

Head.

sets the current to be output when the distance valu e is

measured.

sets the voltage to be output when the distance value

is measured.

Note

The monitor focus can also be set with key operations on the Sensor Controller.

Setting Monitor Focus p.161

26

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 29

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

Multi View Explore : [Device Group] | [(Sensor Name)] | [Bank Group] |

[(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [Analog output]

2 Select ON from [Monitor Focus].

3 Enter the [Distance] and [Output value] at

[Point1].

4 Likewise, enter the [Distance] and [Output

value] at [Point2].

Adjusting the analog output value

2

Parallel I/O Connection

Discrepancies may occur between the current value/voltage value output as analog set on the Sensor

Controller and the current value/voltage value actually measured due to the conditions for the connected

external device or other factors.

The analog output adjustment function can be used to correct this discrepancy.

The output values are corrected by entering the adjustment value for the current or voltage values for any two

points.

Important

Set the output destination and select either current or voltage output beforehand. Also, connect the analog output

signal line to an external ammeter or voltmeter.

Item Setting item Setting value Description

Analog out-

put adjustment

Analog output adjustment ON/OFF (default value) Set analog output correction ON/OFF.

Point1 Reference value

Point2 Reference value

(current/value)

adjustment value -999 to 999 Sets the adjustment value when the reference value is

(current/value)

adjustment value -999 to 999 Sets the adjustment value when the reference value is

4 to 20 [mA]/-10 to 10 [V] Sets the current or voltage to be used as the correction

4 to 20 [mA]/-10 to 10 [V] Sets the current or voltage to be used as the correction

reference in the entry field on the left.

measured in the entry field on the right.

reference in the entry field on the left.

measured in the entry field on the right.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

27

Page 30

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

Multi View Explore : [Device Group] | [(Sensor Name)] | [Bank Group] |

[(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [Analog output]

2 Select ON from [Analog output adjustment].

Important

This setting is allowable only when Online.

3 Click [Setting].

The “Analog Output Adjust” popup menu

appears.

4 Enter the [Distance] and [Output value] at

[Point1], and click [Output].

5 Likewise, enter the [Distance] and [Output

value] at [Point2], and click [Output].

6 Click [Setting].

Note

Analog output values can also be adjusted with key operations on the Sensor Controller.

Adjusting the analog output value p.163

28

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 31

Settings for Judgment Output

The following describes t he settings for outputting the judgment results from the judgmen t output of th e 32-pole

extension connector.

Assigning judgment output

Set the task for which to output the judgment results.

The judgment results for the selected task are output from the following output terminals of the 32-pole

extension connector.

HIGH/PASS/LOW

Item Setting item Setting value Description

Judgment Output object TASK1/TASK2/TASK3/TASK4 Select the task for which to output the judgment result.

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

Multi View Explore : [Bank Group] | [(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [Judgment]

2 Select the task from [Output object].

2

Parallel I/O Connection

Note

Judgment output can also be assigned with key operations on the Sensor Controller.

Assigning judgment output p.164

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

29

Page 32

Setting Operation at Judgment Output

Set the hysteresis width of the judgment upper/lower limit values and judgment output timing.

Refer to “4-4 Setting Threshold Value” described in Displacement Sensor ZW-8000/7000/5000 series

Confocal Fiber T

Item Setting item Setting value Description

Judgment

output

Hysteresis width 0 to 99.9999mm Sets the hysteresis value (difference between operating point and

ype Displacement Sensor User’s Manual (Z362).

recovery point) of the judgment upper/lower limit values when HIGH/

PASS/LOW judgment is unstable near the boundary.

HIGH threshold

value

Measured value

LOW threshold

value

Hysteresis

(hysteresis width)

Action point

Return point

HIGH output

PASS output

LOW output

Satisfy the following conditions.

HIGH threshold value ≥ HIGH threshold value - Hysteresis (hysteresis

width) > LOW threshold value + Hysteresis (hysteresis width) ≥ LOW

threshold value

ON

OFF

ON

OFF

ON

OFF

Timer mode OFF (default value) Outputs the judgment as soon as the judgment result has been applied.

ON

OFF

ON

OFF

ON

OFF

Measured value

HIGH threshold

value

LOW threshold

value

HIGH output

PASS output

LOW output

Off Delay Delays the falling edge of the output s by the value set at [Timer Duration]

after the judgment result has been applied.

Measured value

HIGH threshold

value

LOW threshold

value

HIGH output

PASS output

LOW output

ON

OFF

ON

OFF

ON

OFF

: Timer time

30

Parallel I/O Connection

On Delay Delays the rising edge of the outputs by the value set at [Timer Duration]

after the judgment result has been applied.

HIGH threshold

value

LOW threshold

value

HIGH output

PASS output

LOW output

Measured value

ON

OFF

ON

OFF

ON

OFF

User’s Manual for Communications Settings

: Timer time

ZW-8000/7000/5000

Page 33

Item Setting item Setting value Description

Judgment

output

Timer mode One Shot When the judgment result is turned ON, output by the value set as [Timer

Timer time 1 (default value) to

5000 [ms]

Duration].

ON

OFF

ON

OFF

ON

OFF

Measured value

HIGH threshold

value

LOW threshold

value

HIGH output

PASS output

LOW output

Sets the timer duration when the timer mode is other than OFF.

1 Set the operating mode to the FUNC mode.

Displacement Sensor ZW-8000/7000/5000 series Confocal Fiber Type Displacement Sensor

User's Manual (Z362) "3-2 Switching operation modes"

Multi View Explore : [Bank Group] | [(Bank Data Name)] (double click)

→ Edit pane : [I/O Settings] icon ( )

→ I/O Setting Screen : [Judgment]

2 Set [Hysteresis Width].

3 Select the judgment output timing to match

operation of the external device from [Timer

mode].

4 Sets [Timer time].

: Timer time

2

Parallel I/O Connection

Note

The operations for judgment output can also be set with key operations on the Sensor Controller.

Setting Operation at Judgment Output p.165

Important

• The timer mode cannot be used when the measurement mode is external/PDO synchronous measurement mode.

• Timer time shall be a value rounded up by Measurement Cycle Time un

it.

• When 2 area mode is selected, minimum value shall be doubled Measurement Cycle.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

31

Page 34

Settings for Bank Control

This section describes the settings for controlling banks by using parallel I/O.

Selecting banks

The bank is selected in combinations of the bank select input signals (BANK_SEL1 to 3).

Bank selection input 1

(BANK_SEL1)

OFF OFF OFF BANK1

ON OFF OFF BANK2

OFF ON OFF BANK3

ON ON OFF BANK4

OFF OFF ON BANK5

ON OFF ON BANK6

OFF ON ON BANK7

ON ON ON BANK8

Bank selection input 2

(BANK_SEL2)

Bank selection input 3

(BANK_SEL3)

Selected bank

Important

• At most it takes about 100ms to switch banks.

• During bank switching, the BUSY output becomes ON.

• If the bank mode is set to [JUDGE], the bank cannot be switched at the external

signal input because the number of

banks increases to 32.

Outputting the currently selected bank number

The currently selected bank number is output.

The output bank number depends on the combination of the bank number output signals (BANK_OUT1 to 3).

Bank number output 1

(BANK_OUT1)

OFF OFF OFF BANK1

ON OFF OFF BANK2

OFF ON OFF BANK3

ON ON OFF BANK4

OFF OFF ON BANK5

ON OFF ON BANK6

OFF ON ON BANK7

ON ON ON BANK8

Bank number output 2

(BANK_OUT2)

Bank number output 3

(BANK_OUT3)

Output bank

32

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 35

Timing Chart

The following shows the timing charts when communication is performed with external devices.

Relationship between image capture duration and judgment output

Item Min. Max.

T0 Measuring cycle 60 μs (ZW-8000@)

T1 Exposure time 1 μsT0 - 3 μs

T2 Response time of jud gment output

T3 Refresh cycle of judgment output

T4 Response time of an alog output

T5 Refresh time of analog output

T6 Response delay time of Analog output − Output voltage: Approx 1.5 μs

*1 In 2 area mode, T0 is added to the values in the chart.

*2 P = 0

μs (ZW-7000@/5000@)

100

μs (ZW-8000@)

(1) (2) (3)

*1

*1

*1

*1

T0T1

20 μs (ZW-7000@)

80 μs (ZW-5000@)

− 250 μs + P

− T + 200 μs

− 80 μs (ZW-7000@/5000@)

− TO (1 area mode)

Depends on the set conditions

*2

200 μs (ZW-8000@)

2TO (2 area mode)

Current output: Approx 10 μs

2

Parallel I/O Connection

Exposure

Analog output

Judgment output

(HIGH/PASS/LOW)

T4

T2

T6

T5

T3

Explanation of operations

(1) During each measuring cycle, the light source is lit and exposure is started.

(2) After the end of exposure, measurement starts.

(3) After the end of measurement, the judgment result and the analog output are updated.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

33

Page 36

Hold (peak/bottom/peak to peak/average)

Item Min. Max.

T18 RESET Minimum input time 2 × T0 + C*1 + 1100 μs −

T19 TIMING - BUSY ON maximum response

T20 TIMING minimum input time

T21 TIMING - BUSY OFF maximum response

T22 BUSY OFF - maximum response time of

T23 RESET maximum response time and

T39

*1 C = Filter width of input signal

*2 In 2 area mode, T0 is added to the values in the chart.

*3 P = 0

100

TIMING input

RESET input

BUSY output

Judgment output

(HIGH/PASS/LOW)

Analog output

*2

time

*2

*2

time

judgment/analog output

*2

RESET OFF-TIMING ON minimum time

TIMING OFF - RESET ON minimum time

μs (ZW-7000@/5000@)

μs (ZW-8000@)

(2) (3) (4)(5) (6)

T19

T20 T21

ON

OFF

ON

OFF

ON

OFF

T22

− TO + C*1+ P*3 + 80 μs

(When specify timing to measure

mode is selected)

2 × TO + C

(When specify timing to exposure

mode is selected)

T0 + C*1+ 20 μs

(Minimun OFF time is T0 + C

μs.)

*1

+ 60

−

− T0 + C*1+ P*3 + 300 μs

− 30 μs

− 2 × TO + C*1 + 3000 μs

*2

*2

TO + C*1+ 60 μs

(When specify timing to measure

mode is selected)

2 × TO + C

(When specify timing to exposure

mode is selected)

*1

+ 60 μs

T18T39

T23

−

(8) (7) (9)(1)

T23

*1

+ P*3 + 80 μs

Explanation of operations

(1) The TIMING input is turned ON.

(2) During the TIMING input minimum time, when the TIMING input is ON, sampling is started and the BUSY

output is turned ON.

(3) The TIMING input is turned OFF.

(4) After the TIMING input turns OFF, sampling is ended and the Judgment result and Analog output are

updated. The BUSY output is also turned OFF.

(5) After the Judgment result, and the analog output are updated.

(6) The RESET input is turned ON. If the RESET input is turned ON during the RESET input minimum time, the

measured value is reset.

(7) The judgment result and analog output are reset.

(8) The RESET input is turned OFF.

(9) After the RESET input is turned OFF, the TIMING input can be turned ON again.

34

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 37

Important

RESET input

BUSY output

Judgment output

(HIGH/PASS/LOW)

Analog output

(1) (2) (4)(3)

ON

OFF

ON

OFF

(5)

T18

T24

T25

T22

• Judgment and Analog output may not be updated until BUSY is turned ON after Sampling procedure.

• When the setting for non-measurement is “CLAMP”, if the sampling value is an abnormal value or an undeter

*

, sampling is not executed. If sampling has been started, it is stopped. The output value is as follows.

value

• Hold the clamp value.

• To start and continue sampling even if a sampling value is an abnormal value or an undetermined value, set

“KEEP” as the non-measurement setting.

*: After the star

t of measurement, if measurement results are not obtained the n

umber of times required to take the

average, the measurement result is not applied.

*: The RESET of (6) through (8) can be omitted. When performing T

IMING input consecutively

, make sure that the

interval between TIMING inputs is the minimum OFF time of T20 or longer.

Hold (auto peak/auto bottom/auto peak-to-peak)

Item Min. Max.

T18 RESET minimum input time 2 × T0 + C*1 + 1100 μs −

T22 BUSY-OFF maximum response time of

T24 BUSY OFF maximum response time

T25 RESET - BUSY ON maximum response

*1 C = Filter width of input signal

*2 In 2 area mode, T0 is added to the values in the chart.

judgment/analog output

*2

time

− 0 μs (1 area mode)

*2

− T23

− T23

TO (2 area mode)

mined

2

Parallel I/O Connection

Explanation of operations

(1) The RESET input is turned ON. If the RESET input is turned ON during the RESET input minimum time, the

measured value is reset.

(2) Judgment result is reset. The BUSY output is turned OFF.

(3) After judgement result is reset, Analog output is reset.

(4) The RESET input is turned OFF.

(5) The BUSY output is turned ON.

Important

• Judgment and Analog output may not be updated until BUSY is turned OFF after Sampling procedure.

• When the setting for non-measurement is “CLAMP”, if the sampling value is an abnormal value or an undeter

*

, sampling is not executed. If sampling has been started, it is stopped. The output value is as follows.

value

mined

• Hold the clamp value.

• The BUSY signal is turned OFF.

• To start and continue sampling even if a sampling value is an abnormal value or an undetermined value, set

“KEE

*: After the star

average, the measurement result is not applied.

ZW-8000/7000/5000

User’s Manual for Communications Settings

P” as the non-measurement setting.

t of measurement, if measurement results are not obtained the n

umber of times required to take the

Parallel I/O Connection

35

Page 38

Hold (sampling)

Item Min. Max.

T18 RESET Minimum input time 2 × T0 + C*1 + 1100 μs −

T19 TIMING - BUSY ON maximum response

T20 TIMING minimum input time

T22 BUSY-ON maximum response time of judg-

*2

time

ment/analog output

*2

T23 RESET maximum response time and

RESET OFF-TIMING ON minimum time

T39 TIMING OFF - RESET ON minimum time*2TO + C*1 + 60 μs

*1 C = Filter width of input signal

*2 In 2 area mode, T0 is added to the values in the chart.

*3 P = 0

μs (ZW-7000@/5000@)

100

μs (ZW-8000@)

− TO + C*1 + P*3 + 80 μs

T0 + C*1 + 20 μs

(Minimum OFF time is T0 + C

60 μs.)

(When specify timing to measure

mode is selected)

2 × TO + C

(When specify timing to exposure

mode is selected)

−

*1

+

− 30 μs

− T0+C*1+3000 μs

*2

(When specify timing to measure

mode is selected)

2 × TO + C

(When specify timing to measure

mode is selected)

*1

+ 60 μs

*1

+ P*3+ 80 μs

TIMING input

RESET input

BUSY output

Judgment output

(HIGH/PASS/LOW)

Analog output

OFF

OFF

OFF

ON

ON

ON

(1) (2) (3)

T22

T19

T20

T39

(4)

T18

T23

(6) (5)

T23

(7)

Explanation of operations

(1) The TIMING input is turned ON.

(2) During the TIMING input minimum time, when the TIMING input is ON, sampling is started and the BUSY

output is turned ON. The measurement result is sampled and the judgment result is output.

(3) After the Judgment result, and the analog output are updated.

(4) The RESET input is turned ON. If the RESET input is turned ON during the RESET input minimum time, the

measured value is reset.

(5) The judgment result and the analog output are reset.

(6) The RESET input is turned OFF.

(7) After the RESET input is turned OFF, the TIMING input can be turned ON again.

Important

• Judgment and Analog output may not be updated until BUSY is turned OFF after Sampling procedure.

• When the setting for non-measurement is “CLAMP”, if the sampling value is an abnormal value or an undeter

*

, sampling is not executed. The output value is as follows.

value

mined

• Hold the clamp value.

36

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 39

• The BUSY signal is not turned ON.

*: After the start of measurement, if measurement results are not obtained the n

umber of times required to take the

average, the measurement result is not applied.

*: The RESET of (6) through (8) can be omitted. When performing T

IMING input consecutively

, make sure that the

interval between TIMING inputs is the minimum OFF time of T20 or longer.

Bank Switching

Item Min. Max.

T7 Input response time − 200 ms

T8 Bank switching time − 100 ms

T9 Measurement start response time − Depends on the set conditions

T10 Maximum response time of judgement ON − Depends on the set conditions

2

Parallel I/O Connection

T8

(3) (4) (5)

T9 T10

BANK_SEL input

(BANK_SEL1/2/3)

BANK_OUT output

(BANK_OUT1/2/3)

BUSY output

ENABLE output

STABILITY output

JUDGMENT output

㸦HIGH/PASS/LOW㸧

TASKSTAT output

OFF

OFF

OFF

OFF

OFF

(1) (2)

T7

ON

ON

ON

ON

ON

Explanation of operations

(1) The BANK_SEL signal is switched to the bank nu mber to switch to.

(2) After the input response time, the measurement stops and the B USY output is turned ON, The ENABLE

output, STABILITY output, HIGH/PASS/LOW output, and TASKSTAT output are turned OFF at the same

time.

(3) After bank switching ends, the BUSY output is turned OFF and the BANK_ OUT output is switched.

(4) Measurement is restarted and the ENABLE output, STABILITY output is turned ON.

(5) When the measurement result is applied, the HIGH/PASS/LOW output and TASKSTAT output turn ON.

Important

Under the following conditions, the sensor controller display section does not change in conjunction with the output

signal and will continue to display the previous measurement state.

• When external synchronization measurement mode is set and TRIG input is not on.

• When the PDO syn

chronous measurement mode is set and EtherCAT is not established.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

37

Page 40

LIGHT OFF

Item Min. Max.

T9 LIGHT OFF - ENABLE OFF maximum response

T10 LIGHT OFF minimum input time T0 + C*1 + 20 μs

T11 LIGHT OFF - ENABLE ON maximum response time − 2 × T0 + C*1 + P*2 + 150 μs

*1 C = Filter width of input signal

*2 P = 0

LIGHT OFF input

ENABLE output

time

μs (ZW-7000@/5000@)

100

μs (ZW-8000@)

ON

OFF

ON

OFF

(1) (2) (3) (4)

T10

T9

T11

Explanation of operations

(1) The LIGHT OFF input is turned ON.

(2) After the LIGHT OFF input is turned ON, the light source is turned OFF and the ENABLE output is turned

OFF.

(3) The LIGHT OFF input is turned OFF.

(4) After the LIGHT OFF input is turned OFF, the light source is turned ON and the ENABLE output is turned

ON.

− 2 × T0 + C*1 + P*2 + 300 μs

(Minimum OFF time is T0 +

*1

+ 60 μs.)

C

−

Zero reset

Item Min. Max.

T7 Input response time − 3 ms + T0 × 2

T13 ZERO input time 50 ms 0.8 s

T14 ZERO input cancel time 1s −

(4)

T14

(5)

ZERO input

Judgment output

(HIGH/PASS/LOW)

OFF

(1) (2)

T13 T7

ON

(3)

Explanation of operations

(1) The ZERO input is turned ON.

(2) After the ZERO input time, the ZERO input is turned OFF.

(3) After the ZERO input is turned OFF, the zero reset is executed and the judgment results refl ected in the

measurement results are output.

(4) The ZERO input is turned ON.

(5) After at least the cancel time of ZERO input has passed, the zero reset is cancelled.

38

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 41

Operating Mode Switching

Item Min. Max.

T3 Response time of an alog output − T0 + 20 μs

T9 Measurement start response time − Depends on the set conditions

(1) (2) (3) (4)

T3

MODE

BUSY output

ENABLE output

Judgment output

(HIGH/PASS/LOW)

Analog output

OFF

OFF

ON

ON

RUN FUN RUN

All OFF

CLAMP

Explanation of operations

(1) After the mode is switched from RUN to FUNC mode, the BUSY output and ENABLE output are turned

OFF. The judgment outputs all go OFF.

(2) The response time of analog output after the BUSY output is turned ON, the analog output is output

clamped.

(3) After the mode is switched from the FUNC mode to the RUN mode, the BUSY output is turned OFF.

(4) Measurement is restarted and the ENABLE signal is turned ON, then the measurement results are output.

T9

2

Parallel I/O Connection

Important

Under the following conditions, the sensor controller display section does not change in conjunction with the output

signal and will continue to display the previous measurement state.

• When external synchronization measurement mode is set a

• When the PDO syn

chronous measurement mode is set and EtherCAT is not established.

nd TRIG input is not on.

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

39

Page 42

Measurement cycle

Item Min. Max.

T26 SYNC ON - SYNCFLG_ON maximum response

T27 SYNC_OFF - SYNCFLG_OFF maximum

T28 Response time when restart to capture after

T37 SYNCFLG_ON - SYNC_OFF time 0 μs −

T38 Minimum SYNC cycle T0 + T26 + T27 + T37 −

*1 C = Filter width of input signal

*2 P = 0

time

response time

SYNC input

μs (ZW-7000@/5000@)

200

μs (ZW-8000@)

SYNC input

(1) (3)(2) (4) (5)

T26

− T0 + C*1 + P*2 + 130 μs

− T0 + C*1 + P*2 + 250 μs

− T0 + C*1 + 70 μs

T27T37

SYNCFLG output

Image capture duration

measurement sensor 1

Image capture duration

measurement sensor 2

T28

T38

T0

Explanation of operations

(1) Turns ON SYNC input

(2) After SYNC input was turned ON, the image capture completion signals from the 2 measurement sensors

synchronize and a measurement is performed.

(3) SYNCFLG output turns ON.

(4) The SYNC input is turned OFF.

(5) SYNCFLG output is turned OFF after SYNC input is turned OFF.

Example of minimum SYNC cycle

Measurement cycle T0 ZW-7000@/5000@ ZW-8000@

C = 5 μs C = 100 μs C = 5 μs C = 100 μs

20 μs 450 μs 640 μs 610 μs 800 μs

40 μs 510 μs 700 μs 670 μs 860 μs

60 μs 570 μs 760 μs 730 μs 920 μs

80 μs 630 μs 820 μs 790 μs 980 μs

160 μs 870 μs 1060 μs 1030 μs 1220 μs

250 μs 1140 μs 1330 μs 1300 μs 1490 μs

500 μs 1890 μs 2080 μs 2050 μs 2240 μs

40

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 43

Internal logging

Item Min. Max.

T6 LOGGING ON - LOGSTAT ON maximum

T7 LOGGING minimum input time T0 + C*1 + 20 μs −

T8 LOGGING OFF - LOGSTAT OFF maximum

*1 C = Filter width of input signal

LOGGING input

LOGSTAT output

response time

response time

(1)(2)

ON

OFF

ON

OFF

(3) (4)

T6

T8

T7

Explanation of operations

(1) Turns ON LOGGING input.

(2) Internal logging starts when LOGSTAT output is turned ON after LOGGING input is turned ON.

(3) Turns OFF the LOGGING in pu t.

(4) Finishes the Internal logging when LOGSTAT output is turned OFF after LOGGING input is turned OFF.

However, if an insufficient logging memory occurs, turns ON the LOGERR output. The LOGERR output is

turns OFF simultaneously with the LOGGING input turned OFF.

− T0 + C*1 + 30 μs

− T0 + C*1 + 250 μs

2

Parallel I/O Connection

ZW-8000/7000/5000

User’s Manual for Communications Settings

Parallel I/O Connection

41

Page 44

External synchronous measurement mode

Item Min. Max.

T29 Minimum TRIG ON time C*1 + 20 μs −

T30 Minimum TRIG OFF time C*1 + 60 μs −

T31 Minimum TRIG cycle T29 + T30 −

T32 TRIG - TRIGBUSY response − C*1 + 30 μs

T33 TRIG_BUSY ON time T0 + 100 μs T0 + 200 μs

T34 TRIG - Judgment output response − T0 + T2 + T29

T35 TRIG - Analog output response − T0 + T4 + T29

T36 TRIG-Measurement cycle start time − T29

*1 C = Filter width of input signal

(1) (2) (3) (4) (5)

T29

T31

T30

TRIG input

T33

T32

TRIG BUSY output

T35

Analog output

Judgment output

(H, P, L, TSAK_STAT)

T34

T36

Image capture duration

T0

Explanation of operations

(1) Turns ON TRIG input.

(2) TRIG BUSY output turns ON and capturing images is started to perform a measurement.

(3) TRIG BUSY output turns OFF, allowing the next TRIG input to be received.

(4) After the measurement has been completed, the judgement result and analog output are updated.

(5) Image capture and measurement are not performed without TRIG input.

Example of minimum TRIG cycle

Measurement cycle T0 C = 5 μs C = 100 μs

20 μs 120 μs 280 μs

40 μs 140 μs 280 μs

80 μs 180 μs 280 μs

160 μs 260 μs 280 μs

250 μs 350 μs 350 μs

500 μs 500 μs 600 μs

42

Parallel I/O Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 45

EtherCAT Connection

3-1 EtherCAT Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3

EtherCAT Connection

Page 46

3-1 EtherCAT Connection

Overview of EtherCAT Networks

EtherCA T (Et hernet Control Automati on Technology) is a high-performance industrial network system based on

Ethernet system and can realize faster and more efficient communications.

Each node achieves a short communications cycle time by transmitting Ethernet frames at high speed.

Furthermore, even though EtherCAT is a unique prot ocol, it offers excellent general-purpose applicability. For

example, you can use Ethernet cables because EtherCAT utilizes standard Ethernet technology for the

physical layer. And the effectiveness of EtherCAT can be fully utilized not only in large control systems that

require high processing speeds and system integrity, but also in small and medium control systems.

Features of EtherCAT

EtherCAT has the followin g features.

● Extremely high

It dramatically shortens the I/O response time from generation of input signals to transmission of output

signals.

method, it is possible to efficiently transmit a wide variety of data.

●

EtherCAT is an open network with extremely high compatibility with conventional Ethernet systems.

By fully utilizing the optimized Ethernet frame bandwidth to transfer data using a high-speed repeat

Extremely High Compatibility with Ethernet

-speed communications with speed of 100 Mbps

Structure of EtherCAT

EtherCAT does not send data to individual slave nodes on the network, instead, it passes Ethernet frames

through all of the slave nodes.

When frame passes through a slave node, the slave node reads and writes data in the areas allocated t o it in

the frames in a few nanoseconds.

Ethernet frames sent from the EtherCAT Master Unit go through all the EtherCAT Slave Units without stopping

on the way. Once they reach the final Slave Unit, they are sent back from the final Slave Unit, pass through all

Slave Units again, and return to the EtherCAT Master Unit.

With this structure, EtherCAT secures high-speed and real-time data transmission.

EtherCAT

Master Unit

Slave Unit Slave Unit

Data

OUT

IN

Slave Unit

44

EtherCAT Connection

Ethernet frame

•

Reading output data addressed to the local Slave Units

• Writing input data

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 47

It is the “EtherCAT datagram” stored directly in an Ethernet frame that exchanges data regularly between the

EtherCAT Master Unit and Slave Units.

Each “EtherCAT datagram” is configured with header (data length, including address of one or more Slave

Units, etc.), data, working counter (check bit).

When an Ethernet frame is compared to a “train”, an EtherCAT datagram can be considered as “railway car.”

Ethernet frame

Ethernet

header

EtherCAT

header

1st EtherCAT

datagram

Ethernet data (Maximum 1498 bytes)

2nd EtherCAT

datagram

1...n EtherCAT datagram

. . . . .

DataHeader

WKC

WKC : Working counter

CRC

EtherCAT frame

n th EtherCAT

datagram

3

EtherCAT Connection

ZW-8000/7000/5000

User’s Manual for Communications Settings

EtherCAT Connection

45

Page 48

Communications Types of EtherCAT

EtherCAT provides the following two types of communication functions.

PDO communications are always updating data per communication cycle on EtherCAT, while SDO

communications are processed in between those upda tes.

●

Process data communications functions (PDO communications)

This communicat

By mapping

communications among the EtherCAT Master Unit and Slave Units.

ion function is used to transfer process data in real time in a fixed-cycle.

logical process data space to each node by the EtherCAT Master Unit, it achieves fixed-cycle

EtherCAT Master Unit

Ethernet frame

Logic process data

.

.

.

Data a

.

.

.

Data b

Data c

.

.

.

Ethernet

header

Slave Unit

EtherCAT

header

1st EtherCAT

datagram

Slave Unit Slave Unit

2nd EtherCAT

datagram

3rd EtherCAT

datagram

Slave Unit

. . .

CRC

●

Mailbox communications functions (SDO communications)

It refers t

At any timing,

o message communications.

the EtherCAT Master Unit transmits commands to Sla ve Units and the Slave Units return

responses to the EtherCAT Master Unit.

It performs the following data communications:

• Read and write process data

• Slave Unit Settings

• Monitoring the slave unit state

46

EtherCAT Connection

User’s Manual for Communications Settings

ZW-8000/7000/5000

Page 49

● Synchronization with Distributed Clocks

A mechanism called a distributed clock (DC) is used to synchronize EtherCAT communications.

The DC mode is use

timing.

In DC mode, the master and slav es are synchronized by sharing the same clock.

Interruptions (Sync0) are generated in the slaves at precise intervals based on this clock.

Displacement Sensor control is carried out at this precise timing.

Communications Cycle (DC Cycle)

The communications cycle is determined by setting the Sync0 signal output cycle.

Set the Output cycle 125µs, or longer. For details on the setting procedure, refer to "Sysmac Studio Version 1

Operation Manual" (W504).

d for ZW-8000/7000/5000 series to perform highly accurate control of measurement start

3

EtherCAT Connection

ZW-8000/7000/5000

User’s Manual for Communications Settings

EtherCAT Connection

47

Page 50

Communication Meth ods f or Measure ment Sensor w hen Connecte d via EtherCAT

Communications between the EtherCAT master and the displacement sensor is performed over EtherCAT to

enable control from the master by control signals and data output after measured values are applied.

When the displacement sensor is connected to an NX/NJ series CPU Unit via EtherCAT, Sysmac Studio

(standard edition) is used to register the ZW to the EtherCAT slave configuration on the network configuration

edit pane.

For details on registr ation methods , refer to Sysmac Studio Version 1 Operation Manual (W504) “4-2 Controller

Configuration/Setting.”

Important

• Up to 32 measurement sensors can be connected via EtherCAT.

• If EtherCAT is set to enables to perform communications over EtherCAT

disabled and EtherNet/IP communications is no longer possible.

Setting Communications Specific ations (EtherCAT Communications) p.51