Page 1

Enclosed Switches ZE/ZV/XE/XV F-119

Limit

Switches

Enclosed Switches

ZE/ZV/XE/XV

Long Service Life and Large Breaking Power

• ZE, ZV, and ZV2 incorporate Model Z Basic Switches with rugged diecast cases.

• Available with various models of built-in switches (including split

contact model, maintained operation type, magnetic blowout

model) and various actuators.

Model Number Structure

■ Model Number Legend

1. Built-in Switch

Z: SPDT (AC)

X: SPDT (DC)

2. Mounting Direction

E: Side mounting

V: Base mounting

V2: Diagonal side mounting

3. Actuator

Q: Plunger

Q22: Roller plunger

Q21: Crossroller plunger

QA2: Roller arm lever

QA277: One-way action roller arm lever

N: Sealed plunger

N22: Sealed roller plunger (ZE, ZV, ZV2 only)

N21: Sealed crossroller plunger (ZE, ZV, ZV2 only)

NA2: Sealed roller arm lever

NA277: Sealed one-way action roller arm lever

4. Conduit/Ground Terminal

None: G

1

/2/without ground terminal

G1: G

1

/2/with ground terminal

G: Pg13.5/with ground terminal

SG1:

1

/2-14NPSM/with ground terminal

YG1: M20/with ground terminal

S:

1

/2-14NPSM/without ground terminal

Y: M20/without ground terminal

1

2

3

4

@@-@-2@

Page 2

F-120 Enclosed Switches ZE/ZV/XE/XV

Ordering Information

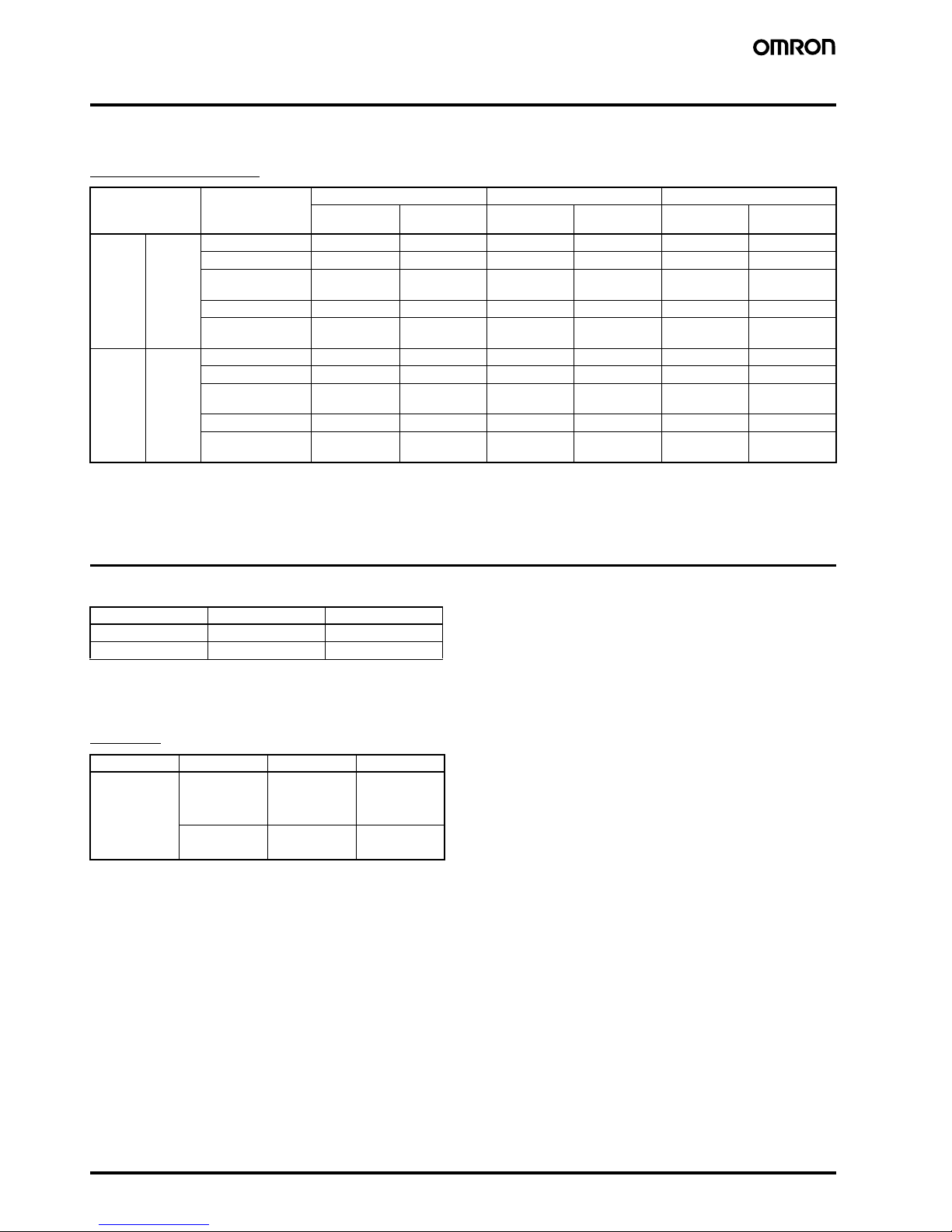

■ List of Models

Standard Switches

Note: 1. The diagonal side mounting model feature improved sealing property, improved mounting strength through use of M5 screws, increased

stability in seating with large mounting width (31 x 75 mm) and permit coupling of a number of Switch units.

2. ZE, ZV, and ZV2 series are approved by UL and CSA.

Specifications

■ Approved Standards

Note: Models XE, XV, and XV2 are not approved by UL and CSA.

■ Approved Standard Ratings

UL/CSA

Contact Actuator Side mounting Diagonal side mounting Base mounting

General

purpose

Sealed

(Booted)

General

purpose

Sealed

(Booted)

General

purpose

Sealed

(Booted)

AC/DC

load

SPDT Plunger ZE-Q-2 ZE-N-2 ZV2-Q-2 ZV2-N-2 ZV-Q-2 ZV-N-2

Roller plunger ZE-Q22-2 ZE-N22-2 ZV2-Q22-2 ZV2-N22-2 ZV-Q22-2 ZV-N22-2

Crossroller plung-erZE-Q21-2 ZE-N21-2 ZV2-Q21-2 ZV2-N21-2 ZV-Q21-2 ZV-N21-2

Roller arm lever ZE-QA2-2 ZE-NA2-2 ZV2-QA2-2 ZV2-NA2-2 ZV-QA2-2 ZV-NA2-2

One-way action

arm lever

ZE-QA277-2 ZE-NA277-2 ZV2-QA277-2 ZV2-NA277-2 ZV-QA277-2 ZV-NA277-2

DC load SPDT Plunger XE-Q-2 XE-N-2 XV2-Q-2 XV2-N-2 XV-Q-2 XV-N-2

Roller plunger XE-Q22-2 --- XV2-Q22-2 --- XV-Q22-2 ---

Crossroller plung-erXE-Q21-2 --- XV2-Q21-2 --- XV-Q21-2 ---

Roller arm lever XE-QA2-2 XE-NA2-2 XV2-QA2-2 XV2-NA2-2 XV-QA2-2 XV-NA2-2

One-way action

arm lever

XE-QA277-2 XE-NA277-2 --- XV2-NA277-2 XV-QA277-2 XV-NA277-2

Agency Standard File No.

UL UL508 E76675

CSA CSA C22.2 No. 14 LR45746

Model Rated voltage Current Horsepower

ZE 125 VAC 15 A 1/8 HP

1/4 HP

250 VAC

480 VAC

125 VDC 0.5 A --250 VDC 0.25 A

Page 3

Enclosed Switches ZE/ZV/XE/XV F-121

Limit

Switches

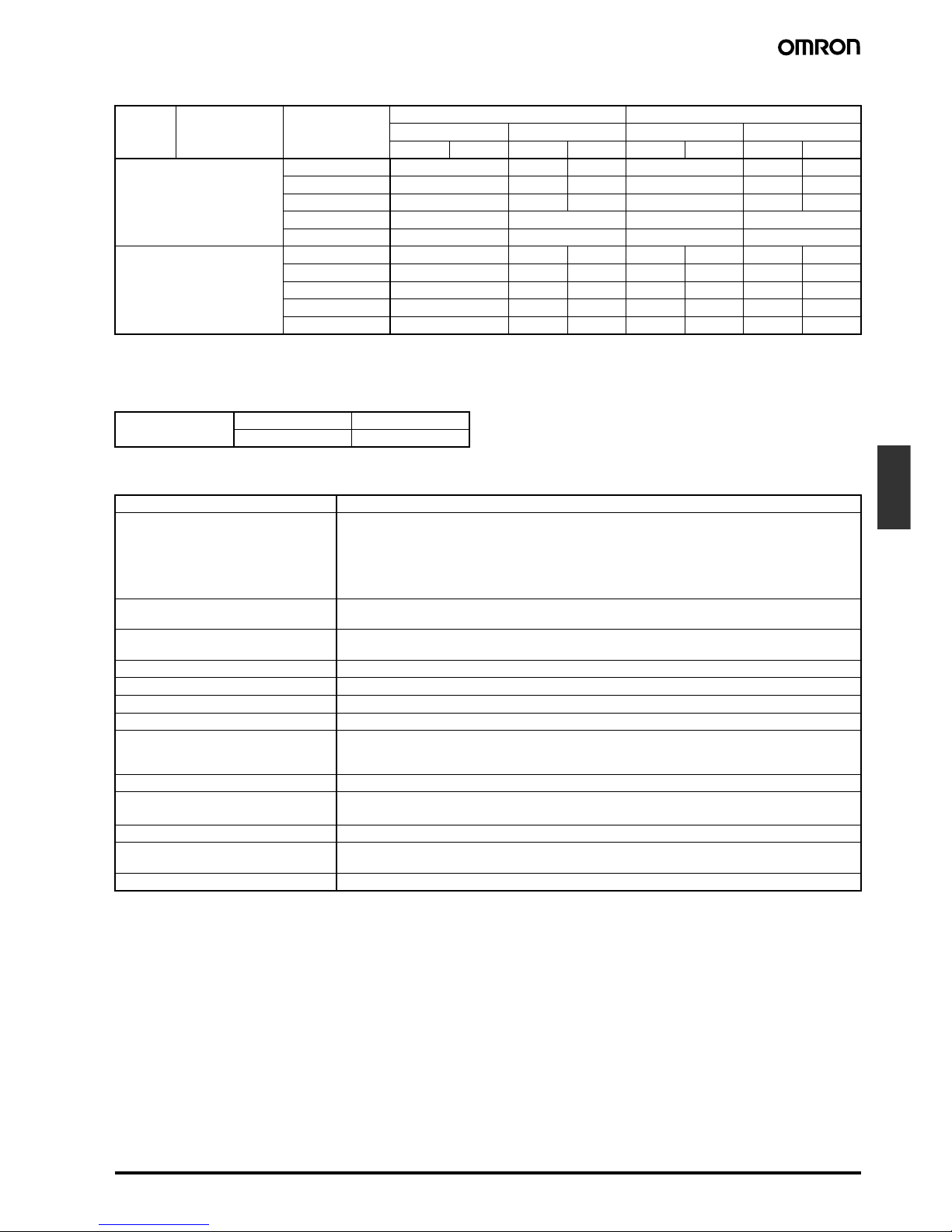

■ Ratings

Note: 1. The above figures are for standard currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

■ Characteristics

Note: 1. The above figures are initial values.

2. IP65 for @E-N models and IP60 for @E-Q models.

3. The values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your OMRON

sales representative for more detailed information on other operating environments.

4. At the operation limit positions.

5. Only for plunger, sealed plunger, roller arm lever, and sealed roller arm lever.

6. Only for crossroller plunger, sealed crossroller plunger, roller plunger, and sealed roller plunger.

Contact Contact Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

ZE-@

ZV-@

ZV2-@

125 VAC 15 A 3 A 1.5 A 15 A 5 A 2.5 A

250 VAC 15 A 2.5 A 1.25 A 15 A 3 A 1.5 A

480 VAC 10 A 1.5 A 0.75 A 6 A 1.5 A 0.75 A

125 VDC 0.5 A 0.5 A 0.05 A 0.05 A

250 VDC 0.25 A 0.25 A 0.03 A 0.03 A

XE-@

XV-@

XV2-@

8 VDC 15 A 3 A 3 A 15 A 15 A 10 A 10 A

14 VDC 15 A 3 A 3 A 15 A 10 A 10 A 10 A

30 VDC 15 A 3 A 3 A 10 A 10 A 10 A 6 A

125 VDC 10 A 3 A 1.5 A 7.5 A 6 A 6 A 4 A

250 VDC 3 A 1.5 A 0.75 A 2 A 1.5 A 2 A 1 A

Inrush current NC 30 A max.

NO 15 A max.

Degree of protection IP65 (see note 2)

Durability (see note 3) Mechanical:

Z@: 10,000,000 operations min.

X@: 1,000,000 operations min.

Electrical:

Z@: 500,000 operations min., for 15 A, 250 VAC resistive load

X@: 100,000 operations min., for 10 A, 125 VDC resistive load

Operating speed Plunger type: 0.01 mm to 0.5 m/s

Lever type: 0.02 mm to 0.5 m/s

Operating frequency Mechanical: 120 operations/min

Electrical: 20 operations/min

Rated frequency 50/60 Hz

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Terminal temperature rise 50° max.

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between terminals of the same polarity

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal part and ground, and between each

terminal and non-current-carrying metal part (1,500 VAC for Z@ models and X@ models)

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note 4)

Shock resistance (see note 4)

Destruction: 1,000 m/s

2

min.

Malfunction: 100 m/s

2

min. (see note 5), 50 m/s2 min. (see note 6)

Ambient temperature (see note 1) Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: General-purpose type: 85% max.

Sealed type: 95% max.

Weight Approx. 260 to 280 g

Page 4

F-122 Enclosed Switches ZE/ZV/XE/XV

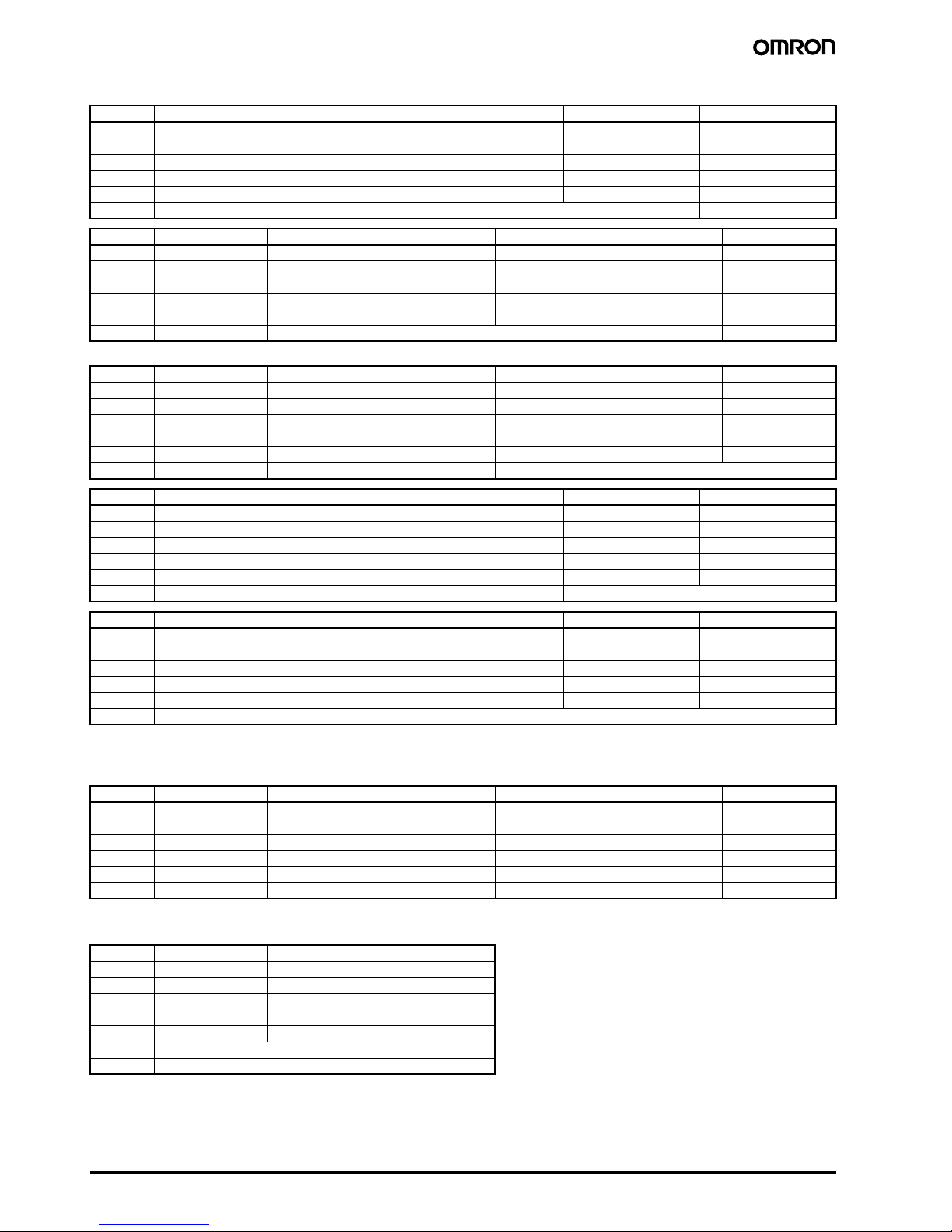

■ Operating Characteristics

Note: 1. The OP of ZV2-Q-2/XV2-Q-2 is 24.2±0.8 mm.

2. The OP of ZV2-Q22-2/XV2-Q22-2 is 35.7±1 mm.

3. The OP of ZV2-Q21-2/XV2-Q21-2 is 35.7±0.8 mm.

Note: 1. The OP of ZV2-N-2/XV2-N-2 is 31.9±0.8 mm.

2. The OP of ZV2-N22-2/ZV2-N21-2 is 35.7±0.8 mm.

Model ZE-Q-2 XE-Q-2 ZE-Q22-2 XE-Q22-2 ZE-Q21-2

OF 2.45 to 3.43 N 5.00 N max. 2.45 to 3.43 N 5.00 N max. 2.45 to 3.43 N

RF min. 1.12 N 1.12 N 1.12 N 1.12 N 1.12 N

PT max. 0.4 mm 0.9 mm 0.5 mm 0.9 mm 0.5 mm

OT min. 5.5 mm 5.5 mm 3.6 mm 3.6 mm 3.6 mm

MD max. 0.05 mm 0.47 mm 0.05 mm 0.47 mm 0.05 mm

OP 38.2±0.8 mm 49.7±1 mm 49.7±1 mm

Model XE-Q21-2 ZE-QA2-2 XE-QA2-2 ZE-QA277-2 XE-QA277-2 ZE-N-2

OF 5.00 N max. 5.59 N max. 6.47N max. 5.59 N 6.47 N 7.85 N

RF min. 1.12 N 1.67 N 1.67 N 1.67 N 1.67 N 2.35 N

PT max. 0.9 mm 4 mm 6 mm 4 mm 6 mm 2 mm

OT min. 3.6 mm 6 mm 5.5 mm 6 mm 5.5 mm 5 mm

MD max. 0.47 mm 0.4 mm 0.72 mm 0.4 mm 0.72 mm 0.1 mm

OP 49.7±1 mm --- 45.8±0.8 mm

Model XE-N-2 ZE-N22-2 ZE-N21-2 ZE-NA2-2 XE-NA2-2 ZE-NA277-2

OF 10.20 N 4.90 N 6.28 N 7.26 N 6.28 N

RF min. 2.35 N 0.98 N 2.26 N 2.26 N 2.26 N

PT max. 3 mm 1 mm 5 mm 6 mm 5 mm

OT min. 4 mm 3.5 mm 6 mm 5.5 mm 6 mm

MD max. 0.47 mm 0.12 mm 0.4 mm 0.72 mm 0.4 mm

OP 45.8±0.8 mm 49.7±0.8 mm ---

Model XE-NA277-2 ZV(2)-Q-2 XV(2)-Q-2 ZV(2)-Q22-2 XV(2)-Q22-2

OF 7.26 N 2.45 to 3.43 N 5.00 N max. 2.45 to 3.43 N 5.00 N max.

RF min. 2.26 N 1.12 N 1.12 N 1.12 N 1.12 N

PT max. 6 mm 0.4 mm 0.9 mm 0.5 mm 0.9 mm

OT min. 5.5 mm 5.5 mm 5.5 mm 3.6 mm 3.6 mm

MD max. 0.72 mm 0.05 mm 0.47 mm 0.05 mm 0.47 mm

OP --- 63.7±0.8 mm (ZV-Q-2, XV-Q-2) (see note 1) 75.2±0.8 mm (ZV-Q-22.2, XV-Q21-2) (see note 2)

Model ZV(2)-Q21-2 XV(2)-Q21-2 ZV(2)-QA2-2 XV(2)-QA2-2 ZV(2)-QA277-2

OF 2.45 to 3.43 N 5.00 N max. 5.59 N max. 6.47 N max. 5.59 N

RF min. 1.12 N 1.12 N 1.67 N 1.67 N 1.67 N

PT max. 0.5 mm 0.9 mm 4 mm 6 mm 4 mm

OT min. 3.6 mm 3.6 mm 6 mm 5.5 mm 6 mm

MD max. 0.05 mm 0.47 mm 0.4 mm 0.72 mm 0.4 mm

OP 75.2±0.8 mm (ZV-Q22-2, XV-Q21-2) (see note 3) ---

Model XV(2)-QA277-2 ZV(2)-N-2 XV(2)-N-2 ZV(2)-N22-2 ZV(2)-N21-2 ZV(2)-NA2-2

OF 6.47 N 7.85 N 10.20 N 4.90 N 6.28 N

RF min. 1.67 N 2.35 N 2.35 N 0.98 N 2.26 N

PT max. 6 mm 2 mm 3 mm 1 mm 5 mm

OT min. 5.5 mm 5 mm 4 mm 3.5 mm 6 mm

MD max. 0.72 mm 0.1 mm 0.47 mm 0.12 mm 0.4 mm

OP --- 71.4±0.8 mm (ZV-N-2, XV-N-2) (see note 1) 75.2±0.8 mm (ZV-N22-2, ZV-N21-2) (see note 2) ---

Model XV(2)-NA2-2 ZV(2)-NA277-2 XV(2)-NA277-2

OF 7.26 N 6.28 N 7.26 N

RF min. 2.26 N 2.26 N 2.26 N

PT max. 6 mm 5 mm 6 mm

OT min. 5.5 mm 6 mm 5.5 mm

MD max. 0.72 mm 0.4 mm 0.72 mm

FP max. --OP ---

Page 5

Enclosed Switches ZE/ZV/XE/XV F-123

Limit

Switches

■ Contact Form

Engineering Data

■ Electrical Durability

COM

NC

NO

ZE-@, ZV-@, ZV2-@

XE-@, XV-@, XV2-@

COM

NC

N

O

EN60947-5-1

Note: With the XE-@, XV-@, and

XV2-@, be sure to connect

COM to the + terminal.

ZE (cosφ = 1)

Durability (x 10

4

operations)

Durability (x 10

4

operations)

Durability (x 10

4

operations)

Durability (x 10

4

operations)

Operating frequency:

20 operations/min

OT: Full stroke

Operating frequency:

20 operations/min

OT: Full stroke

Operating frequency:

20 operations/min

OT: Full stroke

Operating frequency:

20 operations/min

OT: Full stroke

Switching current (A)

Switching current (A)

Switching current (A)

Switching current (A)

ZE (cosφ = 0.4)

XE (L/R = 7 ms)

XE (L/R = 0)

480 VAC

125 VAC

250 VAC

125 VAC

125 VDC

125 VDC

250 VAC

250 VDC

250 VDC

480 VAC

Page 6

F-124 Enclosed Switches ZE/ZV/XE/XV

Nomenclature

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

3. In the drawings for the Base Mounting Type Switches (ZV), the mounting surfaces (flanges) are shown by lines of alternate long and two

short dashes.

Side Mounting

Pin plunger

Separator

Built-in switch

Terminal

Seal rubber (NBR)Cover

Conduit

opening

Case

Tightening band

Rubber cap (CR)

19

25.5

24

86

23

17

25.4

±0.12

2.1

±0.1

25.4±0.3

25.4±0.3

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.1

25.4±0.3

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.1

Plunger

ZE-Q-2, XE-Q-2

12R

(see note)

JIS B0202 G1/2

Effective thread: 4 threads min.

PT

OP

Two, M4

(length: 45)

Note: Stainless steel plunger

Two, M4

(length: 45)

PT

OP

12.7 dia. × 4.8 (see note)

JIS B0202 G1/2

Effective thread:

4 threads min.

Note: Stainless steel roller

Crossroller Plunger

ZE-Q21-2, XE-Q21-2

Two, M4

(length: 45)

PT

OP

12.7 dia. × 4.8 (see note)

JIS B0202 G1/2

Effective thread:

4 threads min.

Roller Plunger

ZE-Q22-2, XE-Q22-2

Note: Stainless steel roller

Page 7

Enclosed Switches ZE/ZV/XE/XV F-125

Limit

Switches

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.1

25.4±0.3

19.3

39.7

44±0.8

(23.1)

(40)

17.4R

39.7

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.1

25.4±0.3

44±0.8

19.3

19

25.5

24

86

23

25.4±0.12

2.1

±0.1

25.4±0.3

17

19

25.5

24

86

23

25.4±0.12

2.1

±0.1

25.4±0.3

17

19

25.5

24

86

23

25.4±0.12

2.1

±0.1

25.4±0.3

17

Roller Arm Lever

ZE-QA2-2, XE-QA2-2

Two, M4

(length: 45)

Note: 1. Stainless sintered roller

2. Adjustable between 0° and 225°

Two, M4

(length: 45)

Two, M4

(length: 45)

(See note 2)

19.1 dia. × 7.9 (see note 1)

JIS B0202 G1/2

Effective thread:

4 threads min.

One-way Action Roller Arm Lever

ZE-QA277-2, XE-QA277-2

18.7 dia. × 9 (see note 1)

← Operate in this direction only

JIS B0202

G1/2

Effective

thread: 4

threads min.

17.4R

(See note 2)

Note: 1. Stainless sintered alloy roller

2. Adjustable between 0° and 225°

Sealed Plunger

ZE-N-2, XE-N-2

Note: Stainless steel plunger

JIS B0202 G1/2

Effective thread:

4 threads min.

12R (see note)

PT

OP

Two, M4

(length: 45)

JIS B0202 G1/2

Effective thread:

4 threads min.

PT

OP

Note: Stainless steel roller

12.7 dia. × 4.8 (see note)

Sealed Roller Plunger

ZE-N22-2

Note: Stainless steel roller

Two, M4

(length: 45)

JIS B0202 G1/2

Effective thread:

4 threads min.

PT

OP

12.7 dia. × 4.8 (see note)

Sealed Crossroller Plunger

ZE-N21-2

Page 8

F-126 Enclosed Switches ZE/ZV/XE/XV

Base Mounting/Diagonal Side Mounting

25.4±0.3

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.1

53.4±0.8

(23.1)

39.7

19.3

Two, M4

(length: 45)

19.1 dia. × 7.9 (see note 1)

Sealed Roller Arm Lever

ZE-NA2-2, XE-NA2-2

JIS B0202

G1/2

Effective thread:

4 threads min.

Note: 1. Stainless steel roller

2. Adjustable between 0° and 225°

(See note 2)

19.3

25.4±0.3

19

25.5

24

86

23

17

25.4±0.12

2.1

±0.12

53.4±0.8

(40)

39.7

25.4±0.1

Two, M4

(length: 45)

18.7 dia. × 9 (see note 1)

Note: 1. Stainless steel roller

2. Adjustable between 0° and 225°

One-way Action Sealed Roller Arm Lever

ZE-NA277-2, XE-NA277-2

(See note 2)

17.4R

JIS B0202

G1/2

Effective thread:

4 threads min.

← Operates in this direction only

Mounting Hole

Two, 4.3 dia.

mounting holes or

M4 screw holes

25.4±0.3

5

26.1

54

86

23

17

75±0.2

5.5

31±0.2

36.6

41.3±0.2

3

10.5±0.3

PT

12R (see note 1.)

Note: 1. Stainless steel plunger

2. Only the ZV2-Q-2 and

XV2-Q-2 incorporate

mounting holes.

3. OP for ZV2-Q-2 and

XV2-Q-2 is 24.2 ±0.8 mm.

Plunger

ZV(2)-Q-2, XV(2)-Q-2

JIS B0202

G1/2 Effective

thread: 4

threads min.

Two, 4.3±0.2 dia. holes

OP (see note 3)

OP (see note 4)

53R

−0

Two, 5.4

+0.2

dia. holes (see note 2)

t = 3 (ZV-Q-2/XV-Q-2 flange)

Page 9

Enclosed Switches ZE/ZV/XE/XV F-127

Limit

Switches

25.4±0.3

26.1

23

75±0.2

5.5

31±0.2

41.3±0.2

5

54

36.6

10.5±0.3

17

3

86

31±0.2

PT

12.7 dia. × 4.8 (see note 1)

Note: 1. Stainless steel roller

2. Only the ZV2-Q22-2 and

XV2-Q22-2 incorporate mounting holes.

3. OP for ZV2-Q22-2 and

XV2-Q22-2 is 35.7 ±1 mm.

Roller Plunger

ZV(2)-Q22-2, XV(2)-Q22-2

Two, 4.3±0.2 dia. holes

OP (see note 3)

OP (see note 4)

53R

−0

Two, 5.4

+0.2

dia. holes (see note 2)

JIS B0202 G1/2

Effective thread:

4 threads min.

t = 3 (ZV-Q22-2/XV-Q22-2 flange)

25.4±0.3

26.1

23

75±0.2

5.5

41.3±0.2

5

54

36.6

10.5±0.3

17

3

86

31±0.2

41.3±0.2

54

36.6

10.5±0.3

3

25.4±0.3

23

17

86

23.1 max.

39.7

30±0.8

69.5±0.8

19.3

PT

12.7 dia. × 4.8 (see note 1)

Note: 1. Stainless steel roller

2. Only the ZV2-Q21-2 and XV2-Q21-2

incorporate mounting holes.

3. OP for ZV2-Q21-2 and XV2-Q21-2 is

35.7 ±0.8 mm.

Crossroller Plunger

ZV(2)-Q21-2, XV(2)-Q21-2

Two, 4.3±0.2 dia. holes

OP (see note 3)

OP (see note 4)

53R

−0

Two, 5.4

+0.2

dia. holes (see note 2)

JIS B0202

G1/2

Effective

thread: 4

threads min.

Two, 4.3±0.2 dia. holes

53R

Note: 1. Stainless sintered alloy roller

2. Adjustment between 0° to 225°.

3. Only the ZV2-QA2-2 and XV2-QA2-2

incorporate mounting holes.

19.1 dia. × 7.9 (see note 1)

−0

Two, 5.4

+0.2

dia. holes (see note 3)

JIS B0202

G1/2

Effective

thread: 4

threads min.

23.1 max.

(See note 2)

Roller Arm Lever

ZV(2)-QA2-2, XV(2)-QA2-2

t = 3 (ZV-Q21-2/XV-Q21-2 flange)

t = 3 (ZV-QA2-2/XV-QA2-2 flange)

Page 10

F-128 Enclosed Switches ZE/ZV/XE/XV

25.4±0.3

26.1

23

75±0.2

5.5

5

17

3

86

PT

41.3±0.2

54

10.6±0.3

36.6

41.3±0.2

54

10.6±0.3

36.6

25.4±0.3

26.1

23

5.5

5

17

3

31±0.2

75±0.2

86

31±0.2

53R

One-way Action Roller Arm Lever

ZV(2)-QA277-2, XV(2)-QA277-2

Two, 4.3±0.2 dia. holes

t = 3 (ZV-QA277-2/XV-QA277-2 flanges)

18.7 dia. × 9 (see note 1)

Note: 1. Stainless steel roller

2. Adjustment between 0° to 225°.

3. Only the ZV2-QA277-2 and

XV2-QA277-2 incorporate mounting

holes.

(See note 2)

−0

Two, 5.4

+0.2

dia. holes (see note 3)

JIS B0202

G1/2

Effective

thread: 4

threads min.

Operates in this direction only

PT

Two, 4.3±0.2 dia. holes

OP (see note 3)

OP (see note 4)

−0

Two, 5.4

+0.2

dia. holes (see note 2)

JIS B0202

G1/2

Effective

thread: 4

threads min.

12CR (see note 1)

53R

Note: 1. Stainless steel plunger

2. Only the ZV2-N-2 and XV2-N-2

incorporate mounting holes.

3. OP for ZV2-N-2 and XV2-N-2 is

31.9 ±0.8 mm.

Two, 4.3±0.2 dia. holes

53R

12.7 dia. × 4.8 (see note 1)

JIS B0202

G1/2

Effective

thread: 4

threads min.

PT

OP (see note 3)

OP (see note 4)

−0

Two, 5.4

+0.2

dia. holes (see note 2)

Note: 1. Stainless steel roller

2. Only the ZV2-N22-2 incorpo incorpo-

rate mounting holes.

3. OP for ZV2-N22-2 is 35.7 ±0.8 mm.

Sealed Roller Plunger

ZV(2)-N22-2

Sealed Plunger

ZV(2)-N-2, XV(2)-N-2

t = 3 (ZV-N-2/XV-N-2 flange)

t = 3 (ZV-N22-2 flange)

Page 11

Enclosed Switches ZE/ZV/XE/XV F-129

Limit

Switches

25.4±0.3

26.1

23

75±0.2

5.5

41.3±0.2

5

36.6

10.6±0.3

3

86

31±0.2

PT

54

53R

PT

12.7 dia. × 4.8 (see note 1)

Note: 1. Stainless steel roller

2. Only the ZV2-N21-2 in-

corporate mounting holes.

3. OP for ZV2-N21-2 is 35.7

±0.8 mm.

Sealed Crossroller Plunger

ZV(2)-N21-2

Two, 4.3±0.2 dia. holes

OP (see note 3)

OP (see note 4)

t = 3 (ZV flange)

−0

Two, 5.4

+0.2

dia. holes (see note 2)

JIS B0202 G1/2

Effective thread: 4

threads min.

53R

17.4R

19.1 dia. × 7.9 (see note 1)

Note: 1. Stainless steel roller

2. Adjustment between 0° to 225°.

3. Only the ZV2-NA2-2 and XV2-NA2-2

incorporate mounting holes.

Sealed Roller Arm Lever

ZV(2)-NA2-2, XV(2)-NA2-2

Two, 4.3±0.2 dia.

(See note 2)

t=3 (ZV-NA2-2/XV-NA2-2 flanges)

−0

Two, 5.4

+0.2

dia. holes (see note 3)

JIS B0202 G1/2

Effective thread:

4 threads min.

One-way Action Sealed Roller Arm Lever

ZV(2)-NA277-2, XV(2)-NA277-2

18.7 dia. × 9 (see note 1)

Two ,

4.3±0.2 dia.

t=3 (ZV-NA277-2/XV-NA277-2 flanges)

Operates in this direction only

(See note 2)

−0

Two, 5.4

+0.2

dia. holes (see note 3)

Note: 1. Stainless steel roller

2. Adjustment between 0° to 225°.

3. Only the ZV2-NA277-2 and

XV2-NA277-2 incorporate mounting

holes.

JIS B0202

G1/2

Effective

thread: 4

threads min.

53R

Page 12

F-130 Enclosed Switches ZE/ZV/XE/XV

Precautions

■ Correct Use

Mounting

With the Roller Lever-type Enclosed Switches, the roller arm has

been temporarily tightened prior to shipment, so that its position may

be adjusted later. When mounting the Switch, be sure to re-tighten

the roller arm so as to prevent it from becoming loose during operation.

To adequately maintain the seals at the mounting screw section on

the side of the Enclosed Switch, insert each O-ring correctly and

secure it with the lock nut.

To provide the Switch with improved sealing property, use of the SC

Connector is recommended.

When routing wires into the conduit opening, be sure that cuttings

and other foreign matter do not enter the Switch.

Environmental Precautions

Sealing materials may deteriorate when used outdoors or when

exposed to cutting oil, solvents, or chemicals. Check this on actual

equipment and, if deterioration is foreseen, consult your OMRON

representative in advance.

Be sure to protect part A with grease in order to maintain the

mechanical life and performance of the Limit Switch. The use of

molybdenum disulfide grease is recommended.

Tightening Torque

A loose screw may result in a malfunction. Be sure to tighten each

screw to the proper tightening torque as shown below.

Note: 1. This torque range applies to side mounting or bottom

mounting. (M4 screws for head)

2. This torque range applies to side diagonal mounting. (M5

Allen-head bolt)

Mounting

Mounting Holes

Operation

• Operating method, shape of cam or dog, operating frequency, and

the overtravel (OT) have significant effect on the service life and

precision of the Limit Switch. Make sure that the shape of the cam

is smooth enough.

• Check that OT has a sufficient margin. The actual OT should be

rated OT x 0.7 to 1.

Dedicated Wrench

The roller arm can be set freely within a range of 225° after loosening

the nut.

The roller arm mounting bracket can be set in any direction after

loosening the nut.

A dedicated wrench is provided separately.

Model: SUPANA FOR ZE

Make sure that the nut is free of foreign substances when the nut is

loosened.

No. Type Torque

1 Cover mounting screw 1.18 to 1.37 N·m

2 Switch mounting screw (see note 1) 1.18 to 1.37 N·m

3 Switch mounting screw (see note 2) 4.90 to 5.88 N·m

4 Switch terminal screw (M4 screws for

head)

0.78 to 1.18 N·m

5 Roller arm mounting nut 4.90 to 5.88 N·m

Side Mounting Bottom Mounting

Side Diagonal Mounting

Two, 4.3 dia.

mounting holes or

M4 screw holes

Two, 4.3 dia.

mounting holes or

M4 screw holes

Two, 5.4 dia.

mounting holes or

M5 screw holes

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C020-E1-09

Loading...

Loading...